Page 1

Rosemount™ RDO

Optical Dissolved Oxygen Sensor and Analyzer

Manual

LIQ-MAN-RDO, Rev B

May 2017

Page 2

Page 3

Contents

Contents

Chapter 1 Installation .......................................................................................................................1

1.1 Box contents .................................................................................................................................. 1

1.2 Optional mounting kit ....................................................................................................................1

1.3 Mounting options ...........................................................................................................................2

1.3.1 Analyzer dimensions ........................................................................................................2

1.3.2 Pipe mounting .................................................................................................................3

1.3.3 Wall mounting using mounting tabs ................................................................................5

1.3.4 Wall mounting with user-supplied screws and hardware ..................................................6

1.4 Installing dome connectors and plugs ............................................................................................ 7

Chapter 2 Wiring ............................................................................................................................. 9

2.1 Electrostatic discharge (ESD) recommendations ............................................................................ 9

2.2 Customer-supplied electrical equipment ........................................................................................9

2.3 Ensuring good electrical connections ............................................................................................. 9

2.4 AC power and high voltage relay connections .............................................................................. 10

2.5 Analog and digital outputs and low voltage relay connections ..................................................... 13

2.6 RDO probe wiring .........................................................................................................................16

2.7 Tighten dome connectors ............................................................................................................ 16

Chapter 3 Placing the RDO probe in service .................................................................................... 17

3.1 Unpacking ....................................................................................................................................17

3.2 Assembling the probe .................................................................................................................. 17

3.3 Installing the probe ...................................................................................................................... 18

Chapter 4 Display and Operation ....................................................................................................19

4.1 Display and keypad ...................................................................................................................... 19

4.2 Using the view function and customizing the display ....................................................................21

Chapter 5 Programming the analyzer .............................................................................................23

5.1 Initial configuration ......................................................................................................................23

5.2 Menu tree .................................................................................................................................... 25

5.3 Configuring the RDO probes ........................................................................................................ 25

5.3.1 Options (Barometer, Salinity, and Calibration Interval) .................................................. 26

5.3.2 Parameters (Concentration, Temperature, Saturation, and Partial Pressure ...................26

5.3.3 Replacing a probe .......................................................................................................... 27

5.3.4 Deleting a probe ............................................................................................................ 28

5.3.5 Adding a probe .............................................................................................................. 28

5.4 Configuring the analyzer .............................................................................................................. 28

5.5 Configuring outputs .....................................................................................................................29

5.5.1 Current loops .................................................................................................................29

5.5.2 Alarm relays ................................................................................................................... 30

5.6 Changing the date and time .........................................................................................................32

5.7 Changing the appearance of the screens ......................................................................................32

5.7.1 Locking the display ........................................................................................................ 32

5.7.2 Changing the display contrast ....................................................................................... 32

5.7.3 Changing the language ..................................................................................................32

5.8 Changing power settings ............................................................................................................. 33

5.9 Setting the polling (update) interval .............................................................................................33

Manual i

Page 4

Contents

5.10 RS485 communications ............................................................................................................... 33

5.10.1 Setting the device address for the analyzer .................................................................... 33

5.10.2 Setting RS485 parameters for the analyzer .................................................................... 33

5.11 Setting security codes .................................................................................................................. 34

5.12 Defaults ....................................................................................................................................... 34

5.13 Placing the output and relays on hold ...........................................................................................34

5.14 Diagnostics .................................................................................................................................. 35

Chapter 6 Calibration ..................................................................................................................... 37

6.1 Calibration options .......................................................................................................................37

6.2 One-point calibration (100% saturation) .......................................................................................38

6.3 Two-point calibration (100% and 0% saturation) ...........................................................................39

6.4 Concentration calibration .............................................................................................................41

Chapter 7 Maintenance .................................................................................................................. 43

7.1 Analyzer ....................................................................................................................................... 43

7.1.1 Cleaning the analyzer enclosure .................................................................................... 43

7.1.2 Replacing the dessicant ................................................................................................. 43

7.1.3 Replacing the clock battery ............................................................................................43

7.2 RDO probe ................................................................................................................................... 44

7.2.1 Cleaning the sensing cap ............................................................................................... 44

7.2.2 Cleaning the probe body ............................................................................................... 44

7.2.3 Cleaning the optical window ..........................................................................................44

7.2.4 Replacing the sensing cap ..............................................................................................45

7.2.5 Storing the probe .......................................................................................................... 46

7.3 Replacement parts ....................................................................................................................... 46

Chapter 8 Specifications .................................................................................................................47

8.1 RDO probe ................................................................................................................................... 47

8.2 RDO analyzer ............................................................................................................................... 47

ii Rosemount RDO

Page 5

1 Installation

1.1 Box contents

Remove the analyzer from the shipping box. The shipping box should contain:

• Analyzer (1)

• Enclosure plugs (5)

• Dome connectors (3)

• O-rings (6)

• Large lock nuts (6)

• Sealed dessicant pack (1) that will be placed in the installed analyzer

• Opened dessicant pack (1) that protected the instrument during shipping. Discard

after opening the analyzer.

Installation

WARNING!

Only properly trained and qualified personnel should install the RDO instrument described in

this manual. This instrument should be installed for use in nonhazardous locations only.

1.2 Optional mounting kit

The mounting kit (PN R0087560) contains the following:

• Two stainless steel mounting brackets

• Two 1 1/2 to 3 1/2 in. diameter hose clamps

• One package containing mounting tabs (4), nuts (4), and screws (4)

• DIN rail mounting brackets

The nuts and screws supplied with the mounting tabs are suitable for use with the

mounting brackets.

