Page 1

Product Data Sheet

PDS 106-350.A01

May, 2003

Oxymitter™ 5000

In Situ Oxygen Transmitter with

FOUNDATION™ fieldbus Communications

• Digital FOUNDATION™ fieldbus

communications

®

– PlantWeb

– AMS

• Unique architecture – electronics

mounted in the probe head

• Outstanding accuracy

• Simplified installation

– no electronics box, probe cable or

conduit

– universal power supply provides

automatic line voltage selection

• Advanced sensor diagnostics

– calibration recommended diagnostic

– Asset Management Solutions permits

diagnostics from DeltaV™ console

• Robust, highly integrated electronics

– consumes 95% less power

– surface-mount technology improves

reliability and vibration resistance

• Optional explosion-proof rating

• Fully field-repairable

THE LATEST BREAKTHROUGH FOR

COMBUSTION FLUE GAS ANALYSIS

The Oxymitter 5000 FOUNDATION fieldbus Oxygen

Transmitter: the world's first in situ, zirconium oxidebased oxygen transmitter for flue gas measurement.

These oxygen measurements can be used in a control

system or by a boiler operator to fine tune burner fuel/air

ratios for maximum efficiency. Ideal for:

• boilers • kilns

• process heaters • reheat furnaces

Rosemount Analytical is the leader in oxygen flue gas

analyzer technology. The Oxymitter 5000 integrates an

oxygen probe and field electronics into a single, compact

package.

compatible

Pictured with optional SPS Autocal Package

FOUNDATION fieldbus communications provide operators

with constant updates of all critical parameters and

diagnostics with no additional wiring. The probe inserts

directly into a flue gas duct to measure oxygen in combustion processes. No sampling system is required.

A NEMA 4X, IP66 Rosemount transmitter housing

mounts directly to the probe and contains the transmitter's

electronics, replacing common stand-alone field electronics. This integrated design minimizes the costs of

installing separate probe cable, conduit, and electronics.

The Oxymitter 5000's electronics also require 95% less

power to operate. Therefore, its components last longer.

The FOUNDATION fieldbus protocol provides a link into

Emerson Process Management’s PlantWeb

architecture. Instrument technicians can interface with the

Oxymitter from the operator console in the control room.

Service diagnostics and calibrations can be performed

remotely.

The Oxymitter 5000 is fully field-repairable. The probe's

design provides convenient access to internal probe

components so technicians can service the unit in house.

The cell and heater/thermocouple are fully field-replaceable. The Oxymitter 5000 contains no potentiometer

adjustments or jumpers.

The Oxymitter 5000 Oxygen Transmitter operates at

process temperatures up to 1300°F (700°C), providing a

fast response with high accuracy and reliability. Available

in lengths from 18 inches (457 mm) to 12 feet (3.66 m).

Optional accessories for the Oxymitter 5000 include:

– Auto calibration gas sequencer

– Remote, loop-powered LCD display of O

– High temperature accessories for temperatures up

to 1832°F (1000°C)

– Flame arrestor

– Abrasive shield

®

field-based

reading

2

Visit our website at www.processanalytic.com

On-line ordering available.

