Page 1

Model Solu Comp®II

Dual Input pH/Conductivity Analyzer

Instruction Manual

PN 51-1055pHC/rev.K

February 2006

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Your purchase from Rosemount Analytical, Inc. has

resulted in one of the finest instruments available for

your particular application. These instruments have

been designed, and tested to meet many national

and international standards. Experience indicates

that its performance is directly related to the quality of

the installation and knowledge of the user in operating and maintaining the instrument. To ensure their

continued operation to the design specifications, personnel should read this manual thoroughly before

proceeding with installation, commissioning, operation, and maintenance of this instrument. If this equipment is used in a manner not specified by the

manufacturer, the protection provided by it against

hazards may be impaired.

• Failure to follow the proper instructions may cause

any one of the following situations to occur: Loss

of life; personal injury; property damage; damage

to this instrument; and warranty invalidation.

• Ensure that you have received the correct model

and options from your purchase order. Verify that

this manual covers your model and options. If not,

call 1-800-854-8257 or 949-757-8500 to request

correct manual.

• For clarification of instructions, contact your

Rosemount representative.

• Follow all warnings, cautions, and instructions

marked on and supplied with the product.

• Use only qualified personnel to install, operate,

update, program and maintain the product.

• Educate your personnel in the proper installation,

operation, and maintenance of the product.

• Install equipment as specified in the Installation

section of this manual. Follow appropriate local

and national codes. Only connect the product to

electrical and pressure sources specified in this

manual.

• Use only factory documented components for

repair. Tampering or unauthorized substitution of

parts and procedures can affect the performance

and cause unsafe operation of your process.

• All equipment doors must be closed and protective

covers must be in place unless qualified personnel

are performing maintenance.

• If this equipment is used in a manner not specified

by the manufacturer, the protection provided by it

against hazards may be impaired.

WARNINGS

RISK OF ELECTRICAL SHOCK

Equipment protected throughout by double insulation.

• Installation of cable connections and servicing of this product require access to shock hazard voltage levels.

• Main power and relay contacts wired to separate power

source must be disconnected before servicing.

• Do not operate or energize instrument with case open!

• Signal wiring connected in this box must be rated at least

240 V.

• Non-metallic cable strain reliefs do not provide grounding

between conduit connections! Use grounding type bushings

and jumper wires.

• Unused cable conduit entries must be securely sealed by

non-flammable closures to provide enclosure integrity in

compliance with personal safety and environmental protection requirements. Unused conduit openings must be

sealed with NEMA 4X or IP65 conduit plugs to maintain

the ingress protection rating (NEMA 4X).

• Electrical installation must be in accordance with the

National Electrical Code (ANSI/NFPA-70) and/or any other

applicable national or local codes.

• Operate only with front and rear panels fastened and in

place over terminal area.

• Safety and performance require that this instrument be

connected and properly grounded through a three-wire

power source.

•

Proper relay use and configuration is the responsibility of

the user.

CAUTION

This product generates, uses, and can radiate radio frequency

energy and thus can cause radio communication interference.

Improper installation, or operation, may increase such interference. As temporarily permitted by regulation, this unit has not

been tested for compliance within the limits of Class A computing devices, pursuant to Subpart J of Part 15, of FCC Rules,

which are designed to provide reasonable protection against

such interference. Operation of this equipment in a residential

area may cause interference, in which case the user at his

own expense, will be required to take whatever measures may

be required to correct the interference.

WARNING

This product is not intended for use in the light industrial, residential or commercial environments per the

instrument’s certification to EN50081-2.

Emerson Process Management

Rosemount Analytical Inc.

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2005

Page 3

QUICK START GUIDE

FOR MODEL SOLU COMP II pH/CONDUCTIVITY ANALYZER

(Model Option 1055-22-30)

1. Refer to Section 2.0 for installation instructions.

2. Wire sensor(s) to the analyzer. See the drawings below. Refer to the sensor instruction sheet for details. Make alarm

and output connections as shown below.

NOTE

For sensors without solution ground, please use the RC kit included with the instrument.

CONTINUED ON THE FOLLOWING PAGE

3. Once connections are secured and verified, apply power to the analyzer.

Wiring Connections for Solu Comp II Model 1055-01-10

(Panel Mount with 115/230 Vac Power)

Wiring Connections for Solu Comp II Model 1055-02-10

(Panel Mount with 24 Vdc Power)

Wiring Connections for Solu Comp II Model 1055-01-11

(Surface/Pipe Mounting with 115/230 Vac Power)

Wiring Connections for Solu Comp II Model 1055-02-11

(Surface/Pipe Mounting with 24 Vdc Power)

Page 4

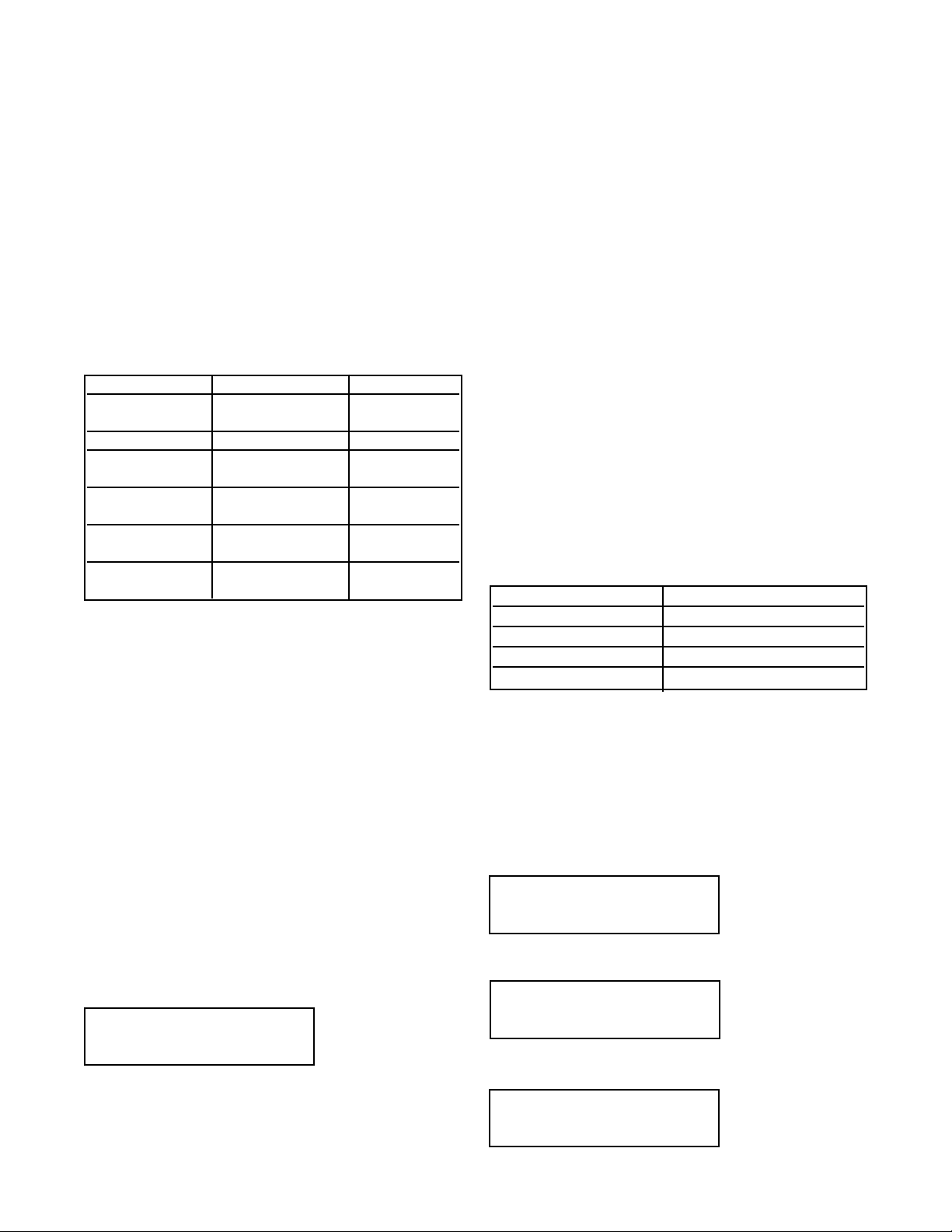

5. Choose the desired language. Select >> to show more choices.

6. Choose the number of sensors wired to the analyzer.

NOTE

If One sensor is chosen, only

S1 (pH/ORP) will be available

.

S2 (conductivity) cannot be chosen for single measurement.

7. Select the measurement for sensor 1.

8. Select the measurement for sensor 2. This screen will not appear if one sensor

is selected.

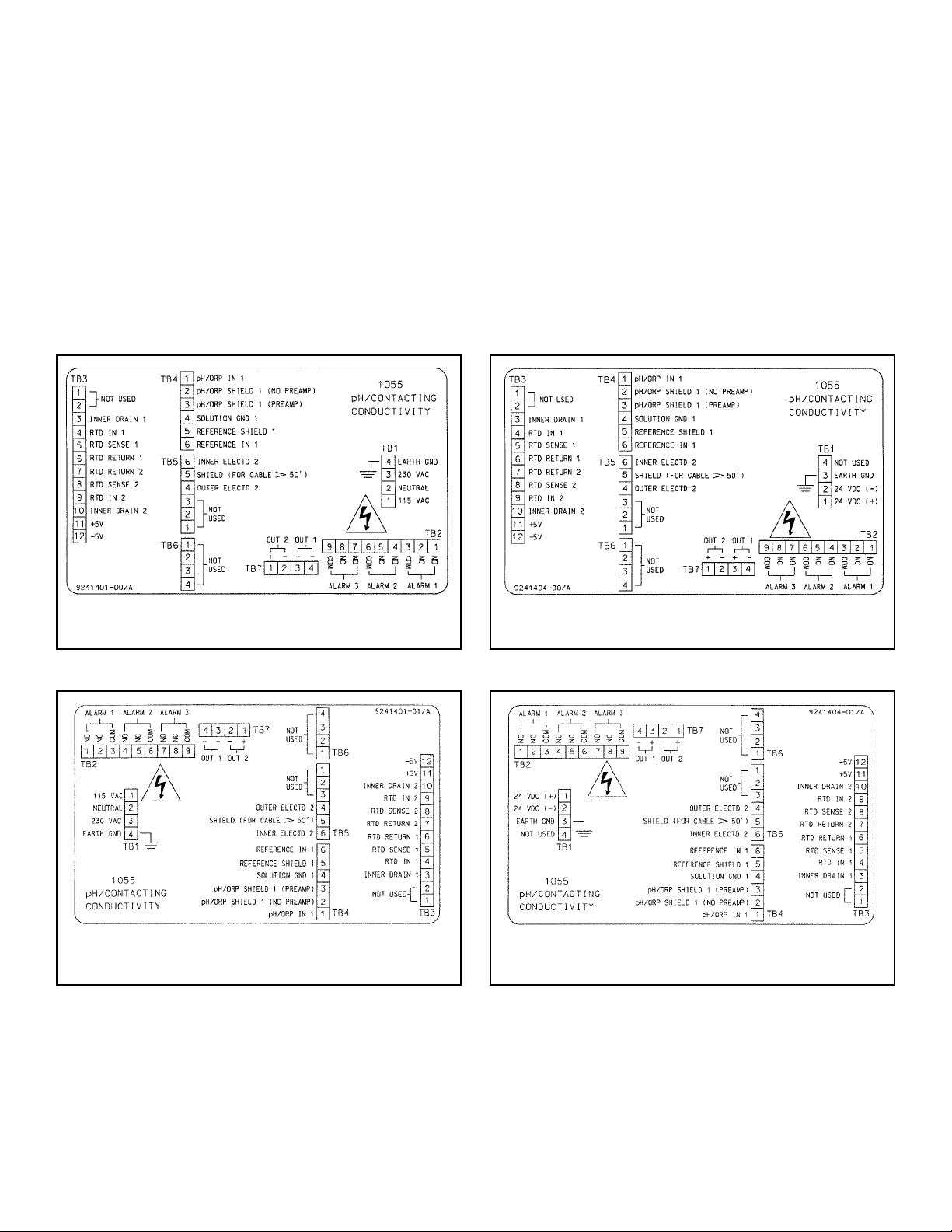

9. Enter the cell constant for the conductivity sensor (sensor 2). See label attached

to sensor.

10. Choose temperature units.

11. The main display appears. The outputs and alarms are assigned to default values. To change settings, refer to Section 5.0, Programming the Analyzer. To

reinstall factory settings and return to Quick Start, see Section 5.10.

# of sensors?

One

TTwwoo

Temperature in?

*

CC

*

F

S1 Measure?

ppHH

Redox ORP

S2 Measure?

CCoonndd

TDS Resistivity

4. When the analyzer is powered up for the first time, Quick Start screens appear. Using Quick Start is easy.

a. A blinking field shows the position of the cursor.

b. Use the or key to move the cursor left or right. Use the or key to move the cursor up or down or to

increase or decrease the value of a digit. Use the or key to move the decimal point.

c. Press ENTER to store a setting. Press EXIT to leave without storing changes. Pressing EXIT also returns the

display to the previous screen.

EEnngglliisshh

Fran ais

Espa ol >>

&

If there is no cell constant on the label, calculate it

from the equation:

cell const = K

500 + cal const

1000

e

j

Cell Constant?

S1:

