Page 1

Rosemount™ CX1100 In-Situ Oxygen

Transmitter

Reference Manual

00809-0100-4110, Rev AA

June 2018

Page 2

Essential instructions

Read this page before proceeding!

EmersonTM designs, manufactures, and tests its products to meet many national and international standards. Because these

instruments are sophisticated technical products, you must properly install, use, and maintain them to ensure they continue to

operate within their normal specifications. The following instructions must be adhered to and integrated into your safety program

when installing, using, and maintaining Emerson products. Failure to comply with instructions may result in: loss of life, personal

injury, property damage, damage to this instrument, and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product, including this manual.

• To ensure proper performance, use only informed and qualified personnel to install, operate, update, program, and

maintain the product.

• Install equipment as specified in the installation instructions of the appropriate instruction manual and per applicable local

and national codes. Connect all products to the proper electrical and pressure sources.

• Use only factory documented components for repair. Tampering and unauthorized substitution and parts can affect

product performance and cause unsafe operation of your process.

WARNING!

RISK OF ELECTRICAL SHOCK

1. Disconnect the main power wire from the separate power source before servicing.

2. Do not operate or energize instrument with case open!

3. Wiring connected in this box must be rated at least 240 Vac and 14 gauge.

4. Non-metallic cable strain reliefs do not provide grounding between conduit connections! Use grounding type bushings and

jumper wires.

5. Seal unused cable conduit entries securely with non-flammable enclosures to provide transmitter's enclosure integrity in

compliance with personal safety and environmental protection requirements. Seal unused conduit openings with Type 4X or

IP66 conduit plugs to maintain the ingress protection rating (Type 4X) of transmitter's enclosure.

6. Operate only with front panel fastened and in place.

7. For safety and performance, connect and properly ground the system through a three wire power source.

8. Proper use and configuration is your responsibility.

9. Install all protective equipment covers and safety ground leads after installation. Failure to install covers and ground leads

could result in serious injury or death.

10. Provide local ground connection to the RosemountTM CX1100 in order to avoid electric shock. The ground conductor should

be equal to or greater than 16 AWG for a copper conductor in free air or 12 AWG for an enclosed copper conductor.

11. Disconnect and lock out power before connecting the power supply.

12. Install all protective covers and safety ground leads after installation. Failure to install covers and ground leads could result

in serious injury or death.

13. Disconnect and lock out power before working on any electrical components. There is voltage up to 240 Vac. Verify the

reliability and continuity of the grounding of the probe connection before powering the equipment.

14. To meet the Safety Requirements of IEC 61010-1 (EC requirement) and ensure safe operation of the equipment, make a

connection to the main electrical power supply through a circuit breaker (max 10A) which will disconnect all currentcarrying conductors during a fault situation. The circuit breaker should also include a mechanically operated isolating

switch. If it does not, then locate another means of disconnecting the supply from the equipment close by. Circuit breakers

or switches must comply with a recognized standard, such as IEC 60947.

15. Ensure that all equipment doors are closed and protective covers are in place, except when maintenance is being performed

by qualified people, to prevent electrical shock and personal injury.

CAUTION!

• If the ducts will be washed down during outage, make sure to power down the probes and remove them from the wash

area.

• When replacement parts are required, ensure that qualified people use replacement parts specified by Emerson.

Unauthorized parts and procedures can affect the product's performance, place the safe operation of your product at risk,

and void your warranty. Look-alike substitutions may result in fire, electrical hazards, or improper operation.

Page 3

NOTICE

The information contained in this document is subject to change without notice.

Symbols used on equipment and in instruction manual

Earth (ground) terminal

Protective conductor terminal

Risk of electrical shock

Hot surface

Refer to reference manual.

Equipment protected throughout by double insulation

(applies to Rosemount CX1100 Remote Transmitter housing only)

NOTICE

If the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired.

Page 4

Page 5

Contents

Contents

Chapter 1 General information .......................................................................................................1

1.1 Overview ..................................................................................................................................... 1

1.2 Rosemount CX1100 Oxygen Probe and Transmitter .................................................................... 1

1.3 Typical system package ............................................................................................................... 2

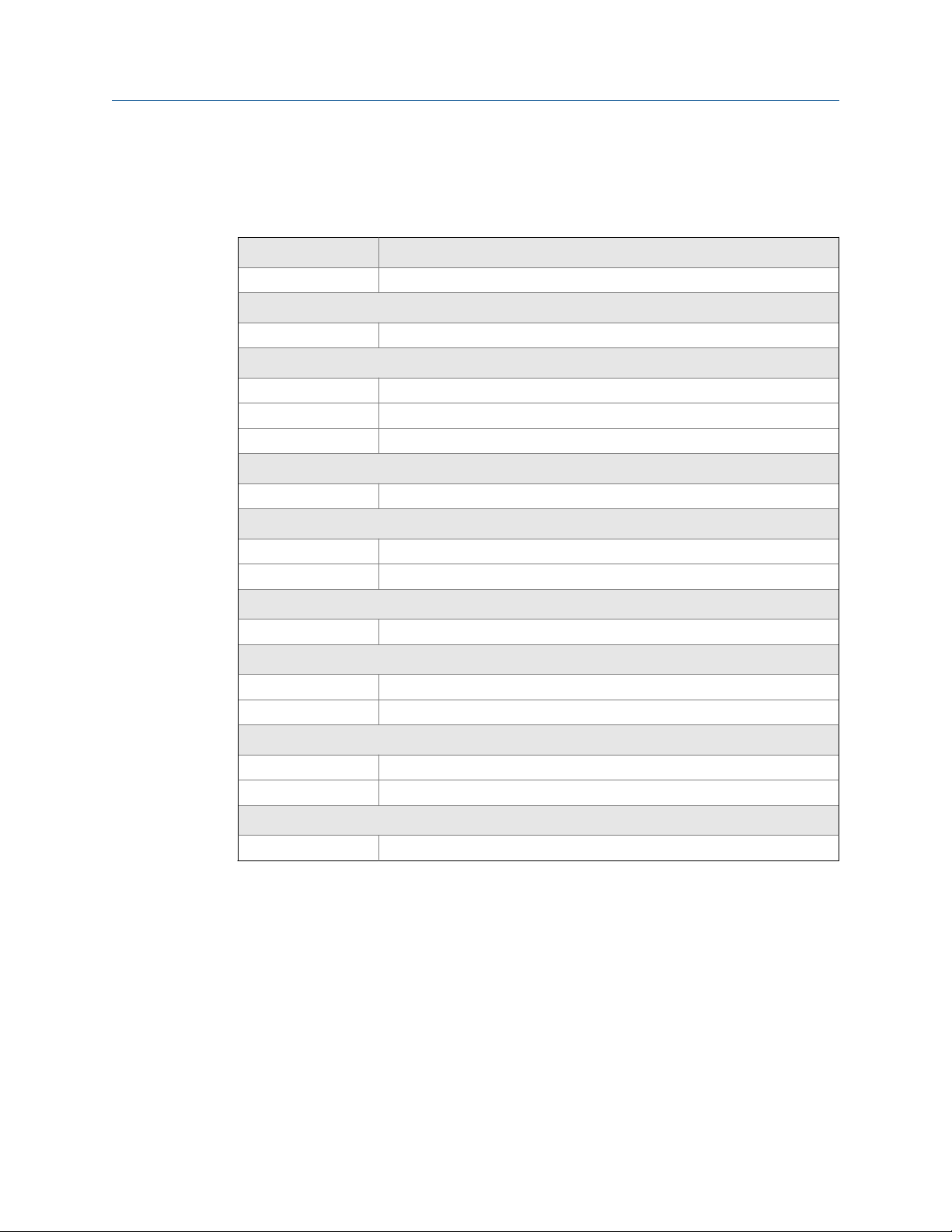

1.4 Rosemount CX1100 In-Situ Oxygen Transmitter ordering information ....................................... 3

1.5 Specifications .............................................................................................................................. 4

Chapter 2 Install .............................................................................................................................7

2.1 Probe installation .........................................................................................................................7

2.2 Mount remote display ................................................................................................................10

