Page 1

Quick Start Guide

LIQ-QSG-338+, Rev BB

January 2018

Rosemount™ Hx338+

Steam Sterilizable and Autoclavable Pre-Pressurized pH Sensor

Page 2

Essential instructions

Read this page before proceeding!

Emerson designs, manufactures, and tests its Rosemount products to meet many national and international standards. Because

these instruments are sophisticated technical products, you must properly install, use, and maintain them to ensure they continue

to operate within their normal specifications. The following instructions must be adhered to and integrated into your safety

program when installing, using, and maintaining Rosemount products. Failure to follow the proper instructions may cause any one

of the following situations to occur: loss of life, personal injury, property damage, damage to this instrument, and warranty

invalidation.

• Read all instructions prior to installing, operating, and servicing this product. If this instruction manual is not the correct

manual, call 1-855-724-2638, and we will provide the requested manual. Save this manual for future reference.

• If you do not understand any of the instructions, contact your Emerson representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of the product.

• Install your equipment as specified in the installation instructions of the appropriate manual and per applicable local and

national codes. Connect all products to the proper electrical and pressure sources.

• Install your equipment as specified in the Installation section and per applicable local and national codes. Connect all

products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts specified by Rosemount.

Unauthorized parts and procedures can affect the product's performance and place the safe operation of your process at

risk. Look alike substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when maintenance is being performed

by qualified people, to prevent electrical shock and personal injury.

About this document

Revision level Date Notes

A 8/2017 This is the initial release of the Quick Start Guide.

B 9/2017 Updated wiring diagrams.

BA 11/2017 Added Section 4.3. Updated 1056, 56, and 1057 wiring diagrams.

Page 3

Contents

Contents

Chapter 1 Plan ..................................................................................................................................1

1.1 Electrode preparation .....................................................................................................................1

1.2 Storage and handling ..................................................................................................................... 1

1.3 Specifications .................................................................................................................................2

1.4 Rosemount Hx338+ pH Sensor design specifications ..................................................................... 3

1.5 Rosemount Hx338+ pH Sensor ordering information ..................................................................... 4

Chapter 2 Install ...............................................................................................................................5

2.1 Installing the sensor ....................................................................................................................... 5

Chapter 3 Wiring ............................................................................................................................. 7

3.1 Wiring the Rosemount™ Hx338+ pH Sensor ....................................................................................7

Chapter 4 Calibration and maintenance .........................................................................................11

4.1 Two point buffer calibration ......................................................................................................... 11

4.2 Recommended pH sensor standardization ...................................................................................11

4.3 Electrode refresh procedure ......................................................................................................... 12

Chapter 5 Troubleshooting ............................................................................................................ 13

5.1 Cleaning or replacing the electrodes ............................................................................................ 13

Rosemount Hx338+ pH Sensor i

Page 4

Contents

ii Quick Start Guide

Page 5

1 Plan

1.1 Electrode preparation

1. Remove electrode from shipping container.

2. Remove the protective boot covering the electrode bulb.

3. Rinse away salt film with clean water and then shake the electrode so that the

internal solution fills the bulb, thus removing any air trapped there.

Note

Do not allow lubricant to coat electrode bulb or reference junction. If it does, wipe it clean

before installation.

1.2 Storage and handling

Plan

Proper storage and handling instructions of the electrodes must be followed to ensure

correct measurements.

1. Store the electrodes in their original shipping containers until needed.

2. Do not store at temperatures below -5 °C (23 °F).

3. Store the electrodes with a protective cap containing KCI solution (PN 9210342).

4. For overnight storage, immerse the sensor in tap water or 4 pH buffer solution.

5. Use the startup and calibration procedure described in Section 4.1 to properly

calibrate the sensors.

6. The standard sensor shelf life is one year from manufacturing date. Follow the

refresh procedure described in Section 4.3 at one year and eighteen months to

extend the shelf life to a maximum of two years.

