Page 1

PowerVUE™

November 2011

Product Data Sheet

PDS 102-222.A01

Fan/Damper Actuators with Optional

FoundationTM fieldbus Communications

n Combines the power and reliability of the

Hagan Pneumatic Drive with the accuracy and

features of the Fisher DVC5000/6000 Digital

Valve Controller

n Integral I/P: FOUNDATION™ fieldbus input or

4-20mA HART® input

n Reliable, closed loop positioning

n Double acting piston – no vanes

n Optional “fail-in-place” upon loss of plant air

n Manual operator

n ValveLink Diagnostics/AMS

n Suitable for hazardous area service;

explosion-proof, flameproof or intrinsically safe

Product description

Hagan Pneumatic Power Positioners have defined the standard

of excellence in fan and damper actuation for more than 70

years.

These actuators convert the linear motion from a pneumatic

piston into an 80° rotation of a drive arm. With few moving

parts, the pneumatic power positioner remains the simplest,

most reliable and most cost-effective method of actuation.

Torque ranges are offered from 400 ft-lbs to 4,600 ft.-lbs.

The PowerVUE design uses the same rugged Hagan actuator and frame construction, combined with the accuracy and

reliability of the Fisher FieldVUE DVC5000/6000 Digital Valve

Controller.

The DVC5000 controller, using the HART or FOUNDATION

fieldbus communications protocols, gives easy access to

information that is critical to process operation.

These instruments use two-wire loop power for low-cost

replacement of existing instruments. The two-wire design

avoids cost of separate power and signal wiring.

Self-diagnostic capabilities allow you to check fan/damper

actuator performance in place. You can compare the present

signature (load, friction, etc.) against stored signatures to

discover performance changes before they cause problems.

Field maintenance of these instruments is easy. Repair consists

of quick replacement of a single master module without

disconnecting wires or tubing. Troubleshooting of the master

module is fast and easy in the instrument shop.

Applications

Fan/Damper actuation for:

n Utilities

The controller uses feedback from the actuator travel position

to diagnose not only the instrument, but the actuator as well.

The information from the DVC5000/6000 can be integrated

into control systems or be received for a single loop.

n Steel mills

n Refineries

n Pulp and paper

n Wastewater (aeration blowers)

