Page 1

1.0 FEATURES AND APPLICATIONS

The Rosemount Analytical Model 399 Sensor measures

the pH or the Oxidation Reduction Potential (ORP) of

aqueous solutions in pipelines, open tanks, or ponds.

It is suitable for virtually all applications where a low

cost, disposable sensor is required. The combination

electrode features a ceramic junction constructed in

an annular design around the pH/ORP sensitive

membrane. The double junction reference cell configuration is resistant to process solutions containing

ammonia, chlorine, cyanides, sulfides, or other poisoning ions.

The glass electrode is housed in a molded Tefzel

®

1

body and sealed with Viton

®

1

O-rings to guard against

process leakage. The cable end of the sensor is also

sealed, eliminating cable shorts caused by exposure

to moisture. This construction makes for a highly

chemical resistant disposable sensor and does not

require electrolyte replenishment.

The custom glass electrode is available with either a

standard hemi bulb or an optional flat bulb to best

meet your application needs. Flat glass is advantageous in abrasive or coating applications that etch or

build up on the glass respectively. In coating applications, such as slurries, the flat surface allows the

process flow to act as a scrubbing agent to reduce

coating and maintenance whereas in abrasive applications pitting from silicates and other similar materials is minimized by the flat surface to provide longer

life. The hemi bulb is ideal for general purpose use

and for those processes requiring greater accuracy

over the entire pH range

The Rosemount Analytical pH/ORP sensor offers an

optional integral preamplifier to convert the high

impedance pH or ORP mV signal into a stable, noisefree signal with transmission capability of up to three

miles. The Rosemount Analytical preamp method has

become the industry standard for pH/ORP measurement reliability.

Installation is easily achieved through the wide variety

of mounting configurations. The Model 399 features

1 in. (MNPT) front and rear facing connections for

insertion, submersion or flow through pH and ORP

applications.

2.0 PHYSICAL SPECIFICATIONS

Materials of Construction: Tefzel

®

1

, glass, ceramic

and Viton

®

1

(also, Platinum for ORP sensor)

Process Connections: 1 in. MNPT

Interconnecting Cable: 5 conductor, 10 or 32 ft cable

undressed (integral preamp)

10 ft coax cable (Code 02, 09)

10 ft shielded coax cable (Code 04)

4 conductor, 20 or 100 ft cable undressed

(Code 12, 13, 33)

Measured Range: pH: 0-14

ORP: –1500 -+1500mV

Percent Linearity over pH range:

Temperature Compensation: Automatic 0 to 85°C

(32° to 185°F) (Temperature compensation is not

required for 399 ORP when used with Models 1060,

1023 or 1181 ORP)

Maximum Pressure: 790 kPa abs (100 psig) at 65°C

(Refer to Graph A on page 4)

Weight/Shipping Weight: 0.45 kg/0.9 kg (1 lb/2 lb)

1

Tefzel and Viton are registered trademarks of DuPont Performance

Elastomers.

Model 399

Combination pH/ORP Sensor

Manual Instruction Sheet

PN 51-399/rev.K

November 2007

Hemi Bulb Flat Bulb

1-2 pH 94% 93%

2-12 pH 99% 98%

12-13 pH 97% 95%

Page 2

3.0 UNPACKING. The sensor is shipped in a con-

tainer with special cushioning material. Before opening

the container, it should be inspected for any damage. If

any damage is detected, the carrier should be notified

before proceeding further. Carefully remove the sensor

from the container and packing material. Inspect the

sensor for any visible damage. If no damage is found,

carefully remove the rubber boot which protects the

glass electrode and keeps the liquid junction wetted.

NOTE

If the sensor is to be stored, the rubber boot

should be filled with pH buffer solution and

replaced on sensor tip until ready to use.

4.0 SENSOR PREPARATION. Shake down the

sensor to remove any air bubbles that may be present

at the tip of the pH glass bulb.

WARNING

Glass electrode must be wetted at all times

(in storage and in line) to maximize sensor

life.

5.0 CALIBRATION USING A STANDARD

BUFFER SOLUTION.

1. Make a temporary electrical connection between

the sensor and instrument.

2. Consult the appropriate pH or ORP analyzer/

transmitter instruction manual for the specific calibration and standardization procedure.

3. After successful completion of the calibration and

standardization procedure, install the Model 399

sensors in the process (see Figures 2 through 9).

6.0 INSTALLATION. The sensor has been

designed to be located in industrial process environments. Temperature and pressure limitations must not

be exceeded at any time (see Graph A).

