Page 1

Instruction Manual

IM-106-880, Rev 2.0

September 2009

OCX 8800

Oxygen/Combustibles Transmitter

http://www.raihome.com

Page 2

Page 3

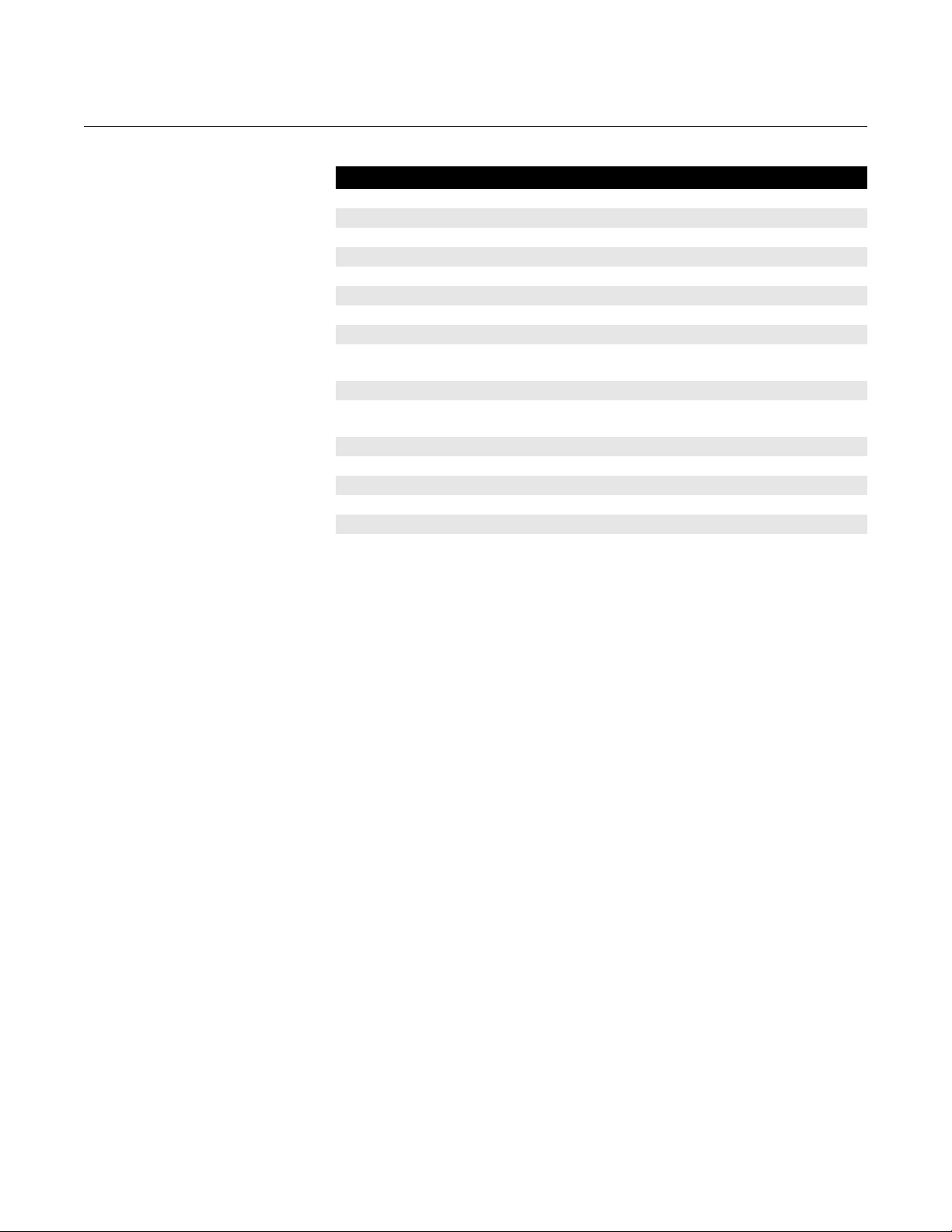

HIGHLIGHTS OF CHANGES

Effective September 2009, Rev 2.0

Page/Section Summary

Throughout IM Included coverage of all General Pu rpose OCX 8800 configurations/options in to this single

Instruction Manual.

Added FOUNDATION Fieldbus communications op tion.

Added coverage of optional COe Purge/Zero function equipment illustrations with related

installation and operating procedures.

Added coverage of three optional in-situ filters.

Added coverage of optional wall-mount or rack-mount blowback panel.

Adde coverage of PlantWeb Alert data for OCX 8800 units with FOUNDATION Fieldbus

communications.

Added Appendix B coverage of optional Moore Indu st rie s Site Pprog ra m m abl e Alar m for

OCX 8800 units with HART communications.

Page 4

Page 5

Instruction Manual

IM-106-880, Rev 2.0

September 2009

OCX 8800

Table of Contents

Essential Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

SECTION i

Introduction

SECTION 1

Description and

Specifications

SECTION 2

Installation

SECTION 3

Configuration and

Startup

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Component Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Pneumatic Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Initial Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Verify Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Initial Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Set Test Gas Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Calibration Solenoids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Blowback Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Calibration Verify Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Calibration Tolerance Feature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

COe Purge / Zero Feature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

OCX 8800 Reset Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

SECTION 4

Using the LOI

SECTION 5

Calibration

http://www..raihome.com

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Display Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

LOI Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

LOI Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

LOI Status Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

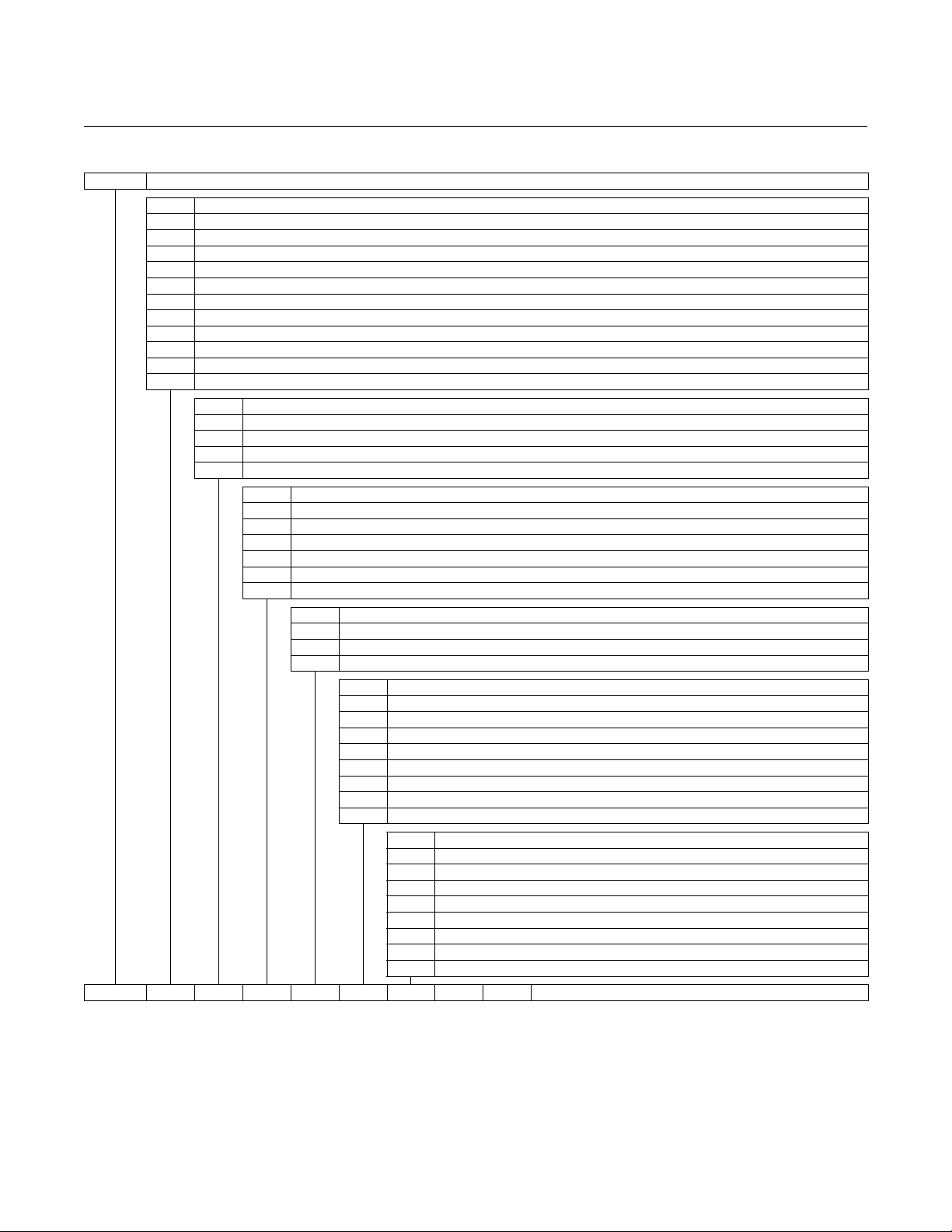

LOI Menu Tree. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Fully Automatic Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Operator - Initiated Autocalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Manual Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

D/A Trim Procedures - LOI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

D/A Trim Procedures - HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Page 6

OCX 8800

Instruction Manual

IM-106-880, Rev 2.0

September 2009

SECTION 6

Field Communicator

SECTION 7

Foundation Fieldbus

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Field Communicator Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Off-Line and On-Line Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

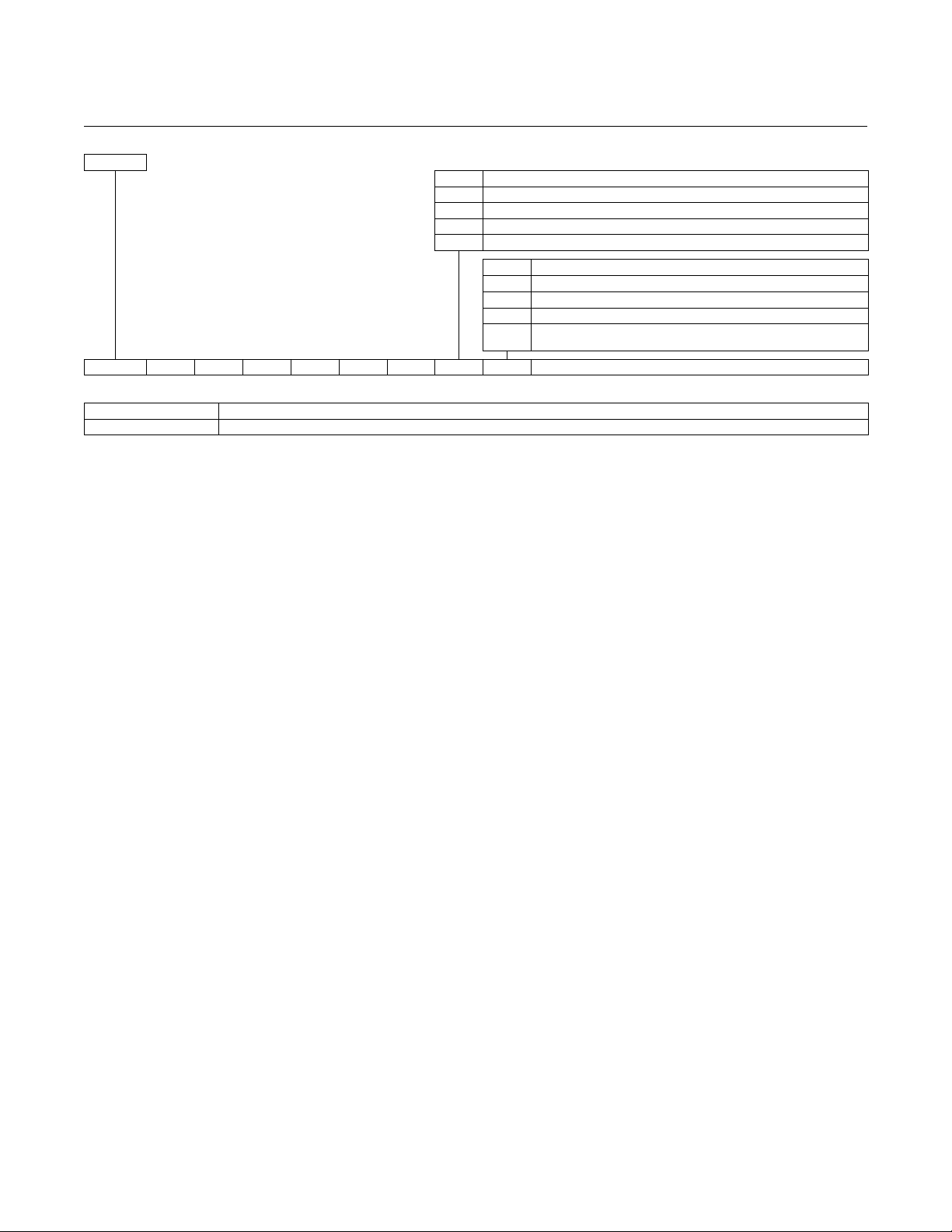

Hart Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Fieldbus Menu Tree. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Foundation Fieldbus Technology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Instrument-Specific Function Blocks . . . . . . . . . . . . . . . . . . . . . . . 7-4

