Page 1

HAGAN POWER

POSITIONER

TORQUE TYPE

6x 10 INCH

Instruction Bulletin IB-102-207 Rev. 2

Supercedes II-102.207 dated January, 1985

FISHER-ROSEMOUIIT”ManagingThe Process Better

Page 2

Page 3

ROSEMOUNT WARRANTY

Rosemount warrants that the equipment manufactured and sold by it will, upon shipment, be free

of defects in workmanship or material. Should any failure to conform to this warranty become apparent

daring a period of one year after date of shipment, Rosemount shall, upon prompt written notice from the

purchaser, correct such nonconformity by repair or replacement, F.O.B. factory of the defective part or parts.

Correction in the manner provided above shall constitute a fulfillment of all liabilities of Rosemount with

respect to the quality of the equipment.

THE FOREGOING WARRANTY IS EXCLUSIVE AND JN LIEU OF ALL OTHER WARRANTIES

OF QUALITY WHETHER WRIT-l-RN, ORAL, OR IMPLIED (INCLUDING ANY WARRANTY OF

MERCHANTABILITY OF FITNESS FOR PURPOSE).

The remedy(ies) provided above shall be purchaser’s sole remedy(ies) for any failure of Rosemount to

comply with the warranty provisions, whether claims by the purchaser are baaed in contract or in tort

(including negligence).

Rosemount does not warrant equipment against deterioration due to environment. Factors such as corrosive

gases and solid particulates can be detrimental and can create the need for repair or replacement as part of

normal wear and tear daring the warranty period.

Equipment supplied by Rosemount Analytical Inc. but not manufactured by it, will be subject to the same

warranty as is extended to Rosemount by the original manufacturer.

Page 4

PURPOSE

The purpose of this manual is to provide a comprehensive understanding of the Hagan 6 x 10

Power Positioner, components, functions, installation, and maintenance.

This manual is designed to provide information about the Hagan 6 x 10 Power Positioner. We

recommend that you thoroughly familiarize yourself with the Description and Installation section before

installing your power positioner.

The overview presents the basic principles of the power positioner along with the it’s performance

characteristics and components. The remaining sections contain detail procedures and information necessary

for installation and servicing of the power positioner.

Before contacting Rosemount concerning any questions, fast consult this manual. It describes most

situations encountered in your equipment’s operation and details necessary action.

DEFINITIONS

The following defmitions apply to WARNINGS, CAUTIONS, and NOTES found throughout this

publication.

WARNING

Highlights an operation or maintenance procedure, practice, condition, statement, etc., if not strictly

observed, could result in injury, death, or long-term health hazards of personnel.

CAUTION

Highlights an operation or maintenance procedure, practice, condition, statement, etc., if not strictly

observed, could result in damage to or destruction of equipment, or loss of effectiveness.

NOTE

Highlights an essential operating procedure, condition, or statement.

NOTE TO USERS

The P- number in the lower right comer of the illustrations in this publication are manual

illustration numbers. They are not part numbers, and are not related to the illustration in any technical

manner.

IB-m2-*07

it

Page 5

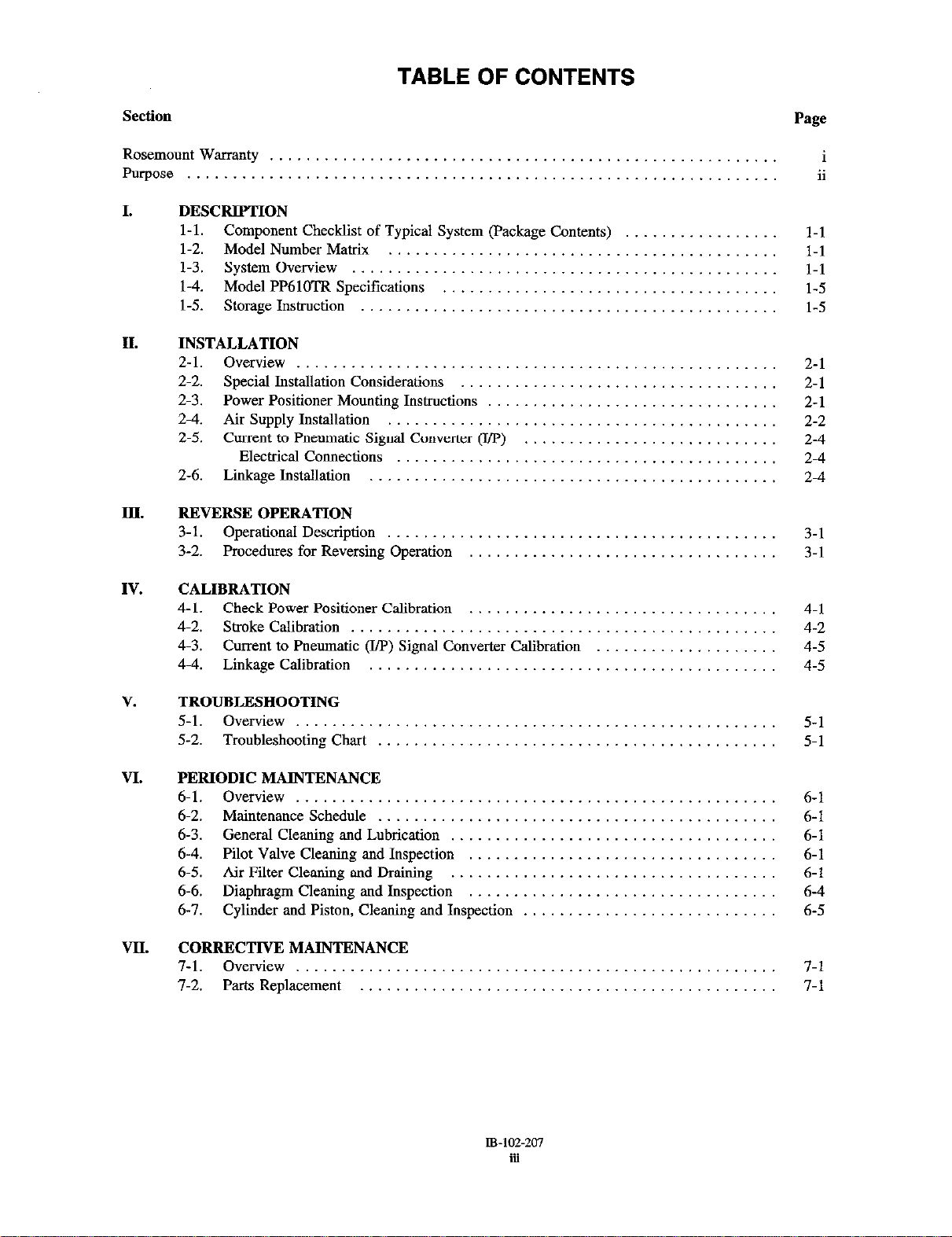

TABLE OF CONTENTS

SWtiOU

RosemountWarranty . . . . ..__................_______.......... i

Purpose . . ..___...................................___...__

I.

II.

III.

DESCRIPTION

l-l. Component Checklist of Typical System (Package Contents)

1-2. Model Number Matrix

l-3. System Overview

l-4. Model PP61OTR Specifications

l-5. storage Instruction

INSTALLATION

2-1. Overview

2-2. Special Installation Considerations

2-3. Power Positioner Mounting Instructions

2-4. Air Supply Installation

2-5. Current to Pneumatic Signal Converter (I/P)

Electrical Connections

2-6. Linkage Installation ..__.

REVERSE OPERATION

3-l. Operational Description

3-2. Procedures for Reversing Operation

. . . . . . . .

..... 2-1

...... 2-1

...... 2-1

...... 2-2

...... 2-4

...... 2-4

...... 2-4

Page

1-l

l-l

l-1

l-5

l-5

3-1

3-1

ii

IV.

V.

VI.

VII.

CALIBRATION

4-1. Check Power Positioner Calibration

4-2. Stroke Calibration

4-3. Current to Pneumatic (I/P) Signal Converter Calibration

4-4. Linkage Calibration

TROUBLESHOOTING

5-l. Overview

5-2. Troubleshooting Chart

PERIODIC MAINTENANCE

6-l. Overview

6-2. Maintenance Schedule

6-3. General Cleaning and Lubrication

6-4. Pilot Valve Cleaning and Inspection

6-5. Air Filter Cleaning and Draining

6-6. Diaphragm Cleaning and Inspection

6-7. Cylinder and Piston, Cleaning and Inspection

CORRECTIVE MAINTENANCE

7-1. Overview

7.2. Parts Replacement

...... 4-l

...... 4-2

...... 4-5

...... 4-5

......

......

...... 6-1

......

...... 6-l

...... 6-l

...... 6-l

...... 6-4

...... 6-5

......

......

5-l

5-l

6-1

7-l

7-l

Page 6

TABLE OF CONTENTS (Continued)

VIII. OPTIONS MAINTENANCE

8-l. Overview _........_...___..........__._...__.__.,,,,__

8-2. AirLock _.____.._........_...._..___..,..._.___....__,,,..,._ 8-l

8-3. Electric Position Transmitter @PT)

8-4. Heatwllwmostat

Ix. RECOMMENDED SPARE PARTS

8-l

8-3

8.3

X.

Figure

l-l.

l-2.

1-3.

2-l.

2-2.

2-3.

2.4.

2-5.

2-6.

2-l.

2-8.

2-9.

2-10.

2-11.

3-1.

4-1.

4-2.

4-3.

4-4.

4-5.

6-l.

6-2.

6-3.

6-4.

7-1.

l-2.

7-3.

l-4.

l-5.

8-l.

8-2.

8-3.

