Rosemount Analytical 400, 400VP Operating Manual

Instruction Manual

IQ-MAN-400

L

Rev. L

May 2017

Rosemount

™

400 and 400VP

Contacting Conductivity Sensors

asgkas

h

Essential Instructions

Read this page before proceeding!

merson designs, manufactures and tests its products to meet many national and international stan-

E

dards. Because these sensors are sophisticated technical products, you MUST properly install, use,

and maintain them to ensure they continue to operate within their normal specifications. The

following instructions MUST be adhered to and integrated into your safety program when installing,

using, and maintaining Rosemount products. Failure to follow the proper instructions may cause

any one of the following situations to occur: loss of life; personal injury; property damage; damage

to this sensor; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson representative for

clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance

of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate

Instruction Manual and per applicable local and national codes. Connect all products to

the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update,

program, and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Emerson. Unauthorized parts and procedures can affect the product's

performance, place the safe operation of your process at risk, and VOID YOUR WARRANTY.

Third-party substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when

maintenance is being performed by qualified persons, to prevent electrical shock and

personal injury.

The information contained in this document is subject to change without notice.

DANGER

Hazardous Area InstallationN

Installations near flammable liquids or in hazardous area locations must be carefully evaluated by

qualified on site safety personnel.

To secure and maintain an intrinsically safe installation, the certified safety barrier, transmitter, and

sensor combination must be used. The installation system must comply with the governing approval

agency (FM, CSA or BASEEFA/CENELEC) hazardous area classification requirements. Consult your

transmitter instruction manual for more details.

Proper installation, operation and servicing of this sensor in a Hazardous Area Installation is entirely

the responsibility of the user.

CAUTION

Sensor/Process Application Compatibility

The wetted sensor materials may not be compatible with process composition and operating

conditions. Application compatibility is entirely the responsibility of the user.

WARNING

Before removing the sensor, be absolutely certain that the process pressure is reduced to 0 psig and

the process temperature is lowered to a safe level!

About This Document

This manual contains instructions for installation and operation of the Rosemount 400 Contacting

Conductivity Sensors. The following list provides concerning all revisions of this document.

Rev. Level Date Notes

J 10/2016 Updated information with new Emerson Style Guidelines, Added

Ordering Information, Added Accessories Information. Added

dimensional drawings.

K 11/2016 Updated Ordering Information and Specification.

L 05/2017 Updated the Emerson Address and Logo.

Instruction Manual Table of Contents

LIQ-MAN-400 May 2017

Contents

Section 1: Specifications

1.1 Specifications ......................................................................................................1

1.2 Ordering Information...........................................................................................2

Section 2: Installing the sensor............................................................................3

2.1 Wiring the sensor.................................................................................................5

2.2 Wiring the sensor to the transmitter....................................................................5

Section 3: Calibration and Maintenance

3.1 Calibrating the sensor .........................................................................................9

3.2 Cleaning the sensor ...........................................................................................12

Section 4: Troubleshooting

4.1 Troubleshooting ................................................................................................13

Section 5: Accessories

5.1 Accessories........................................................................................................15