Page 2

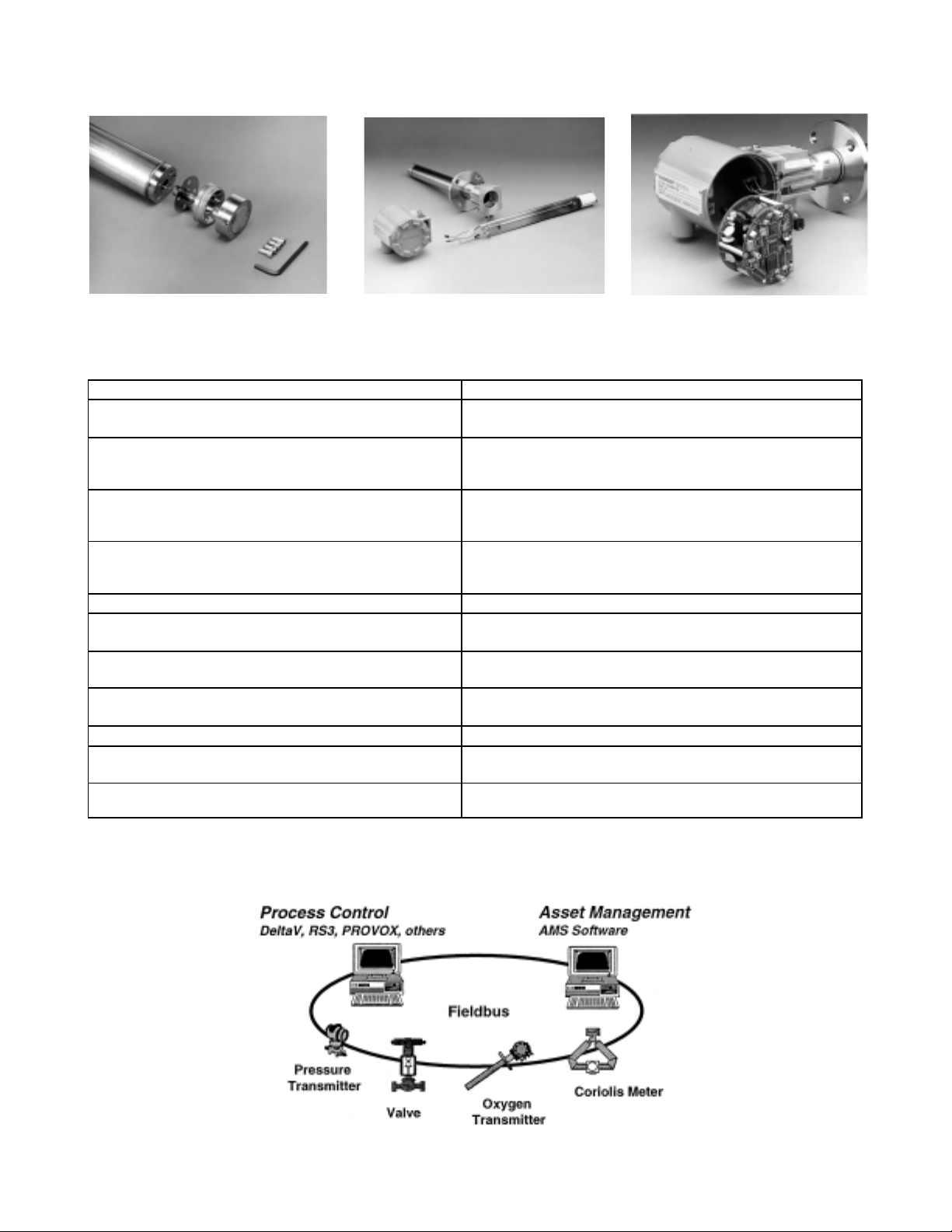

THE OXYMITTER 5000 OXYGEN TRANSMITTER IS COMPLETELY FIELD- REPAIRABLE

Sensor Cell

Assembly

Heater/Thermocouple

Assembly

Plug-In Electronics Module,

With Local Display/Keypad

OXYMITTER 5000 OXYGEN TRANSMITTER FEATURES AND BENEFITS

Features Benefits

FOUNDATION fieldbus communications All Information from analyzer is updated constantly, and

provided to the operator or technician. Low cost to maintain.

Rapid, accurate and reliable measurement of excess Provides inputs for significant fuel savings which normally

oxygen with a single in situ transmitter. pay for the analyzer in less than one year; best accuracy

specification in the industry!

Integrated oxygen probe and electronics simplifies Eliminates costs of mounting separate electronics.

installation. Eliminates cabling and conduit between probe and

electronics.

In situ design. No sample system, sample probes, Low installation and maintenance costs.

scrubbers, or pumps are necessary; test gas calibration

check without disturbing the probe.

Fast speed of response. In situ design ideal for closed loop control.

"Calibration recommended" indication. Online electrical Optimizes plant resources; reduces maintenance and

CAL check indicates need for calibration. calibration costs.