RETURNING EQUIPMENT TO THR FACTORY

INDEX

LIST OF ILLUSTRATIONS

Typical System Package

Power Positioner Operation

Typical Power Positioner Installation

Mounting Dimensions

Cleamnce Requirements

6

x 10 Power Positioner Torque Chart

Air Piping Schematic

Linear Linkage Design

Vertical Arm Travel

Driven Shaft Angular Rotation

Connecting Linkage. Length

Characterized Linear Linkage Design

Cam Bar Shaping

Driven Lever Travel

Reverse Operations

Calibration Flowchart

Stroke Adjustment

Current to Pneumatic Signal Converter

Linear Linkage Calibration

Characterized Linkage Calibration

Lubrication Chat

Pilot Valve Exploded View

Diaphragm Exploded View

Cylinder Exploded View

Air Filter

Pilot Valve

Receiver Exploded View

Cylinder Exploded View

Shaft Exploded View

Air Lock

Air Lock Diaphragm Exploded View

Heaterfllwmostat Replacement

Page

l-l

1-3

l-5

2-l

2-2

2-2

2-3

2-4

2-s

2-6

2-l

2-9

2-10

2-14

3-2

4-l

4-4

4-5

4-6

4-6

6-2

6-3

6-5

6-b

7-l

l-3

l-4

7-6

7-10

8-1

8-2

8-4

Page 7

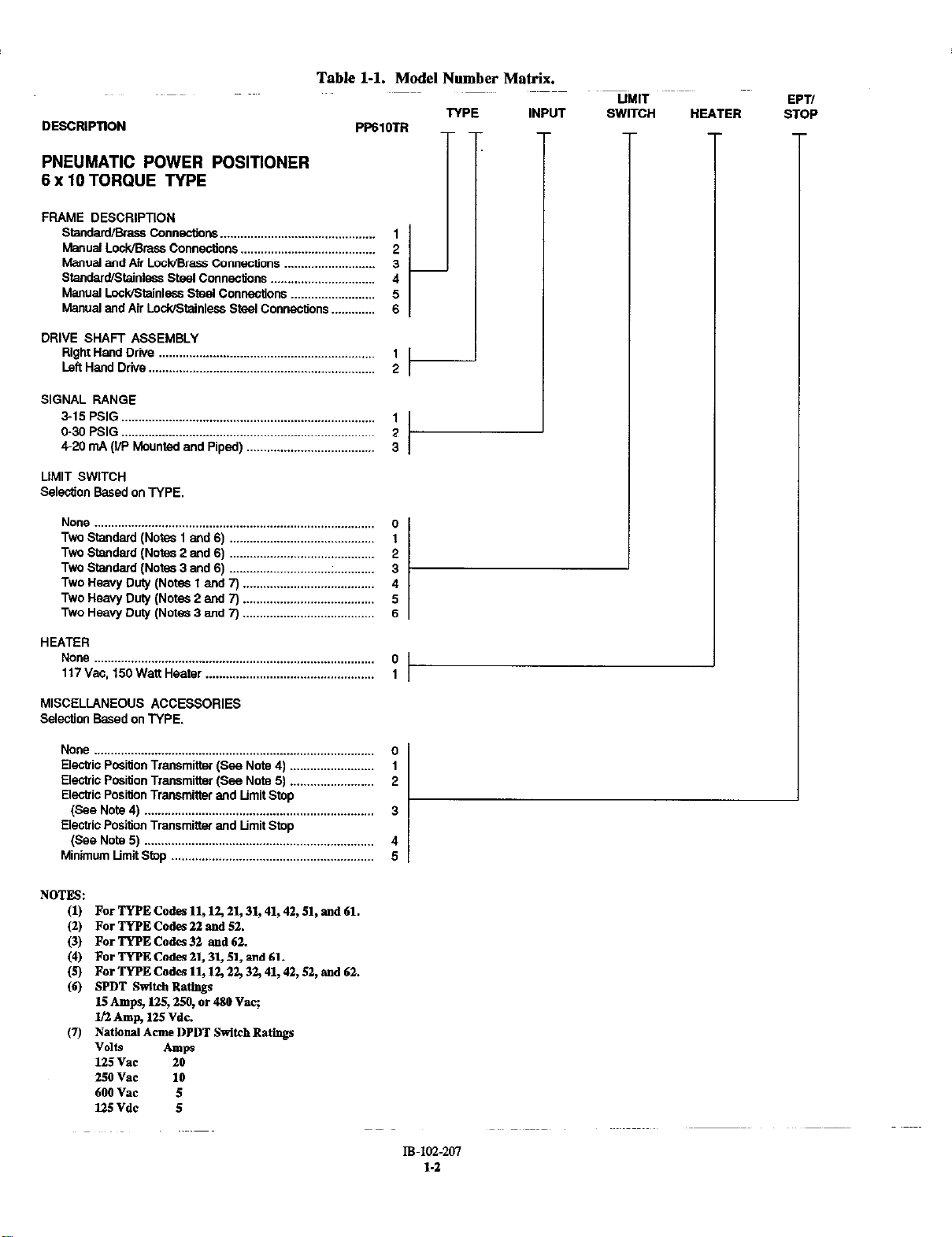

LIST OF TABLES

Table

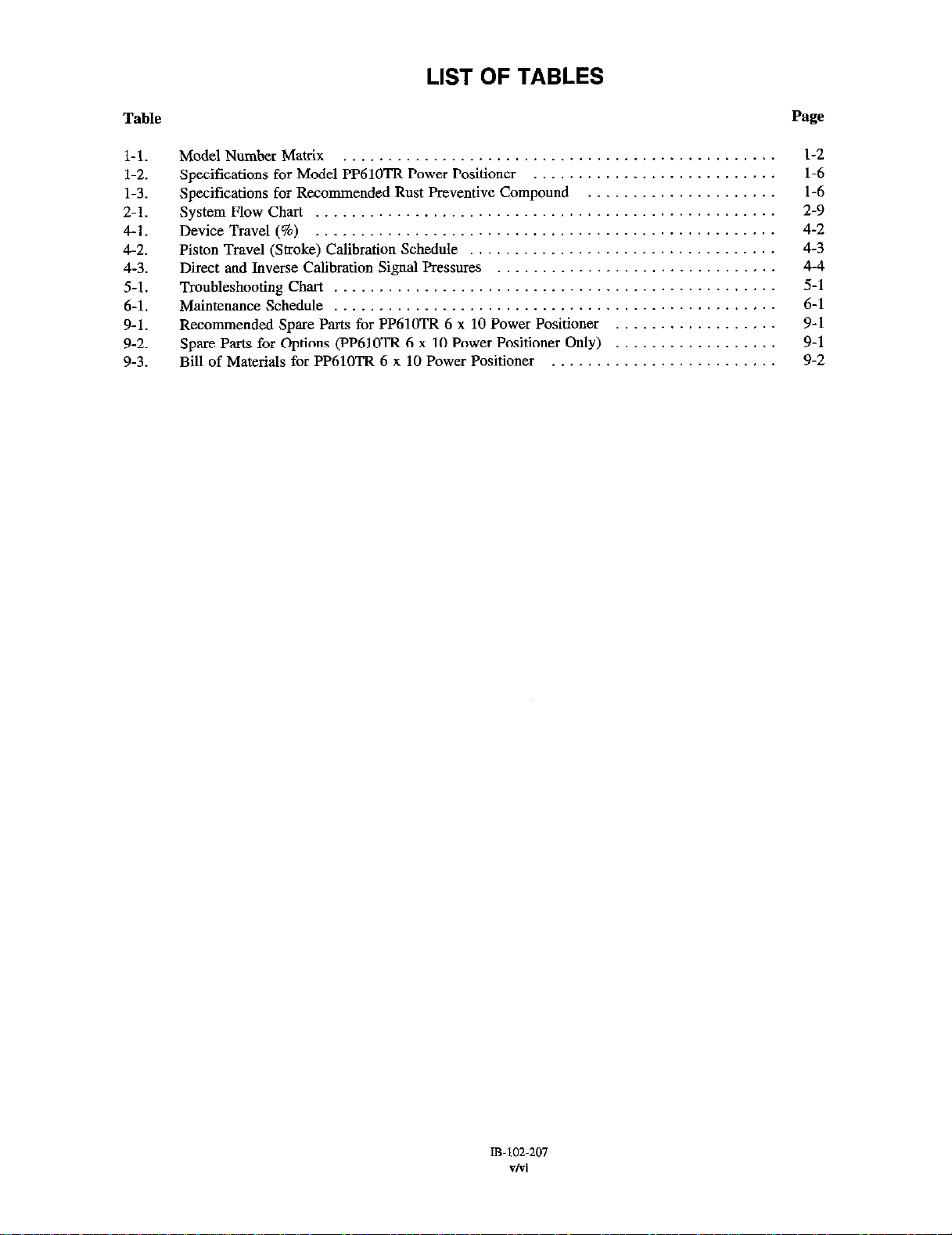

l-1. Model Number Matrix

1-2. Specifications for Model PP61OTR Power Positioner ....................

1-3. Specifications for Recommended Rust Preventive Compound ..............

2-1.

4-1. Device Travel (%)

4-2. Piston Travel (Stroke) Calibration Schedule ...........................

4-3.

5-l.

6-l. Maintenance Schedule ..........................................

9-1.

9-2. Spare Parts for Options (PP61OTR 6 x 10 Power Positioner Only)

9-3.

SystemFlowChart

Direct and Inverse Calibration Signal Pressures ........................

Troubleshooting Chart ..........................................

Recommended Spare Parts for PP61OTR 6 x 10 Power Positioner ...........

Bill of Materials for PP61OTR 6 x 10 Power Positioner ..................

.........................................

............................................

............................................

...........

Page

l-2

1-6

1-6

2-9

4-2

4-3

4-4

5-l

6-1

9-1

9-l

9-2

Page 8

Page 9

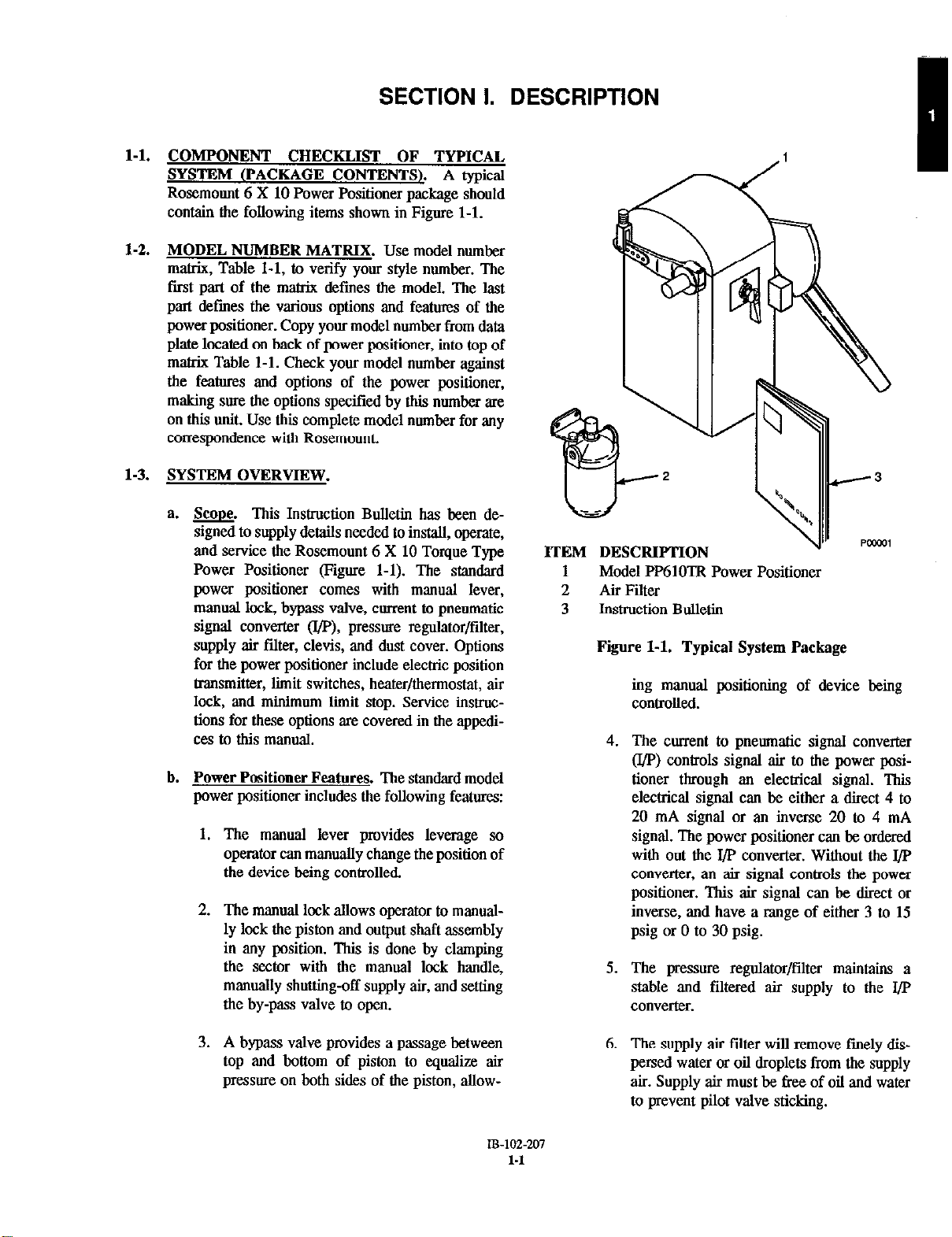

SECTION I. DESCRIPTION

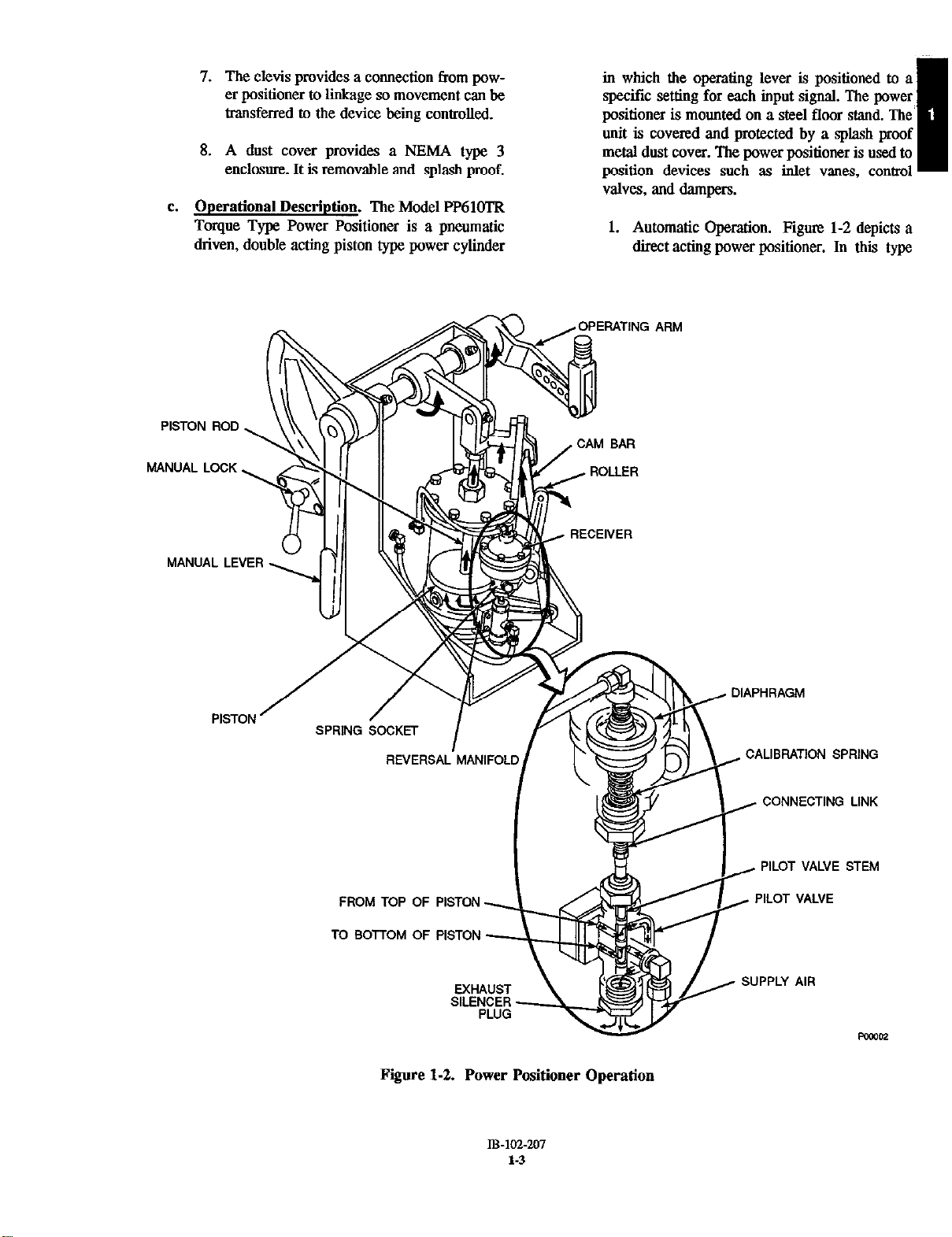

l-l.

COMPONENT CHECKLIST OF TYPICAL

SYSTEM (PACKAGE CONTENTS~. A typical

Rosemount 6 X 10 Power Positioner oackaae should

contain the following items shown in-Figure l-l.

1-2.

MODEL NUMBER MATRIX. Use model number

matrix, Table l-l, to verify your style number. The

first part of the matrix dcfmes the model. The last

part defmes the various options and feataxes of the

power positioner. Copy your model number from data

plate located on back of power positioner, into top of

matrix Table l-l. Check your model number against

the features and options of the p0we.r positioner,

making sure the options specified by this number are

on this unit. Use this complete model number for any

comespondcnce with Rosemount.

1-3.

SYSTEM OVERVIEW.

a.

w. This Instruction Bulletin has been de-

signed to supply details needed to install, operate,

and service the Rosemount 6 X 10 Torque Type

Power Positioner (Figure l-l). The standard

power positioner comes with manual lever,

manual lock, bypass valve, current to pneumatic

signal converter o/p), pressure rcgulator/tilter,

supply air filter, clevis, and dust cover. Options

for the power positioner include electric position

tmnsmitter, limit switches, heater/thermostat, air

lock, and minimum liiit stop. Service instmc-

tions for these options are covered in the appedices to this manual.

b.

Power Positioner Features. The standard model

power positioner includes the following features:

1.

The manual lever provides leverage so

operator can manually change the position of

the device being contilled.

2.

The manual lock allows operator to manually lock the piston and output shaft assembly

in any position. This is done by clamping

the sector with the manual lock handle,

manually shutting-off supply air, and setting

the by-pass valve to open.

ITEM DESCRIPTION

1 Model PP61OTR Power Positioner

2 Air Filter

3 Instruction Bulletin

Fire l-l. Typical System Package

ing manual positioning of device being

controlled.

4.

The current to pneumatic signal converter

(UP) controls signal air to the power posi-

tioner through an electrical signal. Thii

electrical signal can be either a direct 4 to

20 mA signal or an inverse. 20 to 4 mA

signal. The power positioner can be ordered

with out the I/P converter. Without the J/P

converter, an air signal controls the power

positioner. This air signal can be direct or

inverse, and have a range of either 3 to 15

psig or 0 to 30 psig.

5.

The pressure regulator/filter maintains a

stable and filtered air supply to the l/P

converter.

3.

A bypass valve provides a passage between

top and bottom of piston to cqualii air

pressure on both sides of the piston, allow-

IB-102-207

l-1

6.

The supply air filter will remove finely dis-

persed water or oil droplets from the supply

air. Supply air mast be free of oil and water

to prevent pilot valve sticking.

Page 10

Table l-l. Model Number Matrix.

DESCRIPTION

PNEUMATIC POWER POSITIONER

6 x 10 TORQUE TYPE

FRAME DESCRlPTlON

Standard/Brass Connections ___..............................,............

Lodamss C0”“ecti0”s 2

Manual

Manual and Air Lc&‘Brass Connections ____.__............_.......

