PASTA COOKER

COISEUR À PÂTES

GB

FR

80.000 BTU/Hr

GB

The manufacturer reserves the right to modify the appliances presented in this publication without notice.

FR

Le fabricant se réserve le droit de modifier sans préavis les caractéristiques des appareil présentés dans

cette publication.

ENGLISH

1. INDEX

1. INDEX ................................................................................................................................................. 1

2. ANALYTICAL INDEX .......................................................................................................................... 1

3. SAFETY .............................................................................................................................................. 2

4. REGULATIONS AND GENERAL INSTRUCTIONS ........................................................................... 3

4.1. General Information .................................................................................................................. 3

4.2. Warranty ................................................................................................................................... 3

4.3. Description of the Appliance .................................................................................................... 4

4.4. Safety Devices ......................................................................................................................... 4

4.5. Features Plate .......................................................................................................................... 4

4.6. Replacement of Parts ............................................................................................................... 5

5. USE AND FUNCTIONING .................................................................................................................. 5

5.1. Description of the Controls. ...................................................................................................... 5

5.2. Burner Ignition .......................................................................................................................... 6

5.3. Filling the Cooking Tank ........................................................................................................... 6

5.4. Draining the Cooking Tank ....................................................................................................... 6

5.5. Recommendations for Use ....................................................................................................... 7

6. CLEANING AND MAINTENANCE ..................................................................................................... 7

6.1. Recommendations for Cleaning and Maintenance .................................................................. 7

6.2. Routine Maintenance ............................................................................................................... 7

7. FAULTS .............................................................................................................................................. 8

8. INSTALLATION .................................................................................................................................. 8

8.1. Packaging and Unpacking ....................................................................................................... 8

8.2. Installation ................................................................................................................................ 9

8.3. Water Connection ................................................................................................................... 10

8.4. Gas Connection ...................................................................................................................... 10

8.5. Inspection ............................................................................................................................... 11

8.6. Power Supply Transformation ................................................................................................ 11

9. ADJUSTMENTS ............................................................................................................................... 12

9.1. Check The Supply Pressure .................................................................................................. 12

9.2. Adjusting Burner Cock Minimum ............................................................................................ 13

9.3. Replacing Burner Nozzle ....................................................................................................... 13

9.4. Replacing Burner Pilot Light Nozzle ....................................................................................... 14

9.5. Check the output power of the burner .................................................................................... 14

ATTACHMENTS ....................................................................................................................................... I

GB

2. ANALYTICAL INDEX

A

Adjusting Burner Cock Minimum; 14

B

Burner Ignition; 7

C

Check The Supply Pressure; 13

D

Description of the Appliance; 5

Description of the Controls; 6

Draining the Cooking Tank; 7

F

FAULTS; 9

Features Plate; 5

Filling the Cooking Tank; 7

G

Gas Connection; 11

General Information; 4

I

Inspection; 12

Installation; 10

P

Packaging and Unpacking; 9

Power Supply Transformation; 12

R

Recommendations for Cleaning and Maintenance;

8

Recommendations for Use; 8

Replacement of Parts; 6

Replacing Burner Nozzle; 14

Replacing Burner Pilot Light Nozzle; 15

Routine Maintenance; 8

S

SAFETY; 3

Safety Devices; 5

1

ENGLISH

GB

W

Warranty; 4

3. SAFETY

It is recommended to carefully

read the instructions and warnings

contained in this manual before using

the appliance. The information

contained in the manual is for the

safety of use and for machine

maintenance.

! Keep this manual carefully to be able to refer

to it in every case of need.

Keep appliance area clean and clear from

combustibles.

The place where the machine is to be installed

must be enough aerated, this is in order to supply

the necessary air for combustion, to prevent

reaching too high percentages of gas and to aid

evacuation of the products of combustion.

Installation must be conform with local codes, or

in absence of it, with the National Fuel Gas Code,

ANSI Z 223.1 or with the Natural Gas Installation

Code CAN/CGA-B149.1

The appliance and its individual shutoff valve

must be disconnected from the gas supply

piping system during any pressure testing of

that system at test pressures in excess of ½

psig (3.45 kPa).

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shutoff valve during any pressure

testing of that system at test pressures equal

to or less than ½ psig (3.45 kPa).

Make certain that the air intake openings in the

bottom of the appliance are not obstructed. They

are essential for proper combustion and operation

of appliance.

Maintain adequate clearance in front of unit for

servicing and proper operation. NOTE: All

servicing can be done through front door.

! This equipment is to be installed to comply

with the appliance Federal State or local plumbing

codes having jurisdiction.

THIS APPLIANCE IS EQUIPPED FOR

NATURAL GAS, with orifices sized for o peration

with natural gas.

Water Connection; 11

Leave in front view the labels containing the

following warnings:

! WARNING: improper installation,

adjustment, alteration, service or

maintenance can cause property

damage, injury or death.

Read the installation, operating and

maintenance instructions thoroughly

before installing or servicing this

equipment.

FOR YOUR SAFETY: do not store

or use gasoline or other flammable

vapours or liquids in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS.

Do not try to light appliance.

Do not touch any electric switch

Do not use any phone in the

building.

Immediately call your gas supplier

from a neighbours’ phone.

Follow the gas supplier’s

instructions.

If you cannot reach your gas

supplier call the fire department.

In the design and construction phase, the

manufacturer has paid particular attention to the

aspects that can cause risks to safety and health

of persons that interact with the appliance.

Carefully read the instructions stated in the

manual and those applied directly to the machine,

and particularly respect those regarding safety.

Do not tamper with, evade, eliminate or by-pass

the installed safety devices. Failure to comply with

this requisite can lead to serious risks for personal

health and safety.

After having been appropriately documented, on

commissioning, if necessary, simulate some test

manoeuvres to identify the controls, in particular

those relative to switch-on and switch-off and their

main functions.

2

ENGLISH

The appliance is only destined for the use for

which it has been designed; any other use must

be considered improper. The manufacturer

declines all liability for any damage to objects or

injury to persons owing to improper or incorrect

use.