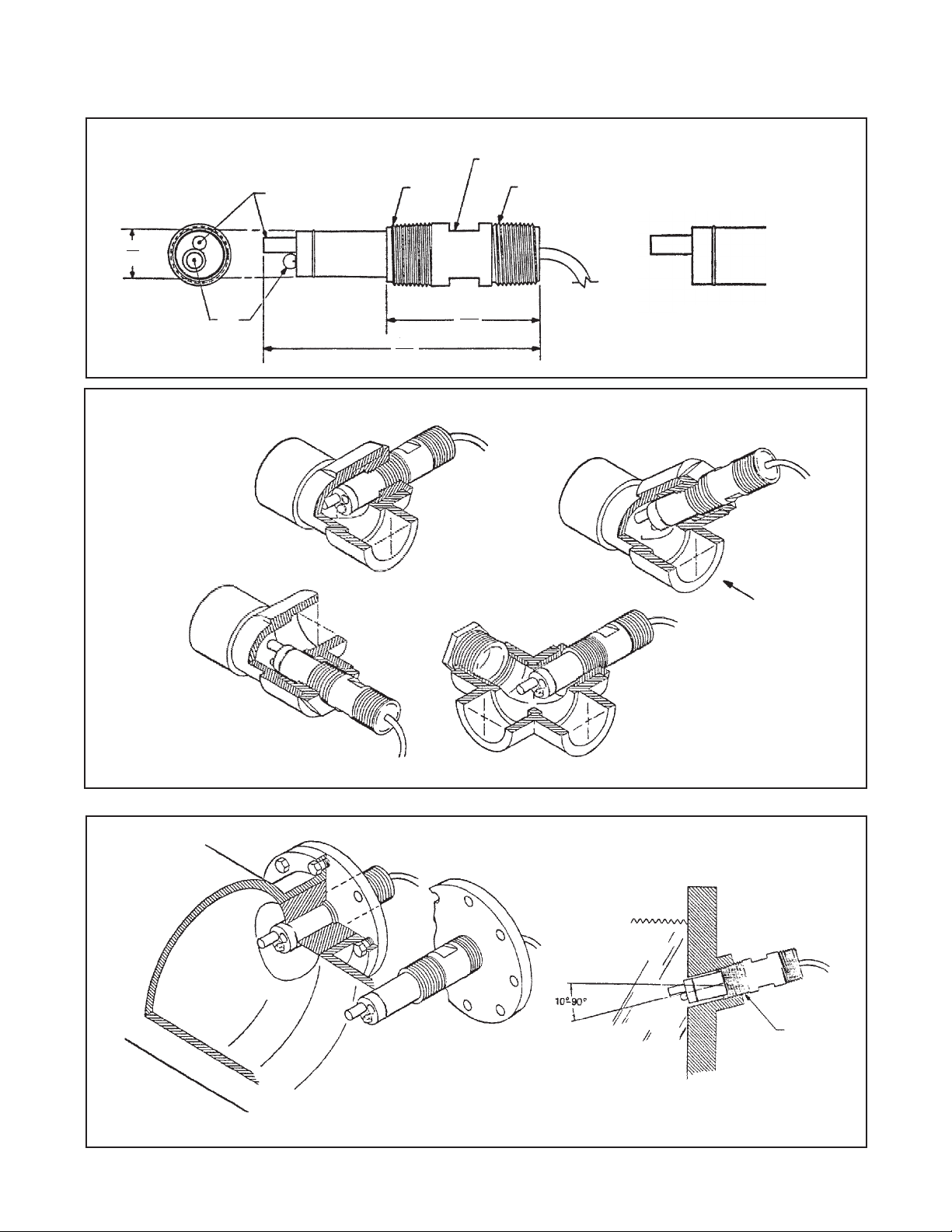

6.1 Flow Through Installations. The Model 399

Sensor has a 1 in. MNPT process connection at the

front of the sensor for mounting directly into a 1-1/2 in.

tee. See Figure 2 for installation configurations. It is

recommended that shut-off valves be provided for sensor removal and service.

6.2 Insertion Installations. The Model 399 sensor has

forward and rear facing 1 in. MNPT process connections for pipeline installations utilizing flange connections. The Model 399 is also suitable for side-of-tank

installation. The Model 399 must be mounted 15°- 30°

above horizontal (see Figure 3).