Sta”da”vstai”lsss stwl Co”“ecocns

Manual Lockistai”less steel Co”mtio”s

Manual and Air Lo&Stainless Steel Connections _________....

PP610TR

1

3

4

5

6

TYPE INPUT

!

UMIT

HEATER

I

EPT/

STOP

DRIVE SHAFT ASSEMBLY

Right Hand

Left Hand Drive . ..______...............................................

SIGNAL RANGE

515PSlG

O-30 PSIG ..__.___________...............,,,,,...................................

4-20 mA (I/P Mounted and Piped) .._.___...................

LIMIT SWITCH

Selection Based on TYPE

None ...................................................................................

Two Standard (Notes 1 and 6)

Two Standard (Notea 2 and 6) ...........................................

Two Standard (Notes 3 and 6) ...........................................

Two Heavy Duty (Notes 1 and 7) .......................................

Two Heavy Duty (Notes 2 aid 7) .......................................

Two Heavy Duty (Notes 3 and 7) .......................................

HEATER

None ._.______..,.,...._................................,..,,,.......................... 0

117Vac. 150WattHeater ._...__..___.........................,.,,,,,,,,,.. 1

MISCELLANEOUS ACCESSORIES

S&&o” Based on TYPE.

None ...................................................................................

El&ic Pmition Transmitter (See Note 4) .........................

Electric Position Transmitter fSee Note 51

Elecb’ic Position Transmitter Ad Ltmit Stop

(See

Electric Position Transmitter and Limit Stop

(See Note 5) _____._._................................,.,........................

Minimum Limit Stop .._........................................

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

........................................... 1

.........................

Note 4) 3

2

t--

2

3

0

2

3

4

5

6

0

1

2

4

5

NOTES:

(1)

For

(2) For TYF’E Codes 22 and 52.

TYPE Codes 11,X?, Zl, 3,,41,42,51, and 61.

(3) For TYPE Codes 32 and 62.

(4) For TYPE Cades 2l,3l, 51, and 61.

Q For TYPE Codes 11,12,22,32,41,42,52,

(6) SPDT Switch Ratings

15 *raps, 125,250, or 480 vat;

l/2 Amp, 125 Vdc.

(7) National Acme DPDT Switch Rat,,,@

VOlf.9

bps

125vae 20

25ovac 10

600 Vat 5

U5Vdc 5

and 62.

IB-1u2-207

1.2

Page 11

7.

The clevis provides a connection from powcr positioner to liige so movement can be

transferred to the device being controlled.

8.

A dust cover provides a NEMA type 3

enclosure. It is removable and splash proof.

e.

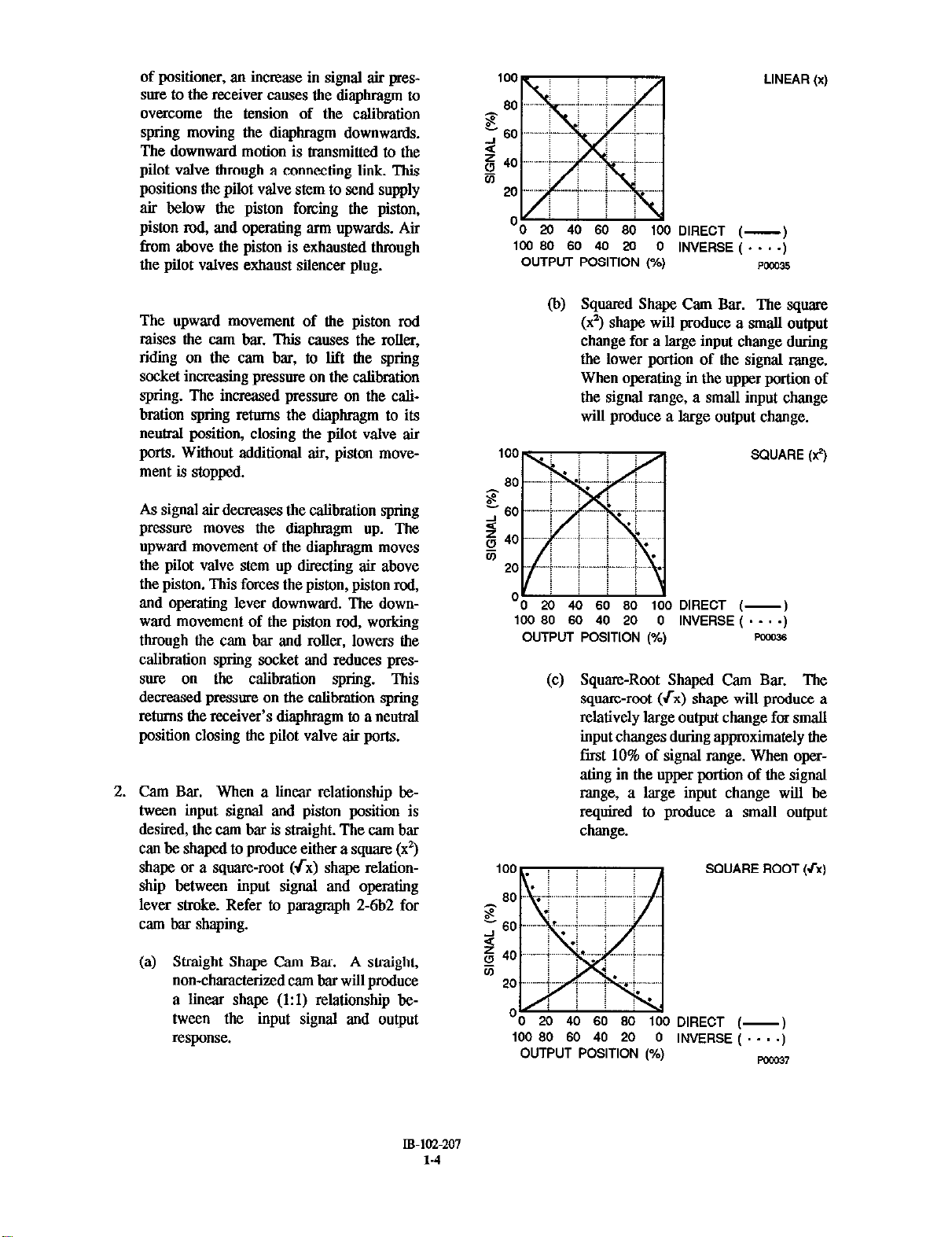

Operational Description. The Model PP61OTR

Torque Type Power Positioner is a pneumatic

driven, double acting piston type power cylinder

in which the operating lever is positioned to a

specific setting for each input signal. The power

positioner is mounted on a steel floor stand. The

unit is covered and protected by a splash proof

metal dust cover. The power positioner is used to

position devices such as inlet vanes, control

valves, and dampers.

1. Automatic Operation. Figure 1-2 depicts a

direct acting power positioner. In thii type

I

PISTON ROD

MANUAL LOCK,

MANUAL LEVER .-

PISTON ’

;1

/

I

/OPERATING ARM

DIAPHRAGM

CALIBRATION SPRING

FROM TOP

TO 801 OF

OF

Fiiure 1-2. Power Positioner Operation

CONNECTING LINK

PILOT VALVE STEM

PILOT VALVE

IB-162-207

t-3

Page 12

of positioner, a” increase in signal air pressure to the receiver causes the diaphragm to

overcome the tension of the calibration

spring moving the diaphragm downwards.

The downward motion is transmitted to the

pilot valve through a connecti”g link. Thii

positions the pilot valve stem to send supply

air below the piston forcing the piston,

piston rod, and operating arm upwards. Air

from above the piston is exhausted through

the pilot valves exhaust silencer plug.

The upward movement of the piston rod

raises the cam bar. This ca”ses the roller,

riding on the cam bar, to lift the spring

socket increasing pressure on the calibration

spring. The increased pressure on the calibration spring retwns the diaphragm to its

neutral position, closing the pilot valve air

ports. Without additional air, piston movcment is stopped.

As signal air decreases the calibration spring

pressure moves the diaphragm up. The

upward movement of the diaphragm moves

the pilot valve stem up directing air above

the piston. This forces the piston, piston rod,

and operating lever downward. The downward movement of the piston rod, working

through the cam bar and roller, lowers the

calibration spring socket and reduces pressure. on the calibration spring. This

decreased pressure on the calibration spring

returns the receiver’s diaphragm to a neutral

position closing the pilot valve air ports.

2.

Cam Bar. When a linear relationship between input signal and piston position is

desired, the cam bar is straight. The cam bar

can be shaped to produce either a square (9)

shape or a square-root (rx) shape relationship between input signal and operating

lever stroke. Refer to paragmph 2-6b2 for

cam bar shaping.

‘0 20 40 60

loo 80 60 40 20 0

OUTPUT POSITION (%)

80 100

DIRECT (-

INVERSE ( . . . .

Squared Shape Cam Bar. The square

(x2) shape will produce a small output

change for a large input change during

the lower portion of the signal range.

When operating in the upper portion of

the signal range, a small input change

will produce a huge output change.

100 80 60 40 20 0

OUTPUT POSITION (%)

DIRECT (-

INVERSE ( . . . .I

(c) Square-Root Shaped Cam Bar. The

square-root (fx) shape will produce a

relatively large output change for small

input changes during approximately the

fast 10% of signal range. When opersting in the upper portion of the signal

range, a large input change will be

rqdred to produce a small output

change.

SQUARE ROOl

LINEAR(x)

Pccnl5

SQUARE (9)

PM036

(a) Straight Shape Cam Bar. A straight,

non-characterized cam bar will produce

a linear shape (1:l) relationship between the input signal and output

02pO”S~.

IB-ICC-207

l-4

‘0 20 40 60

100 80 60

OUTPUT POSITION (%)

80 100

40 20 0

DIRECT (INVERSE ( . . .;

Km37

Page 13

3. Inverse Operation. On inverse acting power

positioners, the cam bar is reversed top to

bottom and the reversal manifold is turned

90”. This causes the supply air to be directed to the top of the piston when signal air

pressure is increased and to the bottom of

the piston when signal air pressure is decreased. In this type of installation, piston

movement is inversely related to the signal-as signal pressure decreases, the piston

raises, as signal pressure raises, the piston

1OUWS.

4. Manual Operation. The power positioner

can be controlled manually through the

manual lever. The movement of this lever

directly controls the position of the device

being controlled. To operate the manual

lever, shut off supply air and open the by-

pass valve.

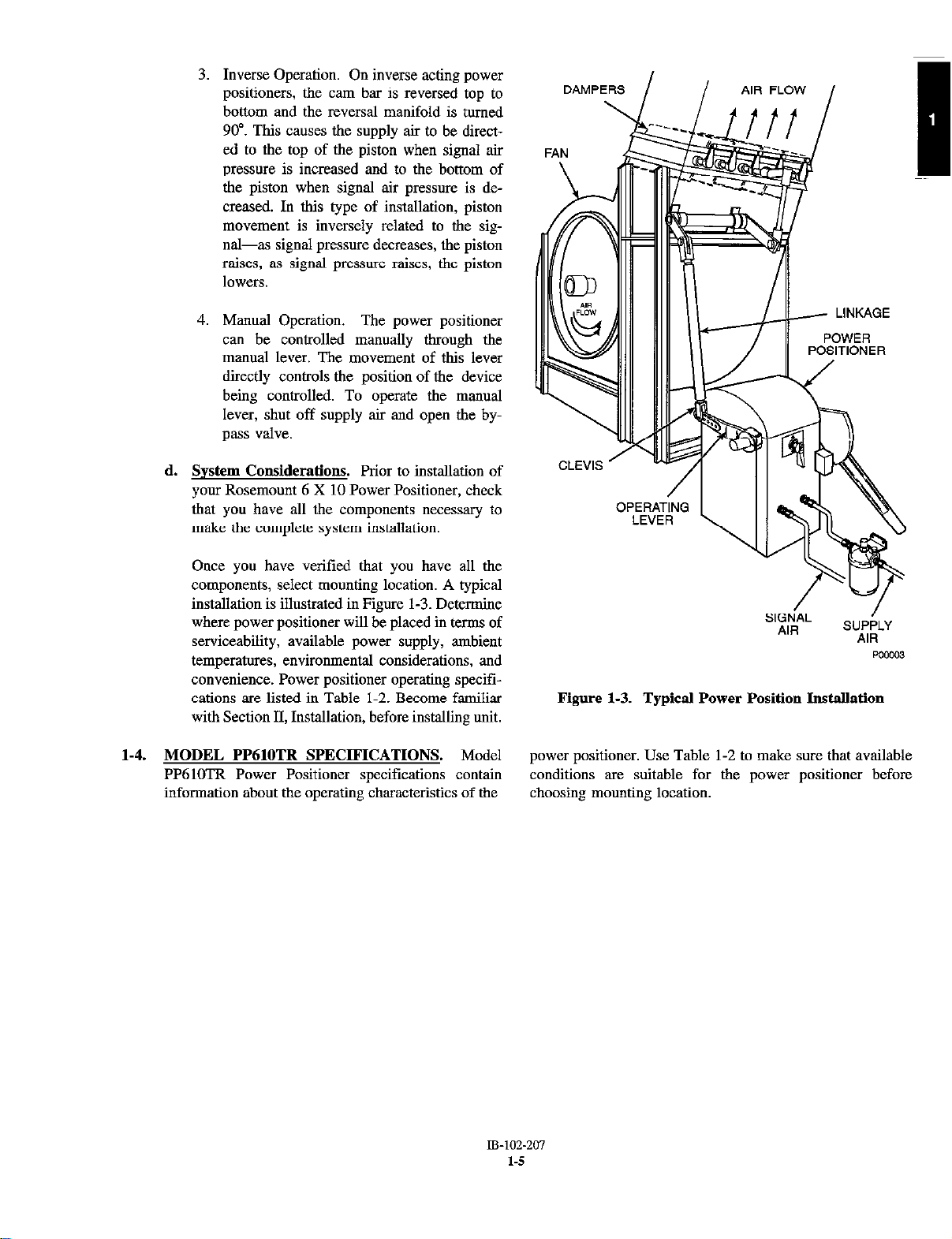

d. System Considerations. Prior to installation of

your Rosemount 6 X 10 Power Positioner, check

that you have all the components necessary to

make. the complete system installation.

POSITIONER

Once you have verified that you have all the

components, select mounting location. A typical

installation is illustrated in Figure 1-3. De&mine

where power positioner will be placed in terms of

serviceability, available power supply, ambient

temperatures, environmental considerations, and

convenience. Power positioner operating specifications are listed in Table l-2. Become familiar

with Section II, Installation, before. installing unit.