Manual 1

Page 6

Installation

1.3 Mounting options

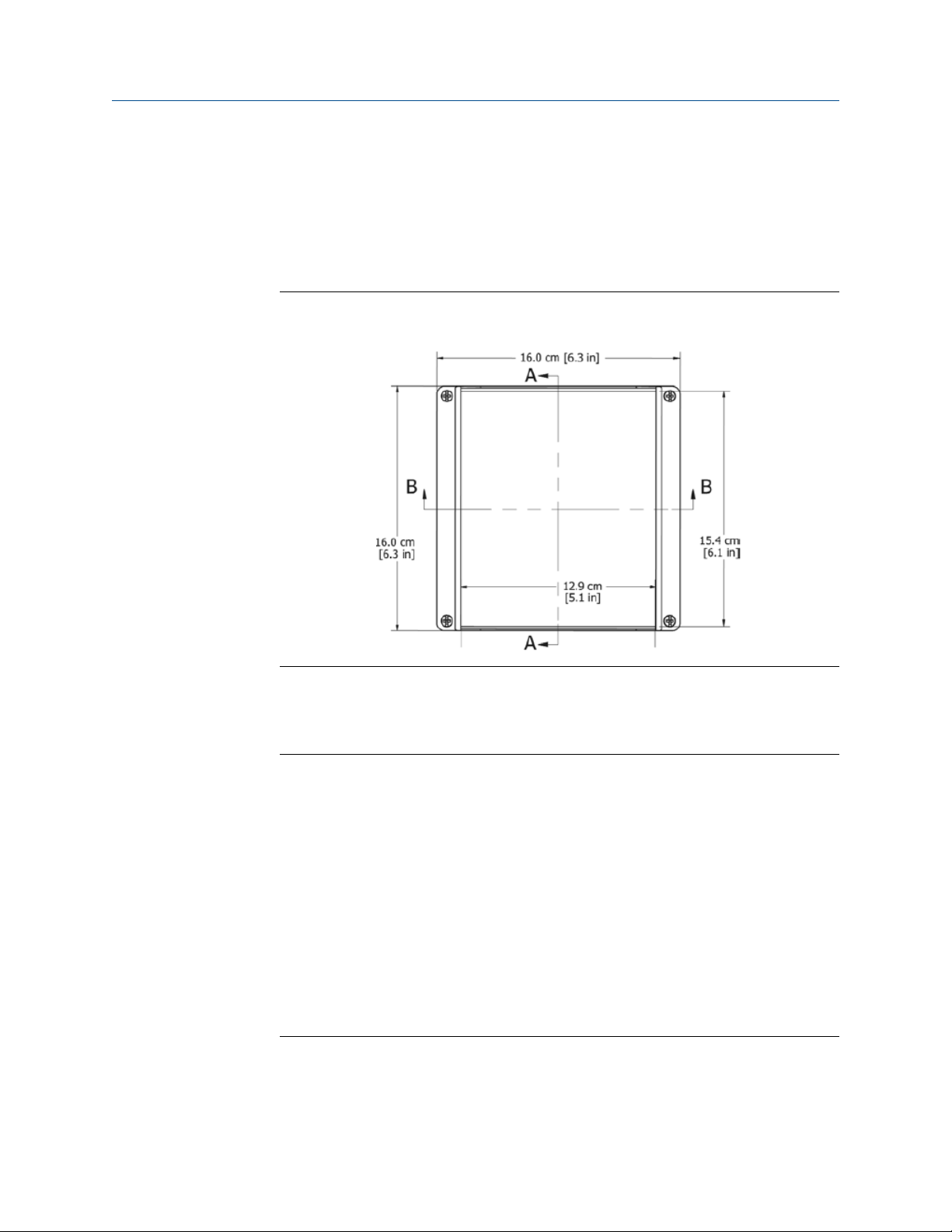

1.3.1 Analyzer dimensions

• Figure 1-1 calls out the analyzer dimensions with the lid closed.

Analyzer Dimensions with Lid ClosedFigure 1-1:

• Figure 1-2 shows the depth dimensions of the analyzer. When wall or panel

mounting, make sure to allow adequate space for opening the enclosure door or

making electrical connections.

Side View Dimensional DrawingsFigure 1-2:

2 Rosemount RDO

Page 7

1.3.2 Pipe mounting

Complete the following steps to mount the analyzer on a pipe.

1. Remove the four nuts and four screws from the mounting kit.

2. Open the enclosure and drop one nut into each drilled corner of the box (Figure 1-3).

Placing the Nut in the EnclosureFigure 1-3:

Installation

3. Use a screwdriver to push the nut down and set it in place (Figure 1-3).

Orient the two brackets on the back of the enclosure so that the flanges in the

4.

brackets point downward (Figure 1-4).

Manual 3

Page 8

Installation

Attaching the Mounting BracketsFigure 1-4:

5. Attach the mounting brackets to the enclosure using two screws for each bracket.

Make sure that the screws properly thread into the nuts you seated in steps 2 and 3.

6. Place two hose clamps over the mounting pipe and tighten them until they are

almost secure.

7. Place the flanges from the mounting bracket into each of the hose clamps

(Figure 1-3).

8. Tighten the hose clamps until the analyzer is secure on the pipe.

4 Rosemount RDO

Page 9

Installation

Back and Side View of Pipe-Mounted AnalyzerFigure 1-5:

1.3.3 Wall mounting using mounting tabs

The optional mounting kit contains a set of wall mounting hardware that includes four

screws, nuts, and tabs for mounting the analyzer to a wall or panel. Follow the instructions

included with the mounting tab hardware to attach the tabs (Figure 1-6).

Manual 5

Page 10

Installation

Back View of Analyzer with TabsFigure 1-6:

1.3.4 Wall mounting with user-supplied screws and hardware

You can supply your own hardware and attach the analyzer to a wall.

Figure 1-3 indicates the placement of the nut. Use a screw that is best suited for your wall

material (Figure 1-7).

6 Rosemount RDO

Page 11

Installation

Back View of AnalyzerFigure 1-7:

1.4 Installing dome connectors and plugs

Complete the following steps to install the dome connector and plugs.

1.

Place the O-ring over the threaded end of the connector or plug.

2. Screw the connector or plug into the opening until it is snug. Then tighten an

additional 1/2 turn.

Do not overtighten.

3. Place the lock nut concave side down on the threads and, using a screwdriver blade

and mallet, tighten the lock nut until there is approximately one thread showing.

4. Thread cable through the dome connectors and secure by tightening the nut to

about 15 in.-lb of torque.

Confirm that cable does not slide or wiggle after the nut has been tightened. Leave

sufficient cable inside the enclosure to make secure connections without placing

stresss on the cable.

Manual 7

Page 12

Installation

Attached plug (left) and attached dome connector (right)Figure 1-8:

8 Rosemount RDO

Page 13

2 Wiring

WARNING!

Only properly trained and qualified personnel should install the RDO instrument described in

this manual. This instrument should be installed for use in nonhazardous locations only.

2.1 Electrostatic discharge (ESD) recommendations

• Before making wiring connections or touching circuit boards or other internal

components, discharge any static electricity from your body by touching a

grounded metal object.

• When making wiring connections, make sure to remain properly grounded by

wearing an ESD wriest strap or similar device.

Wiring

2.2 Customer-supplied electrical equipment

You must supply the following:

• 18-12 AWG wire for electrical connections using conduit or 100-240 Vac power

supply

• 24-12 AWG cable for connecting relays and PLC devices

• A 100-240 Vac or 9-36 Vdc source with over current/disconnect protection for hard-

wired locations using conduit

• Approved suitable wiring for cord-connected plug and socket locations

2.3 Ensuring good electrical connections

To ensure that all sensors and power sourced function properly, make sure that:

• Each individual wire is stripped and tinned to 1/4 in.

• Each wire is tightly screwed into the terminal strip.

• Each wire is touching the terminal strip. If the plastic wire jacket is clamped into the

terminal strip, connections will not be made.

• Clip or cap any unused wires.

Manual 9

Page 14

Wiring

2.4 AC power and high voltage relay connections

The AC power board is located under the metal shield on the right side of the enclosure.

The terminal strip on the board accommodates the AC power connections as well as two

high voltage relay connections.

WARNING!

ELECTRIC SHOCK

Make sure that power to the instrument is disconnected before making any wiring

connections.

WARNING!