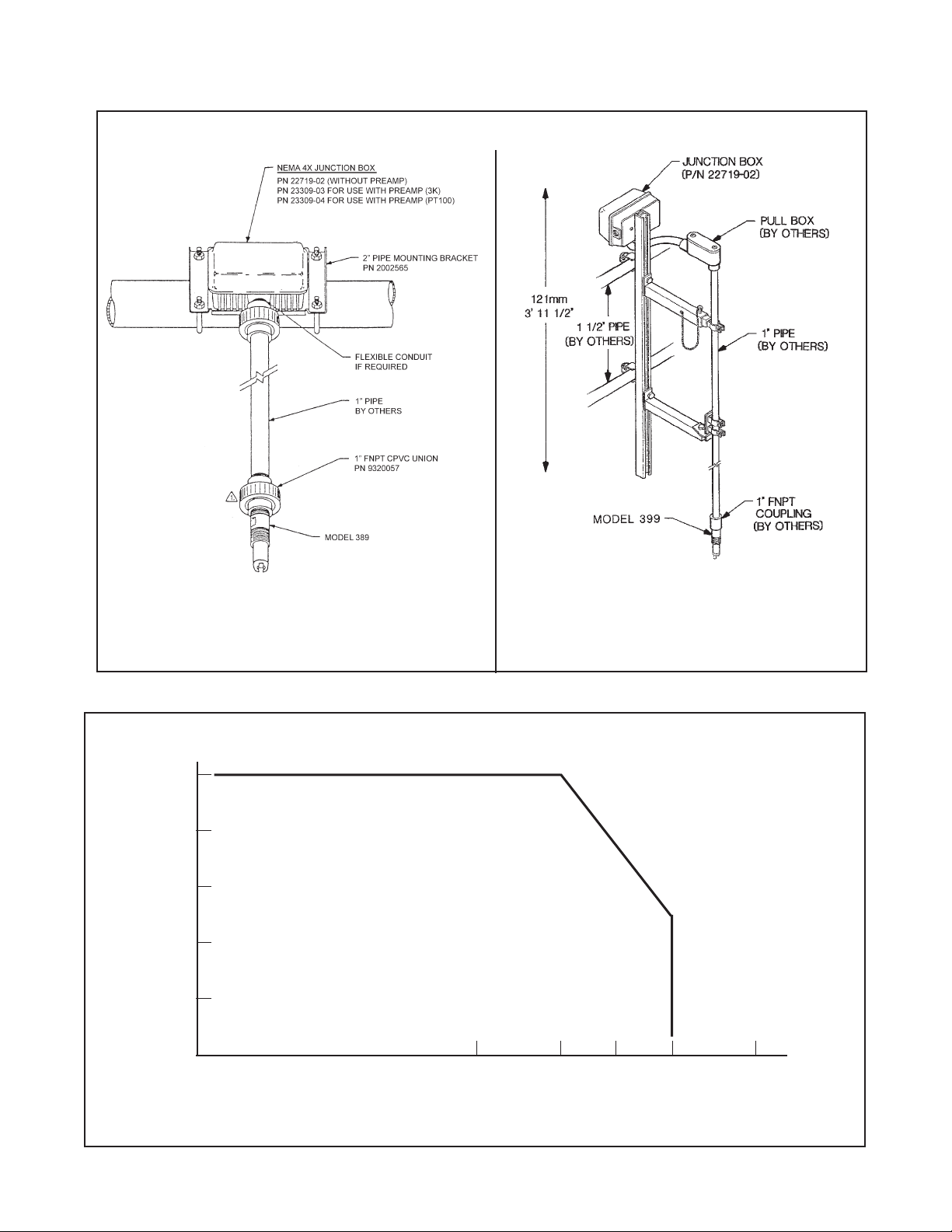

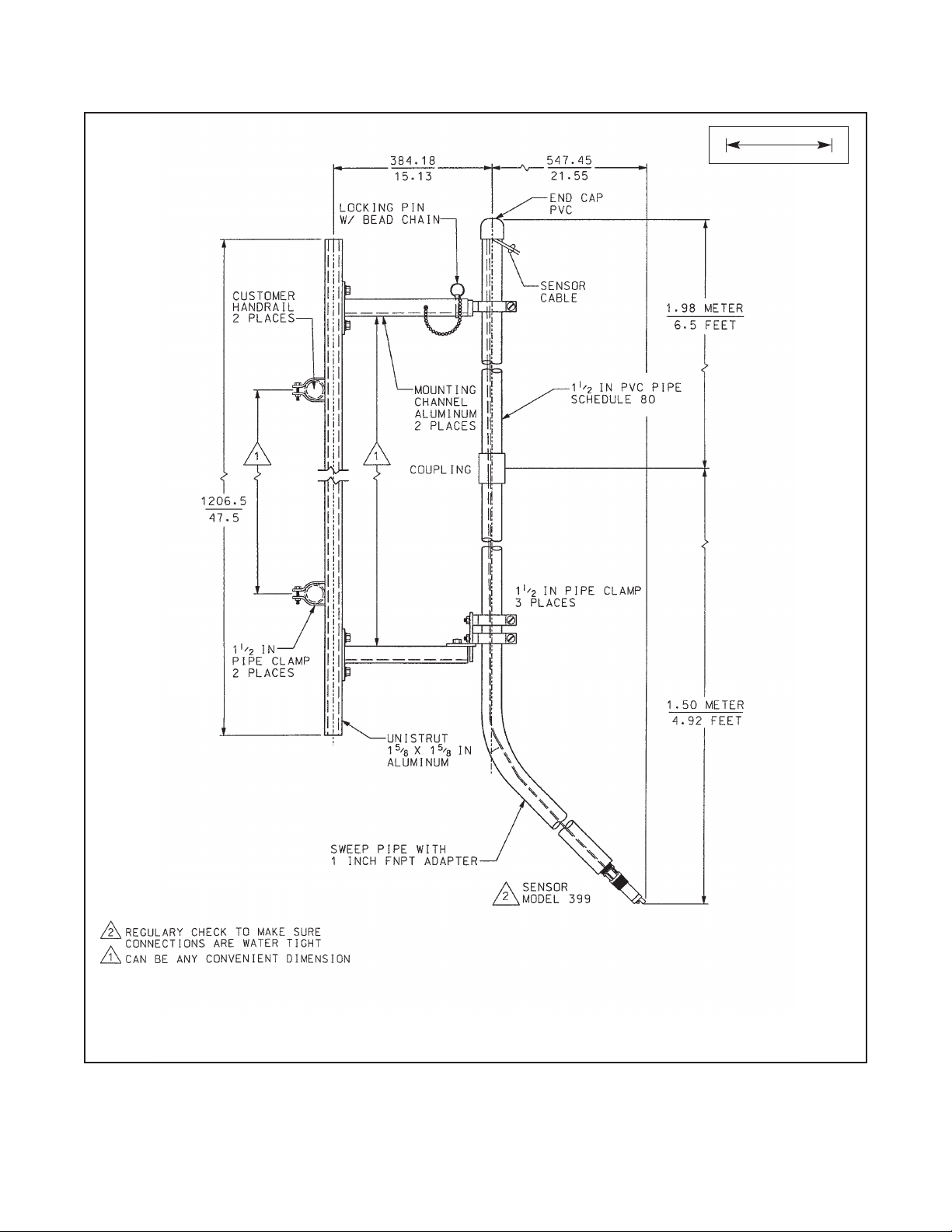

6.3 Submersion Mounting. The Model 399 Sensor

has a 1 in. MNPT process connection at the back of the

sensor (see Figures 4 and 5). Utilizing a standard 1 in.

union, the sensor may be mounted to a 1 in. SCH 80

CPVC or PVDF standpipe. Tapered pipe threads in

plastic tend to loosen after installation. It is therefore

recommended that the tightness of the connection be

checked frequently to assure that no loosening has

occurred. To prevent rain water or condensation from

running into the sensor, a weatherproof junction box is

recommended (Rosemount Analytical PN 22719-02).

The sensor cable must be run through a protective

conduit for isolation from electrical interference or

physical abuse from the process. The sensor should

be installed within 80° of vertical, with the electrode

facing down. The sensor’s cable should not be run with

power or control wiring.

NOTE

LARGE PIPE WRENCHES MUST NOT BE

USED TO TIGHTEN THE SENSOR INTO A

FLANGE OR OTHER TYPE OF MOUNTING.