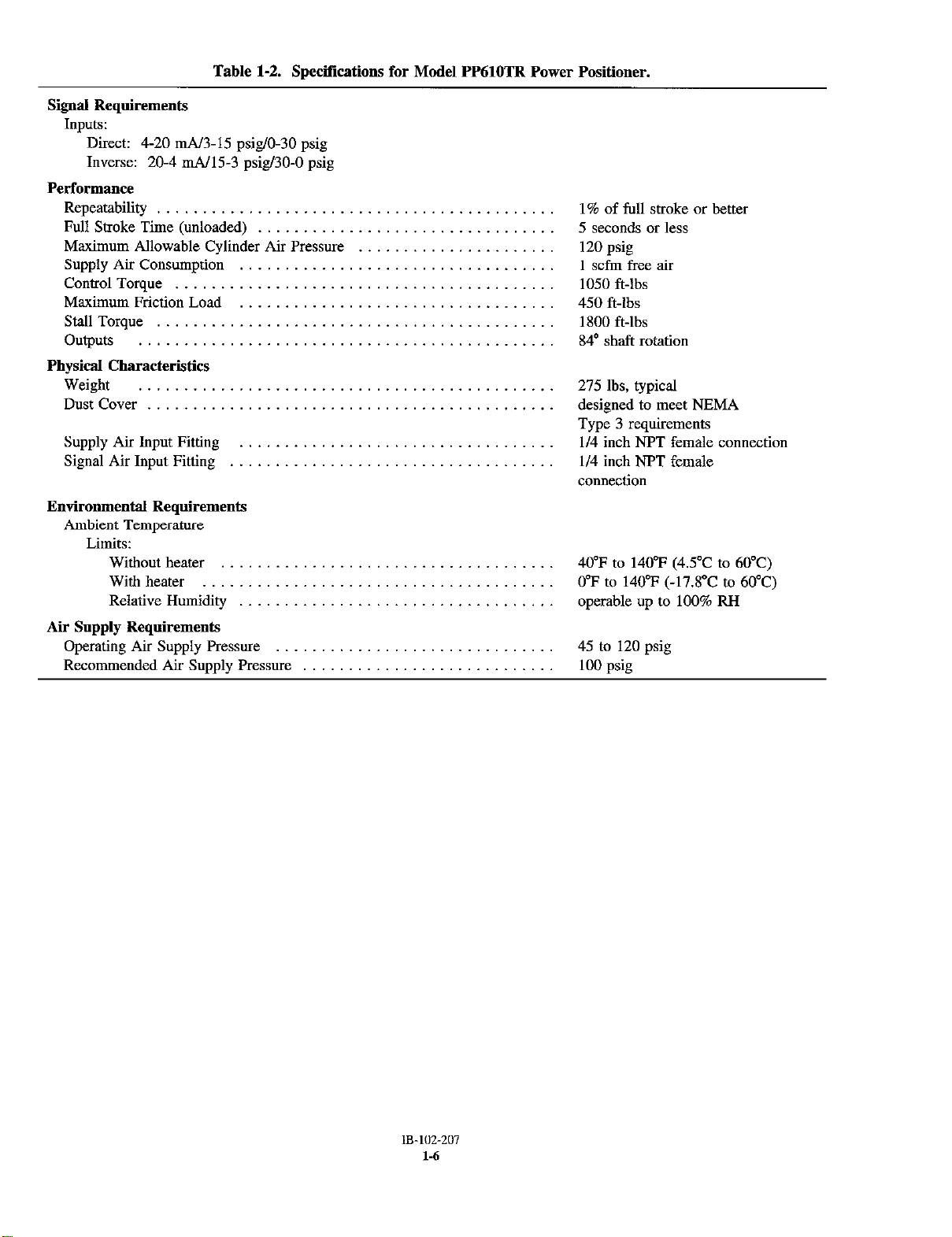

1-4. MODEL PP61OTR SPECIFICATIONS. Model

PP61OTR Power Positioner specifications contain

information about the operating characteristics of the

Figure 1-3. Typical Power Position Installation

power positioner. Use Table l-2 to make sure that available

conditions are suitable. for the power positioner before

choosing mounting location.

Page 14

Table 1-2. Specifications for Model PP61OTR Power Positioner.

Inputs:

Direct: 4-20 mA/3-15 psig/O90 psig

Inverse: 20-4 mA/15-3 psig/30-0 psig

Performance

Repeatability

Full Stroke Time (unloaded)

Maximum Allowable Cylinder Air Pressure

Supply Air Consumption

Control Torque

Maximum Friction Load

Stall Torque

Outputs

Physical Characteristics

Weight

Dust Cover

Supply Air Input Fitting

Signal Air Input Fitting

Environmental Requirements

Ambient Temperature

Limits:

Without heater

With heater

Relative Humidity

1% of full stroke or better

5 seconds or less

120 psig

1 scfm free air

1050 ft-lbs

450 ft-lbs

1800 ft-lbs

84’ shaft rotation

275 lbs, typical

designed to meet NEMA

Type 3 requirements

l/4 inch NPT female connection

l/4 inch NPT female

connection

40’F to 140°F (4S”C to 60°C)

0-F to 140°F (-17.8”C to 60°C)

operable up to 100% RH

Air Supply Requirements

Operating Air Supply Pressure

Recommended Air Supply Pressure

45 to 120 psig

100 psiz

Page 15

1-5. STORAGE INSTRUCTIONS. Use the following

guidelines for storage of the power positioner.

a. Storage Environment. Store power positioner in

a warehouse environment that maintains the

following conditions:

1. Ambient temperatures above 45°F (7°C).

2. Humidity below 80% RH.

b. Power Positioner Preparation for Storage. Coat

all non-painted surfaces and exposed metal with a

rust-preventive compound (Tectyl 506 OI a

substitute with similar properties). The specifications for Tectyl 506 are included in Table l-3.

WARNING

CAUTION

Use only approved thinning methods when applying

rust-preventive compounds. Do not apply heat to

compound. Fire or explosion may result. Refer to

manufacture of rust-preventive compound for

specitlc application, thinning, clean-up and removal

instructions.

c. Storage Preventive Maintenance. If storing power

positioner longer than six months, observe the following preventive maintenance guidelines.

1. Cycle cylinder and piston either manually or by air

every 6 months.

Keep Tectyl506 away from heat, sparks, and open

flames and use with adequate ventibxtion. Ventilation is required for cure and to prevent an explosive

atmosphere from forming.

Table 1-3. Sp&tiications for Recommended Rust Preventive Compound.

REQUIREMENTS PROPERTIES

Approximate air dry time 1 hour

Low Temperature Flexibility -10°F (-22.5”C)

(90” bend with no flaking or cracking)

Volatile Organic Content (V.O.C.) 3.24 1bsRJ.S. Gallon

Accelerated Corrosion Tests: (5% Salt Spray (Hours))

ASTM(seeNotel)B-117atl.3mils _.......______.._.__..___. 2000

(2 x 4 x 118 inch Polished Steel Panels)

DIN (see Note 2) 50021 at 32.5 microns 168

(125 x 200 mm DIN 1623 Panels)

NOTES:

(1) ASTM (American Society for Testing and Materials)

(2) DIN (Deutsche Industrie Normen)

2. Perform General Cleaning and Lubrication (paragraph 6.3), and Cylinder and Piston, Cleaning and

Lubrication (paragraph 6-7), before installing

power positioner.

400 grams/liter

Page 16

Page 17

SECTION II. INSTALLATION

2-1. OVERVIEW. The power positioner is designed to

be installed upright The floor stand is bolted to a

prepared horizontal foundation. A minimum of 45

psig to a maximum of 120 psig supply air pressure is

needed at the mounting location. The power positioner must be controlled by either an elechicaJ signal

or by an air signal. All wiring must conform to local

and national codes.

2-2. SPECIAL INSTALLATION CONSIDERATIONS.

a.

Foundation. The power positioner’s torque is

transmitted to the operating arm of the device,

this torque is transferred to the mass of the

positioner and its foundation. The foundation

mast be designed to handle the torque produced

to keep the power positioner stationary. Refer to

paragraph 2-3 for detailed foundation require-

ments.

b.

SUPP~V

air pressure of 45 to 120 psig, minimum of 1

scfm, is required. A Nter and regulator should be

provided in the supply line.

c.

Linkaee Design Considerations. Final control

components play a large part in a control system.

Special characteristics of the device being controlled affect system response and most be reganied in design and set-up of a power positioning system.

Air Pressure Considerations. A supply

Flow tests mast be conducted before attempting

to limit damper opening. Testing is necessary to

contii actual damper characteristics and to

ensure control response throughout the entire.

flow range. When installing a new power

positioning system, care must be taken to properly design the system for linkage size and

action. In a properly designed system, a percentage change in control signal will produce the

same percentage change in flow rate. Refer to

paragraph 2-6 for detailed information on design

and installation of a linearized control action

power positioning system.

2-3. POWER POSITIONER MOUNTING

INSTRUCTIONS.

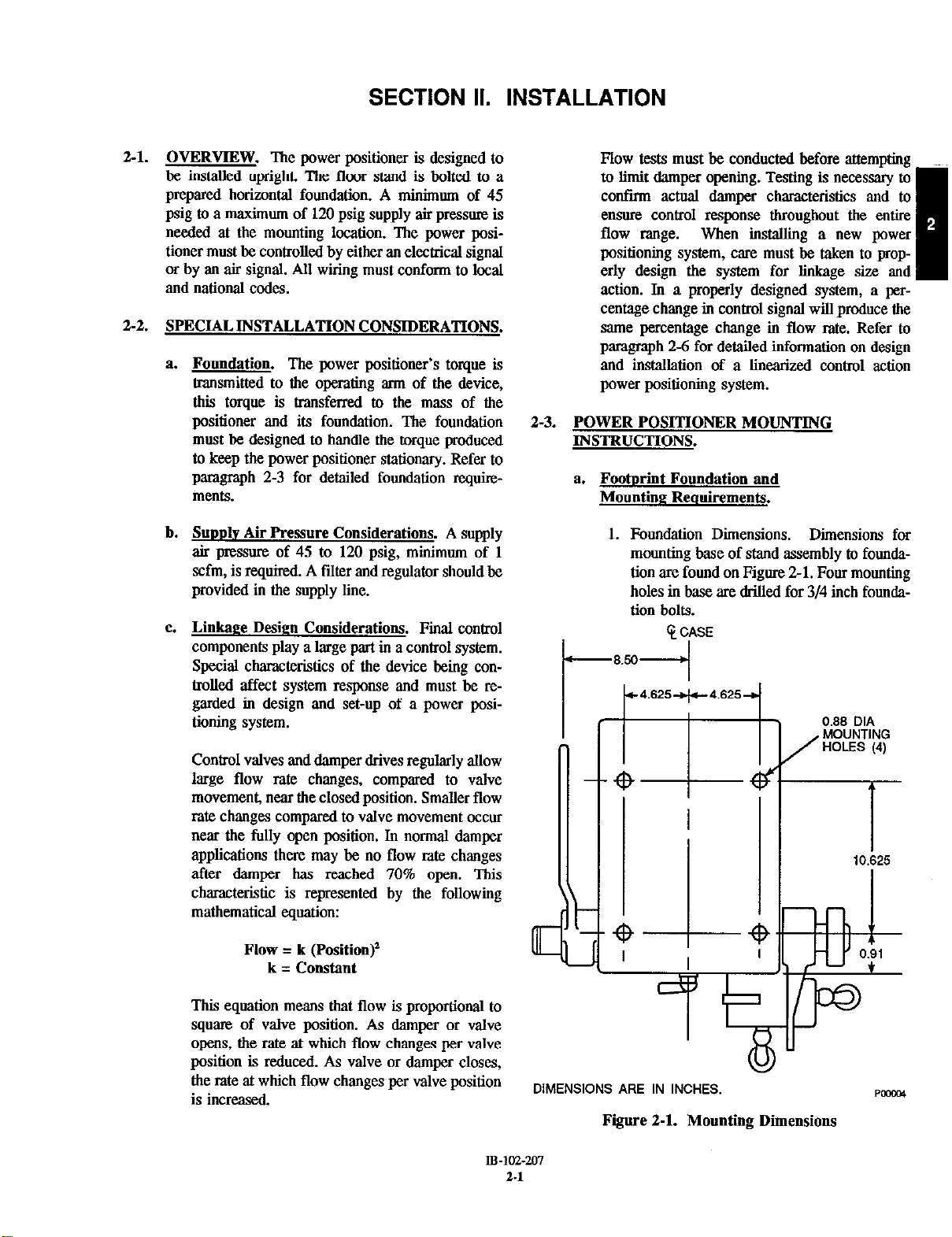

a. Footmint Foundation and

Mounting Requirements.

1.

Foundation Dimensions. Dimensions for

mounting base of stand assembly to foandation are found on Figure 2-1. Four mounting

holes in base are drilled for 3/4 inch foundation bolts.

t-

t-4.625-+-4.6254

Control valvea and damper drives regularly allow

large flow rate changes, compared to valve

movement, near the closed position. Smaller flow

rate changes compared to valve movement occur

near the fully open position. In normal damper

applications there may be no flow rate changes

after damper has reached 70% open. This

characteristic is represented by the following

mathematical equation:

Flow = k (Position)’

k = Constant

This equation means that flow is proportional to

square of valve position. As damper or valve

opens, the rate at which flow changes per valve

position is reduced. As valve or damper closes,

the rate at which flow changes per valve position

is increased.

B-102-207

DIMENSIONS ARE IN INCHES.

Figure 2-1. Mounting Dimensions

2.1

Page 18

1

14.2!