Network Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

OCX Function Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Resource Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

PlantWeb Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Mapping of PWA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

PWA Simulate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Fieldbus/PWA Simulate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Configure Simulation with the Model 375 Field Communicator . . 7-11

Support Resource Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Transducer Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Transducer Block Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Transducer Block Enumerations . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Transducer Block Channel Assignments for AI Blocks . . . . . . . . 7-22

Transducer Block Channel Status . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Transducer Block Simulate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Support Transducer Block Errors. . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Analog Input (AI) Function Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Simulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Filtering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Signal Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Advanced Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

Application Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

Application Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

Proportional/Integral/Derivative (PID) Function Block. . . . . . . . . . . . 7-36

Setpoint Selection and Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

Filtering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

Feedforward Calculation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

Output Selection and Limiting. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

Bumpless Transfer and Setpoint Tracking . . . . . . . . . . . . . . . . . . 7-41

PID Equation Structures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

Reverse and Direct Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

Reset Limiting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

TOC-2

Page 7

Instruction Manual

IM-106-880, Rev 2.0

September 2009

OCX 8800

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

Application Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

Application Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-51

Arithmetic (ARTHM) Function Block . . . . . . . . . . . . . . . . . . . . . . . . . 7-52

Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-54

Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-55

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-55

Block Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-55

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-56

Application Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-56

Advanced Topics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-57

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-59

Input Selector (ISEL) Function Block. . . . . . . . . . . . . . . . . . . . . . . . . 7-59

Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-61

Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-61

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-62

Block Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-62

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-62

Application Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-63

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-64

Operation with Emerson Process Management DeltaV . . . . . . . . . . 7-65

About AMS and DeltaV Software . . . . . . . . . . . . . . . . . . . . . . . . . 7-65

SECTION 8

Troubleshooting

SECTION 9

Maintenance and Service

SECTION 10

Replacement Parts

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Electrical Noise. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Electrostatic Discharge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Total Power Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Diagnostic Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Fault Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Alarm Relay Events. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

OCX 8800 Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

OCX with Integral Electronics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

OCX with Remote Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Repair Sensor Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Sensor Housing Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Sensor Housing Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

Repair Electronics Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-29

Electronics Housing Disassembly . . . . . . . . . . . . . . . . . . . . . . . . 9-29

Electronics Housing Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

Replace Tube Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

Remove Tube Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

Install Tube Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-36

Sensor Housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Electronics Housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

O2 Cell and Heater Strut Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

TOC-3

Page 8

OCX 8800

Instruction Manual

IM-106-880, Rev 2.0

September 2009

APPENDIX A

Safety Data

APPENDIX B

SPA with HART Alarm

APPENDIX C

Return of Materials

Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Safety Data Sheet for Ceramic Fiber Products . . . . . . . . . . . . . . . . .A-24

High Pressure Gas Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-30

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Returning Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

TOC-4

Page 9

Instruction Manual

IM-106-880, Rev 2.0

September 2009

OCX 8800

Oxygen/Combustibles Transmitter

ESSENTIAL

INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Emerson Process Management designs, manufactures and tests its prod uct s

to meet many national and international standards. Because these

instruments are sophisticated technical prod ucts, you MUST properly inst all,

use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions MUST be adhered to

integrated into your safety program when installing, using, and maintaining

Emerson’s Rosemount Analytical products. Failure to follow the proper

instructions may cause any one of the following situations to occur: Loss of

life; personal injury; property damage; damage to this instrument; and

warranty invalidation.

• Read all instructions

product.

• If you do not understand any of the instructions, contact your

Emerson Process Management representative for clarification.

• Follow all warnings, cautions, and instructions

supplied with the product.

• Inform and educate your personnel in the proper installation,

operation, and maintenance of the product.

• Install your equipment as specified in the Installation Instructions

of the appropriate Instruction Manual and pe r a pplicable loca l and

national codes. Connect all products to the proper electrical and

pressure sources.

• To ensure proper performance, use qualified personnel

operate, update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people use

replacement parts specified by Emerson Process Management.

Unauthorized parts and procedures can affect the product's

performance, place the safe operation of your process at risk, and

VOID YOUR WARRANTY. Look-alike substitutions may result in fire,

electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers

are in place, except when maintenance is being performed by

qualified persons, to prevent electrical shock and personal injury.

The information contained in this document is subject to change without

notice.

prior to installing, operating, and servicing the

marked on and

to install,

and

http://www..raihome.com

If a Model 375 Field Communicator is used with this unit, the software within the Model 375

may require modification. If a software modification is required, please contact your local

Emerson Process Management Service Group or National Response Center at

1-800-654-7768.

Page 10

OCX 8800

Instruction Manual

IM-106-880, Rev 2.0

September 2009

ii

Page 11

Instruction Manual

IM-106-880, Rev 2.0

September 2009

OCX 8800

Section i Introduction

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page iii

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page iii

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page iv

PREFACE The purpose of this manual is to provide a comprehensive understanding of

the OCX 8800 components, functions, installation , and maintenance.

We recommend that you thoroughly familiarize yourself with the Introduction

and Installation sections before installing your transmitter.

The introduction presents the basic principles of the transmitter along with its

performance characteristics and components. The remaining sections contain

detailed procedures and information necessary to install and service the

transmitter.

Before contacting Emerson Process Management concerning any questions,

first consult this manual. It describes most situations encountered in your

equipment's operation and details necessary action.

DEFINITIONS The following definitions apply to WARNINGS, CAUTIONS, and NOTES

found throughout this publication.

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in injury, death, or long-term health hazards of personnel.

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in damage to or destruction of equipment, or loss of

effectiveness.

NOTE

Highlights an essential operating procedure, condition, or statement.

http://www..raihome.com

Page 12

OCX 8800

SYMBOLS

Instruction Manual

IM-106-880, Rev 2.0

September 2009

NOTE TO USERS

The number in the lower right corner of each illustration in this publication is a

manual illustration number. It is not a part number, and is not related to the

illustration in any technical manner.

NOTE

Read this manual before working with the product. For personal and system

safety, and for optimum product performance, make sure you thoroughly

understand the contents before installing, using, or maintaining this product.

iv

Page 13

Instruction Manual

IM-106-880, Rev 2.0

September 2009

OCX 8800

Section 1 Description and Specifications

Component Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 1-1

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 1-3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-12

Product Matrix - OCX 8800 . . . . . . . . . . . . . . . . . . . . . . . . . page 1-14

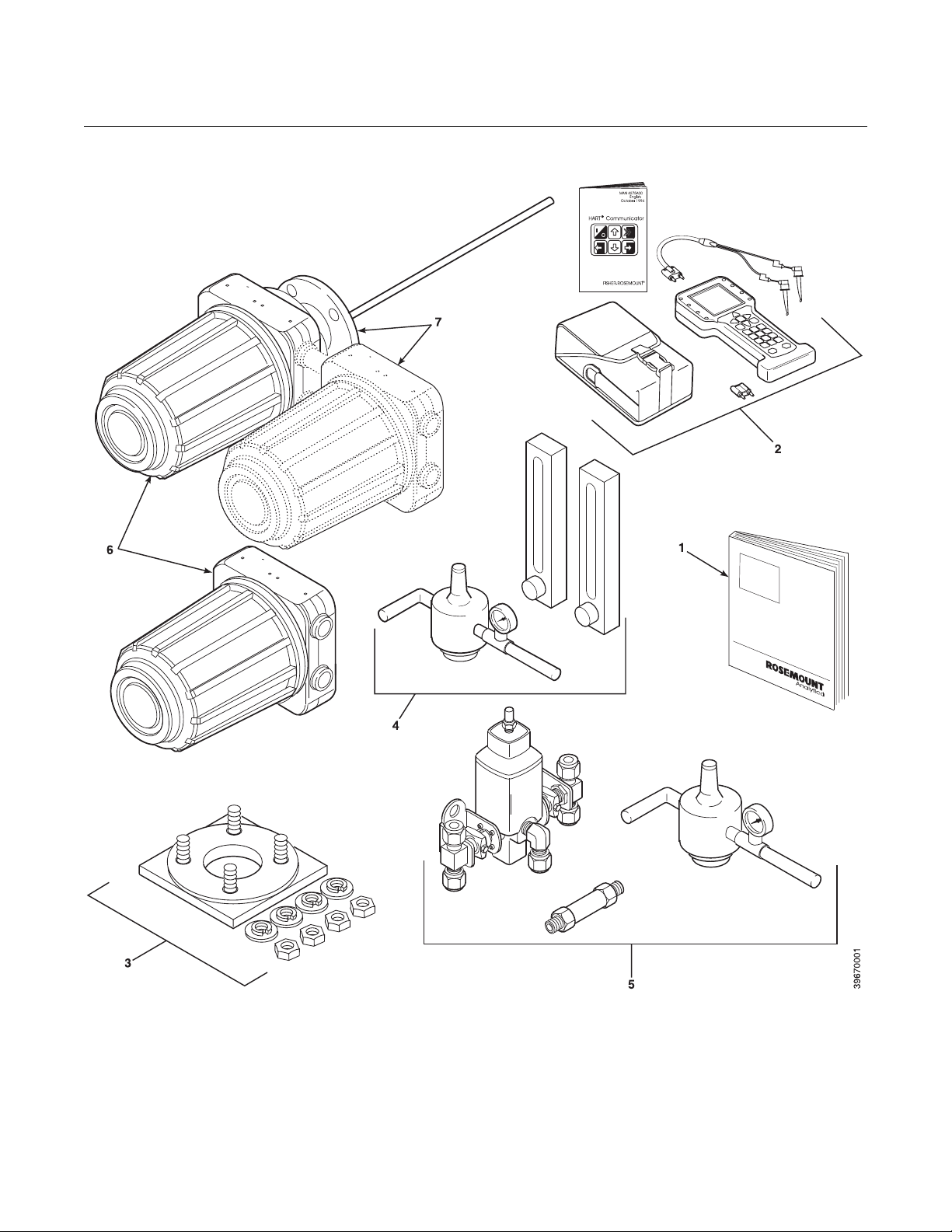

COMPONENT

CHECKLIST

A typical OCX 8800 Oxygen/Combustibles Transmitter package should

contain the items shown in Figure 1-1.

Use the product matrix in Table 1-1 at the end of this section to verify your

order number. The first part of the matrix defines the model. The last part

defines the various options and features of the OCX 8800. Check the model

number against the transmitter features and options, making sure options

specified by this number are on or included with the unit. Use this complete

model number for any correspondence with Emerson Process Management.