7.0 WIRING. The Model 399 has an optional built-in

preamplifier and comes standard with a shielded cable

or coax cable. The cable should be handled carefully

and kept dry and free of corrosive chemicals at all

times. Extreme care should be used to prevent it from

being twisted, damaged or scraped by rough, sharp

edges or surfaces. The cable is supplied undressed.

Please refer to Figures 10 through 28 or the applicable

analyzer/transmitter instruction manual for electrical

connections.

8.0 START-UP. After the sensor has been installed

and the process solution is in contact with the sensor,

the transmitter may need to be recalibrated. A grab

sample method is recommend. Please refer to your

analyzer/ transmitter’s instruction manual for procedure.

The Model 399pH has an automatic temperature compensator. This compensates for changes in the output

of the glass electrode with changes in temperature.

9.0 MAINTENANCE. The Model 399 Sensor is a

throw-away type and therefore requires a minimum of

maintenance. The sensor should be kept clean and

free of debris and sediment at all times. The frequency

of cleaning by wiping or brushing with a soft cloth or

brush is determined by the nature of the solution being

measured. The sensor should be removed from the

process periodically and checked in buffer solutions as

outlined in Section 5.0. If the sensor will not calibrate,

refer to your analyzer/ transmitter instruction manual

for proper test procedures. If it is determined that the

sensor has failed, it should be discarded and replaced.

2 Rosemount Analytical

MODEL 399 MANUAL INSTRUCTION SHEET

Page 3

FIGURE 2. FLOW THROUGH INSTALLATIONS

FIGURE 3. INSERTION INSTALLATIONS

Rosemount Analytical 3

MODEL 399 MANUAL INSTRUCTION SHEET

1-1/2” SCHED 80

CPVC TEE WITH 1”

FNPT CONNECTIONS

(CODE 16) STRAIGHT

FLOW SHOWN

1-1/2” PIPE “Y”

1-1/2” X 1”

REDUCING

BUSHING

1-1/2” SCHED 80 CPVC

WITH VIEW OR

CLEANING PORT

FLOW

ANGLE FLOW

SHOWN

SENSOR SHOULD

ALWAYS BE

MOUNTED AT

LEAST 10° ABOVE

HORIZONTAL

SIDE-OF-TANK

INSTALLATION

PIPELINE INSTALLATION (WITH

FLANGE CONNECTIONS)

1” MNPT

FIGURE 1. MOUNTING AND DIMENSIONAL DRAWINGS

TEMP COMP

1” MNPT

1” MNPT

1” WRENCH

OPENING

pH

Dia

25

1

80

3.15

144

5.67

Option 71

Flat Glass Option

Page 4

GRAPH A

PRESSURE/TEMPERATURE LIMITATIONS FOR MODEL 399*

*Please consult factory for specification, pricing and delivery information of Model 399, less integral preamp.

FIGURE 4. - SUBMERSION INSTALLATIONS

4 Rosemount Analytical

65 75 85 100

TEMPERATURE (°C)

100

80

60

40

20

PRESSURE (PSI)

MODEL 399 MANUAL INSTRUCTION SHEET

Submersion Installation Using a Remote Junction

Box, Mounting Bracket, and Pipe Mount Union

Accessory

Pipe supplied by customer and can be any length.

Submersion Installation Using the Handrail

Mounting Kit (PN 1000857)

Pull box, pipe, and coupling supplied by customer.

Junction box is sold separately.

Page 5

Rosemount Analytical 5

MODEL 399 MANUAL INSTRUCTION SHEET

FIGURE 5. Submersion Installation Using the Handrail Mounting Assembly (PN 11275-01)

All parts shown are supplied; sensor is sold separately.