ELECTRIC SHOCK

Do not connect low voltage circuits (< 50 V) to the terminal connectors on the AC board!

See Figure 2-1.

10 Rosemount RDO

Page 15

Wiring

AC Circuit Board and Terminal ConnectionsFigure 2-1:

Procedure

1.

Remove the front cover of the enclosure.

2. Remove the metal AC power board cover.

3. Thread the power cable and relay wires (if needed) through the dome fittings

nearest the power board.

4. Using the green screw, connect the green earth wire of the power cable to the metal

frame in the bottom of the enclosure.

See Figure 2-2. A green wire connecting the metal frame to the terminal strip should

already be in place.

Manual 11

Page 16

Wiring

Figure 2-2:

Connect the Ground Wire to the Metal Frame Using the Green

Screw

5. Connect the live and neutral power wires to the L and N terminals.

See Figure 2-1.

Terminal Description North America color Euro color

L Live Black Brown

N Neutral White Blue

Protective earth Green Green and yellow

6. Connect relay wires (if required) to the terminal strip.

See Figure 2-1.

Terminal Description

COM Common

NC1 or NC2 Normally closed

NO1 or NO2 Normally open

7. Replace the metal AC power board cover.

Replace the front cover of the enclosure.

8.

Be sure the dessicant pack (PN R0087630) is present.

12 Rosemount RDO

Page 17

2.5 Analog and digital outputs and low voltage relay connections

Complete the following steps to connect the analog and digital outputs and low voltage

relay.

WARNING!

ELECTRIC SHOCK

Make sure that the power to the instrument is disconnected before making any wiring

connections.

WARNING!

ELECTRIC SHOCK

The maximum voltage that can be applied across the loop terminals is 36 V.

WARNING!

Wiring

ELECTRIC SHOCK

Do not connect high voltage circuits (> 50 V) to the terminal connections on the I/O board!

Procedure

1. Remove the front cover of the enclosure.

2. Connect the digital output (Modbus/RS-485) to the PLC terminals.

See Figure 2-3. There is no connection to the GND and POWER terminals. However,

the analyzer supplies 24 Vdc to the GND and POWER terminals, which can be used

to power external accessories.

Terminal Description

GND Signal ground

485- RS-485 negative

485+ RS-485 positive

POWER 24 Vdc

Manual 13

Page 18

Wiring

Input/output boardFigure 2-3:

3. Wire the analog current loops to the 4-20 mA terminals.

Each analog output loop must be powered separately. The maximum voltage at the

terminal must not exceed 36 Vdc. The minimum voltage is 9 Vdc.

Terminal Description

LOOP2- To negative end of device

LOOP2+ To positive end of device

LOOP1- To negative end of device

14 Rosemount RDO

Page 19

Terminal Description

LOOP1+ To positive end of device

GREEN EARTH Cable shield

4. Connect the shield to the green earth ground screw.

See Figure 2-4. Do not ground the device at both ends of the cable.

Earth Ground Screws for Analog Outputs and SensorsFigure 2-4:

Wiring

5. Make the low voltage relay connections.

Important

Do not apply more than 50 V across the low voltage relays.

Terminal Description

GND Signal ground

COM1 or COM2 Common

NC1 or NC2 Normally closed

NO1 or NO2 Normally open

6. Replace the front cover of the enclosure.

Be sure the dessicant pack (PN R0087630) is present.

Manual 15

Page 20

Wiring

2.6 RDO probe wiring

Complete the following steps to wire the RDO probe.

WARNING!

ELECTRIC SHOCK

Make sure that power to the instrument is disconnected before making any wiring

connections.

Procedure

1. Remove the front cover of the enclosure.

2. Wire the RDO probe to the PROBE A or PROBE B terminals on the input/output card.

Terminal Description Wire color

GND Signal ground Black

485A- RS485 negative Green

485+ RS485 positive Blue

POWER Input DC/Output AC Red

GREEN EARTH Shield Shield

3. Connect shield wire to the green earth ground screw.

See Figure 2-4.

4. Cut off or cap the unused brown and white wires.

5. Replace the front cover of the enclosure.

Be sure that the dessicant pack (PN R0087630) is present.

2.7 Tighten dome connectors

The dome connectors installed in Section 1.4 must be tightened securely after the sensor

and electrical cables have been routed through them. The dome connectors are not meant

to be weight bearing. Be sure that:

• The cable does not slide or wiggle after the nut has been tightened.

• Sufficient cable has been threaded through the connector so that secure wiring

connections remain secure.

• There is no weight or force from water pulling on the cable.

16 Rosemount RDO

Page 21

Placing the RDO probe in service

3 Placing the RDO probe in service

3.1 Unpacking

Remove the probe and sensing cap from the box. The sensing cap is shipped in a small

plastic cylinder inserted in a hole in the internal cardboard packaging.

3.2 Assembling the probe

Complete the following steps to assemble the RDO probe.

1. Unscrew the nose cone from the probe and remove the red protective dust cap.

Save the dust cap for later use. Make sure the O-ring grooves are dry and the O-rings

are not rolled or pinched.

2. Remove the RDO sensing cap from its shipping/storage sleeve.

The expected operating lifetime of the cap is two years after the first reading has

been taken. Install the cap by the date printed on the packaging (for PN

R00804230X only).

Note

Keep the cap in its sealed packaging until you are ready to install it. Install promptly. Avoid

allowing moisture, including humidity, inside the cap.

3. Align the arrow on the cap with the index mark on the probe and firmly press the cap

onto the probe, without twisting, until it seals.

Manual 17

Page 22

Placing the RDO probe in service

4. Reattach the nose cone.

Note

The nose cone must be in place whenever the probe is submerged in water.

5. Wire the probe to the analyzer.

See Section 2.6.

Note

If you are replacing an existing RDO probe with a new probe, the analyzer may not recognize

the new probe. If this is the case, the main display will show the probe not talking icon (letter A

or B in reverse video). To establish communication, follow the procedure in Section 5.3.

3.3 Installing the probe

The RDO dissolved oxygen probe can be submerged in basins or ponds.

The nose cone and the thermistor (the small metal disc on the side of the sensor about

1/6 in. [3 mm] above the nose cone) must be completely submerged. Use the 1 1/4 in.

FNPT fitting at the rear of the probe to attach it to a pipe. Be sure the connection is

watertight and the upper end of the pipe is closed to keep out water.

CAUTION!

EQUIPMENT DAMAGE

Do not allow the back end of the sensor to get wet.

18 Rosemount RDO

Page 23

4 Display and Operation

4.1 Display and keypad

Figure 4-1 shows the keypad and display window.

Keypad and displayFigure 4-1:

Display and Operation

The Up/Left arrow key has three functions: it moves the cursor to the left; it moves the

cursor up a list; it increases the value of a digit. The Down/Right arrow key has three

functions: it moves the cursor to the right; it moves the cursor down a list; it reduces the

value of a digit. The left and right function keys perform the operation shown in the screen

immediately above the key.

