Rosito Basani PG100 Installation Manual

Morello Forni

PGPG

ovens manufacturers in Genoa since 1969

FIRE BRICKS GAS OVENS RANGE “PG” WITH SINGLE GAS BURNER,

THERMOSTATIC DIGITAL CONTROLS

INSTRUCTIONS FOR THE INSTALLATION FOR THE USE

FOR THE MAINTENANCE

Builder:

Ofce:

Phone:

Fax:

e-mail:

Assistance : Contact either your retailer or the builder directly.

The builder claims the right to change in any moment without notice

Via B. Parodi 35, 16014 Ceranesi (GE) Italy

the content of this Instructions Manual.

Morello Forni S.a.s.

++39. 010 7401194

++39.0107492194

info@morelloforni.com

rev05_17112011

RANGE PG MORELLO FORNI S. A. S.

1

RANGE PGRANGE PG MORELLO FORNI S. A. S.

2

Gas appliances directive 2009/142/CE

Gas Oven model “PG”

Test certicate: CE 1312 n° C.I.0215

GENERAL INDEX

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter.1 General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Testing and guarantee

1.2 Introduction

1.3 Client’s responsibilities

1.4 Oven description

1.5 General safety standards

1.6 Services for the client’s account

1.7 Instructions for requesting service

1.8 Instructions for ordering spare parts

Pag. 2

Pag. 4

Pag. 4

Pag. 4

Pag. 4

Pag. 5

Pag. 5

Pag. 5

Pag. 5

Pag. 5

Chapter. 2 Instructions for the installer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Weight and dimensions

2.2 Receiving the oven

2.3 Handling and support base assembling

2.4 General directions

2.5 Oven positioning

2.6 Oven decoration directions

Chapter. 3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Wiring and electrical hook-up and power absorption

3.2 Diagrams

3.3 List of components

3.4 Exhaust of combustion products

3.5 Technical data burner

3.6 Oven setting

3.7 Oven pre-arrangment

3.8 Oven adjustment for other types of gas

3.9 Gas connection

3.10 Technical properties

3.11 Feeding pressure check

3.12 Check of gas leaks

Chapter. 4 Oven’s operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Apparatus Safety devices

4.2 Crown burner hi-low ame modulator

4.2/1 Operating directions

4.3 Setting the oven dome temperature

4.4 Moduplus: adjustment, checkout and maintenance

Pag. 6

Pag. 6

Pag. 7

Pag. 8

Pag. 9

Pag. 9

Pag. 10

Pag. 11

Pag. 11

Pag. 11

Pag. 11

Pag. 12

Pag. 13

Pag. 13

Pag. 13

Pag. 13

Pag. 14

Pag. 14

Pag. 14

Pag. 14

Pag. 15

Pag. 15

Pag. 16

Pag. 16

Pag. 16

Pag. 17

Chapter. 5 User’s instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Oven operative instructions

5.2 Safety Gas system and oven check

5.3 Thermal oven system and preheating phase

5.4 Control panel description

5.5 Oven running operations

5.6 Oven cleaning

Chapter. 6 Oven programming and control system “Inteltouch - MF10”. . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Oven Start up

6.2 Burner command description

6.3 Temperature selection

6.4 Dome burner ame tuning

RANGE PG MORELLO FORNI S. A. S.

3

Pag. 18

Pag. 18

Pag. 18

Pag. 19

Pag. 20

Pag. 21

Pag. 21

Pag. 22

Pag. 22

Pag. 23

Pag. 23

Pag. 24

Chapter. 1 General warnings

1.1 TESTING AND GUARANTEE

The oven is tested in our works in compliance with established regulations and then shipped ready

for use.

The guarantee is valid for a full 24 months from the date of delivery of the oven and it covers the

repair or replacement of any defective parts.

Manifest defects or differences with respect to the client’s order must be communicated to the

manufacturer within 5 days from the receipt of the goods or they will not be covered by the

guarantee terms.

Any hidden or other defects must be communicated to the manufacturer within 5 days from the

time that they are discovered and, in any event, within the maximum guarantee term.