Field-replaceable cell, heater/thermocouple assembly Ease of maintenance.

and plug-in electronics module.

Suitable for use in process temperatures up to 1300°F Suitable for use in most combustion applications.

(700°C). Optionally up to 1832°F (1000°C).

Material of construction 316 LSS (all wetted parts). High resistance to corrosion.

Cell sensitivity increases logarithmically when oxygen Very useful for low oxygen levels.

decreases. Ideal for low excess air burners.

Automatic line voltage selections. Automatically selects from 85 to 265 VAC and 50/60 Hz.

without configuration or setup.

FOUNDATION fieldbus communications provides digital communications from field

device to field device over a single pair of wires.

Page 2

Page 3

SPECIFICATIONS

1

OXYMITTER 5000 OXYGEN TRANSMITTER

Net O2 Range 0-40% O

Accuracy: ±0.75% of reading or 0.05% O2,

whichever is greater

Lowest detectable limit - .05% O

System Response to Test Gas:

Initial response in less than

3 seconds

T

90

Temperature Limits:

Process: 32° to 1300°F (0° to 704°C)

up to 1832°F (1000°C) with

optional accessories

Electronics: -40° to 185°F (-40° to 85°C)

Operating temperature of

electronics inside of instrument

housing, as measured via Asset

Management Solutions software.

Probe Lengths, Nominal and Approximate Shipping

Weights:

18 in. (457 mm) package: 16 pounds (7.3 kg)

3 foot (0.91 m) package: 21 pounds (9.5 kg)

6 foot (1.83 m) package: 27 pounds (12.2 kg)

9 foot (2.74 m) package: 33 pounds (15.0 kg)

12 foot (3.66 m) package: 39 pounds (17.7 kg)

15 foot (4.6 m) package: 45 pounds (20.5 kg)

18 foot (5.5 m) package: 51 pounds (23 kg)

Mounting and Mounting Position:

Vertical or horizontal 12 inch (30 cm)

spool pieces are available to offset

transmitter housing from hot mounting

surfaces

(P/N 3D39761G02)

Materials:

Probe: Wetted or welded parts – 316L

stainless steel

Non-wetted parts – 304 stainless

steel, low-copper aluminum

Electronics

Enclosure: Low-copper aluminum

Calibration: Semi-automatic or automatic

Calibration Gas Mixtures

Recommended: 0.4% O

8% O2, balance N

(Ref. test gas kit #6296A27G01)

Calibration Gas

Flow: 5 scfh (2.5 l/m)

Reference Air: 2 scfh (1 l/m), clean, dry,

instrument-quality air (20.95% O

regulated to 5 psi (34 kPa)

2

in less than 8 seconds

, balance N

2

2

2

2

),

2

Electronics: NEMA 4X, IP 66 with fitting and pipe

on reference exhaust port to clean

dry atmosphere

Two 3/4” – 14 NPT conduit ports

Electrical Noise: Meets EN 50082-2 Electromagnetic

Compatibility Generic Immunity

Std., Part II

Includes ENG 1000 4-R for electrostatic discharge 4 Kv contact, 8 Kv

in air

Optionally ENG 1000 4-R "NamurIncreased" 8 Kv contact, 16 Kv in air

Includes IEC 801-4 fast transients-2

Kv on power supply and control lines

Hazardous Area

Certifications: NEC Class I, Div. 1, Groups B, C, D

CENELEC EExd II B + H2T2/T6

(electronics )

The Oxymitter 5000 complies with the

European Union PED 97/23/EC

Directive by virtue SEP.

ATEX compliant

Line Voltage: Universal 90 to 250 VAC, 48 to 62 Hz.

no switches or jumpers required 3/4"

– 14 NPT conduit port

Isolated Output: Digital

FOUNDATION fieldbus

Logic Signals: One logic I/O configured as a bi-

directional calibration handshake

signal optional calibration gas

sequencer.

