Page 1

Installation Guide

Software Issue: 16.10-S100

Ross Video Limited

Page 2

Synergy 100 • Installation Guide

• Ross Part Number: 4100D-002

• Document Issue: 16A

• Release Date: May 30, 2006. Printed in Canada.

• Software Issue: 16.10-S100

The information contained in this Installation Guide is subject to change without notice or obligation.

Copyright

© 2006 Ross Video Limited. All rights reserved.

Contents of this publication may not be reproduced in any form without the written permission of

Ross Video Limited. Reproduction or reverse engineering of copyrighted software is prohibited.

Notice

The material in this manual is furnished for informational use only. It is subject to change without

notice and should not be construed as commitment by Ross Video Limited. Ross Video Limited

assumes no responsibility or liability for errors or inaccuracies that may appear in this manual.

Trademarks

• is a registered trademark of Ross Video Limited.

• Ross, ROSS, ROSS

• All other product names and any registered and unregistered trademarks mentioned in

this guide are used for identification purposes only and remain the exclusive property of

their respective owners.

, and MLE are registered trademarks of Ross Video Limited.

Page 3

Important Regulatory and Safety Notices to Service Personnel

Before using this product and any associated equipment, refer to the “Important Safety

Instructions” listed below to avoid personnel injury and to prevent product damage.

Product may require specific equipment, and/or installation procedures to be carried out to satisfy

certain regulatory compliance requirements. Notices have been included in this publication to call

attention to these specific requirements.

Symbol Meanings

Protective Earth

Warning

Caution

Notice

Warning Hazardous

Voltage

ESD Susceptibility

This symbol identifies a Protective Earth (PE) terminal, which is

provided for connection of the supply system’s protective earth (green

or green/yellow) conductor.

This symbol on the equipment refers you to important operating and

maintenance (servicing) instructions within the Product Manual

Documentation. Failure to heed this information may present a major

risk of damage or injury to persons or equipment

The symbol with the word “Warning” within the equipment manual

indicates a potentially hazardous situation, which if not avoided, could

result in death or serious injury.

The symbol with the word “Caution” within the equipment manual

indicates a potentially hazardous situation, which if not avoided, may

result in minor or moderate injury. It may also be used to alert against

unsafe practices.

The symbol with the word “Notice” within the equipment manual

indicates a situation, which if not avoided, may result in major or

minor equipment damage or a situation, which could place the

equipment in a non-compliant operating state.

This symbol is intended to alert the user to the presence of uninsulated

“dangerous voltage” within the product enclosure that may be of

sufficient magnitude to constitute a risk of shock to persons.

This symbol is used to alert the user that an electrical or electronic

device or assembly is susceptible to damage from an ESD event.

Warning

Important Safety Instructions

1) Read these instructions.

2) Keep these instructions.

3) Heed all warnings.

4) Follow all instructions.

5) Do not use this apparatus near water.

6) Clean only with a dry cloth.

7) Do not block any ventilation openings. Install in accordance with manufacturer’s instructions.

Page 4

Warning

8) Do not install near heat sources such as radiators, heat registers, stoves, or other apparatus

(including amplifiers) that produce heat.

9) Do not defeat the safety purpose of the polarized or grounding-type plug. A polarized plug has

two blades with one wider than the other. A grounding type plug has two blades and a third grounding

prong. The third prong is provided for your safety. If the provided plug does not fit in to your outlet,

consult an electrician for replacement of the obsolete outlet.

10)Protect the power cord from being walked on or pinched, particularly at plugs, convenience

receptacles, and the point where they exit from the apparatus.

11)Only use attachments/accessories specified by the manufacturer.

12)Unplug this apparatus during lightning storms or when unused for long periods of time.

13)Refer all servicing to qualified service personnel. Servicing is required when the apparatus has

been damaged in any way. This includes power-supply cord or plug damage, liquid being spilled or

objects having fallen into the apparatus, the apparatus being exposed to rain or moisture, the

apparatus having been dropped, or the apparatus not operating normally.

14)Do not expose this apparatus to dripping or splashing, and ensure that no objects filled with

liquids, such as vases, are placed on the apparatus.

15)To completely disconnect this apparatus from the AC Mains, disconnect the power supply cord

plug from the AC receptacle.

16)The mains plug of the power supply cord shall remain readily operable.

17)The SD (Video Production Switcher) chassis is to be rack mounted only.

18) Indoor Use: WA R NI N G : To reduce the risk of fire or electric shock, do not expose this

apparatus to rain or moisture.

19)The safe operation of this product requires that a protective earth connection be provided. A

grounding conductor in the equipment's supply cord provides this protective earth. To reduce the risk

of electrical shock to the operator and service personnel, this ground conductor must be connected to

an earthed ground.

20)WARNING: This apparatus, when equipped with multiple power supplies, can generate high

leakage currents. To reduce the risk of electric shock, ensure that each individual supply cord is

connected to its own separate branch circuit with an earth connection.

21)CAUTION: These service instructions are for use by qualified service personnel only. To reduce

the risk of electric shock, do not perform any servicing other than that contained in the operating

instructions unless you are qualified to do so. (Installation Guide only.)

22)This apparatus contains a Lithium battery, which if replaced incorrectly, or with an incorrect type,

may cause an explosion. Replace only with the same type. Dispose of used batteries according to the

manufacturer’s instruction.

23)Service barriers within this product are intended to protect the operator and service personnel from

hazardous voltages. For continued safety, replace all barriers after servicing.

24)Certain parts of this equipment still present a safety hazard with the power switch in the OFF

position. To avoid electrical shock, disconnect all A/C power cords from the chassis' rear appliance

connectors before servicing.

25)This product contains safety critical parts, which, if incorrectly replaced, may present a risk of fire

or electrical shock. Components contained within the product’s power supplies and power supply area

are not intended to be customer-serviced and should be returned to the factory for repair.

26)To reduce the risk of fire, replacement fuses must be the same type and rating.

Page 5

27)Use only power cords specified for this product and certified for the country of use. Refer to the

Product Power Cord Requirement section that follows.

28)The safe operation of this equipment requires that the User heed and adhere to all installation and

servicing instruction contained within the equipment’s manuals.

Product Power Cord Requirements

Caution

North American Line Voltages 100 - 120 Volt

This product is supplied with certified 10A/125V SVT type supply cords. Conductors are color coded

white (neutral), black (line) and green or green/yellow (ground).

Operation of this equipment at line voltages exceeding 130V requires that alternative supply cords

with appropriate voltage and current ratings be used.

International Line Voltages 200 - 240 Volts

This product has been designed for use with certified IEC 320- C13 10A/250V - H03 VV-F3G

1.00mm

International product orders are supplied with a certified 10A/250V line cords, utilizing a molded

3-pin IEC 320-C13 type connector at one end and stripped conductors on the other. One line cord is

provided. Conductors are CEE color coded; blue (neutral), brown (line), and green/yellow (ground).

Installation by a qualified electrician, of an appropriately approved A/C wall plug certified for the

country of use, is required.

Alternatively, other IEC 320 C-13 type power cords may be used, provided that they meet the

necessary safety certification requirements for the country in which they are to be used. Refer to the

correctly specified line cord above.

2

type line cord.

EMC Notices

United States of America

FCC Part 15

This equipment has been tested and found to comply with the limits for a class A Digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Notice

Changes or modifications to this equipment not expressly approved by

Ross Video Limited could void the user’s authority to operate this

equipment.

CANADA

This Class “A” digital apparatus complies with Canadian ICES-003.

Cet appariel numerique de la classe “A” est conforme a la norme NMB-003 du Canada.

Page 6

EUROPE

This equipment is in compliance with the essential requirements and other relevant provisions of CE

Directive 93/68/EEC.

INTERNATIONAL

This equipment has been tested to CISPR 22:1997 along with amendments A1:2000 and A2:2002,

and found to comply with the limits for a Class A Digital device.

