INSTRUCTION MANUAL

ROSITO BISANI

Gas Cooker

MODEL:

CPG

These instructions should be read thoroughly before attempting installation.

Set up and installation should be performed by qualified installation personnel.

Keep area around appliances free and clear from combustibles.

PLEASE RETAIN THIS MANUAL

FOR FUTURE REFERENCE.

THE MONTAGUE COMPANY

1830 Stearman Avenue P.O. BOX 4954

HAYWARD,CA 94540-4954

TEL: 510/785-8822 FAX: 510/785-3342

TABLE OF CONTENTS

1. INSTRUCTIONS TO PREVENT ACCIDENTS ………. 4

2. INSTALLATION ………. 5

2.1 Preliminary Instructions ………. 5

2.2 Handling and Unpacking ………. 5

2.3 Connecting to the water-main ………. 6

2.4 Connecting to the gas supply mains ………. 6

2.4.1 Setting up and adjusting ………. 6

2.4.2 Checks ………. 7

3. USER INSTRUCTIONS ………. 8

4. SPECIFICATIONS ………. 9

5. PUTTING INTO OPERATION ………. 10

5.1 Operations prior to starting ………. 10

5.2 Lighting and shutdown instructions ………. 10

5.3 Instructions to prevent accidents ………. 11

6. TROUBLE SHOOTING ………. 12

7. CLEANING AND MAINTENANCE INSTRUCTIONS ………. 13

7.1 Special Maintenance ………. 13

7.1.1 Replacing the main burner ………. 13

7.1.2 Replacing the pilot burner ………. 14

7.1.3 Replacing the valve cock ………. 14

FIGURES ………. 15-22

PAGE

2

IMPORTANT

WARNING:

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage, injury

or death. Read the operating

and maintenance instructions

thoroughly before installing or

Do not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or

any other appliance.

FOR YOUR SAFETY:

servicing this equipment.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS MUST BE

POSTED IN A PROMINENT LOCATION. THIS INFORMATION MAY BE OBTAINED BY

CONSULTING THE LOCAL GAS SUPPLIER.

SHIPPING DAMAGE CLAIM PROCEDURE

For your protection, please note that equipment in this shipment was carefully inspected

and packed by skilled personnel before leaving the factory. The transportation company

assumes full responsibility for safe delivery upon acceptance of this shipment.

If shipment arrives damaged:

1. VISIBLE LOSS OR DAMAGE—Be certain this is noted on freight bill or express receipt,

and signed by person making delivery.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY—Regardless of the extent of damage.

3. CONCEALED LOSS OR DAMAGE—If damage is unnoticed until merchandise is un-

packed, notify transportation company or carrier immediately, and file “concealed damage” claim with them. This should be done within fifteen (15) days of date that delivery

was made to you. Be sure to retain container for inspection.

We cannot assume responsibility for damage incurred in transit. We will, however, be glad

to furnish you with necessary documents to support your claim.

3

INSTRUCTIONS TO PREVENT ACCIDENTS

Read this manual carefully to be able to refer to it in every case of need.

Keep appliance area clean and clear from combustibles.

The place where the machine is to be installed must be aerated enough. This is in order to sup-

ply the necessary air for combustion, to prevent reaching too high percentages of gas to aid

evacuation of the products of combustion.

Installation must conform with local codes, or in absence of it, with the National Fuel Gas Code,

ANSI Z223.1 or with the Natural Gas Installation Code CAN/CGA-B149.1.

A. The appliance and its individual shutoff valve must be disconnected from the gas supply

piping system during any pressure testing of that system at test pressures in excess of 1/2

psig (3.45 kPa).

B. The appliance must be isolated from the gas supply piping system by closing its individual

manual shut off valve during any pressure testing of that system at test pressures in excess

of 1/2 psig (3.45 kPa).

Make certain that the air intake openings in the bottom of the appliance are not obstructed. They

are essential for proper combustion and operation of the appliance.

Maintain adequate clearance in front of unit for servicing and proper operation. NOTE: All

servicing can be done through the front door.

This equipment is to be installed to comply with the appliance Federal State or local

plumbing codes having jurisdiction.