Chapter 3 Wire .............................................................................................................................15

3.1 Installation specifications - interconnect cable ...........................................................................15

3.2 Connect the cables .................................................................................................................... 15

Chapter 4 Startup .........................................................................................................................21

Chapter 5 Calibration and maintenance ....................................................................................... 23

5.1 Procedure .................................................................................................................................. 23

5.2 Calibration record ......................................................................................................................25

Chapter 6 Rosemount™ CX1100 In Situ Oxygen Transmitter menu trees ....................................... 27

6.1 System menu tree ......................................................................................................................27

6.2 Probe menu tree ........................................................................................................................28

Chapter 7 Parameters .................................................................................................................. 31

7.1 System and probe parameters ................................................................................................... 31

7.2 Rosemount™ CX1100 In Situ Oxygen Transmitter system alarms ............................................... 34

Appendices and reference

Appendix A Rosemount™ CX1100 product certifications ..................................................................37

A.1 European Directive information ................................................................................................. 37

A.2 Ordinary location certification ................................................................................................... 37

A.3 Installing equipment in North America ...................................................................................... 37

A.4 Rosemount CX1100 In-Situ Oxygen Transmitter ........................................................................37

A.4.1 North America .............................................................................................................37

Reference Manual i

Page 6

Contents

ii Rosemount CX1100

Page 7

1 General information

1.1 Overview

The Rosemount™ CX1100 In Situ Oxygen Transmitter provides a continuous, accurate

measurement of the oxygen remaining in flue gases coming from a combustion process.

Accurate measurements of furnace exhaust excess oxygen are critical for combustion

optimization, which result in reduced energy costs, increased safety, and lower emissions.

This product is intended for use for combustion applications only.

The Rosemount CX1100 probe contains a zirconia type oxygen sensor. At high

temperatures, zirconia produces an electrical potential that is proportional to the

difference in process oxygen concentration and ambient reference air. This voltage is

transmitted to the Rosemount CX1100 remote transmitter and output as an analog signal.

The sensor is mounted at the end of the probe tube which extends into a flue gas duct or

stack. Varying lengths of the probe are available to achieve desired insertion depths. The

probe tube also houses a heating element to precisely control the temperature of the

sensor, reducing errors induced by varying process temperatures.

General information

1.2 Rosemount CX1100 Oxygen Probe and Transmitter

A complete Rosemount CX1100 In Situ Oxygen Transmitter system includes a probe and

remote transmitter. Raw signals (sourced from the heater thermocouple and oxygen

sensor) and power are transmitted between the Rosemount CX1100 probe and the

Rosemount CX1000 remote transmitter, interconnect wiring consisting of nine

conductors. The specifications of the wiring arrangement can be found in Chapter 3. If

following the specifications, 200 ft (61 m) is the maximum cable length allowed.

Reference Manual 1

Page 8

General information

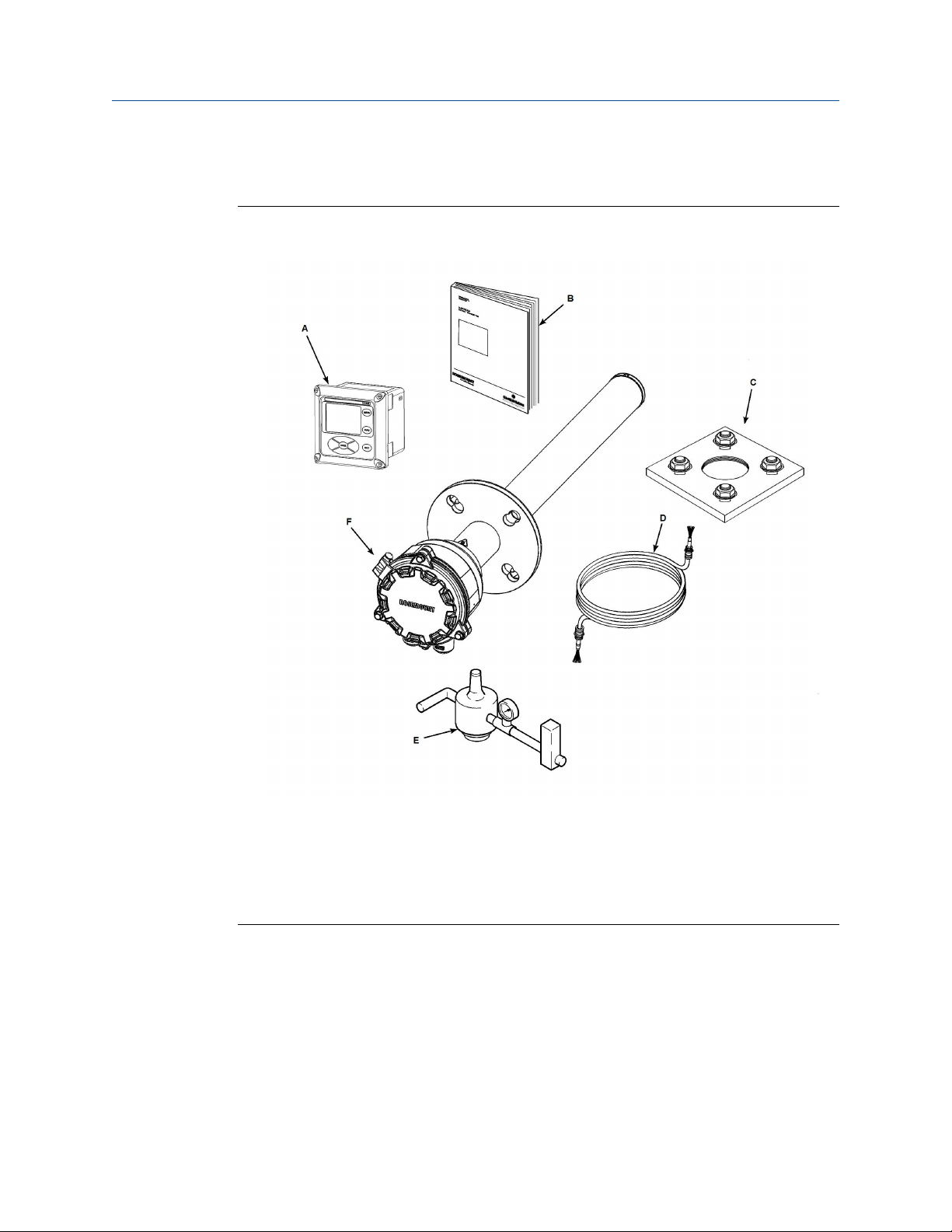

1.3 Typical system package

Typical System PackageFigure 1-1:

A. Rosemount CX1100 Remote Transmitter

B. Quick Start Guide

C. Optional mounting or adapter plate

D. Interconnect cable (user-supplied)

E. Optional calibration gas flowmeter

F. Rosemount CX1100 Probe

2 Rosemount CX1100

Page 9

General information

1.4 Rosemount CX1100 In-Situ Oxygen Transmitter ordering information

Model Product description

CX1100 In Situ Oxygen Transmitter

Material

A 304L stainless steel

Probe length

050 1.64 ft. (0.5 m) oxygen probe

100 3.28 ft. (1.0 m) oxygen probe

200 6.56 ft. (2.0 m) oxygen probe

Probe mounting flange

F20 ANSI/DIN: 4.75 in. / 5.71 in. bolt circle, 0.75 in. holes

Transmitter

M7 Remote transmitter with LCD display and interface

M0 Probe only (no transmitter)