Page 2

PowerVUE™

November 2011

Theory of operation

Product Data Sheet

PDS 102-222.A01

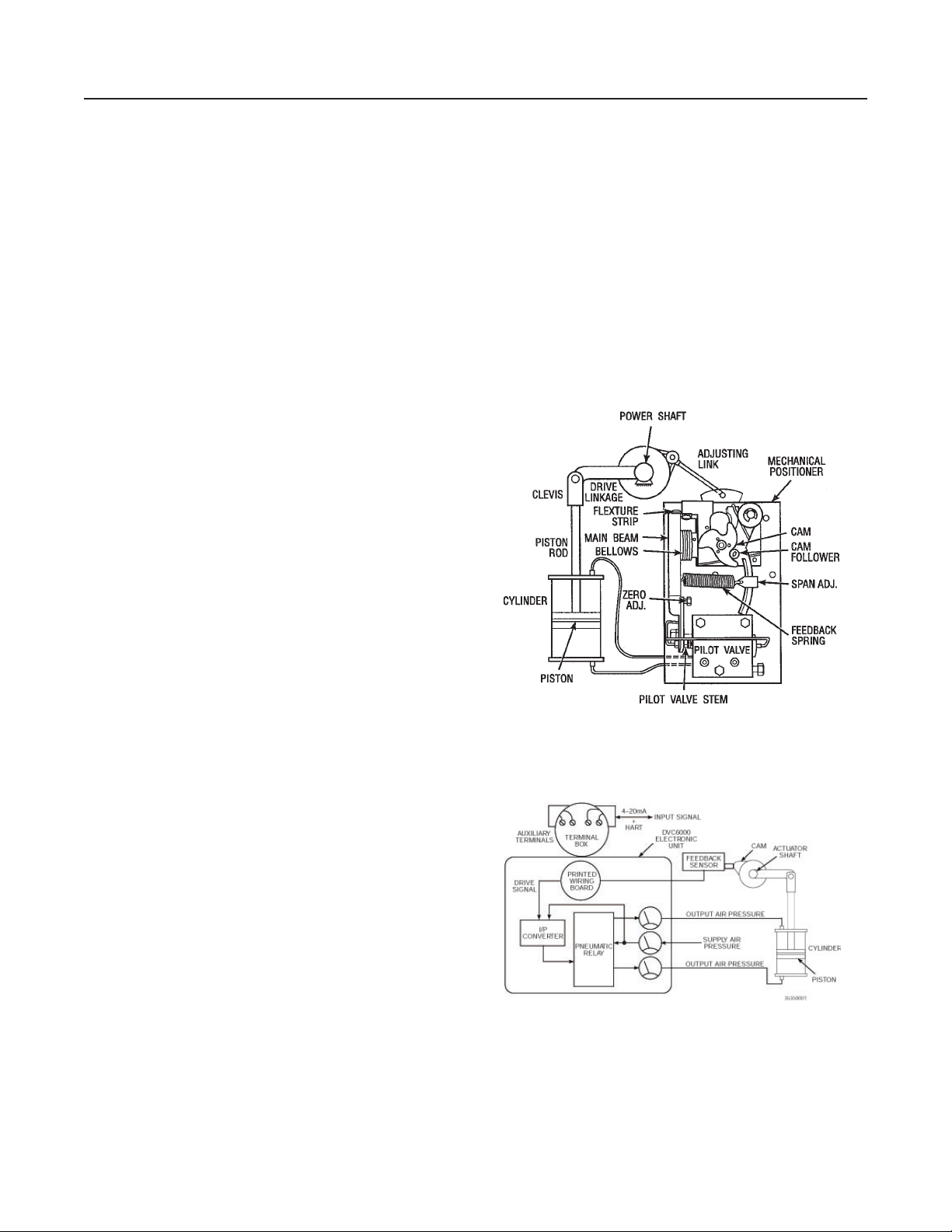

Traditional positioners use a mechanical force/balance concept,

whereby a pneumatic input signal forces a diaphragm down,

actuating a valve which ports air into one side of a piston and

vents the other side. A feedback spring provides a

counterbalancing force as the actuator approaches setpoint.

Mechanical positioners have worked well for many years, but

are subject to sticking as mechanical components become

soiled, resulting in a situation where the actuator “hunts” for

the proper position. The process variable is always above or

below setpoint, providing poor control that costs significant

money and causes excessive wear on the actuator/linkage/

dampers system.

The FieldVUE DVC5000/6000 Digital Valve Controller directly

receives a 4-20 mA or fieldbus input signal. An independent

feedback transducer provides an actuator position input,

ensuring that the PowerVUE drive always moves to the setpoint

demanded by the control system. Fieldbus versions of the

DVC5000/6000 also offer PID loop control capability.

Options

Air Lock - mechanically locks the drive in place upon the loss of

plant air.

Valvelink advanced

diagnostics

In addition to the standard features, advanced diagnostic features provide additional capabilities to diagnose

problems with the DVC5000, the actuator, and even in

the damper/ linkage systems. Actuator can be tested

as it is put into service, and this data compared to an “as

found” condition after years in service. Maintenance

can be scheduled based upon actual need vs. traditional

“time in service” criteria.

Manual Operator - handwheel/lever arm permits manual

adjustment of drive.

Limit Switches - proof of position for purge/lightoff conditions

may be accomplished by traditional mechanical microswitches.

Electric Position Transmitter - provides a 4-20 mA feedback

signal representing actuator position. (HART versions only.)

Digital communications

4-20mA HART versions:

All operator information for setup and diagnostics is transmitted digitally via HART communications. A Rosemount 375

Hand-held or similar communicator may be used or a laptop

computer with ValveLink Software. Emerson’s AMS offers the

ValveLink software as an optional “snap-on” application.

Instruments may be accessed individually or multiplexed

through an “interchange” unit, providing continuous access to

any number of Emerson’s instruments.

FOUNDATION fieldbus versions:

All operator interface is via the host computer console.

A hand-held device is available.