11

.0000/cm

Page 5

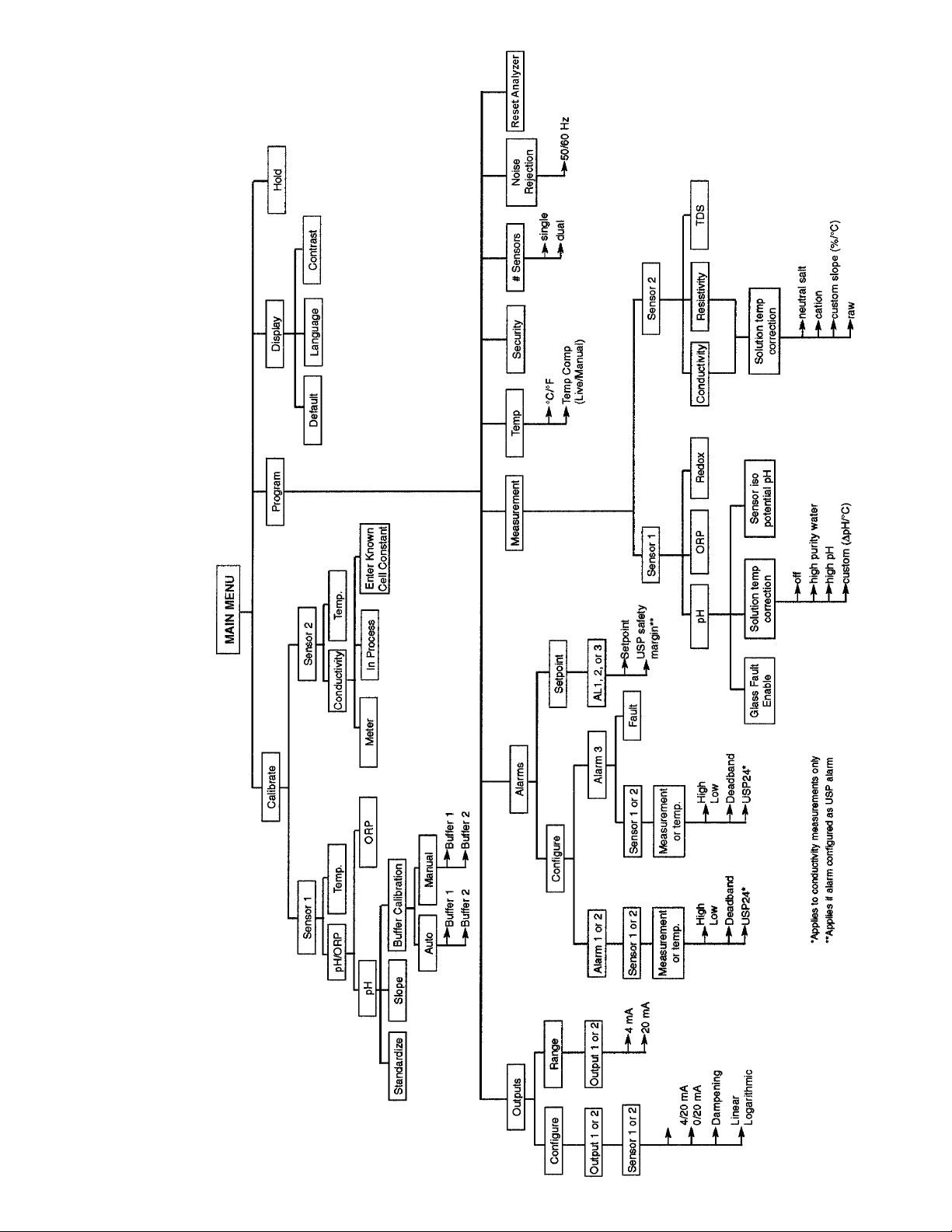

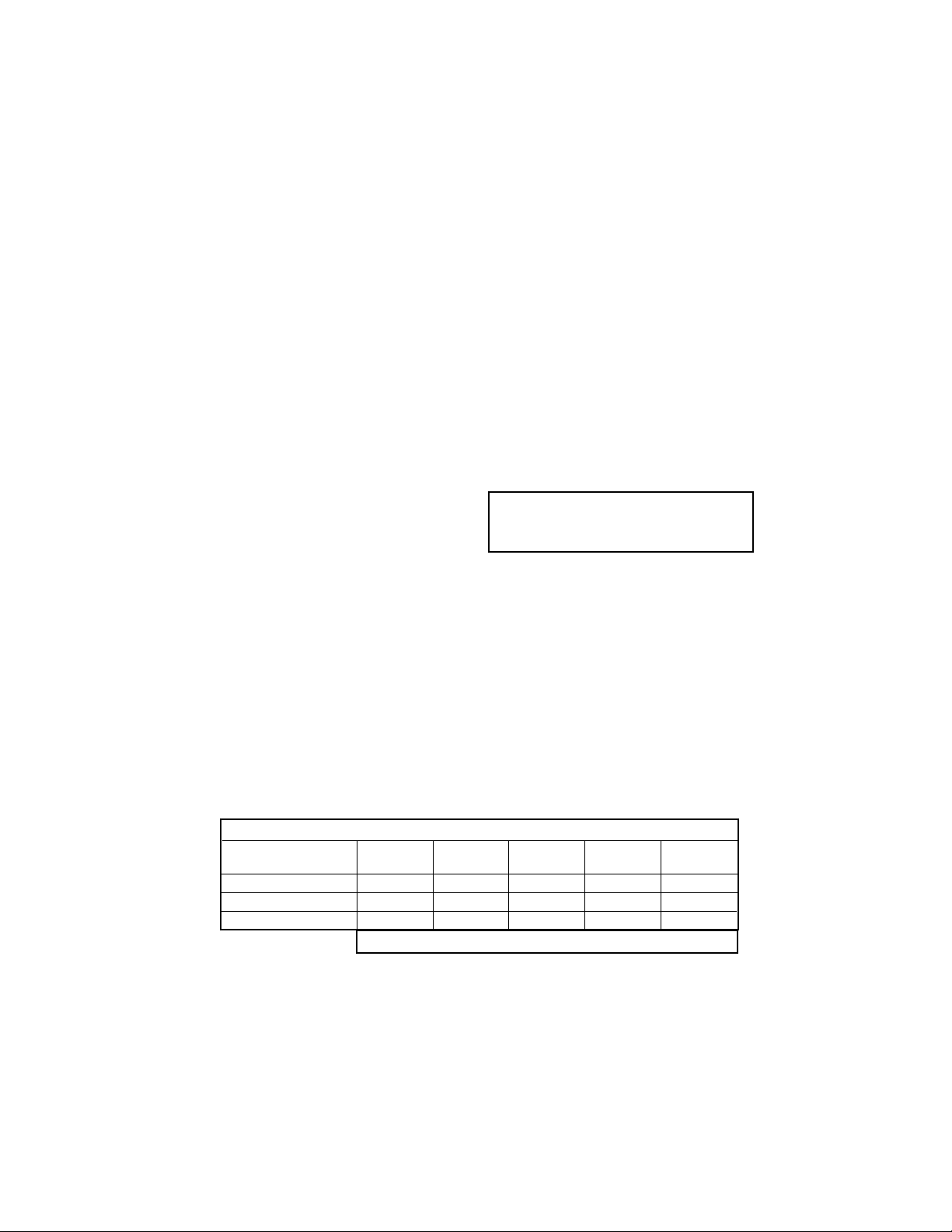

QUICK REFERENCE GUIDE

MENU TREE FOR pH/ORP/REDOX/CONDUCTIVITY/RESISTIVITY/TDS MEASUREMENTS

pH/cond/temp

Page 6

i

MODEL SOLU COMP II TABLE OF CONTENTS

MODEL SOLU COMP II

DUAL INPUT pH/CONDUCTIVITY ANALYZER

TABLE OF CONTENTS

Section Title Page

1.0 DESCRIPTION AND SPECIFICATIONS ................................................................ 1

1.1 Features and Applications........................................................................................ 1

1.2 Specifications........................................................................................................... 2

1.3 Ordering Information ................................................................................................ 8

2.0 INSTALLATION ....................................................................................................... 11

2.1 Unpacking and Inspection........................................................................................ 11

2.2 Installation................................................................................................................ 11

3.0 WIRING.................................................................................................................... 15

3.1 Preparing Conduit Openings.................................................................................... 15

3.2 Power, Alarm, Output, and Sensor Connections ..................................................... 15

4.0 DISPLAY AND OPERATION ................................................................................... 26

4.1 Display ..................................................................................................................... 26

4.2 Keypad..................................................................................................................... 26

4.3 Programming and Calibrating the Solu Comp II - Tutorial ....................................... 27

4.4 Security .................................................................................................................... 28

4.5 Using Hold ............................................................................................................... 28

5.0 PROGRAMMING THE ANALYZER ........................................................................ 29

5.1 General .................................................................................................................... 29

5.2 Changing StartUp Settings....................................................................................... 29

5.3 Configuring and Ranging the Outputs...................................................................... 32

5.4 Configuring Alarms and Assigning Setpoints ........................................................... 34

5.5 Selecting Type of Measurement and Activating Solution Temperature Correction .. 35

5.6 Choosing Temperature Units and Manual/Automatic Temperature Compensation . 40

5.7 Setting a Security Code ........................................................................................... 41

5.8 Noise Rejection........................................................................................................ 42

5.9 Single Sensor or Dual Sensor Input......................................................................... 42

5.10 Resetting Factory Calibration and Factory Default Settings .................................... 43

5.11 Selecting a Default Screen, Language, and Screen Contrast ................................. 43

Page 7

ii

Section Title Page

6.0 CALIBRATION ........................................................................................................ 45

6.1 Introduction .............................................................................................................. 45

6.2 Calibrating Temperature........................................................................................... 46

6.3 Two-Point Buffer Calibration (Auto Calibration) ....................................................... 48

6.4 Two-Point Buffer Calibration (Manual Calibration) ................................................... 50

6.5 Making the Analyzer Reading Match a Second Instrument (Standardization) ......... 52

6.6 Entering a Known Slope .......................................................................................... 53

6.7 ORP Calibration ....................................................................................................... 54

6.8 Calibrating an In-Service Sensor - Conductivity ...................................................... 55

6.9 Placing a New Sensor in Service - Conductivity ...................................................... 59

6.10 Calibrating the Analyzer - Conductivity .................................................................... 60

7.0 MAINTENANCE ..................................................................................................... 62

7.1 Overview .................................................................................................................. 62

7.2 Replacement Parts .................................................................................................. 62

8.0 TROUBLESHOOTING ............................................................................................ 65

8.1 Overview .................................................................................................................. 65

8.2 Troubleshooting Using Fault Codes......................................................................... 65

8.3 Troubleshooting When No Error Message is Showing - pH..................................... 67

8.4 Troubleshooting When No Error Message is Showing - Conductivity...................... 70

8.5 Troubleshooting When No Error Message is Showing - General ............................ 71

8.6 Simulating Inputs - pH.............................................................................................. 72

8.7 Simulating Inputs - Conductivity............................................................................... 73

8.8 Simulating Temperature ........................................................................................... 74

8.9 Measuring Reference Voltage.................................................................................. 75

9.0 RETURN OF MATERIAL ........................................................................................ 76

LIST OF TABLES

Number Title Page

5-1 Default Settings ........................................................................................................ 30

7-1 Replacement Parts for Solu Comp II (Panel Mount Version) ................................... 63

7-2 Replacement Parts for Solu Comp II (Pipe/Surface Mount Version) ........................ 64

MODEL SOLU COMP II TABLE OF CONTENTS

TABLE OF CONTENTS CONT’D

Page 8

MODEL SOLU COMP II TABLE OF CONTENTS

LIST OF FIGURES

Number Title Page

2-1 Panel Mount Installation ........................................................................................... 12

2-2 Pipe Mount Installation ............................................................................................. 13

2-3 Surface Mount Installation........................................................................................ 14

3-1 Removing the Knockouts ......................................................................................... 15

3-2 Wiring Connections for Solu Comp II Model 1055pH-01-10 ....................................

(Panel Mount with 115/230 Vac Power).................................................................... 16

3-3 Wiring Connections for Solu Comp II Model 1055pH-02-10 ....................................

(Panel Mount with 24 Vdc Power) ............................................................................ 16

3-4 Wiring Connections for Solu Comp II Model 1055pH-01-11 ....................................

(Wall/Pipe Mounting with 115/230 Vac Power)......................................................... 17

3-5 Wiring Connections for Solu Comp II Model 1055pH-02-11 ....................................

(Wall/Pipe Mounting with 24 Vdc Power) ................................................................. 17

3-6 Panel Mount Wiring to Models 399-09-62, 400, 401, 402, 403, and 404 ................. 18

3-7 Pipe/Wall Mount Wiring to Models 399-14, 400, 401, 402, 403, and 404 ................ 19

3-8 Pipe/Wall Mount Wiring to Models 399VP-09, 400, 401, 402, 403, and 404............ 20

3-9 Panel Mount Wiring to Models 399VP-09, 400, 401, 402, 403, and 404 ................. 21

3-10 Pipe/Wall Mount Wiring to Models 399-09-62, 400, 401, 402, 403, and 404 ........... 22

3-11 Panel Mount Wiring to Models 399-14, 400, 401, 402, 403, and 404 ...................... 23

3-12 Wiring Model 1055-11-22-32 to Models 399-09-62 and GP-1.................................. 24

3-13 Wiring Model 1055-10-22-32 to Model 399-14......................................................... 25

3-14 Wiring Model 1055 to Models 320HP-58 and 400, 401, 402, 403, or 404 ............... 25

4-1 Displays During Normal Operation........................................................................... 26

4-2 Solu Comp II Keypad ............................................................................................... 26

5-1 Assigning Outputs 1 and 2 ...................................................................................... 32

5-2 High Alarm Logic ..................................................................................................... 34

5-3 Low Alarm Logic ....................................................................................................... 34

6-1 Calibration Slope and Offset .................................................................................... 48

6-2 Calibration Against a Standard Cell .......................................................................... 55

7-1 Exploded View of Solu Comp II (Panel Mount Version) ........................................... 63

7-2 Exploded View of Solu Comp II (Pipe/Surface Mount Version) ................................ 64

8-1 Continuity and Leakage Check ................................................................................ 66

8-2 Simulating Inputs When the Preamplifier is in the Analyzer ..................................... 72

8-3 Simulating pH Input When the Preamplifier is in the Sensor.................................... 72

8-4 Simulating Conductivity ............................................................................................ 73

8-5 Three-Wire RTD Configuration................................................................................. 74

8-6 Simulating RTD Inputs.............................................................................................. 74

8-7 Checking for a Poisoned Reference Electrode ........................................................ 75

iii

Page 9

About This Document

This manual contains instructions for installation and operation of the Solu Comp II

Model 1055 Dual Input pH/Conductivity Analyzer.

The following list provides notes concerning all revisions of this document.

Rev

. Level

Date Notes

0 1/01 This is the initial release of the product manual. The manual

has been reformatted to reflect the Emerson documentation

style and updated to reflect any changes in the product offering.

A 2/02 Revised specs.

B 7/02 Added 399 wiring diagrams.

C 7/02 Added UL specs.

D 11/02 Deleted option code -41.

E 4/03 Revised CE info, maintenance info, and drawing #41055112.

F 3/04 Revised H2SO4 specs & recommended sensors on pages 4 & 6.

G 10/04 Updated mounting drawings on pages 13 & 14.

H 11/04 Updated mounting drawing on page 12.

I 12/04 Revised USP references

J 4/05 Revised panel mount drawing

K 2/06 Revised Case and Analog Output specifications on page 2.

Page 10

MODEL SOLU COMP II SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

SECTION 1.0.

DESCRIPTION AND SPECIFICATIONS

1.1 FEATURES AND APPLICATIONS

1.2 SPECIFICATIONS

1.3 ORDERING INFORMATION AND ACCESSORIES

1

1.1 FEATURES AND APPLICATIONS

The Solu Comp II analyzers offer the choice of single or dual sensor input with measurement choices

of pH/ORP, resistivity/conductivity/TDS, % concentration, ratio conductivity, total and free chlorine, dissolved oxygen, dissolved ozone, flow and temperature. Dual measurement analyzers offer a wide

choice of measurement combinations thus reducing

the cost per loop and needed panel space.

FIELD COMMISSION OPTION: The Solu Comp II

can be ordered with the ability to commission measurements in the field. This added flexibility can

greatly reduce the number of spare instruments

required for field servicing.

QUICK START PROGRAMMING: Exclusive Quick

Start screens appear the first time the Solu Comp II

is powered up. Screen prompts direct the user to

register the number of sensors, the measurement

unit(s) and the language to display. Some measurement specific prompts are also displayed. The

measurement loop is ready for use in a matter of

minutes.

MENUS: Menu screens for calibrating and registering choices are simple and intuitive. Plain language

prompts guide the user through the procedures.

There are no service codes to enter before gaining

access to menus.

DUAL SENSOR INPUT AND OUTPUT: The Solu

Comp II accepts single or dual sensor input. The

two 4-20 mA outputs can be independently programmed to correspond to any selected measurement or temperature. Output damping and linear or

log output may also be field selected.

ALARMS: The Solu Comp II has three fully programmable alarm relays that can be assigned to

any selected measurement or temperature. Alarms

can be configured as high, low, or USP1. The third

relay has the additional choice of fault alarm operation. When selected, a fault alarm will activate the

relay when a sensor or analyzer fault occurs.

ENCLOSURE: The panel mount version fits standard ½ DIN panel cutouts, and its shallow depth is

ideally suited for easy mounting in Hoffman-type

enclosures. A panel mount gasket is included to

maintain the weather rating of the panel.

Surface/pipe mount enclosure includes self-tapping

screws for surface mounting. A pipe mounting

accessory kit is available for mounting to a 2-inch

pipe.

DISPLAY: The two-line, 16-character, back-lit display can be customized to meet user requirements.

All operations and descriptive messages can be

field selected for English, French, German, Italian,

Spanish, or Portuguese. Informative screens, which

permit data not shown in the regular display, may

be seen at the push of a button.

TEMPERATURE: Most measurements (except

ORP and flow) require temperature compensation.