Product certification

G6 CSA ordinary location

Probe mounting hardware

N1 New installation plate - ANSI pattern

N2 New installation plate - DIN pattern

Transmitter mounting hardware

T2 Panel mount kit with gasket

T3 2-in. pipe / wall mount kit

Calibration accessories

F1 Calibration gas flowmeter

Reference Manual 3

Page 10

General information

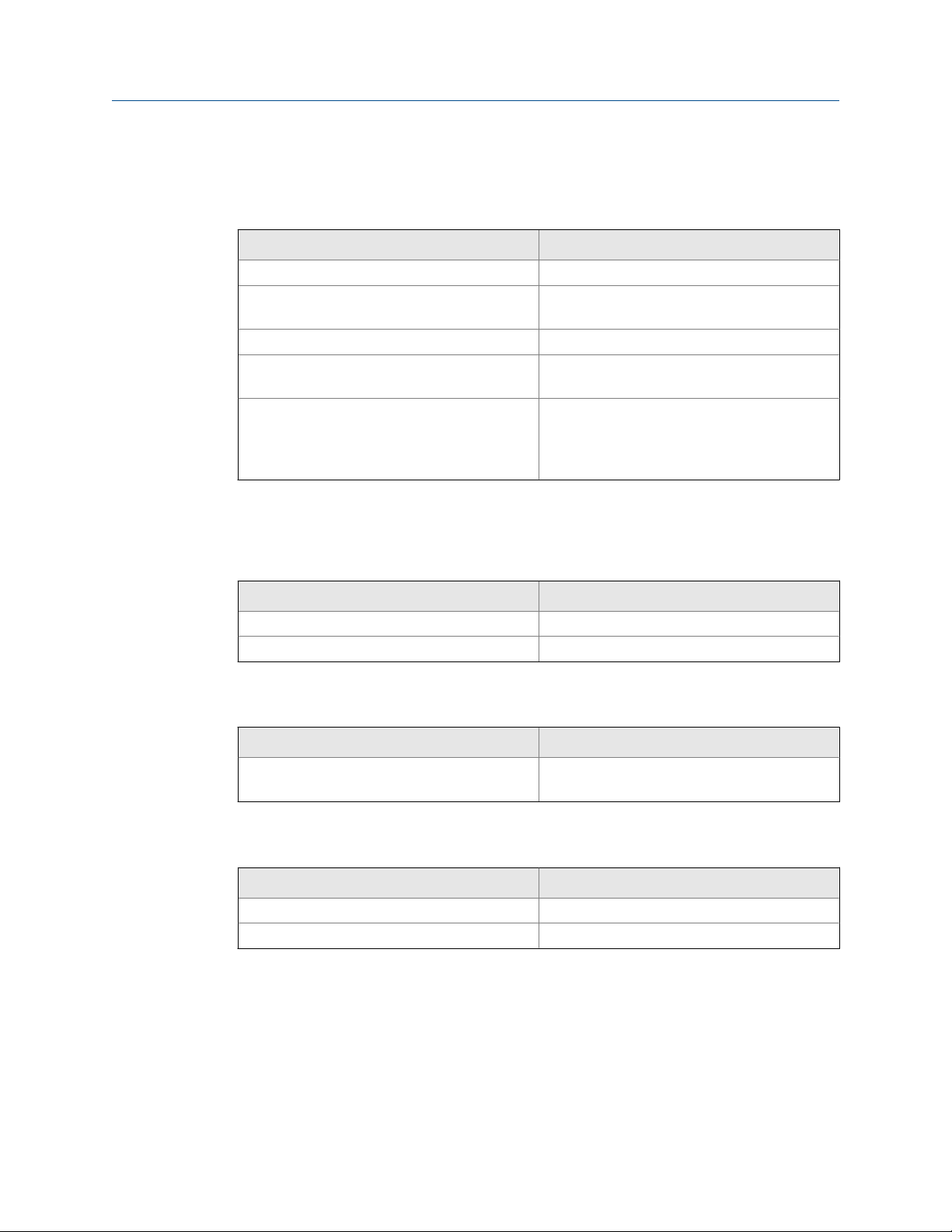

1.5 Specifications

System Measurement SpecificationsTable 1-1:

Specification Description

Net O2 range 0 - 23%

Repeatability 0.1% of O2 or 1.0% of reading, whichever is low-

Lowest detectable limit 0.05% O

Process temperature effect Less than 0.3% O2 from 77 to 1292 °F (25 to

System speed of response to calibration gas Initial response in less than 3 seconds, T90 in 10

Environmental specifications

er

2

700 °C)

seconds. Response to process gas changes will

vary depending on process gas velocity and particulate loading of the diffuser.

ProbeTable 1-2:

Specification Description

Probe Process wetted materials are 304 stainless steel.

Maximum process temperature 752 °F (400 °C)

Probe TerminationsTable 1-3:

Specification Description

Rosemount CX1100 probe ambient temperature limits

-4 to 158 °F (-20 to 70 °C)

Remote DisplayTable 1-4:

Specification Description

Materials Polycarbonate

Ambient temperature limits -4 to 122 °F (-20 to 50 °C)

4 Rosemount CX1100

Page 11

General information

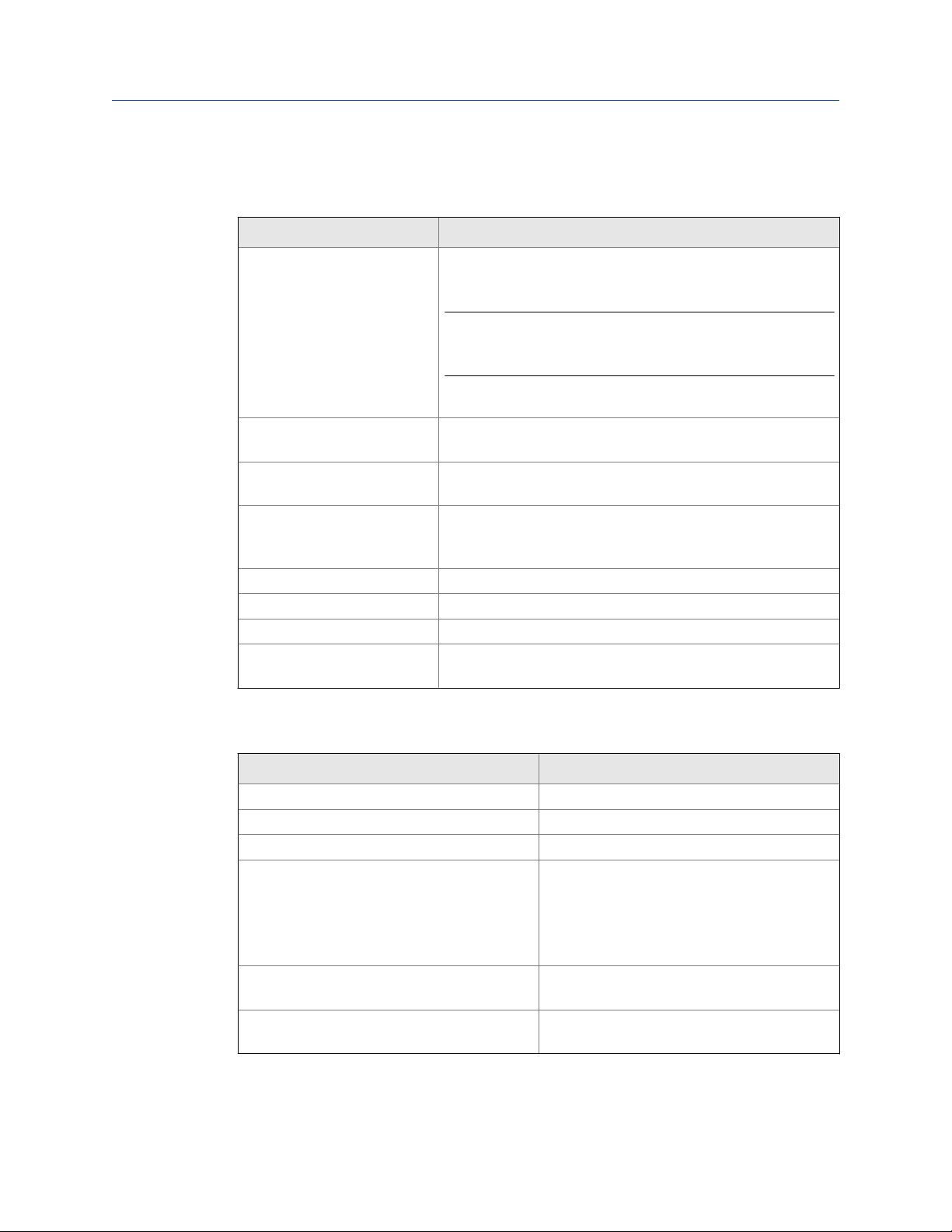

Installation specifications

ProbeTable 1-5:

Specification Description

Probe mounting range Vertical or horizontal: 2-in. 150# (4.75 in. (121 mm) bolt circle)

and DIN145

Note

Flanges are flat-faced and for mounting only. Flanges are not

pressure-rated. A 2.5-in. diameter hole in the process is required.

