Page 1

2.0 INSTALLATION

2.1 UNPACKING AND INSPECTION

Inspect the carton for damage. If damage is found, contact the carrier immediately.

2.2 SENSOR PREPARATION

Sensor Preparation Guidelines: Carefully remove the plastic cap covering

the sensing end of the sensor. Avoid causing a vacuum by gently and slowly

twisting the sensor and cap until it is removed. Sensor is shipped dry, so electrolyte must be added prior to installation.

Remove membrane cartridge. Add 2 ml of electrolyte to the membrane cartridge. Screw membrane cartridge back onto sensor body. Refer to Section

6.3 for additional details.

Connection of the Sensor to the Analyzer/ Transmitter:

1. Wire the sensor to the analyzer/transmitter. See the wiring tables in

Section 3.0.

2. Apply power to the analyzer/transmitter. After 24 hours, the sensor should

be ready for calibration. The polarization time is necessary to get stable

signals from the sensor. If the sensor is disconnected from the

analyzer/transmitter for a short time, allow the sensor to stabilize for at

least three times longer than the time is was disconnected. Time needed

for stabilization should not exceed 24 hours.

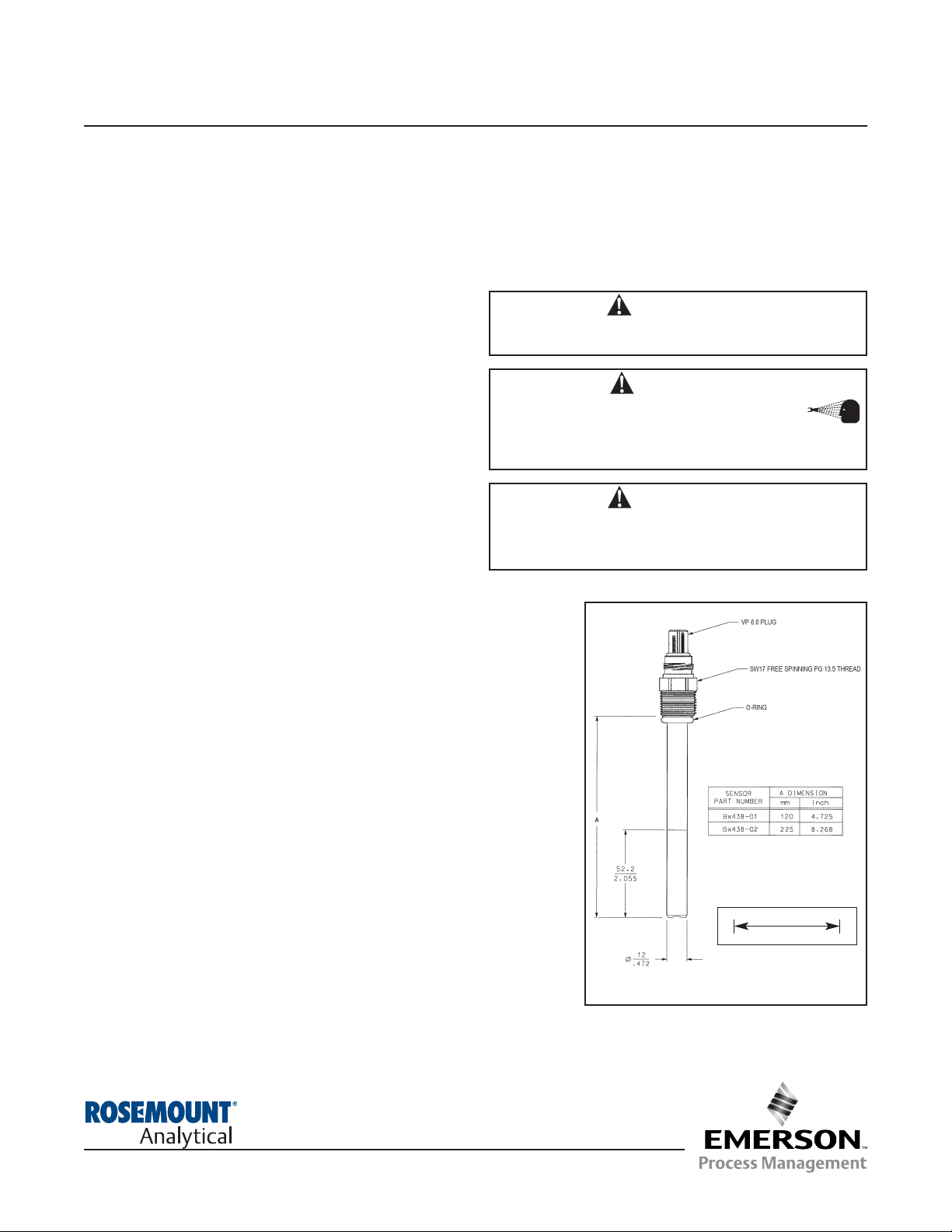

Mounting Guidelines: Mount the sensor using the PG 13.5 process thread.

NOTE