All maintenance interventions that require precise

technical skill or particular ability must be

performed exclusively by qualified staff.

In order to guarantee hygiene and protect the

foodstuffs from contamination, the elements that

come into direct or in direct contact with the

foodstuffs must be cleaned very well along with

the surrounding areas. These operations must

only be performed using detergents that can be

used with foodstuffs, avoiding inflammable

products or those that contain substances that are

harmful to personal health.

At the end of use, ensure that the burners are

switched off, with the control knobs deactivated

and the connection lines disconnected.

In the case of prolonged inactivity, as well as

disconnecting all the supply lines, it is necessary

to accurately clean all internal and external parts

of the appliance.

4. REGULATIONS AND GENERAL INSTRUCTIONS

4.1. General Information

This manual has been designed by the

manufacturer to provide the necessary information

to those who are authorised to interact with the

appliance.

It is advisable for the receivers of the information

to read it carefully and apply it strictly.

Reading the information contained in this

document will allow the user to prevent risks to

personal health and safety.

Keep this manual for the entire operating life of

the appliance in a place which is well-known and

easily accessible, so that it is always available

when its consultation becomes necessary.

4.2. Warranty

The warranty of the appliance and the

components we produce has duration of 2 (two)

year from the date of delivery and translates into

the supply, free of charge, of parts that we

consider to be faulty.

These faults must, however, be independent from

incorrect use of the product in compliance with the

indications stated in the manual.

Particular symbols have been used to highlight

some parts of the text that are very important or to

indicate some important specifications. Their

meanings are given below.

! Indicates important information

regarding safety. Behave appropriately so as

not to risk the health and safety of persons or

cause damage.

Indicates particularly important technical

information that must not be ignored.

Fees deriving from labour, journeys and transport

are excluded from the warranty.

The materials replaced under warranty are our

property and must therefore be returned under the

responsibility and expense of the customer.

GB

3

GB

ENGLISH

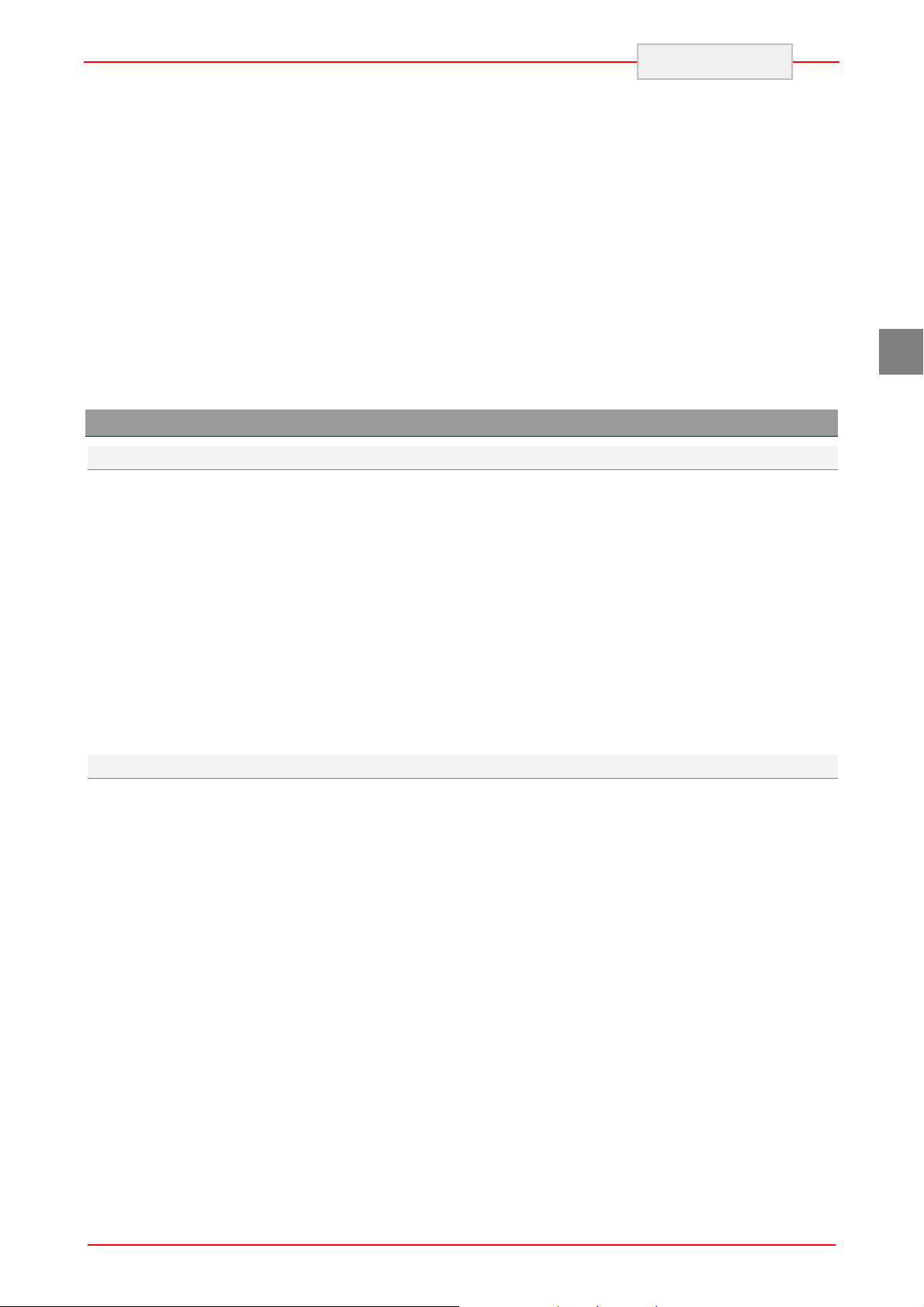

4.3. Description of the Appliance

The appliance defined as a pasta cooker has

been designed and manufactured for cooking

pasta in water for professional use in the catering

industry. On the basis of requirements, one or two

tanks are available.

1) Cooking tanks.

