Page 1

Installation & Calibration Equipment

Sensor & Instrument Mounting, Accessories, Systems and More

Visualize > Analyze > Optimize

Page 2

INSTALLATION & CALIBRATION EQUIPMENT

Emerson Process Management offers a variety of

Rosemount Analytical accessories to fit many

requirements. This brochure includes mounting tees, ball

valve kits, and other configurations used for mounting

conductivity, pH, ORP and amperometric (dissolved

oxygen, chlorine, and ozone) sensors and instruments.

Please note that each mounting accessory is only valid for

the stated sensor(s). Also included is information on

instrument mounting, cables, junction boxes and various

chemicals. The accessories in this brochure can be used in

a wide variety of applications commonly found in the

following industries:

TABLE OF CONTENTS

Mounting Recommendations for Sensors includes best practices for in-line and tank mounting............................4-5

> Chemical

> Food and Beverage

> Water and Wastewater Treatment

> Power

> Water Treatment

> Utilities

> Pulp and Paper

> Metals and Mining

> Hydrocarbon Processing

> Textile

> Pharmaceutical

Insertion Sensor Mounting including tees, low flow cells, handrail mounting, floating balls,

jet spray cleaner, mounting adapters, and process connectors.............................................................................6-18

Retraction Assemblies including ball valve kits, retraction assemblies

for higher pressures, and a rotary retraction unit ...............................................................................................19-27

Instrument Mounting with mounting brackets for wall, pipe, or panel mount....................................................28-30

Wiring Accessories includes best practices for cable lengths. Also includes junction boxes,

extension cables, VP connector cables and cable glands....................................................................................31-37

Calibration Accessories with pH buffer solutions and conductivity standard solutions

Also included is a conductivity validation unit, a pH benchtop calibration unit,

a pH simulator, and VP plug simulator for pH and conductivity ..........................................................................38-40

Flow Accessories including rotameters and a constant head flow controller.......................................................41-42

Tags for Sensors and Instruments............................................................................................................................43

Sample Cooler.........................................................................................................................................................43

Special Parts and Assemblies including examples of customer requested panels with sensors,

flow cells, instruments, and sample cooling system mounted for easy installation.............................................44-45

Certificates for Sensors, Instruments and Chemicals including Certificate of Calibration,

Electronic Calibration, Loop Calibration, & Material Certificates. .............................................................................46

Index for quick and easy searching for parts by number or description....................................................................47

2

Page 3

CHOOSING THE RIGHT MOUNTING SOLUTION

VP CONNECTOR SHOWN; SENSORS ARE

ALSO AVAILABLE WITH INTEGRAL CABLE

PROCESS END (FRONT END)

THREADS, CLOSEST TO

SENSING/MEASURING END

OF THE SENSOR

Figure 1. The 3900 general purpose pH sensor is offered with 1 inch MNPT

threads in two locations: one on the process end and one on the cable end. It also

has a 3/4” MNPT process end thread.

Understanding sensor process

connections:

Rosemount Analytical sensors are offered with a wide

variety of threaded process connections.

The sensor shown above is a 3900 pH sensor. All sensors

use similar terminology for process connection threads.

Note that not all sensors are offered with front and back

end threads. Below are examples of sensors using other

types of sensor-to-process connection threads.

The sensors shown in Figures 2 and 3 are much

different than the sensor shown in Figure 1. Figure 2 is

a 228 Toroidal sensor with 3/4" MNPT threads and is

also available with 5/8" UNC threads. Figure 3 shows a

non-threaded 3300HT pH sensor which is used with a

BACK END PROCESS THREADS, CLOSEST

TO CABLE OR VP CONNECTOR

process connector (sold separately) to allow variable

insertion depths for the sensor and easy sensor

removal without twisting the cable.

Ordering Information

All sensors used with the accessories mentioned in this

catalog must be purchased separately. Also, please note

that additional accessory items must be purchased

along with the stated mounting accessories in order for

the complete mounting to be accomplished. Please

consult your local representative for more information

about sensors or consult the factory at 1-800-854-8257

(in the U.S.) or 1-949-757-8500 (outside of the U.S.).

You can also visit us at RosemountAnalytical.com.

Figure 2. The 228 Toroidal Conductivity Sensor is offered

with back end process threads only.

3

Process connector required for

connection of sensor to process.

Figure 3. The 3300HT sensor is offered without process

threads. A compression fit, process connector is used on

the sensor body and gives the user flexibility for insertion.

Retractable sensors (a longer version of what is shown

above) are also offered without process threads. This is so

the sensor can be mounted through a ball valve.

Page 4

MOUNTING RECOMMENDATIONS FOR SENSORS

Sensors mounted in

tees and flow cells:

> To prevent leakage, wrap the sensor threads with pipe

tape before inserting into its mounting.