2

www.EmersonProcess.com

Page 3

PowerVUE™

November 2011

Product Data Sheet

PDS 102-222.A01

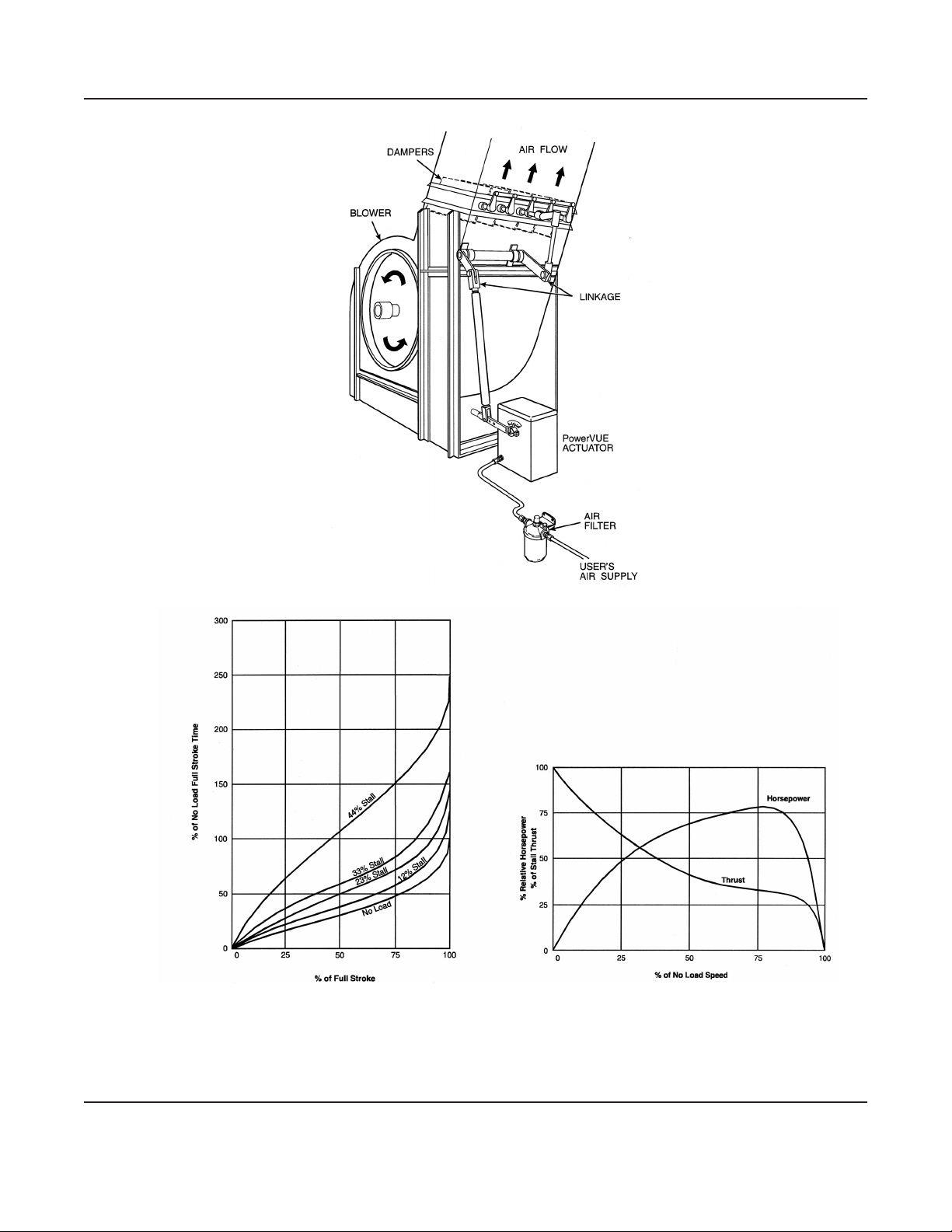

Performance Curves

Typical

arrangement

Set of characteristic curves for a typical air-operated power

cylinder. Piston displacement and time are plotted for suddenly

applied full-range positioning inputs to the cylinder. The linear

sections of the curves correspond to steady speed.

Note: Stall torques are specified for all models. Emerson recommends that a 60% factor be applied to ensure fast control response.

Rosemount Analytical power positioners are not recommended for reversing loads or heavy mass loads.

www.EmersonProcess.com

A typical cylinder-thrust vs. speed characteristic. The curve of

relative horsepower output is also shown.

