Page 1

Instruction Manual 397

LIQ_MAN_ABR_397 November 2013

TUpH pH Sensors

For additional information, please refer visit our website at www.rosemountanalytical.com.

Specifications

397 Performance and Physical

Specifications

pH Range: AccuGlass: 0–14 pH

Wetted Materials: glass, polypropylene, EP

Interconnecting Cable: 15 ft (4.6 m), for use with remote

preamplier

Temperature Rating: 0 to 100 °C (32 to 176 °F)

Pressure Range: 100–790 kPa abs (0–100 psig)

Minimum Conductivity: 75 μS/cm, nominal 100 μS/cm

Weight/Shipping Weight: 0.45 kg/0.9 kg (1 lb/2 lb)

Process Connections: NONE; must use Quik-Loc Kit which

includes a 1 in. MNPT Process Connection

Quick-Loc Kit Physical Specifications

Process Connections: 1-in. MNPT

Wetted Materials: 316 SST, EP, PEEK

Weight/Shipping Weight: 0.45 kg/0.9 kg (1 lb/2 lb)

Storage

1. It is recommended that electrodes be stored in their

original shipping containers until needed.

2. Do not store at temperatures below -5 °C (23 °F).

3. Electrodes should be stored with a protective cap

containing KCl solution.

4. For overnight storage, immerse the sensor in tap water

or 4 pH buffer solution.

5. A pH glass electrode has a limited shelf life of one year.

Electrode Preparation

1. Remove electrode from shipping container.

2. Remove the protective boot covering the electrode

bulb.

3. Rinse away salt lm with clean water, then shake the

electrode so that the internal solution lls the bulb, thus

removing any air trapped there.

CAUTION

Sensor/Process Application Compatibility

The wetted sensor materials may not be compatible with

process composition and operating conditions.

Application compatibility is entirely the responsibility of

the user.

WARNING

Before removing the sensor, be absolutely certain that the

process pressure is reduced to 0 psig and the process

temperature is lowered to a safe level!

ATEX DIRECTIVE

Special Conditions for safe use

1. All pH/ORP sensors have a plastic enclosure which must

only be cleaned with a damp cloth to avoid the danger

due to a build up of an electrostatic charge.

2. All pH/ORP sensor Models are intended to be in contact

with the process fluid and may not meet the 500V r.m.s.

a.c. test to earth. This must be taken into consideration

at installation

Note

Do not allow lubricant to coat electrode bulb or reference

junction. If it does, wipe it clean before installation.

Sensor Installation

For sensor dimensions, see Figure 1.

For recommended installation, see Figure 2

For wiring, see Figures 3 - 13.