THIS APPLIANCE IS EQUIPPED FOR NATURAL GAS, with orifices sized for operation with

natural gas.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY, OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE

INSTALLING OR SERVICING THIS EQUIPMENT.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light appliance.

Do not touch any electric switch; do not use any phone in the building.

Immediately call your gas supplier from a neighbor’s phone. Follow the gas

supplier’s instructions.

If you cannot reach your gas supplier, call the fire department.

4

INSTALLATION

INSTALLATION

2.1 Preliminary Instructions

Installation must be carried out by following the instructions contained in this handbook and only by

a licensed tradesman in accordance with local codes, or in absence of it, with the National Fuel

Gas Code ANSI Z223.1 or with the Natural Gas Installation Code CAN/CGA-B149.1. The

manufacturer cannot be held liable for any damage caused by faulty installation.

The place where the machine is to be installed must have aeration equal to at least that give

in Table 1.1. This is in order to supply the necessary air for combustion, to prevent reaching too

high percentages of gas and to aid evacuation of the products of combustion. The installation room

must be in conformity with the current fire regulations.

The unit must operate in a level position. Slight floor irregularities can be compensated by turning

the adjustable feet of the cooker either clockwise or counterclockwise.

Clearances from combustible and noncombustible construction are give in table 1.2.

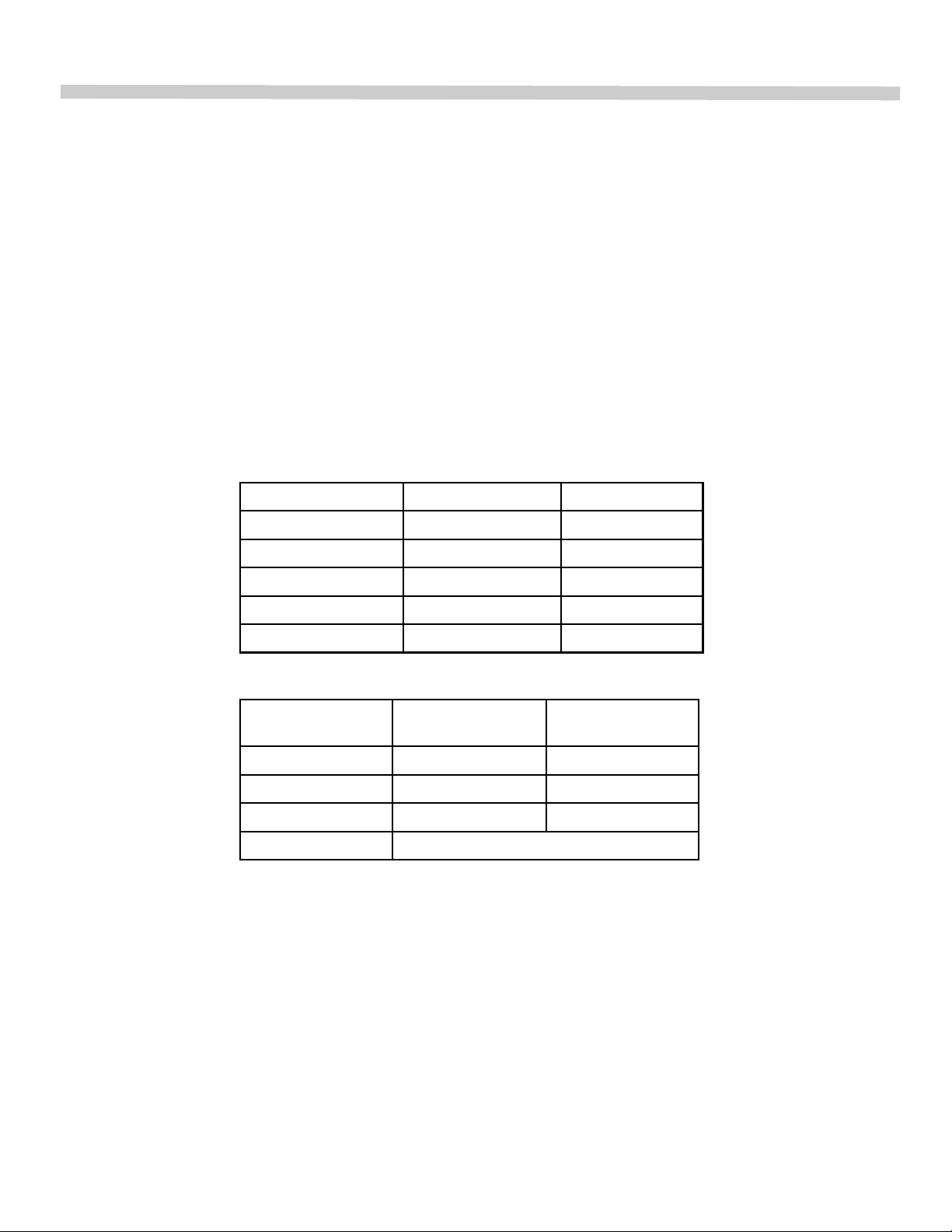

Model Power (BTU/hr) Air flow (m³/h)

CPG1 60000 (13.2 kW) 490

CPG2 120000 (26.4 kW) 980

CPG3 180000 (39.6 kW) 1470

CPG7/1 31000 (9 kW) 315

CPG7/2 62000 (18 kW) 630

Table 1.1 Minimum change of air in relation to the thermal power installed.

Clearances Combustible

construction

Side 6.0” 0”

Rear 6.0” 0”

Floor 6.0” 0”

Ceiling 48”

Noncombustible

construction

Table 1.2 Clearances from combustible and noncombustible construction.

2.2 Handling and Unpacking

To move the machine to the place of installation, use a fork lift truck. Do not drag the appliance on

the floor. Take the adhesive protection off the steel surfaces, taking care not to leave any remains

of glue, in which case, use appropriate thinner to remove them.

5

INSTALLATION

2.3 Connecting to the water-main

The unit should be connected to your water supply by way of a water faucet. The water pressure should fall

