Page 1

Model FCL Product Data Sheet

LIQ-PDS-FCL

July 2017

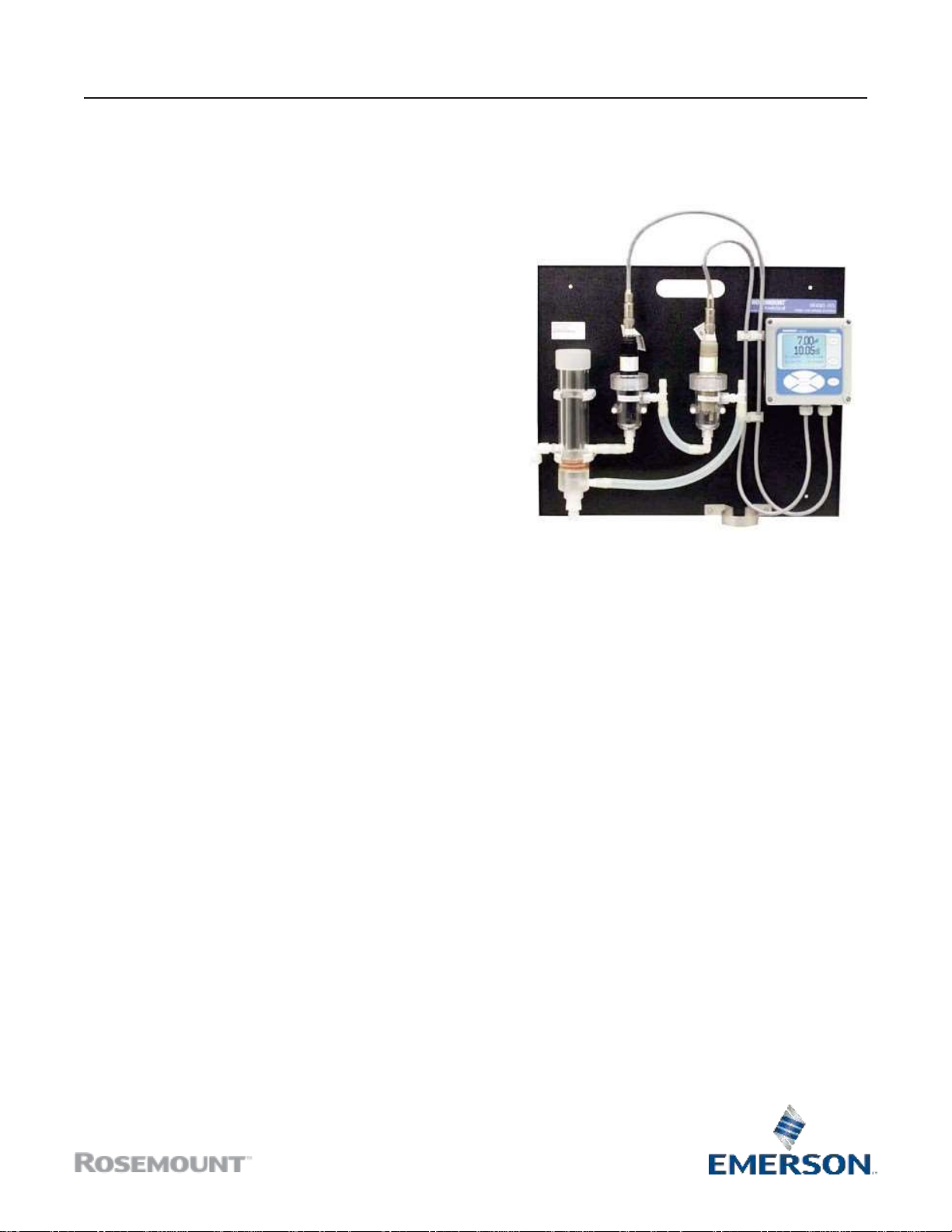

Free Chlorine Measuring System

Complete system includes sensor, connecting

cable, analyzer, and flow controller.

Continuous pH correction eliminates expensive

and messy reagents and troublesome sample

conditioning systems.

Measures free chlorine in samples having pH as

high as 9.5.

(1)

Variopol quick-disconnect fittings make

replacing sensors easy.