Rosemount Hx338+ pH Sensor 1

Page 6

Plan

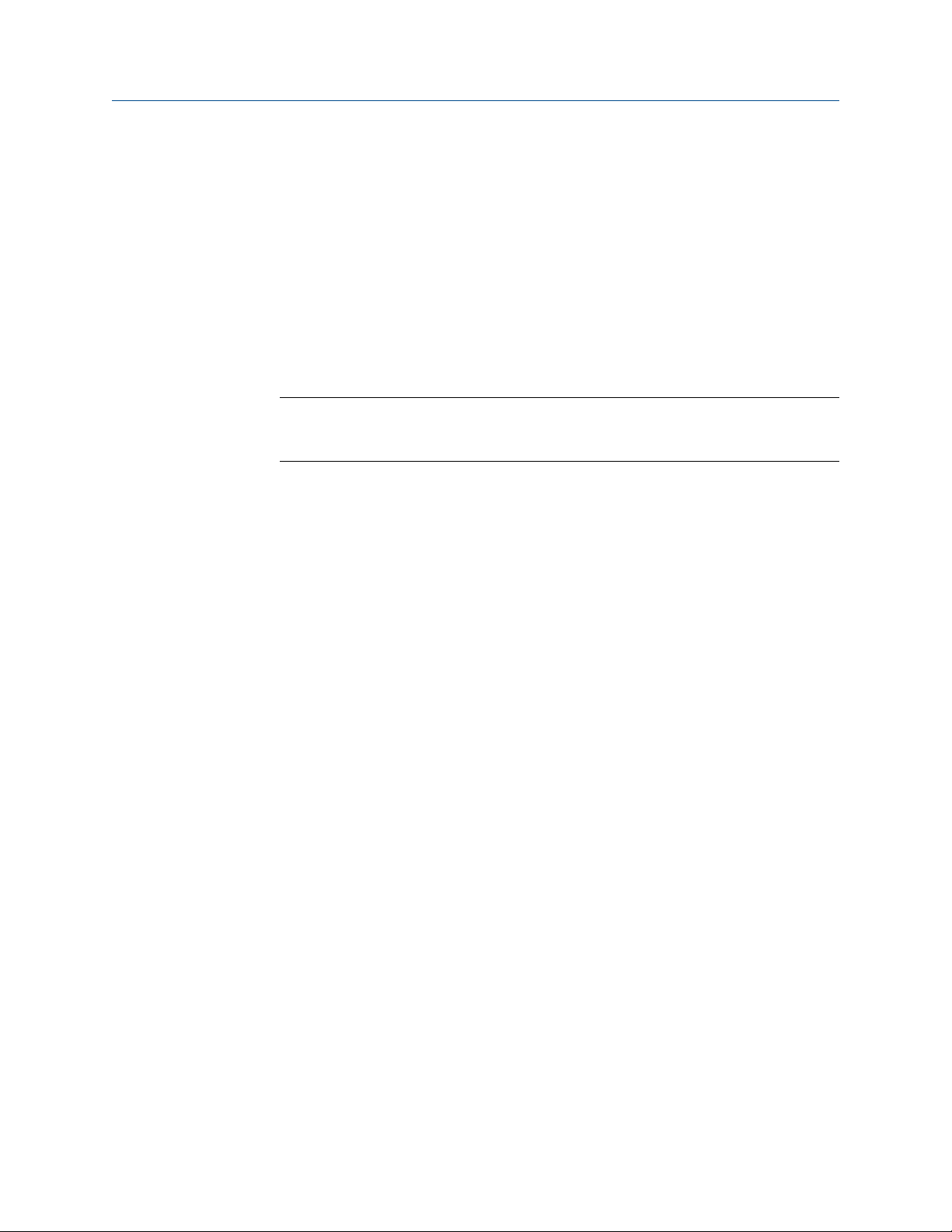

1.3 Specifications

Rosemount™ Hx338+ pH Sensor SpecificationsTable 1-1:

Rosemount Hx338+ Sensor specifications Materials and units

Operating temperature range 0 to 140 °C (32 to 283 °F)

Pressure range 0 to 6 bar

pH range 0 to 14

Measuring method

Combination electrode pH potential measured against reference electrode

Wetted materials

pH electrode Glass

O-ring EPDM (FDA approved)

Operations parameters

Process connection PG 13.5

Electrical connector Variopol (VP 6.0)

Minimum conductivity of sample 100 µS/cm

Zero-point 0 ±20 mV

Sensitivity 57 - 59 mV / pH at 25 °C (77 °F)

Electrolyte Pressurized

Temperature sensor Pt-100

WARNING!

Do not exceed temperature and pressure limitations of 140 °C (284 °F) and 6 bar.

WARNING!

Before removing the sensor, be absolutely certain that the process pressure is reduced to 0

psig and the process temperature is lowered to a safe level!

WARNING!

CORROSIVE SUBSTANCE

Hydrofluoric acid and the mixture of hydrochloric acid and thiorea is toxic and highly corrosive.

Avoid skin contact; wear protective gloves. Use only in a well-ventilated area. Do not inhale

fumes. In case of an accident, consult a doctor immediately.

2 Quick Start Guide

Page 7

CAUTION!