3

Page 4

PowerVUE™

November 2011

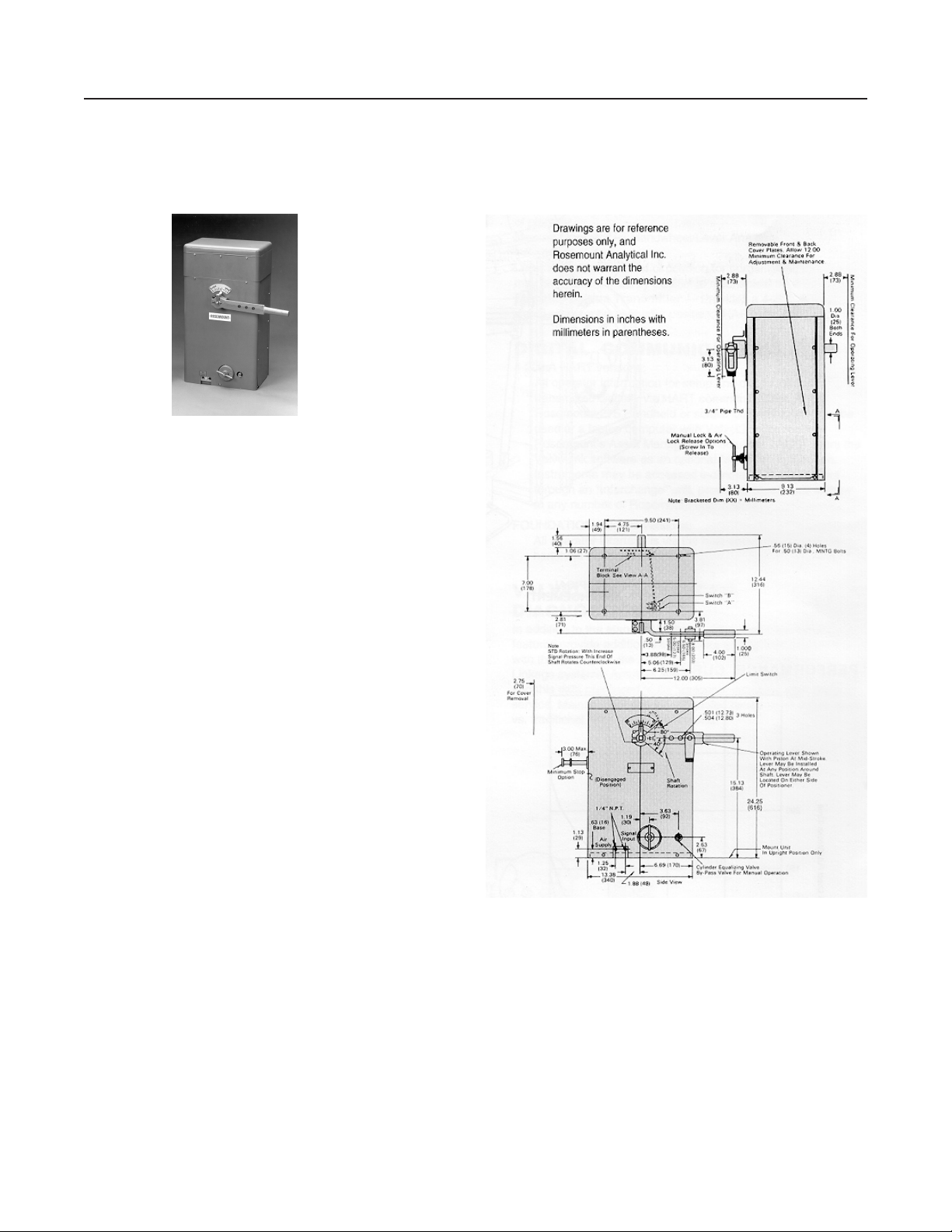

4 X 5 torque type floor mounted

features, accessories and options

Features

n Digitally-controlled positioner system with HART® or

FOUNDATION™ fieldbus communications

Product Data Sheet

PDS 102-222.A01

n Repeatability better than ±0.5%

n Direct 4-20 mA signal input – integral I/P

n Characterizable

n Reverse or direct acting

n Standard rotation – counterclockwise

Accessories

Clevis and pin are included P/N 174469

Air filter/regulator included P/N 4505C21G03

Options

n Mechanical air lock upon loss of plant air supply

n 4-20 mA position feedback signal – 4-20 mA

HART versions only

n Manual lock

n Limit switches

n Minimum limit stop

4

www.EmersonProcess.com

Page 5

PowerVUE™

November 2011

4 X 5 torque type floor mounted

specifications

1

Product Data Sheet

PDS 102-222.A01

Specifications

1

Actuator

Repeatability

±0.5% of full stroke or better

No load full stroke time

3 sec.

Stall torque

400 ft.-lbs. (542 N•m) with 100 psig (689 kPa gage) air supply

Maximum friction load

50% of control torque.

Maximum weight load

140 ft.-lbs. (189 N•m)

Maximum allowable cylinder air pressure

100 psig (689 kPa gage)

Power air consumption

10 scfm steady state.

Stroke length

5 in. (127 mm), 80° rotation.

Relative humidity

Operable up to 100% RH

Electronics

See DVC5000/6000 specifications

Pneumatic

Operating air supply pressure

45 to 100 psig (310 to 689 kPa gage)

Recommended air supply pressure

100 psig (689 kPa gage)

Electrical Optional heater power consumption

150 watts

Signal requirements

Control signal inputs

4-20 mA signal with HART® or FOUNDATION™ fieldbus

1

Specifications are subject to change without notification. Our policy is

one of continuous improvement, and we reserve the right to change

specifications.