Choose from two feature-packed analyzers

(1) In some cases, the sensor can be used in samples having pH as great as 10.0.

Consult the factory.

Applications

The Model FCL free chlorine system is intended for the determination of free chlorine in fresh water. Unlike free chlorine analyzers from other manufacturers, the Model FCL does not use

expensive sample conditioning systems or messy reagents to control

pH. Instead, the analyzer automatically compensates for changes in

the pH of the sample. The Model FCL is not intended for the

determination of total chlorine or combined chlorine (like

monochloramine). Nor, can the FCL be used for the deter- mination

of chlorine in seawater.

Features

The Model FCL uses a membrane-covered amperometric sensor. A

polarizing voltage applied to a platinum cathode behind the

membrane destroys any chlorine that diffuses through the

membrane, keeping the concentration of chlorine in the sensor equal

to zero. The current generated by the cathode reaction is

proportional to the rate of diffusion of chlorine through the

membrane. Because the concentration of chlorine in the sensor is

zero, the diffusion rate and the current are proportional to the

concentration of chlorine in the sample.

All amperometric free chlorine sensors respond to changes in pH.

Although free chlorine is a mixture of hypochlorous acid and

hypochlorite ion, hypochlorous acid alone is responsible for the

sensor current. Because the relative amounts of hypochlorous acid

and hypochlorite ion depend on pH, a pH change will cause the

current and the apparent free chlorine concentration to change, even

though the true concentration remained con- stant. Most

manufacturers solve the problem by treating the sample with acid,

which lowers the pH and converts hypochlo- rite ion into

hypochlorous acid. The Model FCL avoids the expense and

inconvenience of sample conditioning by measur- ing the pH and

applying a correction to the raw chlorine sensor signal. The

correction is valid between pH 6.0 and 9.5. Below pH

6.0, no correction is needed. For samples having pH between

9.5 and 10.0, consult the factory.

The Model FCL is available in two options: Model FCL-01 with

manual pH correction and Model FCL-02 with continuous pH

correction. Choose the FCL-01 if the pH varies less than 0.2 or if

pH changes are predictable or seasonal. Choose the FCL-02 if the pH

varies more than 0.2. To provide the continuous pH correction, the

Model FCL-02 requires a separate pH sensor.

Page 2

Model FCL July 2017

2

www.Emerson.com/RosemountLiquidAnalysis

Maintenance is fast and easy. Replacing a membrane requires no

special tools or fixtures. A screw cap holds the pre-tensioned

membrane in place. Replacing the electrolyte solution takes

only minutes.

Valves, rotameters, and pressure regulators to control sample flow

are things of the past with the Model FCL. A constant head

overflow sampler ensures the correct sample flow to the sensors. To

eliminate wiring hassles, quick-disconnect Variopol cable prewired

to the analyzer is standard.

The Model FCL is available with the choice of two easy to use

analyzers.

Stable free chlorine standards do not exist. The chlorine sensor

must be calibrated using the results of a laboratory test run on a grab

sample.

Specifications – General

Sample requirements:

Pressure: 3 to 65 psig (122 to 549 kPa abs). A check valve in

the inlet prevents the sensor flow cells from going dry if

sample flow is lost. The check valve opens at 3 psig (122 kPa

abs). If the check valve is removed, minimum pressure is

1 psig (108 kPa abs).

Temperature: 32 to 122°F (0 to 50°)

Minimum Flow: 3 gal/hr (11 L/hr)

Maximum flow: 80 gal/hr (303 L/hr); high flow causes the

overflow tube to back up.

Sample Conductivity: >50 μS/cm at 25°C

Process connection: 1/4-in OD tubing compression fitting (can be

removed and replaced with a barbed fitting for use with soft

tubing).

Drain connection: 3/4-in barbed fitting. Sample must drain to

open atmosphere.

Wetted parts:

Overflow sampler and flow cell: acrylic, polycarbonate,

polyester, Kynar

®

(1)

, nylon, silicone

Chlorine sensor: Nor yl

®

(2)

, Viton

®

(3)

, wood, silicon e,

polyethersulfone, polyester, and platinum

pH sensor (3900VP): Stainless steel, glass, Teflon

®

(4)

,

polyphenylene sulfide, EPDM, and silicone

Response time to step change in chlorine concentration:

<80 sec to 95% of final reading for inlet sample flow of 3 gph

(11 L/hr).