5V, self-powered, 5 mA maximum

output

Fieldbus Logic:

Function Blocks: AI – execution time: 75 ms O

Heater temperature

2

Case temperature

Power Consumption Limits:

Power Consumption

of Probe Heater: 175 W nominal maximum

Power Consumption

of Electronics: 10 W nominal maximum

Fieldbus segment

power consumption: 17.5 mA

Emerson Process Management has satisfied all

obligations coming from the European legislation

to harmonize the product requirements in Europe.

1

All static performance characteristics are with operating variables constant. Specifications subject to change without notice.

The Oxymitter 5000's field electronics mount directly to

the oxygen probe in a standard NEMA 4X, IP 66 housing.

Page 3

Page 4

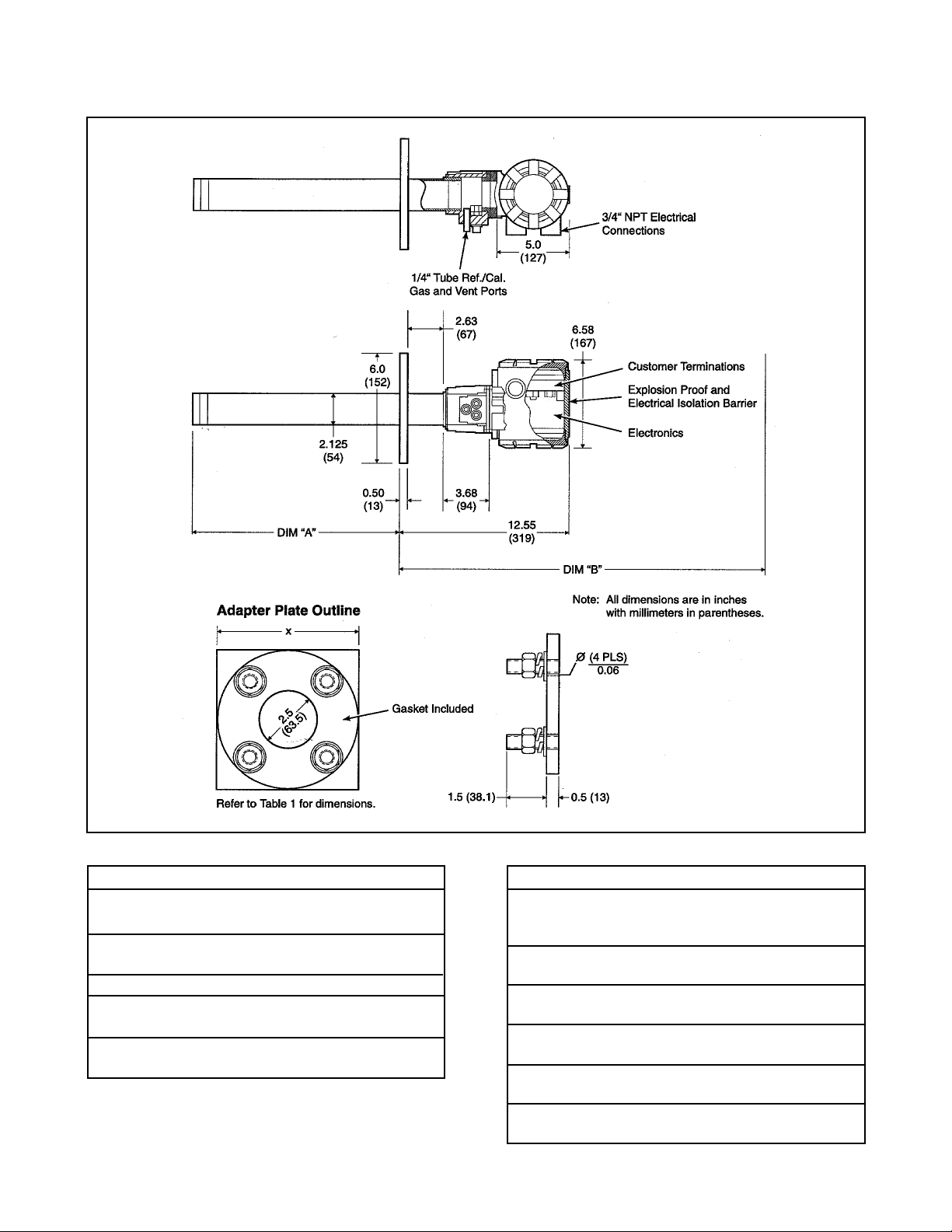

OUTLINE DIMENSIONS FOR OXYMITTER 5000 OXYGEN TRANSMITTER

Table I. Mounting Plate

Dimensions Dia. in. (mm)