Notice

This is a Class A product. In domestic environments, this product may

cause radio interference, in which case the user may have to take

adequate measures.

General Handling Guidelines

• Careful handling, using proper ESD precautions, must be observed.

• Power down the system before PCB removal.

A Word About Static Discharge

Throughout the many procedures in this guide, please observe all static discharge precautions.

Notice

Avoid handling the switcher circuit boards in high static environments

such as carpeted areas, and when synthetic fiber clothing is worn.

Touch the frame to dissipate static charge before removing boards

from the frame, and exercise proper grounding precautions when

working on circuit boards.

Page 7

Warranty and Repair Policy

Ross Video Limited (Ross) warrants its switchers and related options, to be free from defects under

normal use and service for a period of THREE YEARS from the date of shipment. Fader handle

assemblies are warranted for the life of the product. If an item becomes defective within the warranty

period Ross will repair or replace the defective item, as determined solely by Ross.

Warranty repairs will be conducted at Ross, with all shipping FOB Ross dock. If repairs are conducted

at Customer Site, reasonable out-of-pocket charges will apply. At the discretion of Ross, and on a

temporary loan basis, plug in circuit boards or other replacement parts may be supplied free of charge

while defective items undergo repair. Return packing, shipping, and special handling costs are the

responsibility of the customer.

Software upgrades for switchers may occur from time to time, and are determined by Ross Video. The

upgrades are posted on the Ross Video website, and are free of charge for the life of the switcher.

This warranty is void if products are subjected to misuse, neglect, accident, improper installation or

application, or unauthorized modification.

In no event shall Ross Video Limited be liable for direct, indirect, special, incidental, or consequential

damages (including loss of profit). Implied warranties, including that of merchantability and fitness

for a particular purpose, are expressly limited to the duration of this warranty.

This warranty is TRANSFERABLE to subsequent owners, subject to Ross’ notification of change of

ownership.

Page 8

Environmental Information

The equipment that you purchased required the extraction and use of natural

resources for its production. It may contain hazardous substances that could impact

health and the environment.

To avoid the potential release of those substances into the environment and to diminish the need for

the extraction of natural resources, Ross Video encourages you to use the appropriate take-back

systems. These systems will reuse or recycle most of the materials from your end-of-life equipment in

an environmentally friendly and health conscious manner.

The crossed-out wheeled bin symbol invites you to use these systems.

If you need more information on the collection, reuse, and recycling systems, please contact your

local or regional waste administration.

You can also contact Ross Video for more information on the environmental performances of our

products.

Page 9

Company Address

Ross Video Limited

8 John Street

Iroquois, Ontario, K0E 1K0

Canada

General Business Office:

Technical Support:

After hours emergency:

E-mail (Technical Support):

E-mail (General Information):

Web si te :

Fax:

Ross Video Incorporated

P.O. Box 880

Ogdensburg, New York

USA 13669-0880

(+1) 613 • 652 • 4886

(+1) 613 • 652 • 4425

(+1) 613 • 652 • 4886

(+1) 613 • 349 • 0006

techsupport@rossvideo.com

solutions@rossvideo.com

http://www.rossvideo.com

Page 10

Page 11

Contents

Introduction 1

A Word of Thanks ................................................................................................................1-1

About This Guide .................................................................................................................1-2

Documentation Conventions ................................................................................................1-3

Documentation Terms ..........................................................................................................1-4

Abbreviations .......................................................................................................................1-5

Product Overview ................................................................................................................1-6

Product Highlights ................................................................................................1-6

Standard Features ..................................................................................................1-8

System Options ....................................................................................................1-11

A Word about Technical Support .......................................................................................1-16

Product Comparison Charts ...............................................................................................1-17

Feature Comparison Chart ...................................................................................1-17

Options Comparison Chart ..................................................................................1-18

Tally Comparison Chart ......................................................................................1-18

Installation 2

In This Chapter ....................................................................................................................2-1

Static Discharge ..................................................................................................................2-2

Getting Started .....................................................................................................................2-3

Unpacking ..............................................................................................................2-3

A Word About Serial Numbers .............................................................................2-3

Equipment Overview ...........................................................................................................2-4

Control Panel, Top View .......................................................................................2-4

Control Panel, Rear Connector Panel ....................................................................2-6

Frame, Front View .................................................................................................2-7

Frame, Rear Connector Panel View ......................................................................2-8

Installation at a Glance ........................................................................................2-10

Hardware Installation .........................................................................................................2-12

Installing the Control Panel .................................................................................2-12

Installing Optional Remote Aux Bus Panels .......................................................2-16

Installing the Electronics Frame ..........................................................................2-18

Connecting Frame Power ....................................................................................2-19

Jumpers and Switches ........................................................................................................2-20

Jumper Positions ..................................................................................................2-20

Frame Jumpers and Switches ..............................................................................2-20

System Reset Notes .............................................................................................2-23

Software Upgrade ..............................................................................................................2-24

System Backup ....................................................................................................2-24

Software Upgrade ................................................................................................2-25

Restoring Registers ..............................................................................................2-27

Options Menu ....................................................................................................................2-28

Menu Access .......................................................................................................2-28

Options Menu ......................................................................................................2-28

Installing Software Options .................................................................................2-30

Synergy 100 Installation Guide (v16.10-S100) Contents • i

Page 12

Preliminary Cabling and Check 3

In This Chapter .................................................................................................................... 3-1

Cabling ................................................................................................................................ 3-2

Control Cable Installation ..................................................................................... 3-2

Remote Aux Panel Cabling .................................................................................. 3-3

Reference Signal Connection ............................................................................... 3-4

Monitor Connection .............................................................................................. 3-4

Power Up ............................................................................................................................. 3-5

Resetting the System ...........................................................................................................3-6

Full Reset .............................................................................................................. 3-6

Software Reset ...................................................................................................... 3-6

Preliminary Functional Check ............................................................................................. 3-7

Basic Troubleshooting .......................................................................................... 3-8

Switcher Timeout .................................................................................................. 3-8

Preliminary Video Installation 4

In This Chapter .................................................................................................................... 4-1

Input Worksheet .................................................................................................................. 4-2

Connecting and Verifying Inputs ........................................................................................ 4-4

Input Connection .................................................................................................. 4-4

Input Verification .................................................................................................. 4-4

Pushbutton Inserts ............................................................................................................... 4-5

Control Panel Pushbutton Inserts .......................................................................... 4-5

Aux Bus Panel Pushbutton Inserts ........................................................................ 4-6

Output Connection ..............................................................................................................4-7

Connecting and Verifying Outputs ...................................................................................... 4-8

Output Connection ................................................................................................ 4-8

Output Verification ............................................................................................... 4-8

Using the Menu System 5

In This Chapter .................................................................................................................... 5-1

Menu System Basics ........................................................................................................... 5-2

Menu Information ...............................................................................................................5-4

BNC Configuration and Check 6

In This Chapter .................................................................................................................... 6-1

BNC Configuration Menu Setup Tree ................................................................................ 6-2

Setting Up BNC Inputs ....................................................................................................... 6-3

Setting Up BNC Types ......................................................................................... 6-3

Setting Up Tallies .................................................................................................. 6-5

Setting Up Auto Keys ........................................................................................... 6-6

Setting Up Panel Buttons ...................................................................................... 6-8

Checking Inputs ...............................................................................................................6-10

Checking Keys .................................................................................................................6-11

Communication Setup 7

In This Chapter .................................................................................................................... 7-1

Communication Menu Trees ............................................................................................... 7-2

Editor Communication Setup .............................................................................................. 7-6

Editor Setup .......................................................................................................... 7-6

ii • Contents Synergy 100 Installation Guide (v16.10-S100)

Page 13

Remote Audio Mixer Communication Setup ....................................................................7-11

Remote Audio Mixer Setup .................................................................................7-11

Setting Up Communication with a Remote Audio Mixer ...................................7-13

Audio Mixer Interface Specifics .........................................................................7-15