between 14.5 and 72.5 PSI. If the water pressure is excessive, a pressure regulator must be installed.

The pipe used to discharge the water must be heat resistant and allow for the free flow of the discharge

water. A funnel may be used between the unit discharge pipe and the floor drain but you should never

restrict or reduce the diameter of the discharge pipe.

The following operations are to be carrier out only by specialized technical personnel.

Having verified that the available water system is adequate, you can go ahead and make the connection:

1. Clear the pipe of any ferrous waste by letting a certain amount of water flow through.

2. Place the cooker in the desired position and close to the water-main.

3. Position the appliance level, adjusting the feet of the cooker.

4. Connect mains pipe to machine pipe (fig. 1) using a mechanical filter and an interception cock.

5. Connect machine outlet pipe (Fig. 1) to a suitable manifold that withstands high temperature.

2.4 Connecting to the gas supply mains

Before connecting up the gas, consult the gas board, all the installation and maintenance

operations should be carried out by gas board or authorized fitters. Make sure the data of the rating

plate correspond to the mains values. The rating plate is located at the bottom of the screen door panel.

Having verified that the gas supply system available is adequate, you can go ahead with the connection:

1. Connect the mains pipe to the machine pipe (pos. G. in fig. 1) using a quick closing interception cock

which is easy to reach. You must use a pressure regulator to set the manifold pressure as in tab

4.1.

2. Go ahead with setting up and adjusting as described in paragraph 2.4.1.

3. Make all the checks listed below.

2.4.1 Setting up and adjusting

The first operation to carry out is to check the supply pressure, proceeding as follows:

1. Make sure the gas supply has been cut off.

2. Open the front door, unscrew the closing screw (pos. 9 in fig. 6) of the pressure socket of the supply

pipe (pos. 1 in fig. 6).

3. Connect a pressure gauge to the socket (e.g. a manometer).

4. Open the gas interception cock and measure the value of the supply pressure.

5. CAUTION: If the value of the supply pressure measured lies outside the interval shown in table

2.2, it is not possible to go ahead with installation and it is necessary to inform the gas board of

the anomaly with the mains.

6. Close the gas interception cock, disconnect the pressure gauge, screw the closing screw back on and

close the front door.

