Page 1

CHECK

VALVE

CHECK

VALVE

C1

C1

Pilot Pilot

V1 V1

OPERATING

VALVE

ExhaustExhaust

CYLINDER

B

C

A

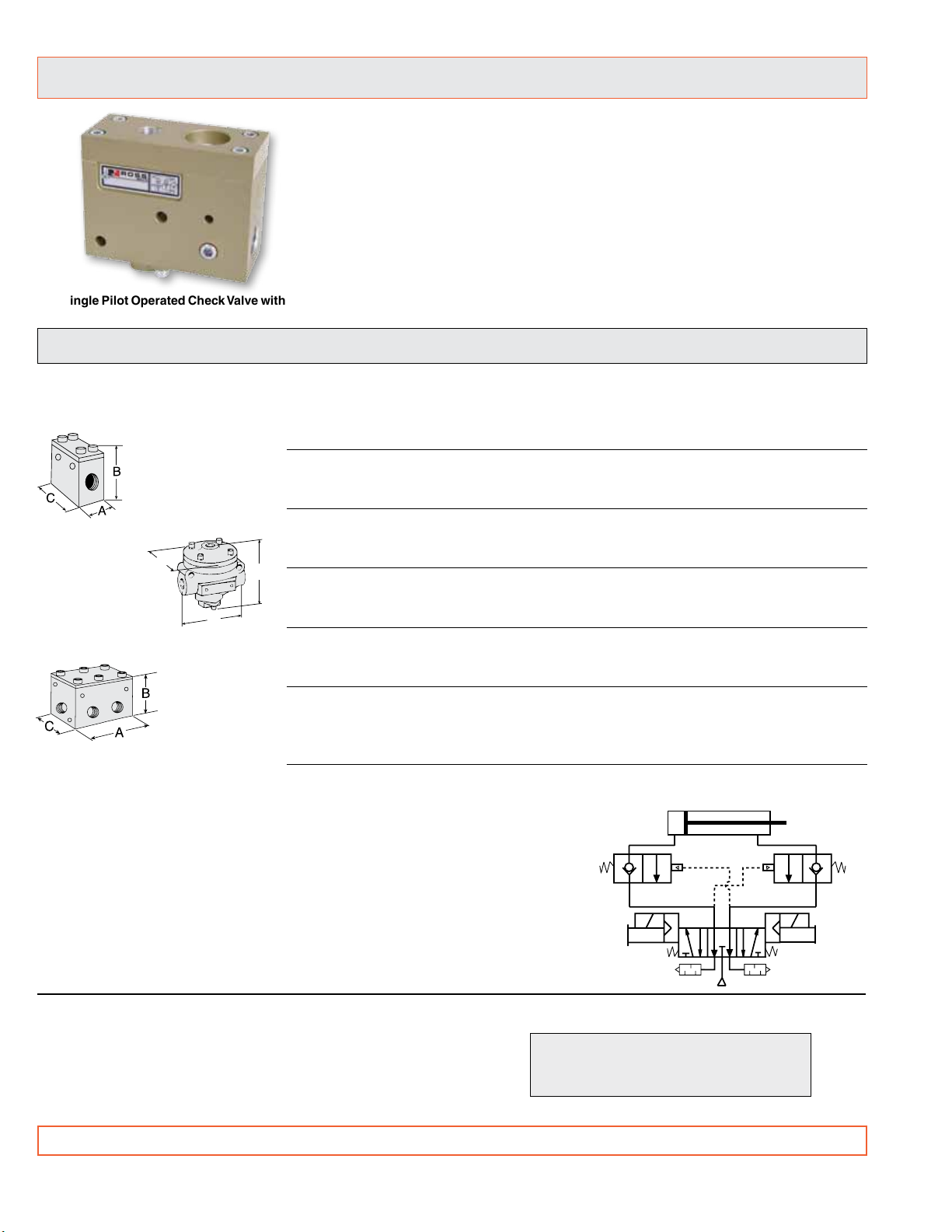

Series 27 Pilot Operated Check Valves

• Can be used wherever a high-flow or remotely-controlled checking

function is needed.

• Can be used in a circuit to provide automatic stopping of a cylinder

in the event of the loss of electrical or pneumatic power.

• Also available with an automatic exhausting function, remote and

manual trapped pressure relief function, or solenoid dual pilot

operated check.