The purchaser shall be entitled only to request repair or replacement of the goods.

The purchacer is not entitled to claim compensation for direct or indirect damages of any

whatsoever nature. In any event, the entitlement to repair or replacement of the materials must be

exercized wihin the maximum term of the guarantee, which is contractually stipulated to cover a

shorter period than the maximum term established by law.

Repairs or replacement of defective materials will be carried out at the manufacturer’s works;

material returned to the manufacturer must be shipped carriage paid and will be returned to the

purchaser carriage forward.

1.2 INTRODUCTION

This manual is supplied in order to provide all the instructions for a correct use and maintenance of the

oven, and the maximum safety of users.

The description of the following professional qualications and related duties are provided for further

clarication.

Installer:qualied technician in charge of the installation and commissioning of the oven in

accordance with the instructions of this manual.

User: any person who is familiar with the content of the manual and who uses the oven for the intended

use and in accordance with the instructions provided. Users are always expected to carefully read and

consult the manual. Users are recommended to specically and frequently read and refer to paragraph 1.5

Safety Precautions.

Technician responsible for ordinary maintenance: qualied technician trained to perform ordinary

maintenance operations in accordance with the instructions of this manual.

Technician responsible for extraordinary maintenance: qualied technician trained to perform

extraordinary maintenance on the unit.

This symbol appears at certain points in the manual to draw the reader’s

attention to important safety information.

The manufacturer declines any whatsoever responsibily in the case of improper use of the oven

deviating from the reasonably construed intended use, and for all operations carried out that are

not in compliance with the instructions laid down in the manual.

This manual must be conserved in a place that is accessible and known to all operators (installer,

user, routine maintenance technician, special maintenance technician).

This manual must not be reproduced or divulged, in whole or in part, using any whatsoever means

or in any whatsoever form.

1.3 CLIENT’S RESPONSIBILITIES

The customers is required to:

- make sure of a guaranted and proper installation of the oven received

- electrical supply of the oven

- gas supply of the oven

- chimney connection

- provide consumable materials for cleaning

- perform routine maintenance

RANGE PGRANGE PG MORELLO FORNI S. A. S.

4

1.4 OVEN DESCRIPTION

It is a stone heart gas oven made as a cylindrical monocoque body in painted iron that contains a

composite heavy refractory structure, it’s heated by a doble burner gas sistem with independent

temperature regulation digitally controlled (FIG.1).

The arc brick front and the bracket are made in stone and granite and the lower shelf contain the

controls and its front comand panel.

1.5 GENERAL SAFETY STANDARDS

Before starting up the oven read carefully the instructions in the manual for use and

maintenance,bering in mind that the manual is

a component of the oven and must be carefully

preserved.

In event of loss or damage, ask for a new copy,

stating the model and date of purchase.

PRINCIPAL GENERAL SAFETY REGULATIONS:

• Do not switch on the oven until installation

has been completed fully.

• Do not touch the oven when your hands or

feet are wet.

• Do not insert screwdrivers or other objects

into the protective grilles or moving parts.

• Do not pull the power cable to disconnect

the machine from the power supply.

• Do not allow minors or untrained personnel

to use the oven.

• Before carrying out any cleaning or

• Maintenance operations disconnect the

oven from the power supply by switching off

the main switch.

• In case of breakdown and/or malfunction of

the oven switch it off and do not attempt to

repair it. Suitably qualied personnel must be contacted in this situation.

FIG.1

1.6 SERVICES FOR THE CLIENT’S ACCOUNT

The following are to be provided at the Client’s expense :

- the machine’s electrical connection

- the machine’s gas connection

- the provision and connection of the smoke stack

- preparation of the area for installation.

- cleaning consumables.

- routine maintenance.

1.7 INSTRUCTIONS FOR REQUESTING SERVICE

Should any problems of a technical nature arise or for any requests for assistance, contact your

supplier.

1.8 INSTRUCTIONS FOR ORDERING SPARE PARTS

To order spare parts consult the relevant parts list that is in your supplier’s possession.