The Solu Comp II will automatically recognize either

a Pt100 or Pt1000 RTD, normally built into the sensor. When this RTD is present, the Solu Comp II

can be set up to display the temperature in °C or °F

as well as set any one or more of the alarms and/or

outputs to respond to this sensor input. If two measurements with temperature are present either can

be chosen for each alarm and output selected.

1

USP alarm applies to conductivity/resistivity only.

Page 11

MODEL SOLU COMP II SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

2

1.2 SPECIFICATIONS - General

Case: ABS (panel-mount), polycarbonate (pipe- and

surface-mount). All versions are NEMA 4X/CSA 4

(IP65).

Dimensions

Panel (code -10): 6.10 x 6.10 x 3.72 in. (155 x

155 x 94.5 mm)

Surface/Pipe (code -11): 6.23 x 6.23 x 3.23 in.

(158 x 158 x 82 mm); see page 5 for dimensions

of pipe mounting bracket.

Conduit openings: Accepts PG13.5 or 1/2 in. con-

duit fittings

Display: Two line, 16-character, back-lit display.

Character height: 4.8 mm. Display can be customized to meet individual requirements.

Depending on number of sensors, as many as 14

display screens are available.

Ambient temperature and humidity: 0 to 50°C, (32

to 122°F) RH 5 to 95% (non-condensing)

Note: The analyzer is operable from -20 to 60°C

(-4 to 140°F) with some degradation in display

performance.

Power:

Code -01: 115/230 Vac ±15%, 50/60 Hz ±6%, 8.0W

Code -02*: 24 Vdc ±15%, 6.0W

Installation Category II

*

For +24Vdc Power Supply use only devices meeting

NEC Class II or UL recognized (UL 1950).

Equipment protected throughout by double insulation.

Hazardous Location:

Class I, Division 2,

Groups A, B, C, & D

POLLUTION DEGREE 4: Extended Environment

Outdoor use where conductive contamination

such as rain, snow, or dust may be present.

(Hazardous Location only)

RFI/EMI: EN-61326

LVD: EN-61010-1

Input: Choice of single or dual sensor input with

measurement choices of pH/ORP, conductivity/

resistivity, toroidal conductivity, flow, chlorine, dissolved oxygen, and dissolved ozone. Field-commissioned units allow user to change measurements on either or both inputs. See combination

guide for valid combinations. For contacting conductivity measurements, temperature element

must be a Pt 1000 RTD. For other measurements, use either a Pt100 RTD, Pt1000 RTD, or

22k NTC (D.O. only).

Outputs: Two 4-20 mA or 0-20 mA isolated outputs.

Continuously adjustable. Linear or logarithmic.

Maximum load 500 ohms. Output dampening with

time constant of 5 sec is user-selectable.

Alarms: Three alarm relays for process measure-

ment(s) or temperature. Alarm 3 can be

configured as a fault alarm, instead of a

process alarm. Each relay can be configured

independently. Alarm logic (high or low activation

or USP*) and deadband are user-programmable.

The USP* alarm can be programmed to activate

when the conductivity is within a user-selectable

percentage of the limit.

*conductivity/resistivity measurement only

Relays: Form C, single pole double throw, epoxy sealed

Terminal Connections Rating: 26-14 AWG wire size

Weight/Shipping weight (rounded up to nearest lb or

nearest 0.5 kg): 3 lb (1.5 kg)/4 lb (2.0 kg)

Resistive Inductive

28 Vdc 5.0 A 3.0 A

115 Vac 5.0 A 3.0 A

230 Vac 5.0 A 1.5 A

Ordinary Location: (-68 only)

POLLUTION DEGREE 2: Normally only non-conductive pollution occurs. Occasionally, however, a

temporary conductivity caused by condensation

must be expected.

12RN

Page 12

MODEL SOLU COMP II SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

Measures conductivity in the range 0 to 20,000 µS/cm.

Display choices are conductivity, resistivity, and TDS

(total dissolved solids). Three temperature corrections

are available: high purity water (dilute sodium chloride), cation conductivity (dilute hydrochloric acid),

and adjustable linear temperature coefficient (0 to

5.00%/°C). Temperature correction can be disabled,

allowing the analyzer to display raw conductivity.

PERFORMANCE SPECIFICATIONS -

ANALYZER (CONDUCTIVITY INPUT)

Accuracy (Resistivity)**: 0.9% of reading

Accuracy (Temperature)**: ±0.1°C between 5°C and

100°C; ±1°C between 101°C and 200°C

Stability: 0.5% of reading/month

Ambient Temperature Effect: ±0.05% of reading/°C

Output Accuracy: ±0.1 mA

Temperature correction: High purity water (dilute

sodium chloride), cation conductivity (dilute

hydrochloric acid), linear temperature coefficient

(0.0 to 5.00%/°C), or none. High purity water and

cation conductivity temperature correction apply

between 0 and 100°C. Linear temperature coefficient can be applied between -5 and 200°C.

Measurement Range: 0.0 to 20,000 µS/cm, 0.05 to

20 MΩ-cm, or 0 to 10,000 ppm TDS

Temperature Range: -5°C to 200°C (23°F to 392°F)

1

whichever is greater

2

Accuracy values pertain to Endurance Model 400

Series conductivity sensors only

RECOMMENDED SENSORS FOR

CONDUCTIVITY:

The Solu Comp II is intended for use with the

ENDURANCE Model 400 series conductivity sensor

(Pt 1000 RTD).

Model 400 Screw-in/Insertion

Model 400VP Screw-in/Insertion with 6.0 VP connector

Model 401 Screw-in/Insertion (except 401-15)

Model 402 Retractable

Model 402VP Retractable with 6.0 VP connector

Model 403 Sanitary Flanged

Model 403VP Sanitary Flanged with 6.0 VP connector

Model 404 Flow-Through

The analyzer can also be used with Rosemount

Analytical conductivity sensor Models 140, 141, 142, and

150 having a Pt 100 RTD.

Refer to the table to select the appropriate cell constant.

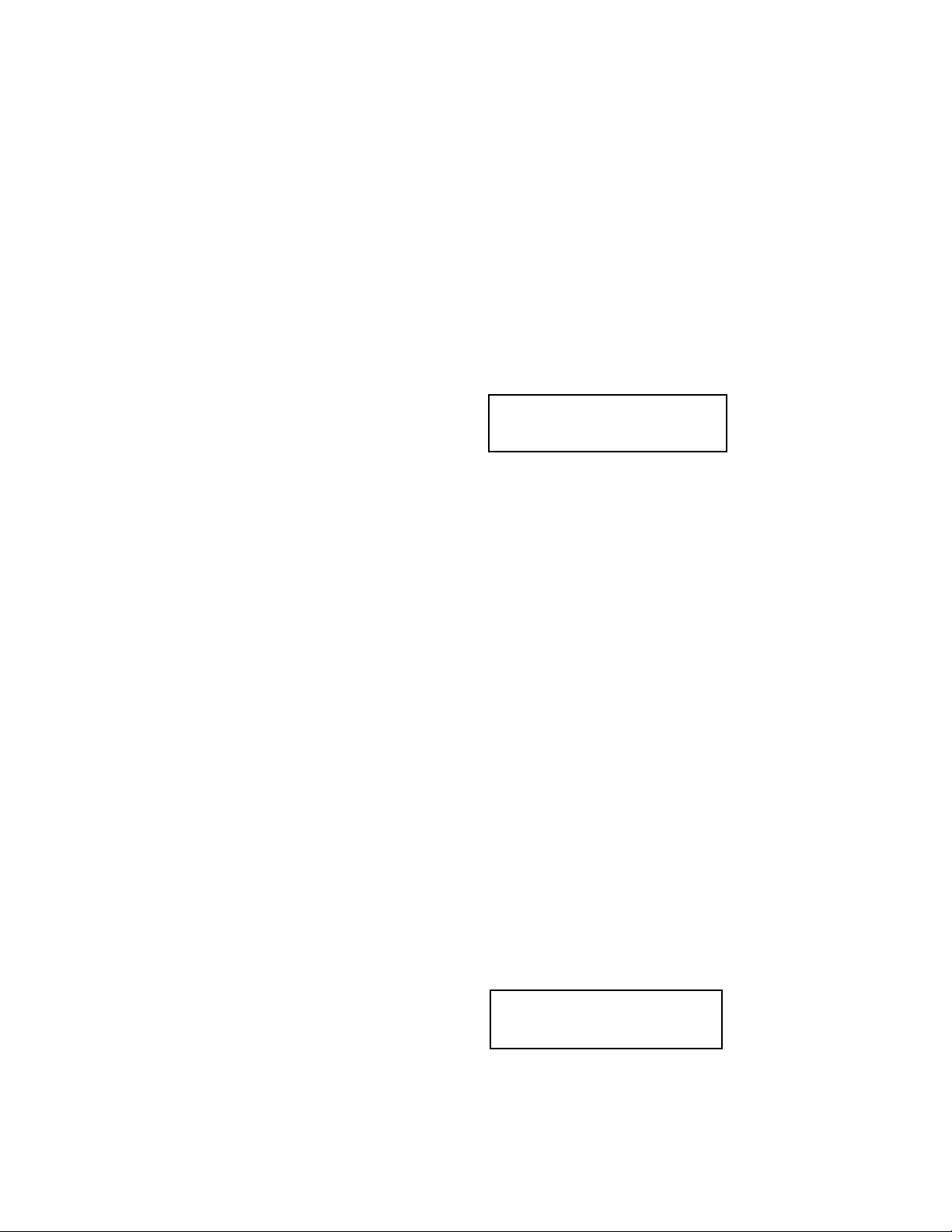

Ratio Conductivity (Codes -20-30):

The Dual Conductivity Solu Comp II can function as a

ratio analyzer or recovery device (% passage or %

rejection). Product sensor 2’s conductivity reading is

always displayed.

Ratio

%Pass

%Reject

CONTACTING CONDUCTIVITY (Codes -20 and/or -30)

Range Cell constant (/cm) Accuracy

1,2

0.055 - 9.99 µS/cm 0.01 0.9% of reading

or ±0.002 µS/cm

10 - 50 µS/cm 0.01 ±2% of reading

0.055 - 500 µS/cm 0.1 ±2% of reading

or ±0.1 µS/cm

0.055 - 5000 µS/cm 1.0 ±2% of reading

or ±1 µS/cm

0 - 5 mS/cm 1.0 ±2% of reading

or ±0.001 mS/cm

0 - 20 mS/cm 10 ±2% of reading

or ±0.01 mS/cm

Range, µµS/cm Cell constant, /cm

0.0 to 50 0.01

5 to 500 0.1

50 to 5,000 1.0

500 to 20,000 10

12.34 µS/cm 40.3 C

7.34pH 25.3 C

Ratio .3325

S2 4.621 µS/cm

%Passage 12.1

S2 4.621 µS/cm

%Reject 87.9

S2 4.621 µS/cm

3

Page 13

MODEL SOLU COMP II SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

4

When used with Model Series 200 Toroidal

Conductivity Sensors, display choices are conductivity, resistivity, and percent concentration. The percent concentration selection includes the choice of

four common solutions (0-12% NaOH, 0-15% HCl,

and 0-25% or 96-99.7% H2SO4). The conductivityconcentration algorithms for these solutions are fully

temperature compensated. For other solutions, a

simple-to-use menu allows the customer to enter his

own data. The analyzer accepts as many as five (5)

data points and fits either a linear (two [2] points) or

a quadratic function (three [3] or more points) to the

data. Reference temperature and linear temperature

slope may also be adjusted for optimum results.

PERFORMANCE SPECIFICATIONS -

Measurement Range: see table below

Accuracy: ± 1% of reading and ± 0.01 mS/cm

Repeatability: ± 0.5% of reading and ± 0.005 mS/cm

Stability: ± 0.25% of reading and ± 0.005 mS/cm/month,

noncumulative

Ambient Temperature Effect: ± 0.05% of reading/°C

Temperature Compensation: -15 to 200°C (5 to

392°F) automatic or manual. Automatic requires

a Pt100/1000 RTD

Temperature correction: Linear temperature

coefficient (0.0 to 5.00%/°C) neutral salt (dilute

sodium chloride) or none

RECOMMENDED SENSORS:

Model 222 Flow-through conductivity sensor

Model 225 Clean-in-place conductivity sensor

Model 226 Large bore conductivity sensor

Model 228 Toroidal conductivity sensor

Model 242 Flow-through conductivity sensor

Model 247 Economy conductivity sensor

TOROIDAL CONDUCTIVITY (Codes -21 and/or -31)

FULL SCALE MICROSIEMENS/cm

INDUCTIVE SENSORS

Conductivity Sensor

Model Number 226 228 225 222 (1in.) 222 (2 in.)

Cell Constant* 1.0 3.0 3.0 6.0 4.0

Minimum Range 50 250 250 500 500

Maximum Range 1,000,000 2,000,000 2,000,000 2,000,000 2,000,000

* Typical

S1 1027mS/cm 100 C

S2 847.1µS/cm 100 C

Page 14

MODEL SOLU COMP II SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

For use with any standard pH or ORP sensor and all

Uniloc sensors and junction boxes with built-in diagnostic style preamplifiers, display choices are pH,

ORP or Redox. The automatic buffer recognition feature uses stored buffer values and their temperature

curves for the most common buffer standards available worldwide. The analyzer will recognize the value

of the buffer being measured and perform a self stabilization check on the sensor before completing the

calibration. Manual or automatic temperature compensation is keypad selectable. Change in pH due to

process temperature can be compensated using a

programmable temperature coefficient or isopotential

point. Measurement and display of pH glass and reference impedance helps alert the user to sensor

maintenance needs.

*reference impedance is suppressed with amperometric/pH

combinations (-24, -25, -26)

PERFORMANCE SPECIFICATIONS ANALYZER (pH INPUT)

Measurement Range [pH]: 0 to 14 pH

Accuracy: ±0.01 pH

Repeatability: ±0.01 pH

Stability: ±0.01 pH/month, non-cumulative

Temperature Coefficient: ±0.003 pH/°C

Temperature Compensation: Pt100/Pt1000 RTD,

Automatic or Manual -15 to 100°C (5 to 212°F)

Temperature Correction: Choose from standard

measurement compensation, solution temperature

correction for high purity or dilute base solutions,

and custom temperature correction.