Single Pilot Operated Check Valve with

trapped pressure relief illustrated

Pressure Controlled Pilot Operated Check Valves

WITHOUT Trapped Pressure Relief Function

Valve Port Valve Model Avg. CV Dimensions inches (mm) Weight

Type Size Number

Type A Single

PO Check Valve

Ports: 1/4 through 1/2

Type B Single

PO Check Valve

Ports: 1/4 through 1½

Type C Dual

PO Check Valve

Ports: 3/8 through 1

1/4 2751A2908 2.2 1.5 (38) 3.6 (91) 2.0 (51) 2.3 (1.0)

A 3/8 2751A3908 2.9 1.5 (38) 3.6 (91) 2.0 (51) 2.3 (1.0)

1/2 2751A4915 3.2 1.5 (38) 3.6 (91) 2.5 (64) 2.3 (1.0)

1/4 2751A2903 2.3 3.6 (91) 3.8 (95) 3.1 (79) 1.3 (0.6)

B 3/8 2751A3901 3.8 3.6 (91) 3.8 (95) 3.1 (79) 1.3 (0.6)

1/2 2751A4902 4.0 3.6 (91) 3.8 (95) 3.1 (79) 1.3 (0.6)

1/2 2751A4905 7.7 4.6 (116) 4.4 (112) 3.1 (79) 2.3 (1.0)

B 3/4 2751A5903 9.0 4.6 (116) 4.4 (112) 3.1 (79) 2.3 (1.0)

1 2751A6901 9.0 4.6 (116) 4.4 (112) 3.1 (79) 2.3 (1.0)

1 2751B6904 24 6.7 (169) 6.5 (165) 4.1 (104) 6.0 (2.7)

B 1¼ 2751B7901 29 6.7 (169) 6.5 (165) 4.1 (104) 6.0 (2.7)

1½ 2751B8902 29 6.7 (169) 6.5 (165) 4.1 (104) 6.0 (2.7)

3/8 2768C3900 2.9 3.4 (89) 3.7 (94) 2.4 (61) 2.0 (0.9)

C 1/2 2768C4900 3.2 3.4 (89) 3.7 (94) 2.4 (61) 2.4 (1.1)

Dual 3/4 2768C5900 8.5* 4.4 (111) 4.1 (104) 3.0 (76) 3.8 (1.7)

1 2768A6900 8.5* 5.8 (147) 4.1 (104) 3.9 (99) 6.8 (3.1)

*Effective CV varies with load and pressure drop. Consult ROSS for specifics on your system.

(Fully open) A B C lb (kg)

TYPICAL APPLICATION

In the schematic diagram at the right, two single PO check valves (Type A or B) are

used in a typical cylinder circuit. Their function is to provide automatic stopping of

the cylinder if either electrical or pneumatic power is lost. This circuit can also be

used for jogging the cylinder as well as providing for an emergency stop.

In certain port sizes the two check valves could be replaced by just one Type C dual

PO check valve. The dual PO check valve contains the functions of two individual

checks in a single compact housing, and eliminates the need to connect externally

the inlet of one check to the pilot of the other.

STANDARD SPECIFICATIONS: For valves on this page.

Ambient/Media Temperature: 40° to 175°F (4° to 80°C).

Flow Media: Filtered air; 5 micron recommended.

Inlet Pressure: 15 to 150 psig (1 to 10 bar).

Signal Pressure: Must be equal to or greater than inlet.

Port Threads: NPT standard, BSPP. For BSPP threads add a

“D” prefix to the model number, e.g., D2751A2908.

2 © 2009, ROSS CONTROLS®.

IMPORTANT NOTE: Please read carefully and thoroughly all of the CAUTIONS on page 11.

PIPING NOTE FOR TYPE B VALVES

Port 1 should be piped to the cylinder,

and port 2 to the operating valve.

All Rights Reserved.