2) Inspection hatch.

3) Adjustable feet.

4) Gas connection.

5) Exhaust vent : evacuation of combustion

flue gases.

6) Water loading knob: loads and regulates

the quantity of water in the tank.

7) Power adjustment knob: regulates

burner power (minimum maximum).

8) Burner ignition : piezoelectric burner

ignition.

9) Water distributor: water input in tank.

10) Minimum and maximum water levels in

tank.

4.4. Safety Devices

The appliance is equipped with safety systems.

The illustration shows the positioned of the

devices.

A) Gas supply cock; to open and close

connection to the gas power supply line.

B) Safety thermocouple; blocks the gas power

supply in the event that the flame goes out.

10

9

ID 01

1

6

7

2

3

5

8

4

Safety

Device

B

!Check daily that the safety devices are

installed correctly and efficient.

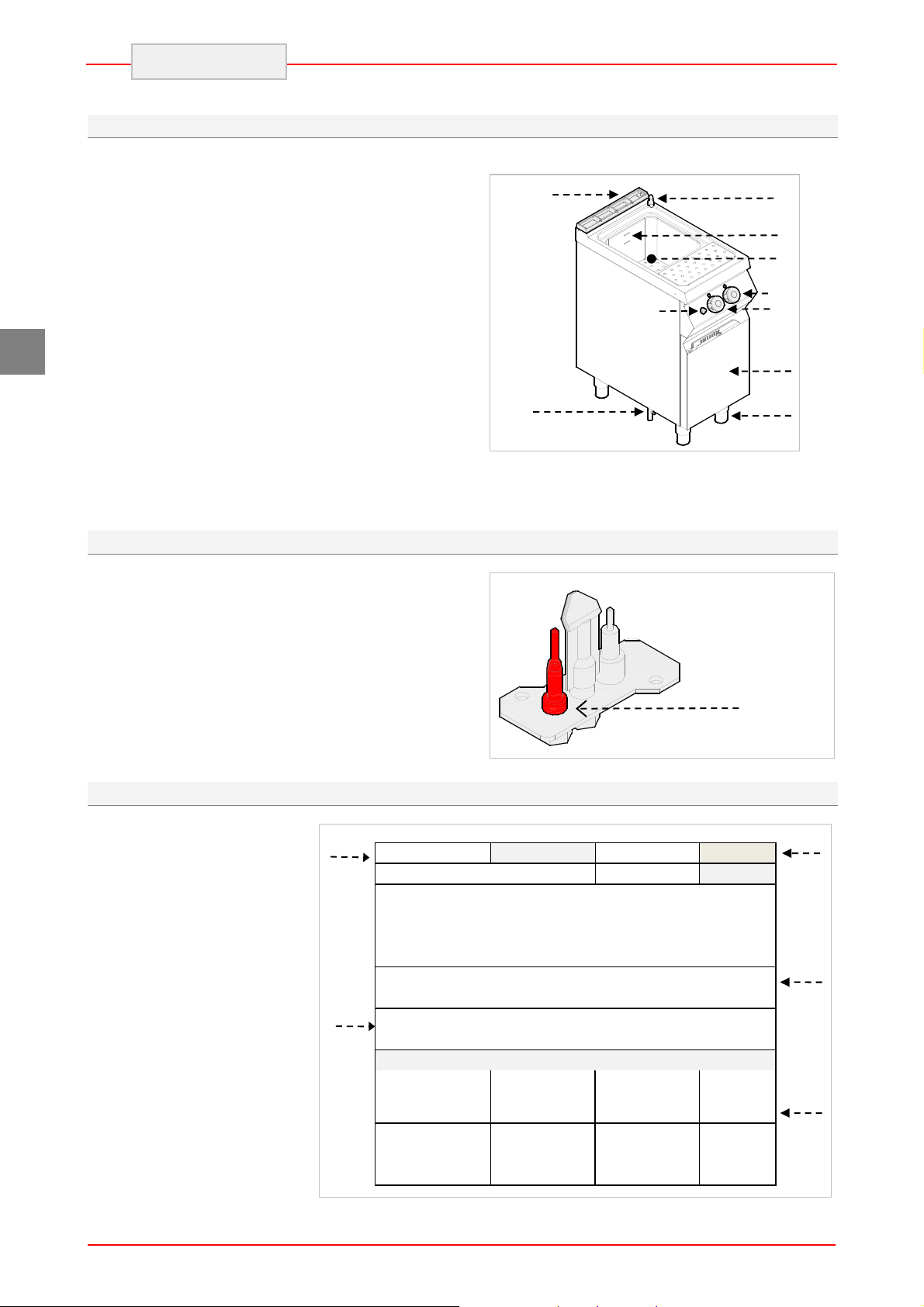

4.5. Features Plate

The identification plate

shown is applied directly

onto the appliance. It states

the references and all

indications indispensable for

working in safety.

1) Gas type and

pressure

2) Appliance model

3) Serial number

4) Declared power

5) Clearance

2

Model N° / Modéle N°

GAS / GAZ :

Manifold pressure / Pres sion d'aliment ation :

1

Manifold pressure / Pres sion d'aliment ation :

GAS / GAZ :

Back / Arrière 0 in 6 in

Right S ide / A droit 0 in 6 in

Left Side / A gauche 0 in 6 in

80.000 BTU/Hr

CPG1

Intended for other than hous ehol d use

Pas destiné à l 'us age dom estique

Suit abl e for ins tallati on on combustible floors

Convient à l'ins tallati on sur un plancher c om bust i ble

Natu r al / Nat u r el

LP Gas

CLEA RANCE / DEGAG EMENTS

Non combustible

Construction

Paroi non inf amable Paroi infamabl e

Serial N° / N°de S éri e

Input Burner / Bruleur

4 i.w.c.

Input Burner / Bruleur

11 i.w.c.

Combustible

Construction

XXXX.XXXX

80.000 BTU/h r

80.000 BTU/h r

3

4

5

4

g

4.6. Replacement of Parts

! Before carrying out any replacement

intervention, activate all envisioned safety

devices.

