Page 1

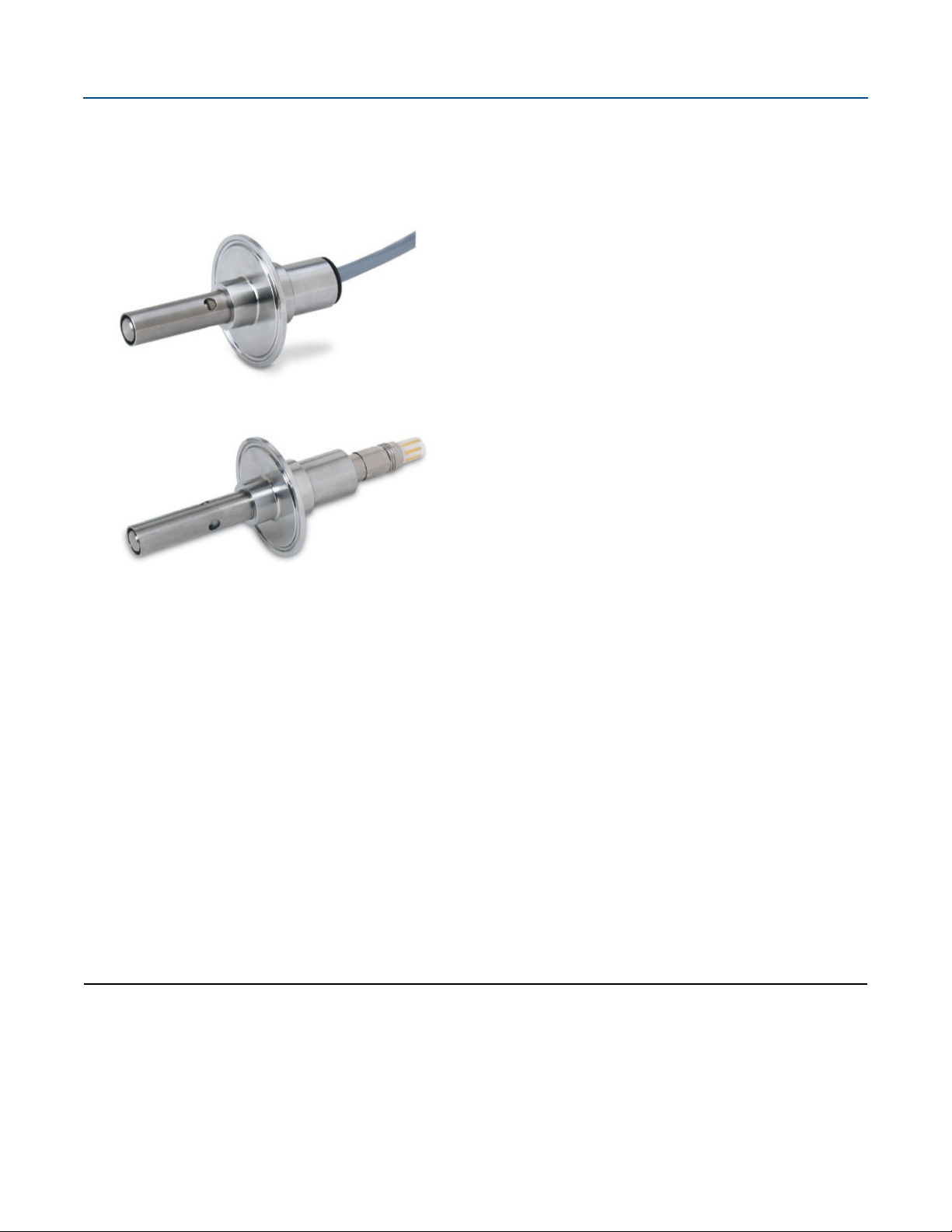

Rosemount™ 403/403VP

Contacting Conductivity Sensors

Product Data Sheet

June 2017

LIQ-PDS-403

Reliably measure conductivity with PURSense™ sensors

Rosemount 403 and 403VP contacting conductivity sensors are sanitary flange sensors commonly used in water purification systems

in the food and beverage industry. These sensors are ideal for measuring electrolytic conductivity in Water-for-Injection (WFI).

Page 2

Rosemount 403/403VP Contacting Conductivity Sensors

Overview

Meet Sanitary and Hygienic Requirements

Available with 1-1/2 in. and 2-in. sanitary flange process

connections.

All wetted plastics and elastomers are compliant with

21CFR177.

All wetted surfaces have a 16 microinch (0.4 micrometer) Ra

finish.

O-rings meet USP Class VI requirements.

High Performance Design

Available in 0.01, 0.1, and 1.0/cm cell constants.

Internal platinum RTD for temperature compensation.

Steam sterilizable up to 135 °C.

Operates in pressures up to 250 psig.