> Do not over tighten the sensor when installing. Hand

tighten the sensor, and then tighten with a wrench.

> The electrodes must be completely submerged in the

process liquid to measure properly

> Air bubbles accumulating on sensors will cause erro-

neous or erratic readings.

> To control air bubble formation, apply a small amount

of back pressure to the flow cell or pipe.

> All sensor cables should be run through a conduit to

protect the back end from moisture intrusion.

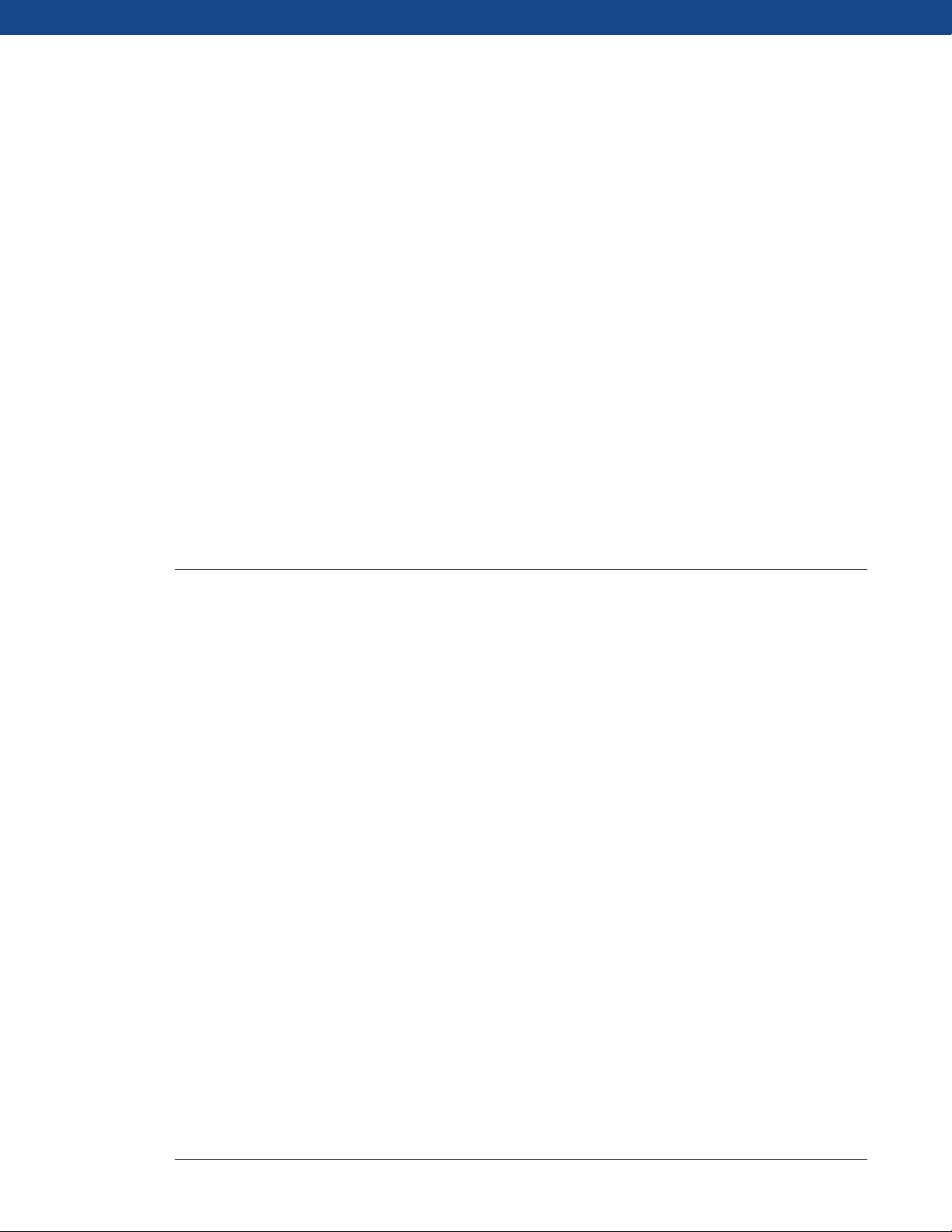

Figure 4. pH sensor recommended mounting orientation. pH sensors should be mounted at least 10° from the

horizontal to ensure correct measurement. Sensors can

also be mounted vertically.

Figure 5. Chlorine, dissolved oxygen, and ozone sensor

recommended mounting orientation. Chlorine, dissolved

oxygen, ozone sensors should be mounted vertically or

within 45° of the horizontal position. Also, these sensors

have recommended flow rates that should be observed.

Check instruction manual for more information on recommended flow rates.

Figure 6. Conductivity (contacting) sensors should have at

least 1/4 in. (0.6 cm) clearance between electrodes and

piping (as shown in both illustrations above). The recom-

mended sensor orientation is either horizontal or no more than

30° below horizontal. It is best that the inlet flow is facing the

sensor to ensure full pipe and minimal air bubbles.