RANGE PG MORELLO FORNI S. A. S.

5

Chapter. 2 instructions for the installer

2.1 WEIGHT AND DIMENSIONS

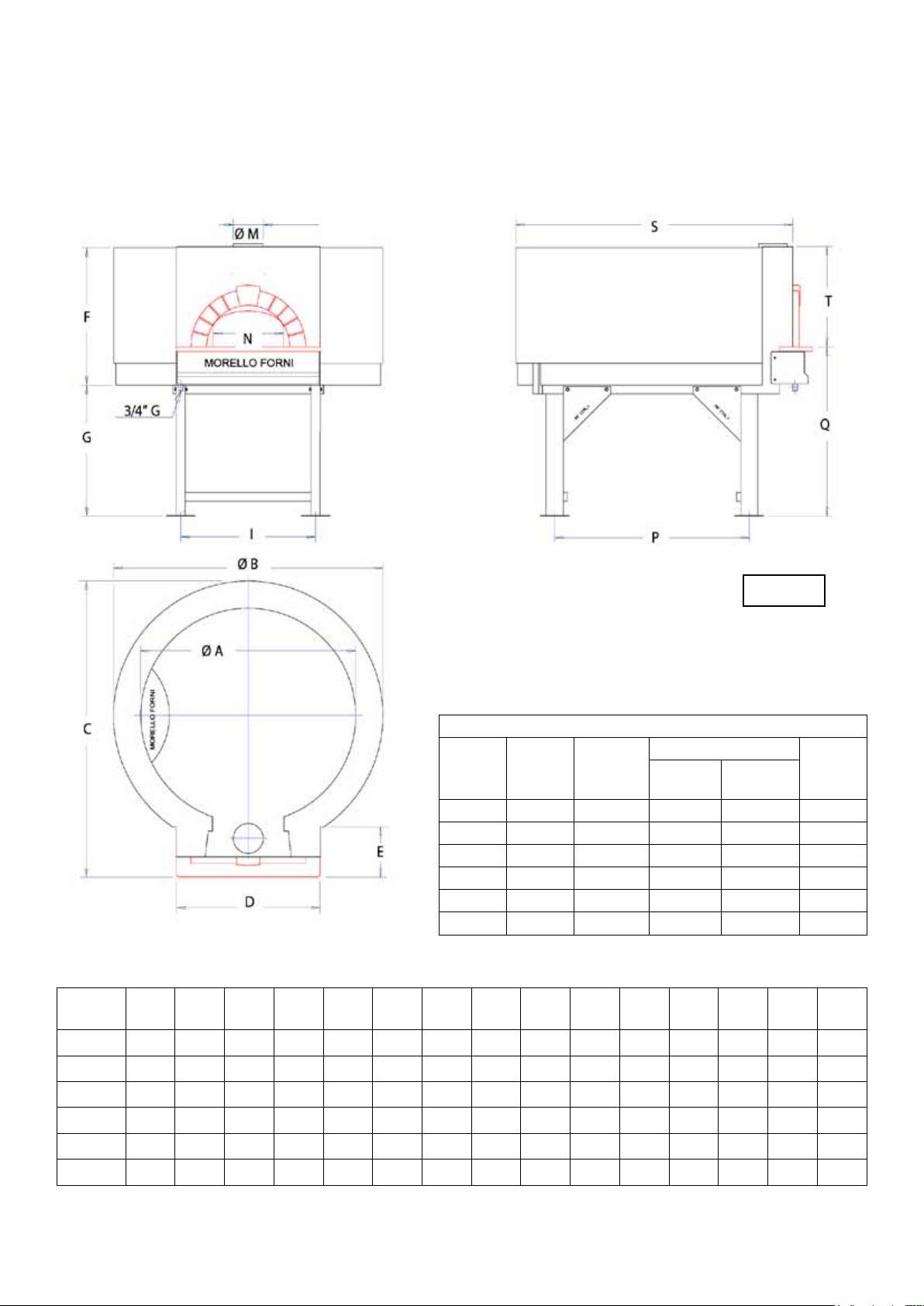

Here after you can nd in a schematic way the views of the oven with the dimension on

centemeters (FIG.2) .