ANSI DIN JIS

Flange (x) 6.00 7.5 6.5

(153) (190) (165)

Stud Size 5/8" – 11 M16 x 2 M12 x 1.75

4 Studs Eq. 4.75 BC 5.71 BC 5.71 BC

Sp. on BC

Flange (Y) 6.0 7.3 6.1

(153) (185) (155)

Page 4

Table II. Removal/Installation

Dim “A” Dim. “B”

Probe Insertion Removal

Length Depth Envelope

18 in. (457 mm) 16.00 32.38

Probes (407) (822)

3 ft. (0.91 m) 34.00 50.38

Probes (864) (1280)

6 ft. (1.83 m) 70.00 86.38

Probes (1778) (2194)

9 ft. (2.74 m) 106.00 122.38

Probes (2692) (3108)

12 ft. (3.66 m) 143.00 158.38

Probes (3607) (4023)

Page 5

ORDERING INFORMATION

OXT5A OXYMITTER 5000 IN SITU OXYGEN TRANSMITTER WITH FOUNDATION™ FIELDBUS COMMUNICATIONS

Oxygen Transmitter – Instruction Book

Code Sensing Probe Type

1 Ceramic diffusion element probe (ANSI) (N. American Std.)

2 Ceramic diffusion element flame arrestor probe (ANSI) (N. American Std.)

3 Snubber diffusion element (ANSI) (N. American Std.)

4 Ceramic diffusion element probe (DIN) (European Std.)

5 Snubber diffusion element flame arrestor probe (DIN) (European Std.)

6 Snubber diffusion element (DIN) (European Std.)

7 Ceramic diffusion element probe (JIS) (Japanese Std.)

8 Ceramic diffusion element probe flame arrestor probe (JIS) (Japanese Std.)

9 Snubber diffusion element (JIS) (Japanese Std.)

Code Probe Assembly

0 18 in. (457 mm) Probe

1 18 in. (457 mm) Probe with abrasive shield

2 3 ft. (0.91 m) Probe

3 3 ft. (0.91 m) Probe with abrasive shield

4 6 ft. (1.83 m) Probe

5 6 ft. (1.83 m) Probe with abrasive shield

6 9 ft. (2.74 m) Probe

7 9 ft. (2.74 m) Probe with abrasive shield

8 12 ft. (3.66 m) Probe

1

9 12 ft. (3.66 m) Probe with abrasive shield

A 15 ft. (4.6m) Probe with abrasive shield

B 18 ft. (5.5 m) Probe with abrasive shield

1

1

1

1

1

1

1

Code Mounting Hardware – Stack Side

0 No adaptor plate (“0” must also be chosen under “Mounting hardware – probe side” below)

1 New installation – square weld plate with studs

2 Mounting to Model 218 mounting plate (with Model 218 shield removed)

3 Mounting to existing Model 218 support shield

4 Competitor’s mounting

2

5 Mounting to Model 132 adapter plate

Code Mounting Hardware – Probe Side

0 No mounting hardware/no adaptor plate

1 Probe only (ANSI) (N. American Std.)

2 New bypass or new abrasive shield (ANSI) (N. American Std.)

4 Probe only (DIN) (European Std.)

5 New bypass or new abrasive shield (DIN) (European Std.)

7 Probe only (JIS) (Japanese Std.)

8 New bypass or new abrasive shield (JIS) (Japanese Std.)

Code Electronic Housing – NEMA 4X, IP 66

11 Standard filtered termination

12 Transient protected filtered termination

OXT5A 3 2 1 1 12 Cont’d Example

Note:

1

Recommended usages: high velocity particulates in flue stream, installation within 3.5 m (10 ft.) of soot blowers or heavy salt cake build up.