4

Page 5

MOUNTING RECOMMENDATIONS FOR SENSORS

Metal Pipe

Plastic Pipe

True

Conductivity

Distance to Wall

Measured Conductivity

3/4 to 1 Toroidal

Sensor diameter

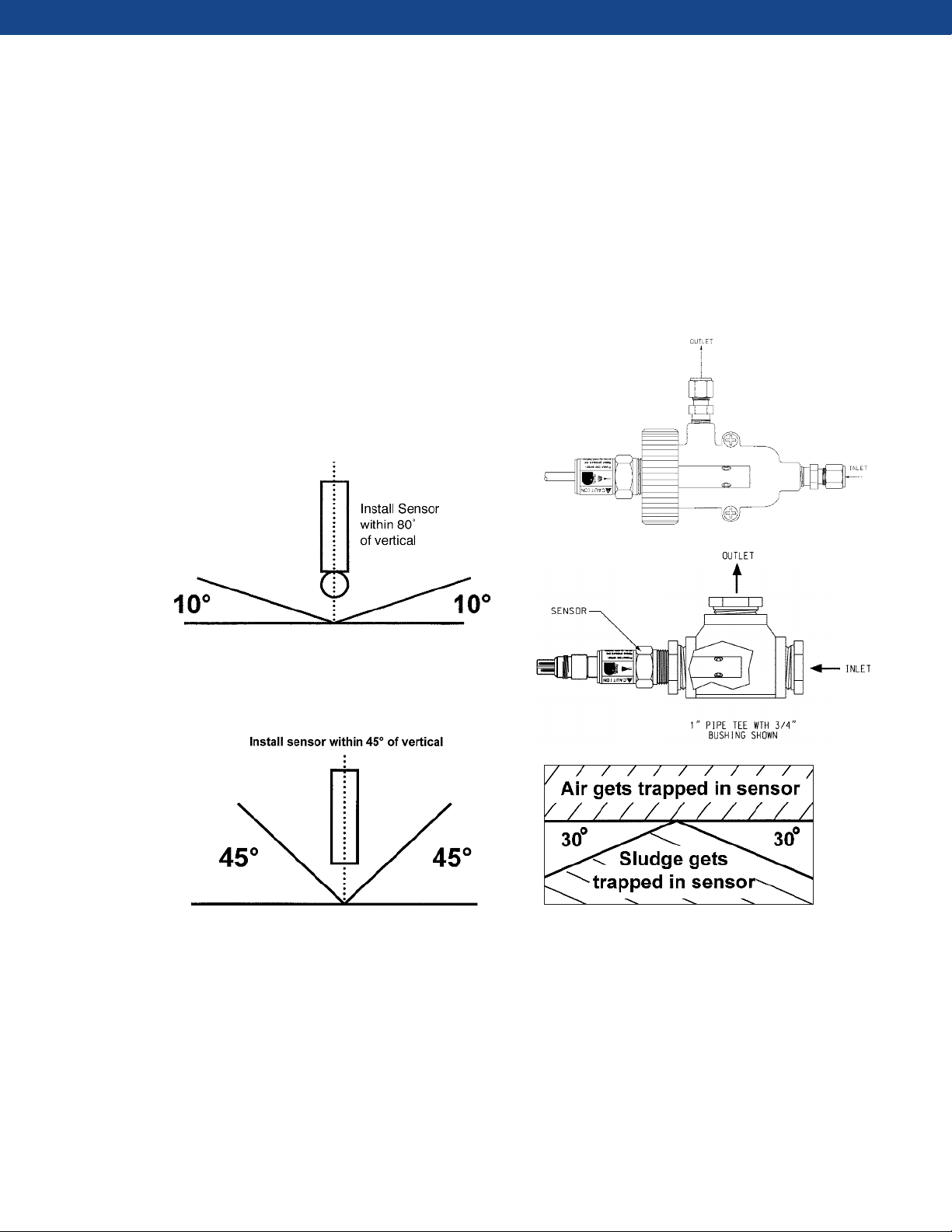

Conductivity (toroidal) sensors should be kept at a far

enough distance between sensor and pipe wall to ensure

the pipe wall does not interfere with the reading. If

clearance is too small, the sensor should be calibrated

Figure 7. The measured toroidal conductivity value can be

affected when installed close to a pipe wall.

Sensors submerged in tanks,

ponds, or basins

> To prevent leakage, wrap the sensor threads with pipe

tape before inserting into its mounting part.

> Do not over tighten the sensor when installing. Hand

tighten the sensor, and then tighten one or two (1–2)

turns with a wrench.

while in the pipe. The sensor should be completely

submerged in liquid. Mounting the sensor in a vertical

pipe run with the flow from bottom to top is best. If the

sensor must be mounted in a horizontal pipe run, orient

the sensor in the 3 o’clock or 9 o’clock position.