A list of accessories for use with the OCX 8800 is provided in Table 1-2.

http://www..raihome.com

Page 14

OCX 8800

Figure 1-1. Typical System Package

Instruction Manual

IM-106-880, Rev 2.0

September 2009

1. Instruction Manual

2. Field Communicator Package (optional)

3. Adapter Plate with Mounting Hardware and Gasket

4. Reference Air and Calibration Set (optional)

5. Blowback Hardware (optional)

6. OCX 8800 with Remote Electronics

7. OCX 8800 with Integral Electronics

1-2

Page 15

Instruction Manual

IM-106-880, Rev 2.0

September 2009

SYSTEM OVERVIEW Scope

This Instruction Manual supplies details needed to install, startup, operate,

and maintain the OCX 8800. Signal conditioning electronics outputs a digit al

signal representing oxygen (O

information, plus additional details, can be accessed with the 375 Field

communicator or Emerson Process Management AMS softwar e. The optional

local operator interface (LOI) also provides a communications interface with

the electronics.

System Description

The OCX 8800 is designed to measure oxygen and combustible

concentrations in flue gas temperatures up to 2600°F (1427°C). Electrical

connections, power and communications are made through two 3/4 NP T ports

in the flameproof electronics enclosure using fittings and cables provided by

the customer. Cable installation must meet NEC, IEC and/or other applicable

national or local codes for Class I, Zone 1, Group IIB +H2 T3/T6 permanently

mounted equipment. The transmitter is close coupled to the process and

requires minimal sample conditioning requirements.

The equipment measures oxygen percentage by reading the voltage

developed across a heated electrochemical cell, which consists of a small

yttria-stabilized, zirconia disc. Both sides of the disc are coated with porous

metal electrodes. When operated at the proper temperature, the millivolt

output of the cell is given by the following Nernst equation:

OCX 8800

) and combustibles (COe) values. This

2

EMF = KT log10 (P

Where:

1. P

is the partial pressure of the oxygen in the mea sured gas on one side

2

of the cell.

is the partial pressure of the oxygen in the reference air on the

2. P

1

opposite side of the cell.

3. T is the absolute temperature.

4. C is the cell constant.

5. K is an arithmetic constant.

NOTE

For best results, use clean, dry instrument air (20.95% oxygen) as the

reference air.

When the cell is at operating temperature and there are unequal oxygen

concentrations across the cell, oxygen ions will travel from the high oxygen

partial pressure side to the low oxygen partial pressure side of the cell. The

resulting logarithmic output voltage is approximately 50 mV per decade. The

output is proportional to the inverse logarithm of the oxygen concentration.

Therefore, the output signal increases as the oxygen concentration of the

sample gas decreases. This characteristic enables the OCX 8800 to provide

exceptional sensitivity at low oxygen concentrations.

1/P2

) + C

1-3

Page 16

OCX 8800

Instruction Manual

IM-106-880, Rev 2.0

September 2009

The OCX 8800 measures net oxygen concentration in the presence of all the

products of combustion, including water vapor. Therefore, it may be

considered an analysis on a "wet" basis. In comparison with older metho ds,

such as the portable apparatus, which provides an analysis on a "dry" gas

basis, the "wet" analysis will, in general, indicate a lower percentage of

oxygen. The difference will be proportional to the water content of the

sampled gas stream.

The OCX 8800 combustibles sensor is a catalytic sensor consisting of two

Resistance Devices (RTD). One RTD is the reference element covered with

an inert coating. The other RTD element is active, coated with a catalyst. As

the sample gases flow by the sensor, the combustible gases oxidize on the

surface of the active element. The oxidation that occurs produces heat and a

temperature rise in the active element. The temperature differ ence produces

a resistance relationship between the two elements that is directly

proportional to the concentration of combustibles in the sample gases.

The catalyst is specifically designed to detect carbon monoxide (CO), but the

sensor responds to other combustible gases. The sensor is calibrated using

CO, thus the output should be expressed in terms of CO. However, since the

sensor detects other combustible gases, the output cannot just be labeled

CO. The response of the sensor to other combustible gases gives an output

that is equivalent to the sensor detecting CO.

The term COe is used in this manual to describe the sensor output. This term

indicates that the sensor is calibrated in terms of CO, and that the sensor

output is equivalent to CO but not specific to CO.

Dilution air is provided to the COe sensor to ensure there is adequate oxygen

to fully oxidize any combustible gases regardless of the concentration of

oxygen in the process.

System Configuration

Transmitters are available in four lengths, giving the user the flexibility to use

a penetration appropriate to the size of the stack or duct. The length optio ns

are 18 in. (457 mm), 3 ft (0.91 m), 6 ft (1.83 m), or 9 ft (2.7 m). Probes are

available in three material options, 316L stainless steel, Inconel 600, and

ceramic to accommodate higher temperatures.

The electronics are contained in a separate housing from the sensors. When

the transmitter is configured with the integral electronics option the electronics

and sensor housings are mounted as a unit at the stack mounting flange.

When the transmitter is configured with the remote electronics option the

electronics are contained in a separate housing from the sensors. The

electronics housing may be mounted up to 150 feet from the sensor housing.

The electronics control both sensor temperatures and provide output signals

in one of two ways:

1. Individual 4-20 ma isolated outputs that are proportional to the

measured oxygen and combustibles co ncentrations. The oxygen ou tput

also contains HART communication.

2. Single FOUNDATION fieldbus output.

1-4

Page 17

Instruction Manual

IM-106-880, Rev 2.0

September 2009

OCX 8800

The power supply can accept voltages of 100 to 240 VAC and 50 to 60 Hz.

The electronics accepts millivolt signals generated by the sensors and

produces the outputs to be used by remotely connected devices. Refer to

Section 3, Configuration and Startu p for specific instructions upon initial

power up.

System Features

1. The O

concentration decreases.

2. HART or FOUNDA TION fieldbus communication is st andard. To use this

capability, you must have either:

a. Model 375 Field Communicator.

b. AMS software for the PC.

3. Oxygen cell and heater/thermocouple assembly are field replaceable.

4. Electronics are automatically configured for line voltages from 100 to

240 VAC.

5. An operator can calibrate and diagnostically troubleshoot the OCX 8800

in one of two ways:

a. LOI. The LOI is mounted to the end of the electronics module and

b. HART or FOUNDATION fieldbus interface. The OCX 8800's output

6. When the transmitter is configured without the LOI an operator must

calibrate and diagnostically troubleshoot the OCX 8800 using the HAR T

or FOUNDATION fieldbus Interface.

7. Optional Blowback System. The blowba ck sys tem pe rio dic ally blows

instrument air back through the sample line filter and out the sample

tube. This clears out particulate and keeps the sample line filter from

clogging.

cell output voltage and sensitivity increase as the oxygen

2

allows local communications with the electronics. Refer to Section 4,

Using the LOI, for more information.

line transmits a digital signal with the detected oxygen or

combustible levels encoded in a digital format. This infor mation can

be accessed through the following:

• Model 375 Field Communicator - The handheld field

communicator requires Device Description (DD) software specific

to the OCX 8800. The DD software will be supplied with many

Model 375 units, but can also be programmed into existing units

at most Emerson Process Management service offices. Refer to

Section 6, Field Communicator, for additional information.

• Personal Computer (PC) - The use of a personal computer

requires AMS software available from Emerson Process

Management.

• Selected Distributed Control Systems - The use of distributed

control systems requires input/output (I/O) hardware and AMS

software which permit HART or FOUNDATION fieldbus

communications.

1-5

Page 18

OCX 8800

Instruction Manual

IM-106-880, Rev 2.0

September 2009

System Operation

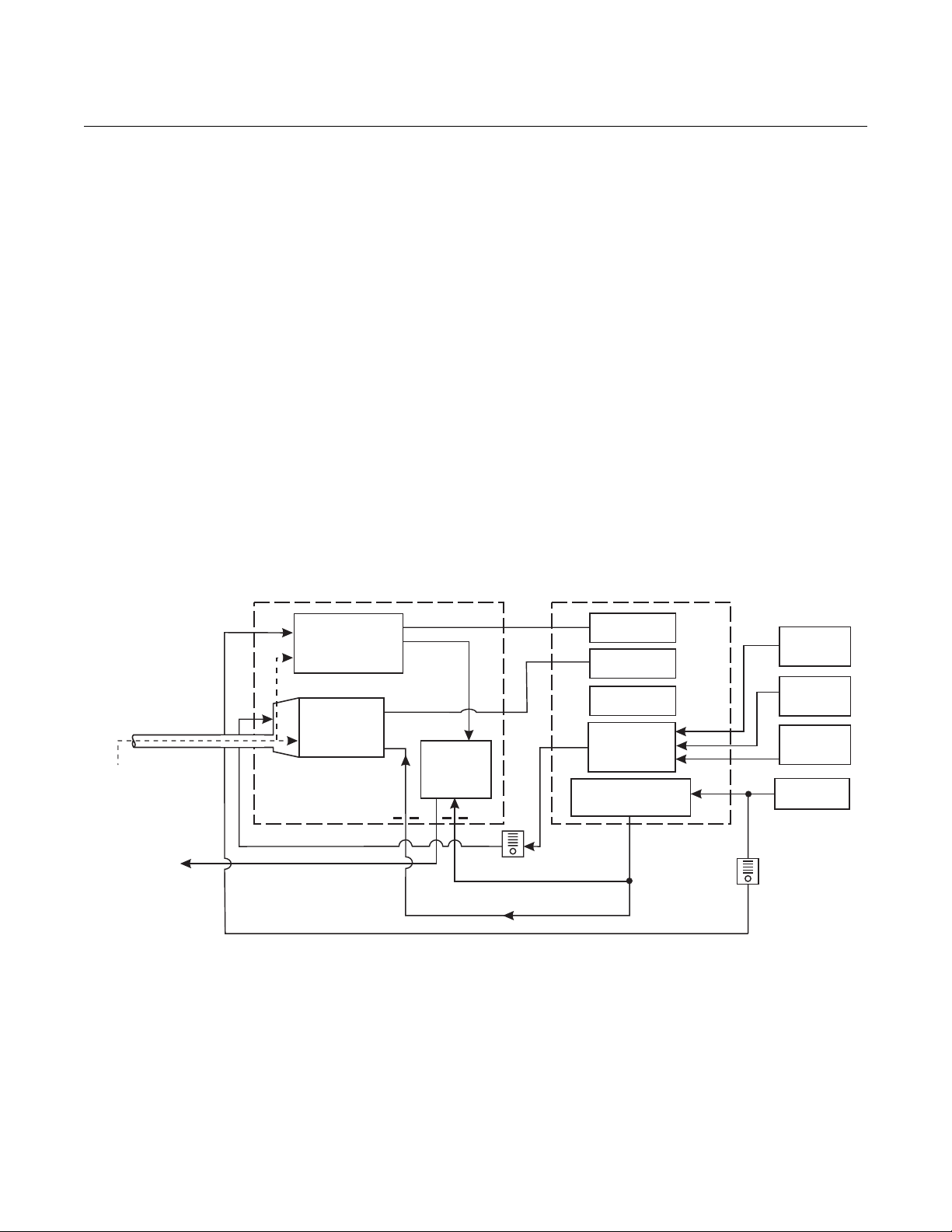

Figure 1-2 shows the relationship between the components of the OCX 8800.

The sensors and the electronics are contained in separate housings. The

sensor housing and probe mounts to a duct or process wall so that the prob e

protrudes into the flue gas stream. An air powered eductor continuously pulls

samples of the process flue gas through the probe to a chamber in front of the

sensor housing where the sample passes the O

the COe sensor. Dilution air is prov ided to the COe sensor and reference air

to the O

sensor. After the gas sample flows past the O2 sensor and through

2

the COe sensor, it is drawn through the eductor where it mixes with the

eductor air and exits through exhaust back into the system. The electronics

housing contains the CPU and communication boards which convert the

sensor inputs into digital output signals. The CPU can also initiate and

perform calibrations. Three test gasses and instrument air can be turned on

and off by solenoids. Test gas flow to the sensors is regulated by a flow meter

between the electronics and sensor housings. Instrument air is separated into

eductor air , reference air , and dilutio n air . The instrument air solenoid does not

allow air flow until the heaters are up to temperature. This minimizes the

amount of sampled process flue gas being pulled into cold sensors causing

condensation.

sensor and continues on to

2

Figure 1-2. System Operation Diagram

COe

Combustibles

Sensor

Probe

Sample

Gas

Exhaust

O

Sensor

SENSOR

HOUSING

2

Eductor

Eductor Air

ELECTRONICS

Solenoids

Instrument Air

Flow Meter

7 scfh

Reference Air

HOUSING

CPU

COMM

Board

Power

Supply

Optional

Test Gas

Solenoid

Dilution Air

Low O

Test Gas

High O

Test Gas

CO

Test Gas

Instrument

Air

Flow Meter

50 cc/min.