Applications: pulverized coal, recovery boilers, lime kiln. Regardless of application, abrasive shields with support brackets are recommended for

9 ft. (2.74 m) and 12 ft. (3.66 m) probe installations, particularly horizontal installations.

2

Where possible, specify SPS number; otherwise provide details of existing mounting plate as follows:

Plate with studs Bolt circle diameter, number and arrangement of studs, stud thread, stud height above mounting plate.

Plate without studs Bolt circle diameter, number and arrangement of holes, thread, depth of stud mounting plate with accessories.

Page 5

Page 6

ORDERING INFORMATION (Continued)

Cont’d Code Communications/Operator Interface

1 Membrane keypad – fieldbus

Code Language

1 English

2 German

3 French

4 Spanish

5 Italian

Code Termination Filtering

00 No option – specified as part of electronic housing

Code Calibration Accessories

00 No hardware

01 Cal. gas rotometer and reference gas set

02 Intelligent multiprobe sequencer Refer to Table 2

XX Single probe sequencer, mounted to Oxymitter Refer to Table 1

Code Basic Control Suite Functionality

00 Basic control suite

01 Deduct basic control suite

Cont’d 1 1 00 02 00

3

Start-up, calibration and operation can be implemented using the standard membrane keypad. Remote access and additional functionality available via fieldbus

communications (DeltaV™)

3

TABLE 1

ENTRY CODE NO YES BRASS/TEFLON STAINLESS STEEL HORIZONTAL VERTICAL

REFERENCE AIR SET FITTINGS/TUBING OXYMITTER MOUNTING

03 X X X

04 X X X

05 X X X

06 X X X

07 X X X

08 X X X

09 X X X

10 X X X

TABLE 2

LIST PART NUMBERS AS SEPARATE LINE ITEMS:

The Intelligent Multiprobe Sequencer (IMPS) will automatically calibrate up to 4 probes.

Part Number Description Number of Probes

3D39695G01 Intelligent Multiprobe Sequencer (IMPS) 1

3D39695G02 Intelligent Multiprobe Sequencer (IMPS) 2

3D39695G03 Intelligent Multiprobe Sequencer (IMPS) 3

3D39695G04 Intelligent Multiprobe Sequencer (IMPS) 4

3D39695G05 Intelligent Multiprobe Sequencer (IMPS) w/115 V heater 1

3D39695G06 Intelligent Multiprobe Sequencer (IMPS) w/115 V heater 2

3D39695G07 Intelligent Multiprobe Sequencer (IMPS) w/115 V heater 3

3D39695G08 Intelligent Multiprobe Sequencer (IMPS) w/115V heater 4

3D39695G09 Intelligent Multiprobe Sequencer (IMPS) w/220 V heater 1

3D39695G10 Intelligent Multiprobe Sequencer (IMPS) w/220 V heater 2

3D39695G11 Intelligent Multiprobe Sequencer (IMPS) w/220 V heater 3

3D39695G12 Intelligent Multiprobe Sequencer (IMPS) w/220 V heater 4

Rosemount Analytical no longer offers an integral Z-purge option for its oxygen (O2) analyzers. However, the IFT, MPS and IMPS

enclosures are still capable of Z or X purge by the customer.

CALIBRATION GAS BOTTLES

1

Part Number Description

1A99119G01 Two disposable calibration gas bottles – .4% and 8% O2 balance nitrogen 550 liters each

1A99119G02 Two flow regulators for cal. gas bottles

1A99119G03 Bottle rack

1

Bottles cannot be shipped via airfreight.

* When used with “calibration recommended” feature, bottles should provide 2 to 3 years of calibrations in normal service.