Table 2.2 Permissible limits for the gas supply pressure

Type of gas Supply pressure Inches Water column (kPa)

natural gas (methane)

minimum maximum rated

3.5" (0.87) 10.5" (2.61) 7.0" (1.74)

6

INSTALLATION

INSTALLATION

Setting up and adjusting

After checking the supply pressure, it is necessary to adjust the pressure at the nozzle, proceeding

as described below:

1. Make sure the gas supply as been cut off.

2. Take off the door by unscrewing the screw fixing it to the support.

3. Remove the water loading knob (1 di fig. 3) and unscrew the two screws fixing the instrument

panel to the under-panel. Remove the instrument panel taking care over the wire of the igniter.

4. Open the gas inception cock and ignite the burner flame by following the instructions of par 5.2

positioning the knob onto the maximum position.

5. Adjust the pressure regulator since the manifold pressure is 4” W.C.

6. Operate the appliance in the maximum conditions for at least 15 minutes, and then turn the

knob onto the minimum position.

7. Turn the minimum adjustment screw (pos. a in fig. 7) to obtain a reduced flame but sufficiently

stable and homogeneous.

8. Turn off the burner by following the instructions of par. 5.2, close the gas interception cock,

disconnect the pressure gauge, screw the closing screw back and refit the instrument panel

and the front door.

2.4.2 Checks

For the purposes of operating safety it is essential to make the following checks:

*Checking air-tightness: Check there are no leaks in gas pipe using a solution of soap water.

*Checking operation: Check the burner, the regularity and extinguishing of the flame, following

the instructions in this handbook.

*Checking the flue gas evacuation system: Make sure there is a functional flue gas evacuation

system.

7

USER INSTRUCTIONS

This manual is an integral part of the product. It is recommended to read the instructions and

notices contained in it carefully before starting to use the cooker since it contains essential

information on using and servicing the machine safely.

This approach is designated for professional use. All the personnel assigned to using this machine

must be trained to use it.

CAUTION: THE UNIT HAS BEEN DESIGNED AND MADE TO BE USED TO

COOK OR STEAM WITH WATER ONLY. WHEN IN USE, THE EQUIPMENT

SHOULD NOT BE LEFT UNATTENDED.

The machine should be destined only for the use it has been designed for, every other use is to be

considered improper and therefore unreasonable. The manufacturer declines all liability for any

damage to persons or things caused by improper, erroneous, or unreasonable use.

Any tampering or modification to the appliance that has not previously been authorized by the

manufacturer frees the manufacturer from damage deriving from or referable to the above

mentioned acts.

8

SPECIFICATION

MODELS:

CPG 1: Gas unit with a single tank of 10.56 gallons.

CPG 2: Gas unit with two tanks of 10.56 gallons each.

CPG 3: Gas unit with three tanks of 10.56 gallons each.

CPG 7/1: Gas unit with a single tank of 7.4 gallons.

CPG 7/2: Gas unit with two tanks of 7.4 gallons each.

TECHNICAL DATA CPG1 CPG2 CPG3 CPG7/1 CPG 7/2

Length 35.4" (900mm) 27.6" (700 mm)

Width 17" (430mm) 31.5" (800mm) 47.2" (1200mm) 15.7" (400mm) 31.5" (800mm)

Height 34.4" (875mm)

Adjustable feet height 115" (175mm)

Weight 65Kg 101Kg 144Kg 50Kg 93Kg

10.6+10.6+10.6

Tank capacity at maximum level 10.6 gal (45l) 10.6+10.6 gal

Gas supply mains connection Φ1/2"

Water mains connection Φ1/2"

Water outlet connection Φ 1"

Rated thermal power 60000 BTU/hr 120000 BTU/hr 180000 BTU/hr 31000 BTU/hr 62000 BTU/hr

Thermal power at minimum 13000 BTU/hr 26000 BTU/hr 39000 BTU/hr 13000 BTU/hr 26000 BTU/hr

Natual gas manifold pressure 4" W.C.

Primary air adjustment FIXED

NOZZLE Natural gas G20

main burner 335 275

pilot burner 50 110161 50

minimum screw (bypass) adjustable adjustable

Diameter (1/100 mm) code diameter (1/100mm)

gal 7.4 gal (28l) 7.4+7.4 gal

Tab. 4.1 Main technical particulars of the CPG gas cooker

9

PUTTING INTO OPERATION

PUTTING INTO OPERATION

5.1 OPERATIONS PRIOR TO STARTING

WARNING! If you do not follow these instructions exactly, a fire or explosion may result,

causing property damage, personal injury, or loss of life.