Figure 8. Correct sensor orientation

> The electrodes must be completely submerged in the

process liquid to measure properly.

> All sensor cables should be run through a pipe conduit;

do not use the sensors cable to dangle the sensor into

the tank, pond, or basin.

Do not install sensor by hanging it directly into water.

Incorrect Installation

Figure 9. Correct sensor installation is critical to to proper sensor performance.

Correct Installation

Always install sensor using pipe conduit.

5

Page 6

INSERTION SENSOR MOUNTING

he mounting parts contained in this section include in-

T

line tees, low flow cells, a handrail mounting assembly, a

floating ball system, a jet spray cleaner, mounting

dapters, and process connectors. The in-line tees are

a

offered in various configurations to assist in easy sensor

insertion and removal without twisting cables. The low

low cells are available for sidestream samples with 1/4"

f

OD tubing. The handrail mounting assembly is available

with all the parts needed to install a sensor into a pond

S

e

nsor

P

r

o

d

uct

N

um

b

MEASUREMENT

e

TYPE

pH and ORP

389, 396, 396P

, T

F396, 3300HT

Conductivity

r basin; the jet-spray cleaner can be used with this

o

assembly for dirty applications. The floating ball system

can be used as an alternative method of installing a

ensor into a pond or basin. Many mounting adapters

s

are offered for tank and pipe insertion, as well as for

submersion applications. The process connectors are

ffered specifically for use with metal body sensors for

o

insertion, submersion, and retractable applications.

r

s*

, 3500, 3900, Hx338, 3800, RB546

140, 400, 228

Dissolved Oxygen

499ADO, 499AT

RDO

Ozone

4

99AOZ

Chlorine

499ACL, 498Cl

* Sensors with integral cable or VP connector can be used.