5

1

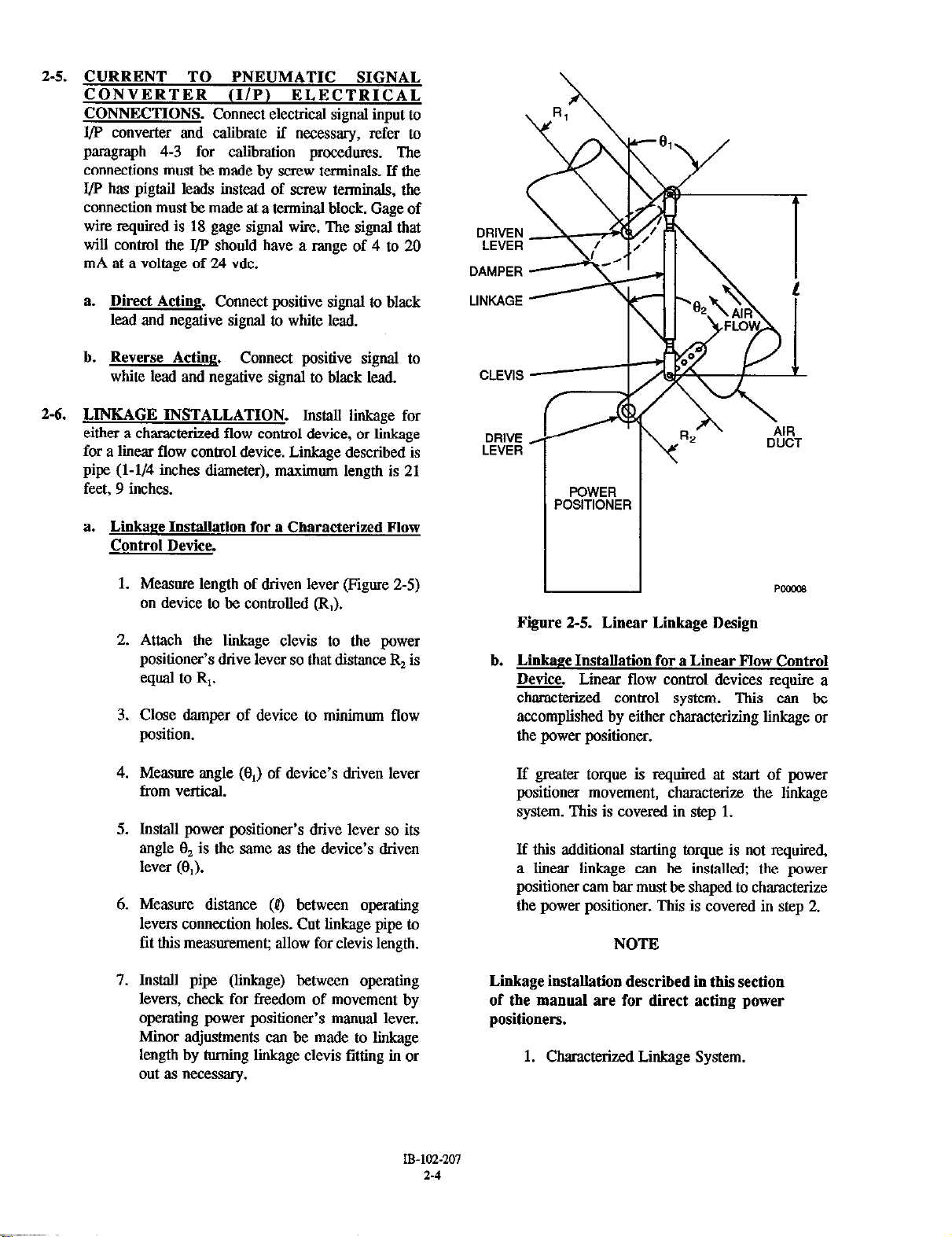

ffiter, Figure 2-4. The air filter will remove finely

dispersed water or oil droplets, preventing

sticking of the pilot valve stem.

If your unit is not equipped with an IiF’ signal

converter, a separate signal line must be installed

as shown in Figure 2-4, View B. Tbis signal line

must be either 0 to 30 psig or 3 to 15 psig. Refer

to your model number and model number matrix

(Table l-l) to determine type of air signal

required.

b. Supply Air and Signal Air Connections. Basic

schematics are shown in Figure 2-4. The

installation of the air filter is as follows:

1. Mount bracket for air filter directly on the

back of the stand assembly. If tbis is

unsuitable, mount air filter within 15 feet of

power positioner.

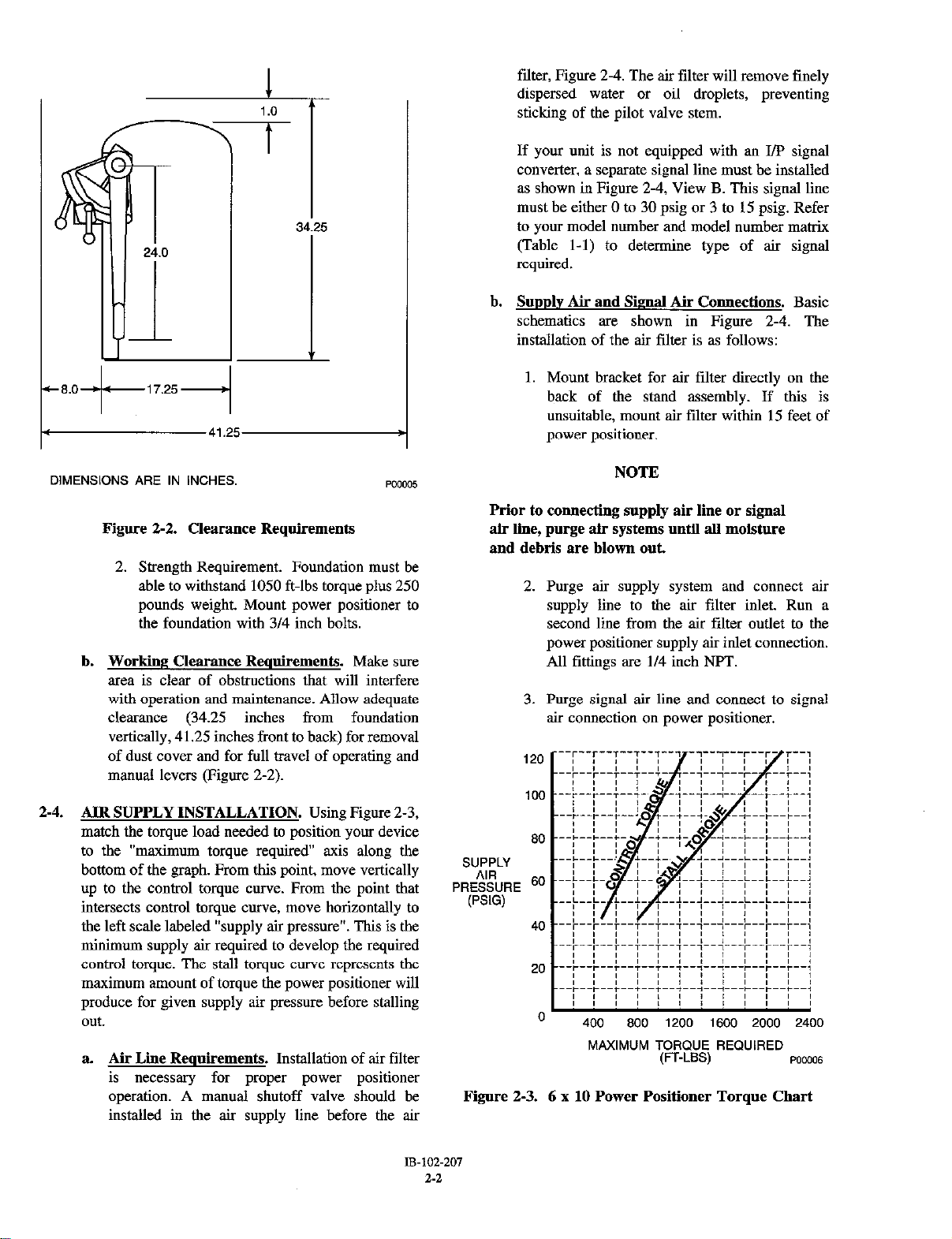

DIMENSIONS ARE IN INCHES.

Figure 2-2. Clearance Requirements

2. Strength Requirement. Foundation must be

able to withstand 1050 ft-lbs torque plus 250

pounds weight. Mount power positioner to

the foundation with 3/4 inch bolts.

b. Working Clearance Requirements. Make sure

area is clear of obstructions that will interfere

with operation and maintenance. Allow adequate

clearance (34.25 inches from foundation

vertically, 41.25 inches front to back) for removal

of dust cover and for full travel of operating and

manual levers (Figure 2-2).

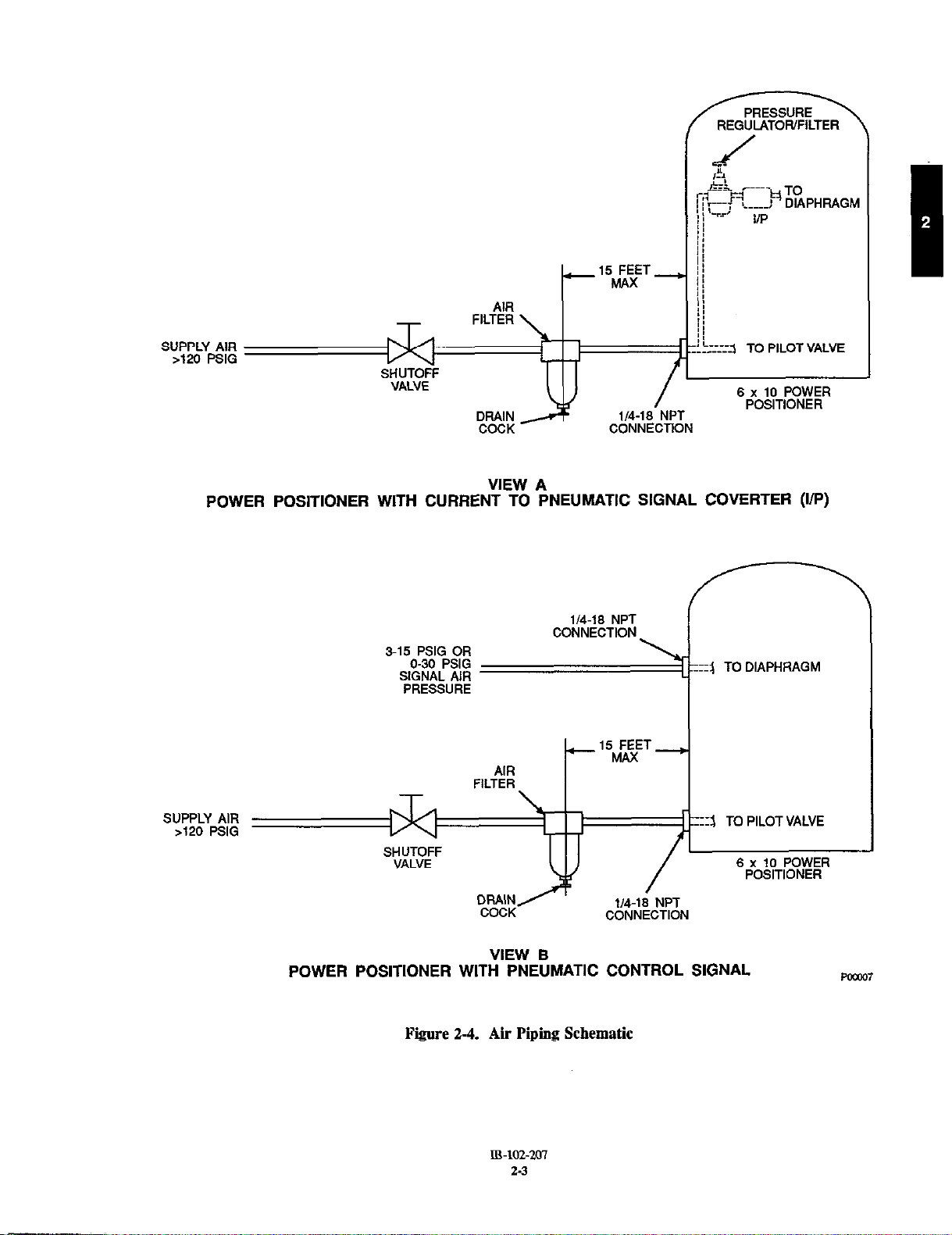

2-4. AIR SUPPLY INSTALLATION. Using Figure 2-3,

match the torque load needed to position your device

to the “maximum torque required” axis along the

bottom of the graph. From this point, move vertically

up to the control torque curve. From the point that

intersects control torque curve, move horizontally to

the left scale labeled “supply air pressure”. This is the

minimum supply air required to develop the required

control torque. The stall torque curve represents tbe

maximum amount of torque the power positioner will

produce for given supply air pressure before stalling

out.

a. Air Llle Requirements. Installation of air filter

is necessary for proper power positioner

operation. A manual shutoff valve should be

installed in the air supply line before the air

NOTE

Prior to comvxting supply air line or signal

air line, purge air systems until all moisture

and debris are blown out

2. Purge air supply system and connect air

supply line to the air filter inlet. Run a

second line from the air filter outlet to the

power positioner supply air inlet connection.

All fittings are l/4 inch NPT.

3. Purge signal air line and connect to signal

air connection on power positioner.

120

100

80

s”EiLy

PFIESES~FIE 6o

40

20

0

MAXIMUM TORQUE REQUIRED

(FT.LSS)

Figure 2-3. 6 x 10 Power Positioner Torque Chart

POW06

18-102-207

2-2

Page 19

REGULATOWFILTER

SHUTOFF

VALVE

CONNECTION

6

x 10 POWER

POSITIONER

VIEW A

POWER POSITIONER WITH CURRENT TO PNEUMATIC SIGNAL COVERTER (I/P)

SUPPLY AIR

>120

PSIG

l/4-16

CONNECTION

NPT

+--‘5tvhFT---+

AIR

FILTER

:I3 TO PILOT VALVE

l/4-18

COCK

CONNECTION

VIEW B

POWER POSITIONER WITH PNEUMATIC CONTROL SIGNAL

Figure 2-4. Air Piping Schematic

NPT

6 x IO POWER

POSITIONER

Page 20

2-5. CURRENT TO PNEUMATIC SIGNAL

CONVERTER (I/P) ELECTRICAL

CONNECTIONS. Connect electrical signal input to

I/F’ converter and calibrate if necessary, refer to

paragraph 4-3 for calibration procedures. The

connections most be made by screw terminals. If the

I/P has pigtail leads instead of screw terminals, the

connection must be made at a terminal block. Gage of

wire required is 18 gage signal wire. The signal that

wiU control the W should have a range of 4 to 20

mA at a voltage of 24 vdc.

a. Direct Acting. Connect positive signal to black

lead and negative signal to white lead.

h. Reverse Acting.. Connect positive signal to

white lead and negative signal to black lead.

2-6. LINKAGE INSTALLATION. lnstxdl liige for

either a characterized flow control device, or linkage

for a linear flow control device. Linkage described is

pipe (l-1/4 inches diameter), maximum length is 21

feet, 9 inches.

a. Linkage Installation for a Characterized Flow

Control Device.

DRIVE

LEVER

POWER

POSITIONER

1. Measure length of driven lever (Figure 2-5)

on device to be controlled (R,).

2. Attach the linkage clevis to the power

positioner’s drive lever so that distance & is

equal to R,.

3. Close damper of device to minimum flow

position.

4. Measure angle (6,) of device’s driven lever

from vertical.

5. Inslall power positioner’s drive lever so its

angle l$ is the same as the device’s driven

lever (0,).

6. Measure. distance (p) between operating

levers connection holes. Cut linkage pipe to

fit this measoremenr allow for clevis length.

7. Install pipe (linkage) between operating

levers, check for freedom of movement by

operating power positioner’s manual lever.

Minor adjustments can be made to linkage

length by turning linkage clevis fitting in or

out as “L?ceSsary.

Pwme

Figure 2-5. Linear Linkage Design

b. Linkage Installation for a Linear Flow Control

Device. Linear flow control devices require a

characterized control system. This can be

accomplished by either characterizing linkage or

the power positioner.

If greater torque is required at start of power

positioner movement, characterize the linkage

system. This is covered in step 1.

If this additional starting torque is not required,

a linear linkage can be installed; the power

positioner cam bar must be shaped to characterize

the power positioner. This is covered in step 2.