In particular, close the gas supply cock and

prevent access to all the devices which, if

activated, could lead to unexpected dangerous

situations putting personal safety and health at

risk.

5. USE AND FUNCTIONING

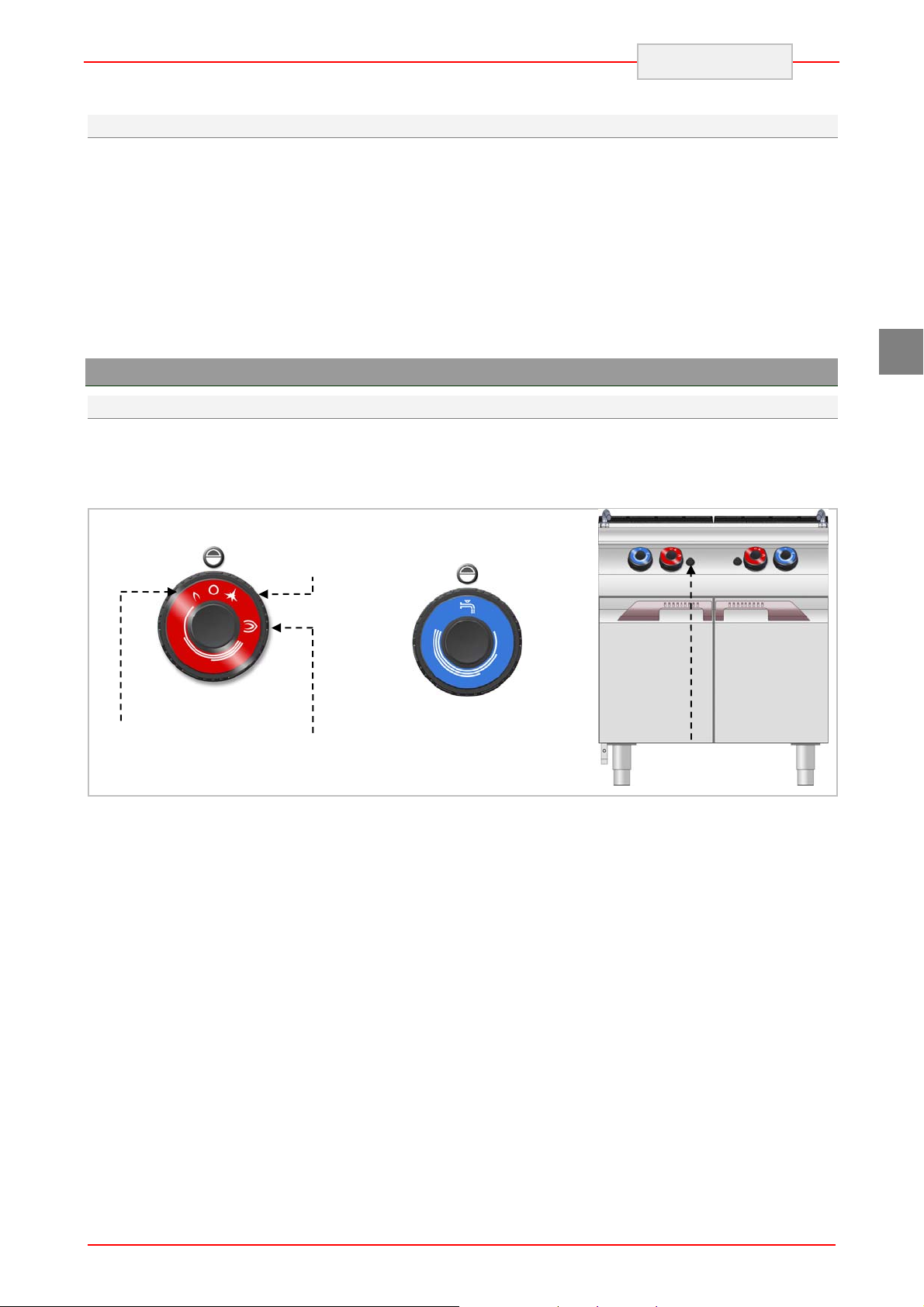

5.1. Description of the Controls.

On the appliance instrument panel, there are the

controls for activating the main functions.

A) Burner control knob: to switch on and

off and adjust the main burner.

ENGLISH

When worn components must be replaced, only

use original spare parts.

All responsibility is declined for injury to

persons or damage to components deriving from

the use of non-original spare parts and

interventions which could modify the safety

requisites, without authorisation of the

manufacturer.

B) Water loading knob: to fill the cooking

tank.

C) Piezoelectric ignition: to switch the

burner pilot light on and off.