MIDIator Interface Cable Specifications .............................................................7-21

Assigning Audio Channels ..................................................................................7-21

Serial Tally Protocol Setup ................................................................................................7-28

Serial Tally Setup ................................................................................................7-28

Additional Installation Setups 8

In This Chapter ....................................................................................................................8-1

Before You Begin .................................................................................................................8-2

Additional Installation Setup Menu Tree .............................................................................8-3

Setting Up Outputs ...............................................................................................................8-4

Aspect Ratio ..........................................................................................................8-4

Reference Delay ....................................................................................................8-5

Clean Feed Setup ...................................................................................................8-6

Ancillary Data Setup .............................................................................................8-7

Setting Up Remote Aux Panels .............................................................................8-9

Remote Aux Panel GPI Programming ................................................................8-12

Field Dominance .................................................................................................8-13

Personality Setup ...............................................................................................................8-15

Transition Preview ...............................................................................................8-15

DSK Drop ............................................................................................................8-16

Sleep Time ...........................................................................................................8-17

Menu Button Setup ..............................................................................................8-18

Auto Recall Setup ................................................................................................8-19

GPI Mode ............................................................................................................8-19

Show Knob Values Mode Setup ..........................................................................8-20

GPI Setup Menu Tree ........................................................................................................8-21

Standard Frame GPI Input Worksheet ...............................................................................8-22

Setting up Frame GPIs .......................................................................................................8-23

Standard GPI Connections ..................................................................................8-26

Setting up Remote Aux Panel GPIs ...................................................................................8-27

Remote Aux Panel GPI Input Worksheet ............................................................8-27

Remote Aux Panel GPI Connection ....................................................................8-30

Setting Up CCU Joystick Aux Control ...............................................................8-30

Setting Up GPI Outputs .....................................................................................................8-34

Completing Setup 9

In This Chapter ....................................................................................................................9-1

Disk Menu Tree ...................................................................................................................9-2

About the Synergy File Storage System ..............................................................................9-3

Notes on Using a USB Key ...................................................................................9-4

Saving Configurations .........................................................................................................9-6

Recalling Configurations ...................................................................................................9-10

Restoring Factory Default Settings ....................................................................................9-13

Recall Factory Procedure ....................................................................................9-13

When Configuration is Complete ......................................................................................9-15

Synergy 100 Installation Guide (v16.10-S100) Contents • iii

Page 14

Appendix A. Specifications 10

In this Appendix ................................................................................................................ 10-1

Standard Components ....................................................................................................... 10-2

Physical Characteristics .................................................................................................... 10-3

General Specifications ....................................................................................... 10-3

Control Panel Specifications ............................................................................... 10-3

Rack Frame ......................................................................................................... 10-3

Rack Frame Connector Types ............................................................................. 10-4

Control Panel Connector Types .......................................................................... 10-4

Power Consumption ............................................................................................ 10-4

Power Rating - Tallies ......................................................................................... 10-5

Environmental ..................................................................................................... 10-5

Video Characteristics ........................................................................................................ 10-6

Video Processing ................................................................................................. 10-6

System Timing .................................................................................................... 10-6

Video Inputs ........................................................................................................ 10-6

Video Outputs ..................................................................................................... 10-6

Output Characteristics ........................................................................................ 10-7

Pinouts ............................................................................................................................... 10-8

Frame Pinouts ..................................................................................................... 10-8

Control Panel Pinouts ....................................................................................... 10-14

Remote Aux Panel Pinouts ............................................................................... 10-17

Aux Panel Programming Mode Summary ...................................................................... 10-20

Appendix B. Hardware Options 11

In this Appendix ................................................................................................................ 11-1

Hardware Option Overview .............................................................................................. 11-2

Clean Feed Installation ...................................................................................................... 11-3

Squeeze & Tease 2D Installation ...................................................................................... 11-4

Floating Border Generator Installation ............................................................................. 11-6

Ultimatte Insider Installation ............................................................................................. 11-7

Ultimatte Insider Board Installation ................................................................... 11-7

Appendix C. Diagnostics 12

In this Appendix ................................................................................................................ 12-1

Diagnostics Overview ....................................................................................................... 12-2

Potentiometer Test .............................................................................................. 12-2

Fader Test ............................................................................................................ 12-3

Positioner Test ..................................................................................................... 12-3

Button Test .......................................................................................................... 12-3

Lamp Test ........................................................................................................... 12-4

Communication Port Monitoring ...................................................................................... 12-5

Switcher Calibration .......................................................................................................... 12-8

iv • Contents Synergy 100 Installation Guide (v16.10-S100)

Page 15

Appendix D. Installation Worksheets 13

In This Appendix ...............................................................................................................13-1

Input Worksheet .................................................................................................................13-2

Output Worksheet ..............................................................................................................13-3

Standard Frame GPI Input Worksheet ...............................................................................13-4

Glossary of Terms GL

Index IX

Synergy 100 Installation Guide (v16.10-S100) Contents • v

Page 16

vi • Contents Synergy 100 Installation Guide (v16.10-S100)

Page 17

Introduction

A Word of Thanks

Congratulations on choosing the Ross Synergy 100 SD digital video production switcher. You have

purchased the power and versatility of an advanced Multi-Level Effects (MLE) digital switcher that is

ready to take on all creative challenges in today’s competitive broadcast environment. You will be

pleased at how easily your Synergy 100 switcher fits into your working environment.

Synergy 100 Installation Guide (v16.10-S100) Introduction • 1–1

Page 18

About This Guide

This guide covers the installation of the Synergy 100 switcher. The following chapters are included:

• Chapter 1, “Introduction” summarizes the guide and provides important terms,

conventions and a system-wide comparison chart.

• Chapter 2, “Installation” provides instructions for installing Synergy 100 hardware and

software, and performing software upgrades.

• Chapter 3, “Preliminary Cabling and Check” outlines procedures for making basic

control panel, main frame, reference and monitor connections. A preliminary functional

check procedure is provided.

• Chapter 4, “Preliminary Video Installation” provides instructions for connecting video

and key signals to all areas of the switcher.

• Chapter 5, “Using the Menu System” provides an introduction to the menu system of

the Synergy 100.

• Chapter 6, “BNC Configuration and Check” provides instructions for configuring and

checking your BNC inputs.

• Chapter 7, “Communication Setup” provides instructions for setting up

communication parameters with an audio mixer, a serial tally interface, or external

editors.

• Chapter 8, “Additional Installation Setups” provides instructions for additional setup

procedures such as setting up outputs, clean feed, GPIs, and DSK Drop.

• Chapter 9, “Completing Setup” provides instructions for storing switcher

configurations to a storage device and resetting factory defaults.

• Appendix A, “Specifications” provides technical specifications and connector pinout

diagrams.

• Appendix B, “Hardware Options” provides instruction for installing a variety of

hardware options.

• Appendix C, “Diagnostics” provides information on the Synergy 100 panel diagnostics

tools.

• Appendix D, “Switcher Installation Worksheets” contains copies of the worksheets

described throughout this guide. Use these blank worksheets to plan and record your

switcher installation and wiring connections.

• The Glossary provides a reference list of important switching and video terms used

throughout this guide.

•An Index is also provided for your reference.

Note

If, at any time, you have a question pertaining to the installation of your Ross Synergy 100 switcher,

please contact us at the numbers listed in the front of this guide. Our technical staff are always

available for consultation, training or service.

Refer to the Synergy 100 Operation Guide for a comprehensive

outline of product highlights, plus a complete overview of standard

and optional system features.

1–2 • Introduction Synergy 100 Installation Guide (v16.10-S100)

Page 19

Documentation Conventions

The following conventions are used throughout this guide:

• Rear panel connectors are indicated in bold-faced upper case letters. For example:

The AUX 1 connector is …

• Control Panel buttons are indicated in bold-faced upper case letters, using a sans-serif

font. For example:

Press WIPE to …

• Menu names on the preview overlay are indicated in bold-faced text. For example:

The Inputs Menu allows you to…

Synergy 100 Installation Guide (v16.10-S100) Introduction • 1–3

Page 20

Documentation Terms

The following terms are used throughout this guide:

•A “1+1 DVE” has both a video (fill) and an key (alpha) connection from Synergy to the

DVE. Both key and fill signals are connected from the DVE to Synergy.