FIG.2

Capacity

Oven

Mod.

PG75 375 13 kW 1,8 1,1 3/4” G

PG100 975 19 kW 2,0 1,4 3/4” G

PG110 1200 21 kW 2,2 1,6 3/4” G

PG130 1450 28 kW 3,0 2,2 3/4” G

PG150 1800 34 kW 3,6 2,7 3/4” G

PG180 2850 68 kW 7,2 5,4 2x3/4” G

Ref. /

Mod

PG75 75 110 130 80 29 50 92 66 74 15 35 68 118 122 50

PG100 100 138 152 80 29 86 92 66 74 20 45 104 118 144 60

PG110 110 148 165 80 29 96 92 66 74 20 45 108 118 155 70

PG130 130 168 185 80 29 96 92 66 74 20 50 130 118 170 70

PG150 150 188 208 100 35 96 92 66 94 20 50 135 118 192 70

PG180 180 220 240 120 35 114 92 66 114 25 80 160 118 235 86

Sizes on cm

Ø A Ø B C D E F G H I Ø M N P Q S T

Weight

(Kg)

Total gas

potential

Consumption

Methane

(mc/h)

L.P.G.

(Kg/h)

ttings

Gas/

RANGE PGRANGE PG MORELLO FORNI S. A. S.

6

2.2 RECEIVING THE OVEN

You have just received an oven produced by “MORELLO FORNI”. Before starting with the installation operations read this manual carefully.

The oven you received has been treated with great attention, handle it with care and make sure it

is intact when the carrier delivers it.

Efcient and appropriate capacity load machines are required to unload and place the oven.

For the base transportation the base of the oven has not been assembled to it because the oven

barycenter lying high from the ground might cause danger and damaging during transportation.