Do not install the sensor upside down.

Model Bx438

Dissolved Oxygen Sensor

Instruction Sheet

PN 51A-Bx438/rev.D

July 2005

MILLIMETER

INCH

WARNING

The electrolyte is acidic. Protect your hands with gloves and

use safety goggles. Avoid contact of the electrolyte with the

skin, eyes, and mucous membranes.

WARNING

Do not exceed temperature and pressure limitations of

100°C (212°F) and 174 psig (1200 kpa abs, 12 bar).

WARNING

Before removing the sensor, be absolutely

certain that the process pressure is reduced to

0 psig and the process temperature is lowered

to a safe level!

1.0 SPECIFICATIONS

Temperature Range: -10 to 100°C (14 to 212°F)

Maximum Pressure: 174 psig (1200 kpa abs, 12 bar)

Measurement Range: 10 ppb to 20 ppm or 0.1% to 200%

saturation, depending on instrument

Wetted Materials: Stainless Steel, Gold, Silicone, FDA-

approved EPDM

Process Connections: PG 13.5 thread

Cable Connector: Variopol

Cable Compatibility: VP 6.0

Compatible Analyzers: Rosemount Analytical Models 54eA,

5081-A, and Xmt-A

Compatible Mounting Accessory: Insertion or Retractable

Mounting Assembly, TriClamp Assembly

MODEL Bx438

For additional information, please refer to the Instruction Manuals CD shipped with this

product, or visit our website at www.emersonprocess.com/raihome/liquid/.