• “Crosspoint” is synonymous with “Button”. Both refer to the switcher crosspoints or

buttons on the Synergy 100 control panel.

•“DVE” refers to the DVE (either single or multi-channel) that is connected to a Synergy

100 switcher via RS-422 serial control.

• “Input #” refers to the “BNC input #” on the rear of the Synergy 1 frame and vice

versa.

•“Frame” and “Electronics Frame” both refer to the Synergy switcher’s electronics

frame.

•“Operator” and “User” refer to the person who uses the Synergy 100 production

switcher.

•“Panel” and “Control Panel” both refer to the Synergy switcher’s large multi-button

control panel.

•“SDI” refers to Serial Digital Interface, a digital video signal that is distributed via a

single coaxial cable with BNC connectors.

•“Storage device” refers to a standard 1.44 MB high-density floppy disk or a USB key.

Either type of storage device can be used to save and recall configurations, setups and

certain files to the Synergy switcher.

•“System” refers to the entire Synergy 100 system, consisting of its electronics frame and

control panel.

•“Video system” refers to the mix of interconnected digital equipment (including the edit

controller, VTRs, DVEs, etc.) in which the Synergy 100 system is included.

1–4 • Introduction Synergy 100 Installation Guide (v16.10-S100)

Page 21

Abbreviations

The following abbreviations are used throughout the text:

A-D

Abbreviations

Abbreviation Definition

Analog-to-Digital

BKGD

AUX

CG

D-A

DA

DDR

DSK

DVE

DVR

ID Identification

MLE

PST

PST PATT

PV

RU

TD

VCR

Background Bus

Auxiliary

Character Generator

Digital-to-Analog

Distribution Amplifier

Digital Disk Recorder

Downstream Keyer

Digital Video Effects

Digital Video Recorder

Multi-level Effects

Preset Bus

Preset Pattern

Preview

Rack Unit

Technical Director

Video Cassette Recorder

VDCP Video Disk Communications Protocol

VTR

Synergy 100 Installation Guide (v16.10-S100) Introduction • 1–5

Video Tape Recorder

Page 22

Product Overview

Ross Video developed the Synergy series for live news, live sports and live production. Because the

switcher is the center of the action, it must be powerful and versatile, yet easy to operate. This

operational simplicity frees operators to concentrate on the content — instead of the equipment.

The Synergy series (our fourth generation of switchers) was designed with the direct input of video

professionals experienced in news, sports, and mobile production. Key members of the Synergy

design team are part of an ongoing program where they demonstrate the product, assist with

installations and provide operator training. As a result, the Synergy line continues to advance Ross

Video’s traditions — power, ease of use and logical panel layouts.

Product Highlights

The following list summarizes the Synergy 100’s key features:

• Fully Digital System. The Synergy 100 switcher is fully-digital, including the reference

video connection. No analog input/output circuitry is provided. This unique concept

simplifies the design, minimizes the power requirements and reduces the overall cost.

By requiring all A-D and D-A conversion to be performed outside the system, digital

noise stays out of the converters. In addition, customers are guaranteed the latest

converter technology, without burdening the cost of the switcher and with the added

option to use those converters for other purposes — as they gradually convert to the

digital domain.

• Multi-Panel Flexibility. For superb flexibility and versatility, the Synergy 1 frame is

designed to operate with eight different control panels, four of which previously

operated in an analog environment:

~ GVG 100 (analog)

~ GVG 110 (analog)

~ RVS-210A (analog)

~ RVS-216A (analog)

~ RVS-210D (digital)

~ RVS-216D (digital)

~ Synergy 1 (digital)

~ Synergy 100 (digital)

• Large Input Matrix. The Synergy 1 frame can accept up to 16 digital video inputs —

not including black and two color background signals (which are generated internally).

On the Synergy 100 panel with its 10 available crosspoints, you have several crosspoint

layout options:

~ Assuming that Black and Color Background are mapped to crosspoints 1 and

10, respectively, and you have not mapped a SHIFT button, the panel gives you

direct access to 8 inputs. The remaining sources can be mapped internally, allowing

you to associate key (alpha) signals with their respective fill sources.

~ If you wish to map a SHIFT button to crosspoint 10, with Black and Color

Background mapped to crosspoints 1 and 9, respectively, the panel gives you

direct (and shifted) access to all 16 inputs. In this configuration you can also

internally associate key and fill inputs, for full input matrix flexibility.

1–6 • Introduction Synergy 100 Installation Guide (v16.10-S100)

Page 23

Note

• Compact Size. The 2 RU frame accepts 16 inputs and one fully optioned MLE,

• Low Power. The only power requirements are a maximum 180 watts for the frame and a

• Growth Path. The Synergy 1 frame provides a versatile growth path, regardless of your

• Three Powerful Keyers (Standard). The Synergy 100 panel provides access to three

If you prefer, the SHIFT button can be mapped to crosspoint 1, with

Black being mapped to an alternate crosspoint.

including eight untimed Aux Buses. There is no extender board available, but the frame

top can be removed easily for servicing if required. The CPU board has convenient

ejector handles on each side and plugs easily into the frame’s backplane.

maximum of 19 watts for the control panel. The frame’s power supply is designed for

easy removal if an exchange is required.

entry point within the system. If you start with a GVG 100, GVG 110, Ross RVS-210A

or 210D, Ross RVS-216A or 216D control panel, or a Synergy 100 control panel, you

can move up to the Synergy 1 control panel and benefit from a full range of advanced

features. If you start with the Synergy 1 control panel already in place, you can

optionally add two more Downstream Keyers for added flexibility and creativity in your

productions. Furthermore, knowledge and skill gained on the Synergy 1 panel allows a

seamless transition to the larger Synergy switchers — as operation is almost identical.

powerful keyers (two Effects keyers and one Downstream keyer):

~ The Effects Keyers provide self, auto select, preset pattern and chroma key

capabilities.

~ The Downstream Keyer provides self and auto select keys.

~ A key border can be generated on the downstream key if the optional border card is

installed.

~ With the optional Squeeze & Tease 2D or Squeeze & Tease WARP feature

installed, the Effects Keyers can also perform simple 2D or more complex 3D DVE

effects and Squeeze & Tea se 2D boxes. Refer to the section “Squeeze & Tease ” on

page 1-12 or the Squeeze & Tease 3D/WARP Owner’s Guide for more information.

• Squeeze & Tease 2D and Squeeze & Tease WARP. A simple 2D or more complex 3D

DVE can be built into the Effects Keyers. With either option installed, all key types can

be repositioned, squeezed, and zoomed.

With 2 D, you can simultaneously crop, reposition, squeeze or zoom, and adjust the

border on a key inside a single keyer. With WARP, you can simultaneously crop, rotate,

squeeze or zoom, and reposition a key in 3D space inside a single keyer.

Refer to the section “Squeeze & Tease ” on page 1-12 or the Squeeze & Tease

3D/WARP Owner’s Guide for more information.

• Chroma Keying. A standard feature in the Effects Keyers, the chroma keyer features

auto chroma key, hue suppression, rejection, and adjustable clip and gain parameters.

Our chroma keyer was designed for use in today’s fast-paced productions.

• Two Pattern Generators (Standard). The Synergy 100 is equipped with a primary

pattern generator for creating wipes, plus a secondary pattern generator for PST PATT

keys. The primary generator is equipped with extensive classic, rotary, and matrix wipes.

Synergy 100 Installation Guide (v16.10-S100) Introduction • 1–7

Page 24

• Fully Featured “Program/Preset.” The Program/Preset buses have full multi-level

effects capability including wipes, chroma keys, and preset patterns.