(0.1 scfh)

2

2

39690001

1-6

Page 19

Instruction Manual

IM-106-880, Rev 2.0

September 2009

OCX 8800

Handling the OCX 8800

It is important that printed circuit boards and integrated circuits are handled only when

adequate antistatic precautions have been taken to prevent possible equipment damage.

The OCX 8800 is designed for industrial application. Treat each component of the system

with care to avoid physical damage. The probe may contain components made from

ceramics, which are susceptible to shock when mishandled.

System Considerations

Prior to installing your OCX 8800, make sure you have all the components

necessary to make the system installation. Ensure all the components are

properly integrated to make the system functional.

After verifying that you have all the component s, select mounting locations

and determine how each component will be placed in terms of available line

voltage, ambient temperatures, environmental considerations, convenience,

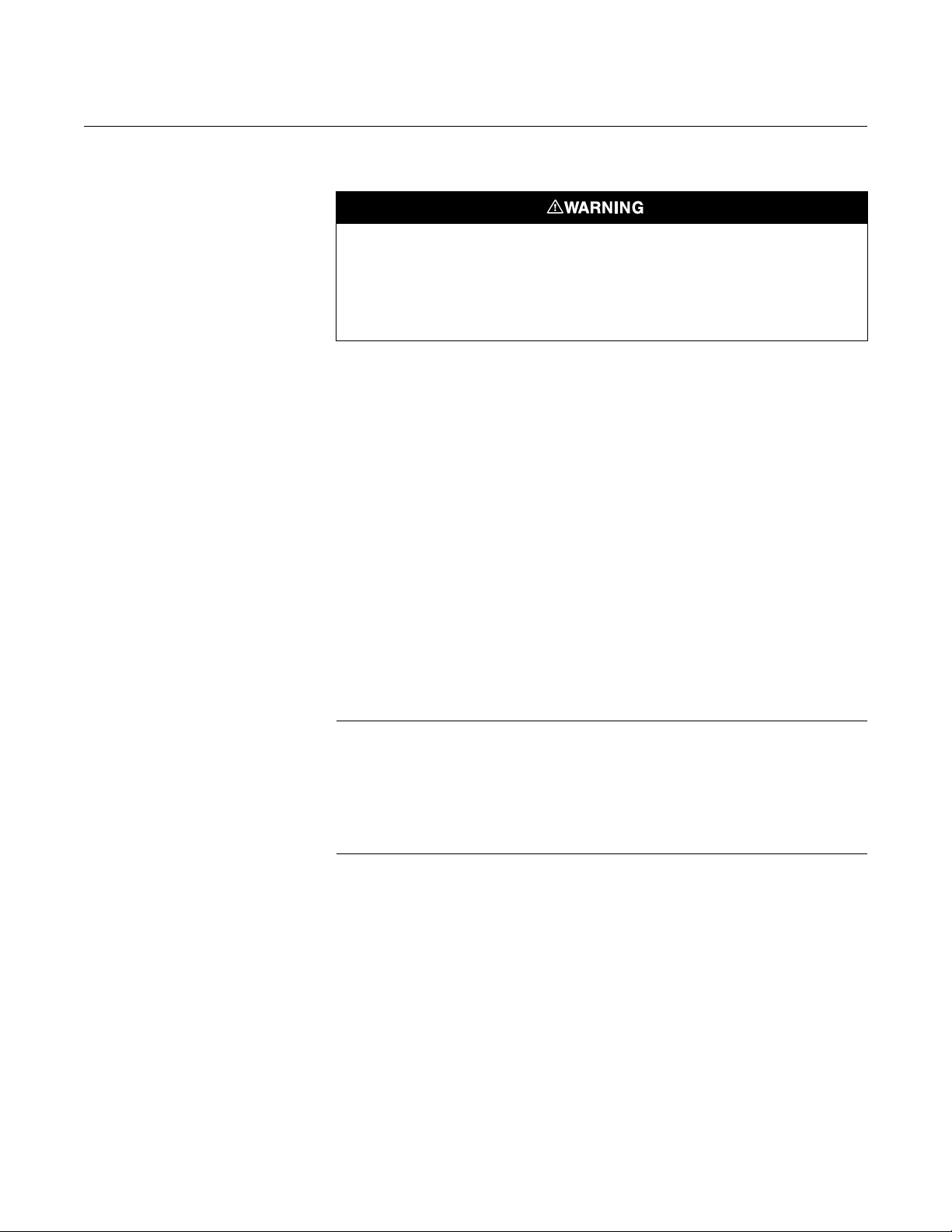

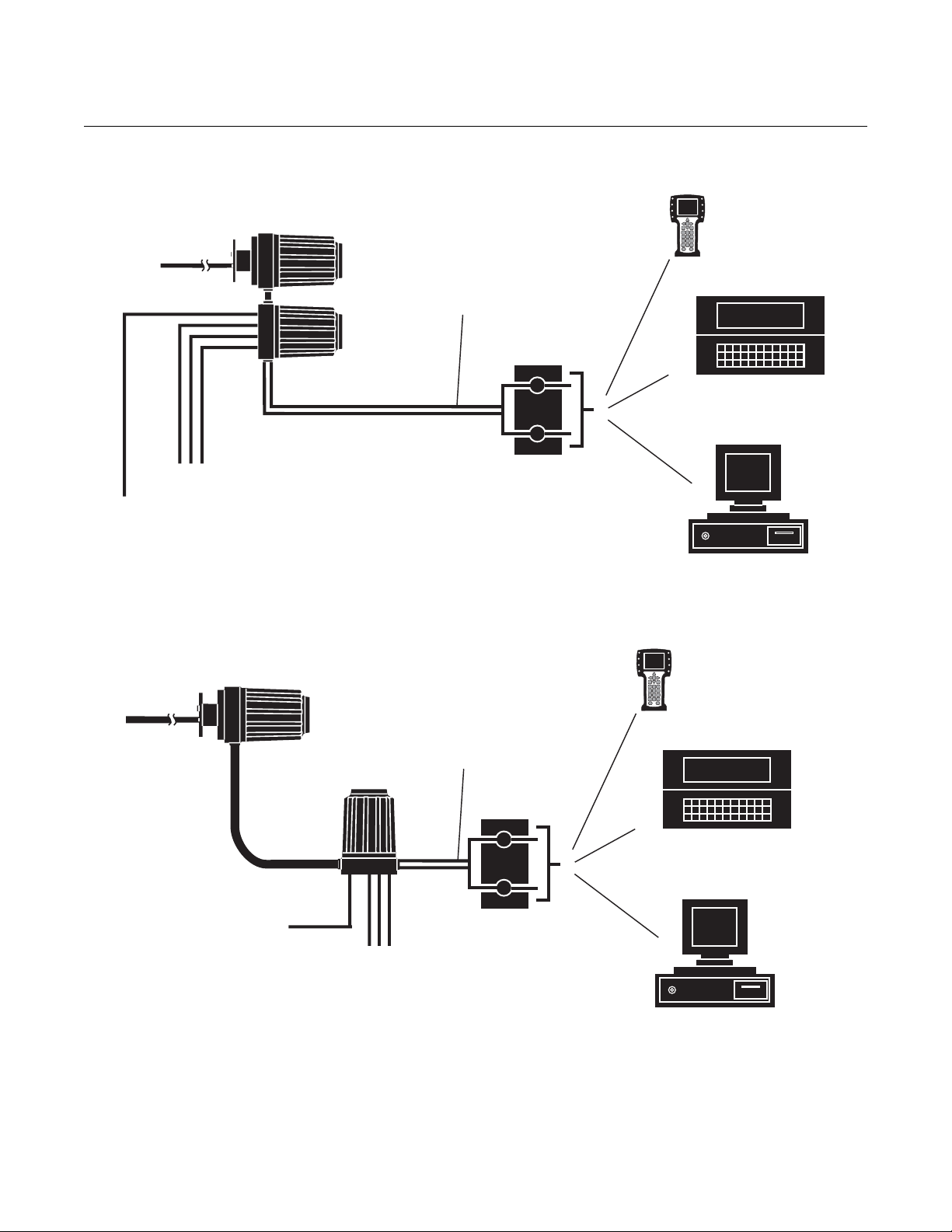

and serviceability. Figure 1-3 shows a typical system wiring for a system with

integral electronics. Figure 1-4 shows a typical system wiring for a system

with remote electronics. Simplified installations for the OCX 8800 are shown

in Figure 1-5 and Figure 1-6. Figure 1-7 shows the dimensions for the

optional sample tube support. Figure 1-8 shows the dimensions for the

optional in-situ filters. Figure 1-9 shows the optional panel mounted blowback.

A source of instrument air is required at the OCX 8800 for reference air,

dilution air, and eductor air. Since the OCX 8800 is equipped with an in-place

calibration feature, provision should be made for connecting test gas tanks to

the OCX 8800 when it is to be calibrated.

NOTE

The electronics module is designed to meet Type 4X and IP66 and the

electronic components are rated to temperatures up to 185°F (85°C).

Retain packaging in which the unit arrived from the factory in case any

components are to be shipped to another site. This packaging has been

designed to protect the product.

1-7

Page 20

Instruction Manual

IM-106-880, Rev 2.0

OCX 8800

Figure 1-3. Communication Connections and AMS Application - OCX 8800 with Integral Electronics

September 2009

Model 375

Field

Communicator

Customer’s Laptop

with AMS

AMS

Instrument

Air

OCX 8800 with

Integral Electronics

3 calibration

gas lines by

customer

[300 ft (91 m) max.)

Signal Output

(Twisted Pairs)

Termination in

Control Room

Figure 1-4. Communication Connections and AMS Application - OCX 8800 with Remote Electronics

38850003

OCX 8800

Sensor Housing

Instrument

Air

OCX 8800

Electronics Housing

3 calibration

gas lines by

customer

[300 ft (91 m) max.)