Page 2

2

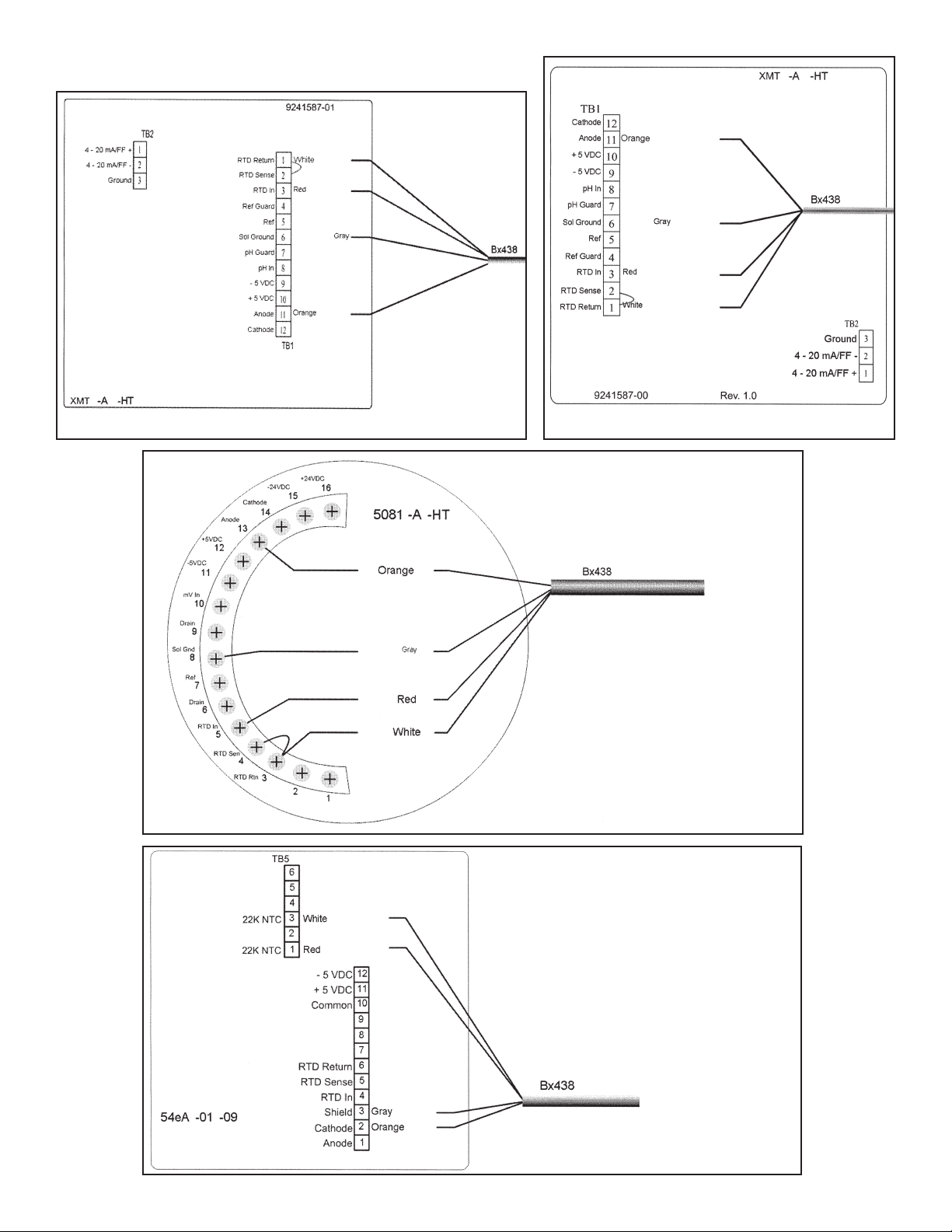

3.0 WIRING

Model 54eA Wiring

Model Bx438 uses a 22k NTC thermistor. The

thermistor is wired to terminals 1 and 3 of TB5.

Model Xmt-A-HT-10 WiringModel Xmt-A-HT-11 Wiring

Model 5081-A Wiring

Page 3

4.0 STERILIZATION

Before autoclaving the sensor, cover the connector end of

the sensor with a tight protective cap (PN 9160490). If the

connector end gets wet despite the protective cap, dry the

connector with pressurized air or a hair dryer. Drying prevents corrosion and damage to insulation.

No protection is necessary when doing in-situ sterilization.

5.0 INSTRUMENT SET-UP

The analyzer must be set up for the proper service.

5.1 MODEL 54eA

Program the 54eA as follows:

Measure: Oxygen

Sensor: SSDO other

Measure Units: % sat, ppb or ppm (depending on

service)

5.2 MODEL Xmt-A

Program the Xmt-A as follows:

Measure: Oxygen

Manufacturer: Rosemount

Application: Biopharm

Units: % sat, ppb or ppm (depending on service)

Refer to Model Xmt-A manual (PN 51-Xmt-A-HT) for additional set-up instructions.

5.3 MODEL 5081-A

Program the Xmt-A as follows:

Type: O

2

Units: ppm, ppb, or % (depending on service)

Sensor: Sd01

Refer to Model 5081-A manual (PN 51-5081A-HT) for additional set-up instructions.

6.0 CALIBRATION AND MAINTENANCE

Dismounting the sensor: Unscrew the free rotating PG

13.5 threaded connector and pull the sensor out of the

process or mounting assembly.

6.1 CALIBRATION

1. Refer to the analyzer instruction manual for details.

2. Be sure the sensor has been operating for at least 24

hours before zeroing and calibrating.