SENSOR/PROCESS APPLICATION COMPATIBILITY

The wetted sensor materials may not be compatible with process composition and operating

conditions. Application compatibility is entirely your responsibility.

1.4 Rosemount Hx338+ pH Sensor design specifications

See Figure 1-1 for sensor dimensions.

Rosemount Hx338+-01-72 Dimensional DrawingFigure 1-1:

Plan

A. VP 6.0 plug

B. SW-19 free spinning PG13.5 screw thread

C. Washer

D. O-ring

Rosemount Hx338+ pH Sensor 3

Page 8

Plan

1.5 Rosemount Hx338+ pH Sensor ordering

information

Rosemount Hx338+ pH Sensor Ordering InformationTable 1-2:

Model Sensor type

Hx338+ pH Sensor

Sensor length

01 4.8 in. (120 mm)

Cable connection

72 Pt-100 RTD with Variopol (VP6) Connector (Requires accessory mating cable)

Typical model number: Hx338+-01-72

AccessoriesTable 1-3:

Part number Description

24281-00 15 ft (4.6 m) VP8 cable

24281-01 25 ft (7.6 m) VP8 cable

24281-02 2.5 ft (0.8 m) VP8 cable

24281-05 4 ft (1.2 m) VP8 cable

24281-06 10 ft (3.0 m) VP8 cable

24281-07 20 ft (6.1 m) VP8 cable

24281-08 30 ft (9.1 m)VP8 cable

Mounting accessories

Part number Description

9160478 Insertion assembly, 2.75 in. (70 mm) insertion, for 4.72 in. (120 mm) sensor, G 1-1/4 in.

9160483 15 degree weld-in socket, G 1-1/4 in. thread, 44 mm

9160484 Service kit for insertion mounting assembly

Other accessories

Part number Description

9210012 Buffer solution, pH 4.01, 16 oz

9210013 Buffer solution, pH 6.86, 16 oz

9210014 Buffer solution, pH 9.18, 16 oz

4 Quick Start Guide

Page 9

2 Install

2.1 Installing the sensor

Procedure

1. Mount the sensor in a vertical pipe run with flow from bottom to top.

If the sensor must be mounted in a horizontal pipe run, orient the sensor in the

3 o'clock or 9 o'clock position.

2. Orient the sensor within 80 ° of vertical. See Figure 2-1.

Sensor OrientationFigure 2-1:

Install

Rosemount Hx338+ pH Sensor 5

Page 10

Install

6 Quick Start Guide

Page 11

3 Wiring

3.1 Wiring the Rosemount™ Hx338+ pH Sensor

Use the following wiring diagrams to wire the sensor to the Rosemount 56, Rosemount

1056, Rosemount 1057, Rosemount 1066, and Rosemount 5081 transmitters.

1. See Figure 3-1 to wire the Rosemount Hx338+ pH Sensor to the Rosemount 56,

1056, or 1057 Transmitter.

Wiring

Figure 3-1:

Wire the Rosemount Hx338+ pH Sensor to the Rosemount 56,

1056, or 1057 Transmitter

Rosemount Hx338+ pH Sensor 7

Page 12

Wiring

2. See Figure 3-2 to wire the Rosemount Hx338+ pH Sensor to the Rosemount 1066

Transmitter.

Figure 3-2:

Wire the Rosemount Hx338+ pH Sensor to the Rosemount 1066

Transmitter

8 Quick Start Guide

Page 13

3. See Figure 3-3 to wire the Rosemount Hx338+ pH Sensor to the Rosemount 5081

Transmitter.

Wiring

Figure 3-3:

Wire the Rosemount Hx338+ pH Sensor to the Rosemount 5081

Transmitter

Rosemount Hx338+ pH Sensor 9

Page 14

Wiring

10 Quick Start Guide

Page 15

Calibration and maintenance

4 Calibration and maintenance

4.1 Two point buffer calibration

Prerequisites

Select two stable buffer solutions, preferably pH 4.0 and 7.0 (pH buffers other than pH 4.0

and pH 7.0 can be used as long as the pH values are at least two pH units apart).

Note

A pH 7.0 buffer solution reads an mV value of approximately zero, and pH buffers read approximately

±59.1 mV for each pH unit above or below pH 7.0. Check the pH buffer manufacturer specifications

for millivolt values at various temperatures, as it may affect the actual value of the buffer solution

mV/pH value.

Procedure

1. Immerse sensor in the first buffer solution. Allow sensor to equilibrate to the buffer

temperature (to avoid errors due to temperature differences between the buffer

solution and sensor temperature) and wait for reading to stabilize.

