Page 1

Rosemount™ CX1100

In-Situ Oxygen Transmitter

Product Data Sheet

00813-0100-4110, Rev AA

July 2018

Page 2

Rosemount CX1100

Product benefits

Reliable combustion measurement

July 2018

■ Robust zirconia oxygen sensor provides measurement of furnace exhaust gas critical for boiler trim applications.

■ Good measurement repeatability of 0.1% O2 or 1.0% of reading and multiple probe length options to suit your application needs.

■ Optional remote mounted LCD display and interface for easy

access to process information and simplified maintenance.

CX1100 remote display

Remote display and interface for configuration, calibration,

■

and maintenance without the need for additional tools.

■ Bright, back-lit display and an easy-to-use keypad.

Contents

Product benefits ........................................................................................................................................................... 2

Specifications ............................................................................................................................................................... 4

Product certifications ................................................................................................................................................... 6

Dimensional drawings .................................................................................................................................................. 7

2 www.Emerson.com

Page 3

July 2018

Rosemount CX1100

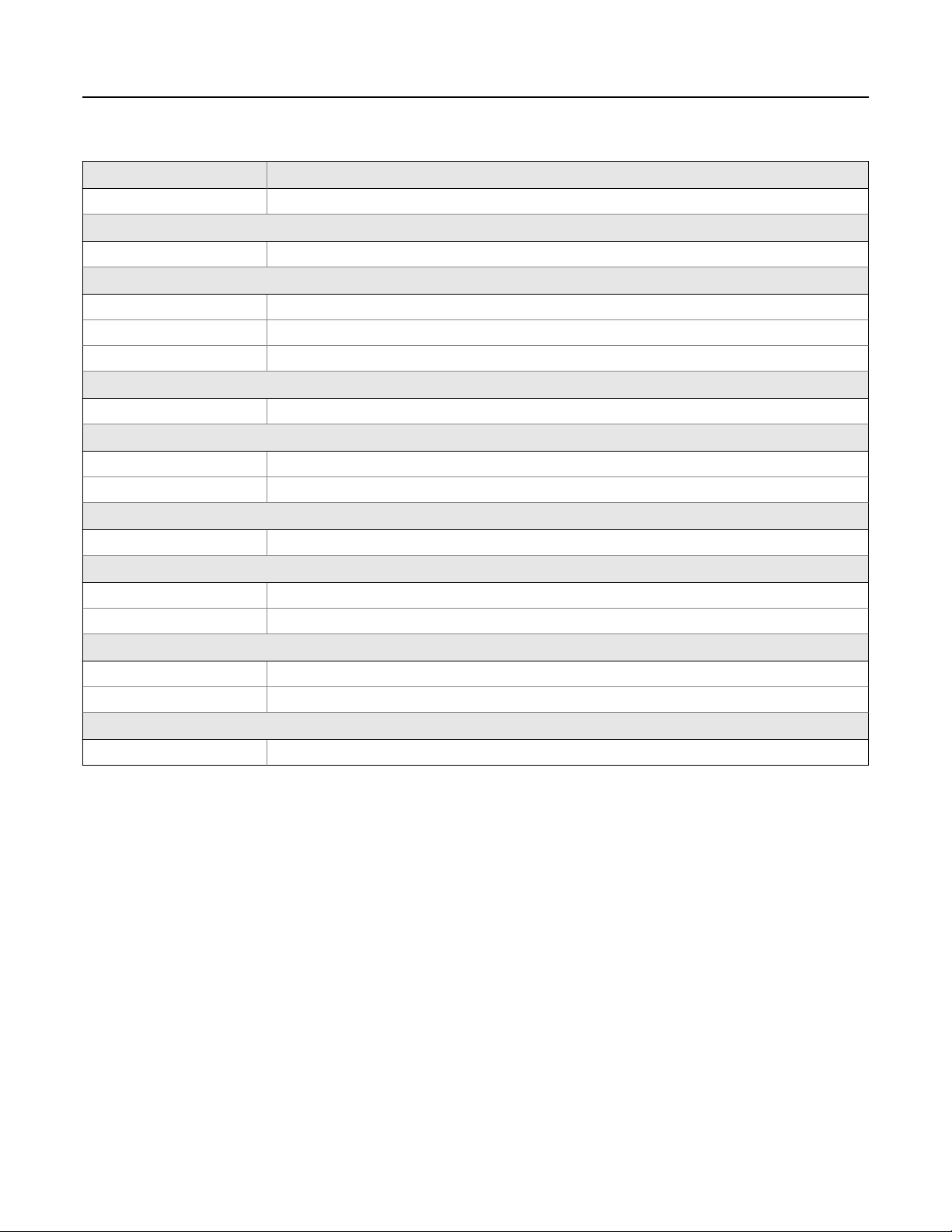

Rosemount CX1100 In-Situ Oxygen Transmitter ordering information

Model Product description

CX1100 In Situ Oxygen Transmitter

Material

A 304L stainless steel

Probe length

050 1.64 ft. (0.5 m) oxygen probe

100 3.28 ft. (1.0 m) oxygen probe

200 6.56 ft. (2.0 m) oxygen probe

Probe mounting flange

F20 ANSI/DIN: 4.75 in. / 5.71 in. bolt circle, 0.75 in. holes

Transmitter

M7 Remote transmitter with LCD display and interface

M0 Probe only (no transmitter)

Product certification

G6 CSA ordinary location

Probe mounting hardware

N1 New installation plate - ANSI pattern

N2 New installation plate - DIN pattern

Transmitter mounting hardware

T2 Panel mount kit with gasket

T3 2-in. pipe / wall mount kit

Calibration accessories

F1 Calibration gas flowmeter

www.Emerson.com 3

Page 4

Rosemount CX1100

July 2018

Specifications

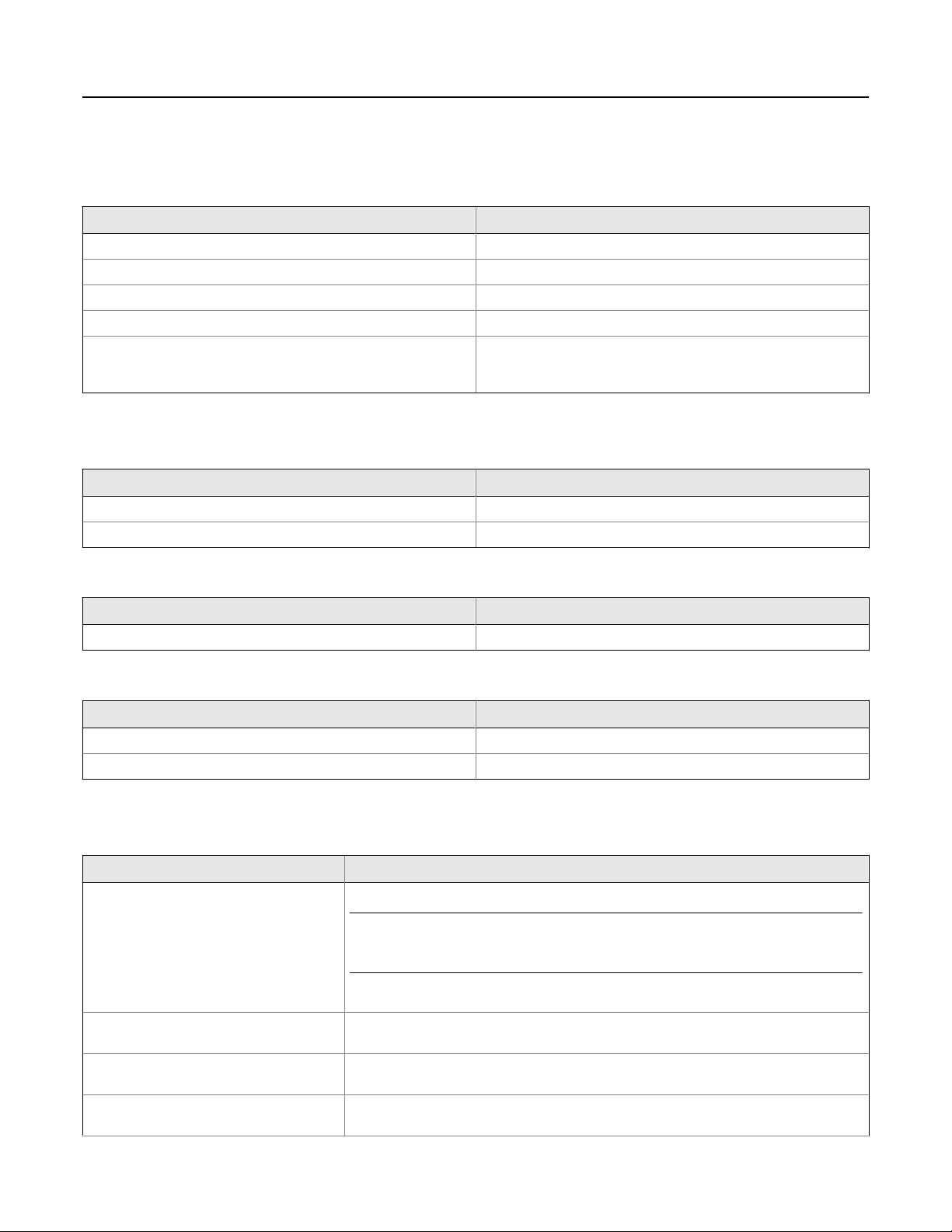

System Measurement SpecificationsTable 1:

Specification Description

Net O2 range 0 - 23%

Repeatability 0.1% of O2 or 1.0% of reading, whichever is lower

Lowest detectable limit 0.05% O

Process temperature effect Less than 0.3% O2 from 77 to 1292 °F (25 to 700 °C)

System speed of response to calibration gas Initial response in less than 3 seconds, T90 in 10 seconds. Re-

sponse to process gas changes will vary depending on process

gas velocity and particulate loading of the diffuser.

Environmental specifications

ProbeTable 2:

Specification Description

Probe Process wetted materials are 304 stainless steel.

Maximum process temperature 752 °F (400 °C)

2

Probe TerminationsTable 3:

Specification Description

Rosemount™ CX1100 probe ambient temperature limits -4 to 158 °F (-20 to 70 °C)

Remote DisplayTable 4:

Specification Description

Materials Polycarbonate

Ambient temperature limits -4 to 122 °F (-20 to 50 °C)

Installation specifications

ProbeTable 5:

Specification Description

Probe mounting range Vertical or horizontal: 2-in. 150# (4.75 in. (121 mm) bolt circle) and DIN145

Note

Flanges are flat-faced and for mounting only. Flanges are not pressure-rated. A 2.5-in.

diameter hole in the process is required.

Many adapter flanges are available to mate to existing flanges.

Reference air No instrument air required. Ambient air diffuses into the probe passively. Ensure that

ambient air is fresh (20.95% O2).

Calibration Semi-automatic manual gas switching. New calibration values are calculated in the

remote electronics.

Cal gases 0.4% and 8% O2, balance N2 recommended. Instrument air may be used as a high cal

gas, but is not recommended. 100% nitrogen cannot be used as a low cal gas.

4 www.Emerson.com

Page 5

July 2018

Rosemount CX1100

Probe (continued)Table 5:

Specification Description

Calibration gas flow 5 scfh (2.5 l/min) at 15 PSI

Heater electrical power 120/240 Vac, 50/60 Hz, 1.8 A Max

Traditional architecture cable Customer-supplied

Power consumption of probe heater 150 watts max. during initial warm-up

Remote ElectronicsTable 6:

Specification Description

Electrical power 120/240 Vac, 50/60 Hz, 1.8 A Max

Power consumption 150 watts during initial warm-up

Analog output 4-20 mA. Max load 550 Ohms

Alarms relays Two SPDT Form C, epoxy sealed contacts rated 5A, 30 Vdc, 120

Vac, or 230 Vac; user configurable to alarm.

Resistive load: 5A at 28 Vdc or 300 Vac

Inductive load: 1/8 HP at 120/240 Vac

Probe sensing cable 3 twisted pair conductors, 22 ga overall shielded cable to con-

nect the TC, O2, and CJC signals

Heater cable 3 multi conductor 18 ga shielded cable to connect the heater

control signal

Rosemount CX1100 Probe Shipping weight Actual weight

19.68 in. (0.5 m) 19 lb. (8.6 kg) 13.5 lb. (6.1 kg)

39.37 in. (1 m) 23 lb. (10.43 kg) 16.8 lb. (7.6 kg)

78.74 in. (2 m) 30.5 lb. (13.8 kg) 23 lb. (10.43 kg)

Rosemount CX1100 Remote

Transmitter dimensions in

inches (millimeters) Shipping weight Actual weight Part number

6.10 x 6.10 x 5.15 in. (155 x

155 x 131 mm)

Accessory Part number

Calibration flowmeter 771B635H01

Cal gas adaptor kit to mate to existing tubing arrangement 1A98771H07

4 lb. (1.8 kg)_ 3 lb. (1.4 kg) 24490-00

www.Emerson.com 5

Page 6

Rosemount CX1100

July 2018

Product certifications

European Directive information

A copy of the EC Declaration of Conformity can be found at the end of the Quick Start Guide. The most recent revision of the EC

Declaration of Conformity can be found at Emerson.com/Rosemount.

Ordinary location certification

As standard, the transmitter has been examined and tested to determine that the design meets the basic electrical, mechanical,

and fire protection requirements by a nationally recognized test laboratory (NRTL) as accredited by the Federal Occupational Safety

and Health Administration (OSHA).