PERFORMANCE SPECIFICATIONS ANALYZER (ORP INPUT)

Measurement Range [ORP]: -1400 to +1400 mV

Accuracy: ±2.0 mV

Repeatability: ±1.0 mV

Stability: ±1.0 mV/month, non-cumulative

Temperature Coefficient: ± 0.2 mV/°C

Temperature Measurement: -15 to 100°C

(5 to 212°F)

Temperature Correction: none required

RECOMMENDED SENSORS FOR pH:

Model 320B Flow Through pH

Model 320HP High Purity pH

Model 328A Steam Sterilizable pH

Model 370 and 371 EuroSenz pH

Model 381+ Insertion/Submersion/Flow Through pH

Model 385+ Insertion/Submersion/Retractable pH

Model 389 Insertion/Submersion pH

Model 396 Insertion/Submersion pH

Model 396VP Insertion/Submersion pH with VP 6.0 connector

Model 396P Insertion/Submersion pH

Model 396PVP Insertion/Submersion pH with VP 6.0 connector

Model 396R Retractable pH

Model 396RVP Retractable pH with VP 6.0 connector

Model 397 Quik Disconnect pH

Model 398 Insertion/Submersion pH

Model 398VP Insertion/Submersion with VP 6.0 connector

Model 398R Retractable pH

Model 398RVP Retractable pH with VP 6.0 connector

Model 399 Insertion/Submersion pH

Model Hx338 Steam Sterilizable pH

Model Hx348 Steam Sterilizable pH

When used with conductivity (-20-32 or -22-30):

Model 320HP High Purity pH

Model 381+ Insertion/Submersion/Flow Through pH

Model 385+ Insertion/Submersion/Retractable pH

Model 396P Insertion/Submersion pH

Model 396PVP Insertion/Submersion pH with VP 6.0 connector

Model 396R Retractable pH

Model 396RVP Retractable pH with VP 6.0 connector

RECOMMENDED SENSORS FOR ORP:

Model 330 Flow Through ORP

Model 371 EuroSenz ORP

Model 381+ Insertion/Submersion/Flow Through ORP

Model 385+ Insertion/Submersion/Retractable pH

Model 389 Insertion/Submersion ORP

Model 396P Insertion/Submersion ORP

Model 396PVP Insertion/Submersion ORP with VP 6.0 connector

Model 396R Retractable ORP

Model 398 Insertion/Submersion ORP

Model 398VP Insertion/Submersion with VP 6.0 connector

Model 398R Retractable ORP

Model 398RVP Retractable ORP with VP 6.0 connector

When used with conductivity (-20-32 or -22-30):

Model 320HP High Purity ORP

Model 381+ Insertion/Submersion/Flow Through ORP

Model 385+ Insertion/Submersion/Retractable ORP

Model 396P Insertion/Submersion ORP

Model 396PVP Insertion/Submersion ORP with VP 6.0 connector

Model 396R Retractable ORP

Model 396RVP Retractable ORP with VP 6.0 connector

pH/ORP (Codes -22 and/or -32)

S1 4.34pH 25 C

S2 12.34pH 27 C

5

Page 15

MODEL SOLU COMP II SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

When used with a chlorine specific membrane-covered

amperometric sensor, display choices are free chlorine

or total chlorine. (Total chlorine measurement requires

the use of the Model SCS921 or other sample conditioning system). Because the permeability of the membrane is a function of temperature, a correction is necessary when the sensor is used at a temperature different from the one at which it was calibrated. The

Solu Comp II automatically applies the temperature

correction factor. The process temperature is measured by an RTD in the sensor. An input filter allows the

user to configure the analyzer for rapid response or

low noise. The low noise option is recommended for

samples containing less than 0.1 ppm chlorine.

pH is also a factor in the measurement of free chlorine. An aqueous solution of free chlorine is a mixture

of hypochlorous acid and hypochlorite ion. The relative amount of each depends on the temperature and

pH. Generally, increasing the pH and temperature

reduces the amount of hypochlorous acid in the mixture. Because the response of the sensor to

hypochlorous acid is greater than its response to

hypochlorite, accurate determination of chlorine

requires knowledge of the pH and temperature of the

sample. If the pH is relatively constant, a fixed pH correction factor can be entered into the analyzer. If the

pH is greater than 7 and fluctuates by more than 0.2,

continuous measurement of the pH and automatic pH

correction is necessary. For automatic pH correction,

select code -32 and an appropriate pH sensor.

PERFORMANCE SPECIFICATIONS

Measurement Range: 0-20 ppm (mg/L) chlorine

(as Cl2)

Resolution: 0.001 ppm

Automatic pH Correction (requires Code -32): 5.0

to 9.5 pH

Temperature Correction: Automatic (with Pt100 RTD

in sensor) or manual 0-50°C. Can be disabled if

desired.

Input filter: time constant 1 - 999 sec

RECOMMENDED SENSORS

Chlorine: 499A CL-01 Free Chlorine or 499A CL-02

Total Residual Chlorine (requires sample conditioning)

pH: 399-09-62, 399VP-09, 399-14

For use with most pulse signal flow sensors, the Solu

Comp II's user selectable units of measure include

flow rates in GPM (Gallon per minute), LPM (liters per

minute), or m3/hr (cubic meters per hour), and velocity in ft/sec or m/sec. When configured to measure

flow, the unit also acts as a totalizer in the chosen unit

(gallons, liters, or cubic meters).

Dual flow instruments can be configured as a %

recovery device or a flow difference device.

PERFORMANCE SPECIFICATIONS

Frequency Range: 0.5 - 4000 Hz

Flow Rate: 0 - 9999 GPM, LPM, m3/hr

Totalized Flow: 0 - 9,999,999 Gallons;

37,850,000 Liters; 37,850 m3

Accuracy: ±1% (±1.5% from 3000 to 4000 Hz)

Repeatability: ±1%

RECOMMENDED SENSORS

+GF+ Signet 515 Rotor-X Flow sensor Model

515/8510-XX (PN P51530-PO)

Fluidyne Flow Sensor Model 2300A

(PN Hydro-Flow-2300-A-10-5R-3-1-1)

Consult factory for other pulse type sensor compatibility.

FREE AND TOTAL CHLORINE (Code -24)

FLOW

(Standard on all models or stand alone, Code -23 and/or -33)

S2 12.34 GPM

S2 47.25K Gal

12.34 ppm

26.3 C 8.34pH

6

Page 16

MODEL SOLU COMP II SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

7

When used with an oxygen permeable membranecovered amperometric sensor, display choices are

ppb or ppm dissolved oxygen or % saturation.

Because the permeability of the membrane is a function of temperature, a correction is necessary when

the sensor is used at a temperature different from the

one at which it was calibrated. The Solu Comp II

automatically applies the temperature correction factor. The process temperature is measured by an RTD

in the sensor. Calibrating the analyzer is as simple as

exposing the sensor to air and keying in the barometric pressure. If removing the sensor from the process

is impractical, the analyzer can also be calibrated

against a standard instrument. Solubility correction

factors for liquids containing high concentrations of

electrolytes can be registered into the analyzer. The

Solu Comp II automatically calculates ppb/ppm dissolved oxygen taking into account the high salt concentration.

PERFORMANCE SPECIFICATIONS

Measurement Range: 0-20 ppm (mg/L) dissolved

oxygen; 0- 250% saturation

Resolution: 0.01 ppm; 0.1 ppb for 499A TrDO sensor

(when O2<1.00 ppm); 0.1%

Temperature Correction for Membrane Permeability:

Automatic (with Pt100 RTD in sensor) or manual

0-50°C. Can be disabled if desired.

Input filter: 1- 255 samples

RECOMMENDED SENSORS

Model 499A DO Dissolved Oxygen Sensor

Model Hx438 Steam Sterilizable Dissolved Oxygen

Sensor

Model Gx438 Steam Sterilizable Dissolved Oxygen

Sensor

Model 499A TrDO Trace Dissolved Oxygen Sensor

(soon to be released)

DISSOLVED OXYGEN (Code -25)

For use with an ozone permeable membrane-covered

amperometric sensor. Because the permeability of the

membrane is a function of temperature, a correction is

necessary when the sensor is used at a temperature

different from the one at which it was calibrated. The

Solu Comp II automatically applies the temperature

correction factor. The process temperature is measured by an RTD in the sensor. The Solu Comp II is

calibrated taking a measurement of the ozone level in

the process by an independent chemical method and

setting the display equal to the measured value. An

input filter allows the user to configure the analyzer

for rapid response of low noise. The low noise option

is recommended for samples containing less than 0.1

ppm dissolved ozone.

PERFORMANCE SPECIFICATIONS

Measurement Range: 0-10 ppm (mg/L)

Resolution: 0.001 ppm dissolved ozone

Temperature Correction for Membrane Permeability:

Automatic (with Pt100 RTD in sensor) or

manual 0-35°C. Can be disabled if desired.

Input filter: time constant 1 - 999 sec

RECOMMENDED SENSOR

Model 499A OZ Dissolved Ozone Sensor

LOOP SPECIFICATIONS WITH A MODEL

499A OZ SENSOR

Loop Accuracy: ±5% of reading or ± 3 ppb at 25°C,

whichever is greater

Repeatability: ±2% of reading at a constant tempera-

ture

DISSOLVED OZONE (Code -26)

10.34 ppm

29.3 C 12.34mA

10.34 ppm

29.3 C 12.34mA

Page 17

MODEL SOLU COMP II SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

8

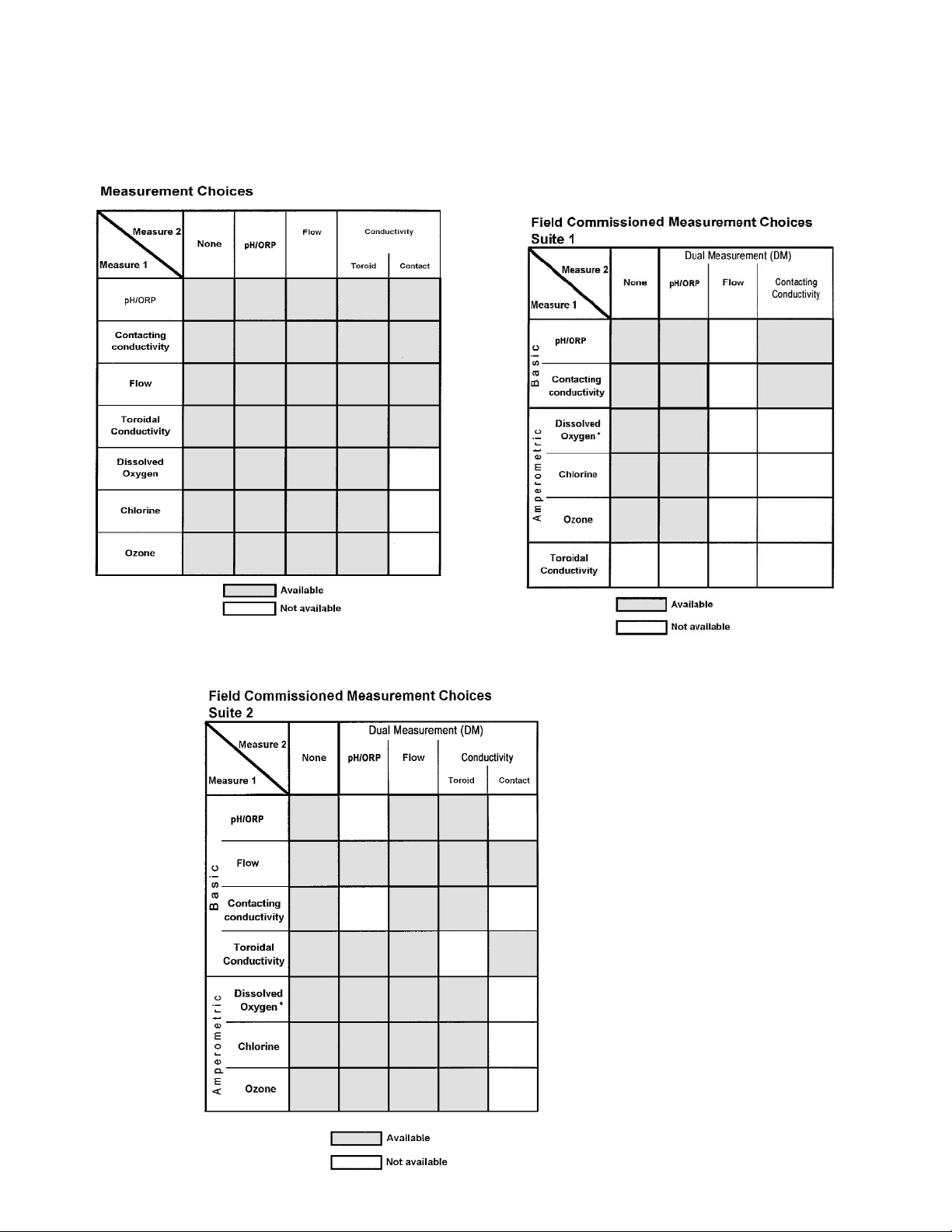

1.3 ORDERING INFORMATION

The Solu Comp II analyzers offer the choice of single or dual sensor input with measurement choices of pH/ORP, conductivi-

ty/resistivity, toroidal conductivity, flow, chlorine, dissolved oxygen, and dissolved ozone. See combination guide (on the following page) for valid combinations. Standard features include two isolated outputs, three alarm relays, customizable two-line

display, and temperature correction.

MODEL 1055 SOLU COMP II ANALYZER

CODE MEASUREMENT 2 (Optional)

30 Contacting Conductivity

31 Toroidal Conductivity

32 pH/ORP

33 Flow

CODE FIELD-COMMISSIONED SUITES (Optional) see tables below

S1 Suite 1 - Field Commissioned Measurement

(basic)

S1A Suite 1 - Field Commissioned Measurement

(includes amperometric)

S2 Suite 2 - Field Commissioned Measurement

(basic)

S2A Suite 2 - Field Commissioned Measurement

(includes amperometric)

CODE OPTIONAL

68 UL Approval

CODE POWER

01 115/230 Vac, 50/60 Hz

02 24 Vdc

CODE MEASUREMENT 1 (Required Selection)

20 Contacting Conductivity

21 Toroidal Conductivity

22 pH/ORP

23 Flow

24 Chlorine

25 Dissolved Oxygen

26 Ozone

CODE MOUNTING

10 Panel mounting enclosure

11 Pipe/Surface mounting enclosure

(Pipe mounting requires accessory kit PN 23820-00)

MODEL 1055 SOLU COMP II ANALYZER

CODE POWER

01 115/230 Vac, 50/60 Hz

02 24 Vdc

CODE MOUNTING

10 Panel mounting enclosure

11 Pipe/Surface mounting enclosure

(Pipe mounting requires accessory kit PN 23820-00)

CODE OPTIONAL

DM Dual Measurement

CODE OPTIONAL

68 UL Approval

Field Commisssioned Suites option offers the user the ability to commission the Solu Comp II to any valid measurement

combination. This feature provides the benefit of a reduction in the number of spare instruments required to meet emergency

inventory needs. Please refer to the Suites tables (on the following page) for valid measurement combinations. Suites include

a complete set of instrument wiring labels.

Page 18

MODEL SOLU COMP II SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

9

COMBINATION GUIDE

5

5

* For D.O. sensors with 22k thermistor,

use Suite 1 only.

Page 19

MODEL SOLU COMP II SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

10

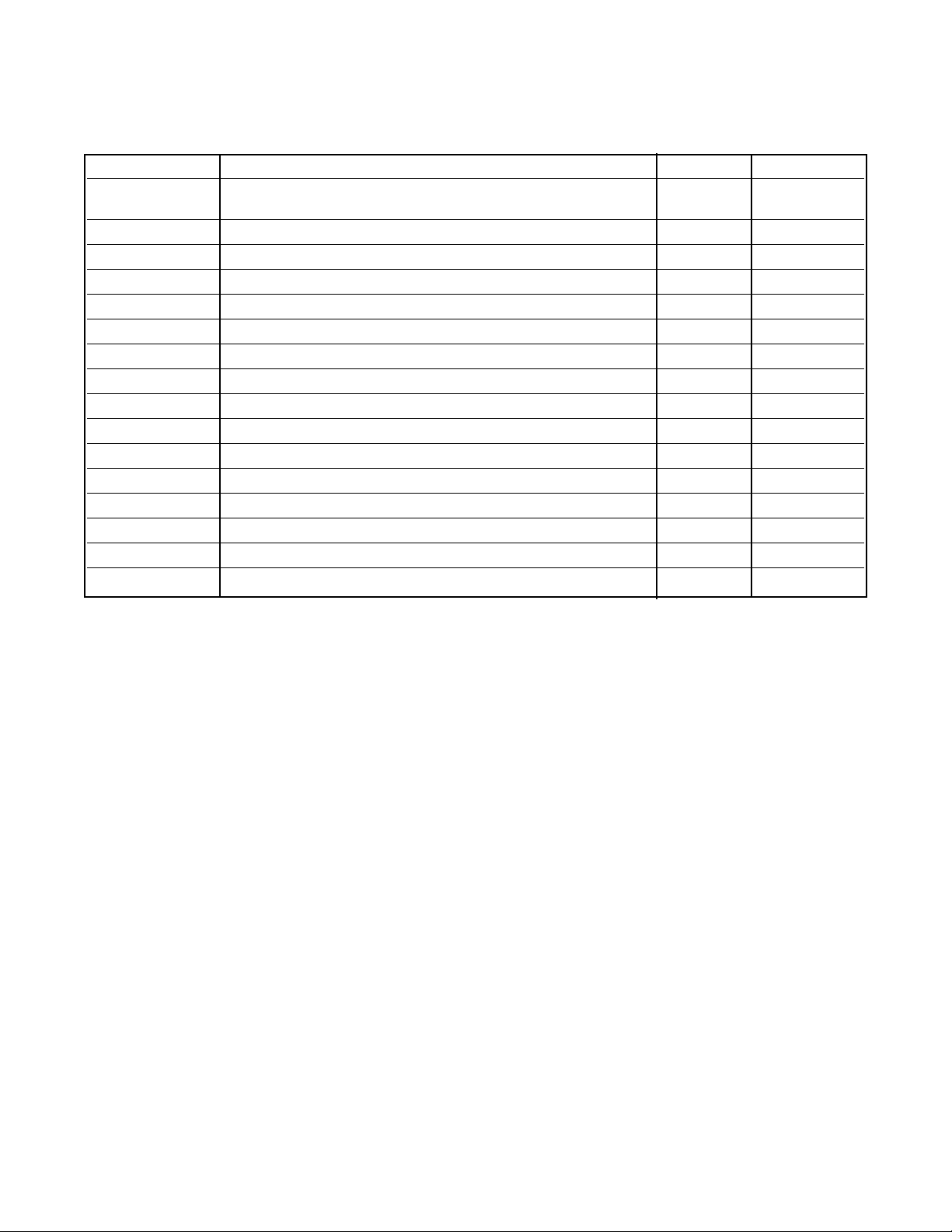

ACCESSORIES (Weights are rounded up to nearest whole lb or 0.5 kg)

PART NUMBER DESCRIPTION WEIGHT SHIPPING WT.