NOTE

Linkage installation described in thii section

of the manual are for direct acting power

positioners.

1. Characterized Linkage System.

IB-102.207

2-4

Page 21

Sine Function (SIN)

Square Function (x’)

Use the following procedure to

determine Y, the vertical distance

travell.xl by drive lever:

1 Add value of 8, to value of &.

2 Divide answer from step 1. by 2.0.

3 Enter answer from step 2. aad press

sine key (SJN).

\ DRIVE

LEVER

POWER

POSITIONER

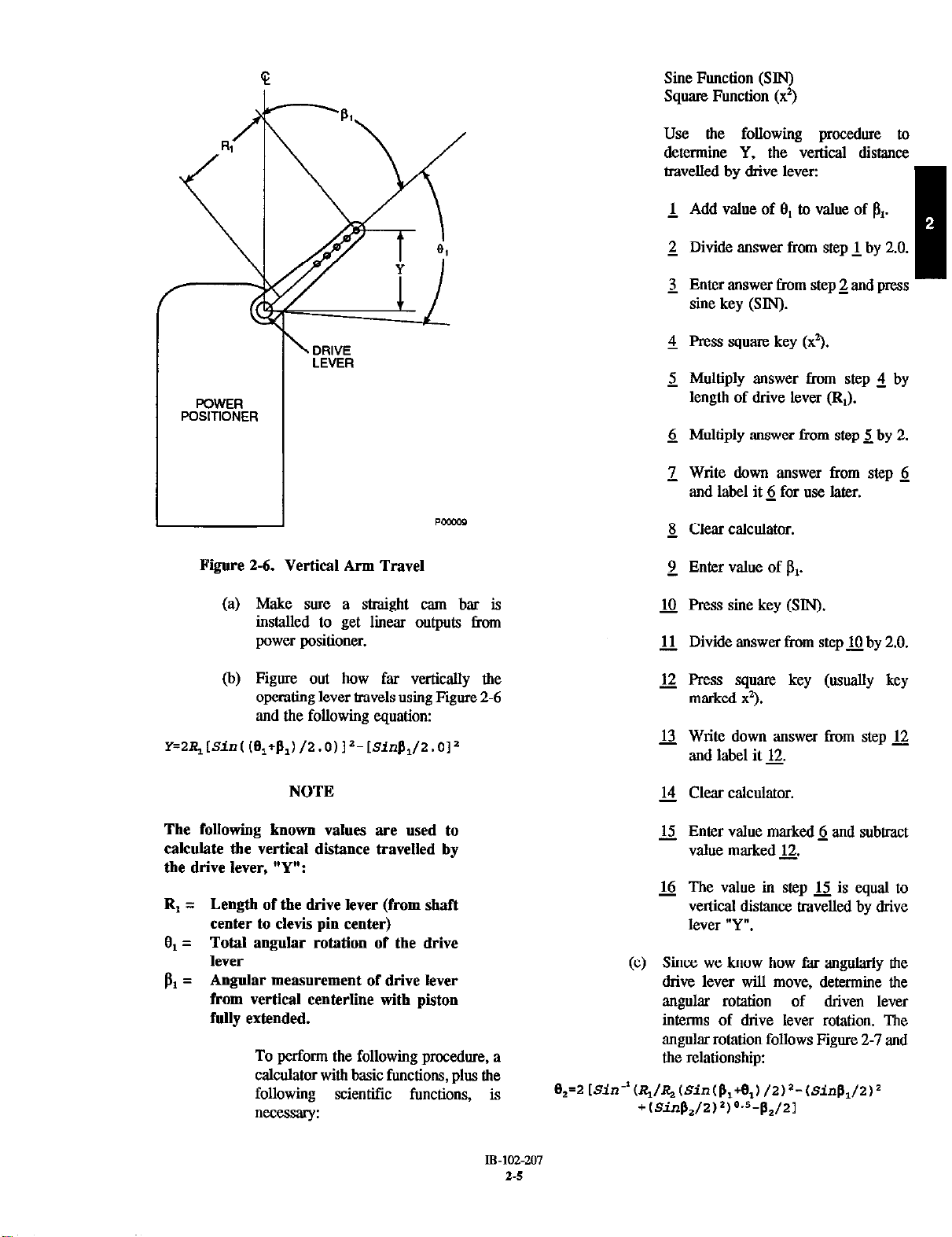

Figure 2-6. Vertical Arm Travel

(a) Make sore a straight cam bar is

installed to get linear outputs from

power positioner.

(b) Figure out how far vertically the

operating lever travels using Figure 2-6

aad the following equation:

NOTE 14 Clear calculator.

4 Press square. key (x”,.

2 Multiply answer from step 2 by

length of drive lever (RI).

6 Multiply answer from step 5 by 2.

z Write down answer from step 6

and label it 6 for use later.

& Clear calculator.

2 Enter value of pP

a Press sine key (SIN).

.lJ Divide answer from step jQ by 2.0.

12 Press square key (asaally key

marked x3.

12 Write down answer from step 12.

and lab4 it 12.

The following known values are used to

calculate the vertical distance travelled by

the drive lever

“Y”-

, .

R, = Length of the drive lever (from shaft

center to clevis pin center)

Total angular rotation of the drive

Cl1 =

lever

Angular measurement of drive lever

PI =

from vertical centerline with piston

fully extended.

To perform the following procedure, a

calculator with basic functions, plus the

following scientific fanctions, is

necessary:

IF-102-207

2-s

u Enter value marked fi aad subtract

value marked 12.

16 The value in step u is equal to

vertical distance travelled by drive

lever “Y”.

(c) Since we know how far angularly the

drive lever will move, determine the

angular rotation

of driven lever

interms of drive lever rotation. The

angular rotation follows Figure 2-7 aad

the relationship:

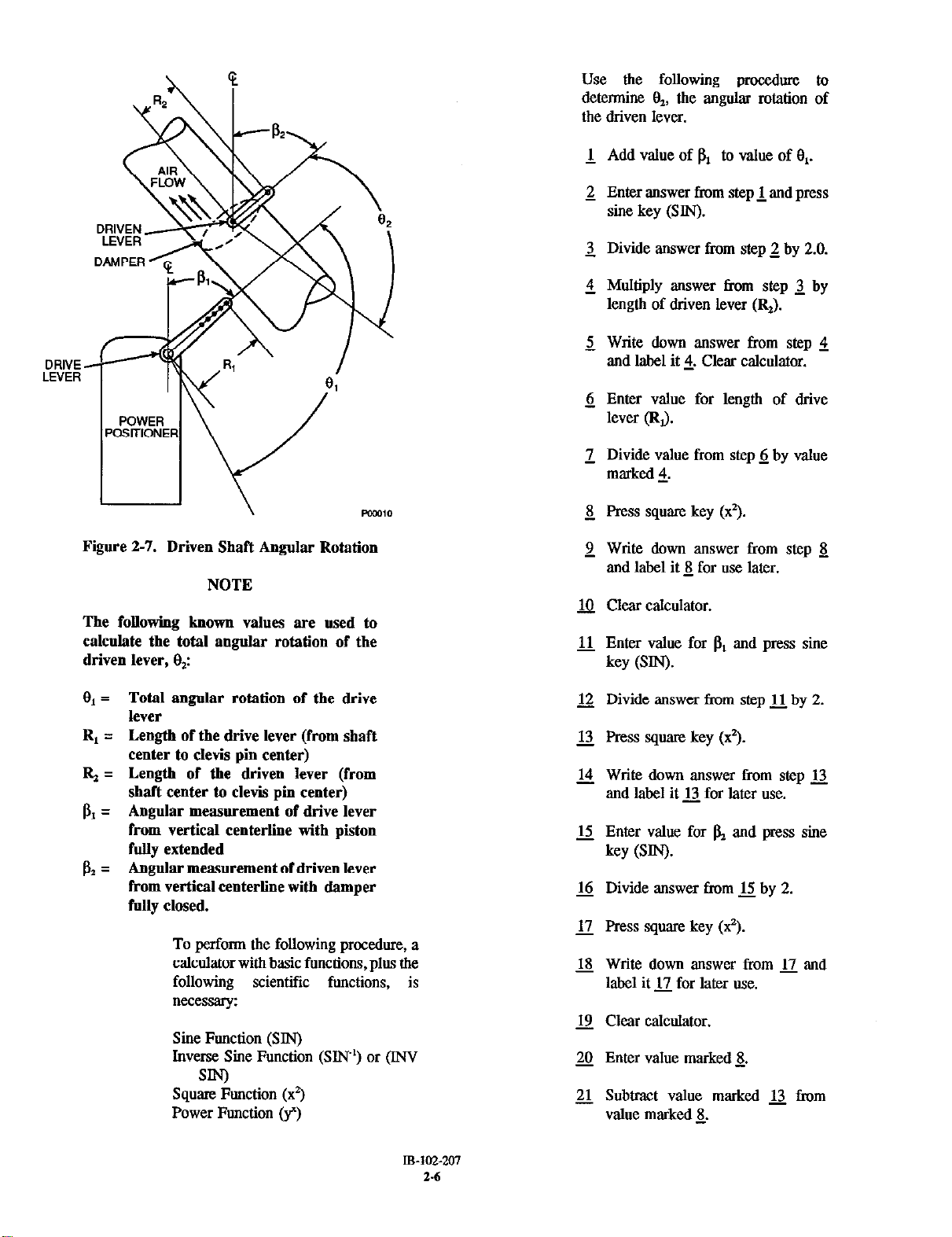

Page 22

DRIVE

LEVER

use the following procedure to

determine O,, the angular rotation of

the driven lever.

1 Add value of PI to value of 8,.

2. Enter answer from step 1. and press

sine key (SIN).

3 Divide answer from step 2 by 2.0.

4 Multiply answer from step 3 by

length of driven lever (&).

2 Write down answer from step 4

and label it 2. Clear calculator.

6 Enter value for length of drive

lever (Rd.

1 Divide value. from step 6 by value

marked 5.

8 Press square key (x3.

Figure 2-7. Driven Shaft Angular Rotation

NOTE

The followiag known values are used to

calculate the total angular rotation of the

driven lever, 8,:

8, = Total angular rotation of the drive

lever

R, = Length of the drive lever (from shaft

center to clevis pin center)

& = Length of the driven lever (from

shaft center to clevis pin center)

f& = Angular measurement of drive lever

from vertical centerline with piston

folly extended

bt = Angular measurement of driven lever

from vertical centerline with damper

fully closed.

To perform the following procedure, a

cakxlator with basic functions, plus the

following scientific functions, is

lN%Xssary:

Sine Function (SIN)

Inverse Sine Function (SIN’) or (INV

SIN)

Square Function (x3

Power Function (y”)

2 Write down answer from step 8

and label it 5 for use later.

g Clear calcolator.

11. Enter value for PI and press sine

key (SW.

12 Divide answer from step 11 by 2.

12. Press square key (x”).

14 Write down answer from step .lJ

and label it 13 for later use.

u Enter value for a and press sine

key (SW.

16 Divide answer from u by 2.

12 Press square key (x2).

B Write down answer from u and

label it ,lJ for later use.

19 Clear calcllhtor.

20 Enter value marked &

21. Subtract value marked 13 tiom

value marked 8.

m-102-207

2.6

Page 23

Subtract value marked 11 from

step 21.

Press power function key (fl.

Enter 0.5.

Press inverse sine (INV SIN or

SW).

Write down answer from step 25

and label it 2.

Clear calc”lator.

Enter value for bL.

Divide value Fran step 28 by 2.

Write down answer from step 29

and label it 29. Clear calculator.

Enter value fmm step 2.

Subtract value f?om step 2.

Multiply answer from step 32 by 2.

The value in step 33 is equal to

total angular rotzl of driven

lever V,“.

(d) To calculate length of connecting

linkage based on the length of drive

lever, driven lever, and the initial offset

of both, “se Figure 2-8 and the

following relationship:

t= [I,- ~R@s~,+R#x&) ‘+

(R,SfnflI-R@$,)

NOTE

The following known values are used to

calculate the length of the linkage I in

inches:

L=

Length between drive and driven

shaft center lines

R, =

Length of the drive lever (from shaft

center to clevis pin center)

rc,=

Length of the driven lever (from

shaft center to clevis pin center)

Angular measurement of drive lever

I% =

from vertical centerline with piston

fully extended

Angular measurement of driven lever

P2 =

from vertical centerline with damper

fully closed

I o.5

Figure 2-8. Connecting Linkage Length

To perform the following procedure, a

calculator with basic functions, plus

the following scientific functions, is

“ecessaly:

Sine Function (SIN)

Cosine Function (COS)

Square Function (x’)

Power Function (y”)

Use the following procedure to

determine 4, the length of connecting

linkage in inches:

1 Clear calc”lator,

IB-10%2Q7

2.7

Page 24

Enter value for b1 and press cosine

2

key (COS).

Multiply answer from step 21 by

length of driven lever (RJ.

3 Multiply answer from step 2 by

length of drive lever (R,).

3 Write. down answer from step 2

and label 2.

2 Clear calculator.

Enter value for pz and press cosine

6

key (COS).

1 Multiply answer from step 6 by

length of drive lever (R,).

& Write answer from step 1 down

and label 1. Clear calculator.

2 Add answer from step 8 to value

marked 2.

@ Press sqnare key (x3.

11 Write down answer from step g

and label lo.

Write down answer from step 22.

and label g. Clear calculator.

Subtract value marked 22 tiom

value marked u.

Add answer from step 2 to value

marked~.

Press power function key (y”).

Enter 0.5 into calculator.

The value in step 27 is eqaal to

length of connectingiige “P “.

Design linkage system by using values

for lengths of drive aad driven levers,

angular position of both levers from

vertical (offsets), and distance between

drive and driven levers centers to

calcnlate length of lib&age. These

values were determined in the previous

steps.

12 Clear calc”lator.

13 Enter distance between drive and

driven shaft (L).

14 Subtract value marked 3 from

step JJ.

.Q Write down answer from step 14

and label H.

6 Clear calculator

12 Enter value for fil and press sine

key (SIN).

u Multiply answer from step 17 by

length of drive lever (R,).

19 Write down answer from step 18

aad label B.

20 Clear calc”lator.

21 Enter vale for fiz and press sine

key (SW.

(e) Close damper to minimum flow

position. Make sore driven lever is at

angle (PJ and drive lever is at angle

(BI).

Cat linkage pipe to length (#). Install

(0

linkage between operating levers.

(g) Check for freedom of movement by

operating power positioner’s manual

lever. Minor adjustments linkage length

can be made by turning pipe to clevis

fitting in or oat as necessary.

Record values on Figure 2-8 for p,, pz,

(h)

P, R,, and R,.

2. Characterized Power Positioner.

Determine open and closed positions of

(a)

controlled damper.

Install mechanical linkage so the power

(b)

positioner will travel through its ten

inch stroke while positioning the

damper from minimum to maximum

opening.