Weight/shipping weight:

Model FCL-01: 10 lb/13 lb (4.5 kg/6.0 kg)

Model FCL-02: 11 lb/14 lb (5.0 kg/6.5 kg)

[rounded to the nearest 1 lb. (0.5 kg)]

Specifications

–

Chlorine Sensor

Free chlorine range: 0 to 10 ppm as Cl2. For higher ranges,

consult the factory.

pH correction range: 6.0 to 9.5. For samples having pH

between 9.5 and 10.0, consult the factory. Correction is not

needed if pH < 6.0. For manual pH correction, choose option -

01. For continuous pH correction choose option -02.

Accuracy: Accuracy depends on the accuracy of the chemical

test used to calibrate the sensor.

Interferences: Monochloramine, permanganate, peroxides.

Electrolyte volume: 25 mL (approx.)

Electrolyte life: 3 months (approx.); for best results replace

electrolyte monthly.

Specifications

–

Model 1056 Analyzer

Case: Polycarbonate NEMA 4X/CSA 4 (IP65).

Conduit openings: Accepts PG13.5 or 1/2 in. conduit fittings

Display: Monochromatic back-lit LCD. Main character height

0.6 in (15mm). Display is user-programmable

Languages: English, French, German, Italian, Spanish, Portuguese,

and Chinese.

Ambient temperature and humidity: 32 to 131°F (0 to 55°C);

RH 5 to 95% (con-condensing)

Storage temperature: -4 to 140°F (-20°C and 60°C)

Power: 84-265 Vac, 47.5 to 65.0 Hz, switching, 15 W

Equipment protected by double insulation

(1) Kynar is a registered trademark of Elf Atochem North America.

(2) Noryl is a registered trademark of General Electric.

(3) Viton is a registered trademark of E.I. duPont de Nemours & Co.

(4) Teflon is a registered trademark of E.I. duPont de Nemours & Co

Page 3

July 2017 Model FCL

www.Emerson.com/RosemountLiquidAnalysis

3

RFI/EMI: EN-61326

LVD: EN-61010-1

Outputs: Two 4-20 mA or 0-20 mA isolated outputs.

Continuously adjustable. Linear or logarithmic. Maximum

load 550 Ω. Output dampening is user-adjustable.

Alarms: Four alarm relays. Any relay can be configured as a fault

alarm

instead

of a process alarm. Each relay can be configured

independently and each can be programmed with interval

timer settings.

Relays: Form C, SPDT, epoxy sealed

Relay Contact ratings:

5 A at 28 VDC or 300 VAC (resistive)

1/8 HP at 120/240 VA

C.

Terminal Connections Rating: Power connector (3-leads):

18-12 AWG wire size. Current output connectors (2-leads):

24-16 AWG wire size. Alarm relay terminal blocks: 18-16

AWG wire size

Hazardous Location Approvals: For more information refer to

the Model 1056 product data sheet 71-1056. Approvals apply

to the analyzer only. The FCL is not suitable for use in

hazardous areas.

Specifications

–

Model 56 Analyzer

Case: Polycarbonate

Display: Full color LCD, 3.75 x 2.20 in. (95 x 56 mm); display can

be customized by the user.

Languages:

English, French, German, Ital ian, Spanish, Portuguese,

Chinese, Russian, and Polish.

Ambient Temperature and

Humidity:

14 to 140°F (-10 to 60°C);

RH 5 to 95% (non-condensing). Between 23 and 131°F

(-5 to 55°C) there is no visible degradation in display

response or performance.

Storage temperature: -4 to 140°F (-20 to 60°C)

Power: 85 to 265 VAC, 47.5 to 65.0 Hz, 20 W

RFI/EMI: EN-61326

LVD: EN-6101-01

Outputs: Four 4-20 or 0-20 mA isolated current outputs;

assignable to measurement or temperature; fully scalable;

maximum load 550 Ω. HART digital signal is superimposed

on output 1.

Alarms and Timers: Four relays, fully configurable as a setpoint

alarm, interval timer, TPC, bleed and feed timer, delay timer,

date and time timer, and fault alarm.