The main display has two lines. The measurement from probe A appears in the top line,

and the measurement from probe B appears in the bottom line. If no probe B is connected,

a row labeled C appears. References to probe C refer to the analyzer, which is called the

ConTROLL Pro. See Figure 4-2.

Manual 19

Page 24

Display and Operation

Two-line displayFigure 4-2:

Lines labeled A and B refer to probes A and B. C refers to measurements made by the analyzer. See also

Section 4.2.

Display Icons and Their DescriptionsTable 4-1:

Icon Description

Error with parameter

Calibration stabilizing

Calibration stable

View

View locked

View unlocked

Factory calibration for RDO cap has expired.

User calibration has expired, based on the Calibrate Interval.

Probe A not talking

Probe B not talking

Relay 1 active

Relay 2 active

20 Rosemount RDO

Page 25

Display and Operation

4.2 Using the view function and customizing the display

The view function allows you to view parameters measured by each probe and the

analyzer. It also allows you to customize the display.

1. Select the View option.

An arrow points to the first line in the display.

2. Select View again to move the arrow to the second line in the display.

3. With the arrow pointing at any line, use the Up and Down arrow keys to cycle

through the parameters being measured by the probe and analyzer.

4. To customize the display, move the arrow to the desired line and press the Up or

Down arrow key until the desired measurement appears. Then select View to move

to the next line.

Manual 21

Page 26

Display and Operation

22 Rosemount RDO

Page 27

5 Programming the analyzer

5.1 Initial configuration

Enter the following information upon first use or any time after you have restored the

default settings.

1. Choose English, Spanish, or French. Use the arrow keys to move up or down to the

appropriate language. Select Enter.

2. Use the arrow keys to adjust the contrast level. Select Enter.

3. Enter the time zone.

a. Refer to Table 5-1. Choose the appropriate time zone and find the corresponding

UTC value (Universal Time, Coordinated, formerly GMT).

Selected Regions and Their Time in UTCTable 5-1:

Region UTC value (± numeric value)

Australia Northern Territory +9.5

Australia Lord Howe Island +10.5 (Daylight Savings Time +11)

Australia New South Wales +10 (Daylight Savings Time +11)

Australia Queensland +10

Australia Victoria +10 (Daylight Savings Time +11)

Australia Australian Cap. Terr. +10 (Daylight Savings Time +11)

Australia South +9.5 (Daylight Savings Time +10.5)

Australia Tasmania +10 (Daylight Savings Time +11)

Australia Western +8

Canada Central -6 (Daylight Savings Time -5)

Canada Eastern -5 (Daylight Savings Time -4)

Canada Mountain -7 (Daylight Savings Time -6)

Canada Yukon & Pacific -8 (Daylight Savings Time -7)

Canada Atlantic -4 (Daylight Savings Time -3)

Canada Newfoundland -3.5 (Daylight Savings Time -2.5)

England 0 hours (Daylight Savings Time (+1)

USA Puerto Rico -4

USA Central -6 (Daylight Savings Time -5)

USA Eastern -5 (Daylight Savings Time -4)

USA Mountain -7 (Daylight Savings Time -6)

USA Arizona -7

USA Indiana East -5

Programming the analyzer

Manual 23

Page 28

Programming the analyzer

4. Enter the date using the Up/Left arrow key. Select Enter.

5. Enter the time using the Up/Left arrow key. Select Enter.

Selected Regions and Their Time in UTC (continued)Table 5-1:

Region UTC value (± numeric value)

USA Pacific -8 (Daylight Savings Time -7)

USA Alaska -9 (Daylight Savings Time -8)

USA Aleutian -10

USA Hawaii -10

b. Use the Up/Left arrow key to enter a positive or negative value.

c. Press the Down/Right arrow key to move to the appropriate numeric position.

d. Use the Up/Left arrow key to enter the correct numeric value. Repeat for

additional digits as needed.

e. Select Enter.

The Add Probe A screen appears. The name of the probe wired in the position also

appears.

6. Select Enter to configure this probe.

The Add Probe B screen appears. The name of the probe wired in this position also

appears. If there is no probe B, the display shows Probe not connected.

7. Select Enter to configure this probe if it exists or to proceed to the next screen if it

does not.

The main display appears.

For additional information on setting up the probes, see Section 5.3.3 and Section 5.3.4.

24 Rosemount RDO

Page 29

5.2 Menu tree

The menu tree for the analyzer is shown in Figure 5-1.

Menu TreeFigure 5-1:

Calibrate Hold outputs Settings Diagnostics

Saturation

One point

Two point

Concentration

Default

Programming the analyzer

Menu

Probes

(A or B)

Options

Barometer

Salinity

Cal Interval

Parameters

Concentration*

Temperature*

Saturation*

Pressure*

Replace probe

Delete probe

Probe C

(analyzer)

Barometer*

Temperature*

Outputs

Current loops

Enable/disable

Parameter

4-20 mA values

Trim

Relays

Enable/disable

High/low

Parameter

Setpoint

Deadband

Test

Date and

time

Note

*For each parameter:

• Enable or disable

• Choose units

• Choose resolution

• Set sentinel

5.3 Configuring the RDO probes

Display

Lock/unlock

Contrast

Language

Power save

Polling interval

Communications

Device address

RS485 parameters

Security code

Default

Configure the RDO probes one at a time.

There are four submenus available for each probe: Options, Parameters, Replace Probe,

and Delete Probe.

Manual 25

Page 30

Programming the analyzer

5.3.1 Options (Barometer, Salinity, and Calibration Interval)

Three settings can be made under Options.

• Barometer: The analyzer has a built-in pressure sensor to measure barometric

pressure, which is needed for percent saturation (air) calibration. Emerson strongly

recommends the use of automatic barometric pressure.

• Salinity: Salinity is an important setting if dissolved oxygen is being measured in

brackish water and percent saturation (air) calibration is being used to calibrate the

probe.

• Calibration Interval: The analyzer can be programmed to remind you when a calibration

is due.

1.

Select Menu > Settings > Probes. Select RDO Probe A or RDO Probe B, if it is present,

and then select Options.

2. Scroll to Barometer and then select it. The choices are Fixed and Automatic. If you

choose Fixed, enter the barometric pressure here before you start percent saturation

(air) calibration. If you choose Automatic, the analyzer automatically measures the

barometric pressure and uses it during percent saturation (air) calibration.

3. Scroll to Salinity and select it. Choose Fixed. Automatic is not available. Enter the salinity

of the process water in PSU (practical salinity units in parts per thousand).

4. Scroll to Calibration Interval. Select a calibration interval. The analyzer will display a

message when the next calibration is due.

5.3.2 Parameters (Concentration, Temperature, Saturation, and Partial Pressure

Each RDO probe can measure concentration, temperature, percent saturation, and partial

pressure. There are four settings to make for each parameter.

• Enable or disable the measurement. If the measurement is enabled, the probe

makes the measurement, and the analyzer displays the result. If the measurement is

disabled, the probe does not make the measurement.

• Select units in which measurement results will be displayed.

• Set the display resolution.

• Set a sentinel. The sentinel is the value that will be displayed when the probe returns

an error condition for the measurement.