Many adapter flanges are available to mate to existing flanges.

Reference air No instrument air required. Ambient air diffuses into the probe

passively. Ensure that ambient air is fresh (20.95% O2).

Calibration Semi-automatic manual gas switching. New calibration values

are calculated in the remote electronics.

Cal gases 0.4% and 8% O2, balance N2 recommended. Instrument air may

be used as a high cal gas, but is not recommended. 100% nitrogen cannot be used as a low cal gas.

Calibration gas flow 5 scfh (2.5 l/min) at 15 PSI

Heater electrical power 120/240 Vac, 50/60 Hz, 1.8 A Max

Traditional architecture cable Customer-supplied

Power consumption of probe

heater

150 watts max. during initial warm-up

Remote ElectronicsTable 1-6:

Specification Description

Electrical power 120/240 Vac, 50/60 Hz, 1.8 A Max

Power consumption 150 watts during initial warm-up

Analog output 4-20 mA. Max load 550 Ohms

Alarms relays Two SPDT Form C, epoxy sealed contacts rated

5A, 30 Vdc, 120 Vac, or 230 Vac; user configurable to alarm.

Resistive load: 5A at 28 Vdc or 300 Vac

Inductive load: 1/8 HP at 120/240 Vac

Probe sensing cable 3 twisted pair conductors, 22 ga overall shielded

cable to connect the TC, O2, and CJC signals

Heater cable 3 multi conductor 18 ga shielded cable to con-

nect the heater control signal

Reference Manual 5

Page 12

General information

Rosemount CX1100 Probe Shipping weight Actual weight

19.68 in. (0.5 m) 19 lb. (8.6 kg) 13.5 lb. (6.1 kg)

39.37 in. (1 m) 23 lb. (10.43 kg) 16.8 lb. (7.6 kg)

78.74 in. (2 m) 30.5 lb. (13.8 kg) 23 lb. (10.43 kg)

Rosemount CX1100

Remote Transmitter

dimensions in inches

(millimeters) Shipping weight Actual weight Part number

6.10 x 6.10 x 5.15 in.

(155 x 155 x 131 mm)

Accessory Part number

Calibration flowmeter 771B635H01

Cal gas adaptor kit to mate to existing tubing arrangement 1A98771H07

4 lb. (1.8 kg)_ 3 lb. (1.4 kg) 24490-00

6 Rosemount CX1100

Page 13

2 Install

WARNING!

ELECTRIC SHOCK

Install all protective equipment covers and safety ground leads after installation. Failure to

install covers and ground leads could result in serious injury or death.

CAUTION!

EQUIPMENT DAMAGE

Do not allow the temperature of the Rosemount™ CX1100 Probe electronics to exceed 194 °F

(90 °C) or damage to the unit may result.

2.1 Probe installation

Install

A weld plate for welding to the flue gas duct can be supplied for new installations.

1. If using the standard square weld plate (Figure 2-2) or an optional flange mounting

plate, weld or bolt the plate onto the duct.

The through hole diameter in the stack or duct wall and refractory material must be

at least 2.5 in. (63.5 mm).

2. Insert probe through the opening in the mounting flange and bolt through the

probe gasket and flange.

For horizontal installations, the breather port must be oriented such that it is facing

downward.

Reference Manual 7

Page 14

Install

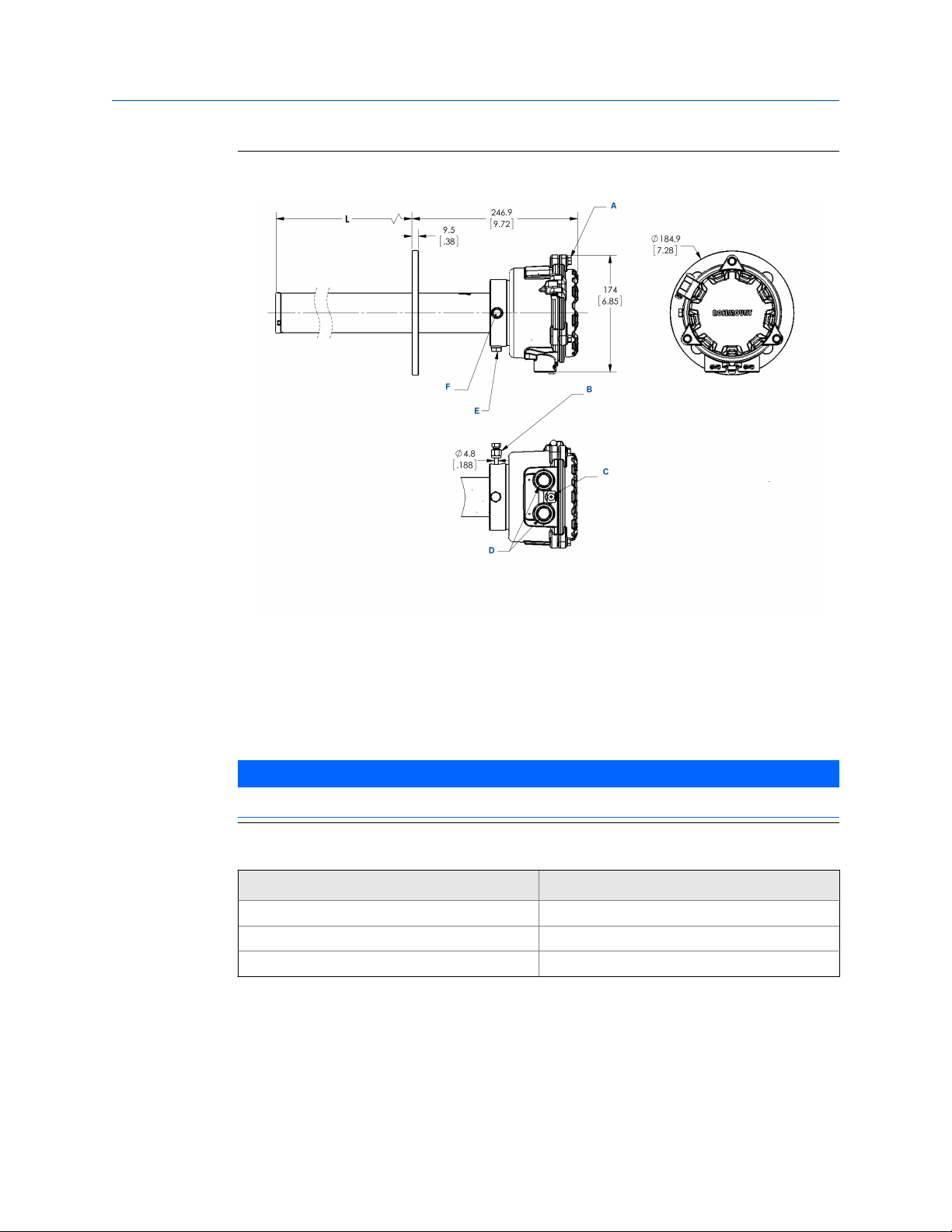

Probe InstallationFigure 2-1:

A. M6 X 1 X 25 hex head machine screw (3X)

B. Calibration gas, 3/16-in. tube fitting, 2.82 liter/min (10 SCFH), 138 kPa (20 psi)

C. M5 X 0.8 x 10 pan head machine screw, ground screw

D. 1/2 NPT conduit connection (power, signal)

E. Breather port

F. Calibration gas connection

NOTICE

All dimensions are in millimeters with inches in parentheses.

Removal/InstallationTable 2-1:

Probe length Removal envelope

.5 m (19.68 in.) 750 mm (30 in.)

1 m (39.37 in.) 1250 mm (49 in.)

2 m (78.74 in.) 2250 mm (89 in.)