• Effects Functions (Preview Overlay). This powerful feature presents safe title, center

crosshairs, and more. Displays are individually selectable on the preview monitor for

quick reference.

• Rugged Construction. Ross products are tough — they’re built to handle years of

demanding, continuous use. In addition, the Synergy series is backed by a three-year

transferable warranty.

Standard Features

The following features are standard in the Synergy 100 switcher:

• Complete Control Panel

Regardless of what options are ordered, your control panel is always equipped with

every button, knob, display, and light. This means that your Synergy 100 switcher and

your control room will look their very best – even if your budget is tight.

• Serial Digital Inputs

Sixteen serial digital inputs are standard on the Synergy 100. Any input can be assigned

to any button on the Program/Preset bus, thus simplifying installation and your ability to

customize the panel layout. Inputs can be used for either video or alpha channels.

• Panel Tallies

There are 16 panel tallies on the Synergy 100 control panel.

Full MLE Effects

The Synergy 100 switcher includes a full-featured MLE that includes the following functions:

• Two wipe generators are standard.

• The MLE includes three keyers that each offer matte fill, key invert, mask, adjustable

clip and gain, and self (luminance) key and linear (auto select) key modes.

• The downstream keyer offers extensive optional bordering that works with both key

types.

• The optional Squeeze & Tease 2D or Squeeze & Tease WARP feature can be installed

in the Effects Keyers, allowing you to squeeze, zoom, or in the case of the WARP

option, rotate any key type. Refer to the section “Squeeze & Tease ” on page 1-12 or the

Squeeze & Tease 3D/WARP Owner’s Guide for details.

• The MLE features five comprehensive matte generators.

• Full preview capability is provided.

Copy and Swap Functions

The following convenient copy and swap functions are available as standard:

• Copy Key – allows you to copy the contents of one keyer to another keyer.

• Swap Key – allows you to swap the contents of one keyer with another keyer.

1–8 • Introduction Synergy 100 Installation Guide (v16.10-S100)

Page 25

Pattern Generators

The Synergy 100 includes (as standard) both primary and secondary pattern generators that are used

for wipe transitions and preset patterns. The primary generator is equipped with extensive classic,

rotary, and matrix wipes. The secondary generator provides classic patterns.

Chroma Keying

Chroma keying is available in the Effects Keyers. Each high quality chroma keyer features internal

4:4:4 chroma channel interpolation from any of the 4:2:2 inputs. Using the control panel, you can

adjust the Chroma key’s clip, gain, rejection, suppression, and hue. The Auto Chroma Key feature

allows the user to quickly and automatically achieve the best chroma key for a selected color.

Untimed Aux Buses

Eight untimed Aux Buses are standard, each of which can be used to route video to monitors, DVE

channels, still stores, tape machines, etc. Aux Buses 3 through 10 can be used to route any untimed

signals to other external sources, including:

• Black (as supplied by the “601 REF IN” BNC), plus all primary inputs

• Clean feed (if the option is installed)

• MLE program and preview outputs

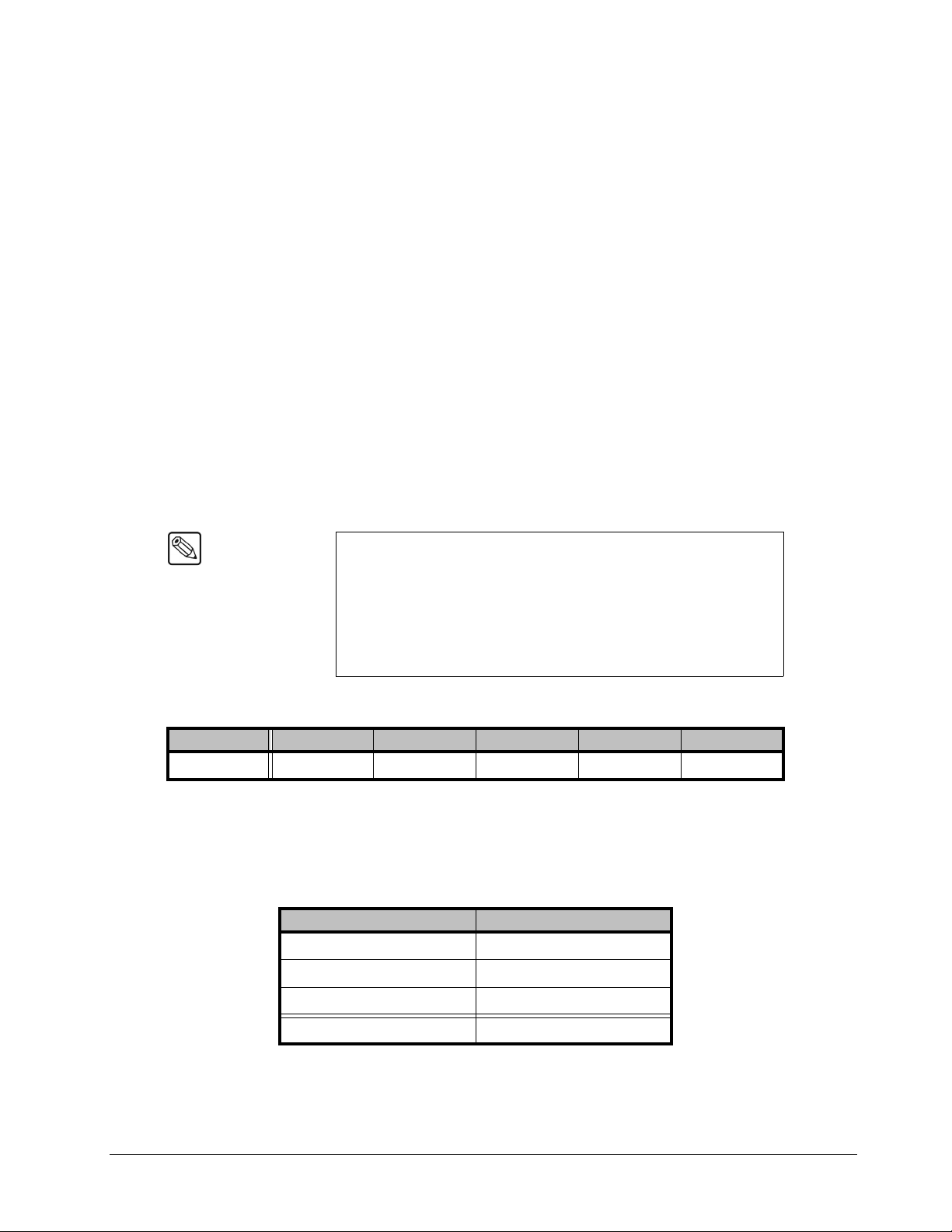

Note

Aux Bus Timing Black PV Clean Feed PGM

3 - 10 Untimed Ref Yes Yes Yes

Black, clean feed, and program and preview outputs can only be routed

to the Aux Buses using a Remote Aux Panel. All other signals

(primary inputs) can be routed using either the remote panels or the

Synergy 100 control panel itself.

Since the Synergy 1 frame generates its own internal black signal,

selecting BLACK on an untimed Aux Bus will route to the output

whatever is connected to your “601 REF IN” BNC. See table below.

Aux Bus Capabilities by Timing Status

Standard Digital Outputs

The following table lists all standard Synergy 100 digital outputs:

Synergy 100 Digital Outputs

Output Type Quantity

Program 2

Preview 2

Aux Bus 8

Total Outputs 12

Synergy 100 Installation Guide (v16.10-S100) Introduction • 1–9

Page 26

Note

If the Clean Feed option is installed, an additional output is provided,

for a total of 13 outputs.

Aux Buses 1 and 2 are available with the Synergy 1 panel. Contact

Technical Support for information.

Disk Drive

Using a standard high-density 3.5-inch floppy disk, you can quickly and easily upgrade your switcher

software as new versions are released. In addition, each operator can store and recall their own

complete switcher setups, including memory functions, switcher personalities, installation parameters,

and 3D wipes.