6

Page 7

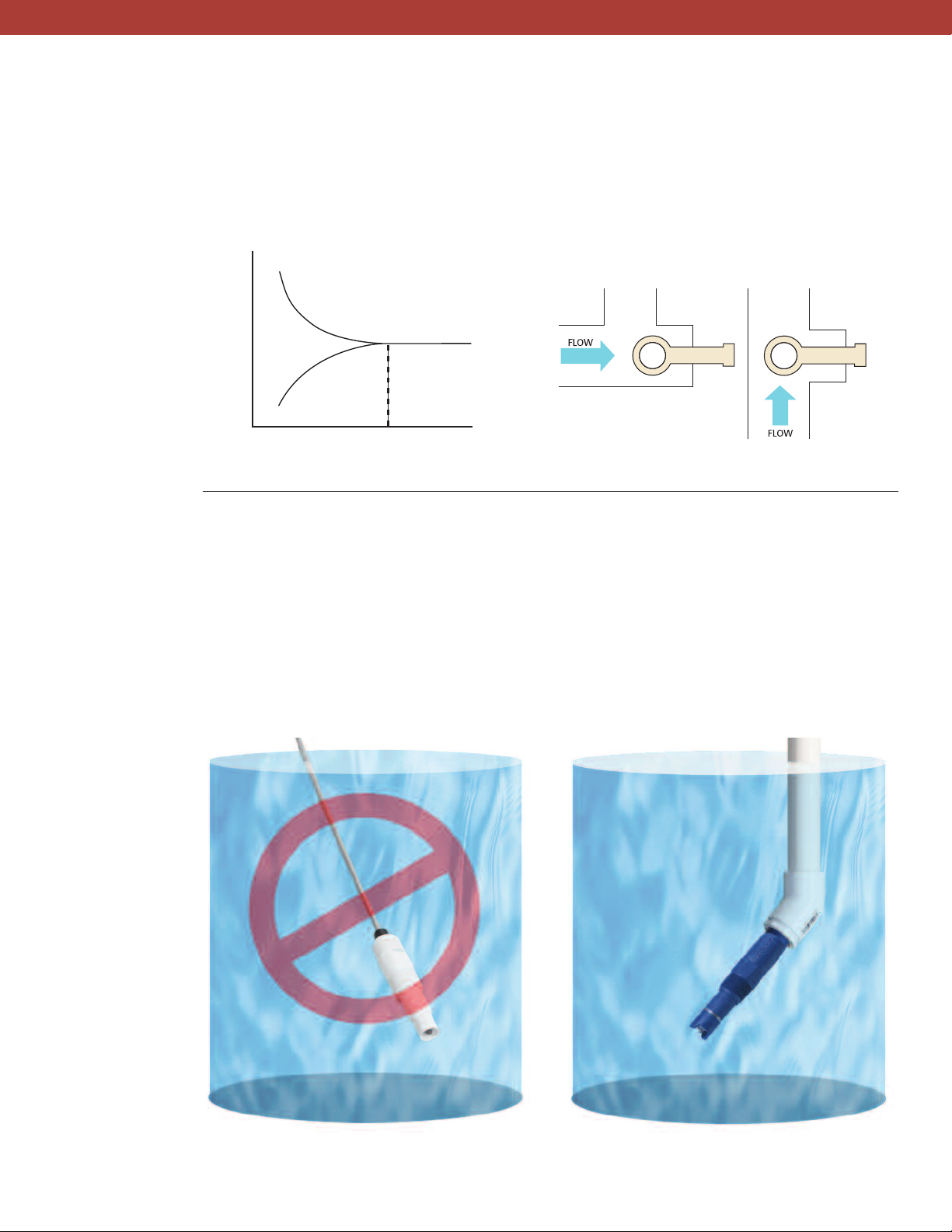

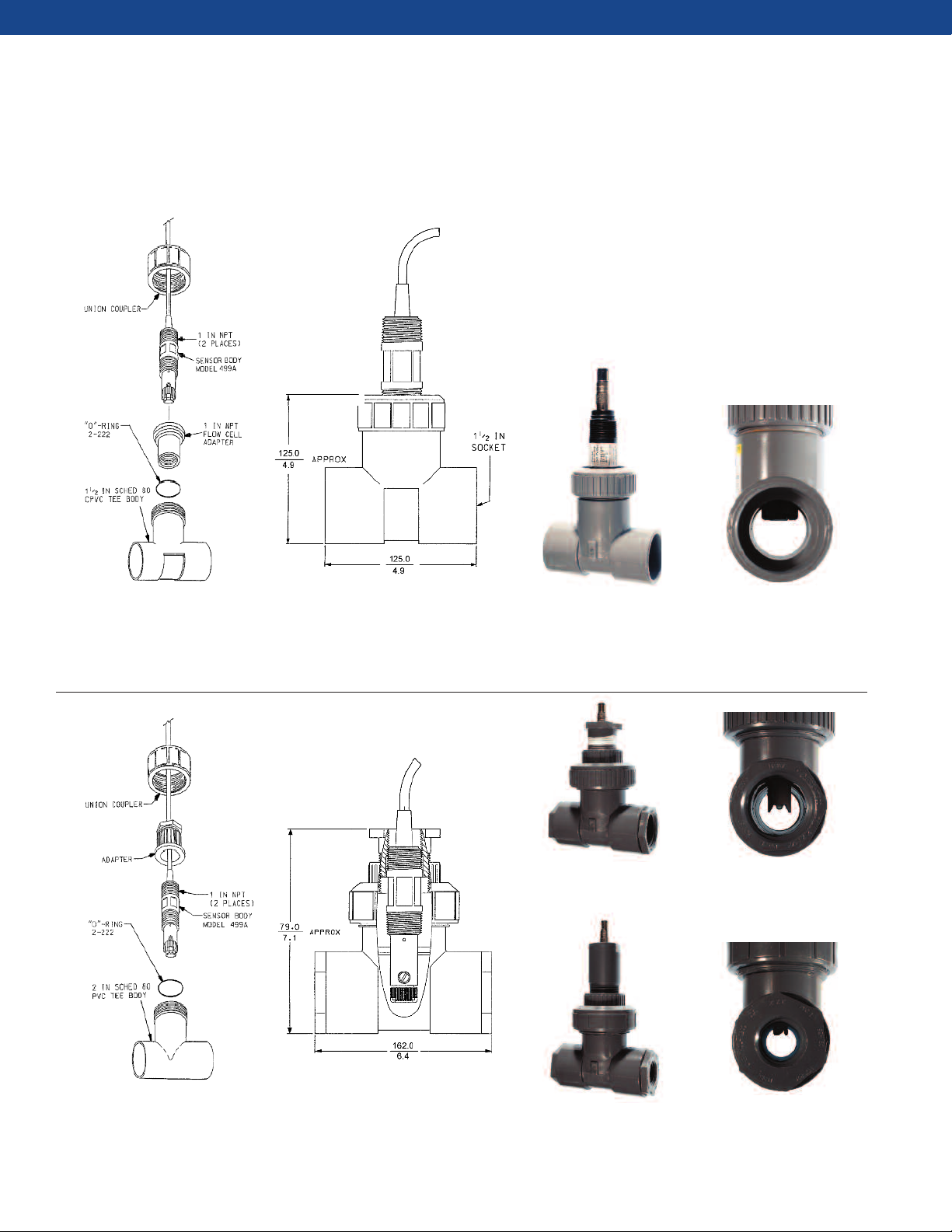

IN-LINE TEES

These versatile in-line tees can be used with Rosemount

Analytical pH, ORP, conductivity, dissolved oxygen,

ozone, and chlorine sensors having 1-inch process

connections. Compatible sensor models are listed in the

table below. Tees can be installed directly in process

piping or in slip streams. PN 23567-00 and PN 91524003, -04, and -05 have union fittings that allow the sensor