Page 2

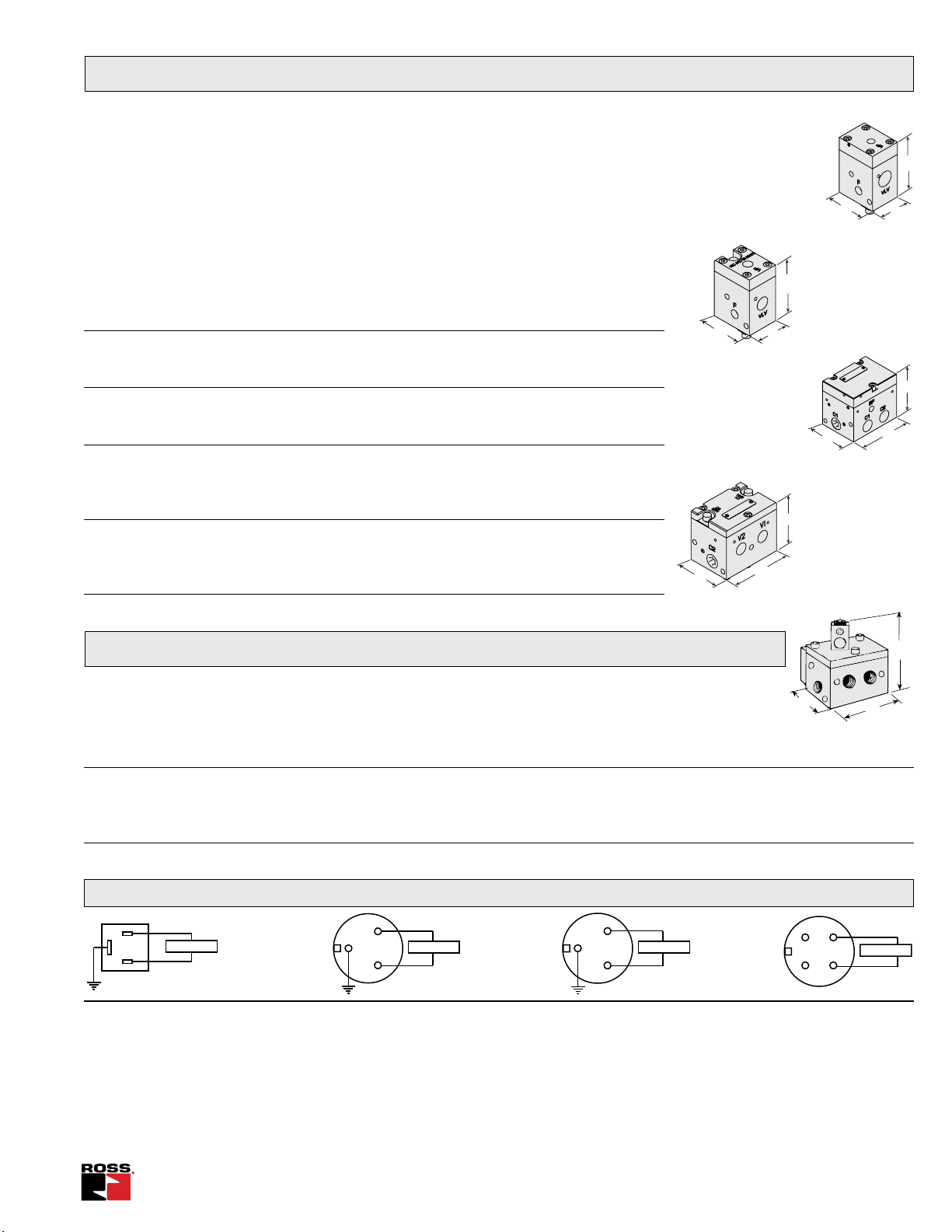

Pressure Controlled Pilot Operated Check Valves

B

A

C

WITH Trapped Pressure Relief Function

Air pilot or solenoid pilot operated check valves with trapped pressure relief can be used to control

a pneumatic cylinder in several important ways. For example:

• Maintaining a cylinder (horizontal or vertical) in a stationary position upon loss of electrical power.

• Jogging a cylinder.

• Relieving pressure trapped between check valve and cylinder.

Correct installation of a dual check valve is essential. It should be mounted as close to the cylinder

as possible. Minimizing the air volume by keeping the air lines short will reduce cylinder “bounce,”

and help to give the best performance.