Signal Output

(Twisted Pairs)

Termination in

Control Room

Model 375

Field

Communicator

Customer’s Laptop

with AMS

AMS

38850004

1-8

Page 21

Instruction Manual

IM-106-880, Rev 2.0

September 2009

Figure 1-5. Typical System Installation - Integral Electronics

OCX 8800

Gases

Stack

Test Gas

Flow Meter

Dilution

Air

Flow

Meter

Adapter

Plate

Duct

Figure 1-6. Ty pical System Installation - Remote Electronics

Gases

OCX 8800 with

ELECTRONICS

Pressure

Regulator

High O Test Gas

2

Low O Test Gas

2

CO Test Gas

Duct

INTEGRAL

Signal Outputs

(Twisted Pairs)

Line Voltage

Instrument Air

Supply

(Reference Gas)

37390063

OCX 8800 with

REMOTE

ELECTRONICS

Heater

Power Cable

[up to 150 ft (46 m)]

Signal Cable

[up to 150 ft (46 m)]

Stack

Dilution

Air

Flow

Meter

Test Gas

Flow Meter

Pressure

Regulator

High O Test Gas

Low O Test Gas

CO Test Gas

Signal Outputs

(Twisted Pairs)

Line Voltage

Instrument Air

Supply

(Reference Gas)

2

2

37390064

1-9

Page 22

OCX 8800

Figure 1-7. Optional Sample Tube Support

Instruction Manual

IM-106-880, Rev 2.0

September 2009

1-10

Page 23

Instruction Manual

IM-106-880, Rev 2.0

September 2009

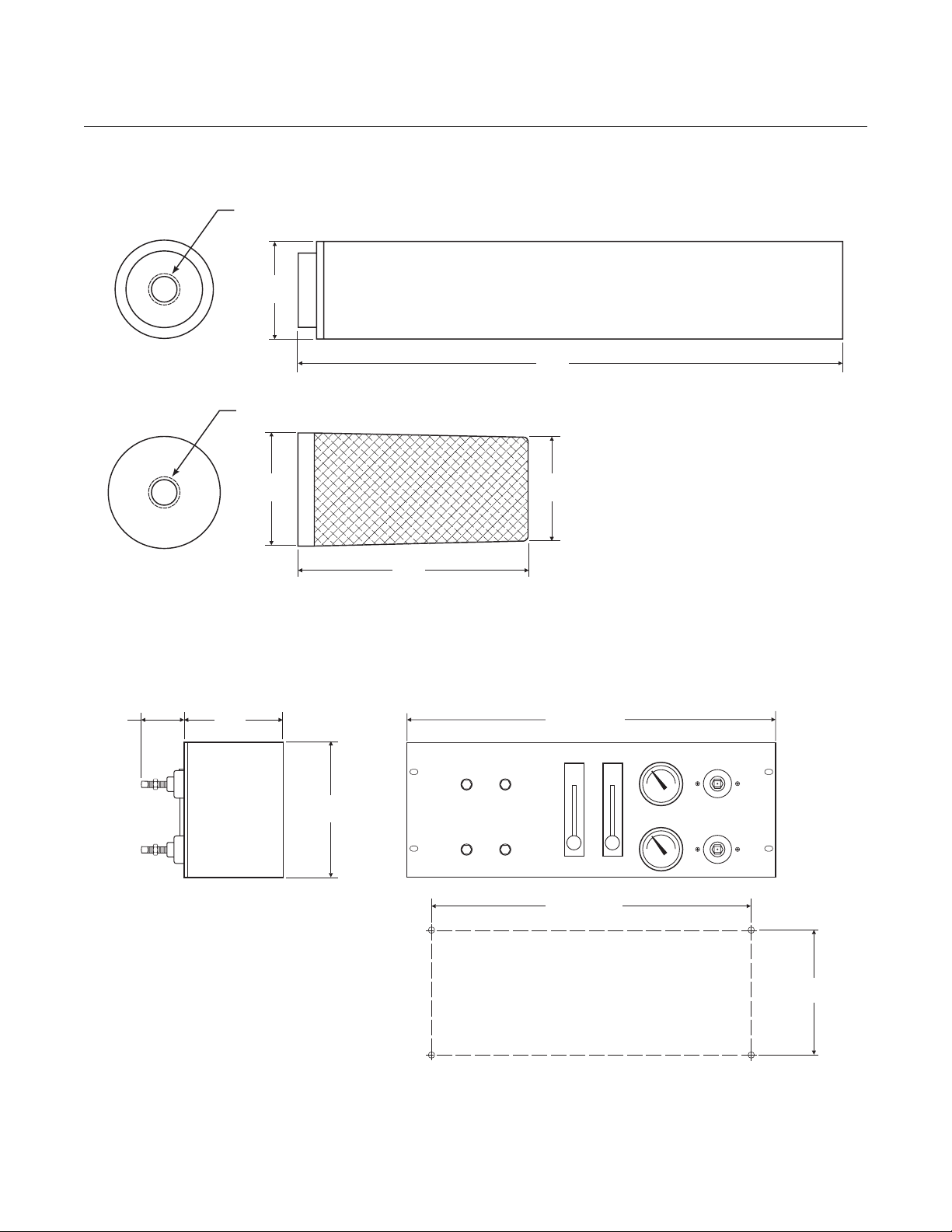

Figure 1-8. Optional InSitu Filters

1/4-18 NPT

1.3

(33)

1/4-18 NPT

7.3

(186)

InSitu Stainless Steel or Hastolloy Filter

OCX 8800

2.0

(50)

4.0

(102)

1.8

(46)

InSitu High Surface Area Stainless Steel Filter

Figure 1-9. Optional Panel Mounted Blowback and Calibration/Reference Air Set (19” Rack or Wall Mount)

2.2

(55.9)

5.00

(127)

6.97

(177)

CALIBRATION/BLOWBACK

PANEL

OCX 8800

PROCESS ANALYTICAL DIVISION

1-440-914-1261

www.raihome.com

19.00 (482.6)

DILUTION GAS CAL GAS

16.5 (419.1)

Wall Mount

SET TO 55 PSIG BLOWBACK AIR

OCX88A: 35 PSIG

OCX88C: 45 PSIG

PRESSURE

REFERENCE AIR

PRESSURE

39930006

Wall Mount Hole Pattern

6.0 (152.4)

Wall Mount

39930007

1-11

Page 24

OCX 8800

SPECIFICATIONS

Instruction Manual

IM-106-880, Rev 2.0

September 2009

Specifications

Range 0-1% to 0-40% O2, fully field selectable

Net O

2

Combustibles 0-1000 ppm to 0-5%, fully field selectable

Accuracy

Oxygen ± 0.75% of reading or 0.05% O2 (whichever is greater)

Combustibles ± 2% range

System Response to

Test Gas

Oxygen 10 sec T90

Combustibles 25 sec T90

Temperature Limits

Process 32° to 2600°F (0° to 1427°C)

Sensors Housing -40° to 212°F (-40° to 100°C), ambient

Electronics Housing -40° to 149°F (-40° to 65° C), ambient

Local Operator

Interface

Nominal and Approximate

Shipping Weights

18 in. (457 mm)

probe package

3 ft (0.91 m) probe

package

6 ft (1.83 m) probe

package

9 ft (2.74 m) probe

package

Housings Mounting Integral Electronics

Mounting and Mounting

Positions - Remote

Electronics

Sensors Housing Flange

Electronics Housing Wall/Pipe

Materials

Probes 316L stainless steel - 1300°F (704°C)

Enclosures Low-copper aluminum

Calibration Semi-automatic or automatic

Calibration Gas Mixtures

Recommended

(Ref. test gas bottles

kit #1A99119G04)

Calibration Gas Flow 7 scfh (3.3 l/m), regulated to 20 to 30 psi (138 to 207 kPa)

Reference Air 2 scfh (1 l/m), clean, dry instrument-quality air (20.95% O

Eductor Air 5 scfh (2.5 l/m), clean, dry, instrument-quality air 20.95% O2),

Dilution Air 0.1 scfh (0.05 l/m), clean, dry, instrument-quality air (20.95% O

-40° to 185°F (-40° to 85°C), internal - operating temperature of

electronics inside instrument housing, as read by HART or

FOUNDATION fieldbus

-40° to 158°F (-40° to 70°C), ambient

[At temperatures above 158°F (70°C) inside instrument housing,

the infrared keypad will cease to function, but the OCX 8800 will

continue to operate properly.]

54 lbs (20 kg)

55 lbs (20.5 kg)

57 lbs (21 kg)

59 lbs (22 kg)

Flange

Inconel 600 - 1832°F (1000°C)

Ceramic - 2600°F (1427°C)

0.4% O

8% O2, Balance N

1000 ppm CO, Balance Air

regulated to 35 psi (241 kPa)

regulated to 35 psi (241 kPa)

regulated to 35 psi (241 kPa)

, Balance N

2

Table continued on next page

2

2

),

2

)

2

1-12

Page 25

Instruction Manual

IM-106-880, Rev 2.0

September 2009

OCX 8800

Specifications

Blowback Air (optional) Clean, dry, instrument-quality air (20.95% O2), regulated to 55 psi

(379 kPa)

Sensors Housing Type 4X, IP66 with fitting and pipe on reference exhaust port to

clean, dry atmosphere, two 3/4-14 NPT conduit ports

Electronics Housing Type 4X, IP66 with fitting and pipe on reference exhaust port to

clean, dry atmosphere, two 3/4-14 NPT conduit ports

Certifications

CUS

Electrical Noise EN 61326-1, Class A

Line Voltage Universal 100 to 240 VAC ±10%, 50 to 60 Hz, no switches or

jumpers required, 3/4-14 NPT conduit port

Pollution Degree 2

Over Voltage Category II

Relative Humidity 5 to 95% (non-condensing)

Isolated Output

Oxygen 4-20 mAdc, 950 ohm maximum, with HART or FOUNDATION

fieldbus capability only

Combustibles 4-20 mAdc, 950 ohm maximum (Not present with FOUNDATION

fieldbus)

Alarm Alarm output relay - dry contact, form C, 30mA, 30VDC capacity

Power Consumption 750 W maximum

NOTE

All static performance characteristics are with operati ng variables const ant. Specific ations subject t o change

without notice.

APPROVED

1-13

Page 26

OCX 8800

Table 1-1. Prod uct Matrix - OCX 8800

OCX88A O2/Combustibles Transmitter

Code Probe Length and Material

00 No Probe or Exhaust Tube

11 18 in. (457 mm) 316 SST up to 1300°F (704°C)

12 3 ft (0.91 m) 316 SST up to 1300°F (704°C)

13 6 ft (1.83 m) 316 SST up to 1300°F (704°C)

14 9 ft (2.7 m) 316 SST up to 1300°F (704°C)

21 18 in. (457 mm) Inconel 600 up to 1832°F (1000°C)

22 3 ft (0.91 m) Inconel 600 up to 1832°F (1000°C)

23 6 ft (1.83 m) Inconel 600 up to 1832°F (1000°C)

24 9 ft (2.7 m) Inconel 600 up to 1832°F (1000°C)

31 18 in. (457 mm) Ceramic up to 2600°F (1427°C)

32 3 ft (0.91 m) Ceramic up to 2600°F (1427°C)