In-Line Tees

2002011 23567- 00 915240- 03 915240- 04 915240-05

Size 1.5" 2.0"

Process Connection Ends 1.0" thread 1.5" socket .75" threads 1.0" threads 1.5" threads

Material CPVC, Schedule 80 PVC, Schedule 80

O- ring or Gasket Material – Buna N

Maximum rating 150 psig (1136 kPa) 65 psig (549 kPa) 60 psig (515 kPa) at 120°F (49°C)

@150°F (65°C) @ 122°F (50°C)

Compatible Sensor Models*

pH and ORP 396P, 389, 3500, 3900 396P, 389, 3500,

Conductivity 150 –

Dissolved Oxygen 499ADO 499ADO

Ozone 499AOZ 499AOZ

Chlorine 499ACl 499ACl

*Note: All sensor models noted in this graph are listed with integral cables.

The sensor models with the “VP” connectors can also be used.

In-Line Tee Part Number

to be removed without the need to unscrew it, thus

eliminating the possibility of the cable becoming twisted

and damaged. Tees are offered in PVC and CPVC and can

connect to ¾, 1, and 1 ½ inch process lines.

lways install tees so that the sensor is completely

A

submerged in the process liquid, and allow enough

headroom to remove the sensor.

3900 using adapter PN S10283-LQD

Figure 10. When using sensor Model 3900VP

with Tee PN 915240-03, -04, or -05, order

adapter PN S10283-LQD (top of photo)

Direct mount into tee threads

IN-LINE TEE (PN 2002011)

PRESSURE/TEMPERATURE

SPECIFICATIONS

psig (kPa) °F (°C)

150 (1136) 150 (65)

128 (984) 160 (71)

102 (805) 170 (77)

80 (653) 180 (82)

57 (494) 200 (93)

48 (432) 210 (99)

FIGURE 11. 11⁄2 in. tee with 1 in. threaded process

connection (PN 2002011) shown with TUpH 396P

mounted for angle or straight process flow.

Figure 12. 389 pH sensor in

PN 2002011 Tee

Figure 13. Sensor tip in

process stream flow path.

7

Page 8

IN-LINE TEES

Tees with union adapters offer quick and easy access and eliminate damage from cable twisting.

Figure 14. 1½ in. tee with 1½ in. socket process connection (PN 23567-00)

shown with a Model 499A amperometric sensor. The tee assembly is offered with

a sensor mounting adapter that allows the user to remove the sensor without twisting

the cable.

Figure 15. 499ACL sensor

in PN 23567-00 Tee

Figure 18. PERpH-X

3500VP pH sensor in PN

915240-03 Tee

Figure 16. Sensor tip in

process stream flow path.

Figure 19. Sensor tip in

process stream flow path

Figure 17. 2 in. tee with ¾, 1, or 1½ in. threaded process connections (PN

915240-03, -04, -05 respectively) shown with a Model 499A amperometric

sensor. The tee assembly is offered with a sensor mounting adapter that allows the

user to remove the sensor without twisting the cable.