23820-00 Pipe mounting kit, includes U-bolts, mounting bracket, nuts, 2 lb (1.0 kg) 4 lb (2.0 kg)

washers, and screws (complete)

23554-00 Gland fittings, PG 13.5, 5 per package 1 lb (0.5 kg) 2 lb (1.0 kg)

9240048-00 Tag, stainless steel (specify marking) 1 lb (0.5 kg) 1 lb (0.5 kg)

pH INPUT

9210012 Buffer Solution, 4.01 pH, 16 oz. 1 lb (0.5 kg) 2 lb (1.0 kg)

9210013 Buffer Solution, 6.86 pH, 16 oz. 1 lb (0.5 kg) 2 lb (1.0 kg)

9210014 Buffer Solution, 9.18 pH, 16 oz. 1 lb (0.5 kg) 2 lb (1.0 kg)

CONDUCTIVITY INPUT

SS-1 Conductivity Standard, 1409 µS/cm at 25°C, 1 quart (945 mL) 2 lb (1.0 kg) 4 lb (2.0 kg)

SS-1A Conductivity Standard, 1409 µS/cm at 25°C, 1 gallon (3785 mL) 9 lb (4.0 kg) 11 lb (5.0 kg)

SS-5 Conductivity Standard, 1000 µS/cm at 25°C, 1 quart (945 mL) 2 lb (1.0 kg) 4 lb (2.0 kg)

SS-5A Conductivity Standard, 1000 µS/cm at 25°C, 1 gallon (3785 mL) 9 lb (4.0 kg) 11 lb (5.0 kg)

SS-6 Conductivity Standard, 200 µS/cm at 25°C, 1 quart (945 mL) 2 lb (1.0 kg) 4 lb (2.0 kg)

SS-6A Conductivity Standard, 200 µS/cm at 25°C, 1 gallon (3785 mL) 9 lb (4.0 kg) 11 lb (5.0 kg)

SS-7 Conductivity Standard, 5000 µS/cm at 25°C, 1 quart (945 mL) 2 lb (1.0 kg) 4 lb (2.0 kg)

SS-7A Conductivity Standard, 5000 µS/cm at 25°C, 1 gallon (3785 mL) 9 lb (4.0 kg) 11 lb (5.0 kg)

Page 20

11

SECTION 2.0.

INSTALLATION

MODEL SOLU COMP II SECTION 2.0

INSTALLATION

2.1 UNPACKING AND INSPECTION

2.2 INSTALLATION

Type of Mounting Section

Panel 2.2.2

Pipe 2.2.3

Surface 2.2.4

2.1 UNPACKING AND INSPECTION

Inspect the shipping container. If it is damaged, contact the shipper immediately for instructions. Save the box. If

there is no apparent damage, unpack the container. Be sure all items shown on the packing list are present. If

items are missing, notify Rosemount Analytical immediately.

2.2 INSTALLATION

2.2.1 General Information

1. Although the analyzer is suitable for outdoor use, do not install it in direct sunlight or in areas of extreme temperatures.

2. Install the analyzer in an area where vibrations and electromagnetic and radio frequency interference are minimized or absent.

3. Keep the analyzer and sensor wiring at least one foot from high voltage conductors. Be sure there is easy

access to the analyzer.

4. AC power and relay wiring should not enter via top conduit openings and should be kept separated

from other wiring in the analyzer after installation.

5. The analyzer is suitable for panel, pipe, or surface mounting. Refer to the table below.

6. See Section 3.1 for removal of conduit knockouts.

7. To reduce the likelihood of stress on wiring connections, the hinged front panel (-11 models) shall not be

removed from the base during wiring installation, and there shall be sufficient wire leads to avoid stress on conductors.

8. For UL-approved models (-68), the clear wiring shield must be installed prior to operation.

Page 21

12

MODEL SOLU COMP II SECTION 2.0

INSTALLATION

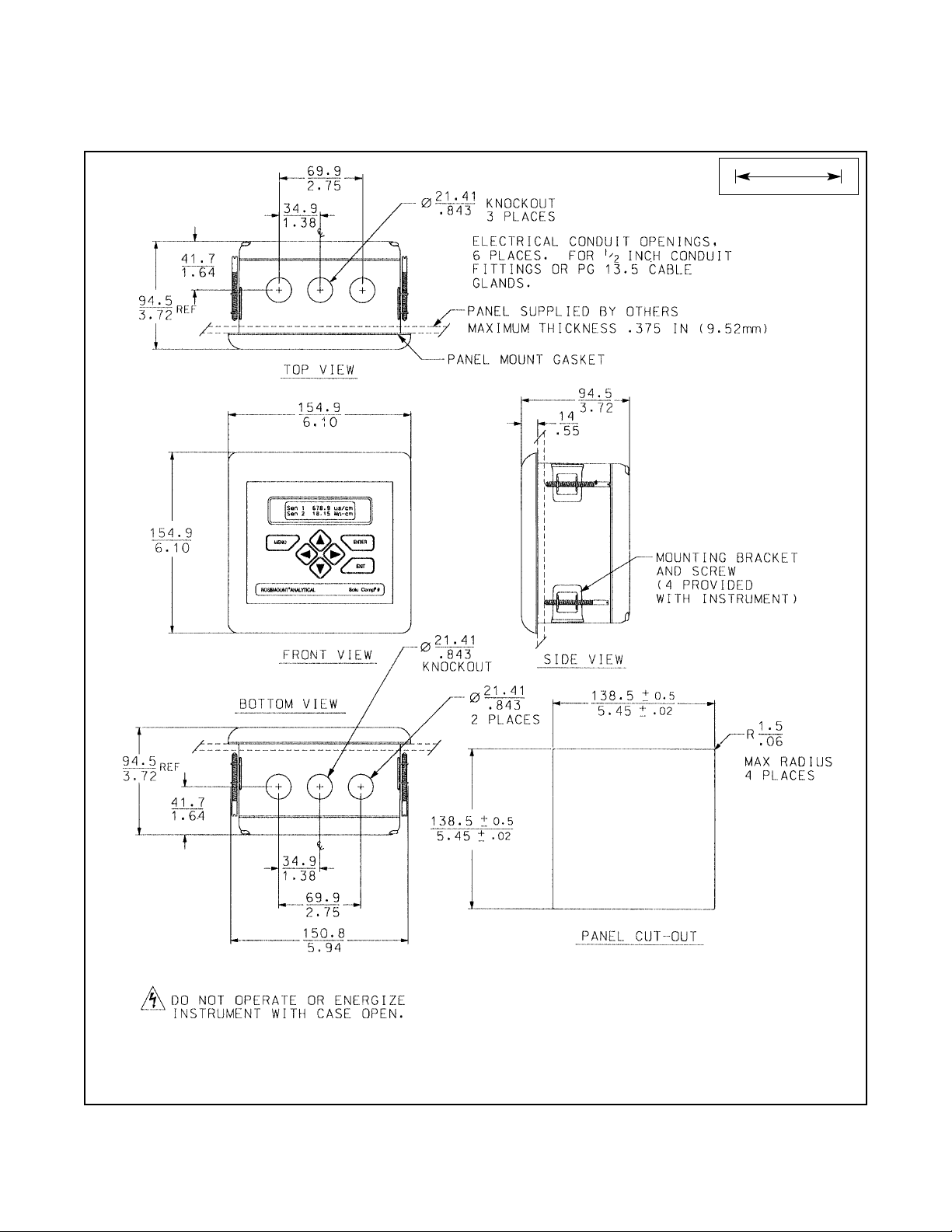

FIGURE 2-1. Panel Mount Installation

Access to the wiring terminals is through the rear cover. Four screws hold the cover in place.

2.2.2 Panel Mounting.

MILLIMETER

INCH

Page 22

MODEL SOLU COMP II SECTION 2.0

INSTALLATION

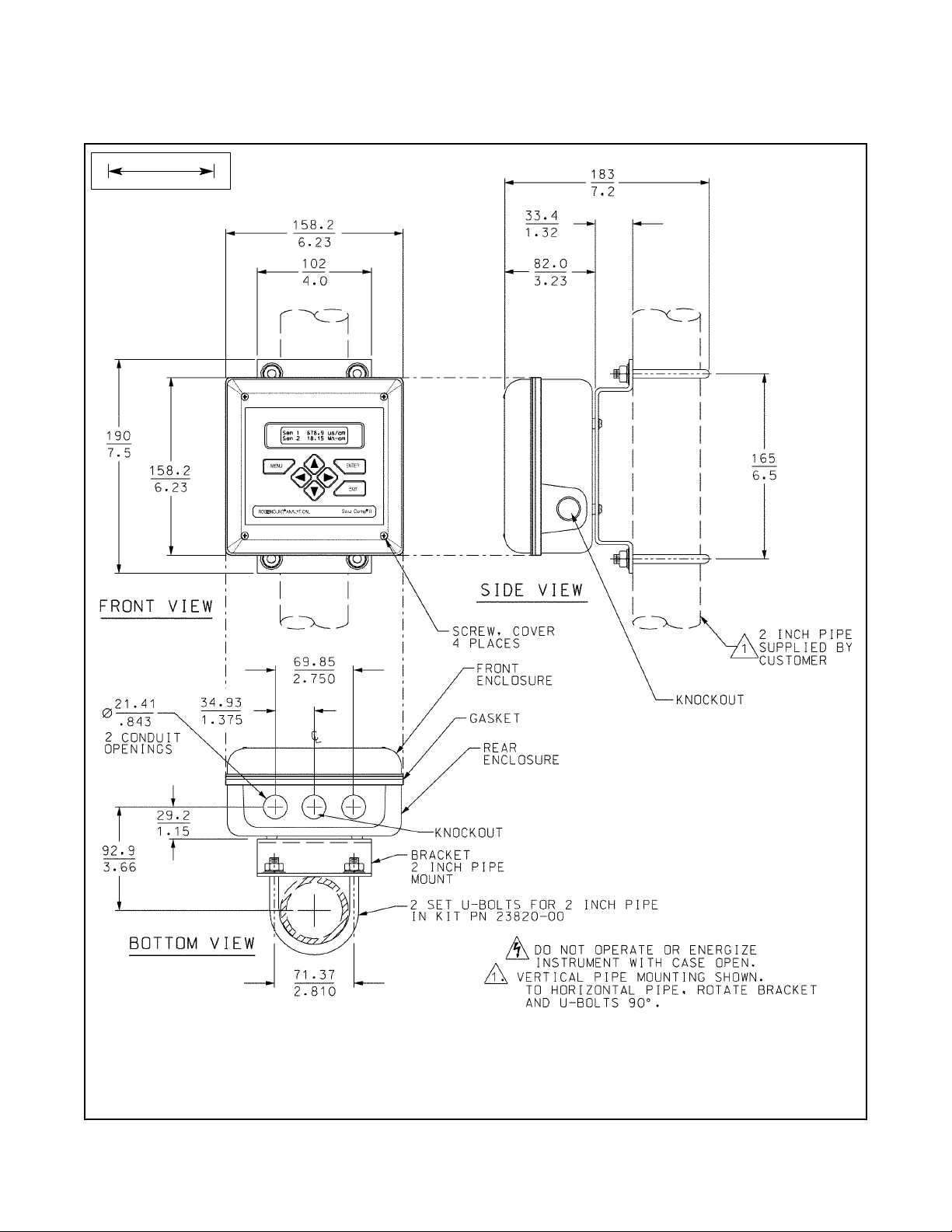

FIGURE 2-2. Pipe Mount Installation

The front panel is hinged at the bottom. The panel swings down for access to the wiring terminals.

2.2.3 Pipe Mounting.

MILLIMETER

INCH

13

Page 23

MODEL SOLU COMP II SECTION 2.0

INSTALLATION

14

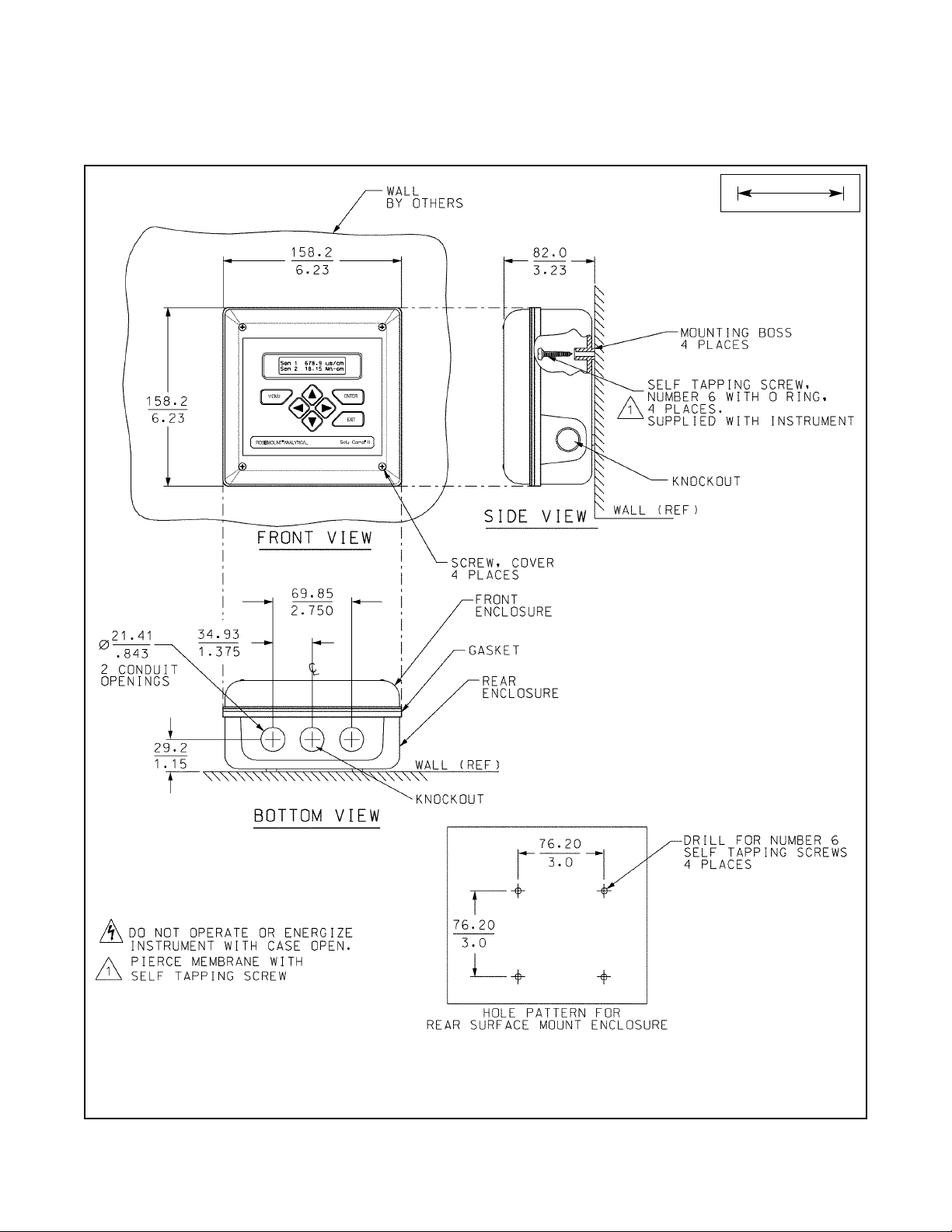

FIGURE 2-4. Surface Mount Installation

The front panel is hinged at the bottom. The panel swings down for access to the wiring terminals.