MILLIMETER

INCH

Page 6

MODEL 399 MANUAL INSTRUCTION SHEET

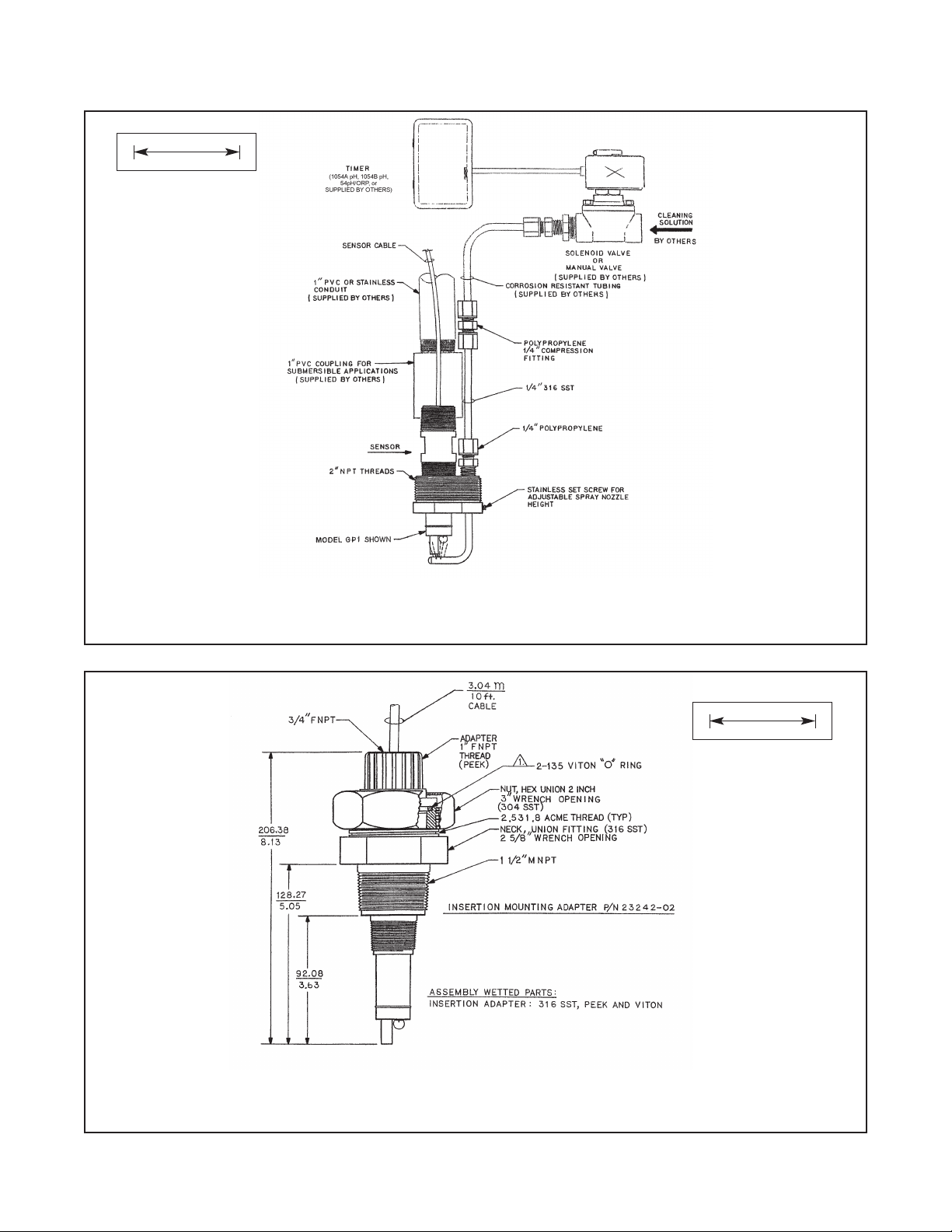

FIGURE 6. Jet Spray Cleaner (PN 12707-00) for Submersion Installations

This accessory is especially useful for keeping the sensor clean in dirty ponds or tanks. It can be mounted using the Handrail

Mounting Assembly or a similar submersion accessory.

FIGURE 7. Sensor With Insertion Adapter (PN 23242-02)

This accessory fits the sensor into 1-1/2 inch threaded pipe tees.

The sensor can be removed easily and without twisting the sensor cable.

MILLIMETER

INCH

MILLIMETER

INCH

6 Rosemount Analytical

Page 7

MODEL 399 MANUAL INSTRUCTION SHEET

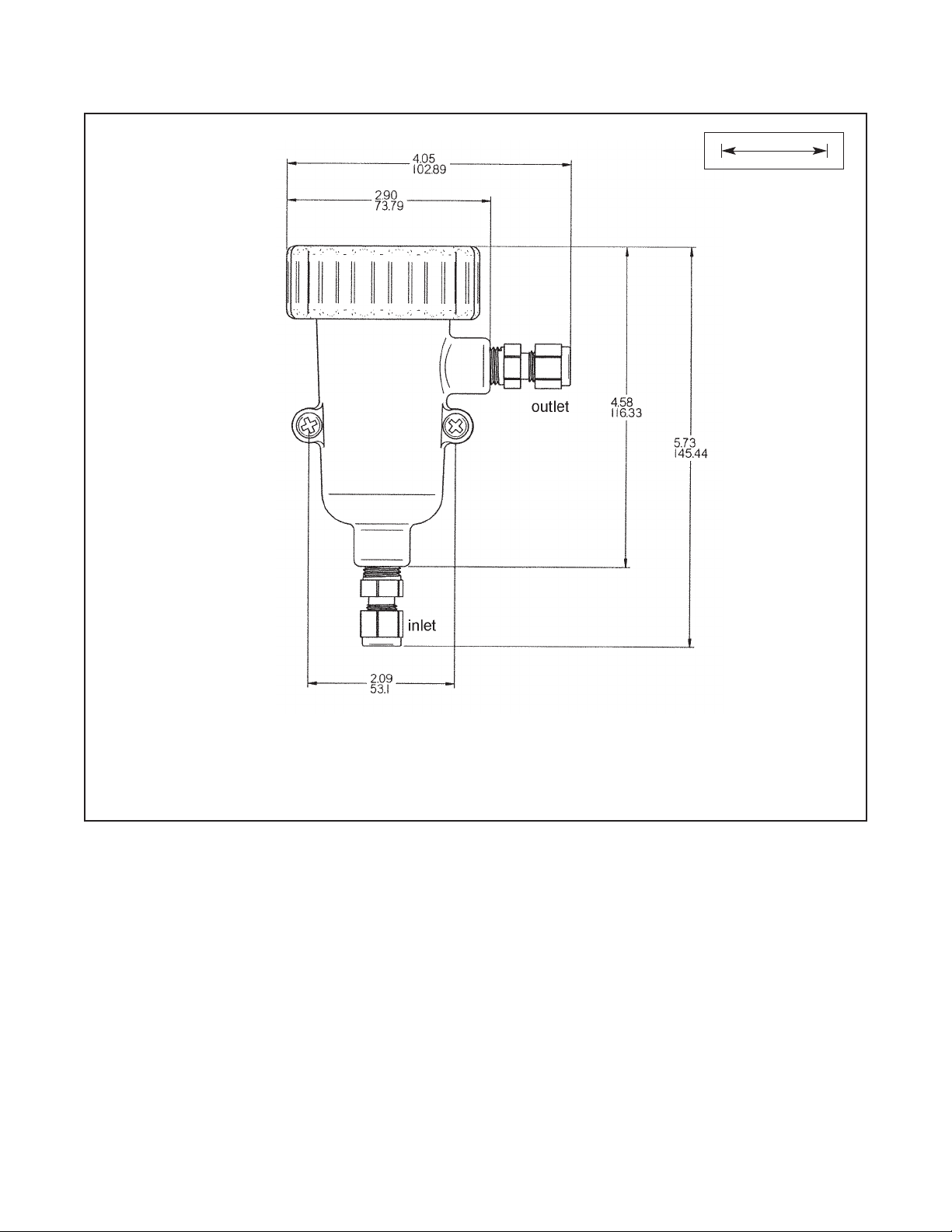

FIGURE 8. Sensor Shown in Low Flow Cell Assembly (PN 24091-00)

Ideal for tapping into existing pipe lines or for minimal process flow requirements.