8 Rosemount CX1100

Page 15

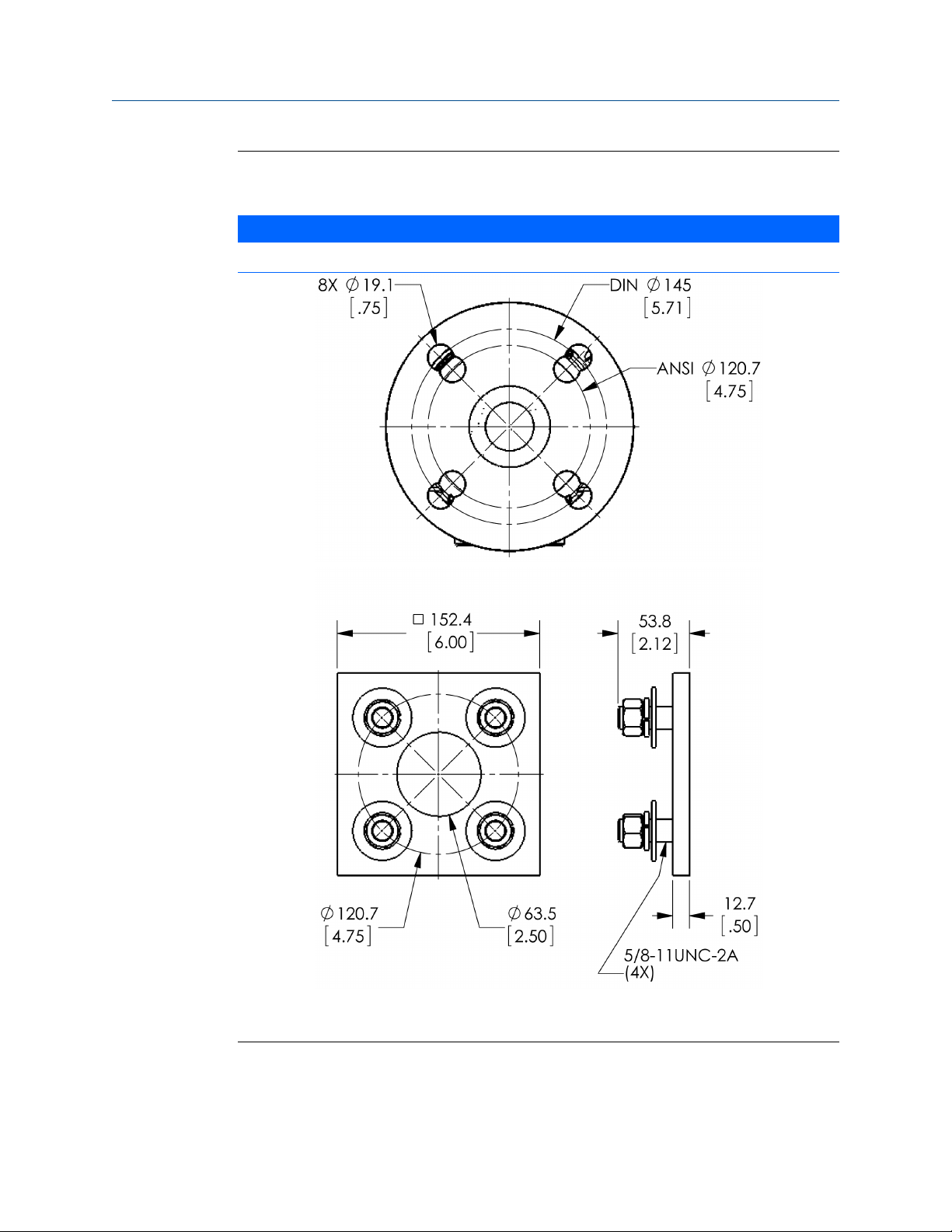

Rosemount CX1100 Probe InstallationFigure 2-2:

NOTICE

All dimensions are in millimeters with inches in parentheses.

Install

Square weld plate, ANSI pattern part 4512C34G01

Reference Manual 9

Page 16

Install

Mounting FlangeTable 2-2:

ANSI DIN

Flange dia 185 mm (7.28 in.)

Hold dia 19.1 mm (.75 in.)

4 holes eq sp on BC 120.7 mm (4.75 in.) 145 mm (5.71 in.)

Drip loop and Insulation RemovalFigure 2-3:

A.

Note

Replace insulation after installing CX1100.

B. Drip loop

C. Stack duct or metal wall

D. Adapter plate

E. Insulation

NOTICE

Probe installation may be vertical or horizontal.

2.2

10 Rosemount CX1100

Mount remote display

Complete the following steps to install the Rosemount CX1100 Remote Transmitter.

Page 17

Install

The Rosemount CX1100 Remote Transmitter is available in a panel mounting or wall/pipe

mounting configuration. Refer to Figure 2-4 or Figure 2-5 for the panel, wall, or pipe

mounting details. You need a wrench and bolts to mount the transmitter.

Procedure

1. Ensure all components are available to install the Rosemount CX1100 Remote

Transmitter.

2. Select a mounting location near or removed from the Rosemount CX1100 Probe.

Consider the temperature limitations of the Rosemount CX1100 Remote

Transmitter. Refer to product specifications when selecting the mounting location.

3. Mount at a height convenient for viewing and operating the interface.

Emerson recommends approximately 5 ft. (1.5 m).

4. The keypad window on the Rosemount CX1100 Remote Transmitter may have an

exterior protective membrane. Remove the protective membrane prior to use of the

Rosemount CX1100 Remote transmitter.

Failure to remove the protective membrane may cause the display to appear

distorted. The membrane may become difficult or impossible to remove after

extended use at elevated temperatures.

Reference Manual 11

Page 18

Install

Wall/Surface and Pipe MountFigure 2-4:

12 Rosemount CX1100

Page 19

Install

Panel MountFigure 2-5:

Reference Manual 13

Page 20

Install

14 Rosemount CX1100

Page 21

3 Wire

All wiring must conform to local and national codes.

WARNING!

Before installing the equipment, read the Safety Instructions at the front of this manual. Failure

to follow safety instructions could result in serious injury or death.

NOTICE

To maintain proper earth grounding, ensure a positive connection exists between the probe

terminations housing and earth. The connecting wire must be 14 AWG minimum.

NOTICE

Line voltage, signal, and relay wiring must be rated for at least 221 °F (105 °C).

Wire

3.1

3.2

NOTICE

If metal conduit is used with the Rosemount™ CX1100 Remote Transmitter, reliably bond the

conduit to protective earth. The grounding plate inside the Rosemount CX1100 Remote

Transmitter is not bonded to PE and does not provide adequate grounding.

Installation specifications - interconnect cable

Customer supplied cable up to 200 ft. (60 m) long, rated for -40 to 194 °F (-40 to 90 °C)

and voltage 300 VACrms.

Heater power: 3 multi conductor 18ga shielded cable to connect the heater control signal

Probe sensing: 3 twisted pair conductors 22ga overall shielded cable to connect the TC,

O2, and CJC signals.

Cable may be purchased as two separate cables.

Connect the cables

Raw voltages from the oxygen sensor and heater thermocouple are transmitted from the

Rosemount CX1100 Probe to the Rosemount CX1100 Remote Transmitter. The remote

transmitter also controls power to the probe heater in order to maintain the correct sensor

temperature.

This arrangement calls for interconnect wiring consisting of nine conductors. Given the

recommended wire specifications, the maximum length for this cable is 200 ft (60 m)

(refer to Section 3.1).

Reference Manual 15

Page 22

Wire

NOTICE

To maintain EMC/EMI noise protection, connect the customer supplied 9 conductor cable and

cable glands properly to ground.

Procedure

1. Run the signal and power cables between the probe and the installation site for the

optional Rosemount CX1100 Remote Transmitter.

2. Remove the covers from the probe and the remote transmitter (if applicable).

3. Feed all probe wiring through the conduit port of the probe.

4. Refer to Figure 3-2. Connect probe heater power leads to probe connector.

5. Connect O2 signal, thermocouple, and cold junction (CJC) wires from probe to the

Rosemount CX1100 Remote Transmitter.