Relays: Form C, SPDT, epoxy sealed.

Relay Contact ratings:

5 A at 28 VDC or 300 VAC (resistive)

1/8 HP at 120/240 VAC

Control features: PID control (analog output) and time

proportional control or TPC (relays) are standard.

Data logger: Data automatically stored every 30 seconds for 30

days; older data removed to make room for new data. The

following data are automatically stored:

Chlorine: date and time, ppm, temperature, raw

sensor current

pH: date and time, pH, temperature, mV, glass impedance, and

reference impedance (if available)

Event logger: Stores up to 300 events with data and time stamp:

faults, warnings, calibration data, calibration results (pass or

fail), power on/off cycles, and hold on/off. Alarm relay

activation and deactivation can also be stored. Older events are

automatically removed to make room for new events.

Data and event downloading: through USB port on front

panel.

Graphical display: Dual graphical display shows measurement

data on the y-axis and time on the x-axis. Y-axis is fully

assignable and scalable. X-axis can be set to one hour, one

day, seven days, or 30 days.

Digital communications: HART digital communications is

standard.

Hazardous Location Approvals: For more information refer to

the Model 56 product data sheet 71-56. Approvals apply to

the analyzer only. The FCL is not suitable for use in

hazardous areas.

Page 4

Model FCL July 2017

4

www.Emerson.com/RosemountLiquidAnalysis

Model FCL-01-220 shown. All versions of the FCL-01 have the same overall dimensions

INCH

MILLIMETER

Model FCL-02-221 shown. All versions of the FCL-02 have the same overall dimensions

INCH

MILLIMETER

Page 5

July 2017 Model FCL

www.Emerson.com/RosemountLiquidAnalysis

5

Model FCL-1056 Engineering Specification

1. The system shall be suitable for the determination of free

chlorine in water having conductivity greater than about 50

uS/cm at 25°C and pH between about 5.5 and 9.5 without the

use of reagents.

2. The system shall consist of an analyzer, a free chlorine sensor, a

pH sensor (if required), flow cells for each sensor, and a flow

controller. The components shall be mounted on a back plate.

Sensor cables shal l be pre-wired to the analyzer. Sensors shall

plug into the cables using Variopol quick dis- connect fittings.

The sensor flow cells shall be clear plastic to allow the sensors to

be easily inspected for fouling. The inlet shall be fitted with a

check valve to ensure the sensors remain wet in the event sample

flow is lost.

3. The system shall use no mechanical devices, such as pressure

regulators, valves, or rotameters, to control flow. Instead, flow

shall be regulated using a constant head flow controller.

Minimum sample flow shall be no more than about 3 gallons per

hour (11 liters per hour). Maximum flow can be as high as

80 gallons per hour (303 liters per hour). The flow controller

shall be able to handle inlet pressure between 3 and 65 psig (122

to 549 kPa abs) and temperature between 32 and 122°F (0 and

50°C).

4. The free chlorine sensor shall be a two-electrode, membranecovered amperometric sensor. The free chlorine sensor shall be

fitted with an RTD to allow continuous correction for changes in

membrane permeability caused by temperature. The linear range

of the free chlorine sensor shall be at least between 0 and 10 ppm

as Cl2.

5. The pH sensor shall be a combination electrode having a

glass sensing membrane and a double junction reference

electrode.

6. The pH sensor shall be required if the pH of the sample varies

more than about 0.2 units peak-to-peak. For pH variations less

than 0.2, the pH sensor shall generally not be required.

7. The analyzer shall have dual input, one for the free chlorine

sensor and the other for the pH sensor (if needed). The analyzer

shall receive the raw signal from the free chlorine sensor and

automatically correct it for temperature and pH effects. Results

shall be displayed as ppm Cl2.

8. The analyzer shall require single point calibration. A correction for

the sensor zero current shall also be available.

9. The analyzer shall have automatic buffer recognition for pH

sensor calibration.

10. The analyzer shall have a four line, back lit display. The display

shall show ppm chlorine, pH (if required), and temperature on

one screen. The display shall be programmable to show

additional information such as raw sensor current.

11. The analyzer shall be capable of operating between 32 and

131°F (0 and 55°C) and between 5 and 95% relative humidity

(non-condensing).