Valve Port Valve Model Avg. CV Dimensions inches (mm) Weight

Type Size Number

(Fully open) A B C lb (kg)

3/8 2751B3922 2.6 1.65 (41.9) 3.57 (90.6) 2.2 (55.9) 1.8 (0.8)

A 1/2 2751B4922 2.8 1.65 (41.9) 3.57 (90.6) 2.2 (55.9) 1.8 (0.8)

Remote

3/4 2751B5917 9.2 4.3 (110) 4.2 (107) 2.2 (56) 2.9 (1.3)

3/8 2751B3920 2.6 1.65 (41.9) 3.47 (88) 2.2 (55.9) 1.8 (0.8)

A 1/2 2751B4920 2.8 1.65 (41.9) 3.47 (88) 2.2 (55.9) 1.8 (0.8)

Manual

3/4 2751B5919 9.2 4.3 (110) 4.2 (107) 2.2 (56) 2.9 (1.3)

3/8 2768D3901 2.9 3.6 (91.4) 3.64 (92.4) 2.6 (66.1) 3.5 (1.6)

D 1/2 2768D4901 3.2 3.6 (91.4) 3.64 (92.4) 2.6 (66.1) 3.5 (1.6)

Remote 3/4 2768D5901 8.5* 4.98 (126.5) 4.24 (107.7) 3.4 (86.4) 5.2 (2.3)

1 2768D6901 8.5* 4.98 (126.9) 4.24 (107.7) 3.4 (86.4) 8.8 (4.0)

3/8 2768D3904 2.9 3.6 (91.4) 3.6 (91.4) 2.6 (66.1) 3.2 (1.4)

D 1/2 2768D4904 3.2 3.6 (91.4) 3.6 (91.4) 2.6 (66.1) 3.5 (1.6)

Manual 3/4 2768D5904 8.5* 4.8 (122) 4.24 (107.7) 3.4 (86.4) 5.2 (2.3)

1 2768D6904 8.5* 4.8 (122) 4.24 (107.7) 3.4 (86.4) 8.8 (4.0)

*Effective CV varies with load and pressure drop. Consult ROSS for specifics on your system.

Type A Single

PO Check Valve

(Remote Trapped

Pressure Relief)

Ports: 3/8 through 3/4

B

Ports: 3/8 through 3/4

C

Type D Internal Pilot Dual

PO Check Valve

(Remote Trapped

Pressure Relief)

Ports: 3/8 through 1/2

C

A

Type D Internal Pilot

Dual PO Check Valve

B

Ports: 3/8 through 1/2

A

C

Type A Single

PO Check Valve

(Manual Trapped

Pressure Relief)

C

(Manual Trapped

Pressure Relief)

B

A

B

A

Solenoid Controlled Pilot Operated Check Valves

Type E Solenoid Pilot

Dual PO Check Valve

24 volts DC 24 volts DC

Valve Port Avg. DIN 3-Pin Mini 3-Pin Mini 4-Pin Micro Dimensions inches (mm) Weight

Type Size C

Connector Connector Connector Connector A B C lb (kg)

V

3/8 2.9 2778C3900 2778C3901 2778C3902 2778C3904 3.60 (91.4) 5.67 (144) 2.60 (66.1) 4.0 (1.8)

E 1/2 3.2 2778C4900 2778C4901 2778C4902 2778C4904 3.60 (91.4) 5.67 (144) 2.60 (66.1) 4.2 (1.9)

3/4 8.5* 2778C5900 2778C5901 2778C5902 2778C5904 4.98 (126.5) 6.77 (172) 3.40 (86.4) 6.1 (2.8)

1 8.5* 2778A6900 2778A6901 2778A6902 2778A6904 4.98 (126.5) 6.77 (172) 3.40 (86.4) 6.1 (2.8)

*Effective CV varies with load and pressure drop. Consult ROSS for specifics on your system.

Connector Wiring

3

1

SOLENOID

2

SOLENOID

DIN

Connector

AC Mini

Connector

STANDARD SPECIFICATIONS: For valves on this page.

INTERNAL PILOT MODELS:

Ambient/Media Temperature: 40° to 175°F (4° to 80°C).

Inlet Pressure: 15 to 150 psig (1 to 10 bar).

SOLENOID PILOT MODELS:

Solenoids: AC or DC power.

Standard Voltages:

24 volts DC; 3-pin Mini and 4-pin Micro connectors.

100-110 volts, 50 Hz; 100-120 volts, 60 Hz;

DC Mini

Connector

Power Consumption: 8 VA inrush, 6 VA holding on AC; on DC 4.5

watts with 4-pin Micro connector, 60 watts with 3-pin connector.