GB

Minimum

power

symbol

A B

Pilot

li

ht

Maximum

power

symbol

Water

loading

knob

Piezoelectric

C

ignition

5

GB

ENGLISH

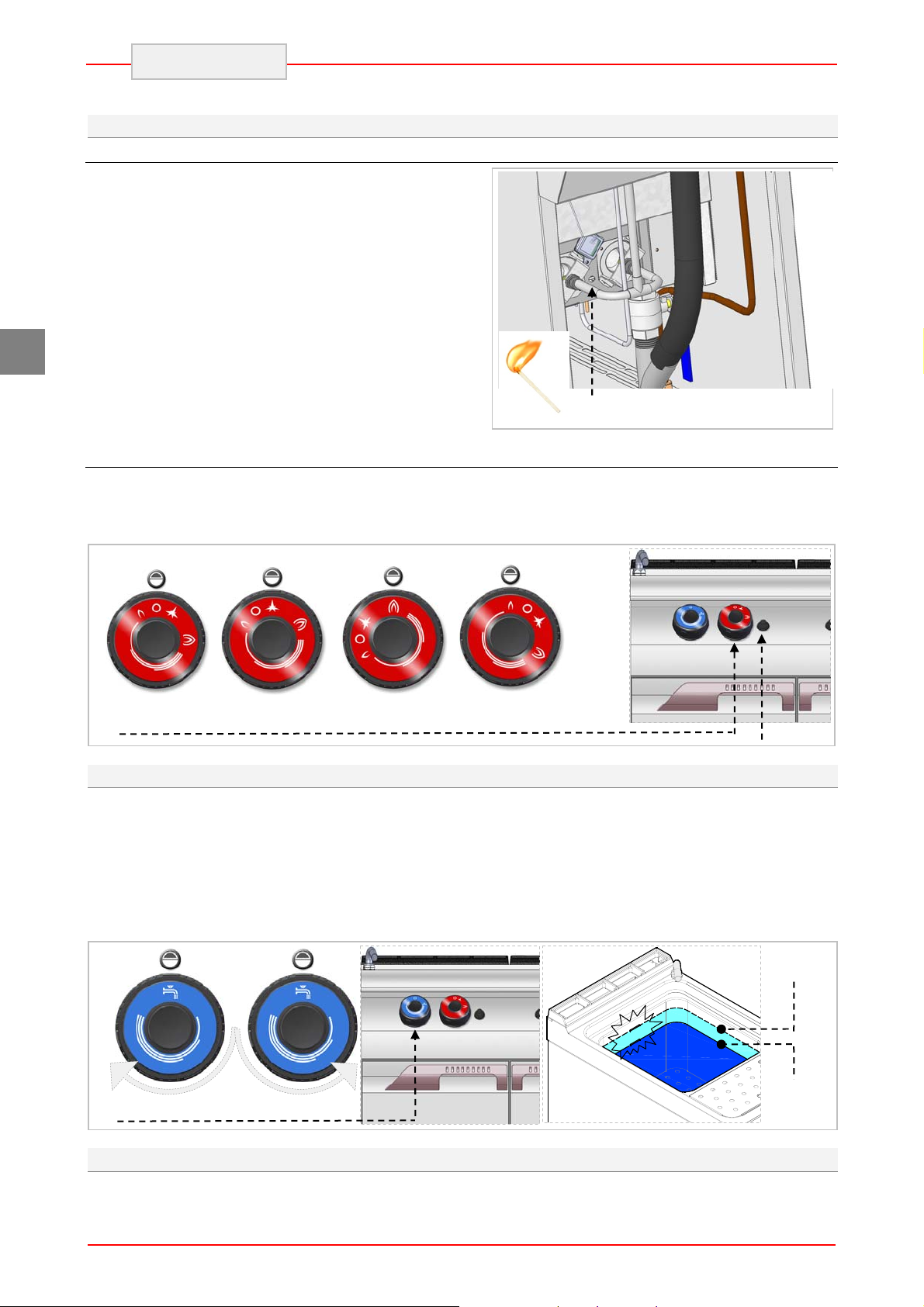

5.2. Burner Ignition

SWITCH-ON

A) Press and turn the knob in an anti-

clockwise direction (position 1); at the

same time, press the button (B) to switch

on the pilot light. The ignition of the pilot

light can also be carried out manually

through the cover positioned on the

bottom (C).

B) Hold down the knob for about 10 seconds

in order to heat then release the knob.

C) Turn the knob in an anti-clockwise

direction to switch-on the burner (position

2).

D) Adjust burne r power (position 3).

SWITCH-OFF

A) Turn the knob in a clockwise direction to

switch off the burner (position 1); the pilot

light stays on.

C

B) Turn the knob in a clockwise direction to

switch off the pilot light (position 0).

C) Wait five (5) minutes to clear out any gas

before relighting.

Pos 1 Pos 2 Pos 3Pos 0

5.3. Filling the Cooking Tank

Turn the water loading knob to fill the tank up to

the desired level. Once the maximum level has

been reached, it is possible to switch on the

burner.

After having filled the tank, it is necessary to close

the cock to avoid dangerous overflowing.