12. The analyzer shall have dual 0/4-20 mA isolated outputs.

Outputs shall be fully scalable and assignable independently to

chlorine, pH, or temperature.

13. The analyzer shall have four alarm relays fully programmable for

logic (high or low operation), dead band, and setpoint. Relays

shall also be configurable to energize when the analyzer detects a

fault with the sensor or itself.

14. All analyzer programming shall be through a front panel

membrane keypad. The language (English, Spanish, Italian,

Portuguese, German, French, or Chinese) used in the menu

screens shall be selectable by the user.

15. The analyzer shall have a security feature to prevent unautho-

rized tampering with calibration and configuration settings.

16. The analyzer shall be Rosemount Model FCL-01-220 (free

chlorine only) or Model FCL-02-221 (free chlorine with

continuous pH correction) or approved equal.

Page 6

Model FCL July 2017

6

www.Emerson.com/RosemountLiquidAnalysis

Model FCL-56 Engineering Specification

1. The system shall be suitable for the determination of free

chlorine in water having conductivity greater than about 50

uS/cm at 25°C and pH between about 5.5 and 9.5 without the

use of reagents.

2. The system shall consist of an analyzer, a free chlorine sensor, a

pH sensor (if required), flow cells for each sensor, and a flow

controller. The components shall be mounted on a back plate.

Sensor cables shall be pre-wired to the analyzer. Sensors shall

plug into the cables using Variopol quick disconnect fittings.

The sensor flow cells shall be clear plastic to allow the sensors to

be easily inspected for fouling. The inlet shall be fitted with a

check valve to ensure the sensors remain wet in the event sample

flow is lost.

3. The system shall use no mechanical devices, such as pressure

regulators, valves, or rotameters, to control flow. In-stead, flow

shall be regulated using a constant head flow controller.

Minimum sample flow shall be no more than about 3 gallons per

hour (11 liters per hour). Maximum flow can be as high as

80 gallons per hour (303 liters per hour). The flow controller

shall be able to handle inlet pressure between 3 and 65 psig (122

to 549 kPa abs) and temperature between 32 and 122°F (0 and

50°C).

4. The free chlorine sensor shall be a two-electrode, membranecovered amperometric sensor. The free chlorine sensor shall be

fitted with an RTD to allow continuous correction for changes in

membrane permeability caused by temperature. The linear range

of the free chlorine sensor shall be at least between 0 and 10 ppm

as Cl2.

5. The pH sensor shall be a combination electrode having a glass

sensing membrane and a double junction reference electrode.

6. The pH sensor shall be required if the pH of the sample varies

more than about 0.2 units peak-to-peak. For pH variations less

than 0.2, the pH sensor shall generally not be required.

7. The analyzer shall have dual input, one for the free chlorine

sensor and the other for the pH sensor (if needed). The analyzer

shall receive the raw signal from the free chlorine sensor and

automatically correct it for temperature and pH effects. Results

shall be displayed as ppm Cl2.

8. The analyzer shall require single point calibration. A correction for

the sensor zero current shall also be available.

9. The analyzer shall have automatic buffer recognition for pH

sensor calibration.

10. The analyzer shall have a four line, full color display. The display

shall show ppm chlorine, pH (if required), and temperature on one

screen. The display shall be programmable to show additional

information such as raw sensor current.

11. The analyzer shall be capable of operating between 14 and

140°F (-10 and 60°C) and between 5 and 95% relative

humidity (non-condensing).

12. The analyzer shall have four 0/4-20 mA isolated outputs and

HART digital communications. Outputs shall be fully scalable

and

assignable

independently to chlorine, pH, or temperature. PID

control shall be available as a standard fe ature.

13. The analyzer shall have four alarm relays fully programmable as

a high/low alarm with adjustable deadband or as a timer. Timer

functions shall include an interval timer, bleed and feed timer,

delay timer, and date and time timer. Time- proportional

control shall also be available. In addition relays shall be

configurable to energize when the analyzer detects a fault with

itself or the sensor.

14. All analyzer programming shall be through a front panel

membrane keypad. The language (English, Spanish, Italian,

Portuguese, German, French, Russian, Polish, or Chinese) shall

be selectable by the user.