6. At the Rosemount CX1100 Remote Transmitter, connect the cable leads to the

connectors on the sensor board as indicated in Figure 3-1.

16 Rosemount CX1100

Page 23

Wire

Wiring DiagramFigure 3-1:

A. Heater power to probe

B. Alternate 4-20 mA out

C. Signal from probe

D. Power to remote transmitter

E. Alarm relay

Reference Manual 17

Page 24

Wire

F. 4-20 mA out

G. Power supply

H. Combustion sensor

I. Shield ground

J. Heater power terminates to underside of the sensor board.

K. Probe sensing connect shield to GND

L. S1 Dip switch is for factory use only and should be in the Off position.

AC power wires from power supply board to the underside of the sensor board are provided with

the sensor board.

18 Rosemount CX1100

Page 25

Wire

Closeup Wiring DiagramFigure 3-2:

A. M4 X 0.7 X 8 pan head screw machine screw (internal ground)

Reference Manual 19

Page 26

Wire

20 Rosemount CX1100

Page 27

4 Startup

1. Apply AC line power to the Rosemount™ CX1100 Remote Transmitter.

The probe takes approximately 45 minutes to warm up to the 1357 °F (736 °C)

setpoint. The 4-20 mA signal remains at a default value of 3.5 mA, and the O

reading remains at 0% through the warmup period.

2. After warmup, the probe begins reading oxygen, and the 4-20 mA output is based

on the default range of 0-10% O2.

If there is an error condition at startup, an alarm message is displayed on the

Rosemount CX1100 Remote Transmitter.

Startup

2

Reference Manual 21

Page 28

Startup

22 Rosemount CX1100

Page 29

Calibration and maintenance

5 Calibration and maintenance

The Rosemount™ CX1100 In Situ Oxygen Transmitter can be calibrated in the installed

position without removing the instrument from the process duct and also while the

combustion process is online.Gas is applied to the sensor through the calibration gas

fitting. New Rosemount CX1100 In Situ Oxygen Transmitter systems are factory calibrated

and are generally acceptable for initial startup and operation. High accuracy can be gained

by calibrating a system during normal operating conditions. Emerson ™recommends

calibrating on a semi-annual to annual basis for most applications; however actual

calibration frequency may vary per process unit.

Calibrations are conducted using a two point calibration. Factory calibration uses 0.4% O

and 8.0% O2 gases with a balance of nitrogen and is therefore recommended. Calibration

gases with other oxygen concentrations are acceptable. If using different calibration gas

values, additional configuration through the Rosemount CX1100 Remote Transmitter is

required. Emerson does not recommend pure nitrogen as a calibration gas.

5.1 Procedure

The calibration of the Rosemount CX1100 Probe is initiated from the Rosemount CX1100

Remote Transmitter. The Rosemount CX1100 Remote Transmitter display prompts you

with the calibration instructions.

1. Press the x1 or x2 menu button on the Rosemount CX1100 Remote Transmitter

display to enter the probe.

2. Navigate, using Up and Down buttons to Setup; press Enter.

3. Navigate to Cal Gas values; press Enter.

4. Navigate to Cal Gas 1 and press Enter twice to highlight the value setting.

5. Use the Up and Down buttons to set Cal Gas 1 value and Left and Right buttons

to move to decimals setting.

6. After setting the correct value, press Enter and press Left to go to the Calibration

Setup for Cal Gas 2, Gas time, and Purge time settings.

2

7. After setting the values (0.4% O2, 8.0% O2, and 300s are the defaults), press Left to

go up to the Calibration submenu.

8. Navigate using the Up and Down buttons to Calibration and press Enter to start.

9. Follow the instructions on the display, manually applying calibration gases (0.4% and

8.0% O2 at 5 SCFH are recommended) to the calibration port.

10. After the calibration is finished, press Left and use the Up and Down buttons the

check the current and previous 10 calibrations log.

After completing the procedure, the Rosemount CX1100 software calculates new

calibration values and determines whether they meet an acceptance criteria. If successful,

the new calibration values automatically replace the previous values. In the event the

Reference Manual 23

Page 30

Calibration and maintenance

calibration values do not meet the accepted performance criteria, the existing calibration

values remain in effect, and Emerson recommends replacing the Rosemount CX1100

Probe.

EQUIPMENT DAMAGE

Make sure that the calibration gas cap is replaced tightly after calibration is complete. Many

combustion processes operate at a slight negative pressure (draft pressure) and can draw

ambient air down the cal gas lines and into the sensing cell, causing a false elevated oxygen

reading. The same phenomenon is possible if the calibration gas hoses become degraded or

loose.

CAUTION!

24 Rosemount CX1100

Page 31

5.2 Calibration record

For Rosemount CX1100 In-Situ O2 Probe

Probe serial number:

Probe tag number:

Probe location:

Date placed into service:

Calibration and maintenance

NOTICE

Response

valve of the second calibration gas bottle.

Response

concentration after closing the valve of the second calibration gas bottle.

Reference Manual 25

: The time (sec) to observe the initial change in oxygen reading after closing the