Page 2

397 Instruction Manual

November 2013 LIQ_MAN_ABR_397

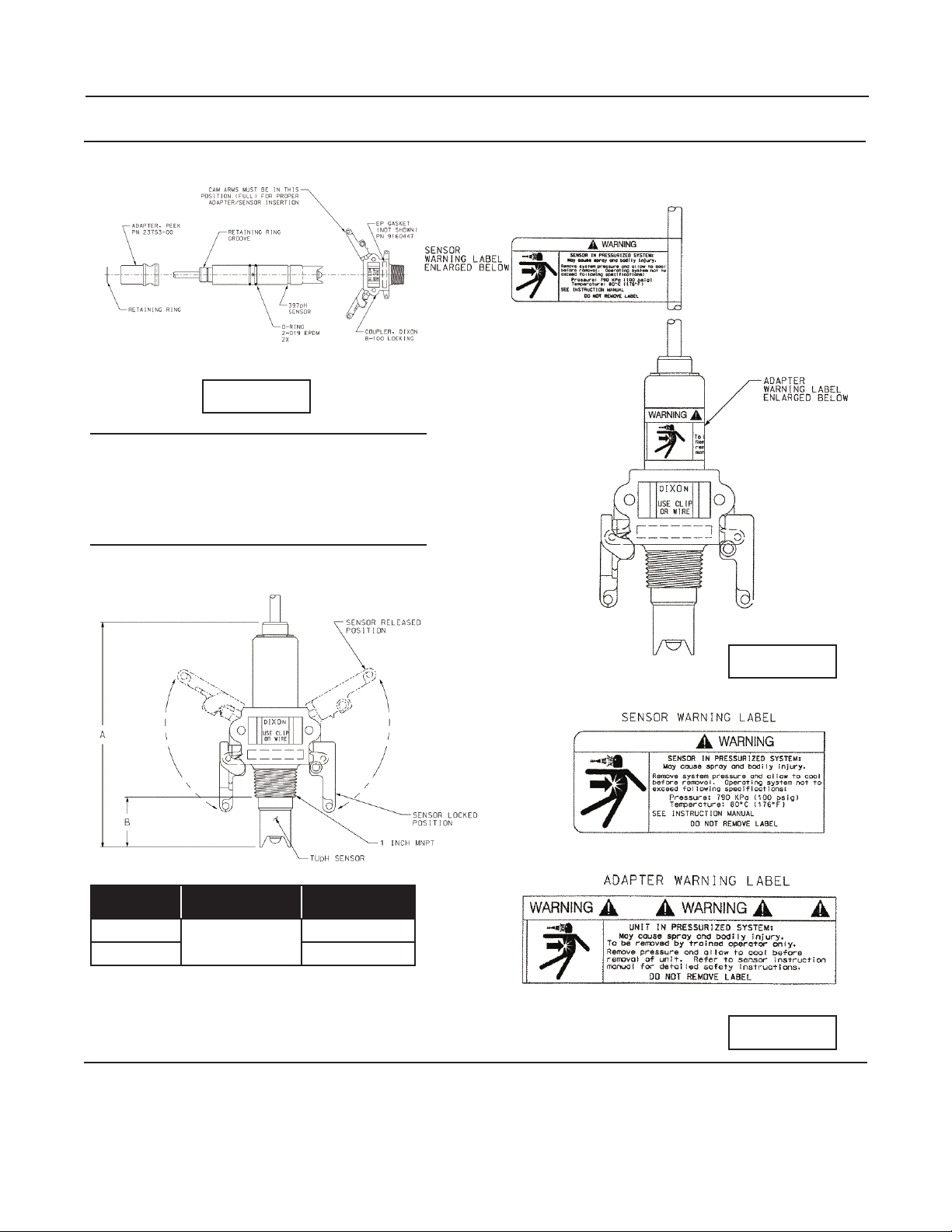

Figure 1. Dimensional Drawings For the 397 in the Quik-Loc Unit

DWG. No. RE V.

40039702 C

Note

The EP gasket (see drawing #40039702) provided

with the coupler should be periodically inspected. If

gasket shows signs of corrosion, replacement will be

necessary to ensure a proper and secure seal between

the coupler and adapter.

Quik-Loc Kit

23757-00

23757-01 2.0 in. / 50 mm

6.15 in. / 156 mm

A

Sensor Length

1.4 in. / 35 mm

B

Insertion Depth

DWG. No. RE V.

40039704 B

DWG. No. RE V.

40039701 C

2

Page 3

Instruction Manual 397

LIQ_MAN_ABR_397 November 2013

Quick-Loc Mounting

Wrap the pipe threads of the coupler with Teon tape

before placing it into the process pipe. The coupler can be

connected to any 1 in. process connection and must be

mounted within 80° of vertical, with the electrode facing

down. Once the coupler is in place, the adapter should be

positioned onto the back end of the sensor.

Remove the paralm wrapping from the two 0-rings on

the sensor, grease the o-rings with the lube provided,

and feed the sensor cable through the adapter. Once

the adapter is slipped over the sensor’s back end, the

retaining ring (which is included with every 397 sensor)

should be installed on the black, grooved, back end of the

sensor body. The retaining ring secures the sensor into the

adapter. The adapter/sensor assembly is now ready to be

inserted into the coupler. With both arms of the coupler in

the released position, insert the adapter/sensor assembly

into the coupler.

Note

The adapter can not be inserted completely or properly

unless both arms are in the fully released position (see Figure

1).

Once the adapter has been properly placed in the coupler, both

arms should be positioned in the locked position.

Note

The sensor may obstruct ow through smaller

pipes.