OPEN

CLOSE

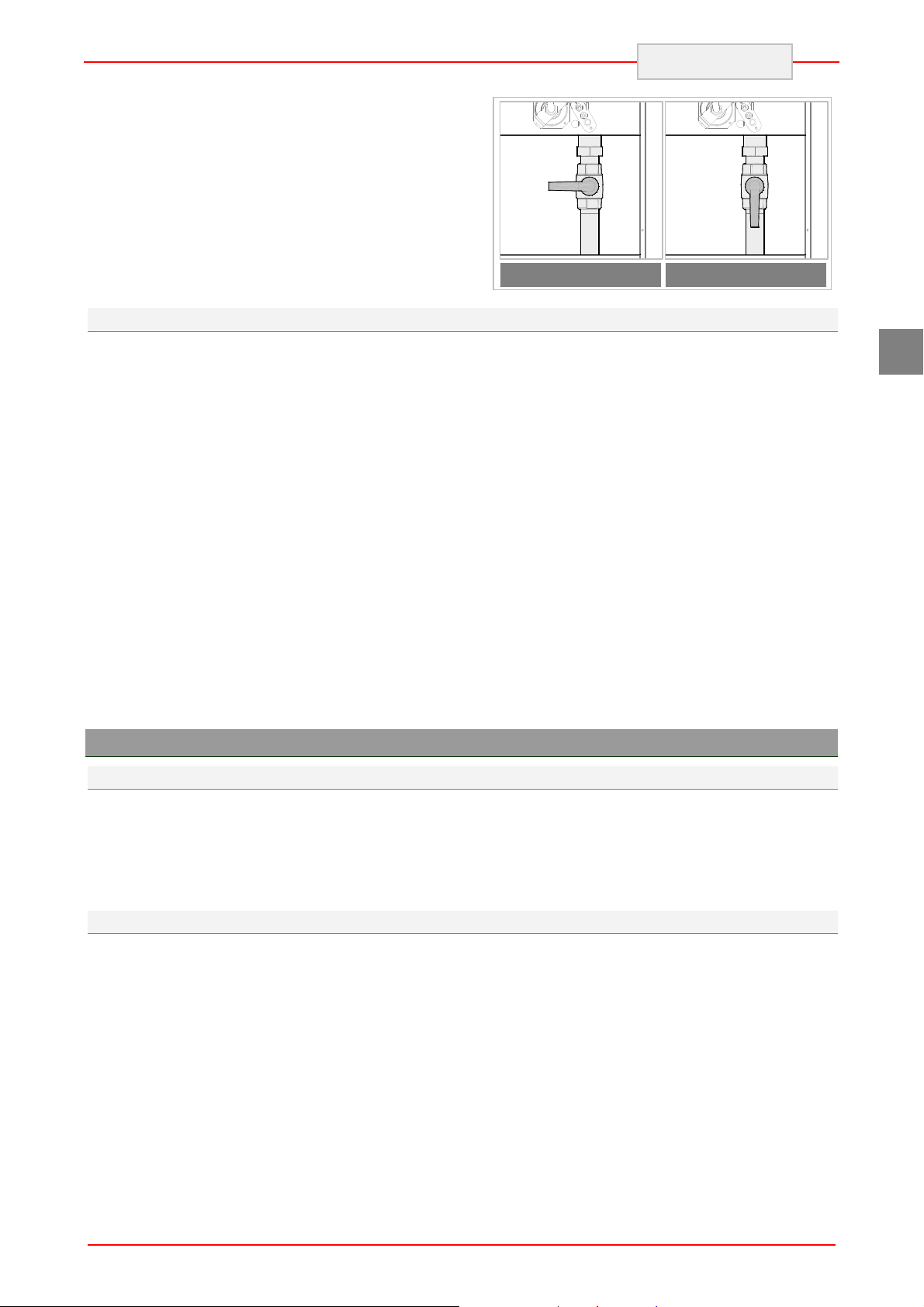

5.4. Draining the Cooking Tank

B

If the water level drops blow the minimum value,

remember to open the cock.

! Do not use the appliance when the water

level is lower than the minimum level marked on

the tank.

Maximum

level

Minimum

level

6

The waste water must be evacuated through a

suitable manifold, which is resistant to a

temperature of at least 212°F (100°C). To drain

the water from the tank, turn the cock handle (A)

downwards.

! Before filling the tank, check that the drain

cock (A) is closed.

ENGLISH

A

ID 05

5.5. Recommendations for Use

If the appliance remains inactive for a long period,

proceed as follows:

1. close the gas supply cock;

2. clean the appliance and surrounding areas

thoroughly;

3. spread a layer of cooking oil onto the stainless

steel surfaces;

4. carry out all maintenance operations;

5. leave the appliance uncovered and the

cooking room open.

! Always drain the cooking tank after use.

In order to ensure correct use of the appliance, it

is advisable to apply the following

recommendations:

use only accessories indicated by the

manufacturer;

use the cooking baskets in an appropriate

way;

Cock CLOSED

Check that the drain cock is closed before

filling the cooking tank;

Check that the water level never drops below

the minimum marked on the tank.

Cock OPEN

! Never use the appliance without water in the

tank. This could jeopardise the structure of the

appliance itself irreparably.

Periodically, have the following operations carried

out by specialised personnel:

check the system pressure and sealing

check the efficiency of the thermocouples

check the correct operation of the exhaust

vent and clean if necessary

check the gas taps and grease if necessary.

GB

6. CLEANING AND MAINTENANCE

6.1. Recommendations for Cleaning and Maintenance

activated, could lead to unexpected dangerous

! Before carrying out any maintenance

operations, activate all envisioned safety devices.

In particular, close the gas supply cock and

prevent access to all the devices which, if

6.2. Routine Maintenance

Routine maintenance consists of daily cleaning of

all the parts which can come into contact with

foodstuffs and the periodic maintenance of the

burners, nozzles and draining pipes. Correct

maintenance allows the user to maximise

performance levels and operating life and

constantly maintain safety requirements.

Do not spray the appliance with direct jets of

water or high pressure appliances.

When cleaning stainless steel, do not use iron

wool, brushes or scrapers as ferrous particles

could be deposited which, on oxidising, could lead

to rust. To remove hardened residues, use

situations putting personal safety and health at

risk.

wooden or plastic spatulas or abrasive rubber

pads.

During long periods of inactivity, spread a

protective layer on all stainless steel surfaces by

wiping them with a cloth soaked in Vaseline oil

and airing the rooms periodically.

! Do not use products which contain

substances which are harmful and dangerous for

personal health (solvents, petrol etc.).

7

ENGLISH

7. FAULTS

GB

The information shown below aims to help with

the identification and correction of any anomalies

and malfunctions which could occur during use.

Some of these problems can be resolved by the

Problem Causes Solutions

Smell of gas.

The pilot light does not ignite.

The pilot light does not stay on.

The flame is yellow. The burner is dirty or wet.

Difficulty in turning the burner

control knob.

Occasional leak due to flame

going out.

The spark ignition system does

not work

Presence of air in the pipes

after prolonged inactivity.

The thermocouple is not hot

enough.

Cock malfunction.

user. For the other, precise competency is

required and they must therefore only be carried

out by qualified personnel.

Close the gas supply cock and air

the room.

Check the efficiency of the ignition

devices. Ignite the pilot light

manually.

Contact the after-sales

centre.

Prolong the ignition operation.

Clean the burner and let it dry.

If the problem persists,

contact the after-sales centre.

Contact the after-sales

centre.