2.2.4 Surface Mounting.

MILLIMETER

INCH

Page 24

3.2 POWER, ALARM, OUTPUT, AND SENSOR CONNECTIONS

The Solu Comp II is available in two mounting configurations.The positions of the power, alarm, output, and sensor terminal blocks are different in each. Refer to the table to find the correct drawing.

For best EMI/RFI protection use

shielded output signal cable

enclosed in an earth-grounded

metal conduit. Connect the

shield to earth ground at terminal 4 on TB1.

AC wiring should be 14 gauge or greater. Provide a switch or breaker to disconnect the analyzer from the main power

supply. Install the switch or breaker near the analyzer and label it as the disconnecting device for the analyzer.

Keep sensor and output signal wiring separate from power wiring. Do not run sensor and power wiring in the same

conduit or close together in a cable tray.

NOTE

For sensors without solution ground, please use the RC kit included with the instrument.

MODEL MOUNTING POWER FIGURE

1055pH-01-10 Panel 115/230 Vac 3-2

1055pH-02-10 24 Vdc 3-3

1055pH-01-11 Surface/Pipe 115/230 Vac 3-4

1055pH-02-11 24 Vdc 3-5

WARNING: RISK OF ELECTRICAL SHOCK

AC connections and grounding must be in compliance

with UL 508 or local electrical code. DO NOT apply

power to the analyzer until all electrical connections are

verified and secure.

SECTION 3.0.

WIRING

3.1 PREPARING CONDUIT OPENINGS

3.2 POWER, ALARM, OUTPUT, AND SENSOR

CONNECTIONS

MODEL SOLU COMP II SECTION 3.0

WIRING

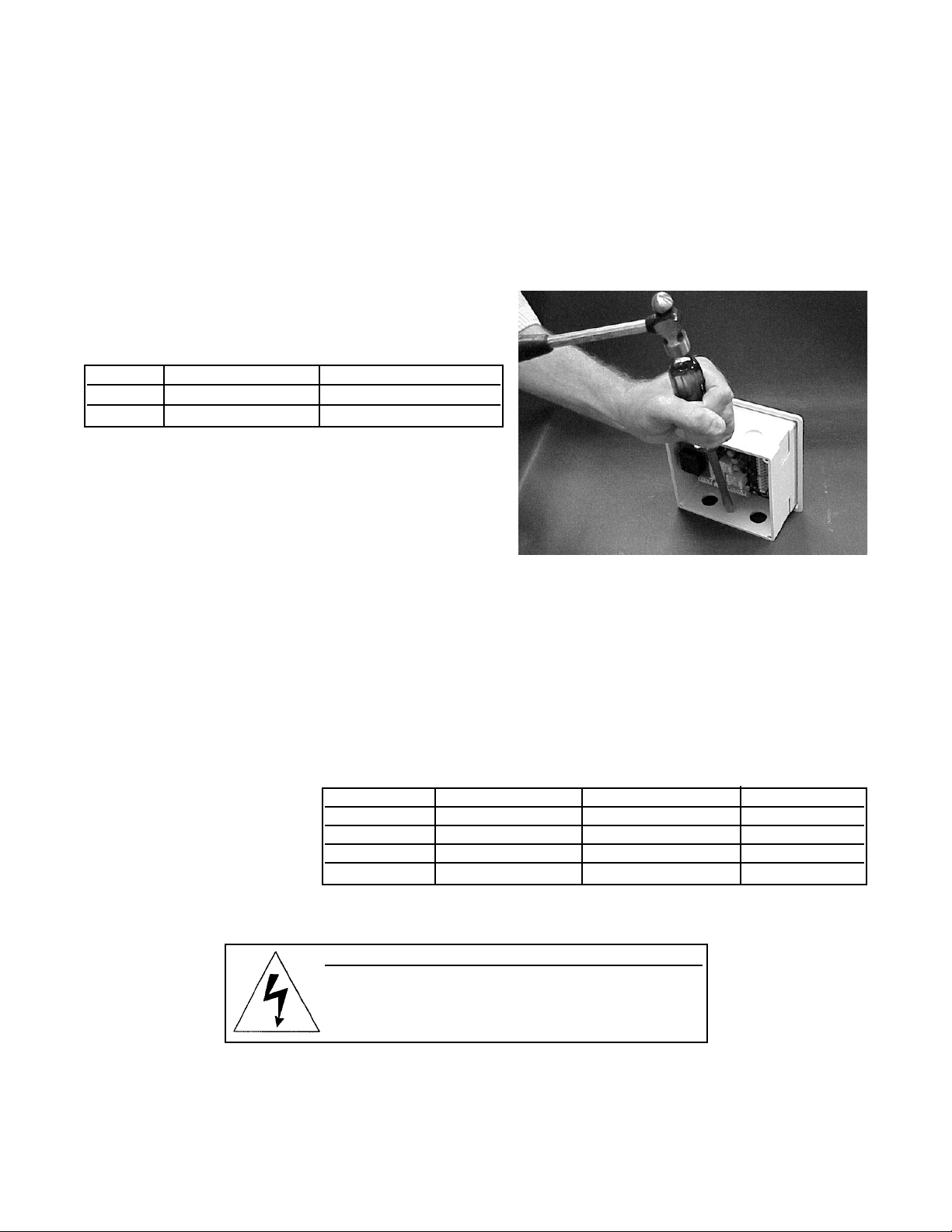

3.1 PREPARING CONDUIT OPENINGS

The number of conduit openings and the location depend on

the model.

Conduit openings accept 1/2-inch conduit fittings or PG 13.5

cable glands. To keep the case watertight, block unused

openings with NEMA 4X or IP65 conduit plugs.

NOTE

Use watertight fittings and hubs that comply with the

requirements of UL514B. Connect the conduit hub to the

conduit before attaching the fitting to the analyzer (UL508-

26.16).

Figure 3-1 shows how to remove the knockouts. The knockout grooves are on the outside of the case. Place the

screwdriver blade on the inside of the case and align it approximately along the groove. Rap the screwdriver sharply

with a hammer until the groove cracks. Move the screwdriver to an uncracked portion of the groove and continue

the process until the knockout falls out. Use a small knife blade to remove the flash from the inside of the hole.