Variopol (VP6) cable connection option, for quick

cable-to-sensor release, eliminates cable twisting.

June 2017

Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Minimize Start-up and Installation Time

A factory-measured cell constant ensures out-of-the-box

accuracy and no initial calibration requirements.

Installation Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2

Engineering Specification . . . . . . . . . . . . . . . . . . . . . . . . .10

www.Emerson.com/RosemountLiquidAnalysis

Page 3

June 2017

Rosemount 403/403VP Contacting Conductivity Sensors

Ordering Information

The Rosemount 403 and 403VP contacting conductivity sensors are ideal for measuring

electrolytic conductivity in clean water applications in the pharmaceutical and food and

beverage industries. All wetted polymers are 21CFR177 (FDA) compliant, and the

O-rings also meet USP Class VI requirements. All wetted surfaces have a 16 micro inch

(0.4 micrometer) Ra finish. A certificate of conformance is provided with each sensor.

For a copy of supplier material traceability certificates, order option -99Q8.

Interconnecting VP cable is sold separately (for Rosemount 403VP).

Table 1. Rosemount 403 Contacting Conductivity Sensor ordering information

Model Sensor type

403 Contacting Conductivity Sensor

Cell Constant

11 0.01/cm

12 0.1/cm

13 1.0/cm

Flange Size

20 1-1/2 in. Stainless Steel Sanitary Fitting

21 2 in. Stainless Steel Sanitary Fitting

Temperature Compensation

_ No Selection – Pt-1000

54 Pt-100

Optional Options

(2)

(1)

Insertion Length

_ No Selection – Standard Insertion Length

36 Extended Insertion Length

(3)

Cable Length

_ Standard 10 ft. Integral Cable

50 50 ft. Integral Cable

Special

_ No Selection – Supplier Material Traceability Certificate not Included

99Q8 Supplier Material Traceability Certificate Included

Typical Model Number: 403VP-11-20-_-36-99Q8

1. For compatibility with Rosemount 56, 1056, 1057, 1066, and 5081 Transmitters. Also compatible with legacy transmitter models 1055,

54e, 4081, 6081, and XMT.

2. For compatibility with legacy transmitter models 1054, 2054, and 2081.

3. Extended insertion length is 6 inches from inside face of flange to end of sensor.

www.Emerson.com/RosemountLiquidAnalysis

3

Page 4

Rosemount 403/403VP Contacting Conductivity Sensors

Table 2. Rosemount 403VP Contacting Conductivity Sensor ordering information

Model Sensor type

403VP Contacting Conductivity Sensor

Cell constant

11 0.01/cm

12

13

Flange Size

20 1-1/2 in. Stainless Steel Sanitary Fitting

21 2 in. Stainless Steel Sanitary Fitting

Temperature Compensation

_ No Selection – Pt-1000

54 Pt-100

Optional Options

0.1/cm

1.0/cm

(1)

(2)

June 2017

Insertion Length

_ No Selection – Standard Insertion Length

36 Extended Insertion Length

(3)

Special

_ No Selection – Supplier Material Traceability Certificate not Included

99Q8 Supplier Material Traceability Certificate Included

Typical Model Number: 403VP-11-20-_-36-99Q8

1. For compatibility with Rosemount 56, 1056, 1057, 1066, and 5081 Transmitters. Also compatible with legacy transmitter models 1055,

54e, 4081, 6081, and XMT.

2. For compatibility with legacy transmitter models 1054, 2054, and 2081.

3. Extended insertion length is 6 inches from inside face of flange to end of sensor.

4

www.Emerson.com/RosemountLiquidAnalysis

Page 5

June 2017

Rosemount 403/403VP Contacting Conductivity Sensors

Specifications

Table 3. Rosemount 403/403VP Contacting Conductivity Sensor specifications

Cell constants

0.01, 0.1 and 1.0/cm

Wetted materials

titanium; 316 stainless steel; PCTFE (Neoflon), compliant with 21CFR 177.1380; EP, compliant with 21CFR177.2600 and

USP Class VI

Surface finish

All wetted surfaces have 16 micro in. (0.4 micrometer) Ra finish.

Process connection

1-1/2 in. or 2-in. sanitary flange

Temperature

32–221 °F (0–105 °C). Sensors are steam sterilizable to 275 °F (135 °C)

Pressure

250 psig (1825 kPa abs) maximum

Cable length

10 ft (3.1 m) standard; 50 ft (15.2 m) optional

Weight/shipping weight

403 sensor with 10 ft (3.1 m) cable 2 lb (1.0 kg)/3 lb (1.5 kg)

403 sensor with 50 ft (15.2 m) cable 4 lb (2.0 kg)/5 lb (2.5 kg)

403VP sensor 1 lb (0.5 kg)/2 lb (1.0 kg) (rounded up to nearest 1 lb or 0.5 kg)

www.Emerson.com/RosemountLiquidAnalysis

5

Page 6

Rosemount 403/403VP Contacting Conductivity Sensors

Installation Drawings

Figure 1. Rosemount 403 and 403VP Sensor Installation

June 2017

The Tri-Cover tee, clamp, and gasket are supplied by the user. Install the sensor so that it is completely submerged in the process

liquid. Installation in a vertical pipe run is best. If the sensor must be installed in a horizontal pipe run, place the sensor in the 3 o’clock

position.