B-102-207

2.8

Page 25

DRIVEN

LEVER

CLEVIS

DRIVE

LEVER

POWER

POSITIONER

Install power positioner’s drive

lever at the same angle as the

device’s operating lever (El,) with

power positioner’s piston fully

extended.

MeaSUre distance between

operating levers connection holes

(0. Subtract distance of clevis

and connection to the damper’s

operating lever. Cut pipe to fit this

measorement

Install pipe (linkage) between

operating arms.

Check for freedom of movement

by operating power positioner’s

manual lever. Minor adjustments to

linkage length can be made by

tuning pipe to clevis fdtiag in or

out as necessary.

u

Fiire 2-9. Characterized Linear Linkage Design

Measure. length of driven lever

(Figure 2-9) from its shaft center

to center of clevis pin (R,).

Attach the linkage clevis to the

power positioner’s drive lever so

that distance R, is equal to R,.

Close damper of device to

minimum flow position.

Measure angle (63 of device’s

driven lever from vertical

centerline with damper closed.

Table 2-1. System Flow Chart.

INPUT

SIGNAL

10% 20%

30% 40% 50% 60% 70%

NOTE

Follow calibration procedures carefully.

Proper power positioner calibration is

essential to accurately shape the cam bar.

(c) Calibrate the stroke of power

positioner. Refer to paragraph 4-1. It is

essential to calibrate carefully.

(d) Measure and record actual flow of

system being controlled starting at zero

input signal and increasing signal in

10% increments to 100%. Record these

vahm in Table 2-1, System Flow

Chart. These values will be used later

to plot the shape of the cam bar.

80% 90% 100%

FLOW

wm

IB-IM-207

2-9

Page 26

DIMENSION

DIMENSION 6

A

t

- POW13

Figure 2-10. Cam

ROLLER AT BOTTOM

LOCK SCREW

DIMENSION C

Bar Shaping

(g) Near bottom of a sheet of graph paper,

draw a base line (Graph 1). Draw a

vertical line near left side of paper.

Label this line “% of Input Signal”.

(h) Mark point “A” to right of “% of Input

Signal” line. This point is 10 inches up

from base line and at dimension “A’

from “% of Input Signal” line.

(i) Mark point “B” to right of input signal

line. Point “B” is on base line at same

distance from “% Input Signal” line as

dimension “B”.

(i) Lay cam bar on graph with lock screw

hole at bottom. Point “A” and point

“B” as marked on cam bar should line

up with point “A” and point “B” as

plotted on graph. Draw a heavy line

thra points “A” and point “B” and label

cam bar line.

(e) Measure and record dimensions A, B,

and C as follows:

1 Using air pressure, move piston

and clevis head to bottom of

stroke. Mark point that roller

touches cam bar. This is point “A”

(Figure 2-10).

2. Measure distance from point “A”

to face of guide bar to the nearest

1/64th inch. Record thii as

dimension “A”.

2 Using air pressure, move piston

and clevis head to top of stxoke.

Mark point that roller touches cam

bar. This is point “B”.

4 Measure distance from point “B”

to guide bar to nearest 1/64th inch.

Record this as dimension “B”.

5 Dimension “C” is the distance

between guide bar to center of lock

screw. Measure to nearest 1/64th

inch.

(0 Using signal air move piston to bottom of

stroke and remove lock screw (Figure 2-10).

Remove compensating bar from positioner.

(k) Refer to Graph 2. Mark input signal

points, in 10% increments, on % of

input signal line at right edge of graph.

0% will be at the top of the graph,

Point A, and 100% will be at the base

he, Point B. Each 10% signal will be

one inch apart

(1) Draw a line from each “% Input

Signal” horizontally to cam bar line.

From this point of intersection, draw a

vertical line to top of graph. Label top

of graph “% of Horizontal Roller

Travel”.

(m) On base line, label ten points recorded

in step d that represent flow of ten

different signal positions. Record these

ten flow points along base line between

0 and 100% flow (Graph 3).

NOTE

For this purpose, we used a 100% flow of 7

scfm. At 10% iaput signal we had flow of

18 scfm, at 20% input signal we had flow

of 3.1 scfm, etc. These values noted in the

example flow chart on Graph 3.

Page 27

Graph I

% OF

INPUT

SIGNAL

80

Graph 2

: : : : :

Page 28

From base. line, draw a vertical line at

(a

10% mark of 1.8 up to where a line

would extendhorizontally from 10% “%

of Input Signal” scale. Repeat for 20%

mark of 3.1 to a line extending

horizontally from 20% “% of input

signal” scale. Continue in same fashion

for others from 30% flow mark to

100% flow mark. Draw a smooth curve

thru these points from 0% flow to

100%. Label curve “x”.

Draw a straight line from zero flow at

(0)

zero “% of Input Signal” to 100% flow

at 100% “% of Input Signal”. Label

curve “y” (Graph 4).

(p) Draw a horizontal line from 10% “%

of Input Signal” at cam bar line to

curve “Y”. Draw a line from this point

vertically to curve “x”. Draw a line

from curve “x” horizontally back to

10% of “% of Horizontal Roller

Travel” line plotted earlier. Place a

mark on this 10% line as shown in

Graph 4.

(q) Repeat step @) procedure for 20% thm

90% lines. At each point that intersects

with “% of Horizontal Roller Travel

Line”, put a mark as indicated in

Graph 5.

Graph 3

BASE

rNPuT

SIGNAL IN %

Example System Flow Chart

10 20 30 40 50 60

100%

FLOW

(7 SCFM)

PWOIS

70 80 90 100

Page 29

60

L % OF

Graph 4

i

!ERC

f

ZLOVI

BASE LINE

% OF

INPUT

SIGNAL

50

60

70

kx

I zh%L,T~,

100%

FLOW POW,,

Graph 5

ZERO

FLOW

I

\I

IB-102-207

2-13

Page 30

(r) Connect marks with a smooth curve

thm point “A” to point “B” thru each

mark recorded. This will be the

required cam bar shape.

(s) Construct a template from the plotted

curve. Mark points A and B on

template.

(t) Bend cam bar to match template.

Points A and B on template must align

with Points A and B marked on cam

bar earlier.

(u) Dtaw tile face of cam bar as necessary

to obtain a smooth carved sarface. Do

not remove marked points A and B.

(v) Install am bar on power positioner

with lock screw positioned at point C

recorded in step (e). Make sate

dimensions for points A and B match

those recorded in step (e): if necessary

adjust position of lock screw to make

dimensions A and B recoTded in

step (e).

Check results by setting 10%

increments of input signal from 0% to

100%. The flow must change in 10%

increments for 0 flow to 100% flow.

For example: with a 100% of 7 SCFM,

a 10% input signal will flow at 0.7

SCFM, 20% at 1.4 SCFM, etc.

Adjustments to the cam bar can be

made by minor bending or draw fiing.

Figure 2-11. Driven Lever Travel

Set input signal to 0%. Measure

distance controlled devices driven

lever, Figure 2-11, travels for each

10% increase in input signal: up to

100% input signal. Record these values

in Table 4-1, Characterized column as

percent of total travel. These values are

necessary for verifying calibmtion.

Set input signal to 0%. Measure

distance clevis head travels for each

10% increase; up to 100% input signal.

Measurement should be taken from

packing nut to bottom edge clevis

head. Record values measured in Table

4-2, Calibration Schedule D in the

respective columns. These values are

necessary for verifying calibration.

Page 31

SECTION III. REVERSE OPERATION

3-1. OPERATIONAL DESCRIPTION.

I” reverse

acting positioners, the piston and rod operate the same

as when setup for direct acting (Figure l-2). The cam

bar is reversed top to bottom and the reverse manifold

is tomed 90”. The repositioned manifold causes

supply air to be directed to the top of piston when

signal air pressure is increased and to the bottom of

piston when signal air pressure is decreased. In this

case, piston movement is inversely related to the

signal. A falliig signal air pressure raises the piston

and an increasing signal air pressure lowers the

piston,

3-2. PROCEDURES FOR REVERSING OPERATION.

To reverse the operation of the cylinder, refer to

Figure 3-l and use the following procedures:

a. Reverse Compensating Assemble.

1.

Close the supply air valve.

2.

Set signal air to 0.

3.

Remove screw (1) securing spring clip (2) to

compensating assembly (4). Remove spring

clip.

pilot valve (8) and its gasket (9) in the same

position as it was when removed, Secure.

pilot valve and reverse manifold in place

with mounting screws (7).

c. Calibrate Stroke.

1. Disconnect operating lever (12, Figure 3-1)

from device being controlled at clevis (13).

WARNING

Use caution when applying supply air to the

pilot valve. The air pressure will cause the

piston, rod, and operating lever to move

when the piston travels to the top of its

stroke. Personnel injury or damage to equipment may occur during sudden applications of compressed air.

2.

Open supply air valve. This will cause

piston rod (14) to move to top of its stroke.

Set signal air to minimum.

3.

Using an allen wrench, loosen lock screw

(15) holding spring socket (16).

4.

Remove two screws (3) sewing compensating assembly (4) to clevis head (5). Remove

compensating assembly.

5. Reinstall compensating assembly (4) in a

reversed position with stroke adjustment

scwv (6) at the top. Secure compensating

assembly to clevis head (5) with two screws

(3).

6. Reinstall spring clip (2).

b. Rotate Reverse Manifold.

1. Remove screws (7, Figure 3-1) securing

pilot valve (8) and reverse manifold (10) to

cylinder assembly (17). Remove pilot valve

and reverse manifold.

2. Rotate reverse manifold (10) and its gasket

(11) 90” clockwise. The arrow, stamped on

reverse manifold, should point down. Install

4.

Trim spring socket (16) counterclockwise

until piston rod (14) starts to move downward.

5.

Tam spring socket (16) slowly clockwise

until piston rod (14) reaches maximum

position.

6.

Tighten lock screw (15) to hold spring

socket (16) fvmly in place.

7.

Set signal air to its maximum amount and

check movement of piston rod (14) for fall

stroke. The piston rod should just reach bot-

tom of stroke with maximum signal to pilot.

If necessary, tam the stroke adjustment

screw (6) counterclockwiie very slowly until

full stroke is reached.

8.

Reconnect operating lever (12) to device

being controlled at clevis (13).

IB-102-207

3-l

Page 32

ITEM

1

2

3

4

5

6

I

8

9

10

11

12

13

14

1.5

lb

17

18

DESCRUTION

screw

Spring Clip

screw

Compensating Assembly

Clevis Head

Stroke Adjustment Screw

SCEW

Pilot valve

Gasket

Reverse Manifold

Gasket

Operating Lever

Clevis

Piston Rod

Lock Screw

Spring Socket

Cylinder Assembly

Packing Nut

3

-3

7-

5

DIRECT ACTING

COMPENSATING ASSEMBLY

3 -

3

6

?I

7

5

-4

6

REVERSE ACTING

COMPENSATING ASSEMBLY

Fire 3-1. Reverse Operations

WlO%207

3-2

PC.2420

Page 33

SECTION IV. CALIBRATION

4-1.

CHECK POWER POSITIONER CALIBRATION.

Use the following promlure to check calibration of

power positioner. Figure 4- 1, Calibration Flowchart is

provided as a quick reference guide.

NOTE

If cam bar was shaped (characterized),

values of percent output desired must be

recorded upon installation in Table 4-1

Schedule D. This is necessary to check

calibration. If values were not recorded,

refer to 2-6b2 and calculate correct

positions using formulas.

a. Device Travel.

1. Measure distance that the controlled device’s

driven lever arm travels from 0% signal air

to 100% signal air. Record this as total

distance.

2. Set signal air to 0%.

OF TRAVEL OF

DEVICE EQUAL TO

CORRESPONDING

PERCENTAGE OF

CHECK STROKE

POSITION FOR

EACH PERCENT

OF SIGNAL LISTED

IS PISTON IN

PROPER POSITION

FOR EACH SIGNAL

AIR PRESSURE?

3. Measure controlled device’s driven lever

arm travel from 0% to a 10% signal air.

Divide measurement by total distance from

step a. Record this as the percentage of

output travel for 10% signal air. Measure

and record percentage of output travel in the

same fashion in 10% increments up to 100%

signal air.

4. Compare recorded readings with percent

driven lever travel in Table 4-l. Use

respective columns for characterized

systems, linear, square mot, or square cam

bars. If recorded percentages of travel are

equal to those in Table 4-1 the system does

not need calibration. If recorded readings do

not equal those ia Table 4-1 continue.

checking procedure.

b. Piston Travel.

1. Set signal air to 0%.

2. Measure distance fmm top surface of

packing nut (18, Figure 3-1) to bottom

surface of clevis head (5). Label tbii

distance “A”.

CALIBRATE STROKE

AND I/p. REFER TO

PARAGRAPHS 4-2

Fire 4-1. Calibration Flowchart

3. Increase signal to 100%.

4. Measure distance from surface of packiag

nut (18) to bottom surface of clevis head (5).

Label this distance “B”.

5. Subtract distance “A” from distance “B”.

Thii is total stroke travel of the power

positioner. Record this distance as total

stroke travel.

6. Set signal air to 0%.

IB-102-207

Page 34

Table 4-1. Device Travel (%1.

PERCENT SIGNAL

AIR PRESSURE

0 0 0.0

10

20

30 30 54.8 9.0

40

50 50 70.7 25.0

60 60 77.5 36.0

70 70 83.7 49.0

80 80 89.4 64.0

90

100 100 100.0 100.0

7. Measure the piston travel (stroke) when a

10% signal is sent to the power positioner.

Record this as stroke travel for 10% signal

air. Measure and record percentage of output

travel in the same fashion in 10%

increments up to 100% signal air.

l-

PERCENT DRIVE N LEVER TRAVEL

SQUARE ROOT

LINEAR (x)

10 31.6 1.0

20 44.8 4.0

40

90

Ma

63.25

94.9 81.0

4-2. STROKE CALIBRATION. Use the following

procedures to adjust a power positioner’s stroke.

a. Direct Acting Power Positioner.

SQUARE (x3 CHARACTERIZED

0.0

16.0

stroke (paragraph 4-2) and then calibrate I/l’

(paragraph 4-3).

NOTE

Values for characterized stroke measured in

inches and percent corresponding to input

pressures are recorded in Table 4-2

Schedule D. If values were not recorded,

refer to 2-613.2. and calculate correct

positions using formdas.

8. Compare actual stroke movement with

desired stroke movement. Desired stroke

movements appear in Table 4-2, Calibration

Schedule. Schedule “A” is for a linear cam

bar, “B” for a square root cam bar, “c” for

a square cam bar, and “D” for a

characterized cam bar. If actual stroke of

power positioner is equal to desired value in

Table 4-2, refer to paragraph 4-5 and

calibrate linkage. If it is not equal, calibrate

1. Purge air lines to remove any water or

debris.

2. Making sure that by-pass valve is closed, set

signal air to minimum stroke position (0%).