Procedure

1.

Select Menu > Settings > Probes.

2. Select RDO Probe A or RDO Probe B, if it is present, and then select Parameters.

3. Select Concentration.

a. Press the Select key to toggle between Enable and Disable.

If the box is checked, Concentration has been selected.

b. Scroll to Units and select it. Choose between mg/L and ug/L.

26 Rosemount RDO

Page 31

Programming the analyzer

c. Scroll to Resolution. Press Select repeatedly to change the resolution.

The setting is stored as soon as you press any key to leave.

d. Scroll to Sentinel and press Select. Use the arrow keys to change the setting.

4. Select Temperature.

a. Press Select to toggle between Enable and Disable.

If the box is checked, Temperature has been selected.

b. Scroll to Units and select it. Choose between °C and °F.

c. Scroll to Resolution. Press Select repeatedly to change the resolution.

The setting is stored as soon as you press any key to leave.

d. Scroll to Sentinel and press Select. Use the arrow keys to change the setting.

5. Select Saturation.

a. Press Select to toggle between Enable and Disable.

If the box is checked, Percent Saturation has been selected.

b. Scroll to Units.

There is no selection to make. the units are % saturation.

c. Scroll to Resolution. Press Select repeatedly to change the resolution.

The setting is stored as soon as you press any key to leave.

d. Scroll to Sentinel and press Select. Use the arrow keys to change the setting.

6. Select Pressure.

a. Press Select to toggle between Enable and Disable.

If the box is checked, Partial Pressure has been selected.

b. Scroll to Units.

There is no selection to make. The units are torr.

c. Scroll to Resolution. Press Select repeatedly to change the resolution.

The setting is stored as soon as you press any key to leave.

d. Scroll to Sentinel and press Select. Use the arrow keys to change the setting.

5.3.3 Replacing a probe

If you replace the RDO probe with another RDO probe, use Replace Probe to transfer the

existing setting to the new probe.

Manual 27

Page 32

Programming the analyzer

1. Disconnect the existing RDO probe and replace it with the new probe.

See Section 3.3.

2. Select Menu > Settings > Probes. Select RDO Probe A or RDO Probe B, if it is present,

and then select Replace Probe.

The analyzer automatically configures the new probe.

3. Press and hold Back to return to the main display.

5.3.4 Deleting a probe

If you plan to permanently remove a probe, follow the steps below.

1.

Select Menu > Settings > Probes.

2. Highlight the probe you wish to delete and press Select.

3. Scroll to Delete Probe.

4. Press Select and then Enter to confirm.

The probe is deleted from the configuration.

5.3.5 Adding a probe

To add a probe, follow the steps below.

1.

Select Menu > Settings > Probes.

2. Select Probe A or Probe B and then Add Probe.

The Add Probe screen appears with the name of the sensor that is wired in this

position. If there is no Probe B, the display says No probe connected.

3. Select Enter to add the probe.

5.4 Configuring the analyzer

The analyzer (called the ConTROLL PRO) measures two parameters, barometric pressure

and temperature. There are four settings to make for each parameter.

• Enable or disable the measurement. If the measurement is enabled, the analyzer

makes the measurement and displays the result. If the measurement is disabled, the

analyzer does not make the measurement.

• Select units in which measurement results will be displayed.

• Set the display resolution.

• Set a sentinel. The sentinel is the value that will be displayed when the analyzer

returns an error condition for the parameter.

Procedure

1.

Select Menu > Settings > Probes. Select ConTROLL PRO.

28 Rosemount RDO

Page 33

Programming the analyzer

2. Select Barometer.

a. Press Select to toggle between Enable and Disable.

If the box is checked, barometric pressure has been selected.

b. Scroll to Units and select it. Choose the desired units for barometric pressure.

c. Scroll to Resolution. Press Select repeatedly to change the resolution.

The setting is stored as soon as you press any key to leave.

d. Scroll to Sentinel and press Select. Use the arrow keys to change the setting.

3. Select Temperature.

a. Press Select to toggle between Enable and Disable.

If the box is checked, temperature has been selected.

b. Scroll to Units and select it. Choose the desired units for temperature.

c. Scroll to Resolution. Press Select repeatedly to change the resolution.

The setting is stored as soon as you press any key to leave.

d. Scroll to Sentinel and press Select. Use the arrow keys to change the setting.

5.5 Configuring outputs

Outputs refer to the analog current loops and the alarm relays.

Important

Configure the probes before configuring the outputs.

5.5.1 Current loops

There are six settings to make:

• Enable/Disable: Choose to enable or disable the output loop.

• Parameter: Assign a probe and parameter to the output.

• 4 mA Value: Enter the value to correspond with 4 mA.

• 20 mA Value: Enter the value to correspond with 20 mA.

• 4 mA Trim: Adjust the 4 mA value of the analyzer to achieve a loop current of 4 mA.

• 20 mA Trim: Adjust the 20 mA value of the analyzer to achieve a loop current of

20 mA.

Procedure

1.

Select Menu > Settings > Outputs > Current Loops.

2. Choose current loop 1 or current loop 2.

3. Scroll to Enable/Disable and select it. Press Select to toggle between Enable and Disable.

Manual 29

Page 34

Programming the analyzer

If the box is checked, the current loop has been enabled.

4. Scroll to Parameter and select it. Scroll through the list of probes and measurements.

A is probe A, B is probe B, and C is the analyzer.

5. Scroll to 4 mA value and select it. Use the arrow keys to change the setting.

6. Scroll to 20 mA value and select it. Use the arrow keys to change the setting.

7. Scroll to 4 mA Trim. Use the arrow keys to adjust the loop current to 4 mA.

8. Scroll to 20 mA Trim. Use the arrow keys to adjust the loop current to 20 mA.

5.5.2 Alarm relays

There are six settings to make.

• Enable/Disable: Choose to enable or disable the relay.

• Mode: Choose High Alarm or Low Alarm.

• Parameter: Assign a probe and a parameter to the relay.

• Setpoint: See Figure 5-2.

• Deadband: See Figure 5-2.

• Test: Manually energize or de-energize a relay to test it.

30 Rosemount RDO

Page 35

Programming the analyzer

High and Low Alarm Relay ActionFigure 5-2:

Procedure

Select Menu > Settings > Outputs > Relays.

1.

2. Choose Relay 1 or Relay 2.

For each relay, there is a high voltage and low voltage relay. Configuring the relay

configures both the high voltage and low voltage relay.

3. Scroll to Enable/Disable and select it. Press Select to toggle between Enable and

Disable.

If the box is checked, the relay has been enabled.

4. Scroll to Mode and select it. Choose High alarm or Low alarm.

5. Scroll to Parameter and select it. Scroll through the list of probes and measurements.

A is probe A, B is probe B, and C is the analyzer.

6. Scroll to Setpoint and select it. Use the arrow keys to change the setting.

7. Scroll to Deadband and select it. Use the arrow keys to change the setting.

Manual 31

Page 36

Programming the analyzer

8. Scroll to Test and select it. Use the arrow keys to change from yes to no.

5.6 Changing the date and time

Complete the following steps to change the date and time on the RDO analyzer.