6

www.Emerson.com/RosemountLiquidAnalysis

Page 7

June 2017

Figure 2. Rosemount 403 Sensor Dimensional Drawings

Rosemount 403/403VP Contacting Conductivity Sensors

www.Emerson.com/RosemountLiquidAnalysis

7

Page 8

Rosemount 403/403VP Contacting Conductivity Sensors

Figure 3. Rosemount 403VP Sensor Dimensional Drawings

June 2017

8

www.Emerson.com/RosemountLiquidAnalysis

Page 9

June 2017

Rosemount 403/403VP Contacting Conductivity Sensors

Accessories

Table 4. Rosemount 403/403VP Sensor accessories information

Part number Description

23550-00 Interconnecting cable, VP 6, 2.5 ft (0.8 m)

23747-04 Interconnecting cable, VP 6, 4 ft (1.2m)

23747-02 Interconnecting cable, VP 6, 10 ft (3.0 m)

23747-07 Interconnecting cable, VP 6, 15 ft (4.6 m)

23747-08 Interconnecting cable, VP 6, 20 ft (6.1 m)

23747-09 Interconnecting cable, VP 6, 25 ft (7.6 m)

23747-10 Interconnecting cable, VP 6, 30 ft (9.1 m)

23747-03 Interconnecting cable, VP 6, 50 ft (15.2 m)

23747-11 Interconnecting cable, VP 6, 100 ft (30.5 m)

23550-00 Junction Box without Preamplifier

9200275 Interconnect Extension Cable, Unprepped (for use with Junction Box)

23747-00 Interconnect Extension Cable, Prepped (for use with Junction Box)

05010781899 Conductivity standard SS-6, 200 μS/cm, 32 oz (0.95 L)

05010797875 Conductivity standard SS-6A, 200 μS/cm, 1 gal (3.78 L)

05010782468 Conductivity standard SS-5, 1000 μS/cm, 32 oz (0.95 L)

05010783002 Conductivity standard SS-5A, 1000 μS/cm, 1 gal (3.78 L)

05000705464 Conductivity standard SS-1, 1409 μS/cm, 32 oz (0.95 L)

05000709672 Conductivity standard SS-1A, 1409 μS/cm, 1 gal (3.78 L)

05010782147 Conductivity standard SS-7, 5000 μS/cm, 32 oz (0.95 L)

05010782026 Conductivity standard SS-7A, 5000 μS/cm, 1 gal (3.78 L)

www.Emerson.com/RosemountLiquidAnalysis

9

Page 10

Rosemount 403/403VP Contacting Conductivity Sensors

June 2017

Engineering Specification

1. The sensor shall be suitable for the determination of electrolytic conductivity in water for injection and in any water purification

installation where Tri Clamp fittings are used.

2. The sensor shall be available with either 1-½ inch or 2-inch 316 stainless steel sanitary flanges.

3. Electrodes shall be titanium.

4. The insulator shall be PCTFE and shall be compliant with 21CFR177.1380.

5. The O-rings shall be EP and shall be compliant with 21CFR177.2600 and USP Class VI.

6. All wetted surfaces shall have a 16 micro inch (0.4 micrometer) Ra finish.

7. The sensor shall be available with either an integral cable or a Variopol quick disconnect fitting.

8. The sensor shall have an integral platinum RTD for temperature measurement.

9. The sensor shall be Rosemount 403 (integral cable) or 403VP (Variopol fitting) or approved equal.

10

www.Emerson.com/RosemountLiquidAnalysis

Page 11

June 2017

Notes:

Rosemount 403/403VP Contacting Conductivity Sensors

www.Emerson.com/RosemountLiquidAnalysis

11

Page 12

Rosemount 403/403VP Contacting Conductivity Sensors

LIQ-PDS-403

Global Headquarters

Emerson Automation Solutions

8200 Market Blvd

Chanhassen, MN 55317

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

Liquid.CSC@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Product Data Sheet

June 2017

Europe Regional Office

Emerson Automation Solutions GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033,

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Analyticexpert.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

Google.com/+RosemountMeasurement

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

Rosemount and Rosemount logotype are trademarks of Emerson.

All other marks are the property of their respective owners.

© 2017 Emerson. All rights reserved.

Loading...

Loading...