Memory System

The Synergy 100 switcher is equipped with a standard 100-event memory for complete switcher

snapshots. At the touch of a button, the entire switcher setup can be recalled using the numbered

buttons in the Effects Control group, or the 10 and 1 buttons (in conjunction with the SEL button) in

the System Control group.

Matte Generators

The Synergy 100 switcher has five simple color generators. These color generators allow you to adjust

the hue, color saturation, and luminance of the BKGD, wipe pattern borders, Effects key fill, or the

Downstream key border and matte fill.

Displays and Indicators

The Synergy 100 switcher always keeps you informed.

• PGM bus crosspoints are illuminated red, signifying “on-air” status, except when the

panel is faded to black. In this case, the crosspoint LEDs will be orange.

• PST bus crosspoints are lit orange, except during a background transition, when they

will be red.

• KEY bus crosspoints will be lit orange when the key is not on air, and red when the key

is contributing to the program output.

• The secret-till-lit LEDs to the left of each crosspoint bus will be lit green when the

source selected on the bus is synchronous, and orange if the source is non-synchronous.

• Functions that have control of the Effects Control groups will be lit green (e.g. FLY

KEY).

• The ON AIR secret-till-lit LEDs in the Effects Keyers group and under the key and

DSK transition buttons in the Transition Control group glow red when the key is on air.

• The EDIT secret-till-lit LED under the MENU button in the System Control group is lit

when the Editor option is installed and enabled.

• The auto transition rate in the System Control group is constantly visible.

• When the switcher is in “memory mode”, the last memory register accessed is displayed

in the System Control group.

• The four-character MODE displays in the Effects Control, Mattes, and System

Control groups, always inform you of which function has control of each group.

• The LEDs in the Transition Progress Bar show you how far the transition has

progressed, and which direction the fader must travel to complete it.

1–10 • Introduction Synergy 100 Installation Guide (v16.10-S100)

Page 27

General Purpose Interface

The Synergy 100 switcher is equipped with twelve dedicated GPI inputs.

• GPI Inputs allow the switcher to interface with peripheral equipment. Each input can be

assigned to perform functions such as a fade-to-black, a memory recall, or an MLE auto

transition.

Effects Functions (Preview Overlay)

The Effects function makes it possible to present various types of useful information on the two

preview outputs. The overlay can be displayed according to user preferences. A variety of overlay

information is available:

• The “Safe Title and Safe Action Area” overlay places a SMPTE standard safe title or

safe action area indication over the switcher’s main preview output.

~ Safe title is a box that outlines the area within which the vast majority of home TV

sets will be able to read text.

~ Safe action area is a box that outlines the region within which viewers should be

able to follow the action on the screen.

• The “Center Cross Hairs” overlay places cross hairs on the preview output to indicate

the center of the picture. It is useful in the alignment of text and other information.

• The “Menu Bkgd” gives you the option of placing a blue background behind the menu,

as opposed to having the text on top of the preview output.

Digital Reference

The Synergy 100 switcher requires a digital reference signal connected to the 601 REF IN BNC.

Internal black is regenerated from this digital reference. If only an analog reference is available, an

external A-D converter is required.

Synergy Slots

The Synergy 100 incorporates a special mode in which pseudo-random information is statistically

measured on a cumulative basis.

System Options

This section lists the options available for the Synergy 100.

Note

USB Removable Media Drive

The USB Removable Media Drive replaces the floppy disk drive in the control panel, and supports

industry standard USB keys. This option makes it possible to store and recall complete switcher

setups including memory functions, switcher personalities, installation parameters, and more, to a

USB key. Operators and technical staff can easily back up switcher setups and transfer these settings

to other Synergy production switchers.

Refer to the section “Options Menu” on page 2-28 for instructions on

how to verify the status of your installed hardware options.

Note

Synergy 100 Installation Guide (v16.10-S100) Introduction • 1–11

This option requires version 16 or higher Synergy 100 SD software,

and version 3 or higher of the control panel CPU board.

Page 28

Clean Feed

The Clean Feed option provides an additional “program” output that is derived from a different

location than the standard program output. Typical applications are live-to-tape productions and

recording shows for later airing without “call in” numbers inserted.

The Clean Feed output can be generated from different locations in the video path. It can come from

before or after all keys, including the DSK, or after the Effects Keyers but before the DSK. The Clean

Feed alpha output can be derived from any key type on Key 1. The point from which the feed is

derived is software-configurable. Refer to the following diagram:

2 31

PGM

PST

EFFECTS

KEY1

EFFECTS

KEY2

Clean Feed Modes

DSK

PGM

CLEAN

FEED

1. At point 1 above, the clean feed output is pulled after the MLE’s program/preset bus, but

before the three keys are added.

2. At point 2 above, the clean feed output is pulled downstream of the two Effects keyers,

but upstream of the DSK.

3. At point 3 above, the clean feed output is pulled downstream of the three MLE keyers

and effectively mirrors the program output.

Note that the Clean Feed option comprises software plus a hardware “serializer” module that installs

on the Frame Processor Board. Please call Ross Video Technical Support for more details.

Squeeze & Tease

One Squeeze & Tease option puts the power of a simple 2-D (two dimensional) or 3D (three

dimensional), 2 channel, WARP DVE into both Effects keyers. Once installed, the Squeeze & Tease

2D option can perform the following digital video effects – using only one keyer.

• Squeeze, crop, and reposition an image with variable colored borders.

• Squeeze, crop, and reposition a self key or a chroma key.

• Push on and push off any type of key as a transition.

• Squeeze, crop, and reposition an auto select key. Note that this function “steals” the

other Effects keyer’s Squeeze & Tease option in order to process the alpha signal, but the

remaining functionality of the other keyer is unaffected.

• Perform Squeeze & Tease wipes, such as push-offs, pull-ons, and other similar 2D DVE

transitions.

One Squeeze & Tease WARP option can perform the following digital video effects.

• 10-bit processing using sub-pixel motion for great looking pictures.

• Warp effects include page turn, ripple, wave, mirror, swirl, melt, twist, slats, spheres,

lens, gnarl, organics, pixie dust, sand, and more.

• Squeeze, crop, rotate, and reposition any kind of key.

• Create objects (such as slabs) from two images and manipulate them in 3D space.

1–12 • Introduction Synergy 100 Installation Guide (v16.10-S100)

Page 29

• Preprocessor effects include defocus, mosaic, posterization, colorization, and strobe

effects.

• Advanced picture frame borders can be the simple, single color type, or a fancy picture

frame, including Roman column, tubular, beveled, computer style, tri-color, and more.

• All images can have natural lighting effects applied using a positionable light source

with ambient light min/max controls.

Operationally, Squeeze & Tease is exceptionally easy to control. Most effects can be produced simply

by pressing the FLY KEY button in the Effects Keyer group and using the 3-axis joystick and

associated end stop knobs. Additional adjustment can be made through the menu system. Please note:

• Both Squeeze & Tease options comprise software plus “daughter boards” that install on

the Frame Processor Board.

Tally Outputs

There are 16 optional frame tally relays available. Any tally can be assigned to any video input or the

program output. Note that the Tallies option comprises the hardware relays that install in the switcher

frame.

Floating Border Generator

The Floating Border Generator option provides visually dynamic border, shadow, and outline

effects to the Downstream Keyer group, with either hard or “soft” edges. You can move the border to

any position on the screen — even above the key.

Borders are “flown” in real time with the joystick (just like wipe patterns and DVE effects). Please

note:

• All border edge effects can be modified through the parameters of X and Y position,

border size, border color, density, and glow (giving a soft defocused look).

• The Floating Border Generator option comprises software plus a “daughter board”

that installs on the Frame Processor Board.

Editor Interface

The Editor Interface Option allows the Synergy 100 to interface with all popular editing systems.