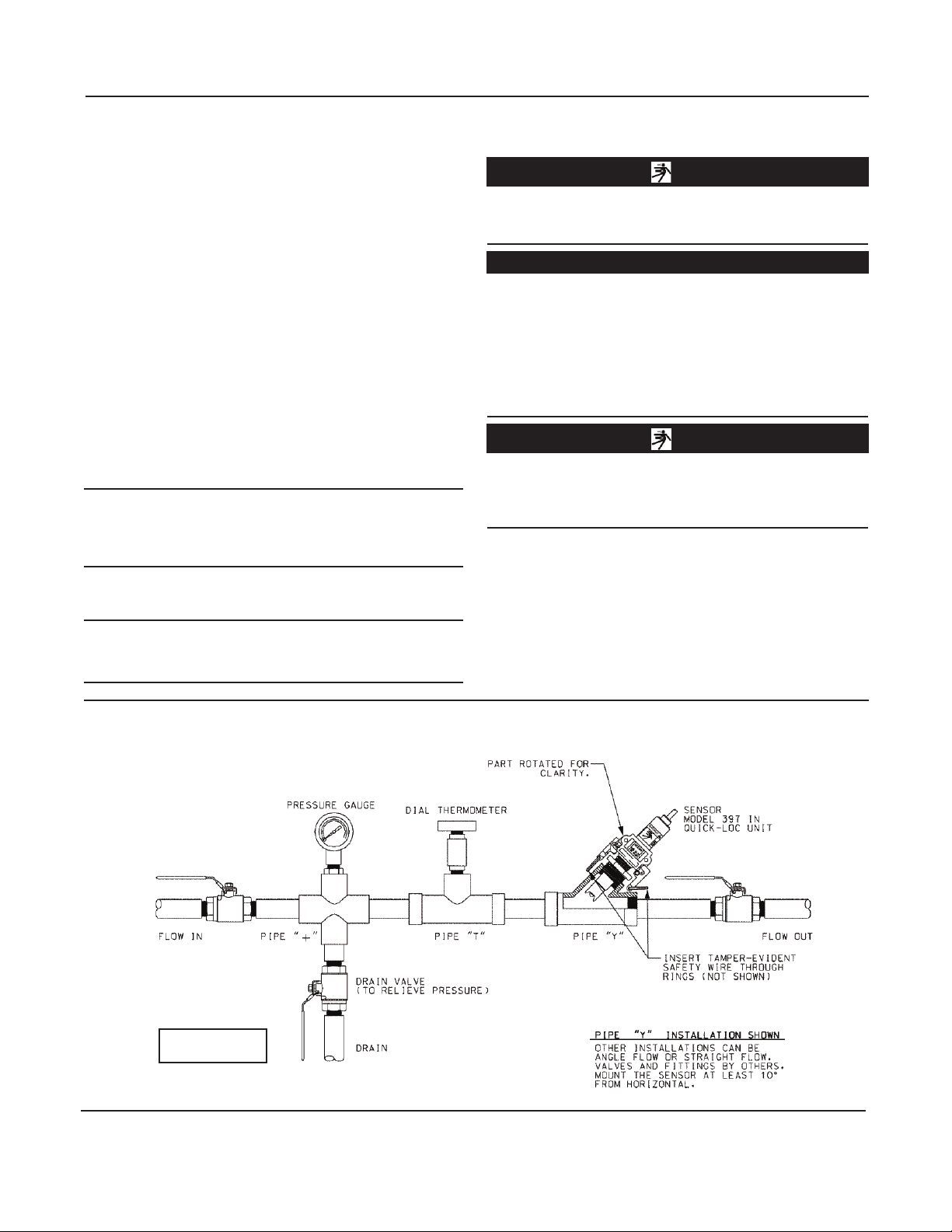

SAFETY WARNING

It is recommended that a thermometer, drain valve to

relieve pressure, and pressure gauge be inserted near the

Quik-Loc assembly (see Figure 2).

WARNING

Once the Quik-Loc unit is installed the operator should

wait for the process to cool to a safe temperature, use the

pressure drain valve to relieve all process pressure and

observe the pressure on the pressure gauge for proper

removal of the sensor without spray or bodily injury. The

Quik-Loc kit used with the 397 TUpH sensor is not recommended for use with hazardous, corrosive, or strong

oxidizing chemicals due to a risk of spray or bodily injury.

SAFETY WARNING

It is the responsibility of each company using the QuikLoc Kit/ 397 TUpH Sensor to train personnel of the injury

risks associated with using a quick-release coupler that is

placed in a hot or pressurized process.

Once the arms of the coupler have been locked in position, use

tamper-evident safety wire on the metal rings of the coupler

arms to prevent unauthorized and/or untrained personnel from

using the Quik-Loc unit.

The Quik-Loc unit should be used only within the pressure and

temperature limits stated for the 397 sensor.

Figure 2. Recommended Flow-Through and Insertion Installation for the 397

DWG. No. RE V.