initial

: The time (sec) in which the oxygen reading returns to process oxygen

final

Page 32

Calibration and maintenance

26 Rosemount CX1100

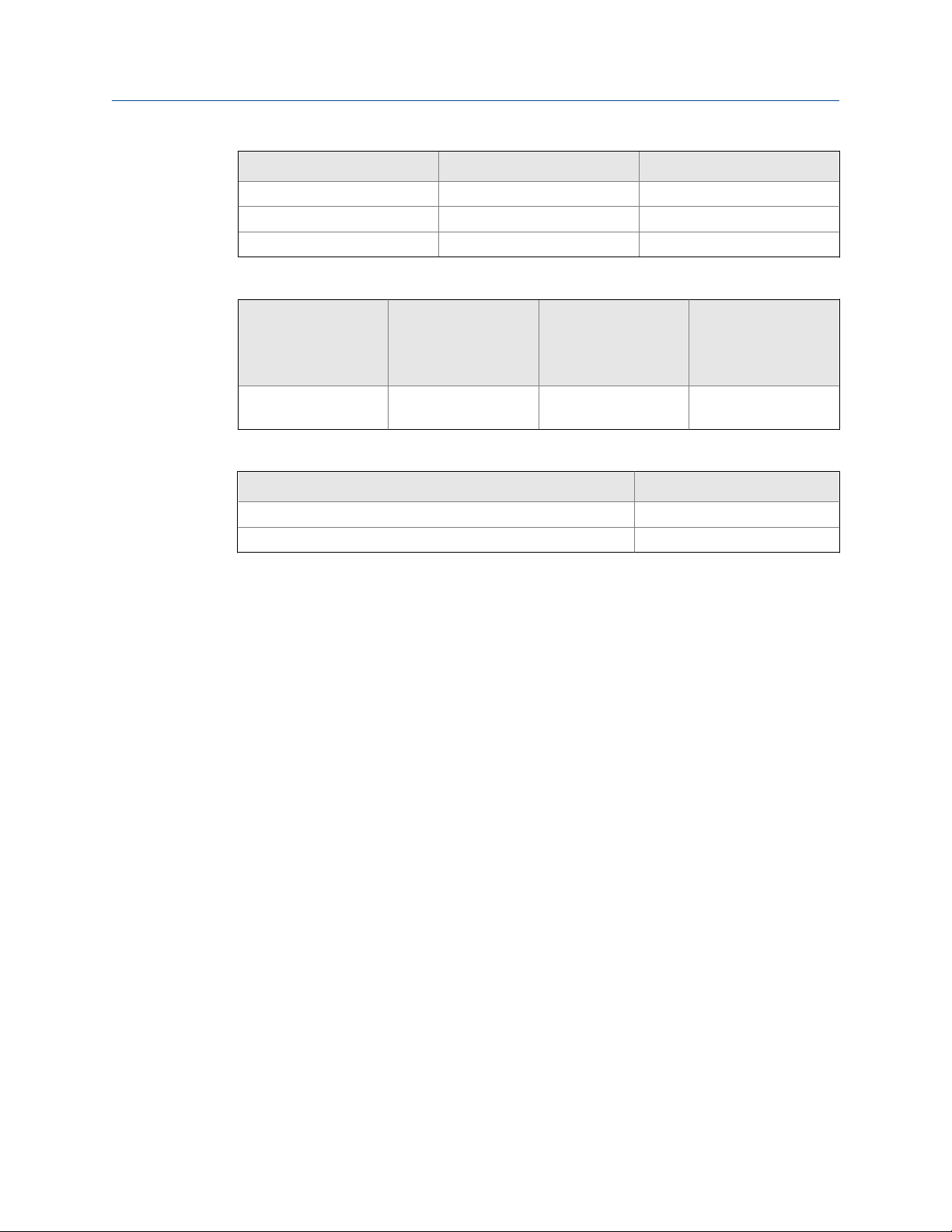

Page 33

1 Diagnostics

2 Setup

1 Active Alarms

2 Status

3 Maintenance

1 Revision

2 NV Memory Status

3 Reset

1 Version

2 Checksum

1 Language

2 Display

3 Security

1 Main Display

2 Revert Time

3 Set Contrast

4 Flash Alarm

1 Line 1

2 Line 2

3 Line 3

1 Center

1 Center

1 Left

2 Right

1 Password

2 Enable Password

1 Restart Counter

2 Reset Restart Count

3 Reset Main Board

4 Factory Defaults

5 Offline

Rosemount™ CX1100 In Situ Oxygen Transmitter menu trees

6 Rosemount™ CX1100 In Situ Oxygen

Transmitter menu trees

6.1 System menu tree

System Menu TreeFigure 6-1:

Reference Manual 27

Page 34

1 Process Variables

1 Process Variables

2 Temperatures

3 Raw Values

4 Analog Output

5 Maximums

6 Heater

1 O

2

Temp

2 CJC Temp

3 Board Temp

4 OP Mode

1 O

2

2 O

2

Temp

3 Cell Imp

4 O

2

Cell

1 O

2

Cell

2 Cell Imp

3 T/C Voltage

4 Heater

5 Update Cell Imp

1 O

2

AO

2 O

2

AO%

3 O

2

LRV

4 O

2

URV

1 Temperature

2 Voltage

3 Ramp Rate

1 O

2

Temp Max

2 CJC Temp Max

3 Board Temp Max

1 Heater Voltage Max

2 Cell Voltage Max

1 Duty Cycle

2 O

2

Temp SP

3 O

2

Temp

4 Heater Ramp Rate

1 Heater Ramp Rate Max

Rosemount™ CX1100 In Situ Oxygen Transmitter menu trees

6.2 Probe menu tree

Probe Menu TreeFigure 6-2:

28 Rosemount CX1100

Page 35

2 Diagnostics

3 Setup

1 Active Alarms

2 Status

3 Acknowledge Alarms

4 Maintenance

1 Current

2 Previous

1 Failed

2 Maintenance

3 Advisory

1 Previous Alarms

1 Ack Previous Alarms

2 Ack Cal Failed

1 Revision

2 Analog Output

3 Operating Status

4 I/O States

5 NV Memory Status

6 Reset

1 Version

2 Checksum

1 Trim mA Output 1

1 Restart Counter

2 Reset Restart Count

3 Reset Sensor Board

1 Sensor

2 Analog Output

3 Relay

4 Calibration

5 Communication

1 T90 Filter

2 Low O

2

Alm SP

1 O

2

LRV

2 O

2

URV

3 AO Range

4 Alarm Level

1 Relay 1

2 Relay 2

1 AO Track

2 Cal Gas 1

3 Cal Gas 2

4 Gas Time

5 Purge Time

1 No Response

2 Bad Response

Rosemount™ CX1100 In Situ Oxygen Transmitter menu trees

Reference Manual 29

Page 36

Rosemount™ CX1100 In Situ Oxygen Transmitter menu trees

30 Rosemount CX1100

Page 37

7 Parameters

7.1 System and probe parameters

System ParametersTable 7-1:

Parameter label Description

Active Alarms Alarms

Status Alarm status bits

Version Main board software version number

Checksum Main board software checksum

Restart Counter Main board restarted counter

Offline The number of times the sensor board is discon-

nected from the main board since last power up

Language Supported languages

Line 1 | Center Main display Line 1 data

Line 2 | Center Main display Line 2 data

Line 3 | Left Main display Line 3 left hand side data

Line 3 | Right Main display Line 3 right hand side data

Revert time The time set for the display to revert back to the

main display after the period of time with no

button press (2-9999 min)

Contrast Display contrast (110 - 200)

Flash Alarm Turn off/on the main display flashing when

alarms detected. (No/Yes)

Password User password: 4 numeric digits. (0 - 9999)

Enable Password Disable/Enable password protection. (No/Yes)

NV Memory Status Main board nonvolatile data memory diagnos-

tic.

Parameters

Probe ParametersTable 7-2:

Parameter label Description

O

2

O2 Temp Current O2 sensor temperature

Cell Imp Cell impedance/sensor resistance measured

O2 Cell Raw voltage value for ZrO2 sensor

CJC Temp Current cold junction temperature

Current oxygen concentration value

Reference Manual 31

Page 38

Parameters

Probe Parameters (continued)Table 7-2:

Parameter label Description

Board Temp Current electronics temperature measured at

the sensor board

OP Mode Device operating mode

T/C Voltage O2 T/C voltage

Heater Heater voltage

O2 AO Analog ouput value represents the O2 concen-

tration measurement

O2 AO% Analog output percentage for O2 AO

O2 Temp Max This is the highest O2 sensor temperature

reached since last reset.

CJC Temp Max This is the highest temperature reached at the

cold junction since last reset.

Board Temp Max This is the highest temperature reached at the

sensor board since last reset.

Heater Voltage Max This is the highest heater voltage reached since

last reset.

Cell Voltage Max This is the highest cell voltage reached since

last reset.

Heater Ramp Rate Max This is the highest heater ramp rate reached

since last reset.

Duty Cycle PID temperature set point

O2 Temp Sp Current O2 sensor temperature

Active Alarms Current alarms

Failed Alarm status

Maintenance Alarm status

Advisory Alarm status

Previous Alarms Previous alarms

Operating Status Operating status

I/O States I/O state

Version Sensor board software version number

Checksum Sensor board software checksum

NV Memory Status Sensor board nonvolatile data memory diag-

nostic

Restart Counter Sensor board software restarts counter.

T90 Filter Analog output T90 time. It represents the time

to take a step change in oxygen to reach 90% of

the final value at the filter output. (0-300 sec)

Low O2 Alm SP Low O2 alarm threshold (0.0 - 50.0%)

32 Rosemount CX1100

Page 39

Parameters

Probe Parameters (continued)Table 7-2:

Parameter label Description

O2 LRV Primary variable, O2%, lower range value. (0.0%

only)

O2 URV Primary variable, O2% upper range value (1.0% -

50.0%)

AO Range Analog ouput polarity

Alarm Level O2 alarm level

Relay 1 Alarm Relay 1 mode

Relay 2 Alarm Relay 2 mode

AO Track Analog output track O2 sensor measurement

during a calibration

Cal Gas 1 Test Gas 1 value. This is the actual value of the

gas being applied during the Test Gas 1 phase

of a calibration. (0.05 - 50.0%)

Cal Gas 2 Test Gas 2 value. this is the actual value of the

gas being applied during the Test Gas 2 phase

of calibration. (0.05 - 50.0%)

Gas Time Test gas application time. This is the length of

time test gases are applied to the O2 probe during low or high test gas phase of a calibration.

(60 - 1200 sec)

Purge Time Test gas purge time. This is the length of time

before the output will be returned to the process reading after a calibration. (60 - 1200 sec)

Imp Check Hold Time to hold analog output during impedance

check. (0 - 60 sec) (Factory mode only)

Remote CJC Use local or remote CJC measurement for cor-

rection. (No/Yes) (Factory mode only)

Raw Counts | Cell Voltage O2 sensor voltage raw counts. (Factory mode

only)

Raw Counts | Cell Imp Cell impedance/sensor resistance raw counts.