1.

Select Menu > Settings > Date & Time.

Three menu items appear:

• Date shown as yyyy-mm-dd

• Time shown as hh:mm:ss (24 hour clock)

• UTC shown as ±xx:xx (see Table 5-1)

2. Scroll to the menu item and select it.

3. Use the arrow keys to change the setting.

4. Select Enter.

5.7 Changing the appearance of the screens

5.7.1 Locking the display

Locking the display prevents the operator from scrolling through the measurement

parameters using the View function.

1.

Select Menu > Settings > Display.

2. Choose Lock View.

3. Use Select to toggle between the lock view and the unlocked view.

The lock symbol at the top of the screen shows whether the screen is locked or

unlocked.

5.7.2 Changing the display contrast

Complete the following steps to brighten or darken the screen.

1.

Select Menu > Settings > Contrast.

2. Use the arrow keys to brighten or darken the screen.

3. Press Enter.

5.7.3 Changing the language

Complete the following steps to change the language.

1. Select Menu > Settings > Language.

2. Choose English, Spanish, or French.

32 Rosemount RDO

Page 37

3. Press Enter.

5.8 Changing power settings

To conserve power the analyzer can be set to turn off the display after idling for a certain

length of time.

1. Select Menu > Settings > Power Save.

2. Select External.

Do not choose Battery.

3. Select the appropriate interval - Off (always on), 15 sec, 30 sec, 1 min, 5 min, or 15 min.

5.9 Setting the polling (update) interval

The polling interval specifies how often the analyzer checks the probe and updates the

configured outputs when the analyzer is in power saving mode.

See Section 5.8. The default polling rate is every 15 minutes. The fastest polling rate is

every minute; the slowest is every 24 hours.

Programming the analyzer

Important

If the analyzer is not in power saving mode, the display, relays, and outputs update once every 5 sec.

Procedure

1.

Select Menu > Settings > Polling Interval.

2. Select the desired interval.

3. Press Enter.

5.10 RS485 communications

5.10.1 Setting the device address for the analyzer

The device address is a number between 1 and 245. The device address of Probe A is the

analyzer address plus 1. The device address of Probe B is the analyzer address plus 2.

1. Select Menu > Settings > Communications > Address.

2. Use the arrow keys to enter a number between 1 and 245.

3. Press Enter.

5.10.2 Setting RS485 parameters for the analyzer

Complete the following steps to set the RS485 parameters for the analyzer.

Manual 33

Page 38

Programming the analyzer

1. Select Menu > Settings > Communication > RS485.

There are six settings to make:

• Mode (choose RTU or ASCII)

• Baud Rate (choose 9600, 19200, 38400, or 57600)

• Data Bits (choose 8)

• Parity (choose Even, Odd, or None)

• Stop Bits (choose 1 or 2)

• Defaults (choose yes to restore RS485 default settings)

2.

Scroll to the menu item and select it.

3. Use the arrow keys to change the setting.

4. Press Enter.

5.11 Setting security codes

You may set up the analyzer with passwords for an administrator and a user. The user can

access the Calibrate, Hold, Options, and Diagnostics menus. The administrator can access

all functions, most notably the Settings menu. If there is no administrator code set, the

user becomes the default administrator and can access all functions. To remove pass codeprotected access, enter 0000 for all codes.

1.

Select Menu > Settings > Security Code.

2. Select Administrator and enter a 4-digit code for the Administrator using the arrow

keys. Press Enter.

3. Select User. Set a 4-digit code for the User using the arrow keys. Press Enter.

5.12 Defaults

Selecting defaults returns all user settings and calibrations to factory default values.

The display also returns to the initial configuration screens described in Section 5.1.

5.13 Placing the output and relays on hold

Occasionally, you may wish to temporarily pause the outputs.

1.

Select Menu, then Hold Outputs.

All measurement updates stop, the current values and outputs are held, and the

phrase Hold Outputs appears at the top of the main display.

2. To take the analyzer out of hold, select Resume.

34 Rosemount RDO

Page 39

5.14 Diagnostics

The following diagnostic information is available for the RDO probe:

• Serial number

• Firmware version number

• Date of last user calibration

• Last calibration slope and offset

• Date next calibration is due

• Expiration date for sensing cap (one year from the date the sensing cap took its first

measurement, for PN R0084230 only)

• For replacement cap, PN R0084230X, there is no expiration date (expected life is

two years)

• Sensing cap serial number

The following diagnostic information is available for analyzer Probe C, also called

ConTROLL PRO:

• Serial number

• Firmware version number

• Hardware version number

• Power source

Programming the analyzer

Procedure

1. Select Menu, then Diagnostics.

2. Select the desired probe (A or B). For analyzer diagnostics, select Probe C.

3. Use the arrow keys to scroll through the diagnostics.

4. To read the last calibration slope and offset, scroll to Last calibration and select it.

The slope should be between 0.80 and 1.20, and the offset should be between -0.2

and +0.2.

Manual 35

Page 40

Programming the analyzer

36 Rosemount RDO

Page 41

6 Calibration

6.1 Calibration options

There are three ways to calibrate the RDO probe.

• Saturation: Both a two-point (100% and 0% saturation) and one-point (100%

saturation) calibration are available. 100% saturation refers to water completely

saturated with atmospheric oxygen. 0% refers to water containing no dissolved

oxygen.

The solubility of atmospheric oxygen in water depends on the barometric pressure,

temperature, and humidity. If these are known, the concentration of oxygen in airsaturated water can be readily calculated, making it a useful calibration standard. In

practice, however, air-saturated water is almost never used. Air is used instead. Air

works because, according to Henry's Law, the concentration of oxygen in airsaturated water (expressed in mg/L) is in equilibrium with the partial pressure of

oxygen in the air used to saturate the water. Therefore, whether the probe is in air or

in air-saturated water, the fluorescence quenching will be exactly the same.

Calibration

During calibration at 100% saturation, the micro-processor uses the temperature

measured by the probe and the barometric pressure measured by the analyzer to

calculate the equilibrium solubility of oxygen in water. Because the calibration

assumes the air is completely saturated with water, the calibration must be done

with the probe in air having 100% humidity.

Calibrating at 0% saturation requires water containing no dissolved oxygen. A good

0% saturation standard is water containing about 5% sodium sulfite (Na2SO3). Add

about one teaspoonful of sodium sulfite crystals to a cup of water.

• Concentration: If the probe is installed in a waste-water aeration basin, it is often

inconvenient to remove it for saturation calibration. In this case, concentration

calibration, in which the probe is calibrated against a referee instrument, is more

suitable.

• Default: Default restores the default calibration.

Although a new probe can be used as received from the factory, Emerson recommends

that you do a two-point saturation calibration when the probe is first placed in service.

Manual 37

Page 42

Calibration

6.2 One-point calibration (100% saturation)

Complete the following steps to do a one-point calibration.