The option itself comprises software plus security codes and once installed, the switcher can be

controlled using an RS-232 or RS-422 interface and industry standard editor protocol. The editor can

be used to read and write switcher functions including video input selection, pushbutton enable and

disable, control settings, and memory registers. If GPI control is not sufficient and control of all

switcher parameters from an editor is necessary, this option is required.

Remote Audio Mixer Control Interface

The Remote Audio Mixer Control Interface Option enables serial control from the Synergy 100

over an audio mixer for enhanced audio-follow-video, making an integrated A/V production possible.

This protocol supports the association of any audio input with any video input, as well as easy audio

voice-over and level control directly from the Synergy 100 control panel.

Serial Tally Interface

The Serial Tally Protocol Option allows you to set up communication parameters with tally system

interface equipment using industry standard protocol. Note that the standard parallel tally interface

will continue to operate normally when this option is enabled.

Synergy 100 Installation Guide (v16.10-S100) Introduction • 1–13

Page 30

Ultimatte Insider

Ultimatte Insider™ Option is a hardware option that adds true Ultimatte capability — directly inside

the Synergy 100 switcher. The option comprises a hardware board designed by Ultimatte, the

Oscar-winning industry leader in compositing technology.

Dedicated and Assignable Remote Aux Panels

A Remote Aux Panel is a self-contained switching unit that has its own power supply. It mounts in a

19-inch rack and fills 1 RU (Rack Unit). There are two types of remote Aux panels available for the

Synergy 100 switcher:

•A Dedicated Remote Aux Panel controls one Aux Bus output. A sample panel is

shown below:

BLACK

2345678 9

1

MLE

CLEAN

DVE

PV

SEND

PGM

FEED

SHIFT

10

Dedicated Remote Aux Panel

•An Assignable Remote Aux Panel controls all 8 Aux Bus outputs. A sample panel is

shown below:

BLACK

2345678

1

MLE

CLEAN

DVE

PV

SEND

PGM

FEED

SHIFT

9

ASSIGN

10

ASSIGN

ASSIGN

ASSIGN

1

2

ASSIGN

ASSIGN

7

6

ASSIGN

ASSIGN

3

4

ASSIGN

ASSIGN

10

9

8

Assignable Remote Aux Panel

5

In addition to the source buttons, each panel includes dedicated buttons for MLE PV, Clean Feed,

Program, and future DVE Send capabilities, plus a bright “on air” LED. Assignable panels include

buttons that are used to access the 8 Aux Bus outputs.

The remote panel itself is connected to the rear of the switcher’s frame via a single six-conductor

Telco control cable. Typical applications include routing signals to one or more DVE channels and

switching a monitor between various signals.

Up to eight Aux panels can be connected to the frame in daisy-chain fashion.

Please note:

• Both the Dedicated and Assignable Aux panel options include a 33-foot (10 meter)

cable. Custom cable lengths are available.

• The maximum cable length between panels (as limited by RS-422 specifications) is

1000 feet (305 meters).

• The communications signal is re-buffered at each Aux panel.

Conversion Frames

All switcher inputs and outputs are 10-bit SDI, including the system reference. Signal sources of other

video formats must be converted to serial digital. Ross Video chose to do this conversion externally to

ensure that the very latest conversion technology and most competitive pricing is available to our

customers. An added bonus of external conversion is the ability to use those converters elsewhere in

your facility as you eventually upgrade your switcher sources to serial digital. The table below lists

the Ross products that qualify as converters.

1–14 • Introduction Synergy 100 Installation Guide (v16.10-S100)

Page 31

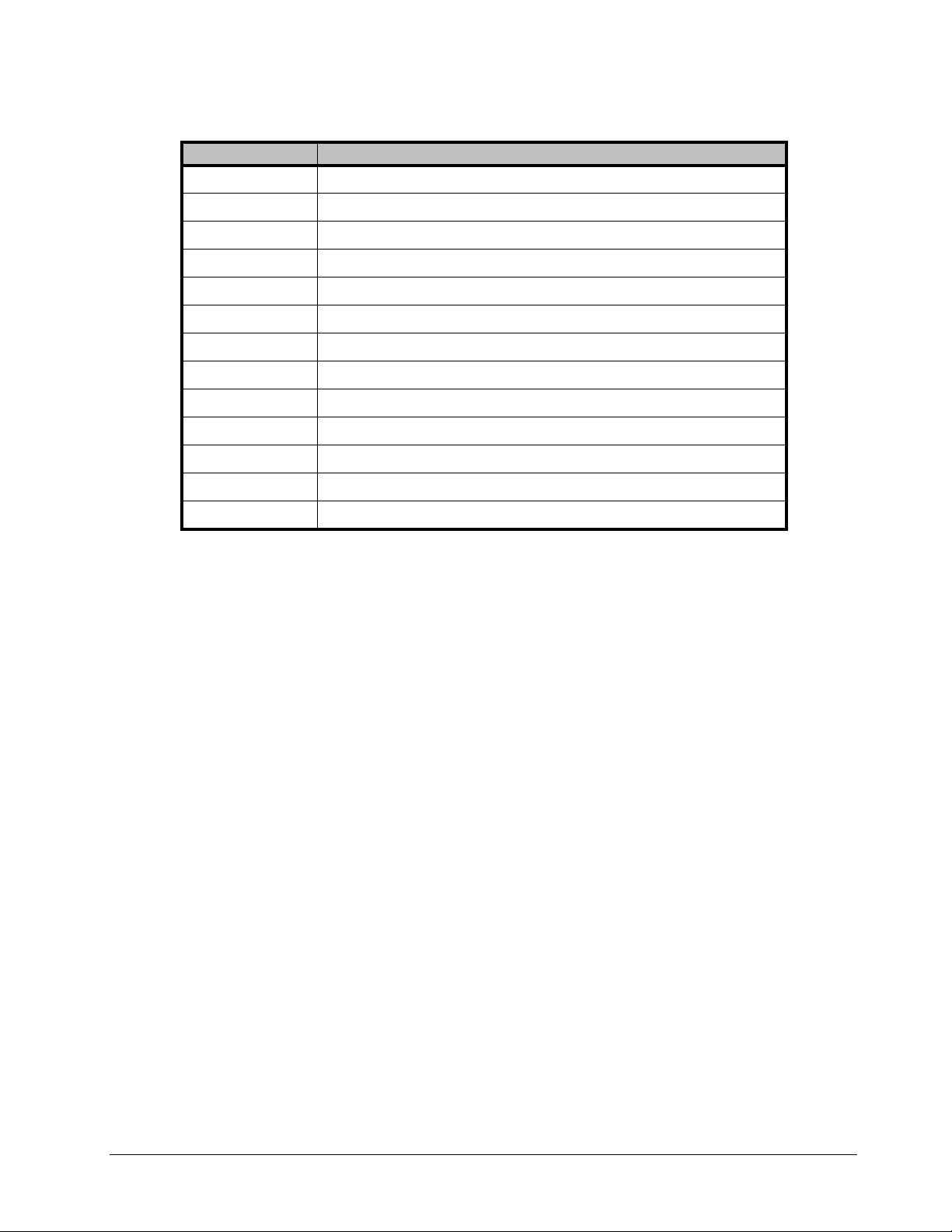

Ross Converters

Converter Description

ADC-8032B Analog Composite to SDI Digital Decoder

ADC-8032B-S Analog Composite to SDI Digital Decoder with Frame Sync

ADC-8033 Analog Component to SDI Converter

ADC-8035 Dual Analog Composite to SDI Converter

CMA-8011A SDI Component Monitoring Amplifier

CMA-8011A-7 SDI Component Monitoring Amplifier with 7 reclocked SDI Outputs

DAC-8013 SDI to Analog Component Converter

DAC-8016A SDI to Analog Composite Converter

DAC-8016A-S SDI to Analog Composite Converter with Frame Sync

DAC-8016A-SX SDI to Analog Composite Converter with Frame Sync and X-Color Filter

DAC-8016A-X SDI to Analog Composite Converter with X-Color Filter

QMA-8044 Quad SDI to Analog Composite Monitoring Amplifier

UMA-8017 Universal SDI Monitoring Amplifier

Please visit our website at http://www.rossvideo.com or contact your Ross Video representative to

obtain a current Ross Video Product Catalog for detailed information on our complete line of

converters.