3. Perform a zero check of the sensor by placing it in

nitrogen gas or in water containing about 5% sodium

sulfite. If using nitrogen gas, be sure the membrane is

dry. Make sure the current output drops below 1 nA. If

the sensor does not reach 1 nA, then either the zero

solution needs to be replaced or the sensor membrane

needs to be replaced.

4. If sodium sulfite was used to zero the sensor, rinse the

sensor with water and gently dry the membrane. Place

the sensor in water-saturated air. Once the reading is

stable, complete the full-scale calibration. Consult the

analyzer instruction manual for details.

5. Calibration can also be done using air-saturated water

or air-saturated medium. Although the sensor has an

extremely low oxygen consumption rate, the liquid

should be gently stirred during calibration.

NOTE

A warning message “Sensor output very low/ high”

may appear on the 54eA. Press cont (F3 key).

Verify that the sensor output in air meets factory

specifications (180 nA - 400 nA).

6.2 SENSOR MAINTENANCE

Periodically check sensor response in air and nitrogen.

1. Place the sensor in air. Allow the reading to become

stable and note the value. Also note the sensor current,

which should be between 180 and 400 nA.

2. Place the sensor in nitrogen. A small plastic bag with a

stream of nitrogen gas discharging into the bottom

works well.

3. After 90 seconds, the sensor current should be less

than 2% of the value in air.

For troubleshooting information, see Section 7.0.

6.3 REPLACING THE ELECTROLYTE AND THE MEM-

BRANE CARTRIDGE:

Replace the membrane cartridge (membrane kit PN

24107-00) as follows:

1. Hold the sensor vertically with the membrane pointing

down. Carefully unscrew the membrane cartridge.

2. Carefully clean the tip of the glass body with a soft tissue, or clean with the polishing tool in one direction

only.

WARNING

Do not polish the cathode!

NOTE

When replacing the membrane cartridge,

do not touch the anode wire.

3. Check the small o-ring above the glass body. If it is

damaged, replace it.

4. Use the plastic pipette in the membrane kit to add

1.5 ml of electrolyte solution to the new membrane

cartridge.

5. Carefully screw the cartridge onto the sensor shaft. If

too much electrolyte solution was used, the excess

must be pushed out. Wash off the excess electrolyte

with water.

3

Page 4

7.0 TROUBLESHOOTING

Below is a list of possible problems and solutions for Model Bx438 dissolved oxygen sensor.

CURRENT IN AIR TOO HIGH SLUGGISH RESPONSE CURRENT IN AIR TOO LOW

(>500 nA at 25°C) (<80 nA at 25°C)

Problem Solution Problem Solution Problem Solution

Very thin or defective Replace with new Contaminated, fouled, Clean membrane or Contaminated, fouled, Clean membrane or

membrane membrane cartridge or dirty membrane replace with new or dirty membrane replace with new

membrane cartridge membrane cartridge

Defective glass body Return to Rosemount Loose membrane Replace with new Dried out electrolyte Loosen membrane

or connector Analytical, Liquid Div. membrane cartridge film cartridge and tighten

Poisoned anode Return to Rosemount Dried out electrolyte Loosen membrane Cathode contaminated Return to Rosemount

Analytical, Liquid Div. film cartridge and tighten by silver Analytical, Liquid Div

— — Cathode contaminated Return to Rosemount Exhausted electrolyte Fill with new

by silver Analytical, Liquid Div electrolyte

— — — — Defective glass body Return to Rosemount

or connector Analytical, Liquid Div

Membrane kit consists of three replacement membranes and spare o-rings. Reference part number 24107-00.

Electrolyte must be purchased separately. Reference part number 24108-00.

Credit Cards for U.S. Purchases Only.

The right people,

the right answers,

right now.

ON-LINE ORDERING NOW AVAILABLE ON OUR WEB SITE

http://www.raihome.com

Specifications subject to change without notice.

Emerson Process Management

Liquid Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2005

Loading...

Loading...