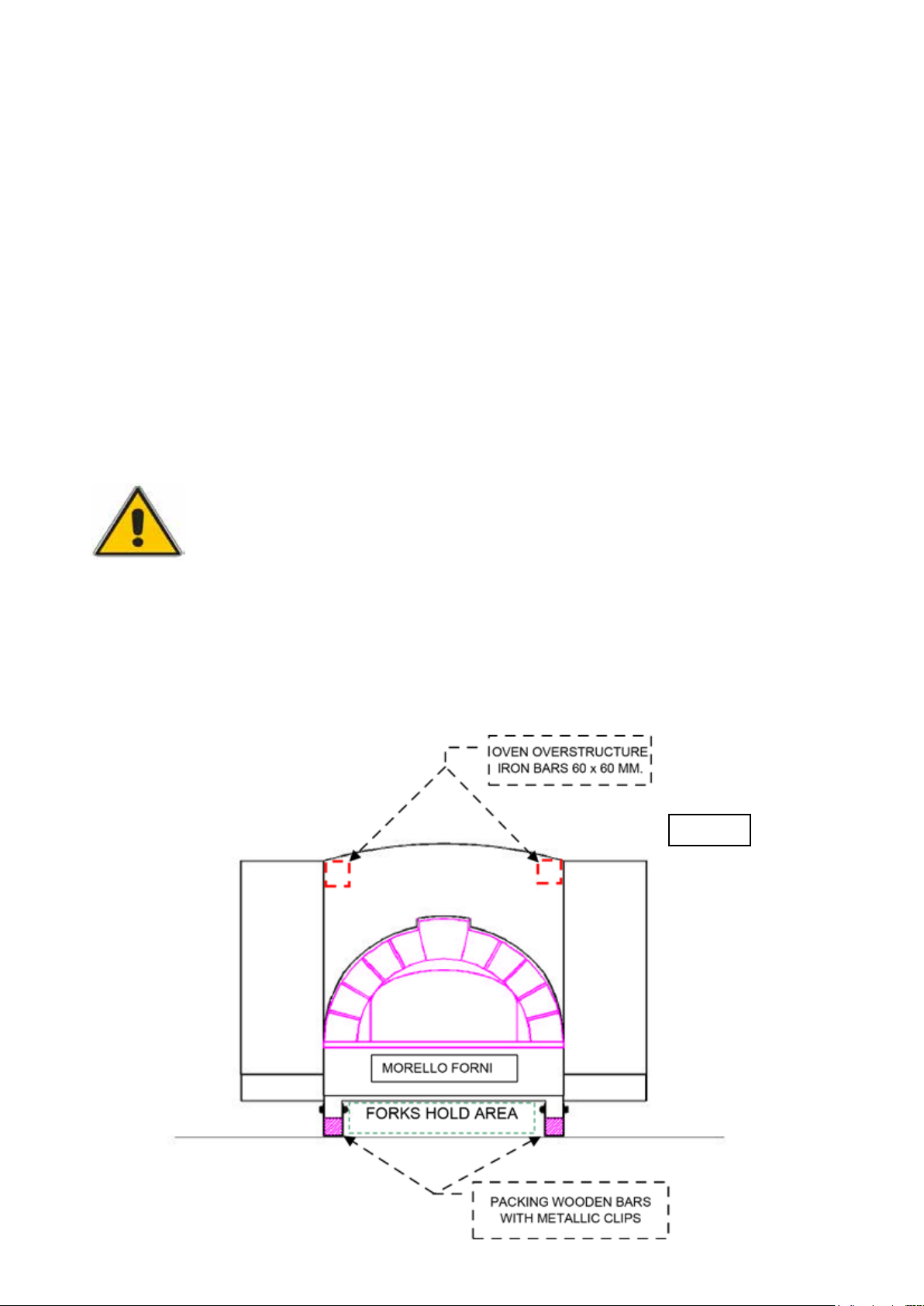

Once the oven has been unpacked you will notice that it lies on two wooden chocks which are

fastened to the oven with metallic clips (FIG.3).

When unloading the oven it will be necessary to unfasten the chocks in order to x to the oven the

two support elements which constitutes its support base and which allow the moving of the oven in

places where bulky capacity load machines cannot go just using a pallet jack.

You will nd the aforementioned support elements, which from now on we will call “front stand” and

“rear stand”, in a special package enclosed to the oven. They come complete with xing nuts and

bolts which must be xed as shown below after removing the clips which fasten the two wooden

chocks on which the oven lies during transportation.

BE SURE TO REPLACE THE BOLTS THAT ATTACH THE FRONT AND REAR STAND TO THE

OVEN.

Carry out this operation or have it carried out by skilled people without

endangering your life!

During this phase do not stand under the oven hung in the air!

The oven metal structure allows its handling with a crane employing the two iron

bars relative to the oven overstructure. At these bars can be properly tted straps

or chains in way to lift the oven with a crane.

The oven metal structure allows to move or lift the oven with a pallet jack or a

forklift that in various moments may be request for its handling.

A special and reinforced FORKS HOLD AREA enables the oven lifting with any

adequate forklift, it is pointed in the FIG.3 .

FIG.3

RANGE PG MORELLO FORNI S. A. S.