FIGURE 3-1. Removing the Knockouts

Model Description Conduit openings

1055-10 panel mount two open, three knockouts

1055-11 surface or pipe mount three open, no knockouts

15

Page 25

16

MODEL SOLU COMP II SECTION 3.0

WIRING

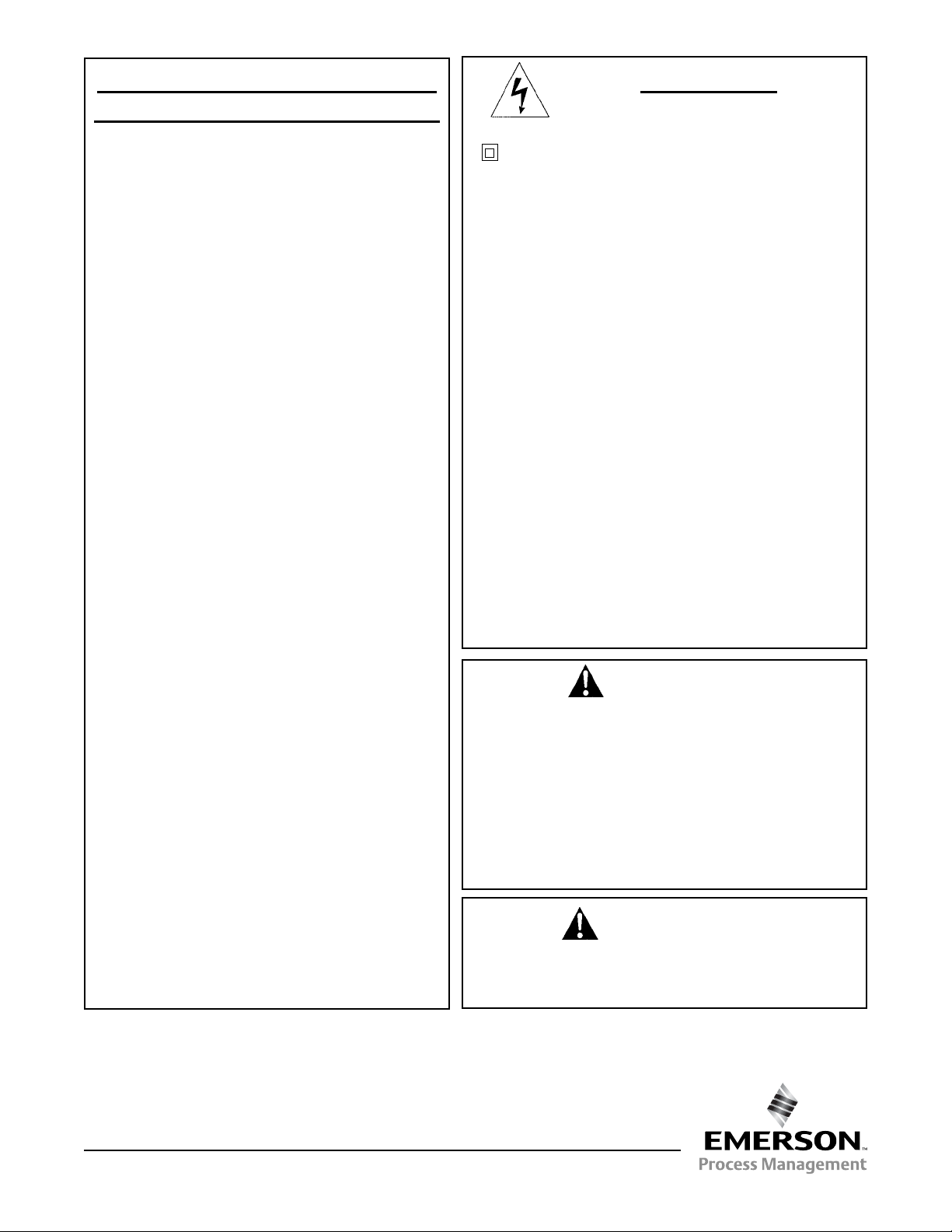

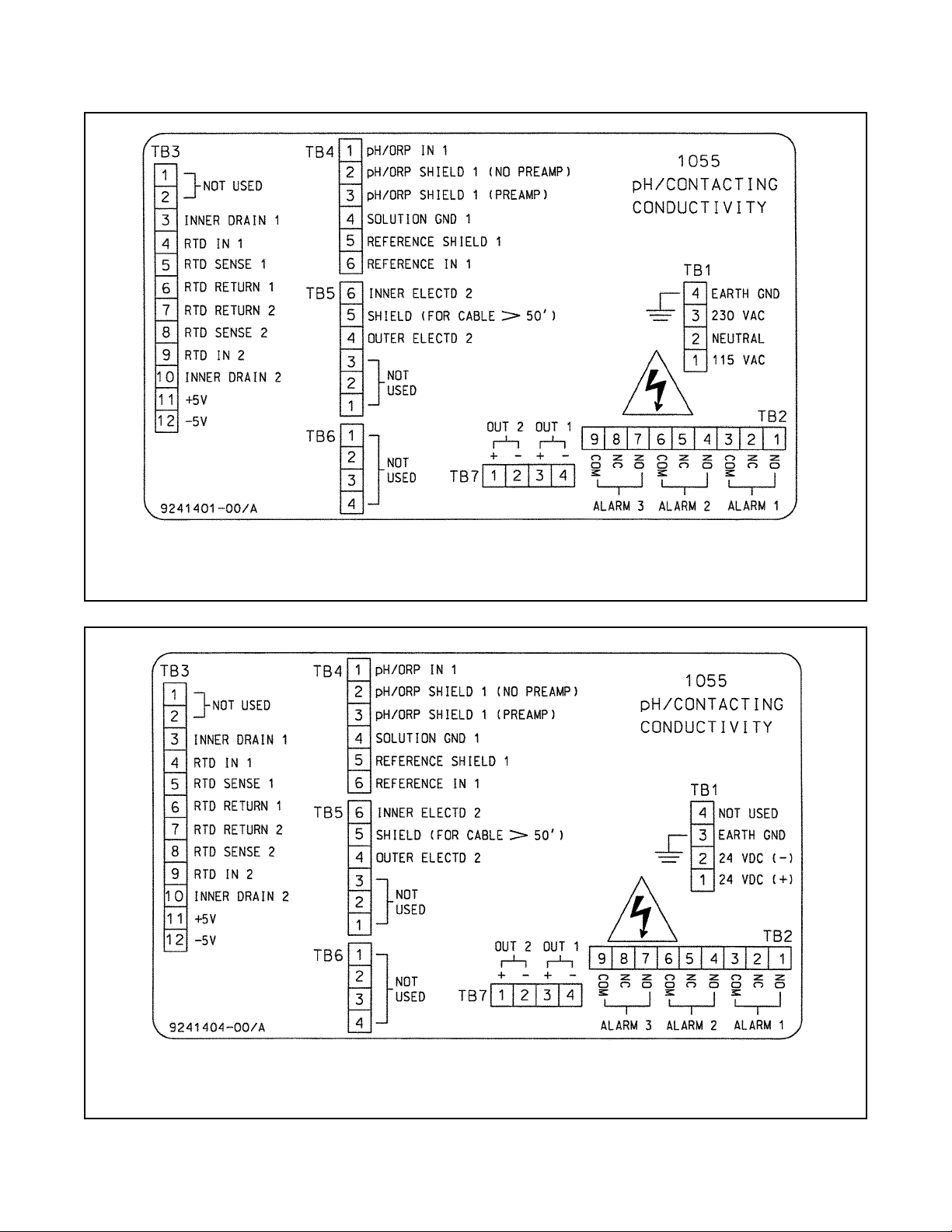

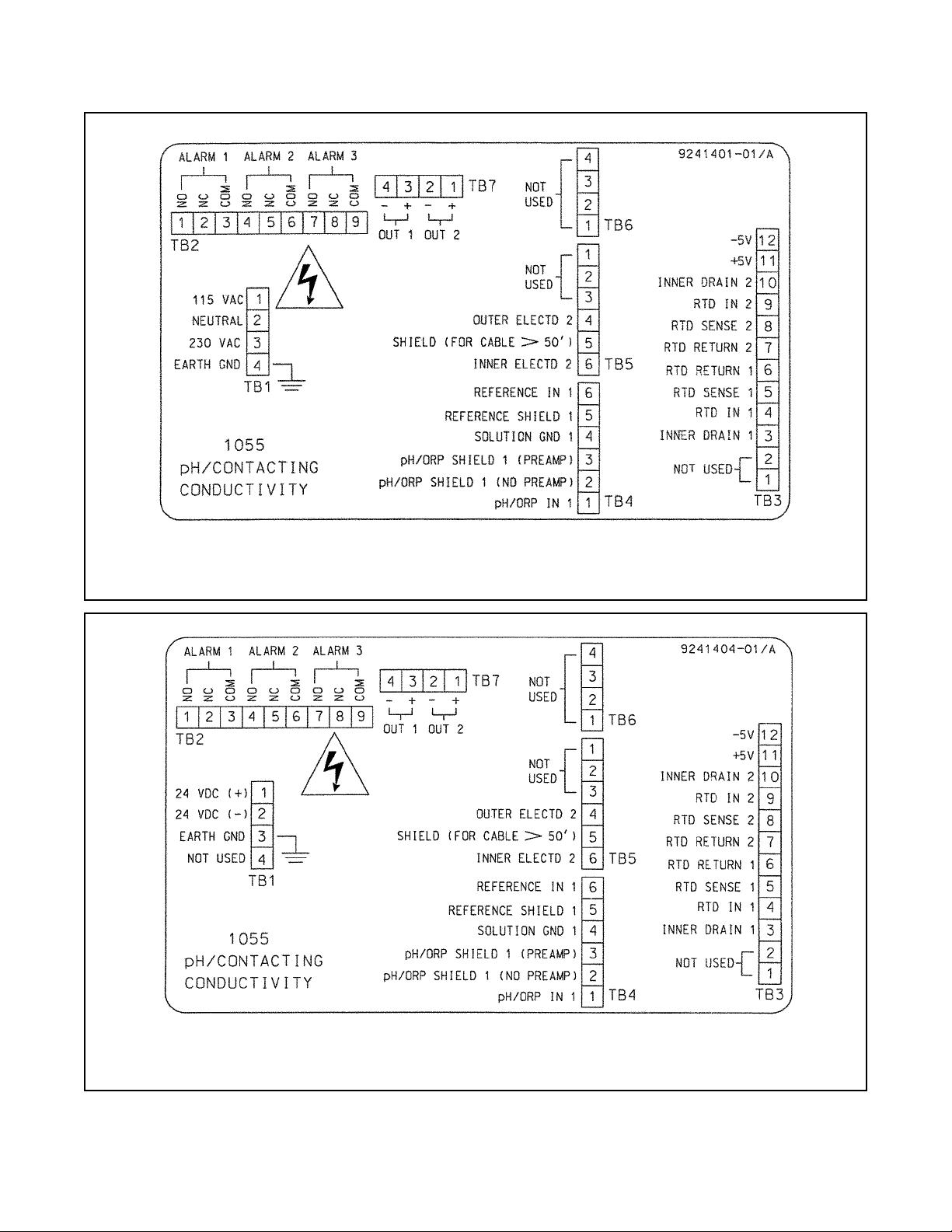

FIGURE 3-2. Wiring Connections for Solu Comp II Model 1055-01-10

(Panel Mount with 115/230 Vac Power)

FIGURE 3-3. Wiring Connections for Solu Comp II Model 1055-02-10

(Panel Mount with 24 Vdc Power)

Page 26

MODEL SOLU COMP II SECTION 3.0

WIRING

FIGURE 3-5. Wiring Connections for Solu Comp II Model 1055-02-11

(Surface/Pipe Mounting with 24 Vdc Power)

FIGURE 3-4. Wiring Connections for Solu Comp II Model 1055-01-11

(Surface/Pipe Mounting with 115/230 Vac Power)

17

Page 27

18

MODEL SOLU COMP II SECTION 3.0

WIRING

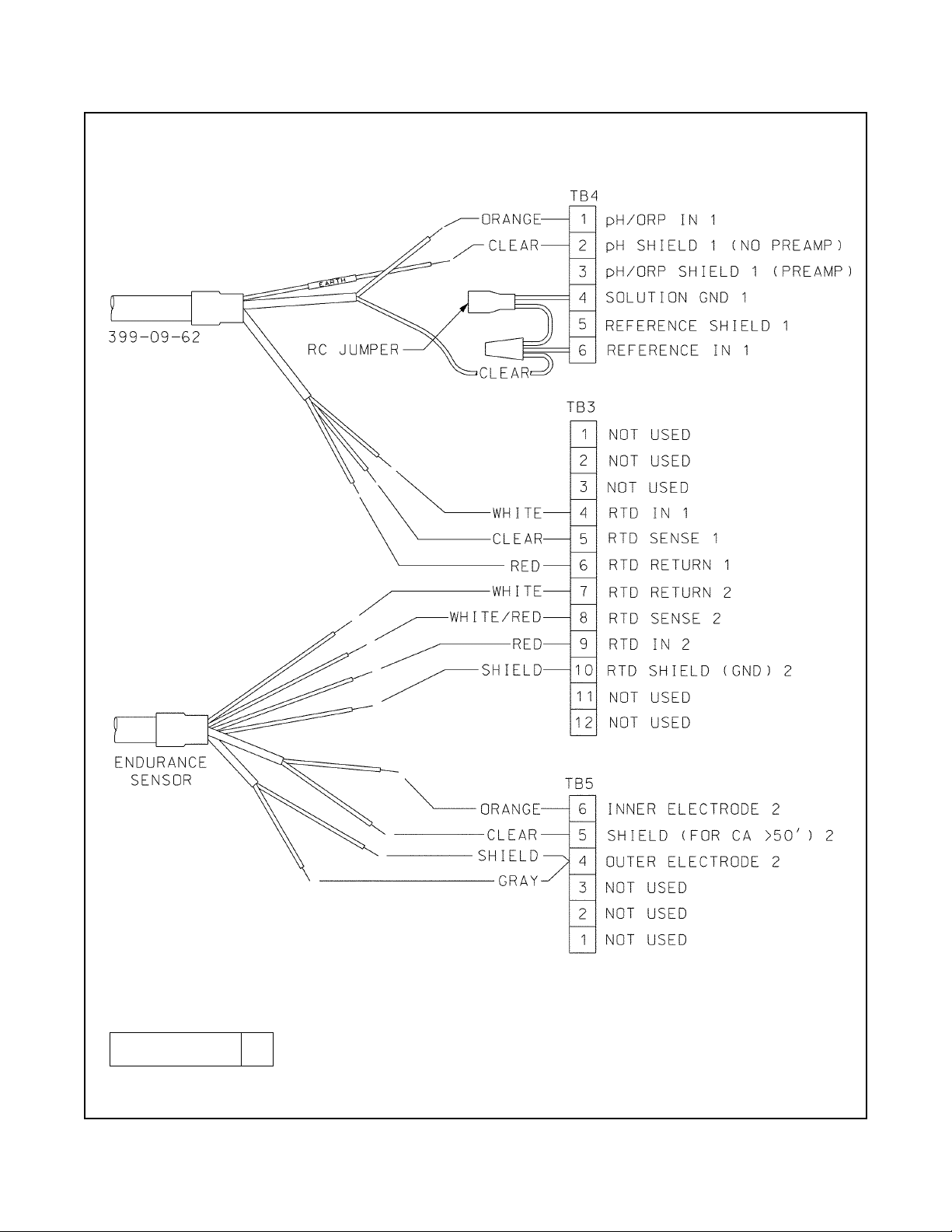

FIGURE 3-6. Panel Mount Wiring to Models 399-09-62, 400, 401, 402, 403, and 404.

DWG. NO. REV.

41055105 B

Page 28

MODEL SOLU COMP II SECTION 3.0

WIRING

19

FIGURE 3-7. Pipe/Wall Mount Wiring to Models 399-14, 400, 401, 402, 403, and 404.

DWG. NO. REV.

41055106 B

Page 29

20

MODEL SOLU COMP II SECTION 3.0

WIRING

FIGURE 3-8. Pipe/Wall Mount Wiring to Models 399VP-09, 400, 401, 402, 403, and 404.

DWG. NO. REV.

41055107 B

Page 30

MODEL SOLU COMP II SECTION 3.0

WIRING

21

FIGURE 3-9. Panel Mount Wiring to Models 399VP-09, 400, 401, 402, 403, and 404.

DWG. NO. REV.

41055108 B

Page 31

22

MODEL SOLU COMP II SECTION 3.0

WIRING

FIGURE 3-10. Pipe/Wall Mount Wiring to Models 399-09-62, 400, 401, 402, 403, and 404.

DWG. NO. REV.

41055109 B

Page 32

MODEL SOLU COMP II SECTION 3.0

WIRING

23

FIGURE 3-11. Panel Mount Wiring to Models 399-14, 400, 401, 402, 403, and 404.

DWG. NO. REV.

41055110 B

Page 33

24

MODEL SOLU COMP II SECTION 3.0

WIRING

FIGURE 3-12. Wiring Model 1055-11-22-32 to Models 399-09-62 and GP-1.

DWG. NO. REV.

40105536 C

Page 34

MODEL SOLU COMP II SECTION 3.0

WIRING

25

FIGURE 3-13. Wiring Model 1055-10-22-32 to Model 399-14

DWG. NO. REV.

40105559 E

FIGURE 3-14. Wiring Model 1055 to Model 320HP-58 and 400, 401, 402, 403, or 404

DWG. NO. REV.

41055112 C

Page 35

26

MODEL SOLU COMP II SECTION 4.0

DISPLAY AND OPERATION

SECTION 4.0

DISPLAY AND OPERATION

4.1 DISPLAY

4.2 KEYPAD

4.3 PROGRAMMING AND CALIBRATING THE SOLU COMP II - TUTORIAL

4.4 SECURITY

4.5 USING HOLD

4.1. DISPLAY

The Solu Comp II has a two-line display.

The display can be customized to meet

user requirements (see Section 5.11).

Figure 4-1 shows some of the displays

available during normal operation. View

A is the default screen for a dual sensor.

View B is the default screen for a single

sensor.

The Solu Comp II has information

screens that supplement the data in the

main display. Press or to view the

information screens. The last informa-

tion screen is the software version.

During calibration and programming,

key presses cause different displays to

appear. The displays are self-explanatory and guide the user step-by-step

through the procedure.

4.2 KEYPAD

Figure 4-2 shows the Solu Comp II keypad.

FIGURE 4-1. Displays During Normal Operation

Screen A shows pH measured by sensor 1 and conductivity measured by

sensor 2. Sensor 1 must always be pH, and sensor 2 must always be conductivity. Although Screen A is the most useful screen, other display

screens are possible. For example, Screen B shows data for sensor 1

(pH) only, and Screen C shows pH and conductivity, as well as temperature, measured by sensor 1 and 2.

FIGURE 4-2. Solu Comp II Keypad

Four arrow keys move the cursor around the screen. A blinking word or

numeral show the position of the cursor. The arrow keys are also used to

change the value of a numeral. Pressing ENTER stores numbers and settings and moves the display to the next screen. Pressing EXIT returns to

the previous screen without storing changes. Pressing MENU always

causes the main menu screen to appear. Pressing MENU followed by

EXIT causes the main display to appear.

Page 36

27

MODEL SOLU COMP II SECTION 4.0

DISPLAY AND OPERATION

4.3 PROGRAMMING AND CALIBRATING THE SOLU COMP II

- TUTORIAL

Setting up and calibrating the Solu Comp II is easy. The following tutorial

describes how to move around in the programming menus. For practice, the

tutorial also describes how to assign conductivity values to the 4 and 20 mA

outputs for sensor 1.

1. If the MENU screen (shown at the left) is not already showing, press

MENU. Calibrate is blinking, which means the cursor is on Calibrate.

2. To assign pH or conductivity values to current outputs, the Program sub-

menu must be open. Press . The cursor moves to Program (Program

blinking). Press ENTER. Pressing ENTER opens the Program sub-menu.

3. The Program sub-menu permits the user to set outputs, alarms, automatic or manual temperature compensation, and a security code. When

the sub-menu opens, Outputs is blinking, which means the cursor is on

Outputs. Press or (or any arrow key) to move the cursor around the

display. Move the cursor to >> and press ENTER to cause a second

screen with more program items to appear. There are three screens in the

Program menu. Pressing >> and ENTER in the third screen causes the

display to return to the first screen (Outputs, Alarms, Measurement).

4. For practice, assign pH values to the 4 and 20 mA outputs for sensor 1.

Move the cursor to Outputs and press ENTER.

5. The screen shown at left appears. The cursor is on Output Range (blinking). Output range is used to assign values to the low and high current outputs. Press ENTER.

6. The screen shown at left appears. The Solu Comp II has two outputs, output 1 and output 2. Move the cursor to the desired output and press

ENTER. For purposes of the example, choose Output 1.

7. The screen shown at left appears. Out1 S1 in the top line means output 1

(Out1) is assigned to sensor 1 (S1). Either output can be assigned to

either sensor (sensor and output assignments are made under the

Output Configure menu shown in step 5). Use the Out1 S1 Range?

screen to assign a pH value to the 4 mA output.

a. Use the arrow keys to change the pH to the desired value. Press or

to move the cursor from digit to digit. Press or to increase or

decrease the value of the digit. Holding or down causes the

numeral to continuously scroll up or down.

b. To move the decimal point, press or until the cursor is on the dec-

imal point. Press to move the decimal point to the right. Press to

move the decimal point to the left.

c. Press ENTER to store the setting.

8. The screen shown at left appears. Use this screen to assign a full scale

pH value to the 20 mA output. Use the arrow keys to change the pH to the

desired value. Press ENTER to store the setting.

9. The screen shown at left appears. To assign values to the low and high

currents for output 2, select Output 2 and follow the prompts.

10. To return to the main menu, press MENU. To return to the main display

press MENU then EXIT, or press EXIT repeatedly until the main display

appears. To return to the previous display press EXIT.

NOTE

To store values or settings, press ENTER before pressing EXIT.

CCaalliibbrraattee

Hold

Program Display

Calibrate Hold

PPrrooggrraamm

Display

OOuuttppuuttss

Alarms

Measurement >>

OOuuttppuutt RRaannggee

Output Configure

Output Range?

OOuuttppuutt11

Output2

Out1 S1 Range?

4mA

00

.00pH

Out1 S1 Range?

20mA

11

4.00pH

Output Range?

OOuuttppuutt11

Output2

Page 37

MODEL SOLU COMP II SECTION 4.0

DISPLAY AND OPERATION

1. If a security code has been programmed, pressing MENU causes the

security screen to appear.

2. Enter the three-digit security code.

3. If the entry is correct, the main menu screen appears. If the entry is incorrect, the Invalid Code screen appears. The Enter Security Code screen

reappears after 2 seconds.

Enter Security

Code

000000

Invalid Code

Calibrate

HHoolldd

Program Display

Hold Outputs and

Alarms?

YYeess

No

28

4.4 SECURITY

4.4.1 How the Security Code Works

Use the security code to prevent accidental or unwanted changes to program settings, displays, and calibration.

4.4.2 Bypassing the Security Code

Enter 555. The main menu will open.

4.4.3 Setting a Security Code

See Section 5.7.

4.5 USING HOLD

4.5.1 Purpose

The analyzer output is always proportional to measured pH or conductivity. To prevent unwanted alarms and

improper operation of control systems or dosing pumps, place the analyzer in hold before removing the sensor for

calibration and maintenance. Be sure to remove the analyzer from hold once

calibration is complete. During hold, both outputs remain at the last value. Once

in hold, the analyzer remains there indefinitely. While in hold, the screen

shown to the left appears periodically.

HHoolldd

4.5.2 Using the Hold Function

To choose a menu item, move the cursor to the item and press ENTER.

To store a number or setting, press ENTER.