Make sure the basin is clean, otherwise clean it as described in paragraph 7.1.

If you are using the cooker for the first time, you need to thoroughly clean all the parts that can

come into contact with foodstuffs. In this case, proceed as follows:

Fill the basin with water and ordinary detergent.

Put the machine into operation as described in the following paragraph.

When the water is boiling, wait for a few minutes, and then turn off the flame as described in the

following paragraph.

Open the door and drain by moving the lever inside into the open position.

Rinse the basin carefully with clean water.

With ordinary use, the first thing to do is to load with water.

Close the drain by moving the drain lever onto the closed position.

Turn knob 1 of figure 3 anticlockwise.

Wait for the basin to fill up to the top notch and then close the inlet cock by turning knob 1 of fig-

ure 3 clockwise.

CAUTION! Do not leave the cooker in operation with no water in the basin.

When lighting the pilot, follow these instructions exactly:

1. BEFORE LIGHTING smell all around the appliance area for gas. Be sure to smell next to the

floor because some gas is heavier than air and will settle on the floor. If you smell gas, you must

follow the instructions placed in front view of the appliance.

2. Never use tools to push in or turn the gas control knob. If it will not push in or turn by hand, don’t

try to repair it, call a qualified service technician. Force or attempted repair may result in a fire or

explosion.

3. Don’t use this appliance if any part has been under water. Call a qualified service technician to

inspect the appliance and to replace any part which has been under water.

5.2 LIGHTING AND SHUTDOWN INSTRUCTIONS

1. Carry out the procedures prior to putting the cooker into operation given in the above paragraph.

CAUTION: fill the cooker basin with water up to the top reference notch.

2. Open the gas interception cock, located upstream of the machine.

3. Turn the knob of valve (pos.2 in fig. 3) onto the OFF position and wait 5 minutes to clear out any

gas. If you smell gas, you must follow the instructions placed in front view of the appliance.

4. Turn the knob of the valve (pos. 2 in fig. 3) onto the PILOT position (pos. 1 in fig 3a). Open the

door.

5. Push the knob fully in and hold in, wait a few seconds and put a flame near the ignition pipe

(see Fig.5a) until the pilot flame ignites, which may be seen through the slot on the frame. Wait

for a few seconds and release the knob. If the flame fails to stay alight, repeat this operation.

ATTENTION: you must not put the flame into the pipe, but only near the edge of the ignition

pipe.

6. Turn knob 2 of figure 3 onto a position between the minimum and maximum ones (2 and 3 of fig.

3a), choosing the optimum value in relation to the quantity of product to be cooked.

7. Close the door and load the basket with the pasta to be cooked.

10

PUTTING INTO OPERATION

PUTTING INTO OPERATION

OPERATIONS PRIOR TO STARTING (continued)

8. Wait for the water in the basin to boil.

9. Put the full basket into the basin, resting it on the edge and wait for the cooking time to elapse.

10. Remove the basket using the special handles.

After cooking, turn off the main burner by turning knob 1 of figure 3 onto position 1 of fig. 3a and

turn off the pilot flame by turning it onto the off position (0 of fig. 3a), wait for at least five minutes

before draining off the water by moving the lever into the open position and finally proceed with the

cleaning.

CAUTION: Remember to close the gas interception cock.

5.3 Instructions to prevent accidents

The personnel assigned to using the electric cooker must keep to the instructions specified in this

manual. If the operator has not been sufficiently well trained, operation will not be optimum and the

risks concerning safety will increase.

It is compulsory to:

Fill the basin with water up to a level between the two notches.

Carry out all the routine maintenance and cleaning operations listed below.

Keep the surfaces that can come into contact with foodstuffs clean.

Make sure the gas pipes are always sound and well connected.

Service the burners periodically— at least once a year.

It is forbidden to:

Use the appliance dry.

Keep or place inflammable objects by the appliance.

Clean the machine using direct jets of water or high-pressure equipment.

Put your hands or other parts of your body into the water in the basin while the machine is in

operation, or when the cooker is switched off but with the water still hot.

Use objects that are not suitable for contact with foodstuffs to contain the pasta to be cooked.