MILLIMETER

INCH

Rosemount Analytical 7

Page 8

8 Rosemount Analytical

MODEL 399 MANUAL INSTRUCTION SHEET

FIGURE 9. Flow-Through Tee with 3/4 in., 1 in., or 1-1/2 in. NPT

Process Connections.

Ideal for direct, in-line process measurement.

FIGURE 13. Model 399-02/09 Wiring for use with preamplifier integral to remote junction box, and

Models 1054, 1054A, 1054B, 2054, 2081, and other various analyzer/transmitter models.

FIGURE 10. Warning Label

PN DIMENSION A

915240-03 3/4 INCH FNPT

915240-04 1 INCH FNPT

915240-05 1-1/2 INCH FNPT

FIGURE 12. Models 399-12, 399-13, and 399-33

wiring for use with the Solu Comp analyzer

FIGURE 11. Models 399-02 and 399-09 wiring to

1181 integral analyzer/transmitter preamplifier

NOTE: BNC must be cut and prepped. See Figures 13 & 14.

Page 9

Rosemount Analytical 9

MODEL 399 MANUAL INSTRUCTION SHEET

FIGURE 15. BNC Preparation Instructions

FIGURE 16. Models 399-02 and 399-09 wiring for use with Models 54, 3081, 81, 4081, 2081, 1054,

1054A, 1054B, and 2054 integral analyzer/ transmitter preamplifier

NOTE: BNC from sensor cable (see Figure 14) must be cut and prepped. See Figure 15.

FIGURE 14. Wire functions for

Models 399-02 and 399-09

FIGURE 17. Model 399-04 wiring for use with the Model Solu Cube analyzer

NOTE: BNC from sensor cable must be cut and prepped. See Figure 15.

NOTE:

Models 54eA, 5081-A,

& 1055-22-24 must

use 399-09-62; field

prep will not work.

Page 10

10 Rosemount Analytical

MODEL 399 MANUAL INSTRUCTION SHEET

FIGURE 19. Wiring Model 399-01, -03, -05, -06, -07, and -08 (preamplifier integral to sensor) to

Transmitter Models 2054, 1054A, 1054B, 2081, 1181, and other various models.

FIGURE 18. Wiring details - remote junction box with Model 399-09-62 sensor

wire to 54/81/3081/54e/4081/5081

FIGURE 17. Model 399-04 wiring for use with the Model Solu Cube analyzer

NOTE: BNC from sensor cable must be cut and prepped. See Figure 15.

Page 11

FIGURE 20. Wiring details - remote junction box with Model 399-09-62 sensor wire to Xmt

Rosemount Analytical 11

Page 12

12 Rosemount Analytical

MODEL 399 MANUAL INSTRUCTION SHEET

FIGURE 22. Wiring Model 399-14 Sensor to Model 1055-22-32 Analyzer

FIGURE 21. Wiring Model 399-14 Sensor to Models 3081, 4081, and 5081-P

Page 13

MODEL 399 MANUAL INSTRUCTION SHEET

FIGURE 23. Wiring Model 399-09-62 Sensor to Model 1055-11-22-32 Analyzer

through a Remote Junction Box

Rosemount Analytical 13

Page 14

14 Rosemount Analytical

MODEL 399 MANUAL INSTRUCTION SHEET

FIGURE 25. Wiring Model 399-09-62 to Model 1055-10-22-32

DWG. NO. REV.

40105548 D

FIGURE 24. Wiring Model 399-04 to Model 1055-10-22-32

DWG. NO. REV.

40105543 C

Page 15

MODEL 399 MANUAL INSTRUCTION SHEET

FIGURE 27. Wiring Model 399-14, 400, 401, 402, 403, and 404 to Model 1055 (Pipe/Wall Mount)

DWG. NO. REV.

41055106 C

FIGURE 26. Wiring Model 399-09-62, 400, 401, 402, 403, and 404 to Model 1055 (Panel Mount)

DWG. NO. REV.

41055105 C

Rosemount Analytical 15

Page 16

16 Rosemount Analytical

MODEL 399 MANUAL INSTRUCTION SHEET

FIGURE 28. Wiring Model 399-09-62, 400, 401, 402, 403, and 404 to Model 1055 (Pipe/Wall Mount)

DWG. NO. REV.

41055109 C

Page 17

MODEL 399 MANUAL INSTRUCTION SHEET

FIGURE 29. Wiring Model 399-14, 400, 401, 402, 403, and 404 to Model 1055 (Panel Mount)

DWG. NO. REV.

41055110 D

Rosemount Analytical 17

Page 18

18 Rosemount Analytical

MODEL 399 MANUAL INSTRUCTION SHEET

ORDERING INFORMATION

The Model 399 pH/ORP Sensor is available with custom glass electrodes housed in a molded Tefzel body with 1

in. MNPT threads suitable for insertion, submersion or flow through installation. The sensor includes a general

purpose hemi bulb pH electrode (flat bulb optional) or a platinum ORP electrode and a double junction gel filled

reference electrode. The Model 399 pH is available with an optional integral hermetically sealed preamplifier. The

Model 399 ORP is available only with an integral preamplifier. Automatic temperature compensation is standard

with the Model 399 pH but is not required on the Model 399 ORP (except when used with the Model 1054A ORP

Microprocessor Analyzer). Variable cable lengths are available for both the 399 pH and 399 ORP.