40039703 B

3

Page 4

397 Instruction Manual

November 2013 LIQ_MAN_ABR_397

Note

For additional wiring information on this product, including sensor combinations not shown here, please refer to either

our online wiring programs or the Manual DVD enclosed with each product.

1056, 1057, 56, 5081, 6081, 54e, and XMT : http://www3.emersonprocess.com/raihome/sp/liquid/wiring/XMT/

1066 and sensors with SMART preamps: http://www2.emersonprocess.com/en-US/brands/rosemountanalytical/Liquid/Sensors/

Pages/Wiring_Diagram.aspx

1055: http://www3.emersonprocess.com/raihome/sp/liquid/wiring/1055/

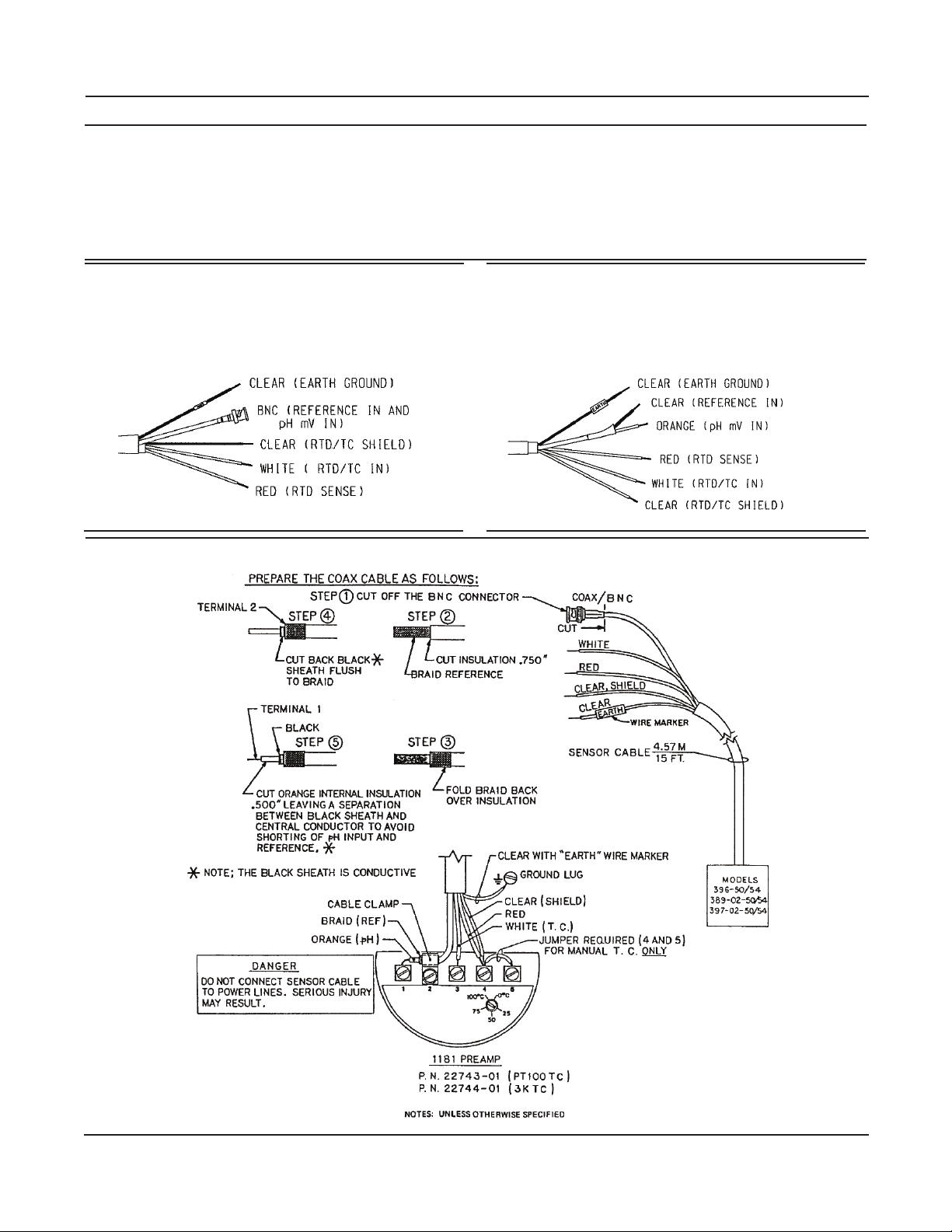

Figure 3. 397 Standard Wiring Option used with

1054A, 1054B, 2054, and Preamplifiers PN 22698-02

and 22698-03

Figure 5. Wiring to 1181 pH Analyzer.