Page 6

Page 7

OUTLINE DIMENSIONS FOR OXYMITTER 5000 HAZARDOUS AREA OXYGEN

TRANSMITTER

6.58

(167)

0.50

(13)

Table I. Mounting Plate

Dimensions Dia. in. (mm)

ANSI DIN

Mtg. Plate (x) 7.75 8.5

(197) (215)

Stud Size 5/8" – 11 M16 x 2

4 Studs Eq. 6.00 BC 6.69 BC

Sp. on BC (152.4) BC (170) BC

Flange (Y) 7.5 6.7

(190) (170)

Table II. Removal/Installation

Dim “A” Dim. “B”

Probe Insertion Removal

Length Depth Envelope

18 in. (457 mm) 18.1 31.6

Probes (460) (803)

3 ft. (0.91 m) 36.1 57.0

Probes (917) (1448)

6 ft. (1.83 m) 72.1 85.6

Probes (1831) (2174)

Page 7

Page 8

ORDERING INFORMATION

OXT5C OXYMITTER 5000 EXPLOSION PROOF – IN SITU OXYGEN TRANSMITTER

Explosion Proof Oxygen Transmitter – Instruction Book

Code Sensing Probe Type with Flame Arrester

1 Ceramic diffusion element probe (ANSI 3 inch 150 lb.)

2 Snubber diffusion element (ANSI 3 inch 150 lb.)

3 Ceramic diffusion element probe (DIN 2527) – 1/4" tube fittings

4 Snubber diffusion element (DIN 2527) – 1/4" tube fittings

5 Ceramic diffusion element probe (JIS)

6 Snubber diffusion element (JIS)

7 Ceramic diffusion element probe (ANSI 3 inch 300 lb. flange)

Code Probe Assembly

0 18 in. probe

1 18 in. probe with 3 ft. bypass

2 18 in. probe with abrasive shield

3 3 ft. probe

4 3 ft. probe with abrasive shield

5 6 ft. probe

6 6 ft. probe with abrasive shield

Code Mounting Adapter – Stack Side

0 No adapter plate ("0" must also be chosen under "Mounting adapter – probe side" below)

1 New installation – square weld plate with studs

2 Model 218 mounting plate (with Model 218 shield removed)

3 Competitor's mount

1

1

1

2

Code Mounting Adapter – Probe Side

0 No adapter plate

1 Probe only (ANSI)

2 New bypass or new abrasive shield (ANSI)

4 Probe only (DIN)

5 New bypass or new abrasive shield (DIN)

7 Probe only (JIS)

8 New bypass or new abrasive shield (JIS)

Code Electronic Housing – NEMA 4X, IP 66

11 Standard filtered termination

12 Transient protected filtered termination

Code Operator Interface

3

1 Membrane keypad – FOUNDATION fieldbus

Code Language

1 English

2 German

3 French

4 Spanish

5 Italian

OXT5C 3 3 1 1 11 1 1 (Cont'd) EXAMPLE

Page 8

Page 9

ORDERING INFORMATION (Continued)

(Cont’d) Code Termination Filtering

00 No option – specified as part of electronic housing

Code Calibration Accessories

00 No hardware

01 Cal./ref. flowmeters and reference pressure regulator

02 IMPS 4000 (safe area only) Refer to Table 1

03 SPS 4000 remote mounted (safe area only) Refer to SPS matrix

Code Hazardous Area Approval

10 CENELEC – EEx d II B + H2T2/T6 (electronics)

20 CSA – Class I, Div. 1, Groups B, C and D Code T2/T6 (electronics)

Code Basic Control Suite Functionality

00 Basic control suite

01 Deduct basic control suite

Cont’d 00 01 10 00

NOTES:

1

Recommended usages: high velocity particulates in flue stream, installation within 3.5 m (10 ft.) of soot blowers or heavy salt cake build up.

Applications: pulverized coal, recovery boilers, lime kiln. Regardless of application, abrasive shields with support brackets are recommended for

9 ft. (2.74 m) and 12 ft. (3.66 m) probe installations, particularly horizontal installations.

2

Where possible specify SPS number; otherwise provide details of existing mounting plate as follows:

Plate with studs Bolt circle diameter, number and arrangement of studs, stud thread, stud height above mounting plate.