1. Press MENU. The main menu screen appears. Choose Hold.

2. The Hold Outputs and Alarms ? screen appears. Choose Yes to place

the analyzer in hold. Choose No to take the analyzer out of hold.

3. The main display screen will appear.

Page 38

29

MODEL SOLU COMP II SECTION 5.0

PROGRAMMING THE ANALYZER

SECTION 5.0

PROGRAMMING THE ANALYZER

5.1 GENERAL

5.2 CHANGING STARTUP SETTINGS

5.3 CONFIGURING AND RANGING THE OUTPUTS

5.4 CONFIGURING ALARMS AND ASSIGNING SETPOINTS

5.5 SELECTING THE TYPE OF MEASUREMENT AND ACTIVATING SOLUTION

TEMPERATURE CORRECTION

5.6 CHOOSING TEMPERATURE UNITS AND MANUAL OR AUTOMATIC TEMPERATURE COMPENSATION

5.7 SETTING A SECURITY CODE

5.8 NOISE REJECTION

5.9 SINGLE SENSOR OR DUAL SENSOR INPUT

5.10 RESETTING FACTORY CALIBRATION AND FACTORY DEFAULT SETTINGS

5.11 SELECTING A DEFAULT SCREEN, LANGUAGE, AND SCREEN CONTRAST

5.1 GENERAL

This section describes how to do the following:

1. configure and assign values to the current outputs

2. configure and assign setpoints to the alarm relays

3. choose pH, ORP, redox, conductivity, resistivity, or TDS

4. choose temperature units and manual or automatic temperature mode

5. set a security code

6. tell the analyzer the frequency of the ac power (needed for optimum noise rejection)

7. tell the analyzer the number of sensors being used

8. reset the analyzer to factory calibration and default settings

9. select a default display screen

Default settings are shown in Table 5-1 on the following page. To change a default setting, refer to the section listed in the table. To reset default settings, see Section 5.10.

5.2 CHANGING STARTUP SETTINGS

When the Solu Comp II is powered up for the first time, startup screens appear. The screens prompt the user to

identify the number of sensors being used and whether pH, ORP, redox, conductivity, resistivity, or TDS is being

measured. If incorrect settings were entered at startup, enter the correct settings now. To change the number of

sensors refer to Section 5.9. To change the measurement, refer to Section 5.5.

FOR BEST RESULTS, ENTER THE NUMBER OF SENSORS BEING USED

(SECTION 5.9) AND WHETHER pH, ORP, REDOX, CONDUCTIVITY, RESISTIVITY, OR TDS IS BEING MEASURED (SECTION 5.5) BEFORE MAKING

OTHER PROGRAM SETTINGS.

Page 39

30

MODEL SOLU COMP II SECTION 5.0

PROGRAMMING THE ANALYZER

TABLE 5-1. DEFAULT SETTINGS

1. SENSOR-OUTPUT ASSIGNMENTS (pH, ORP, redox, conductivity, resistivity, or TDS is selected during Quick Start)

3. OUTPUT RANGES (pH, ORP, redox, conductivity, resistivity, or TDS is selected during Quick Start)

Measurement Range Section

pH 0 to 14 5.3

ORP/Redox -1400 to 1400 mV 5.3

Temperature 0 to 100°C 5.3

Resistivity 0.0 to 20 MΩ-cm 5.3

TDS 0 to 1000 ppm 5.3

Conductivity — 0.01/cm 0 to 10 µS/cm 5.3

Conductivity — 0.1/cm 0 to 100 µS/cm 5.3

Conductivity — 1.0/cm 0 to 1000 µS/cm 5.3

Conductivity — 10/cm 0 to 20 mS/cm 5.3

Sensor(s) Output 1 Output 2 Section

Single sensor pH/ORP/Redox Temperature 5.3 and 5.9

Dual sensor pH/ORP/Redox (sensor 1) Conductivity/Resistivity (sensor 2) 5.3 and 5.9

2. OTHER OUTPUT SETTINGS

Output Dampening 0 or 4 mA Mode Section

1 off 4 Linear 5.3

2 off 4 Linear 5.3

4. ALARM CONFIGURATION AND SETPOINTS

Alarm

1 2 3 Section

Assigned to Sensor 1 (pH, ORP) Sensor 2 (conductivity) (note 1) Fault 5.4

High or low High High (note 2) NA 5.4

Deadband 0 0 NA 5.4

Setpoint (pH) 14 (high); 0 (low) 14 (high); 0 (low) NA 5.4

Setpoint 1400 mV (high); -1400 (low) 1400 mV (high); -1400 (low) NA 5.4

(ORP/Redox)

Setpoint 1000 µS/cm (high); 0 (low) 1000 µS/cm (high); 0 (low) NA 5.4

(conductivity)

Setpoint 20 MΩ-cm (high); 0 (low) 20 MΩ-cm (high); 0 (low) NA 5.4

(resistivity)

Setpoint (TDS) 1000 ppm (high); 0 (low) 1000 ppm (high); 0 (low) NA 5.4

Note 1: For single sensor input, alarm 2 is assigned to sensor 1.

Note 2: For resistivity measurements, alarm is low.

Page 40

MODEL SOLU COMP II SECTION 5.0

PROGRAMMING THE ANALYZER

TABLE 5-1. DEFAULT SETTINGS (continued)

6. MISCELLANEOUS SETTINGS

Section

Language English 5.11

Hold off 4.5

Security code 000 (no security code) 5.7

ac power frequency 60 Hz 5.8

5. TEMPERATURE RELATED SETTINGS

Section

Units °C 5.6

Automatic temperature compensation (pH) On 5.6

Automatic temperature correction (conductivity) On 5.6

Solution temperature correction (pH) Off 5.5

Isopotential pH 7.00 5.5

Temperature correction (conductivity) neutral salt 5.5

Temperature slope 2%/°C 5.5

31

Page 41

32

MODEL SOLU COMP II SECTION 5.0

PROGRAMMING THE ANALYZER

5.3 CONFIGURING AND RANGING THE OUTPUTS.

5.3.1 Purpose

The Solu Comp II accepts input from a pH, ORP, or conductivity sensor and has two current outputs. This section

describes how to configure and range the outputs. CONFIGURE THE OUTPUTS FIRST.

1. Configuring an output means

a. Selecting either a 4-20 mA or 0-20 mA output,

b. Assigning a sensor and a measurement (pH, ORP, redox potential, conductivity, resistivity, or total dis-

solved solids [TDS]) to output 1 and output 2,

c. Turning on or turning off output current dampening,

d. Choosing a linear or logarithmic output.

2. Ranging the outputs means assigning values to the low (0 or 4 mA) and high (20 mA) outputs.

5.3.2 Definitions

1. CURRENT OUTPUTS. The analyzer provides either a continuous 4-20 mA or 0-20 mA output current directly

proportional to pH, ORP, redox potential, conductivity, resistivity, or TDS.

2. ASSIGNING OUTPUTS. Figure 5-1 shows the ways in which the outputs can be assigned.

3. DAMPEN. Output dampening smooths out noisy readings. It also increases the response time of the output.

With output dampening the time to reach 63% of final reading following a step change is 5 sec. Output dampening does not affect the response time of the display.

4. MODE. The current output can be made directly proportional to the displayed value (linear mode) or directly

proportional to the common logarithm of the displayed value (log mode).

FIGURE 5-1. Assigning Outputs 1 and 2

Page 42

MODEL SOLU COMP II SECTION 5.0

PROGRAMMING THE ANALYZER

5.3.3. Procedure: Configure Outputs.

To choose a menu item, move the cursor to the item and press ENTER.

To store a number or setting, press ENTER.

1. Press MENU. The main menu screen appears. Choose Program.

2. Choose Outputs.

3. Choose Output Configure.

4. Choose Output1 or Output2.

5. Choose Sensor1 (pH) or Sensor2 (conductivity). Either sensor can be

assigned to either output.

6. Choose Measurement or Temp. If the output selected was assigned to

Sensor 1, Measurement means pH, ORP, or redox. If the output selected was assigned to Sensor 2, Measurement means conductivity, resistivity, or TDS.

7. Make the appropriate settings:

a. Choose 4-20 mA or 0-20 mA.

b. Choose Yes or No for output dampening.

c. Choose Linear or Log output.

8. The display returns to the Output Config? screen. Select the other output or press EXIT to return to the previous screen. To return to the main

display, press MENU followed by EXIT.

5.3.4. Procedure: Assigning Values to the Low and High Current Outputs (Output Ranging)

To choose a menu item, move the cursor to the item and press ENTER.

To store a number or setting, press ENTER.

1. Press MENU. The main menu screen appears. Choose Program.

2. Choose Outputs.

3. Choose Output Range. Choose Output1 or Output2.

4. Make the appropriate settings.

a. Assign a value to the low current (0 mA or 4 mA) output.

b. Assign a value to the high current (20 mA) output.

5. The display returns to the Output Range screen. Select the other output

or press EXIT to return to the previous screen. To return to the main display, press MENU followed by EXIT.

Calibrate Hold

PPrrooggrraamm

Display

Output Config?

OOuuttppuutt11

Output2

OutM is for?

SSeennssoorr11

Sensor2

OutM is for?

MMeeaassuurreemmeenntt

Temp

Output Range

OOuuttppuutt CCoonnffiigguurree

OOuuttppuuttss

Alarms

Measurement >>

Calibrate Hold

PPrrooggrraamm

Display

OOuuttppuutt RRaannggee

Output Configure

OOuuttppuuttss

Alarms

Measurement >>

33

Page 43

34

Alarm relays are single pole-double throw (SPDT). When an alarm is activated, the coil is energized.

When an alarm activates, AL1, AL2, or AL3 (as appropriate) appears periodically in the display.

4. USP 24 ALARM. Any alarm, if assigned to sensor 2 (conductivity) can be configured as a USP 24 alarm. A

USP 24 alarm activates when the non-temperature-corrected conductivity (raw conductivity) of the water is

within a user-selectable percentage (safety range) of the USP 24 limit. For example, at 40°C the USP 24 limit

is 1.7 µS/cm. If the safety range is 10%, the USP 24 alarm activates when the raw conductivity exceeds 1.7 (0.1 x 1.7) or 1.53 µS/cm.

MODEL SOLU COMP II SECTION 5.0

PROGRAMMING THE ANALYZER

5.4 CONFIGURING ALARMS AND ASSIGNING SETPOINTS

5.4.1 Purpose

This section describes how to do the following:

1. assign an alarm relay to a sensor,

2. set the alarm logic to high or low,

3. assign values to the alarm setpoints,

4. set the alarm deadbands.

ALARM RELAYS MUST BE CONFIGURED BEFORE ASSIGNING SETPOINTS.

5.4.2 Definitions

1. ASSIGNING ALARMS. There are three alarms (AL1, AL2, and AL3). Alarms 1 and 2 can be assigned to any

sensor. For example, AL1 and AL2 can be assigned to sensor 1 with, perhaps, one alarm configured as a high

alarm and the other as a low alarm, and AL3 can be assigned to sensor 2. Alarm 3 can be assigned to either

sensor or used as a fault alarm. The fault alarm activates when a fault exists in a sensor or the analyzer.

2. FAULT ALARM. A fault condition exists when the Solu Comp II detects a problem with a sensor or with the analyzer that is likely to cause seriously erroneous readings. If Alarm 3 was programmed as a fault alarm, the

alarm 3 relay will activate. The word Fault will appear alternately in the display with the reading.

3. ALARM LOGIC, SETPOINTS, AND DEADBANDS. See Figures 5-2 and 5-3.

FIGURE 5-2. High Alarm Logic

The alarm activates when the pH exceeds the high

setpoint. The alarm remains activated until the reading

drops below the value determined by the deadband.

FIGURE 5-3. Low Alarm Logic

The alarm activates when the conductivity drops below the

low setpoint. The alarm remains activated until the reading

increases above the value determined by the deadband.

Page 44

35

MODEL SOLU COMP II SECTION 5.0

PROGRAMMING THE ANALYZER

5.4.3 Procedure: Configuring Alarms

To choose a menu item, move the cursor to the item and press ENTER.

To store a number or setting, press ENTER.

1. Press MENU. The main menu screen appears. Choose Program.

2. Choose Alarms.

3. Choose Alarm Configure.

4. Choose Alarm 1 (AL1), Alarm 2 (AL2), or Alarm 3 (AL3).

5. For AL1 or AL2

a. Choose Sensor 1 (pH) or Sensor 2 (conductivity).

b. Choose Measurement or Temp.

c. Choose High, Low or USP 24. USP 24 appears only if Sensor 2 was

selected.

d. Set the alarm Deadband.

6. The display returns to the Alarm Configure? screen. Select another

alarm or press EXIT to return to the previous screen. To return to the main

display, press MENU followed by EXIT.

7. For AL3

a. Choose Sensor1 (pH), Sensor2 (conductivity), or Fault.

b. For sensor 1 or 2, choose Measurement or Temp.

c. Choose High, Low or USP 24. USP 24 appears only if Sensor 2 was

selected. Set the deadband.

d. Choosing Fault means AL3 will activate when a sensor or analyzer

fault exists. There is no user setting to make.

8. The display returns to the Alarm Configure? screen. Select another

alarm or press EXIT to return to the previous screen. To return to the main

display, press MENU followed by EXIT.

Calibrate Hold

PPrrooggrraamm

Display

Alarm Setpoints

AAllaarrmm CCoonnffiigguurree

Alarm Config?

AALL11

AL2 AL3

AL1 is for?

SSeennssoorr11

Sensor2

AL1 S1 is for?

MMeeaassuurreemmeenntt

Temp

Outputs

AAllaarrmmss

Measurement >>

AL3 is for?

FFaauulltt

Sensor1 Sensor2

Page 45

36

MODEL SOLU COMP II SECTION 5.0

PROGRAMMING THE ANALYZER

5.4.4 Procedure: Programming Alarm Setpoints

To choose a menu item, move the cursor to the item and press ENTER.

To store a number or setting, press ENTER.

1. Press MENU. The main menu screen appears. Choose Program.

2. Choose Alarms.

3. Choose Alarm Setpoints.

4. Choose Alarm 1 (AL1), Alarm 2 (AL2), or Alarm 3 (AL3).

5. The display shows the alarm selected (AL1) and the configuration. The

alarm is for Sensor 1 (S1), and the logic is high. Use the arrow keys to

change the alarm setpoint.

6. If the alarm is USP 24, the display shows the alarm selected and the USP

safety margin. Change the safety margin to the desired value.

7. The display returns to the Select Alarm? screen. Select another alarm or

press EXIT to return to the previous screen. To return to the main display,

press MENU followed by EXIT.

Calibrate Hold

PPrrooggrraamm

Display

AAllaarrmm SSeettppooiinnttss

Alarm Configure

Select Alarm?

AALL11

AL2 AL3

AL1 S2 Setpoint?

USP24

11

0% Safety

AL1 S1 Setpoint?

High

11

4.00pH

Outputs

AAllaarrmmss

Measurement >>

Page 46

37

MODEL SOLU COMP II SECTION 5.0

PROGRAMMING THE ANALYZER

5.5 SELECTING THE TYPE OF MEASUREMENT AND ACTIVATING SOLUTION

TEMPERATURE CORRECTIONS

5.5.1 Purpose

This section describes how to do the following:

1. Program the Solu Comp II to measure pH, ORP, redox potential, conductivity, resistivity, or total dissolved

solids.

2. Enable or disable glass impedance fault.

3. Select a solution temperature correction for pH.

4. Change the analyzer pH isopotential point.

5. Select a solution temperature correction for conductivity.

5.5.2 Definitions — pH/ORP

1. ORP. ORP is oxidation-reduction potential. It is the voltage difference between a noble metal (usually plat-

inum) indicator electrode and a silver/silver chloride reference electrode.

2. REDOX. Redox is redox potential. Redox potential is measured the same way as ORP. The sign of the redox