1. Remove storage cap on top of calibration chamber and replace it with the

calibration cap (cap with the vent hole).

Calibration and storage capsFigure 6-1:

2. Fill the calibration chamber to the lower fill line with approximately 10 mL water.

The water temperature should be as close to the sample temperature as possible.

Fill the calibration chamber to the lower line with water.Figure 6-2:

3. Remove the sensor from the process liquid. If the sensor is fouled or dirty, clean it by

following the procedure in Section 7.2.2. Gently dry the probe and sensor with a soft

cloth, making sure there is no water on the body of the sensor or on the sensing foil.

Important

The sensing foil must remain dry during 100% saturation calibration.

38 Rosemount RDO

Page 43

Calibration

4. Place the probe in the calibration chamber keeping the sensing foil about 1 in. (25

mm) above the surface of the water.

5. Allow at least five minutes for the temperature to stabilize before starting the

calibration.

Keeping the sensor in the shade will help reduce drift caused by the sun's heat. Do

not leave the calibration chamber for more than 30 minutes, lest condensation form

on the surface of the foil, leading to false low readings after calibration. If

condensation does occur, remove the probe and dry the foil. Return the sensor to

the calibration chamber and continue.

6. Once readings are stable, start the calibration. Select Menu > Calibrate > RDO PRO >

Saturation > One-point cal.

The calibration begins immediately. The Calibration Beginning screen shown in

Figure 6-3 appears.

Figure 6-3:

Note the Calibration Beginning icon next to the mg/L reading. As the reading

stabilizes, the bar in the icon shrinks. When the word Nominal appears, the

stabilization is almost complete, and the calibration can be selected at this point by

selecting Nominal. However, for best results, wait until Stable appears.

7.

Select Stable to accept the calibration. To end and return to the previous

calibration, select Cancel.

The figure shows the screens that appear as the calibration

progresses.

6.3 Two-point calibration (100% and 0% saturation)

Complete the following steps to perform a two-point calibration on your RDO analyzer.

1.

Set up the calibration chamber and probe as described in Section 6.2, steps 1

through 5.

Manual 39

Page 44

Calibration

Important

Do the 100% calibration step first.

2. Once readings are stable, start the calibration. Select Menu > Calibrate > RDO PRO >

Saturation > Two-point cal.

The calibration begins immediately. The Calibration Beginning screen shown in

Figure 6-3 appears, and the other two screens appear as the reading stabilizes. Wait

until the word Stable appears.

3. Select Stable to accept the calibraiton and proceed to the 0% saturation step. To

end and return to the previous calibration, select Cancel.

The 0% saturation step starts automatically.

4. Remove the probe and fill the calibration chamber to the upper fill line with

approximately 60 mL of fresh sodium sulfite solution (see Figure 6-4).

Figure 6-4:

Fill the Calibration Chamber to the Upper line with Fresh Sodium

Sulfite Solution.

A teaspoonful of sodium sulfite in a cup of water is adequate.

Place the probe in the sodium sulfite solution. Be sure the thermistor thermowell

5.

(the small metallic disc about 1/8 inch [3 mm] above the nose cone) is completely

submerged. Leave at least 1/2 inch (12 mm) between the surface of the foil and the

bottom of the chamber. Do not allow the sensing foil to rest on the bottom of the

calibration chamber. Allow at least five minutes for readings to stabilize.

The Calibration Beginning screen shown in Figure 6-5 appears.

40 Rosemount RDO

Page 45

Calibration

Figure 6-5:

Note the Calibration Beginning icon next to the mg/L reading. As the reading

stabilizes, the bar in the icon shrinks. When the word Nominal appears, the

stabilization is almost complete. However, for best results, wait until Stable

appears.

6.

Select Stable to accept the calibration. To end and return to the previous

calibration, select Cancel.

The calibration report screen appears. The slope will be between 0.8 and 1.2, and

the offset will be between -0.2 and +0.2.

The Figure Shows the Screens that Appear as the Calibration

Progresses.

7. Press OK.

8. Remove the probe from the calibration chamber. Rinse it and return it to the process

liquid.

6.4 Concentration calibration

Complete the following steps to do a concentration calibration of your RDO analyzer.

1.

Calibrate the referree instrument following the manufacturer's instructions.

2. Immerse the referree sensor in the process liquid as close to the RDO probe as

possible.

3. Allow adequate time for the referree sensor to come to equilibrium with the process

liquid.

4. Once readings are stable, start the calibration. Select Menu > Calibrate > RDO >

Concentration.

5. Enter the value from the referree instrument as the Standard Value shown on

the display. Press Enter.

Manual 41

Page 46

Calibration

42 Rosemount RDO

Page 47

7 Maintenance

7.1 Analyzer

7.1.1 Cleaning the analyzer enclosure

Clean the analyzer case and front panel by wiping with a clean, soft cloth dampened with

water only.

CAUTION!

EQUIPMENT DAMAGE

Do not use organic solvents.

7.1.2 Replacing the dessicant

Maintenance

Periodically inspect the dessicant bag in the analyzer enclosure. Replace the dessicant (PN

R0087630) when the indicator beads turn from blue to pink.

7.1.3 Replacing the clock battery

The clock battery is located at the bottom of the back of the enclosure cover. To replace

the battery:

1. Disconnect AC power to the instrument.

2. Remove the enclosure cover.

3. Remove the clock battery and replace it with a 3 V MnO2-Li battery, CR2032 or

equivalent.

4. Dispose of spent battery properly.

5. Replace the cover.

6. Restore AC power.

Manual 43

Page 48

Maintenance

7.2 RDO probe

7.2.1 Cleaning the sensing cap

Complete the following steps to clean the sensing cap.

Important

Leave the sensing cap and cone attached to the probe body. Do not remove the sensing cap to clean

it.

Procedure

1. Rinse the cap with clean water from a squirt bottle.

2. If biofouling is present, gently wipe the cap with a soft-bristeled brush or soft cloth.

If oil or grease is present, wash with a gentle detergent.

3. If extensive fouling or mineral build-up is present, soak the cap of the sensor - do not

remove the sensing cap - in vinegar for 15 minutes; then soak in deionized water for

15 minutes.

CAUTION!

EQUIPMENT DAMAGE

Do not use organic solvents.

4. After cleaning the sensor, check the calibration in the air. Perform a one or two-

point saturation calibration if necessary.

7.2.2 Cleaning the probe body

Complete the following steps to clean the RDO probe body.

Leave the sensing cap and nose cone attached to the probe body while cleaning it. Do not

remove the sensing cap.

Procedure

1. Gently scrub the probe body with a soft-bristled brush of a nylon dish scrubber. Use

a mild detergent to remove oil or grease.

2. Soak in vinegar followed by deionized water to remove mineral deposits or extensive

fouling.

See step 4 in Section 7.2.1.

7.2.3 Cleaning the optical window

Clean the optical window only when the sensing cap is replaced. See Section 7.2.1.