8. INSTALLATION

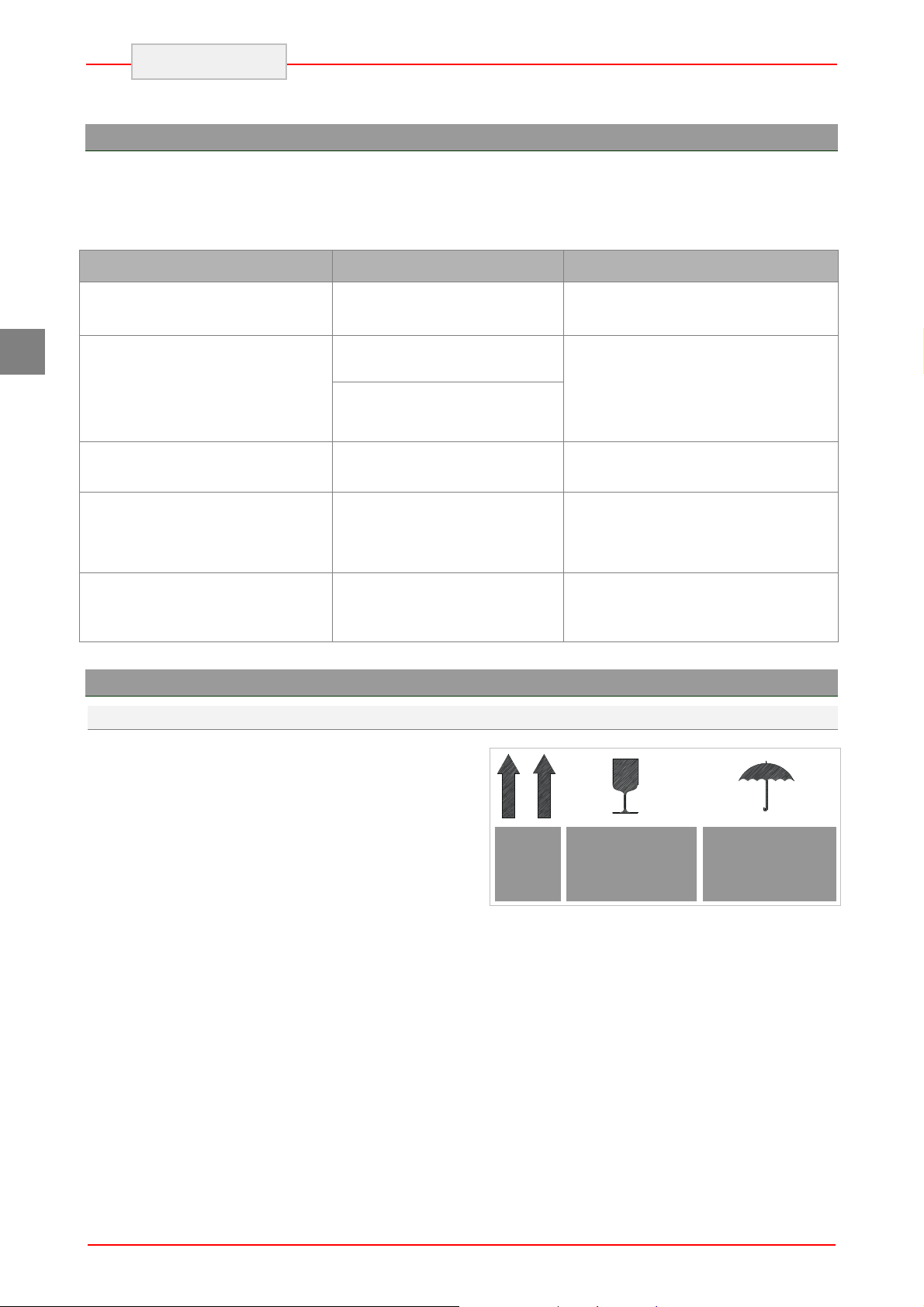

8.1. Packaging and Unpacking

Move and install the appliance respecting the

information provided by the manufacturer, shown

directly on the packaging, on the appliance and in

this manual.

The lifting and transportation system of the

packaged product envisages the use of a fork-lift

truck or a pallet stacker, using which particular

attention must be paid to balancing the weight n

order to prevent the risk of overturning (avoid

excessive tilting!).

! ATTENTION : When inserting the lifting

device, pay attention to the gas supply pipe and

the position of the feet.

The packaging is made of cardboard and the

pallet of wood. A series of symbols is printed on

the cardboard packaging which highlights, in

accordance with international standards, the

provisions which the appliances must be subject

to during loading, unloading, transportation and

storage.

TOP

On delivery, check that the packaging is intact and

has not suffered any damage during

transportation.

Any damage must be notified to the transportation

company immediately.

The appliance must be unpacked as soon as

possible to check that it is intact and undamaged.

Do not cut the cardboard with sharp tools in order

to prevent damage to the steel panels

underneath.

Pull the cardboard packaging upwards.

After having unpacked the appliance, check that

the features correspond to those requested in the

order;

For any anomalies, connect the dealer

immediately.

FRAGILE

HANDLE WITH

CARE

KEEP DRY

8

! Packaging elements (nylon bags,

polystyrene foam, staples …) must not be left

within reach of children.

8.2. Installation

All the installation phases must be considered,

from the moment of creation of the general plan.

The installation area must be equipped with all

power supply and production residue drainage

connections and must be suitably lit and respect

current laws regarding hygiene and sanitary

requirements.

Proceed with machine levelling, adjusting the

individual feet.

! Installation must be carried out by following

the instructions contained in this handbook and

only by a licensed tradesman in accordance with

local codes, or in absence of it, with the National

Fuel Gas Code, ANSI Z 223.1 or with the Natural

Gas Installation Code CAN/CGA-B149.1. The

manufacturer cannot be held liable for any

damage caused by faulty installation.

The place where the machine is to be installed

must have aeration equal to at least that given

in table 1.1, this is in order to supply the

necessary air for combustion, to prevent reaching

too high percentages of gas and to aid evacuation

of the products of combustion.

The installation room must be in conformity with

the current fire regulations.

The unit must operate in a level position. Slight

floor irregularities can be conpensated by turning

the adjustable feet of the cooker either clockwise

or counter clockwise.

Clearances from combustible and noncombustible construction are given in table 1.2

ENGLISH

Remove the protective PVC film from the internal

and external walls, avoiding the use of metal

tools.

Model

CPG1 80.000 780

CPG2 160.000 1560

Table 1.1 Minimum change of air in relation to the

thermal power installed.

Clearances

Side

Rear

Floor

Ceiling

Table 1.2 Clearances from combustible and noncombustible construction.