Table of Contents i

Table of Contents Instruction Manual

May 2017 LIQ-MAN-400

ii Table of Contents

Instruction Manual Specifications

LIQ-MAN-400 May 2017

Section 1: Specifications

1.1 Specifications

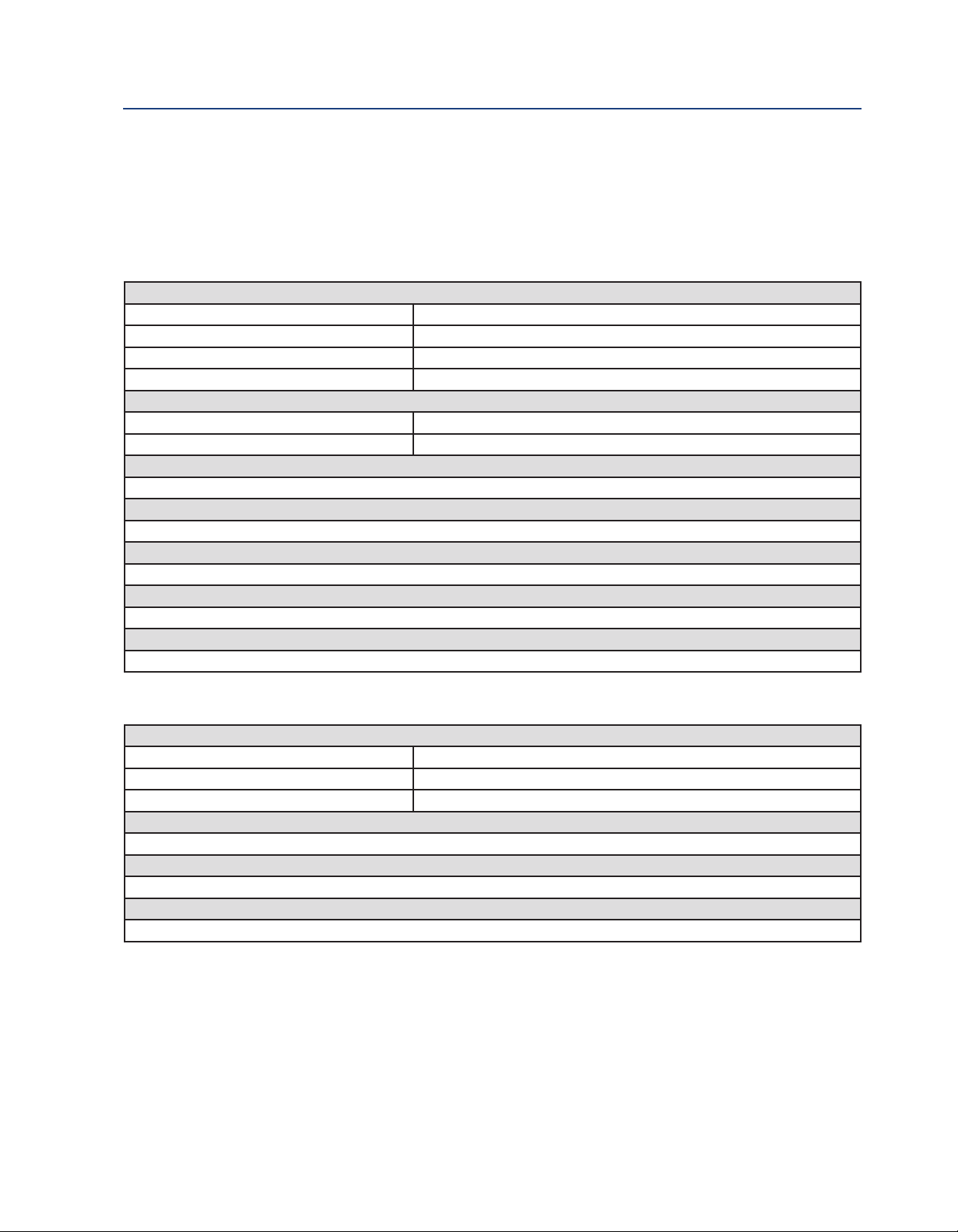

Table 1-1 Rosemount 400/400VP contacting conductivity sensor specifications

Wetted materials

Electrodes Titanium

Insulator Glass Filled PEEK

Body 316 Stainless Steel

O-ring EPDM

Temperature range

Standard 32 to 221 °F (0 to 105 °C)

With Optional Integral Junction Box 32 to 392 °F (0 to 200 °C)

Maximum pressure

250 psig (1825 kPa abs)

Vacuum

At 1.6 in. Hg air leakage is less than 0.005 SCFM (0.00014 m3/min)

Cell constants

0.01, 0.1, and 1.0/cm

Process connection

¾ in. MNPT

Cable

10 ft (3.1 m) standard; 50 ft (15.2m) optional; interconnecting VP6 cables sold separately (see Accessories)

Table 1-2 Flow cell (24092-02) specifications

Wetted materials

Body and Nut Polycarbonate and polyester

¼ in. Fittings 316 Stainless Steel

O-ring Silicone

Process connection

Compression fitting for ¼ in. OD tubing

Temperature range

32 to 158 °F (0 to 70 °C)

Maximum pressure

90 psig (722 kPa abs)

Flow cell sold separately; see Accessories.

Specifications 1

Loading...

Loading...