Physical characteristics

Weight

80 lbs. (36 kg) typical

Air supply and signal air input fittings

1/4 inch NPT female connections

Environmental requirements actuator

Ambient temperature

Without heater:

40° to 122°F (4,44° to 50°C), 140°F

(60°C) with increased maintenance

With heater

-10° to 122°F (-23,3° to 50°C) 140°F (60°C) with increased

maintenance

www.EmersonProcess.com

5

Page 6

PowerVUE™

November 2011

Ordering information

PVD 405 PowerVUE Drive – 4 x 5 Torque Type Floor Mount

Model Product Description

PVD 405 PowerVUE Drive – 4 x 5 Torque Type Floor Mount

Basic Assembly Type and Connection Material

01 Standard brass assembly

02 Manual lock brass assemblyProbe Length

03 Mechanical air lock brass assembly

04 Standard stainless assembly

05 Manual lock stainless assembly

06 Mechanical air lock stainless assembly

Digital Valve Controller

00 None

01 HART

02 Fieldbus with basic control suite

03 Fieldbus without basic control suite

04 Other DVC style selected

Limit Switches

01 None

02 2 Std. limit switch – SPDT

EPT

01 None

02 Digital EPT and 2 limit contacts (HART®versions only)

Heater Option

01 None

02 Heater/thermostat 115V 150 watt (not for use in hazardous areas)

Option Notes

General Notes PowerVUE Drive – 4 x 5 Torque Type Floor Mount

43/95 kg/lb shipping weight

Base price includes air filter-regulator. Style 4505C21G03, clevis style 174469 and IB-102-204

Level 2 Option: 00

Digital Valve Controller (DVC 5000/6000) may be supplied by others but no performance guarantees for

accuracy or speed of responses are provided. Warranty for DVC 5000/6000 will be the responsibility o

the provider

Level 2 Option: 02, 03

DVC 5000 Options: flameproof cable gland: 1/2” NPT (aluminum), EExd IIC; cable entry adaptor (brass):

1/2” NPT M20 x 1.5 ISO, 1/2” NPT, PG 13.5

Level 2 Option: 03

Order as separate line item from addendum price list

Level 2 Option: 03

Standard arrangement calls for Model DVC 5020F-216, certified to FM as intrinsically safe and Division II.

Other certifications available. Advanced diagnostics provided.

Level 2 Option: 01

Standard arrangement calls for Model DVC 5020-116G60, certified to FM as intrinsically safe and

Division II. Other certifications available. Advanced diagnostics provided

Level 2 Option: 02

Standard arrangement calls for Model DVC 5020F-216, certified to FM as intrinsically safe and Division II.

Other certifications available. Advanced diagnostics provided

Level 4 Option: 02

Utilizes Moore Industries Site Programmable HART Alarm. Default configuration: 1 analog output

representing actuator travel; 3 customer selectable position contacts; 1 contact for field device failure

Moore HART SPA may be configured in an intrinsically safe arrangement through an IS barrier..

Accessories

1101588-002ENG Tag SS (engraved)

6

®

Product Data Sheet

PDS 102-222.A01

www.EmersonProcess.com

Page 7

PowerVUE™

November 2011

6 X 10 torque type floor mounted

features, accessories and options

Dimensions in inches with

millimeters in parentheses.

Features

n Digitally-controlled positioner system with HART® or

FOUNDATION™ fieldbus communications

n Repeatability better than ±0.5%

Product Data Sheet

PDS 102-222.A01

n Direct 4-20 mA signal input – integral I/P

n Characterizable

n Reverse or direct acting

n Standard rotation – counterclockwise

Accessories

Clevis and pin are included P/N 274472

Air filter/regulator included P/N 274472

Options

n Mechanical air lock upon loss of plant air supply

n 4-20 mA position feedback signal – 4-20 mA

HART versions only

n Heater and thermostat

n Limit switches

n Manual operator

Drawings are for reference purposes only and Emerson does

not warrant the accuracy of the dimensions herein.

www.EmersonProcess.com

7

Page 8

PowerVUE™

Product Data Sheet

November 2011

Ordering information

PVD 610 PowerVUE Drive – 6 x 10 Torque Type Floor Mount

Model Product Description

PVD 610 PowerVUE Drive – 6 x 10 Torque Type Floor Mount

Assembly Type & Connection Material

01 Manual lock, brass fittings, polymer tubing assembly

02 Manual and mechanical air lock, brass fittings, polymer tubing assemblyProbe Length

03 Manual lock, SS fittings, SS tubing assembly

04 Manual lock and mechanical air lock, SS fittings, SS tubing assembly

DVC 6000 Controller Style

00 None required

01 HART

02 Fieldbus with basic control suite

03 Fieldbus without basic control suite

04 Other DVC style selected

Limit Switches and Position Retransmission

01 No limit switches

02 2 mechanical limit switches SPDT

03 Digital electronic position transmitter & 2 limit contacts, HART® version only

Heater

01 None

02 Heater/Therostat 115 VAC 150 watt (not for use in hazardous area)

Option Notes

General Notes PowerVue Drive – 6 x 10 Torque Type Floor Mount

125/275 kg/lb shipping weight

Base price includes air filter-regulator. Style 4505C21G03, clevis style 174469 and IB-102-204

Level 2 Option: 04

Designate other DVC 6000 model number as a note on order.