Ambient Temperature: 40° to 120°F (4° to 50°C).

Media Temperature: 40° to 175°F (4° to 80°C).

Flow Media: Filtered air; 5 micron recommended.

Inlet Pressure: 30 to 150 psig (2 to 10 bar).

Signal Pressure: Must be equal to or greater than inlet.

Port Threads: NPT standard, BSPP. For BSPP threads add a “D”

prefix to the model number, e.g., D2778D3900.

3

1

2

Ports: 3/8 through 1

Common

SOLENOID

+ 24VDC

DC Micro

Connector

4

1

2

3

+ 24 VDC

SOLENOID

Common

www.rosscontrols.com 3

Page 3

Cylinder

Cylinder

Single Pressure Controlled PO Check Valve Application

TYPICAL APPLICATIONS:

Horizontal or vertical long-stroke cylinders.

CIRCUIT FEATURES:

• Trapped pressure between check valve and cylinder is exhausted when the

air supply at the Blowdown Signal Port (BP) is lost or locked-out.

• Cylinder moves as long as the control valve solenoid is energized. Use for

With Trapped Pressure Relief

L-O-X (Lockout

& eXhaust Valve)

continuous motion or jogging.

• Cylinder remains stationary if neither control valve solenoid is energized, or

if electrical signal is lost.

• The single PO check with pressure relief have an additional 1/8” NPT port

provided for the installation of a pressure sensing device such as a pop-up

Single PO Check Valve

indicator or pressure switch. Standards suggest that machine design should

include a method for verifying the release of stored energy.

IMPORTANT NOTES and CAUTIONS:

» Cylinder movement may occur when inlet pressure is lost. The cylinder’s

movement is slowed only by the restrictions of the flow control valves, and

by the exhaust capacity of the check valve relief flow capacity.

» For best response, flow control valves should be installed between the check

valve and the cylinder.

» Pressurizing the system after supply air has been off may cause rapid movement

3-Position, Open-

Center Control Valve

Vertical

Cylinder

of the cylinder because cylinder air was exhausted while the supply air was off.

Dual Internal Pressure Controlled PO Check Valve Applications

TYPICAL APPLICATIONS: Horizontal or vertical long-stroke cylinders.

Remote Trapped Pressure Relief Manual Trapped Pressure Relief

Flow

Control

Valves

C1 C2

V1 V2

3-Position, OpenCenter Control Valve

Remote-controlled

Check Valve relief

Dual Check

Valve with

Internal Pilot

Holding

P

Pressure

®

L-O-X

Valve

CIRCUIT FEATURES:

• Trapped pressure between check valve and cylinder is exhausted

when the air supply at “P” port is lost or locked-out.

• Cylinder moves as long as a control valve solenoid is energized.

Use for continuous motion or jogging.

• Cylinder remains stationary if neither control valve solenoid is

energized, or if electrical signal is lost.

®

• L-O-X

valve provides lockable shutoff of air supply, and

exhausting of trapped downstream air.

IMPORTANT NOTES and CAUTIONS:

» Cylinder movement may occur when inlet pressure is lost. Its

movement is slowed only by the restrictions of the flow control

valves, and by the exhaust capacity of the check valve relief flow

capacity.

» For best response, flow control valves should be installed

between the check valve and the cylinder.

» Pressurizing the system after supply air has been off may

cause rapid movement of the cylinder because cylinder air

was exhausted while the supply air was off. See page 5 for

soft-startup circuit.

Flow

Control

Valves

C1 C2

V1 V2

3-Position, OpenCenter Control Valve

Manual-controlled

Check Valve relief

Internal Pilot

BA

L-O-X

Valve

Dual Check

Valve with

®

CIRCUIT FEATURES:

• Trapped pressure between check valve and cylinder is

exhausted when pushbuttons A and B are pressed.

• Cylinder moves as long as a control valve solenoid is energized.

Use for continuous motion or jogging.

• Cylinder remains stationary if neither control valve solenoid is

energized, or if electrical signal is lost.

®

• L-O-X

valve provides lockable shutoff of air supply.

IMPORTANT NOTES and CAUTIONS:

» Cylinder movement may occur if only one pushbutton (A or B)

is pressed. To exhaust fully both cylinder ports, push and hold

A and B simultaneously.

» For best response, flow control valves should be installed

between the check valve and the cylinder.