(Factory mode only)

Raw Counts | T/C Voltage O2 T/C raw counts. (Factory mode only)

Raw Counts | Heater Voltage Heater voltage raw counts. (Factory mode only)

Cal State This represents the state of the calibration cycle

it is in.

Time Remain Time remaining in the present calibration cycle

state.

Slope Current calibration slope. This is the slope value

that was calculated as a result of the last successful calibration. (34.5 to 57.5 mV/Dec)

Reference Manual 33

Page 40

Parameters

Probe Parameters (continued)Table 7-2:

Parameter label Description

Constant Current calibration constant. This is the con-

stant value that was calculated as a result of the

last successful calibration. (-20.0 to 20.0 mV)

Impedance Cell impedance. This is the sensor resistance

that was calculated as a result of the last successful calibration.

Time Time stamp of the last successful calibration

Calibration Log | Slope Previous calibration slope. There are ten calibra-

tion results. 1 is the most recent, and 10 is the

least recent calibration slope.

Calibration Log | Constant Previous calibration constant. there are ten cali-

bration results. 1 is the most recent, and 10 is

the least recent calibration constant.

Calibration Log | Impedance Previous cell impedance. This is the sensor re-

sistance that was calculated as a result of previous successful calibration. There are ten calibration results. Index 1 is the most recent, and

Index 10 is the least recent sensor resistance

measured.

Calibration Log | Log Time Time stamp of the previous successful calibra-

tion. There are ten calibration time stamps. In-

dex 1 is the most recent, and Index 10 is the

least recent time stamp.

Cal Result Calibration result

7.2 Rosemount™ CX1100 In Situ Oxygen

Transmitter system alarms

System AlarmsTable 7-3:

Alarm label Help messages and recommended actions

NV Memory Fail Checksum error was detected in the nonvolatile memory

configuration data when the unit was turned on. Default

values have been loaded. Check to see that your configurations have not been changed. Cycle the power to clear

alarm.

SB Disconnect Communication failure detected between the sensor

board and the main board, indicating the sensor board has

been disconnected from the main board.Check the connecting cable pins.

34 Rosemount CX1100

Page 41

Parameters

System Alarms (continued)Table 7-3:

Alarm label Help messages and recommended actions

SB Mismatch The sensor type does not match, indicating wrong sensor

board is connected.

SB Version The sensor board software version does not match the ex-

pected version, indicating the sensor board software needs

to be upgraded. Place the jumper on J1 of the sensor board

and cycle the power to start the sensor board software upgrade.

SB Bootload Mode The Bootload Mode jumper at J1 of the sensor board is on

at power up. This mode should only be used to upgrade

the sensor board software. Remove the jumper from J1 of

the sensor board and cycle the power to clear the alarm.

Probe AlarmsTable 7-4:

Alarm label Help messages and recommended actions

O2 T/C Reversed The sensor heater thermocouple voltage is reading a nega-

tive voltage, indicating the thermocouple wire connections may be reversed. Check wiring.

NV Memory Fail Checksum error was detected in the nonvolatile memory

configuration data when the unit was turned on. Default

values have been loaded. Check to see that your configurations have not been changed. Cycle the power to clear

alarm.

Board Temp High The electronics board tempreature reading is above the

threshold. The board may not function correctly.

Factory Mode The Factory Mode switch is set to On at power up. This

mode should only be uses for factory setup. Turn off the

Factory Mode switch and cycle the power to clear alarm.

Program Integrity Software checksum error detected when the unit was

turned on. Please replace sensor board.

O2 T/C Shorted This diagnostic is only intended to detect a copper short of

the thermocouple connections at the electronics connector. The cell heater T/C voltage is reading close to zero, indicating the thermocouple wires may be shorted.

O2 Sensor Open The cell impedance voltage is reading out of normal range,

indicating the sensor wires may be disconnected or the

sensor junction may be open. Check wiring.

O2 T/C Open The sensor heater thermocouple voltage is out of range,

indicating the T/C wires may be disconnected, or the T/C

junction may be open. Check wiring.

O2 Temp Low The sensor heater temperature is below the low tempera-

ture threshold.

Reference Manual 35

Page 42

Parameters

Probe Alarms (continued)Table 7-4:

Alarm label Help messages and recommended actions

O2 Temp High The sensor heater temperature is above the high tempera-

ture threshold.

RTD Open The CJC temperature is out of range, indicating the RTD

may be open. Check RTD wiring.

Cal Failed Calibration has failed. Check the Cal Result for more de-

tails. Acknowledge Calibration Failed or recalibrate

to clear alarm.

Low O

2

The O2 reading is below the threshold. The threshold is defined by the "Low O2 Alm SP".

36 Rosemount CX1100

Page 43

Rosemount™ CX1100 product certifications

Appendix A

Rosemount™ CX1100 product certifications

A.1 European Directive information

A copy of the EC Declaration of Conformity can be found at the end of the Quick Start

Guide. The most recent revision of the EC Declaration of Conformity can be found at

Emerson.com/Rosemount.

A.2 Ordinary location certification

As standard, the transmitter has been examined and tested to determine that the design

meets the basic electrical, mechanical, and fire protection requirements by a nationally

recognized test laboratory (NRTL) as accredited by the Federal Occupational Safety and

Health Administration (OSHA).

A.3 Installing equipment in North America

The US National Electrical Code (NEC) and the Canadian Electrical Code (CEC) permit the

use of Division marked equipment in Zones and Zone marked equipment in Divisions. The

marking must be suitable for the area classification, gas, and temperature class. This

information is clearly defined in the respective codes.

A.4

A.4.1 North America

Rosemount CX1100 In-Situ Oxygen Transmitter

CSA

Certificate: 70172073

Standards: CAN/CSA C22.2 No. 61010-1-12, CAN/CSA C22.2 No. 61010-2-010:15, UL

61010-1 (3rd Edition), UL 61010-2-10 (3rd Edition), UL 50E (2012), C22.2 No. 94.2-07, IEC

60529:2013 (Edition 2.2)

Markings: Type 4X, IP66

Reference Manual 37

Page 44

Rosemount™ CX1100 product certifications

Condition of acceptability:

1. The measuring of net O2 range is limited 0-23%.

2. The equipment shall be installed in accordance with manufacturer's specification by

qualified personnel.

3. This equipment is for permanently connection to power source with approved

power cord at end installation in accordance with local codes.

4. The Probe unit of the equipment shall be connected to PE separately at end

installation.

5. End installation to provide the means of disconnection from power sources.

6. End installation to comply with the requirement of IP66 and 4X.

38 Rosemount CX1100

Page 45

Rosemount™ CX1100 product certifications

Reference Manual 39

Page 46

Rosemount™ CX1100 product certifications

40 Rosemount CX1100

Page 47

Rosemount™ CX1100 product certifications

Reference Manual 41

Page 48

GLOBAL HEADQUARTERS

Emerson Automation Solutions

6021 Innovation Blvd

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

gas.csc@emerson.com

NORTH AMERICA

Rosemount

8200 Market Boulevard

Chanhassen, MN 55317

+1 800 999 9307

+1 952 949 7001

gas.csc@emerson.com

00809-0100-4110

Rev AA

2018

EUROPE

Emerson Automation Solutions

Neuhofstrasse 19a P.O. Box 1046

CH-6340 Baar

Switzerland

+ 41 (0) 41 768 6111

+ 41 (0) 41 768 6300

gas.csc@emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

twitter.com/rosemount_news

Facebook.com/Rosemount

youtube.com/RosemountMeasurement

google.com/+RosemountMeasurement

AnalyticExpert.com

MIDDLE EAST AND AFRICA

Emerson Automation Solutions

Emerson FZE

Jebel Ali Free Zone

Dubai, United Arab Emirates, P.O. Box 17033

+971 4 811 8100

+971 4 886 5465

gas.csc@emerson.com

©

2018 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount is a

mark of one of the Emerson family of companies. All other marks are the property of their

respective owners.

ASIA-PACIFIC

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

Singapore

+65 777 8211

+65 777 0947

gas.csc@emerson.com

Loading...

Loading...