Level 2 Option: 00

Digital Valve Controller (DVC 6000) may be supplied by others but no performance guarantees for accuracy or

speed of responses are provided. Warranty for DVC 6000 will be the responsibility of the provider.

Level 2 Option: 02, 03

DVC 6000 Options: flameproof cable gland: 1/2” NPT (aluminum), EExd IIC; cable entry adaptor (brass): 1/2” NPT

M20 x 1.5 ISO, 1/2” NPT, PG 13.5

Level 2 Option: 03

order as separate line item from addendum price list.

Level 2 Option: 02

Standard arrangement calls for Model FSDVC6020F-105/G160B/CSA, certified to CSA as intrinsically safe and

Division II. Other certifications available. Advanced diagnostics provided.

Level 2 Option: 01

Standard arrangement calls for Model FSDVC6030F-107/G160B/CSA, certified to CSA as intrinsically safe and

Division II. Other certifications available. HC HART communications. Advanced Diagnostics option available for

additional price.

Accessories

1101588-002ENG Tag SS (engraved)

®

PDS 102-222.A01

8

www.EmersonProcess.com

Page 9

PowerVUE™

November 2011

Product Data Sheet

PDS 102-222.A01

Ordering information

PVD814 PowerVUE Drive – 8 x 14 Torque Type Floor Mount

Model Product Description

PVD814 PowerVUE Drive – 8 x 14 Torque Type Floor Mount

Assembly Type & Connection Material

01 Standard brass assembly

02 Standard stainless assembly

03 Mechanical air lock brass assembly

04 Mechanical air lock stainless assembly

Digital Valve Controller

00 None

01 HART

02 Fieldbus with basic control suite

03 Fieldbus without basic control suite

04 Other DVC style selected

Limit Switches

01 None

02 2 Std. limit switch – SPDT

Electronic Position Transmitter

01 None

02 Digital electronic position transmitter & 2 limit contacts (HART® versions only)

Heater Optionr

01 None

02 Heater/thermostat 115VAC 150 watt (not for use in hazardous areas)

Option Notes

General Notes PowerVue Drive – 8 x 14 Torque Type Floor Mount

249/550 kg/lb shipping weight

Base price includes air filter-regulator. Style 4505C21G03, clevis style 174469 and IB-102-204

Level 2 Option: 04

Designate other DVC 5000 model number as a note on order.

Level 2 Option: 00

Digital Valve Controller (DVC 5000/6000) may be supplied by others but no performance guarantees

for accuracy or speed of responses are provided. Warranty for DVC 5000/6000 will be the responsibility of the provider.

Level 2 Option: 02, 03

DVC 5000 Options: flameproof cable gland: 1/2” NPT (aluminum), EExd IIC; cable entry adaptor (brass): 1/2” NPT

M20 x 1.5 ISO, 1/2” NPT, PG 13.5

Level 2 Option: 03

order as separate line item from addendum price list.

Level 2 Option: 01

Standard arrangement calls for Model DVC5020-116G60, certified to FM as intrinsically safe and Division II.

Other certifications available. Advanced diagnostics provided.

Level 2 Option: 02

Standard arrangement calls for Model DVC5020F-216, certified to FM as intrinsically safe and Division II. Other

certifications available. HC HART communications. Advanced diagnostics provided.

Level 4 Option: 02

Utilizes Moore Industries Site Programmable HART Alarm. Default configuration: 1 analog output representing

actuator travel; 3 customer selectable position contacts; 1 contact for field device failure. Moore HART SPA may

be configured in an intrinsically safe arrangement through an IS barrier.

DVC 5000 Options: flameproof cable gland: 1/2” NPT (aluminum), EExd IIC; cable entry adaptor (brass): 1/2” NPT

M20 x 1.5 ISO, 1/2” NPT, PG 13.5

Accessories

1101588-002ENG Tag SS (engraved)

®

www.EmersonProcess.com

9

Page 10

PowerVUE™

November 2011

DVC6000 series

Specifications

Available configurations

DVC6010

Sliding stem applications

DVC6020

Rotary applications and long-stroke sliding-stem applications

DVC6030

Quarter-turn rotary applications

Input signal

Analog Input Signal

4-20 mA dc, nominal; split ranging available

Minimum Voltage Available at Instrument Terminals

11 VDC for analog control (see instrument instruction manual

for details)

Minimum Control Current

4.0 mA

Minimum Current without Microprocessor Restart

3.5 mA

Maximum Voltage

30 VDC

Overcurrent Protection

Input circuitry limits current to prevent internal damage

Reverse Polarity Protection

No damage occurs from reversal of loop output

1

1

Product Data Sheet

PDS 102-222.A01

Supply pressure

Minimum and Recommended

5 psig (0.3 bar) higher than maximum actuator requirements

Maximum

150 psig (10.2 bar) or maximum pressure rating of the

actuator, whichever is lower

Steady-state air consumption

At 20 psig (1.4 bar) supply pressure

Less than 11 scfh (0.3 normal m3/hr.)