» Pressurizing the system after supply air has been off may

cause rapid movement of the cylinder. See page 5 for softstartup circuit.

NOTE: See Installation and Troubleshooting on page 6.

4 © 2009, ROSS CONTROLS®.

All Rights Reserved.

Page 4

Dual Solenoid Controlled PO Check Valve Application

V1 V2

2-Position

Control Valve

Cylinder

L-O-X

®

Valve

P

Holding

Pressure

Flow

Control

Valves

Dual Check

Valve with

Solenoid Pilot

C1 C2

EEZ-ON

®

Valve

Sol C

Sol A Sol B

V1 V2

3-Position

Open Center

Control Valve

Cylinder

L-O-X

®

Valve

P

Holding

Pressure

Flow

Control

Valves

Dual Check

Valve with

Solenoid Pilot

and Relief

Function

C1 C2

EEZ-ON

®

Valve

Sol C

External

Pilot

Supply

Sol A

Sol B

Cylinder

TYPICAL APPLICATIONS: Overhead lifter circuits; applications where there is

a long distance between the check valve and the operating valve.

Flow

Control

Valves

Sol C

C1 C2

Sol A Sol B

3-Position, OpenCenter Control Valve

V1 V2

Dual Check

Valve with

Solenoid Pilot

and Relief

Function

Holding

P

Pressure

®

L-O-X

Valve

CIRCUIT FEATURES:

• To operate cylinder, simultaneously energize solenoids A and C or B and C.

• Pilot supply and exhaust are independent of control valve. Response time is not affected

by exhaust restrictions of the control valve.

• Cylinder remains stationary if neither control valve solenoid is energized, or if electrical

signal is lost.

• Pressure in cylinder is exhausted when the air supply at “P” port is lost or locked-out.

®

• L-O-X

valve provides lockable shutoff of air supply, and exhausting of trapped

downstream air.

IMPORTANT NOTES and CAUTIONS:

» Cylinder movement may occur when inlet pressure is lost. Its movement is slowed

only by the restrictions of the flow control valves, and by the exhaust capacity of the

check valve relief flow capacity.

» The solenoid of the check valve must be wired so that it is energized whenever either

control valve solenoid is energized.

» Pressurizing the system after supply air has been off may cause rapid movement

of the cylinder because cylinder air was exhausted while the supply air was off. See

below for soft-startup circuit.

Dual PO Check Valve Applications with EEZ-ON® Valve for Soft Startup

With 2-Position Control Valve

With 3-Position Control Valve

TYPICAL APPLICATIONS:

Shuttle and lifter circuits; applications where there is a long distance

between the check valve and the operating valve; applications where

gradual cylinder movement upon pressurization is acceptable.

CIRCUIT FEATURES:

• Cylinder will remain fully extended or retracted if electrical

signal to control valve solenoid is lost.

• Pressure in the cylinder is exhausted when the air supply at

“P” port is lost or locked out.

• When the air supply is turned on, the EEZ-ON

(see page 6) allows slow pressurization of the system so

that the cylinder moves slowly into the fully extended or

retracted position.

• L-O-X

®

valve provides lockable shutoff of air supply, and

exhausting of trapped downstream air.

IMPORTANT NOTES and CAUTIONS:

» For cylinder to move, energizing of solenoids A and C or B and

C must occur simultaneously.

NOTE: See Installation and Troubleshooting on page 6.

www.rosscontrols.com 5

TYPICAL APPLICATIONS:

Shuttle and lifter circuits; applications where cylinder movement

upon pressurization is NOT acceptable.

CIRCUIT FEATURES:

• Regulators are set to compensate for differing areas on either

side of cylinder piston. Provides a steady startup and a gradual

stopping of the cylinder.

®

®

valve

• When the air supply is turned on, the EEZ-ON

page 6) allows pressure to build up on both sides of the piston.

valve (see

This minimizes startup “bounce.”

• Pilot operated check valve prevents drifting, and can be closecoupled to cylinder to reduce “bounce.”

• Pressure in the cylinder is exhausted when the air supply at

“P” port is lost or locked out.

®

• L-O-X

valve provides lockable shutoff of air supply, and

exhausting of trapped downstream air.

IMPORTANT NOTES and CAUTIONS:

» For cylinder to move, energizing of solenoids A and C or B and

C must occur simultaneously.