Figure 1 – Removable top flue grid assembly

Power

(BTU/hr)

Combustible

construction

6.0 ” 0 “

6.0 ” 0 “

6.0 ” 0 “

48.0 ”

Air flow

(m3/h)

Non combustibile

construction

GB

9

GB

ENGLISH

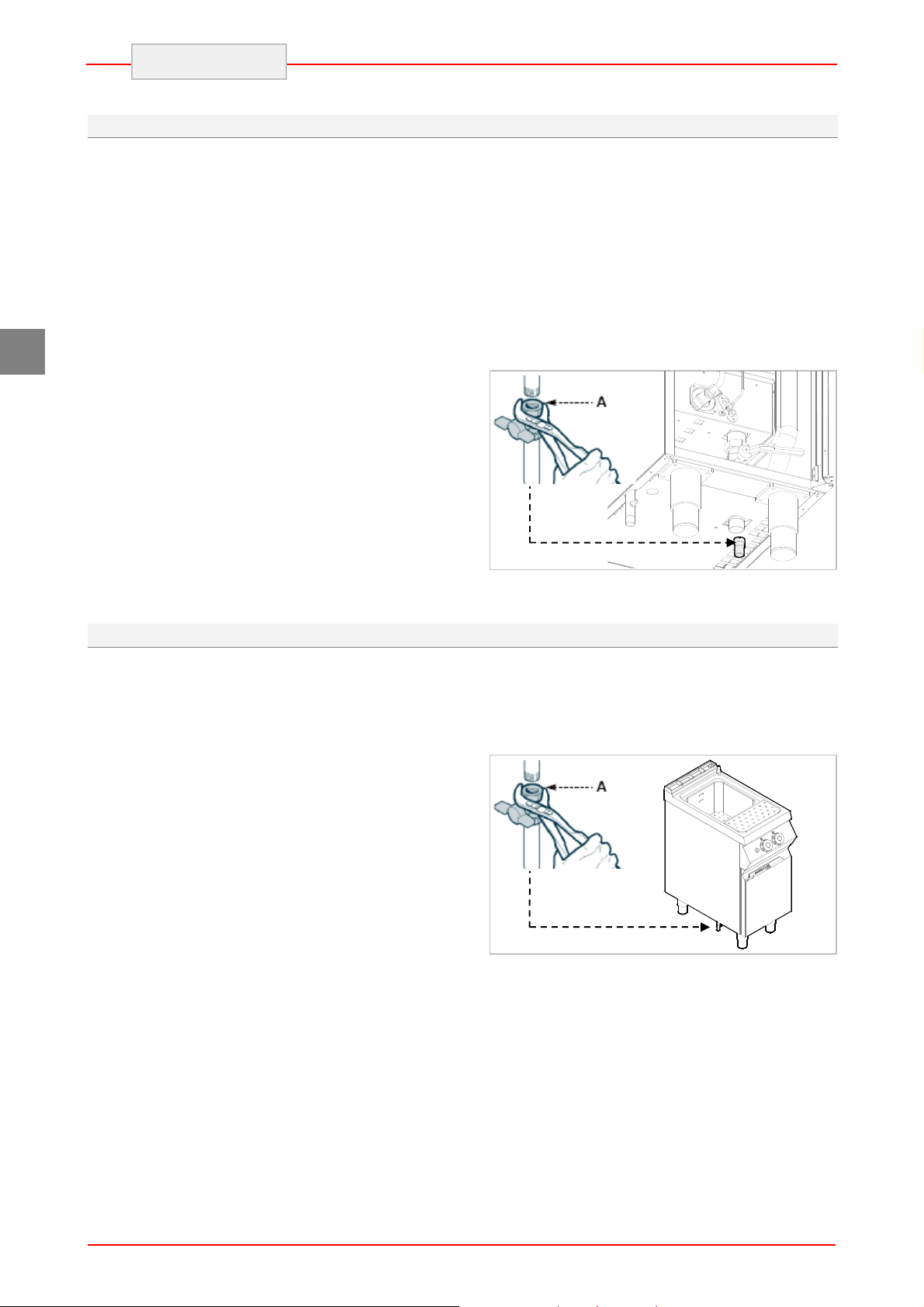

8.3. Water Connection

The unit should be connected to your water

supply by way of a water faucet. The water

pressure should fall between 14.5 and 72.5 PSI. If

the water pressure is excessive, a pressure

regulator must be installed.

To carry out connection, connect the mains pipe

to the appliance connection pipe, interposing a

shut-off cock (A) to interrupt the water supply

when necessary.

The pipe used to discharge the water must be

heat resistant and allow for the free flow of the

discharge water. A funnel may be used between

the unit discharge pipe and the floor drain but you

should never restrict or reduce the diameter of the

discharge pipe.

The following operations are to be carried out only

by specialized technical personnel.

1. Clear the pipe of any ferrous waste by letting

a certain amount of water flow through.

2. Place the cooker in the desired position and

close to the water-main.

3. Position the appliance level, adjusting the feet

of the cooker.

4. Connect mains pipe to machine pipe using a

mechanical filter and an interception cock.

5. Connect machine outlet pipe (fig. 1) to a

suitable manifold that withstands high

temperatures.

! Having verified that available water system

is adequate you can go ahead and make

connection:

8.4. Gas Connection

Before connecting up the gas consult the

gas board, all the installation and maintenance

operations should be carried out by the gas board

or by authorized fitters.

Make sure the data of the rating plate correspond

to the mains values. The rating plate is located at

the bottom of the screen-door panel.

Having verified that the gas supply system

available is adequate you can go ahead with the

connection:

To carry out connection, connect the mains pipe

to the appliance connection pipe, interposing a

shut-off cock to interrupt the water supply when

necessary.

1. Connect the mains pipe to the machine pipe

(see fig.) using a quick closing interception

cock which is easy to reach. You must use a

pressure regulator to set the manifold

pressure (see chapter 9.1)

2. Go ahead with setting up and adjusting.

3. Make all the checks listed below.

After connection, check that there are no gas

leaks.

! Never use flames to search for gas leaks.

10

Loading...

Loading...