At 100 psig (6.9 bar) supply pressure

Less than 45 scfh (1.2 normal m3/hr.)

Xi Temp. limits as measured inside the electronics housing

-20° to 70°C (-4° to 158°F)

Maximum output capacity

At 20 psig (1.4 bar) supply pressure

465 scfh (12.5 normal m3/hr.)

At 100 psig (6.9 bar) supply pressure

1570 scfh (42.1 normal m3/hr.)

Independent linearity

±0.5% of output span

1

1 2 3

2 3

Electrical classification

Hazardous Area

FM, CSA, CENELEC

Other approvals are pending from certifying agencies

Electrical Housing

Designed to meet NEMA 4X, IEC 529 IP 65

Output signal

Ranges

Pneumatic signal as required by the actuator, up to 95% of

supply pressure

Minimum Span

6 psig (0.4 bar)

Maximum Span

140 psig (9.5 bar)

Action

Double, single direct, and single reverse

1

10

Connections

Supply Pressure

1/4-inch NPT female and integral pad for mounting

67 CFR regulator

Output Pressure

1/4-inch NPT female

Tubing

3/8-inch metal, recommended

Vent (pipe-away)

1/4-inch NPT female

Electrical

1/2-inch NPT female conduit connection,

M20 adaptor optional

www.EmersonProcess.com

Page 11

PowerVUE™

November 2011

DVC6000 series

Specifications1 continued

Operating ambient temperature limits

(standard)

-40° to 85°C (-40° to 185°F)

Construction materials

Housing, module base and terminal box

ANSI B360.0 low copper aluminum alloy

Cover

Valox

Elastomers

Nitrile (standard), or Fluorelastomer (optional)

Stem travel

DVC6010

0 to 102 mm (8-1/8 inches) maximum

0 to 19 mm (3/4 inches) minimum

Product Data Sheet

PDS 102-222.A01

DVC6020

0 to 22 inches

Shaft rotation (DVC6020 and

DVC6030)

0 to 90 degrees maximum.

Mounting

Designed for direct actuator mounting. For weatherproof

housing capability, the instrument must be mounted upright to

allow the vent to drain.

Weight

3.5 kg (7.7 lbs.)

Options

Supply and output pressure gauges or tire valves

Integrally mounted filter regulator

1

These terms are defined in ISA Standard S51.1-1979

2

Normal m3/hr. – Normal cubic meters per hour at 0°C and 1.01325 bar, absolute; Scfh-Standard cubic feet per hour at 80°F and 14.7 psia

3

Values at 1.4 bar (20 psig) based on a single-acting relay; values at 6.8 bar (100 psig) based on double-acting relay.

Emerson Process Management has satisfied all obligations coming from the European legislation to harmonize the product requirements in Europe.

The PowerVUE actuator is a subcomponent of an actuating system, including user-provided items such as linkages, bearings, and dampers. The user

must ensure that the entire actuating system is in conformity with the provisions of the European Machinery Directive EC Machinery Directive

89/392/EEC, as amended by directive 91/368/EEC and Directive 93/44/EEC.

www.EmersonProcess.com

11

Page 12

PowerVUE™

November 2011

PowerVue field retrofit kits

for existing hagan power

positioners

Description

An existing Hagan torque-type power positioner can be

retrofitted with the PowerVUE system in a few hours.

The PowerVUE system eliminates most maintenance

requirements associated with mechanical “force balance”

positioning systems, based on pilot valves.

The Hagan PowerVUE retrofit package includes all mounting

brackets, hardware, and pneumatic tubing needed to upgrade

an existing Hagan Pneumatic Power Positioner. No drilling or

tapping of holes is required. (The positioning system mounts

directly to the frame, eliminating the need for connecting

linkages.)

Note: Retrofit kits are not offered for the Hagan

thrust-type units, or the Econotorque Models.