Page 5

Installation and Troubleshooting

ROSS

®

INSTALLATION

• Locate the check valve as close to the cylinder as possible.

This will minimize cylinder bounce and drift.

• Use non-expandable hose between check valve and cylinder.

The expandability of thin-wall flexible hose can magnify cylinder

bounce and drift.

• To install threaded pipe or fittings, engage threads one turn,

apply thread sealant (tape not recommended) to threads, and

tighten pipe or fitting fully.

• After system is pressurized, check all connections with soapy

water to ensure that there are no leaks. Drifting can occur if

leaks are present between the check valve and the cylinder.

Circuit for Control of Rodless Actuators

Rodless

Cylinder

Flow

Flow

Control

Valve

Control

Valves

3-Position,

Pressure Center

Control V alve

EEZ-ON

Valve

L-O-X

®

Valve

TYPICAL APPLICATIONS: Control of rodless cylinders, double-rod cylinders, air motors

on transfer systems, and part loaders.

CIRCUIT FEATURES:

• When the air supply is turned on, the EEZ-ON

the cylinder to provide soft start recharging.

• Allows cylinder to be jogged in either direction.

• L-O-X® valve (see below) provides lockable shutoff of supply air, and exhausting of

®

trapped downstream air.

• Prevents runaways due to loss of air pressure.

• Pressure at port P must be equal to or greater than the pressure

in the cylinder and greater than the minimum operating pressure

of the control valve.

• Do not restrict the exhaust of the control valve.

• In a circuit using a solenoid pilot check valve, the check valve

solenoid and a control valve solenoid must be energized

simultaneously.

TROUBLESHOOTING TIP

The most common cause of unsatisfactory performance is leaky

connections. Always check for leaks with before undertaking any

other repair procedures.

®

valve (see below) slowly pressurizes

Other ROSS Valves Used in the Circuits

EEZ-ON® Valves

An EEZ-ON® valve allows a gradual

buildup of downstream air pressure after

the supply is turned on. Rate of buildup

is adjustable. This controlled action lets

cylinders move slowly and more safely

into normal working positions.

A 3/2 EEZ-ON

which has a shutoff-andexhaust feature is also

available.

Port 2/2 Model Avg.

Size Number C

1/4 2781A2007 2.3

3/8 2781A3007 3.8

1/2 2781A4017 4.0

1/2 2781A4007 7.7

3/4 2781A5007 9.0

1 2781A6017 9.0

1 2781A6007 24

1¼ 2781A7007 29

1½ 2781A8017 29

®

valve

v

L-O-X® Valves

A ROSS L-O-X® valve is an energy isolation valve,

generally the first valve in the air supply line. Air

can be shut off with a push of the red handle, and

downstream air is exhausted at the same time. For

safety, the handle should be padlocked in the closed

position when system maintenance

is being performed.

Th e manu ally contr olled

®

valve is shown here,

L-O-X

but piloted models to control

the flow of air remotely are

also available.

Port Sizes L-O-X® Valve Avg. C

In-Out Exh. Model Numbers In-Out Out-Exh

1/4 1/4 Y1523C2002 1.9 1.9

3/8 3/8 Y1523C3012 2.5 2.6

3/8 3/4 Y1523C3002 6.0 8.0

1/2 3/4 Y1523C4002 7.1 8.3

3/4 3/4 Y1523C5012 8.6 9.5

3/4 1¼ Y1523C5002 13 12

1 1¼ Y1523C6002 13 14

1¼ 1¼ Y1523C7012 20 14

1½ 2 Y1523C8002 38 47

2 2 Y1523C9012 38 47

v

Flow Control Valves

A ROSS flow control valve provides a high

air flow rate into a cylinder, and a precisely

controlled flow rate out of the cylinder. The

adjustable flow can range from near zero

to full flow. A non-rising adjustment knob

turns clockwise to reduce controlled flow.

Flow control valves in

other configurations

are al s o ava i l a b l e

from ROSS.

Port Flow Control Avg. C

Size Model Numbers (Fully open)

1/4 1968E2007 2.3

3/8 1968E3007 2.6

1/2 1968E4007 7.5

3/4 1968E5007 8.3

1 1968E6007 17

1¼ 1968E7007 22

v

6 © 2009, ROSS CONTROLS®.

All Rights Reserved.

Loading...

Loading...