15. The analyzer shall have a data logger that automatically stores

data every thirty seconds for thirty days with older data being

discarded to make room for

newer

data. In addition to storing date

and time, chlorine concentration, pH, and temperature, the

analyzer will store raw sensor current (chlorine sensor) and mV

reading and glass and reference impedance (pH sensor). Stored

data shall be downloadable through a USB port.

16. The analyzer shall have a dual graphical display that allows

stored data to be viewed over one hour, one day, seven days,

and one month intervals.

17. The

analyzer shall have a data logger that stores up to 300

events.

18. The analyzer shall have help screens, available at the touch of a

button, that provide information about configuration,

calibration, and troubleshooting.

19. The analyzer shall have a security feature to prevent unautho-

rized tampering with calibration and configuration settings.

20. The analyzer shall be Rosemount Model

FCL-01-

240 (free

chlorine only) or Model FCL-02-241 (free chlorine with

continuous pH correction) or approved equal.

Page 7

July 2017 Model FCL

www.Emerson.com/RosemountLiquidAnalysis

7

Ordering Information

Model FCL Free Chlorine Measuring System. The FCL is a complete system for the determination of free chlorine in water. It consists of

the sensor(s), analyzer, and constant head overflow cup to control sample flow. All components are mounted on a backplate. Model

option -02 includes a pH sensor for continuous, automatic pH correction. Three replacement membranes and a 4-oz. (120 ml) bottle of

electrolyte solution are shipped with the chlorine sensor.

Model FCL Free Chlorine Measuring System

CODE

pH Correction (required selection)

01

Without continuous pH correction

02

With continuous pH correction

CODE

Analyzer (required selection)

220

1056-03-24-38-AN, single input (chlorine) (option -01 only)

221

1056-03-24-32-AN, dual input (free chlorine) (option -02 only)

240

56-03-24-38-HT, (option -01 only)

241

56-03-24-32-HT, (option -02 only)

FCL-02-221 EXAMPLE

Component Parts

Analyzer Model

Description

1056-03-24-38-AN

1056 analyzer, single input (chlorine), alarm relays, analog output, 85-265VAC, 47.5-65.0 Hz

1056-03-24-32-AN

1056 analyzer, dual input (chlorine and pH), alarm relays, analog output, 85-265VAC, 47.5-65.0 Hz

56-03-24-38-HT

56 analyzer, single input (chlorine), alarm relays, analog / HART output, 85-265 VAC, 47.5-65.0 Hz

56-03-24-32-HT

56 analyzer, dual input (chlorine and pH), alarm relays, analog / HART output, 85-26 5 VAC, 47.5-65.0 Hz

Sensor Model

Description

499ACL-01-54-VP

Free chlorine sensor with Variopol connector

3900VP-02-10

pH sensor with Variopol connector

Sensor Cable

Description

23747-04

Interconnecting cable, Variopol for 499ACL sensor, 4 ft (1.2m)

23645-08

Interconnecting cable, Variopol for 3900VP sensor, (gray) 4 ft (1.2m)

24281-05

Interconnecting cable, Variopol for 3900VP sensor, (blue) 4 ft (1.2m)

Accessories and Spare Parts

Part Number

Description

9240048-00

Tag, stainless steel (specify marking)

23502-08

Membrane assembly with o-ring for free chlorine sensor, quantity 3

9210356

Fill solution for free chlorine sensor, 4 oz. (120 ml)

Page 8

FCL Free Chlorine Measuring System

LIQ-PDS-FCL

Product Data Sheet

July 2017

Global Headquarters

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

Liq.CSC@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 952846 5121

RFQ.RMD-RCC@Emerson.com

Europe Regional Office

Emerson Automation Solutions Europe GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+1 954 846 5030

+1 952846 5121

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions Asia Pacific Pte LTD

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

+971 4 8118100

+971 4 88665465

RFQ.RMTMEA@Emerson.com

Analyticexpert.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

Google.com/+RosemountMeasurement

The Emerson logo is a trademark and service mark of Emerson Electric

Co.

Rosemount and Rosemount logotype are trademarks of Emerson.

All other marks are the property of their respective owners.

© 2017 Emerson. All rights reserved.

Loading...

Loading...