Figure 4. The 397 Option -62 for Wiring to 1054, 1055,

1181, 2081, 54, 54e, 81, 3081, 4081, 5081-P, Xmt-P,

SoluComp, and 2700 Preamplifier (PN 23054-03). Also

for use with remote Junction Box PN 23555-00.

4

Page 5

Instruction Manual 397

LIQ_MAN_ABR_397 November 2013

Figure 6. Preparing Coax Cable for Wiring to 54e, 1055, 81, 2081, 3081, 4081, 5081, and Xmt.

Figure 7. Wiring to 2081

Figure 9. Wiring to Xmt-P-XX-10

Figure 8. Wiring to 54e, 81, 3081, 4081, and 5081

5

Page 6

397 Instruction Manual

November 2013 LIQ_MAN_ABR_397

Figure 10. Wiring to 1054A, 1054B, and 2054

Figure 11. Wiring through Junction Box PN 23309-04 (03) and Remote Preamplifier

6

Page 7

Instruction Manual 397

LIQ_MAN_ABR_397 November 2013

Figure 12. Wiring to 1055-01-10-22-32

Figure 13. Wiring to 1055-11-22-32 through a Remote Junction Box

7

Page 8

397 Instruction Manual

November 2013 LIQ_MAN_ABR_397

Rev. G

Two Point Buffer Calibration

Select two stable buffer solutions (at least two pH units apart), preferably pH 4.0 and 10.0.

Note

A pH 7 buffer solution reads a mV value of approx. zero, and pH buffers read approximately ± 59.1 mV for each pH unit above or

below pH 7. Check the pH buffer manufacturer specications for millivolt values at various temperatures since it may affect the

actual value of the buffer solution mV/pH value.

1. Immerse sensor in the rst buffer solution. Allow sensor to equilibrate to the buffer temperature (to avoid errors due to

temperature differences between the buffer solution and sensor temperature) and wait for reading to stabilize. Value of buffer

can now be acknowledged by analyzer/transmitter.

2. Once the rst buffer has been acknowledged by the analyzer/transmitter, rinse the buffer solution off of the sensor with

distilled or deionized water.

3. Repeat steps 1 and 2 using the second buffer solution.

4. The theoretical slope value, according to the Nernst equation for calculating pH, is approximately 59.17 mV/pH. Over time

the sensor will age, both in the process and in storage, and will result in reduced slope values. To ensure accurate readings, it is

recommended that the electrode be replaced when the slope value falls below 47 to 49 mV/pH.

Recommended pH Sensor Standardization

For maximum accuracy, the sensor can be standardized on-line or with a process grab sample after a buffer calibration has

been performed and the sensor has been conditioned to the process. Standardization accounts for the sensor junction

potential and other interferences. Standardization will not change the sensor’s slope but will simply adjust the analyzer’s

reading to match that of the known process pH.

Maintenance

Electrodes should respond rapidly. Sluggishness, offsets, and erratic readings are indicators that the electrodes may need

cleaning or replacement.

1. To remove oil deposit, clean the electrode with a mild non-abrasive detergent.

2. To remove scale deposits, soak electrodes for 30 to 60 minutes in a 5% hydrochloric acid solution.

3. Temperature effect on life expectancy: If glass electrode life expectancy is 100% @ 25 °C (77 °F), then it will be

approximately 25% @ 80 °C (176 °F), and approximately 5% @ 120 °C (248 °F).

facebook.com/EmersonRosemountAnalytical

AnalyticExpert.com

twitter.com/RAIhome

youtube.com/user/RosemountAnalytical

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

rosemountanalytical.com

© Rosemount Analytical Inc. 2013

©2013 Rosemount Analytical, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Brand name is a mark

of one of the Emerson Process Management family of companies. All other marks are the property of their respective owners.

The contents of this publication are presented for information purposes only, and while effort has

been made to ensure their accuracy, they are not to be construed as warranties or guarantees,

express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and conditions, which are available on request. We reserve

the right to modify or improve the designs or specications of our products at any time without

notice.

8

Credit Cards for U.S. Purchases Only.

Loading...

Loading...