Plate without studs Bolt circle diameter, number and arrangement of holes, thread, depth of stud mounting plate with accessories.

3

Start-up, calibration and operation can be implemented using the standard membrane keypad. Remote access and additional functionality

available via FOUNDATION fieldbus communications (DeltaV™)

High Sulfur Service

For high sulfur applications, please add note to your purchase order requesting high sulfur cell part number 4847B63G02 in lieu of the

standard ZrO2 cell. Price adder is required.

Cell replacement kits for high sulfur service are also available. Consult part number 4849B94GXX in the Combustion Solutions Center

Spare Parts list.

TABLE 1

IMPS – Safe Area Only

LIST PART NUMBERS AS SEPARATE LINE ITEMS:

The Intelligent Multiprobe Sequencer (IMPS) will automatically calibrate up to 4 probes.

Part Number Description Number of Probes

3D39695G01 Intelligent multiprobe sequencer (IMPS) 1

3D39695G02 Intelligent multiprobe sequencer (IMPS) 2

3D39695G03 Intelligent multiprobe sequencer (IMPS) 3

3D39695G04 Intelligent multiprobe sequencer (IMPS) 4

3D39695G05 Intelligent multiprobe sequencer (IMPS) w/115 V heater 1

3D39695G06 Intelligent multiprobe sequencer (IMPS) w/115 V heater 2

3D39695G07 Intelligent multiprobe sequencer (IMPS) w/115 V heater 3

3D39695G08 Intelligent multiprobe sequencer (IMPS) w/115V heater 4

3D39695G09 Intelligent multiprobe sequencer (IMPS) w/220 V heater 1

3D39695G10 Intelligent multiprobe sequencer (IMPS) w/220 V heater 2

3D39695G11 Intelligent multiprobe sequencer (IMPS) w/220 V heater 3

3D39695G12 Intelligent multiprobe sequencer (IMPS) w/220 V heater 4

Page 9

Page 10

OXYMITTER 4000 ACCESSORIES

HART® Handheld 275 Communicator

The HART® 275 Communicator is an interface device

that provides a common communication link to HART

compatible instruments, such as the Sulfur-Resistant

Oxymitter 4000. HART

®

Communications Protocol

permits all the information available from the SulfurResistant Oxymitter 4000's electronics to be transmitted

over standard 4-20 mA signal wires. By attaching the

HART handheld communicator at a termination point

along the 4-20 mA signal line, a technician can diagnose

problems and configure and calibrate the SulfurResistant Oxymitter 4000 as if he or she were standing in

front of the instrument.

For more information, call Rosemount Analytical at

1-800-433-6076.

Bypass Packages

The specially designed Rosemount Analytical Bypass

Package for oxygen analyzers has proven to withstand

the high temperatures in process heaters while providing

the same advantages offered by the in situ sensor.

Inconel tubes provide effective resistance to corrosion,

and the other components common to other sampling

systems.

For more information, call Rosemount Analytical at

1-800-433-6076.

®

O2 Calibration Gas Kits

Rosemount Analytical's O2 Calibration Gas and Service

Kits have been carefully designed to provide a more

convenient and fully portable means of testing, calibrating, and servicing Rosemount Analytical's oxygen

analyzers. These lightweight, disposable gas cylinders

eliminate the need to rent gas bottles.

For more information, call Rosemount Analytical at

1-800-433-6076.

Page 10

Page 11

Page 11

Page 12

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to

be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available on request. We reserve the right to modify or improve the designs or specifications of our products

at any time without notice.

Emerson Process Management

Rosemount Analytical Inc.

Process Analytic Division

1201 North Main Street

P. O . B o x 9 0 1

Orrville, OH 44667-0901 USA

T 330.682.9010

Toll Free in US and Canada 800.433.6076

F 330.684.4434

e-mail : gas.csc@EmersonProcess.com

www.processanalytic.com

© Rosemount Analytical Inc., 2003. All rights reserved.

Printed in U .S . A. on recy cled pa per.

Loading...

Loading...