Installing equipment in North America

The US National Electrical Code (NEC) and the Canadian Electrical Code (CEC) permit the use of Division marked equipment in Zones

and Zone marked equipment in Divisions. The marking must be suitable for the area classification, gas, and temperature class. This

information is clearly defined in the respective codes.

North America

CSA

Certificate: 70172073

Standards: CAN/CSA C22.2 No. 61010-1-12, CAN/CSA C22.2 No. 61010-2-010:15, UL 61010-1 (3rd Edition), UL 61010-2-10 (3rd

Edition), UL 50E (2012), C22.2 No. 94.2-07, IEC 60529:2013 (Edition 2.2)

Markings: Type 4X, IP66

Condition of acceptability:

1. The measuring of net O2 range is limited 0-23%.

2. The equipment shall be installed in accordance with manufacturer's specification by qualified personnel.

3. This equipment is for permanently connection to power source with approved power cord at end installation in accordance with

local codes.

4. The Probe unit of the equipment shall be connected to PE separately at end installation.

5. End installation to provide the means of disconnection from power sources.

6. End installation to comply with the requirement of IP66 and 4X.

6 www.Emerson.com

Page 7

July 2018

Dimensional drawings

Probe Installation DimensionsFigure 1:

Rosemount CX1100

A. M6 x 1 x 25 hex head machine screw (3x)

B. Calibration gas 3/16-in. tube fitting 2.82 liter/min (10 SCFH), 138 kPa (20 psi)

C. M5 x 0.8 x 10 pan head machine screw

D. 1/2 NPT conduit connection (power, signal)

E. Breather port

F. Calibration gas connection

Note

All dimensions are in meters with inches in parentheses.

Removal/InstallationTable 7:

Probe length Removal envelope

.5 m (19.68 in.) 750 mm (30 in.)

1 m (39.37 in.) 1250 mm (49 in.)

3 m (78.74 in.) 2250 mm (89 in.)

www.Emerson.com 7

Page 8

Rosemount CX1100

Mounting FlangeTable 8:

Diameter ANSI DIN

Flange dia 185 mm (7.28 in.)

Hold dia 19.1 mm (.75 in.)

(4) holes eq sp on BC 120.7 mm (4.75 in.) 145 mm (5.71 in.)

July 2018

8 www.Emerson.com

Page 9

July 2018

Rosemount CX1100

Square Weld Plate, ANSI PatternFigure 2:

Square Weld Plate, DIN PatternFigure 3:

www.Emerson.com 9

Page 10

Rosemount CX1100

Panel Mounting DetailsFigure 4:

July 2018

A. Maximum panel thickness 0.375 (9,52)

B. Panel mount gasket

C. 4 X mounting brackets and screws provided

A. 6 x 1/2 in. NPT conduit openings

10 www.Emerson.com

Page 11

July 2018

Wall/Surface Mounting DetailsFigure 5:

A. 4X cover screw

Rosemount CX1100

Pipe Mounting DetailsFigure 6:

A. Front panel

B. 6 x 1/2-in. NPT conduit openings

C. Mounting bracket

D. U-bolts

E. 2-in. pipe supplied by customer

www.Emerson.com 11

Page 12

Rosemount CX1100

00813-0100-4110, Rev AA

Product Data Sheet

July 2018

GLOBAL HEADQUARTERS

Emerson Automation Solutions

6021 Innovation Blvd

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

gas.csc@emerson.com

EUROPE

Emerson Automation Solutions

Neuhofstrasse 19a P.O. Box 1046

CH-6340 Baar

Switzerland

+ 41 (0) 41 768 6111

+ 41 (0) 41 768 6300

gas.csc@emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

twitter.com/rosemount_news

Facebook.com/Rosemount

youtube.com/RosemountMeasurement

google.com/+RosemountMeasurement

AnalyticExpert.com

NORTH AMERICA

Rosemount

8200 Market Boulevard

Chanhassen, MN 55317

MIDDLE EAST AND AFRICA

Emerson Automation Solutions

Emerson FZE

Jebel Ali Free Zone

Dubai, United Arab Emirates, P.O. Box

17033

+1 800 999 9307

+1 952 949 7001

gas.csc@emerson.com

+971 4 811 8100

+971 4 886 5465

gas.csc@emerson.com

©

2018 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount

is a mark of one of the Emerson family of companies. All other marks are the property

of their respective owners.

ASIA-PACIFIC

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

Singapore

+65 777 8211

+65 777 0947

gas.csc@emerson.com

Loading...

Loading...