Code 399 pH (GPLR hemi bulb) Preamplifier/Cable (Required Selection)

01 10 ft cable with integral preamp for Models 1181pH & 1050

05 32 ft cable with integral preamp for Models 1181pH & 1050

03 10 ft cable with integral preamp for Model 1003

06 32 ft cable with integral preamp for Model 1003

07 10 ft cable with integral preamp for Model 1054A/B, 2054, and 2081 pH

08 32 ft cable with integral preamp for Model 1054A/B, 2054, and 2081 pH

02 10 ft coax cable for remote preamp, 3K ohm TC (Models 1181, 1050, and 1003)

04 10 ft cable for remote preamp, Pt100 TC (Solu Cube)

09 10 ft coax cable for remote preamp, Pt100 TC (Models 54e, 1054A/B, 1055, 2054, 2081, 81, 3081, 4081, 5081)

12 20 ft cable for Solu Comp (Formerly pH201)

13 100 ft cable for Solu Comp (Formerly pH201-Z100)

14 32 ft cable with integral preamp for Models 54e, 81, 1055, 3081, 4081, and 5081

Code Specialized Glass Types (optional - choose one)

73 High pH (improved accuracy above 12.5 pH))

15 HF Resistant (up to 300 ppm)

71 GPLR Flat bulb (for abrasives)

Code 399 ORP Preamplifier/Cable (Required Selection)

30 32 ft cable with integral preamp for Models 1181ORP and 1060

31 32 ft cable with integral preamp for Model 1023

32 32 ft cable with integral preamp for Model 1054A/B ORP

33 20 ft cable for Solu Comp (Formerly ORP-201)

Code Other Options

62 Cable prepped without BNC for wiring to Models 54e, 81, 3081, 4081, 5081, 2081 (only available w/option -09)

Code Specialized Reference Fills - valid only with standard hemi glass (optional - choose one)

301 Low ionic strength water, greater than 5 μS/cm

302 Triple reference for improved resistance to poisoning ions (sulfide & heavy metals)

303 Low temperature storage (below freezing)

OPTIONAL OPTIONS

399 01 73 EXAMPLE

MODEL

399 pH/ORP SENSOR

Page 19

MODEL 399 MANUAL INSTRUCTION SHEET

1. Mounting Accessories (optional)

Choose one: PN 23242-02, Mounting adapter kit, 1/2 in. MNPT process connection, 1 in. x 3/4 in. sensor adapter

PN 915240-03, PVC flow through tee, 3/4 in. NPT process connection

PN 915240-04, PVC flow through tee, 1 in. NPT process connection

PN 915240-05, PVC flow through tee, 1-1/2 in. NPT process connection

PN 24091-00, Acrylic low flow cell

PN 2002011, 1-1/2 in. CPVC tee with 1-in. FNPT connection

PN 9320057, Pipe mount union, 1 in. x 1 in. PVC

PN 11275-01, Sensor handrail assembly

PN 1000857, Handrail mounting kit (pipe and sensor coupling supplied by others)

2. Junction Boxes (optional)

Remote Junction Boxes (to extend sensor to analyzer distances)

Choose one: PN 23555-00, includes preamplifier for Models 54, 81, 3081; NEMA 4X

PN 22719-02, Weatherproof junction box for cable extension

PN 23309-03, use with 1181 and 1050 compatible preamplifier

PN 23309-04, use with 1054/A/B, 2054, 2081 compatible preamplifier

3. Preamplifiers (used to amplify signal when mounting sensor further than 15 ft from the analyzer)

Choose one: PN 22698-02, Plug in preamplifier, 1181/1050 compatible (use with junction box PN 23309-03)

PN 22698-03, Plug in preamplifier, 1054/1054A/1054B/2054/ 2081 compatible (use with junction box PN 23309-04)

4. Extension cables (used with remote junction boxes)

Choose one: PN 23646-01, 11 conductor cable, shielded, prepped

PN 9200000, 4 conductor cable, shielded, unprepped

5. Other optional accessories

Choose one: PN 12707-00, Jet spray cleaner

PN 2001492, Stainless steel tag, specify marking (formerly Code -11)

PN 9210012, Buffer solution, 16 oz, 4.01 pH

PN 9210013, Buffer solution, 16 oz, 6.86 pH

PN 9210014, Buffer solution, 16 oz, 9.18 pH

PN 22698-00, Plug-in preamplifier, 1003 compatible

PN R508-16OZ, ORP solution, 460 mV ±10 @ 20°C

FOR FIRST TIME MODEL 399 INSTALLATIONS AND REPLACEMENT PARTS, USE THE FOLLOWING GUIDE:

Rosemount Analytical 19

Page 20

FROM: RETURN BILL TO:

_____________________________ _____________________________ _____________________________

_____________________________ _____________________________ _____________________________

_____________________________ _____________________________ _____________________________

CUSTOMER/USER MUST SUBMIT MATERIAL SAFETY SHEET (MSDS) OR COMPLETE STREAM COMPOSITION, AND/OR

LETTER CERTIFYING THE MATERIALS HAVE BEEN DISINFECTED AND/OR DETOXIFIED WHEN RETURNING ANY PRODUCT, SAMPLE OR MATERIAL THAT HAVE BEEN EXPOSED TO OR USED IN AN ENVIRONMENT OR PROCESS THAT CONTAINS A HAZARDOUS MATERIAL ANY OF THE ABOVE THAT IS SUBMITTED TO ROSEMOUNT ANALYTICAL WITHOUT

THE MSDS WILL BE RETURNED TO SENDER C.O.D. FOR THE SAFETY AND HEALTH OF OUR EMPLOYEES. WE THANK

YOU IN ADVANCE FOR COMPLIANCE TO THIS SUBJECT.