44 Rosemount RDO

Page 49

7.2.4 Replacing the sensing cap

The replacement sensing cap kit (PN R0084230X and PN R084230) contains a sensing cap,

two O-rings, O-ring lubricant, and a lens wipe.

Note

Keep the cap in its sealed packaging until you are ready to install it. Install promptly. Avoid allowing

moisture, including humidity, inside the cap.

Procedure

1. Remove the sensor from the process liquid. Rinse with water and dry the probe body

and nose cone.

2. Unscrew the nose cone.

3. Pull the sensing cap straight off the probe body.

Do not twist.

4. Remove and discard the existing O-rings.

5. Remove any moisture in the O-ring grooves.

Maintenance

Be careful not to touch the lens.

6. Use your finger to apply a thin layer of lubricant around the O-ring grooves.

CAUTION!

EQUIPMENT DAMAGE

Be careful not to get grease on the lens or on the sensor pins.

7. Slide the two O-rings into grooves. Check that the O-rings are not twisted or

pinched. Apply a thin layer of lubricant over the O-rings and grooves.

CAUTION!

EQUIPMENT DAMAGE

Be careful not to get grease on the lens or on the sensor pins.

8. Clean the lens with the wipe provided in the kit and allow it to dry thoroughly.

Inspect the lens for scratches or dirt.

9. Remove the new sensing cap from its sealed packaging. Align the arrow on the cap

with the index mark on the probe and firmly press the cap onto the probe, without

twisting, until it seals. Replace the nose cone.

10. Perform a one or two-point saturation calibration.

Manual 45

Page 50

Maintenance

7.2.5 Storing the probe

Store the probe in the calibration chamber using the storage cap (cap without notch).

Place a few drops of water in the chamber before inserting the probe.

7.3 Replacement parts

Part number Description

R0094030 RDO analyzer, AC power, no data logging

R0086460X RDO Pro-X sensor with 32 ft (10 m) of integral cable

R0082490X RDO Pro-X sensor with twist lock connector

R0087560 RDO analyzer pipe and wall mounting kit

R00CBL10 Twist lock connector cable, 32 ft (10 m)

R00CBL20 Twist lock connector cable, 64 ft (20 m)

R00CBL30 Twist lock connector cable, 96 ft (30 m)

R0084230 RDO sensor cap replacement kit

R0080810 RDO O-ring replacement kit

R0080820 RDO replacement nose cone kit

R0088890 RDO replacement calibration cup

R00087630 RDO replacement dessicant bag for analyzer

R0084230X RDO Pro-X sensor cap replacement kit

46 Rosemount RDO

Page 51

8 Specifications

8.1 RDO probe

Specifications

Wetted materials Delrin

Dimensions Length: 8.0 in. (203 mm); Diameter: 1.9 in. (47 mm)

Rating IP-67 with cap off; IP-68 with cap installed

Process connection 1-1/4 in. FNPT

Integral cable length 32 ft (10 m)

Maximum cable length (quick disconnect cable only) 4000 ft (1219 m)

Pressure Up to 314 psig (2060 kPa abs)

Temperature 0 to 50 °C (32 to 122 °F)

Range 0 to 20 ppm (mg/L) or 0 to 200% saturation

Accuracy ±0.1 ppm between 0 and 8 ppm, ±0.2 ppm between 8 and

Resolution 0.01 ppm (mg/L)

Digital output Modbus/RS485

Response time 30 sec to 90% of final value; 37 sec to 95% of final value (at

Operating life of sensing cap 2 years from first reading

Safety directive 73/23/EEC

EU directives 2004/108/EC for electro-magnetic compatibility (EMC)

Immunity EN 61000-6-2, electromagnetic compatibility (EMC) part

(1)

, ABS, Viton

poly(methyl, methacrylate) blend

20 ppm

25 °C [77 °F])

and 72/23/EEC for Safety

(2)

, titanium, polycarbonate/

6-2

Emissions Class A requirements of CISPR 11: 2004

(1) Delrin is a registered trademark of DuPoint DeNemours, LLC.

(2)

Viton is a registered trademark of DuPoint Dow Elastomers, LLC.

8.2 RDO analyzer

Enclosure Polycarbonate, rated NEMA 4X, IP67

Dimensions (W x H x D) 6.3 x 6.3 x 3.6 in. (16 x 16 x 9.0 cm)

Display Liquid crystal; character height: 0.4 in. (6 mm)

Mounting Suitable for pipe or wall mounting

Manual 47

Page 52

Specifications

Conduit openings Six; PG 13.5 (1/2 in.); three gland fittings and five plugs

ship with the analyzer

Ambient temperature and humidity -20 to 70 °C (-4 to 158 °F); 95% relative humidity (non-con-

densing)

Power 100 to 240 Vac, approximately 0.15 A, 50 - 60 Hz

Analog outputs Two fully scalable 4-20 mA outputs, each loop-powered

(9-36 Vdc)

Digital output Modbus/RS485

Relays Two low voltage relays, <50 Vac or Vdc, maximum current

2 A (resistive or inductive) two high voltage relays, 264 Vac

max, maximum current 5 A (resistive or inductive)

Barometric pressure range 8.86 to 29.53 in Hg (300 to 1000 mbar)

Barometric presssure accuracy ±0.09 in Hg (±3 mbar)

EU directive 2004/108/EC for electromagnetic compatibility (EMC)P

Immunity EN61000-6-2, electromagnetic compatibility (EMC) part

6-2

Emissions EN61000-6-4 electromagnetic compatibility; includes IEC/

EN61000-3-2 and IEC/EN61000-3-3 where applicable

Safety UL 61010-1 and CAN/CSA C22.2 #61010-1

48 Rosemount RDO

Page 53

Specifications

Manual 49

Page 54

Specifications

50 Rosemount RDO

Page 55

Specifications

Manual 51

Page 56

www.Emerson.com/RosemountLiquidAnalysis

Emerson Automation Solutions

8200 Market Blvd

Chanhassen, MN 55317

Toll Free +1 800 999 9307

F +1 952 949 7001

liquid.csc@emerson.com

www.Emerson.com/RosemountLiquidAnalysis

LIQ-MAN-RDO

Rev B

2017

EUROPE

Emerson Automation Solutions

Neuhofstrasse 19a P.O. Box 1046

CH-6340 Baar

Switzerland

T + 41 (0) 41 768 6111

F + 41 (0) 41 768 6300

liquid.csc@emerson.com

www.Emerson.com/RosemountLiquidAnalysis

MIDDLE EAST AND AFRICA

Emerson Automation Solutions

Emerson FZE

Jebel Ali Free Zone

Dubai, United Arab Emirates, P.O. Box 17033

T +971 4 811 8100

F +971 4 886 5465

liquid.csc@emerson.com

www.Emerson.com/RosemountLiquidAnalysis

ASIA-PACIFIC

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

Singapore

T +65 777 8211

F +65 777 0947

liquid.csc@emerson.com

www.Emerson.com/RosemountLiquidAnalysis

©

2017 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. Rosemount is a mark of one of the Emerson family of

companies. All other marks are the property of their respective

owners.

Loading...

Loading...