8

Figure 20. 3900VP pH sensor

in PN 915240-03 Tee with

adapter PN S10293-LDQ

Figure 21. Sensor tip in

process stream flow path

Page 9

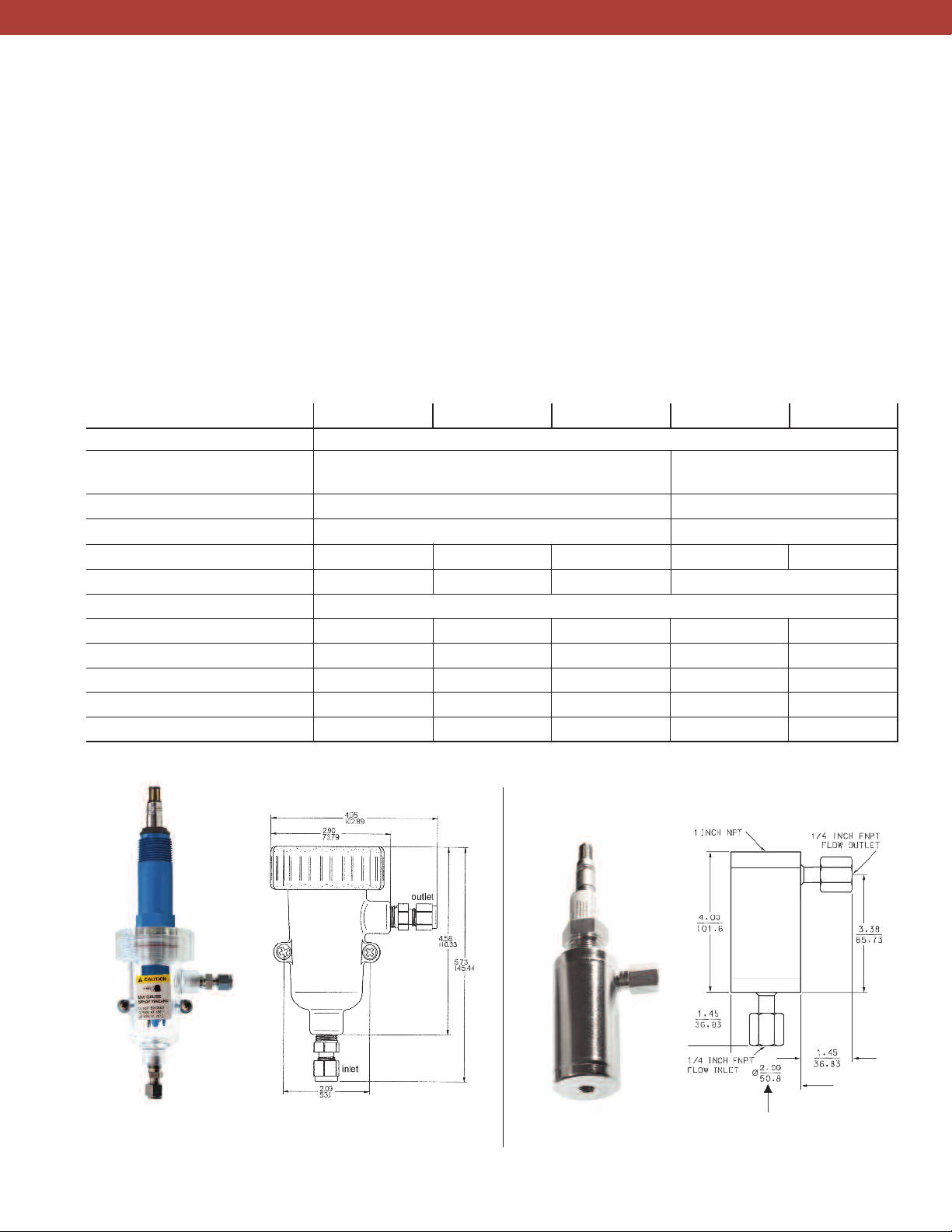

LOW FLOW CELLS

Emerson offers a variety of low flow cells for sidestream

applications where it is impractical to divert a large

volume of sample, particularly if the sample must be

sent to waste. Choose a transparent plastic or stainless

steel body—both have ¼ inch FPT process connections.

Plastic flow cells PN 24091-00, -01, and -02 are also

supplied with ¼ inch MPT to ¼ inch OD tubing fittings

Low Flow Cells

Process Connection 1/4 inch 316 SST male tube connector

Wetted Materials Body and Nut - Polycarbonate/polyester blend; 316 SST

Maximum Temperature 158°F (70°C) Consult Factory

Maximum Pressure 90 psig (621 kPa) Consult Factory

Sensor Threaded Connection 1 inch 1 inch 3/4 inch 1 inch 3/4 inch

Special features None

Compatible Sensor Models*

pH and ORP Sensors

Conductivity Sensors ––400, 400 VP – 400, 400 VP

Dissolved Oxygen 499ATrDO, 499ADO 499ADO – 499A DO –

Ozone 499AOZ ––––

Chlorine 499ACL 498CL, 499ACL –––

*Note: All sensor models noted in this graph are listed with integral cables. The sensor models with the “VP” designation can also be used.

PN 24091-00 PN 24091-01 PN 24091-02 S10240 (SQ 7716 ) S10290 (SQ 7637)

1/4" Fittings - 316 SST; O-ring - Silicone

Bubble shedding nozzle

396P, 389, 3500, 3900

– RB-546

and have a union connection that allows easy removal of

the sensor.

Valved rotameters are also available (see page 41) to

adjust and measure sample flow in sidestream

nstallations. Accurate control of flow is especially

i

important when measuring dissolved oxygen, chlorine,

and ozone.