SENSOR OR CIRCUIT BOARD ONLY:

(Please reference where from in MODEL / SER. NO. Column)

1. PART NO.__________________________1. MODEL_________________________________1. SER. NO. ________________

2. PART NO.__________________________2. MODEL_________________________________2. SER. NO. ________________

3. PART NO.__________________________3. MODEL_________________________________3. SER. NO. ________________

4. PART NO.__________________________4. MODEL_________________________________4. SER. NO. ________________

PLEASE CHECK ONE:

REPAIR AND CALIBRATE DEMO EQUIPMENT NO. __________________________

EVALUATION OTHER (EXPLAIN) _______________________________

REPLACEMENT REQUIRED? YES NO _________________________________________________

DESCRIPTION OF MALFUNCTION:

______________________________________________________________________________________________________

______________________________________________________________________________________________________

______________________________________________________________________________________________________

WARRANTY REPAIR REQUESTED:

YES-REFERENCE ORIGINAL ROSEMOUNT ANALYTICAL ORDER NO. ________________________________________

CUSTOMER PURCHASE ORDER NO. _________________________________________________

NO-PROCEED WITH REPAIRS-INVOICE AGAINST P.O. NO. _________________________________________________

NO-CONTACT WITH ESTIMATE OF REPAIR CHARGES: LETTER __________________________________________

PHONE

___________________________________________

NAME _____________________________________________________ PHONE ________________________________________

ADDRESS ___________________________________________________________________________________________________

______________________________________________________________ ZIP ________________________________________

RETURN AUTHORITY FOR CREDIT ADJUSTMENT [Please check appropriate box(s)]

WRONG PART RECEIVED REPLACEMENT RECEIVED

DUPLICATE SHIPMENT REFERENCE ROSEMOUNT ANALYTICAL SALES ORDER NO.__________

RETURN FOR CREDIT RETURN AUTHORIZED BY: ______________________________________

WARRANTY DEFECT____________________________________________________________________________________

_____________________________________________________________________________________________________

24-6047

RETURN OF MATERIALS REQUEST

•IMPORTANT!

This form must be completed to ensure expedient factory service.

R

E

P

A

I

R

S

T

A

T

U

S

R

E

A

S

O

N

F

O

R

R

E

T

U

R

N

C

U

S

T

O

M

E

R

N

O

T

I

C

E

T

O

S

E

N

D

E

R

Emerson Process Management

Liquid Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.RAuniloc.com

© Rosemount Analytical Inc. 2006

Page 21

WARRANTY

Seller warrants that the firmware will execute the programming instructions provided by Seller, and that the Goods manufactured or Services provided by Seller

will be free from defects in materials or workmanship under normal use and care until the expiration of the applicable warranty period. Goods are warranted

for twelve (12) months from the date of initial installation or eighteen (18) months from the date of shipment by Seller, whichever period expires first.

Consumables, such as glass electrodes, membranes, liquid junctions, electrolyte, o-rings, catalytic beads, etc., and Services are warranted for a

period of 90 days from the date of shipment or provision.

Products purchased by Seller from a third party for resale to Buyer ("Resale Products") shall carry only the warranty extended by the original manufacturer.

Buyer agrees that Seller has no liability for Resale Products beyond making a reasonable commercial effort to arrange for procurement and shipping of the

Resale Products.

If Buyer discovers any warranty defects and notifies Seller thereof in writing during the applicable warranty period, Seller shall, at its option, promptly correct

any errors that are found by Seller in the firmware or Services, or repair or replace F.O.B. point of manufacture that portion of the Goods or firmware found by

Seller to be defective, or refund the purchase price of the defective portion of the Goods/Services.

All replacements or repairs necessitated by inadequate maintenance, normal wear and usage, unsuitable power sources, unsuitable environmental conditions,

accident, misuse, improper installation, modification, repair, storage or handling, or any other cause not the fault of Seller are not covered by this limited warranty, and shall be at Buyer's expense. Seller shall not be obligated to pay any costs or charges incurred by Buyer or any other party except as may be agreed

upon in writing in advance by an authorized Seller representative. All costs of dismantling, reinstallation and freight and the time and expenses of Seller's personnel for site travel and diagnosis under this warranty clause shall be borne by Buyer unless accepted in writing by Seller.

Goods repaired and parts replaced during the warranty period shall be in warranty for the remainder of the original warranty period or ninety (90) days, whichever is longer. This limited warranty is the only warranty made by Seller and can be amended only in a writing signed by an authorized representative of Seller.

Except as otherwise expressly provided in the Agreement, THERE ARE NO REPRESENTATIONS OR WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED,

AS TO MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, OR ANY OTHER MATTER WITH RESPECT TO ANY OF THE GOODS OR SERVICES.

RETURN OF MATERIAL

Material returned for repair, whether in or out of warranty, should be shipped prepaid to:

Emerson Process Management

Liquid Division

2400 Barranca Parkway

Irvine, CA 92606

The shipping container should be marked:

Return for Repair

Model

_______________________________

The returned material should be accompanied by a letter of transmittal which should include the following information (make a copy of the "Return of Materials

Request" found on the last page of the Manual and provide the following thereon):

1. Location type of service, and length of time of service of the device.

2. Description of the faulty operation of the device and the circumstances of the failure.

3. Name and telephone number of the person to contact if there are questions about the returned material.

4. Statement as to whether warranty or non-warranty service is requested.

5. Complete shipping instructions for return of the material.

Adherence to these procedures will expedite handling of the returned material and will prevent unnecessary additional charges for inspection and testing to

determine the problem with the device.

If the material is returned for out-of-warranty repairs, a purchase order for repairs should be enclosed.

Page 22

Credit Cards for U.S. Purchases Only.

The right people,

the right answers,

right now.

ON-LINE ORDERING NOW AVAILABLE ON OUR WEB SITE

http://www.raihome.com

Specifications subject to change without notice.

Emerson Process Management

Liquid Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2007

Sira MC070110/00

Loading...

Loading...