Code Probe Mounting Assembly

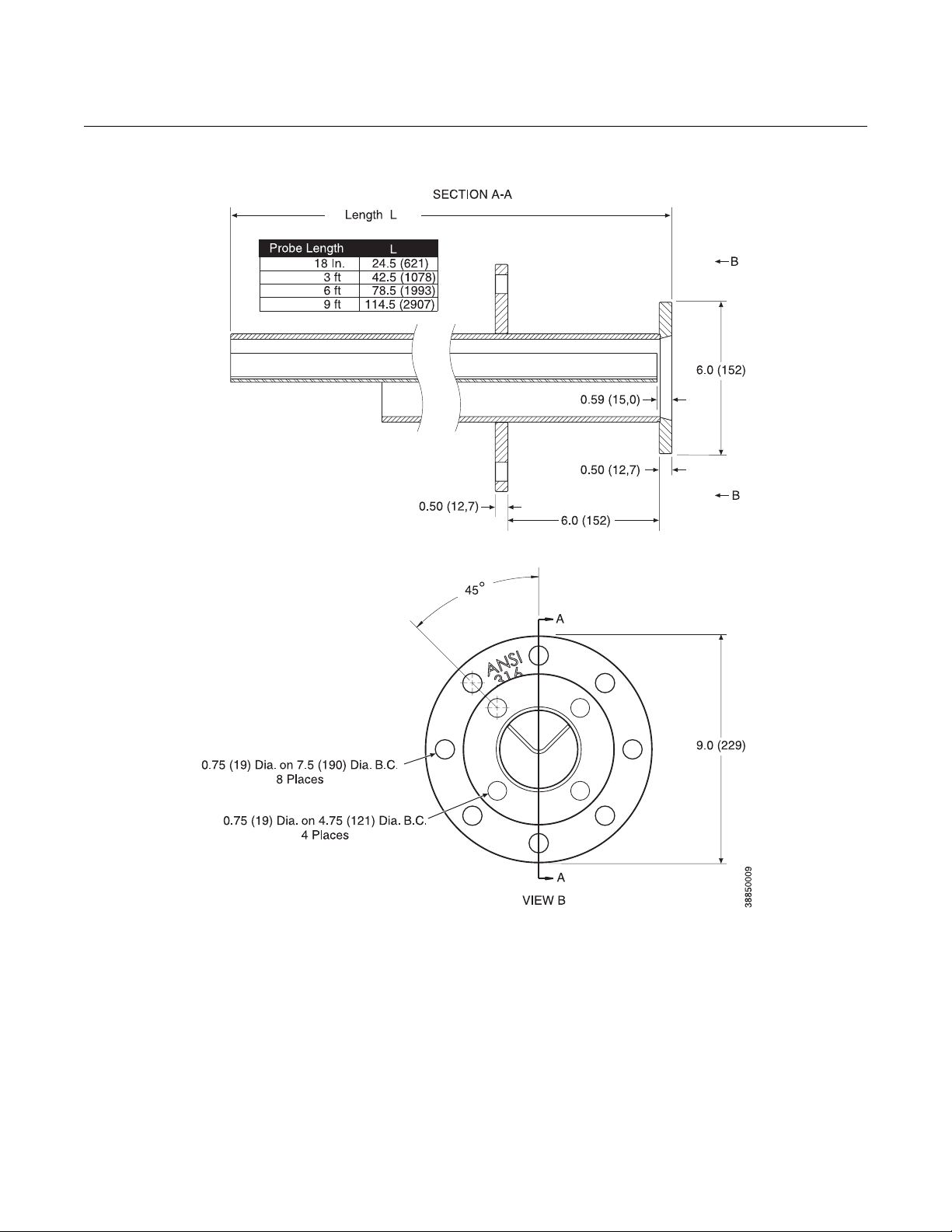

10 (ANSI 2 in. 150 lb) 6" dia. flange, 4.75" BC with 4 x 0.75" dia. holes - Standard O2 Cell

11 (ANSI 2 in. 150 lb ) 6" dia. flange, 4.75" BC with 4 x 0.75" dia. holes - High Sulfur O2 Cell

20 (DIN) 185 mm dia. flange, 145 mm BC with 4 x 18 mm dia. holes - Standard O2 Cell

21 (DIN) 185 mm dia. flange, 145 mm BC with 4 x 18 mm dia. holes - High Sulfur O2 Cell

Code Mounting Hardware - Stack Side

0 No Adapter Plate (“0” must be chose n under “Mounting Adapter - Probe Side” below)

1 New Installation - Square weld plate with studs

2 Model 218/240 Mounting Plate (with Model 218/240 Shield Removed)

3 Existing Model 218/240 Support Shield

4 Competitor’s Mount

5 Model 132 Adapter Plate

Code Mounting Hardware - Probe Side

0 No Adapter Plate

1 Probe Only (ANSI)

4 Probe Only (DIN)

Code Electronics Housing - NEMA 4X, IP66 HART Communications

H1 HART Communications - Basic Unit

H2 HART Communications - Local Operator Interface

H3 HART Communications - Calibration Solenoids

H4 HART Communications - Local Operator Interfac e and Calibration Solenoids

OCX88A 11 10 1 1 H3 06 Example

(1)

F1 Fieldbus Communications - Basic Unit

F2 Fieldbus Communications - Local Operator Interface

F3 Fieldbus Communications - Calibration Solenoids

F4 Fieldbus Communications - Local Operator Interface and Calibration Solenoids

Code Electronics Mount i ng

01 Integral to Sensor Housing Electronics

02 Split Architecture with no cable

03 Split Architecture with 6M (20 Ft.) cable

04 Split Architecture with 12M (40 Ft.) cable

05 Split Architecture with 18M (60 Ft.) cable

06 Split Architecture with 24M (80 Ft.) cable

07 Split Architecture with 30M (100 Ft.) cable

08 Split Architecture with 45M (150 Ft.) cable

Instruction Manual

IM-106-880, Rev 2.0

September 2009

1-14

Page 27

Instruction Manual

IM-106-880, Rev 2.0

September 2009

Cont’d

Code In-Situ Filter

0 None

1 Stainless Steel

2 High Surface Area Stainless Steel

.3Hastelloy

Code

Accessories

0 None

2 Cal. Gas/Flow Rotometers & Ref. Gas Set

3 Cal. Gas/Flow Rotometers & Ref. Gas Set w/ Blowback

Cal. Gas/Flow Rotometers & Ref. Gas Set w/ Blo wback - Panel

4

Mounted

OCX88A 11 10 1 1 H3 06 0 0 Example

NOTES:

(1)

Provide details of the existing mounting plate as follows:

Plate with studs Bolt circle diameter, number, and arrangement of studs, stud thread, stud height above mounting plate.

Plate without studs Bolt circle diameter, number, and arrangement of holes, thread, depth of stud mounting plate with accessories.

OCX 8800

1-15

Page 28

OCX 8800

Table 1-2. Accessories

Instruction Manual

PART NUMBER DESCRIPTION

1A99119H01 Oxygen test gas bottle; 0.4% O

1A99119H02 Oxygen test gas bottle; 8.0% O2, balance N

1A 99119H07 CO test gas bottle; 1000 ppm CO, balance air

1A99120H02 Regulator for Oxygen (may need 2)

1A99120H03 Regulator for CO test gas

1A99119G06 Wall mount bracket for test gas bottles

1A99119G05 Test gas regulators kit

1A99119G04 Test gas bottles kit

1A99292H01

4851B40G02 Wall or Pipe Mounting Kit

1A99784H02

6A00171G01 Power line filter kit

6A00288G01 Sample Tube Support, 18 in. (457 mm)

6A00288G02 Sample Tube Support, 3 Ft. (0.91 m)

6A00288G02 Sample Tube Support, 6 Ft. (1.83 m)

6A00288G04 Sample Tube Support, 9 Ft. (2.7 m)

6P00162H01 Flange Insulator

Moore Industries SPA for Low O

Calibration Status, and Unit Fail

375 Field Communicator with 12 Megabyte buffer,

model no. 375HR1EKLU

, balance N

2

Alarm, High COe Alarm,

2

IM-106-880, Rev 2.0

September 2009

2

2

1-16

Page 29

Instruction Manual

IM-106-880, Rev 2.0

September 2009

Section 2 Installation

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-8

Pneumatic Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-13

Initial Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 2-24

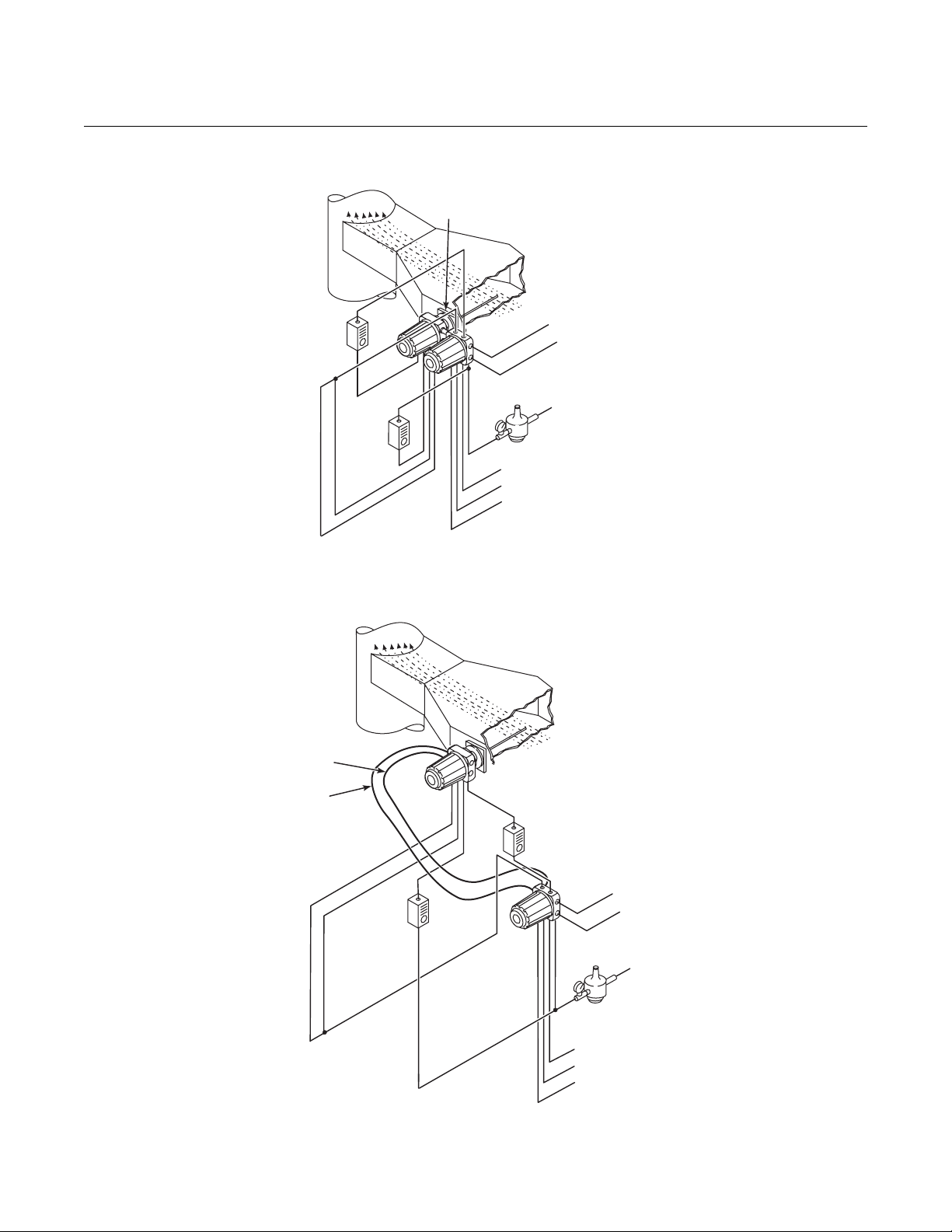

Before installing this equipment, read the "Safety instructions for the wiring and installation

of this apparatus" in Appendix A: Safety Data. Failure to follow the safety instructions could

result in serious injury or death.

OCX 8800

MECHANICAL

INSTALLATION

The OCX88A can be installed in general purpose areas only. Do not install the OCX88A in

hazardous areas.

Selecting Location

1. The location of the OCX 8800 in the stack or flue is most important for

maximum accuracy in the oxygen analyzing process. The probe must

be positioned so the gas it measures is representative of the process.

Best results are normally obtained if the transmitter is positioned near

the center of the duct (40-60% insertion). Longer ducts may require

several transmitters since the oxygen and combustibles can vary due to

stratification. A point too near the wall of the duct or the inside radius of

a bend, may not provide a representative sample because of the very

low flow conditions. The sensing point should be selected so the

process gas temperature falls within the range of probe material used.

Figure 2-1 through Figure 2-5 provide mechanical installation

references. The ambient temperature inside the electronics housing

must not exceed 185°F (85°C).

2. Check the flue or stack for holes and air leakage. The presence of this

condition will substantially affect the accuracy of the oxygen and

combustibles readings. Therefore, either make the necessary repairs or

install the transmitter up stream of any leakage.

3. Ensure the area is clear of internal and external obstructions that will

interfere with installation and maintenan ce access to the unit. Allow

adequate clearance for the removal of the OCX 8800.

http://www..raihome.com

Page 30

OCX 8800

Instruction Manual

IM-106-880, Rev 2.0

September 2009

Do not allow the temperature of the electronics housing to exceed 185°F (85°C) or damage

to the electronics may result.

Whenever a positive stack pressure exists at the installation site, be sure to connect all

pneumatic lines prior to installing the OCX 8800 in the stack or ductwork. Failure to connect

the pneumatic lines can allow the flow of contaminants into the OCX 8800 ports.