11

TROUBLESHOOTING

TROUBLESHOOTING

CAUTION! For all the operations described below, close the gas interception cock and turn

to specialized and authorized personnel who have an adequate knowledge of the functions

of the various parts, and of the precautions to be taken.

Below are listed some possible malfunctions and the likely cause and remedy, if the problem is not

solved, or it is not accounted for in the following table, call our customer technical service.

MALFUNCTION LIKELY CAUSE REMEDY

The pilot burner will not ignite. *Malfunctioning of the spark

plug.

*Insufficient pressure at the pilot

burner.

The pilot burner goes out as

soon as the knob is released.

The main burner will not ignite

even if the pilot burner is ignited.

*The pilot burner does not sufficiently heat the thermocouple.

*Insufficient pressure at the

valve.

*Insufficient pressure at the

burner.

*Burner holes clogged.

*Check the spark plug fixing,

*Check the cable and the connections with the igniter and the spark

plug.

*Check the igniter and spark plug,

and replace if necessary.

*Check the supply pressure

(§2.4.1)

*Check the nozzle and clean it or

replace if necessary.

*Check the valve.

*Repeat the operation, pressing the

valve knob in more fully.

*Check the relative position of the

pilot and of the thermocouple.

*Check the supply pressure

(§2.4.1)

*Check the valve.

*Check the supply pressure and the

pressure at the nozzle (§2.4.1).

*Check the valve.

*Check the nozzle and clean or

replace it if necessary.

*Clean the burner.

12

CLEANING AND MAINTENANCE

Routine maintenance consists of daily cleaning all the parts that can come onto contact with foodstuffs and of the periodical maintenance of the burners, nozzles and of the outlet pipes.

The instructions to be followed for cleaning are listed below:

Use a soft cloth and neutral detergents.

To clean the stainless steel, do not use steel wool, iron scrapers, or brushes since they can

deposit ferrous particles that can oxidize leading to rust. To remove hardened residues, use

wooden or plastic spatulas, or stainless steel wool.

If you use alkaline detergents, thoroughly rinse after washing.

Do not spray with direct jets of water or with high-pressure equipment since any water getting

into the outer shell can jeopardize the safety of the machine.

Periodically check whether any incrustations have formed in the overflow pipe (due to foam)

and clean it if necessary, without using objects that can damage the rubber pipe.

When not being used, do not leave water in the basin.

When the appliance is not to be used for lengthy periods, spread a protective film over all the

stainless steel surfaces by passing a cloth soaked in Vaseline oil over them, and air the rooms

periodically.

The periodic annual maintenance of the burners must be done by specialized and

authorized personnel and it consists of keeping the holes clean for the fuel-comburent mixture to

flow in and out. Access to the burners and nozzles is explained in the following paragraphs.

7.1 Special Maintenance

The special maintenance procedures should be carried out by qualified and authorized personnel,

possibly by means of the technical service of the manufacturer of the component requiring

servicing.

CAUTION! It is recommended to use only genuine spare parts, in compliance with the same

technical specification as the ones replaced. In any case, before starting, the gas

interception cock located upstream of the appliance has to be closed.

7.1.1 Replacing the main burner

1. After making sure you have cut off the gas supply, open the door and unscrew the two screws

fixing the burner to the framework.

2. Unscrew the nuts fastening the valve pipe to the burner (pos. 3 and 4 of fig. 4), and remove the

pipe (pos. 1 of fig. 4).

3. Remove the burner and replace it with the new one, taking care to insert the end of the burner

into the hole from the other side of the frame.

4. Screw the two screws for fixing to the frame back on, and fit the pipe connecting the valve to

the burner. After these operations, it is necessary to check the seal of the gas circuit.

13

CLEANING AND MAINTENANCE

7.1.2 Replacing the pilot burner

1. After making sure you have cut off the gas supply, open the door and unscrew the two screws

fixing the pilot burner to the framework.

2. Unscrew the nuts fastening the thermocouple, the spark plug, and the pipe of the pilot burner

(pos. 7 of fig. 5). Caution, in doing this, keep the pilot unit on the inside of the framework, inserting your hand from beneath.

3. Replace the pilot burner and the other defective parts of the assembly.

4. Screw the two screws for fixing to the framework back on and fit the pipe, thermocouple, and

sparkplug.