Refer to Table 4-3 for percent stroke to

signal air conversion.

3. Loosen lock screw (1, Figure 4-2) holding

spring socket (2) in place. Turn spring

socket counterclockwise until piston rod (3)

begins moving up from bottom of stroke.

Turn spring socket slowly clockwise until

piston rod moves to lowest position. Tighten

lock screw.

4. Increase signal air to maximum (100%).

Refer to Table 4-3 for percent to signal air

conversion.

Page 35

o-60 PSig m

0

6

12

18

24

30

36

42

48

54

60

0

6

12

18

24

30

36

42

48

54

60

0

6

12

18

24

30

36

42

48

54

60

0

6

12

18

24

30

36

42

48

54

60

3-15 pstg

3.0

4.2

5.4

6.6

7.8

9.0

10.2

11.4

12.4

13.8

15.0

CP

3.0

4.2

5.4

6.6

7.8

9.0

10.2

11.4

12.4

13.8

15.0

3.0

4.2

5.4

6.6

7.8

9.0

10.2

11.4

12.4

13.8

15.0

CAL

3.0

4.2

5.4

6.6

7.8

9.0

10.2

11.4

12.4

13.8

15.0

Table 4-2. Piston Travel (Stroke) Calibration Schedule.

CALIBRATION SCHEDULE “A” - LINEAR CAM BAR

INPUT SIGNAL

O-30 psig

0

3

6

9

12

15

18

21

24

27

30

:RATION SCHEDI

0

3

6

9

12

15

18

21

24

27

CA

tATION SCHEDUL

30

LIBRATION SCHI - 3DU1

0

3

6

9

12

15

18

21

24

27

30

0

3

6

9

12

15

18

21

24

27

30

Percent of Signal

0%

10%

%

30%

40%

50%

60%

70%

80%

90%

100%

“B” - SQUARE R<

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

10%

1

LE “C” - SOUARE CAM BAR

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

D” - CHARACTER

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

Inches

)O

l’CAMBAR

ED CAM BAR

0.M)

la0

2.00

3.00

4.00

5.00

6.@3

7.00

8.00

9.03

1om

0.00

3.16

4.48

5.48

6.325

7.07

7.75

8.37

8.94

9.49

10.00

0.00

0.10

0.40

0.90

1.60

2.50

3.60

4.90

6.40

8.10

1oM)

DESlRl

CD STROKE

Percent of Full Stroke

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

lco%

O.co%

31.60%

44.80%

54.80%

62.25%

70.70%

77.50%

83.70%

89.40%

94.90%

100.00%

0%

1%

4%

9%

16%

25%

36%

49%

64%

81%

100%

IB-102-207

4.3

Page 36

ITEM DESCRIPTION

1 Lock Screw

2 Spring Socket

3 Piston Rod

4 Lock Bolt

Stroke Adjustment

NOTE

If stroke length needed is less than standard

10 inches, adjustment of stroke adjustment

screw cau decrease stroke length to seven

inches.

Loosen stroke adjustment screw lock bolt (4,

5.

Figure. 4-2). Tam stroke adjustment screw

(5) clockwise until piston rod moves

downward. Tam screw in opposite direction

until piston rod moves to maximum position

or to desired length of travel. Tighten lock

bolt (4).

h. Inverse Acting Power Positioner.

1.

Purge air lies to remove any water or

d&is.

2.

Making sure that by-pass valve is closed, set

signal air to maximum (100%). Refer to

Table 4-3 for percent to signal conversion.

3.

Loosen lock screw (1, Figure 4-2) holding

spring socket (2) in place. Turn spring

socket clockwise until piston rod (3) begins

moving up from bottom of stroke. Tom

spring socket slowly clockwise until piston

rod moves to lowest position. Tighten lock

SCIZW.

Fire 4-2. Stroke Adjustment

Table 4-3. Direct and Inverse Calibration Signal Pressures.

POWER POSITIONER ACTION

STROKE

POSITION

DIRECT INVERSE

PNRUMATIC UP PNEUMATIC I/P

0 - 30 psig 3 - 15 psig O-60 0

0% 0 3 0

100% 30 15 60

4.

Decrease signal air to minimum (0%). Refer

to Table 4-3 for percent to signal

conversion.

- 30 3 - 15 0 - 60 psig

Psig psig Psig

30 15 60

0 3 0

LB-N-207

4.4

Page 37

NOTE

If stroke length needed is less than standard

10 inches, adjustment of stroke adjustment

screw can decrease stroke length to SEVEN

inches.

5. Loosen stroke. adjustment screw lock bolt

(4). Turn stroke adjustment screw (5)

counterclockwise until piston rod (3) moves

downward. Turn screw in opposite direction

until piston rod moves to maximum position

or to desired length of travel. Tighten lock

bolt (4).

4-3.

CURRENT TO PNEUMATIC (I/P) SIGNAL

CONVERTER CALIBRATION. Calibrate current

to pneumatic signal converter after mounting,

changing mounted position, or when loss of control is

noticed (refer to Troubleshooting, Section V). Use the

following procedures to calibrate the signal converter:

a. Remove plastic caps from “Zero” and “Span”

adjustment holes (Figure 4.3).

NOTE

Make sure the input pressure rating of the

power positioner is the same as the pressure

rating stamped on the current to pneumatic

signal converter.

b.

Set signal value to 4 mA (20 mA if I/p is in an

inverse setup) and adjust “zero” screw until

output pressure is at 0 psig. Turn SCIW

counterclockwise to increase pressure, clockwise

to decrease pressure. If output pressure does not

change when screw is turned, turn screw

counterclockwise until pressure starts to rise.

PRESSURE

GAUGE

Figure 4-3. Current to Pneumatic Signal Converter

4-4. LINKAGE CALIBRATION.

a. Linear

A

Check angular travel of power

positioner’s drive. lever at cl&s. Compare this to

device’s driven lever angular travel. If angular

distances are not the same, use the following

procedure to adjust offset of power positioner’s

drive lever to tbe same angle as tbe device’s

driven lever. When adjustment is complete, both

operating levers must be parallel with each other.

Measure angle p, from vertical line

extending from shaft hub, to power

positioner’s drive lever (Figure 4-4). This is

the power positioner’s drive lever offset.

POW23

c.

Set signal value to 20 mA (4 mA if I/p is in an

inverse setup). Adjust “Span” screw until output

pressure is at 60 psig.

d.

Repeat steps b and c until no further adjustment

is needed.

e.

Replace protective caps.

Measure angle b2 from vertical line

extending from device lever’s hub, to driven

lever of device being controlled. This is the

driven lever offset.

Compare angle PI and angle. bz. Adjust

length of linkage for minor adjustments by

threading pipe in or out of clevis. Change

drive lever angle p, for major adjustments.

IB-102-207

4-s

Page 38

4. Measure length of power positioner’s drive

lever (R,) from shaft center to center of

clevis pin.

5. Measure length of device’s driven lever (RJ

from shaft center to center of clevis pin.

DRIVEN

LEVER

DRIVE _

LEVER

POWER

FOSITIONER

Figure 4-4. Linear Linkage Calibration

b. Characterized. Verify linkage design angles and

length against actual installation. Use the

following procedure, Figure 4-5, and adjust

angles and lengths as necessary.

6. Compare angle B,, b2, distance P, and

lengths R, and R2 with setup dimensions and

angles recorded in Figure 2-8. If setup

dimensions and angles were not recorded,

use formula’s in Section II to calculate

correct design for the positioning system and

record on Figure 2-8. Adjust length of

linkage for minor adjusbnents by threading

pipe in or out of clevis. Change operating

arm angle b, for major adjustments.

1. Measure angle /3, from vertical lie

extending from shaft hub to power

positioner’s drive lever. Tbii is the power

positioner’s drive lever offset.

2. Measure angle b2 from vertical line

extending from device lever’s hub to driven

lever of device being controlled. This is the

driven lever offset.

3. Measure length between connecting levers.

This distance is represented by the letter P.

IB-102-207

Figure 4-5. Characterized Linkage Calibration

4.6

Page 39

SECTION V. TROUBLESHOOTING

5-1. OVERVIEW. Troubleshooting of common problems 5-2. TROUBLESHOOTING CHART. Refer to

is provided for in troubleshooting chart (Table 5-l). Table 5-1.

The chti describes common problems, foUowed by

tbe related probable cause, and fmally by what action

is necessary to correct the defect.

Table 5-1. Troubleshooting Chart.

PROBLEM CAUSE

1. Erratic operation Pilot valve sticking.

Linkage binding or loose.

2. No response from power Manual lock engaged

positioner to a signal air

pressure change

Air supply shutoff valve closed.

Ruptured receiver diaphragm.

3. Power positioner does not Cylinder head gasket leak.

remain at set-point; continues to

cycle

Bypass valve air connection

loose.

Bypass valve leaking internally.

4. System over shoots or under I/F- out of

shoots set-point calibration.

VP failure.

CORRECTION

Clean or replace pilot valve. Refer to

paragraph 6-4 for cleaning proce

dares and paragraph 7-2~ for

replacement procedures.

Liige pivot joints corroded, dirty,

or worn. Clean and lubricate or replace parts.

Disengage manual lock.

Open air supply valve.

Replace diaphragm. Refer to

pamgraph 7-2d.

Replace leaking gasket. Refer to

paragraph 7-2e.

Tighten or replace air connection.

Replace bypass valve.

Calibrate I/F’. Refer to paragraph 4-3.

Replace I/P per paragraph 7-2b.

Piston stroke travel not properly

set.

Cam bar bent.

Pin hole in diaphragm.

5. Sluggish operation Air fdter/separator foU of water,

oil, or sediment.

Air fdter dirty.

Ambient temperature is lowe]

than the power positioner is

designed for.

6. Power positioner operates Device being controlled has a

normally but flow that is being

broken valve stem or connection

controlled remains unchanged to the linkage.

ES-102-207

.5-l/5.2

Calibrate stroke travel of piston.

Refer to paragraph 4-2.

Replace cam bar. Refer to paragraph

7-2h.

Replace diaphragm. Refer to

paragraph 7%.

Drain air filter/separator. Refer to

paragraph 6-5.

Replace filter element. Refer to

paragraph 7%.

Install power positioner heater.

Repair or replace controlled device.

Page 40

Page 41

SECTION Vi. PERIODIC MAINTENANCE

6-1. OVERVIEW. This section describes preventive

maintenance for the Rosemount Model PP61OTR

Power Positioner. Preventive maintenance. is

necessary at specific intervals to reduce wear and tear

on the power positioner.

WARNING

Before performing any maintenance or

repair action on power positioner, shut off

supply air, signal air, and any electrical

supply or electronic signals to power

positioner. Isolate power positioner from alI

systems connected to tbe power positioner.

Severe injury or death may result from

large torque power positioner is capable

of producing, or from electrical shock.

6-2. MAINTENANCE SCHEDULE. Use the

maintenance schedule, Table 6-1, as a guideline for

preventive maintenance. The frequency of this

maintenance varies directly with plant conditions and

operational load on the power positioner. Extremely

dusty conditions or high temperahnes will require.

more frequent maintenance on the power positioner.

6-3. GENERAL CLEANING AND LUBRICATION.

Clean power positioner’s exterior of all grease

buildup with commercial dry cleaning solvent. To

lubricate power positioner, refer to Figure 6-1,

Lubrication Chart.

WARNING

Clean power positioner in a well ventilated

area. Avoid inhalation of solvent fumes and

prolonged exposurt! of skill to cleaning

solvent. FoBow alI instructions on the

Material Safety Data Sheet (MSDS) of the

solvent being used. Severe injury or death

may result from improper usage.

6-4. PILOT VALVE CLEANING AND INSPECTION.

In normal service, the pilot valve assembly (Figure

6-2) requires cleaning and inspection at intervals of

approximately six months, or upon any indication of

sticking.

WARNING

Before performing any maintenance or

repair action on power positioner, shut off

supply air, signal air, and any electrical

supply or electronic signals to power

positioner. Isolate power positioner from all

systems ccnmected to the power positioner.

Severe iojury or death may result from

large torque power positioner is capable

of producing, or from electrical shock.

a. Remove power positioner from service.

I

Time Interval (Approximate)

6 months

6 months

6 months

2 years

2 years

Table 6-1. Maintenance Schedule.

Maintenance Action

Perform general cleaning and lubrication. Refer to paragraph 6-3.

Clean and inspect pilot valve. Refer to paragraph 6-4.

Clean and drain air filters. Refer to paragraph 6-5.

Clean and inspect diaphragm. Refer to paragraph 6-6.

Lubricate and clean cylinder and piston assemblies. Refer to paragraph 6-7.

Page 42

LUBRICATION CHART

f9

GREASE GUN FILLED WITH

MclUBE M&.-793

SEE NOTE 1.

t&LUBE M&-793

SEE NOTE 2.

NOTE 1: USING A GREASE GUN, LUBRICATE

ZERK FIrrINGS AT PISTON ROD

CLEVlS PIN, TRUNN!ON SCREW,

AND SHAFT ASSEMBLY.

NOTE 2: WIPE PISTON ROD WITH A CLEAN

Figure 6-1. Lubrication Chart

PISTON ROD

CLEWS PIN

TRUNNION

SCREW

SHOP TOWEL. APPLY A LIGHT COATING

OF t&LUBE MOS 793. WIPE EXCESS

GREASE OFF W&H CLEAN SHOP

TOWEL.

po(xi

IB-102.207

6.2

Page 43

ITEM

10

11

12

13

DESCRIPTION

1

Stem Assembly

2

Connecting Link

3

Ball Socket Nut

4

Air Supply Tubing

5

Elbow

6

cap screws

7

Reverse Manifold

8

Cylinder Assembly

9

valve cap

Exhaust Silencer Plug

Pilot Valve Body

Pilot Valve Gasket

Reverse Manifold Gasket

Figure 6-2. Pilot Valve Exploded View

b.

Carefully hold upper end of pilot valve stem

assembly (1, Figure 6-2). Free connecting link (2)

from pilot valve stem by turning connecting link

e. Remove valve cap (9), stem assembly (l), and

exhaust silencer plug (10) from pilot valve body

(11).

ball socket nut (3) counterclockwise.

e. Disconnect air supply tubing (4) from elbow (5). WARNING

d. Remove cap screws (6), that secure pilot valve

and reverse manifold (7) to cylinder assembly

(8). Remove pilot valve and reverse manifold.

Note alignment of pilot valve, arrow on ~cverse

manifold, and cylinder.

CAUTION

Do not use an abrasive for cleaning the

valve stem assembly or valve body.

Abrasives even as fine as crocus cloth will

cause scratches in the stem assembly and air

to leak by pilot valve stem assembly.

I&102.207

Clean pilot valve in a well ventilated area.

Avoid inhalation of solvent fumes and

prolonged exposure of skin to cleaning

solvent. Follow all instructions on the

Material Safety Data Sheet (MSDS) of the

solvent being used. Severe injury or death

may result from improper usage.