Installation

1. Ensure all components are available to install the OCX 8800.

2. The OCX 8800 may be installed intact as it is received.

3. Weld or bolt adapter plate (Figure 2-3) onto the duct.

4. Use the pipe or wall mounting hardware as shown in Figure 2-4 to

mount a remote electronics housing. Choose a location not to exceed

the length of the electronics cable ordered.

5. Ensure the conduits drop vertically from the OCX 8800 and the conduit

is routed below the level of the conduit ports on the housing to form a

drip loop. Drip loops minimize the possibility that moisture will damage

the electronics (Figure 2-5).

6. Where a positive stack pressure exists at the inst allation site, connect all

pneumatic lines prior to installing the OCX 8800 in the stack or

ductwork.

2-2

NOTE

If process temperatures will exceed 392°F (200 °C), use anti- s eize compou nd

on stud threads to ease future removal of the OCX 8800.

7. Insert sample and exhaust tubes through the opening in the mounting

flange and bolt the unit to the flange.

Uninsulated stacks or ducts may cause ambient temperatures in the electronics housing to

exceed 185°F (85°C) and damage the electronics.

8. If insulation is removed to access the duct for OCX 8800 mountin g ,

make sure to replace insulation afterward.

Page 31

Instruction Manual

IM-106-880, Rev 2.0

September 2009

Enclosures

The OCX 8800 enclosures are designed to meet ingress conditions of Type

4X and IP66. Each enclosure cover is threaded to its base and sealed with an

o-ring that isolates the threads from external contaminants.

Each cover is secured by a clip attached to the base that engages the cover

between the ribs of the cover sidewall. The clip is held in place by an Allen

head cap screw and lockwasher mounted in a recess. Cover removal and

installation requires an Allen wrench to loosen and tighten the screw.

Figure 2-1. Installation, OCX 8800 with Integral Electronics

NOTE

All dimensions are in inches with millimeters in parentheses.

Insulate if exposed to adverse weather or extreme temperature changes,

install a protective housing and/or insulation around the unit.

OCX 8800

0.06 In. Thick Gasket

ANSI

DIN

3535B18H02

3535B45H01

Flange Dia.

B.C. Dia.

Hole Dia.

Table 1. Mounting Flange

ANSI

Flange

Dia.

Hole

Dia.

(4) Holes

equally

spaced on

B.C. dia

6.00

(152)

0.75

(19)

4.75

(121)

DIN

7.28

(185)

0.71

(18)

5.71

(145)

Allow 9 in.

(229 mm) for

Cover Removal

Dim “B”

Removal Envelope

BOTTOM VIEW

Dim “A”

Insertion Depth

Table 2. Installation/Removal

Probe

18 in.

3ft

6ft

9ft

Dim “A”

18

(457)

36

(914)

72

(1829)

108

(2743)

Optional

In Situ Filter

*

*4.0 (101.6) with high surface

*7.3 (186.4) with Stainless Steel

Stainless Steel Filter

or Hastelloy Filter

Dim “B”

34

(864)

52

(1321)

88

(2235)

124

(3150)

37390008

2-3

Page 32

OCX 8800

Figure 2-2. Installation, OCX 8800 with Remote Electronics

Instruction Manual

IM-106-880, Rev 2.0

September 2009

2-4

Page 33

Instruction Manual

IM-106-880, Rev 2.0

September 2009

Figure 2-3. Adapter Plate Installation

OCX 8800

2-5

Page 34

OCX 8800

Figure 2-4. Wall or Pipe Mounting of Electronics Housing

Instruction Manual

IM-106-880, Rev 2.0

September 2009

2-6

Page 35

Instruction Manual

IM-106-880, Rev 2.0

September 2009

Figure 2-5. Installation with Drip Loops

OCX 8800

Conduit Drip Loops

Conduit Drip Loop Conduit Drip Loop

Duct Wall

Duct Wall

37020004

2-7

Page 36

OCX 8800

Instruction Manual

IM-106-880, Rev 2.0

September 2009

ELECTRICAL

INSTALLATION

All wiring must conform to local and national codes. For reference, factory

wired solenoid power connections are shown in Figure 2-6.

Disconnect and lock out power before connecting the unit to the power supply. Failure to

lock out power could result in serious injury or death.

Install all protective equipment covers and safety ground leads after installation. Failure to

install covers and ground leads could result in serious injury or death.

To meet the Safety Requirements of IEC 1010 (EC requirement), and ensure safe operation

of this equipment, connection to the main electrical power supply must be made through a

circuit breaker (min 10 A) in close proximity and marked for this equipment which will

disconnect all current-carrying conductors during a fault situation. This circuit breaker

should also include a mechanically operated isolating switch. If not, then another external

means of disconnecting the supply from the equipment should be located close by. Circuit

breakers or switches must comply with a recognized standard such as IEC 947.

The OCX88A can be installed in general purpose areas only. Do not install the OCX88A in

hazardous areas.

NOTE

To maintain proper earth grounding, ensure a positive connection exists

between the sensor housing, the electronics housing, and earth. The

connecting ground wire must be 14 AWG minimum. Refer to Figure 2-6.

NOTE

Line voltage, signal, and relay wiring must be rated for at least 105ºC (221ºF ).

Electrical Connections

Electrical connections, power and communications are made to the ele ctronic

enclosure. The connections are made through two 3/4 NPT ports in the

enclosure using fittings and cables provided by the customer. Cable

installation must meet NEC, IEC and/or other applicable national or local

codes for Class I, Zone 1, IIB +H2 T3/T6 permanently mounted equipment.

2-8

Page 37

Instruction Manual

IM-106-880, Rev 2.0

September 2009

OCX 8800

Connect Line Voltage

The OCX 8800 operates on 100 to 240 VAC line voltage at 50 to 60 Hz. The

power supply requires no setup. Connect the line (L wire) to the L terminal,

and the neutral (N wire) to the N terminal on the AC power input terminal

block in the electronics housing. Connect the ground (G wire) to the ground

stud in the electronics housing as shown in Figure 2-6.

Connect Output Signals

The OCX 8800 may be provided with either two 4-20 mA signals with HART

on the O2 signal or a single FOUNDATION fieldbus signal. Connect the

output terminals in the electronics housing as shown in Figure 2-6. Use

individual shielded twisted wire pairs. Terminate the shield at the electronics

housing.

4-20 mA Signal

O

2

One 4-20 mA signal represents the O

signal is the HART information accessible through a Model 375 Handheld

Communicator or AMS software . The O

COe 4-20 mA Signal

Another 4-20 mA signal at the AOUT 2 terminals represents the COe

value.

value. Superimposed on the O2

2

signal is at the AOUT 1 terminals.

2

FOUNDATION fieldbus Signal

The FOUNDATION fieldbus signal provides all output information and is

accessible through a Model 375 handheld communicator.

Alarm Output Relay

Connect any customer-supplied relay input to the alarm output relay terminal.

Use shielded wire and terminate the shield at the electronics housing. The

alarm output relay terminal is a set of dry, no. 2, form C, contacts with 30 mA,

30 VDC capacity.

Remote Electronics Connections to Sensor Housing

Make the following connections between the remote electronics and sensor

housings with the electronics cable ordered with the package (Figure 2-7).

Braided cable is available in lengths up to 150 ft. (46 m).

NOTE

Interconnect wiring shown is for Rosemount Analytical supplied cables. For

customer furnished interconnect wiring or cables, refer to Figure 2-8.

Signal Connections

Connect the electronics housing terminals to the corresponding terminals

in the sensor housing. The twisted wire pairs are numbered on the inner

plastic wrapper. Keep twisted pairs together and match the numbers and

wire colors shown in Figure 2-7.

Heater Power Connections

Use the blue, white, orange black, red, and yellow stranded wires in the

heater power cable to connect power to the three heaters in the sensor

housing. Match the wire colors to the corresponding heater power terminal

blocks in the sensor and electronics housings as shown in Figure 2-7.

2-9

Page 38

OCX 8800

Figure 2-6. Line Voltage, Earth, and 4-20 mA Connections

#1

Instruction Manual

IM-106-880, Rev 2.0

September 2009

F

Not used

F

OUNDATION

Fieldbus

OUNDATION

Fieldbus

-

{

+

-

{

+

NC

COM

NO

Alarm Output Relay

Terminal Block

OR

COe Signal

O Signal/

Typical for Electronics and

HART

AOUT2+

{

AOUT2 -

HART

AOUT1 -

{

AOUT1+

2

TOP VIEW

(1/2 SIZE)

Ground Stud

Earth Ground

Sensor Housing

Terminal Block

EMI Filter

Customer

Signal Output

#1

G

Wiring

Signal Port

3/4 NPT

Terminal

L1

N

Block

G

Ground

Stud

Power Port

3/4 NPT

G

External Tooth

Lockwasher

37390013

2-10

Page 39

Instruction Manual

IM-106-880, Rev 2.0

September 2009

Figure 2-7. Electrical Connections Between Remote Electronics and Sensor Housing

OCX 8800

YEL

RED

BLK

ORG

WHT

BLU

Heater Power

Connector (J3)

RED

BLK

WHT

BLK

GRN

BLK

BLU

BLK

Heater Power Cable

#1

O Sensor and

2

Thermocouple

Connector (J5)

T/C CO+

T/C CO-

T/C SB+

T/C SBT/C O2+

T/C O2-

O2 CELL+

O2 CELL-

SHLD

#1

2HTR CO

1HTR CO

2HTR O

1HTR O

2HTR SB

1HTR SB

To ground

2

2

screw

#1

#1 #1

YEL

BRN

BLK

RED

WHT

ORG

BLK

BLK

#1

EXC+

CO ACT+

CO ACT-

CO REF+

CO REFCJC+

CJCEXC-

GRN

SHIELD

To

ground

screw

COe Sensor

and

Cold Junction

Connector (J4)

ELECTRONICS HOUSING

SENSOR HOUSING

RED

BLK

-

WHT

+

T/C SB

BLK

EXC-

BLK

GRN

BLK

Signal Cable

-

+

BLU

+

T/C O2

O2

-

BLK

-

+

T/C CO

BLK

-

ORG

CJC

CO

BRN

+

ACT

2

WHT

HTR

YEL

+

EXC

SB

1

BLU

To ground screw

GRN

37390014

2-11

WHT

RED

BLK

+

REF

2

YEL

HTR

-

CO

1

RED

2

BLK

HTR

-

O2

1

ORG

CO

+

Page 40

OCX 8800

Figure 2-8. Customer-Furnished Interconnect Wiring or Cables

Instruction Manual

IM-106-880, Rev 2.0

September 2009

SIGNALWIRING OR CABLE

NOTE: For RFI/CE compliance, the connector

must provide 360 degrees of electrical

contact to the cable shield.

ELECTRONICS END

7.25

±0.10

Strip Wire

Ends 3/16”

Typical

Stud Size

#10

7.25 ±0.10

9.25 ±0.10

0.5

Typ.

Heat Shrink

Tubing

2” Long

1/2” Size

2.0 ±0.25

Typical

7.0” Long Teflon Tubing,

0.042” ID (Cut off drain

wire at probe end of

shield).

Overall Cable Length

By Customer

150’Maximum

3/4 NPT Hub Size,

Liquid-tight

Strain Relief

Connector

See Note

Heat Shrink

Tubing

2” Long

1/2” Size

See Note

8 twisted pairs 24 AWG,

stranded, insulated,

tinned copper

conductors, 200 C, 300

volts, with overall braid

of 34 AWG tinned

copper, 90% coverage

and 24 AWG tinned

copper, uninsulated

drain wire.

o

(typical on both ends of wiring)

8.625 ±0.10

6.875 ±0.10

A

3.875

±0.10

4.625

±0.10

5.375

±0.10

6.125

±0.10

#1

#2

DETAIL

PROBE END

12.5 ±0.10

10.375 ±0.10

Heat Shrink Tubing

1” Long, 3/16” Size

A

Ferrule,

Uninsulated

Strip Wire

Ends 3/16”

Typical

Green,

16 AWG

Stud Size

2-12

ELECTRONICS END

4.0 ±0.10

#10

4.5 ±0.10

0.5

Typ.