4.2

The value of the buffer can now be acknowledged by the transmitter.

2. Once the first buffer has been acknowledged by the transmitter, rinse the buffer

solution off of the sensor with distilled or deionized water.

3. Repeat steps 1 and 2 using the second buffer solution.

The theoretical slope value, according to the Nernst equation for calculating pH, is

approximately 59.17 mV/pH. Over time the sensor will age, both in the process and

in storage, and this will result in reduced slope values. To ensure accurate readings,

Emerson recommends replacing the electrode when the slope value falls below 47

to 49 mV/pH.

Recommended pH sensor standardization

For maximum accuracy, the sensor can be standardized on-line or with a process grab

sample after a buffer calibration has been performed and the sensor has been conditioned

to the process. Standardization accounts for the sensor junction potential and other

interferences. Standardization will not change the sensor’s slope, but will simply adjust the

transmitter’s reading to match that of the known process pH.

Rosemount Hx338+ pH Sensor 11

Page 16

Calibration and maintenance

4.3 Electrode refresh procedure

The pressurized electrode in the Rosemount™ Hx338+ has a storage life of one year

without an electrode refresh. At one year of shelf life, all sensors should be refreshed for

peak performance. Please follow this procedure for refreshing the sensor.

Prerequisites

Select the two refresh solutions. A 0.4-4% by weight sodium hydroxide (NaOH) solution for

a base and a 0.73-3.65% by weight hydrochloric acid (HCl) solution for an acid are

recommended. Also, a potassium chloride (KCl) solution is needed for cleaning and

storage.

Record the sensor serial number, lot number, and date of manufacturing on a worksheet.

Remove sensor from the package. Inspect the connection, electrode, and glass for any

defects or scratches and remove the cap by relieving the rubber gasket.

Procedure

1. Clean the sensor with water; bottled or mineral water is recommended.

2. Place the sensor electrodes into the NaOH solution for 10 minutes.

3. Rinse the electrodes with water.

4. Place the electrodes into the HCl solution for 10 minutes.

5. Rinse the electrodes with water.

6. Place the electrodes into the KCl solution for a minimum of 60 minutes.

Zero and calibrate the sensor, following the procedure highlighted in Section 4.1, after the

refresh procedure and replace the cap with fresh KCl solution covering the sensor bulb and

reference junction.

12 Quick Start Guide

Page 17

5 Troubleshooting

5.1 Cleaning or replacing the electrodes

Electrodes should respond rapidly. Sluggishness, offsets, and erratic readings are

indicators that the electrodes may need cleaning or replacement.

1. Use a mild non-abrasive detergent to clean and remove oil deposits from the

electrode.

2. Soak electrodes for 30 to 60 minutes in a 5% hydrochloric acid solution to remove

scale deposits.

Temperature effect on life expectancy: If glass electrode life expectancy is 100% at

25 °C (77 °F), then it will be approximately 25% at 80 °C (176 °F), and approximately

5% at 120 °C (248 °F).

Troubleshooting

Rosemount Hx338+ pH Sensor 13

Page 18

Troubleshooting

14 Quick Start Guide

Page 19

Troubleshooting

Rosemount Hx338+ pH Sensor 15

Page 20

GLOBAL HEADQUARTERS

Emerson Automation Solutions

6021 Innovation Blvd

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

F +1 952 949 7001

liquid.csc@emerson.com

NORTH AMERICA

Emerson Automation Solutions

8200 Market Blvd

Chanhassen, MN 55317

Toll Free +1 800 999 9307

F +1 952 949 7001

liquid.csc@emerson.com

LIQ-QSG-338+

Rev BB

2018

EUROPE

Emerson Automation Solutions

Neuhofstrasse 19a P.O. Box 1046

CH-6340 Baar

Switzerland

T + 41 (0) 41 768 6111

F + 41 (0) 41 768 6300

liquid.csc@emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

twitter.com/rosemount_news

Facebook.com/Rosemount

youtube.com/RosemountMeasurement

google.com/+RosemountMeasurement

AnalyticExpert.com

MIDDLE EAST AND AFRICA

Emerson Automation Solutions

Emerson FZE

Jebel Ali Free Zone

Dubai, United Arab Emirates, P.O. Box 17033

T +971 4 811 8100

F +971 4 886 5465

liquid.csc@emerson.com

©

2018 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount is a

mark of one of the Emerson family of companies. All other marks are the property of their

respective owners.

ASIA-PACIFIC

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

Singapore

T +65 777 8211

F +65 777 0947

liquid.csc@emerson.com

Loading...

Loading...