Product Data Sheet

PDS 102-222.A01

Ease of retrofit

(4 x 5 Unit Pictured)

Features

n Digitally-controlled positioner system

n Factory designed mounting

n Direct 4-20 mA signal input – integral I/P

n Characterizable

n Air lock upon loss of plant air supply

n Reverse or direct acting

n ValveLink diagnostics

Options

n 4-20 mA position feedback signal

n 2 position limit contacts available

Field Retrofit Kits are available for the 4 x 5 and 8 x 14

torque-type models:

PP405TR 4” x 5” Cylinder

452167 8” x 14” Cylinder

457696 8” x 14” Cylinder

Step #1 – remove existing positioning system

452593 8” x 14” Cylinder

443700 8” x 14” Cylinder

457031 8” x 14” Cylinder

12

Step #2 – install PowerVue DVC5000

components

www.EmersonProcess.com

Page 13

PowerVUE™

November 2011

Ordering information

PVD 468R PowerVUE Drive – Retrofit Kit 4x5 or 8x14

Model Product Description

PVD 468R PowerVUE Drive – Retrofit Kit 4x5 or 8x14

Model

00 4x5

01 8x14

03 6x10

Digital Valve Controller

00 None required

01 HART

02 FieldBus with basic control suite

03 FieldBus without basic control suite

04 Other DVC style selected, see addendum

Electronic Position Transmitter

00 None required

01 Digital electronic position transmitter & 2 limit contacts, HART® version only (4)

Option Notes

General Notes PowerVue Drive – Retrofit Kit 4x5 or 8x14

“Base price includes air filter/regular style: 4505C21G03; clevis style: 174469

Instruction manual IB 102-204.

“Performance specifications may vary from the published specifications, depending

on the age of the existing Hagan fan/damper actuator and the quality of the DVC

5000/6000 installation. Setup and calibration of DVC 5000 is responsibility of

others. Fairchild reversing relay is included with or without selection of DVC 5000.”

Level 1 Option: 02

Some drilling and tapping required. Existing covers may be modified in the field or a

precut back cover can be selected, P/N 4851B28G01.

Level 2 Option: 04

Designate other DVC 5020/6020 model number as a note on order.

Level 2 Option: 00

Digital Valve Control (DVC 5000/6000) may be supplied by others, but no

performance guarantees for accuracy or speed of response are provided.

Warranty for DVC 5000/6000 will be the responsibility of the provider. Tubing is

provided, but is not precut or preformed.

Level 2 Option: 02, 03

DVC 5000 Options: flameproof cable gland: 1/2” NPT (aluminum), EExd IIC, cable

entry adaptor (brass): 1/2” NPT M20 x 1.5 ISO, 1/2” NPT, PG 13.5.

Level 2 Option: 03

Order as separate line item from addendum price list.

Level 2 Option: 01

Standard arrangement calls for Model DVC5020-116G60, certified to FM as intrinsically safe,

and Division II. Other certifications available. Advanced diagnostics provided.

Level 2 Option: 02

Standard arrangement calls for model DVC5020F-216, certified to FM as intrinsically safe,

and Division II. Other certifications available. Advanced diagnostics provided.

Option Notes

1101588-002ENG Tag SS (engraved)

®

Product Data Sheet

PDS 102-222.A01

www.EmersonProcess.com

13

Page 14

PowerVUE™

November 2011

Product Data Sheet

PDS 102-222.A01

Scan this QR code to

http://www.EmersonProcess.com

http://www.analyticexpert.com

http://twitter.com/RAIhome.com

Rosemount Analytical

Headquarters & Liquid Analytical

2400 Barranca Parkway

Irvine, CA 92606

United States

Phone: 1.800.854.8257

Fax: 1.949.474.7250

Rosemount Analytical – Latin America

Emerson Process Management

Analytical Division

111000 Brittmoore Park Drive

Houston, TX 77041

Phone: 1.713.467.6000

Fax 1.713.827.3329

© 2011 Emerson Process Management. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Brand name is a mark of one of

the Emerson Process Management family of companies. All other marks are the property of their respective

owners.

The contents of this publication are presented for information purposes only, and while effort has been

made to ensure their accuracy, they are not to be construed as warranties or guarantees, express or implied,

regarding the products or services described herein or their use or applicability. All sales are governed by our

terms and conditions, which are available on request. We reserve the right to modify or improve the designs

or specifications of our products at any time without notice.

Rosemount Analytical

Gas Chromatographs & Service Center

5650 Brittmoore Road

Houston, Texas 77041

United States

Phone: 1.866.422.3683

Fax: 1.713.827.3865

Rosemount Analytical - Europe

Emerson Process Management Services Ltd.

Analytical Division

Blegistrasse 21

PO Box 1046

CH 6341 Baar

Switzerland

Phone: 41.41.768.6111

Fax: 41.41.761.8740

open the Model 6888

product information

web page.

Rosemount Analytical

Process Gas & Combustion Center

6565-P Davis Industrial Pkwy

Solon, OH 44139

United States

Phone: 1.800.433.6076

Fax: 1.440.914.1262

Rosemount Analytical – Asia Pacific

Emerson Process Management

Analytical Division

Asia Pacific Private Ltd.

1 Pandan Crescent

Singapore 128461

Republic of Singapore

Phone: 65.6.777.8211

Fax: 65.6.777.0947

www.EmersonProcess.com

Loading...

Loading...