HEATER WIRING OR CABLE

3/4 NPT Hub Size,

Liquid-tight

Strain Relief

Connectors

Heat Shrink Tubing

2” Long, 1/2” Size

2.0 ±0.25 Typical

4.25” Long Teflon Tubing,

0.042” ID.(Cut off drain wire

at probe end of shield).

PROBE END

5.5 ±0.10

Ferrule, Uninsulated

Heat Shrink Tubing

2” Long, 1/2” Size

Green, 16 AWG

8 Conductors, 16 AWG, Stranded,

O

200 C, 600 volts.

Braided shield - tinned copper, 90%

coverage with 18 AWG 24 tinned copper,

uninsulated, drain wire.

Stud Size #6

37390061

Page 41

Instruction Manual

IM-106-880, Rev 2.0

September 2009

OCX 8800

PNEUMATIC

INSTALLATION

Pneumatic system connections depend on whether reference air set,

calibration solenoids, and/or blowback equipment options are equipped on

your transmitter. Refer to the following paragraphs and select the option that

applies to your transmitter configuration.

Reference Air Set Option (only)

When no options or only the reference air set option is equipped, use the

following procedure to install the pneumatic system components.

1. Refer to Figure 2-9. Connect the reference air set (regulator/filter and

pressure gage) to the instrument air inlet on the electronics housing an d

to the inlet side of the dilution air flow meter.

2. Connect the dilution air flow meter output to the dilution air inlet fitting on

the sensor housing.

3. Install an air line between the instrument air outlet fitting on the

electronics housing and the tee fitting on the sensor housing.

.

Do not use 100% nitrogen as an O2 low gas. It is suggested that O2 low gas be between

0.4% and 2.0% O

parts per million. Failure to use proper gases will result in erroneous readings.

. Do not use gases with hydrocarbon concentrations of more than 40

2

4. One CO gas and two O2 gases are used to calibrate the OCX 8800:

CO - 1000 ppm or up to 4%, Balance air

low gas - 0.4% , Balance N

O

2

O2 high gas - 8%, Balance N

2

2

Connect the output of the test gas sources to the inlet port of the CAL

GAS flow meter. Install an air line between the flow meter outlet port and

the CAL GAS inlet fitting on the sensor housing.

2-13

Page 42

OCX 8800

Figure 2-9. Pneumatic

Installation, OCX with Reference

Air Set without Autocalibration

Instruction Manual

IM-106-880, Rev 2.0

September 2009

Sensor

Housing

Eductor

Air In

Electronics

Housing

CAL Gas In

Reference Air In

Dilution Air In

4

Dilution Air

Flow Meter

0.1 scfh

2

CO

Instrument

Air Out

1

Pressure Reguator/Filter

35 psig - General Purpose

Replacement Parts

1 2” Pressure Gage 0-60 psig 275431-03

2 Combination Filter-Reg. 0-60 psig

3 Flowmeter 1-10 scfh

4 Flowmeter 0.05-0.5 scfh

HI O

2

3

CAL Gas

Flow Meter

7 scfh, 20-30 psig

(

Recommended

2-Stage

Regulators

2

LO O

Instrument

Air Supply

1A99422H01

771B635H01

771B635H08

(

37390011

2-14

Page 43

Instruction Manual

IM-106-880, Rev 2.0

September 2009

Figure 2-10. Pneumatic Installation , OCX with Reference Air Set, Solenoids and Autocalibration,

without COe Zero Function

Sensor

Housing

3

CAL Gas

Flow Meter

7 scfh, 20-30 psig

(

Recommended

Electronics

Housing

(

Eductor

Air In

Reference

Air In

Dilution

Air In

CAL Gas In

4

Dilution Air

Flow Meter

0.1 scfh

OCX 8800

Instrument Air Out

CAL Gas Out

1

Pressure Regulator/Filter

35 psig - General Purpose

2-Stage

Regulators

2

2

HI O

LO O

CO

1 2” Pressure Gage 0-60 psig 275431-03

2 Combination Filter-Reg. 0-60 psig

3 Flowmeter 1-10 scfh

4 Flowmeter 0.05-0.5 scfh

Replacement Parts

2

Instrument

Air Supply

1A99422H01

771B635H01

771B635H08

37390012

Reference Air Set and Solenoids Option without COe Zero Function

When the reference air set and test gas solenoids are included with your

OCX 8800, use the following procedure to install the pneumatic system

components.

1. Install the reference air set according to th e instructions in Reference Air

Set Option, steps 1 through 3.

2. Refer to Figure 2-10. Connect the O

inlet fitting on the electronics housing. Install a shutoff valve and

LO O

2

pressure regulator with gage in the O

3. Connect the O

high gas source to the CAL GAS HI O2 inlet fitting.

2

Install a shutoff valve and pressure regulator with gage in the O

low gas source to the CAL GAS

2

low supply line, as shown.

2

high

2

supply line.

2-15

Page 44

Instruction Manual

IM-106-880, Rev 2.0

OCX 8800

4. Connect the CO high gas to the CAL GAS HI COe inlet fitting. Install a

shutoff valve and pressure regulator with gage in the CO high supply

line.

5. Connect the CAL GAS outlet fitting of the electronics housing to the inlet

port of the CAL GAS flow meter. Install an air line between the flow

meter outlet port and the CAL GAS inlet fitting on the sensor housing.

Reference Air Set and Solenoids Option with COe Zero Function

Figure 2-11 shows the piping arrangement for the OCX 8800 with

autocalibration when the COe Zero Function is used. The arrangement is

similar to Figure 2-10 except instrument air is used as the Hi O

Refer to Section 3 for details of this function.

Figure 2-11. Pneumatic Installation, OCX with Reference Air Set, Solenoids and Autocalibration, with

COe Zero Function

September 2009

2

test gas.

2-16

Page 45

Instruction Manual

IM-106-880, Rev 2.0

September 2009

OCX 8800

Reference Air Set, Solenoids, and Blowback Option with

COe Zero Function

Figure 2-13 shows the piping arrangement for the OCX 8800 with the

blowback and autocalibration options when the COe Zero Function is used.

The arrangement is similar to Figure 2-12 except instrument air is used as the

test gas. Refer to Sectio 3 for details of the function.

Hi O

2

Reference Air Set, Solenoids, and Blowback Option without

COe Zero Function

Installing an OCX 8800 with the blowback option requires the addition of air

operated blowback valve, regulator and gage, and check valve.

Figure 2-12 shows the piping arrangement for the OCX 8800 with the

blowback and autocalibration options. Figure 2-14 shows the piping

arrangement for the OCX 8800 with the blowback option, but without

autocalibration (without test gas solenoids).

When the reference air set, calibration gas solenoids, and blowback options

are included with your transmitter, use the following procedure to install the

pneumatic system components.

1. Connect the calibration gas sources according to the instructions in the

previous paragraph “Reference Air Set and Solenoids Option”, steps 2

through 5.

2. Connect a clean, dry , instrument-quality su pply of air (20.95% O

35 psig and 55 psig pressure regulato rs. The inlet to the 35 psig

regulator accepts a 1/8" NPT fitting. The inlet to the 55 psig regulator

accepts a 1/4" NPT fitting.

3. See the upper leg of the instrument air supply. Connect the output of the

35 psi regulator/filter to one port of the normally-closed air-operated

solenoid valve, and to the inlet side of the dilution air flow meter.

4. Connect the dilution air flow meter output to the DILUTION AIR inlet

fitting on the sensor housing.

5. Install an instrument air line between the open port of the normally-open

air-operated solenoid valve and the tee fitting on the sensor housing.

6. Connect the output of the 55 psi regulator/filter to one port of the

normally-open air-operated solenoid valve, and to the instrument air

inlet on the back of the electronics housing.

7. Install an air line between the open port of the normally-closed

air-operated solenoid valve and the check valve inlet fitting on the

sensor housing.

8. Install an air line between the instrument air outlet fitting on the

electronics housing and the control air inlet fitting on the air-operated

solenoid valve.

) to the

2

2-17

Page 46

Instruction Manual

IM-106-880, Rev 2.0

OCX 8800

Figure 2-12. Pneumatic Installation, OCX with Reference Air Set, Solenoids, Blowback and Autocalibration,

without COe Zero Function

September 2009

2-18

Page 47

Instruction Manual

IM-106-880, Rev 2.0

September 2009

Figure 2-13. Pneumatic Installation, OCX with Reference Air Set, Solenoids, Blowback and Autocalibration,

with COe Zero Function

OCX 8800

Reference Air Set, Solenoids, and Blowback Option

with COe Zero Function

Figure 2-13 shows the piping arrangement for the OCX 8800 with the

blowback and autocalibration options when COe Zero Function is used. The

arrangement is similar to Figure 2-12 except instrument air is used as the Hi

test gas. Refer to Section 3 for details of this function.

O

2

2-19

Page 48

Instruction Manual

IM-106-880, Rev 2.0

OCX 8800

Figure 2-14. Pneumatic Installation, OCX with Reference Air Set and Blowback without Autocalibration

September 2009

Eductor Air In

Electronics

Housing

Instrument Air

*Normally

Open

Solenoid

Valve

7

Check Valve

Reference Air In

Dilution Air In

5

Sensor

Housing

CAL Gas In

*Normally

CAUTION

Pressure regulator with 1/8” inlet port is factory

set for 35 psig. Regulator with 1/4” inlet port is

factory set for 55 psig. If regulators are not

installed in correct locations, the OCX 8800 will

not work.

Closed

Solenoid

Valve

CAL Gas Flow Meter

(

7 scfh, 20-30 psig

Recommended

3

4

Dilution

Air Flow Meter

0.1 scfh

Pressure Regulator/Filter

35 psig - General Purpose

(

2-Stage

Regulators

1

2

2

CO

HI O

LO O

Blowback Valve,

Air Operated

Actuating Air

Replacement Parts

1 2” Pressure Gage 0-60 psig 275431-03

2 Combination Filter-Reg. 0-60 psig

3 Flowmeter 1-10 scfh

4 Flowmeter 0.05-0.5 scfh

5

Pneumatic Actuator

6 Combination Filter/Reg. 0-60 psig

7 Check Valve 5 psig

*NOTE: During blowback operation, states of

both solenoid valves change.

NOTE: Wall mount the air-operated blowback

valve on a suitable mounting plate.

NOTE: Actuating air pressure at blowback valve

inlet port must be at least 51 psig to fully

actuate the valve.

1A99422H01

771B635H01

771B635H08

1A99339H03

4505C21G11

7309A62H01

1

Pressure

Regulator/Filter

55 psig

2

Instrument

Air Supply

6

38850005

2-20

Page 49

Instruction Manual

IM-106-880, Rev 2.0

September 2009

Reference Air Set and Blowback Panels

An optional blowback panel is shown in Figure 1-9. Piping arrangement for

blowback panel without autocalibration without COe Zero Function is shown

in Figure 2-15. Piping arangement for blowback panel with autocalibration

without COe Zero Function is shown in Figure 2-16. Piping arrangement for

blowback panel with autocalibration with COe Zero Function is shown in

Figure 2-17.

Figure 2-15. Pneumatic Installation, Blowback Panel without Autocalibration without COe Zero Function

OCX 8800

Check Valve

Sensor

Housing

Instrument

Air Supply

CAL Gas

Out

CAL Gas

In

Dilution

Air Out

Instrument Air to Electronics

Blowback

Air Out

Blowback

Control Air

Instrument

Eductor Air In

Instrument Air

Air Out

CAL Gas In

Reference Air In

Dilution Air In

Actuating Air

2-Stage

Regulators

2

2

CO

HI O

LO O

Electronics

Housing

39930003

2-21

Page 50

Instruction Manual

IM-106-880, Rev 2.0

OCX 8800

Figure 2-16. Pneumatic Installation, Blowback Panel with Autoca libration without COe Zero Function