7

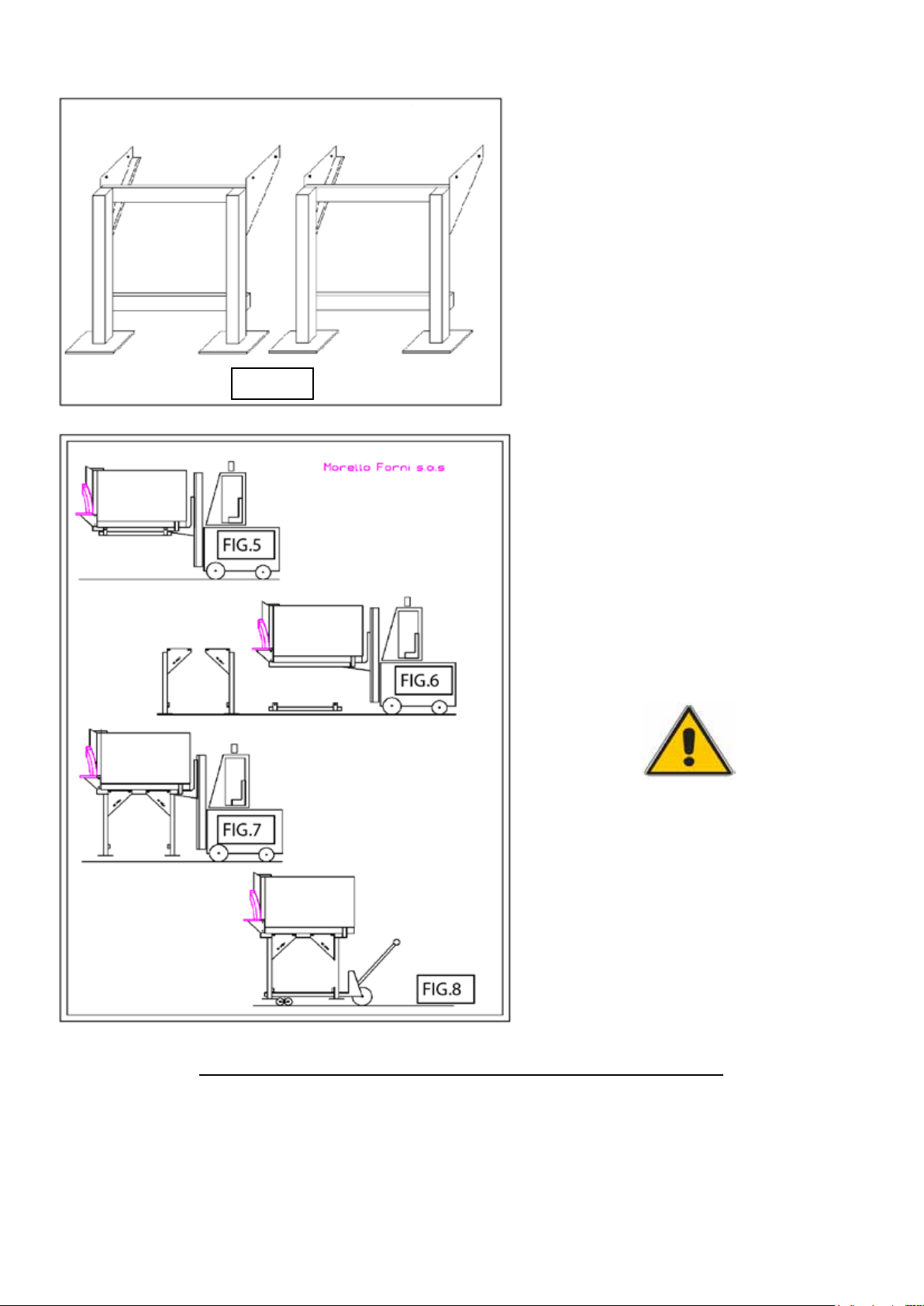

2.3 HANDLING AND SUPPORT BASE ASSEMBLING

In a package enclosed to the oven

you nd two support stands which

constitute the oven base (FIG.4).

This base must be xed to the

oven before moving it to the

installation room in case the lift

truck could not enter it.

If forklift can enter into the room,

place the base directly on the

positioning place and in any case

carry on as follows.

FIG.4

Lift the oven as shown in the

illustration and detach the xing

clips of its transportation wooden

supports (FIG. 5 and 6 ).

Fix the two support stands to the

oven and tighten the respective

xing nuts while the forklift keeps

the oven suspended (FIG. 7).

If forklift can place the oven in the

nal position then do so, otherwise

use a “pallet jack” as shown

(FIG. 8).

ATTENTION ! THE OVEN IS

VERY TOP-HEAVY.

Lifting the oven too high or moving

the oven up or down a ramp might

cause the oscillation or even the

fall of the oven.

THE OVEN BARICENTER LIES

VERY HIGH FROM THE

GROUND!

DO NOT TURN THE OVEN ON ITS SIDE!

RANGE PGRANGE PG MORELLO FORNI S. A. S.

8

Loading...

Loading...