After these operations, it is necessary to check the seal of the gas circuit and the efficiency

of the pilot burner.

7.1.3 Replacing the valve cock

1. After making sure you have cut off the gas supply, remove the door by unscrewing the screw

fixing it to the support.

2. Remove the water inlet knob (1 of fig. 3) and unscrew the two screws fixing the instrument panel to the under-panel. Remove the instrument panel.

3. Disconnect from the valve from the supply pipe, the pipe that goes to the burner and the one

that goes to the pilot burner and the thermocouple (pos. 1,4, 6, and 5 of fig. 6).

4. Disconnect the valve from the under-panel by unscrewing the two screws fixing it and replace it

with the new one.

5. Reconnect the gas pipes and the thermocouple in the same position as before.

6. Refit the instrument panel with the two screws taken out beforehand, fit the water knob onto the

relative shaft and fix the front door to the support.

After these operations, it is necessary to check the seal of the gas circuit, the efficiency of

the pilot burner and to repeat the adjustment operations.

14

DIAGRAM

15

DIAGRAM

16

DIAGRAM

17

DIAGRAM

18

DIAGRAM

19

DIAGRAM

20

DIAGRAM

21

DIAGRAM

22

WARNING

If not installed, operated and maintained

in accordance with the manufacturer's

instructions, this product could expose

you to substances in fuel or in fuel

combustion which can cause death or

serious illness and which are known to

the State of California to cause cancer,

birth defects or other reproductive harm.

The State of California enacted the California Safe Drinking Water and Toxic Enforcement Act of 1986, (Prop.

65), which "prohibits any person in the course of doing business from knowingly and intentionally exposing any

individual to a chemical known to the State of California to cause cancer or reproductive toxicity without first giving clear and reasonable warning to such individuals." The Governor's Scientific Advisory Panel added carbon

monoxide to the list of hazardous chemicals known to cause reproductive harm.

In order to establish full compliance with Proposition 65, we attached a yellow warning label to each gas fired unit

manufactured by the Montague Company.

Carbon monoxide would not be present in concentrations that would pose a "significant risk" to the consumer

when the equipment is installed, operated and maintained as follows:

1. Installed in accordance with all local codes, or in the absence of local codes, with the current

National Fuel Gas Code Z223.1.

2. Installed under a properly designed and operating exhaust hood.

3. Connected to the type of gas for which the unit is equipped.

4. Proper appliance pressure regulator installed on the gas supply line and adjusted for the manifold pressure

marked on the rating plate.

5. Adequate air supply to the unit.

6. The equipment is operated in the manner intended using the proper utensil for that type of appliance.

7. Keep the equipment clean and have it checked periodically.

8. Burner air adjustments, mechanical maintenance and repairs should be performed by qualified

service personnel.

If the equipment is not installed, operated and maintained in accordance with the above, concentrations of carbon monoxide in excess of the established limits could present in the kitchen environment.

ALL PERSONNEL IN THE WORKPLACE WHO MAY BE SUBJECT TO ANY EXPOSURE OF CARBON

MONOXIDE MUST BE WARNED OF SUCH POSSIBLE EXPOSURE. THIS WARNING SHOULD BE

CONVEYED IN A MANNER SO THAT IT IS CLEARLY UNDERSTOOD BY THE EMPLOYEE, AND

THE EMPLOYEE SHOULD BE ASKED IF IN FACT HE OR SHE UNDERSTANDS THE CORRECT

METHOD OF OPERATION OF THE EQUIPMENT AND THAT A RISK OF EXPOSURE EXISTS IF THE

EQUIPMENT IS OPERATED IMPROPERLY.

The MONTAGUE COMPANY

1830 Stearman Avenue, P.O. Box 4954 Hayward, CA 94540-4954

23

IMPORTANT

When ordering parts, to eliminate mistakes and facilitate delivery, always give

the following information:

Serial No. _____________________________________________

Model No. _____________________________________________

Change No. ____________________________________________

Name & No. of Part

Model No. Change No. Serial No.

The Montague Company

1830 Stearman Avenue

P.O. Box 4954

Hayward, CA 94540-4954

24

Loading...

Loading...