Spare Parts Kit

A Spare Parts Kit is available which provides switcher parts according to the following criteria:

• the part comes into frequent contact with the user

• the part can be easily damaged or may wear out with excessive use

• the part can be damaged by connecting excessive voltage to an external connector

• the part is used in system power management

• the part can be lost easily

Custom Main Panel Cable

The Main Panel cable connects the control panel to the electronics frame. It is a shielded 8-pin Telco

cable and the ends are finished with the appropriate connectors. The control panel and frame can be

separated by a maximum of 1,000 feet (305 meters).

A 33-foot (10 meter) control panel cable is supplied as standard with the switcher. If cable lengths

other than 10 meters are needed, a custom cable can be ordered (by the meter).

Synergy 100 Installation Guide (v16.10-S100) Introduction • 1–15

Page 32

A Word about Technical Support

At Ross, we take pride in the quality of our products, but if problems occur, help is as close as the

nearest telephone.

Our 24 Hour Hot Line service ensures you have access to technical expertise around the clock.

After-sales service and technical support is provided directly by Ross personnel. During business

hours (eastern standard time), technical support personnel are available by telephone any time. After

hours and on weekends, a direct emergency technical support phone line is available. If the technical

support personnel who is on call does not answer this line immediately, a voice message can be left

and the call will be returned shortly. These people are available to react to any problem and to do

whatever is necessary to ensure customer satisfaction.

For Technical Support, call (+1) 613-652-4886 and, for After Hours Emergency, dial (+1)

613-349-0006.

1–16 • Introduction Synergy 100 Installation Guide (v16.10-S100)

Page 33

Product Comparison Charts

For your reference, following are detailed charts that compare the features and options that are

available with the Synergy 1’s different control panel configurations.

Feature Comparison Chart

Feature Synergy

100

100 Event Memory Yes (*10) Yes Yes (*10) Yes (*10) Yes (*10)

Number of Keyers 3 4 (3) 2 2 3 (*4)

All 16 Inputs Accessible Yes (*1) Yes Yes (*1) No (*2) Yes

Chroma Key Clip, Gain and Hue controls Yes Yes Yes Yes Yes

Chroma Key Reject, Blue spill suppression controls Yes Yes Yes (*8) No (*9) No (*9)

Custom Control (Macros) No Yes No No No

DSK Borders Yes No (*6) Yes Yes Yes

DSK DVE Send Transitions No (*7) No (*6) No (*7) Yes Yes

DSK Still Store and Animated Logo Generator No Yes (*6) No No No

DVE Send No Yes Yes Yes Yes (*5)

Extended Wipe Patterns Yes Yes Yes Yes Yes

Favorite CG Button Yes Yes No Yes Yes

Internally Generated Black Yes Yes Yes Yes Yes

Internally Generated Color Yes Yes Yes Yes Yes

Key 1 Borders No Yes No No No

Key 1 Squeeze and Tease Yes Yes Yes Yes Yes

Non-Sync LEDs Yes Yes No Yes Yes

Preview Overlay Yes (*11) Yes Yes (*11) Yes (*11) Yes (*11)

Remote Aux Panel GPIs Yes Yes No No No

Software Reset from Panel Yes Yes No No No

Transition Preview Yes Yes No Yes Yes

Synergy 1 GVG

110/100

Ross

210A/D

Ross

216A/D

Notes:

(*1) Panel supports SHIFT button.

(*2) The hidden (inaccessible) inputs can be configured as key signals.

(*3) 2 keyers are standard and 2 external DSKs are optional.

(*4) The Encoded Chroma Key button becomes the MLE Key 2 button. In this mode,

external DVE Sends are not available. The DSK “next transition” button becomes the

MLE Key 2 button and the DSK is then controlled by dedicated buttons (for CUT,

AUTO TRANS).

(*5) In 2 Keyer mode only. Timed Aux Bus option must be installed.

(*6) DSKs on Synergy 1 are optional and external. They only have Self and Auto Select key

capability.

(*7) DSK can only perform Mix (dissolve) and Cut transitions.

(*8) Variable via Chroma Key button hold down.

(*9) Fixed settings.

(*10)Bank selectable via the Auto Trans (System Control) display.

(*11)Centre mark and safe title only.

Synergy 100 Installation Guide (v16.10-S100) Introduction • 1–17

Page 34

Options Comparison Chart

The following chart details options that are available with each Synergy 1 switcher configuration.

Option Synergy 100 Synergy 1 GVG-100/110 Ross 210A/D

216A/D

Audio Server Control No Yes No No

Clean Feed Yes Yes Yes Yes

Dual Aspectizer No Yes No No

Dual Border Generator (*4) Yes Yes Yes Yes

DVE Send No Yes Yes Yes

Editor Interface Yes Yes Yes Yes

External DSKs (up to 2) No Yes No No

Frame Tallies Yes Yes Yes Yes

Panel Tallies Yes (*2) Yes (*2) No Yes (*2)

Redundant Power No Yes (*3) No No

Remote Audio Mixer Control Interface Yes Yes No No

Remote Aux Panels Yes Yes Yes Yes

Remote Camera Control No Yes No No

Routing Switcher Control No Yes No No

Serial Tally Interface Yes Yes No No

Squeeze & Tease Yes Yes Yes Yes

Squeeze & Tease 3-D Yes Yes No No

Still Store Control No Yes No No

Timed Aux Buses No Yes (*1) Yes (*1) Yes (*1)

Ultimatte Insider Yes Yes No No

Video Server Control No Yes No No

VTR Remote Control No Yes No No

Notes:

(*1) Aux Bus 1 and 2 can be timed.

(*2) Panel tallies are standard. See table below.

(*3) In the control panel only.

(*4) Floating Border Generator option for the Synergy 100.

Tally Comparison Chart

The following chart details the optional tally combinations that are available with each Synergy 1

switcher configuration.

Tally Configuration Synergy

100

Panel Tallies 16 (Standard) 16 (Standard) — 8 (Standard) 14 (Standard)

Frame Tallies 16 16 16 16 16

Maximum Tallies 32 32 16 24 30

1–18 • Introduction Synergy 100 Installation Guide (v16.10-S100)

Synergy 1 GVG-100/1

10

Ross

210A/D

Ross

216A/D

Page 35

Installation

In This Chapter

This chapter provides instructions for installing your Synergy 100 SD switcher hardware. The

following topics are discussed:

• Static Discharge

• Getting Started

• Equipment Overview

• Installation at a Glance

• Hardware Installation

• Installing the Control Panel

• Installing Optional Remote Aux Bus Panels

• Installing the Electronics Frame

• Connecting Frame Power

• Jumpers and Switches

• Software Upgrade

• Options Menu

• Installing Software Options

Operating

Tip

Refer to Appendix D. Installation Worksheets on page 13–1 for

worksheets you can use to record switcher installation and wiring

connections.

Synergy 100 Installation Guide (v16.10-S100) Installation • 2–1

Page 36

Static Discharge

Throughout this chapter, please heed the following cautionary note:

Caution

Static discharge can cause serious damage to sensitive semiconductor

devices. Avoid handling the switcher circuit boards in high static

environments such as carpeted areas and when synthetic fiber clothing

is worn. Touch the frame to dissipate static charge before removing

boards from the frame and exercise proper grounding precautions

when working on circuit boards.

2–2 • Installation Synergy 100 Installation Guide (v16.10-S100)

Page 37

Getting Started

The following topics are covered in this section:

• Unpacking

• A Word About Serial Numbers

Unpacking

A complete Synergy 100 system is typically shipped in three boxes as outlined below. Your shipping

configuration may vary.