None Order as a special request only

396P, 389, 3500, 3900

–

Figure 22. PN 24091-00

with 3900VP pH sensor

Figure 23. Low Flow Cell (PN 24091-00,

24091-01 or 24091-02) dimensions

Figure 24. PN S10290

with 400VP sensor

9

Figure 25. Metal Low Flow Cell

(PN S10240 and S10290) dimensions

Page 10

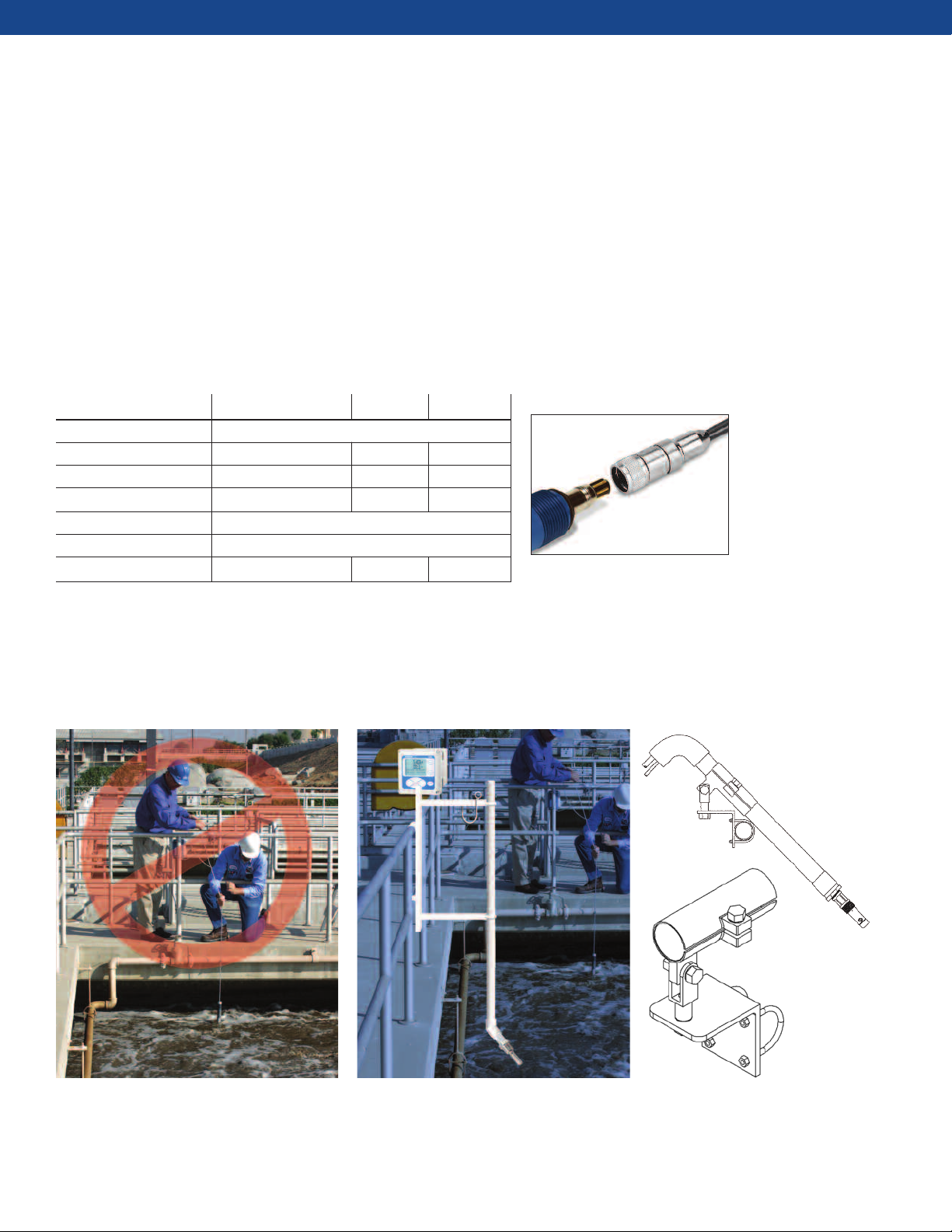

HANDRAIL MOUNTING

Use a handrail mounting assembly whenever a pH, ORP,

or dissolved oxygen sensor must be installed in a tank,

aeration basin, pond, or open channel. Two versions are

available. PN 11275-01 consists of a 13-ft (4.0-m) long

PVC pipe with a 45° bend about two feet (0.6 m) from

the lower end where the sensor is connected. The angle

allows bubbles to slide off the sensor. Clamps attach

the pipe to a frame that can be bolted to a handrail.

Handrail Mounting Assemblies

Part Number 11275-01

Process Connection Mounting brackets for Various Sizes of Handrails

Wetted Materials PVC NA NA

Temperature Rating 140°F (60°C) max. NA NA

Compatible Sensors*

pH and ORP Sensors 396P, 389, 3500, 3900

Dissolved Oxygen Sensors 499ADO**

Optional Accessory

* Note: All sensor models noted in this graph are listed with integral cables. The sensor models with the “VP”

connector can also be used.

* If used with the Handrail Mounting Assembly in a tank, the correct measurement can only be made if there is a

*

continuous flow or movement past the membrane of the sensor. These sensors will not operate properly in

standing liquid.

*** 1 1/2 inch pipe not supplied in these systems.

Jet Spray Cleaner (see pg 13)

HRMS-01

***

HMRS-02

***

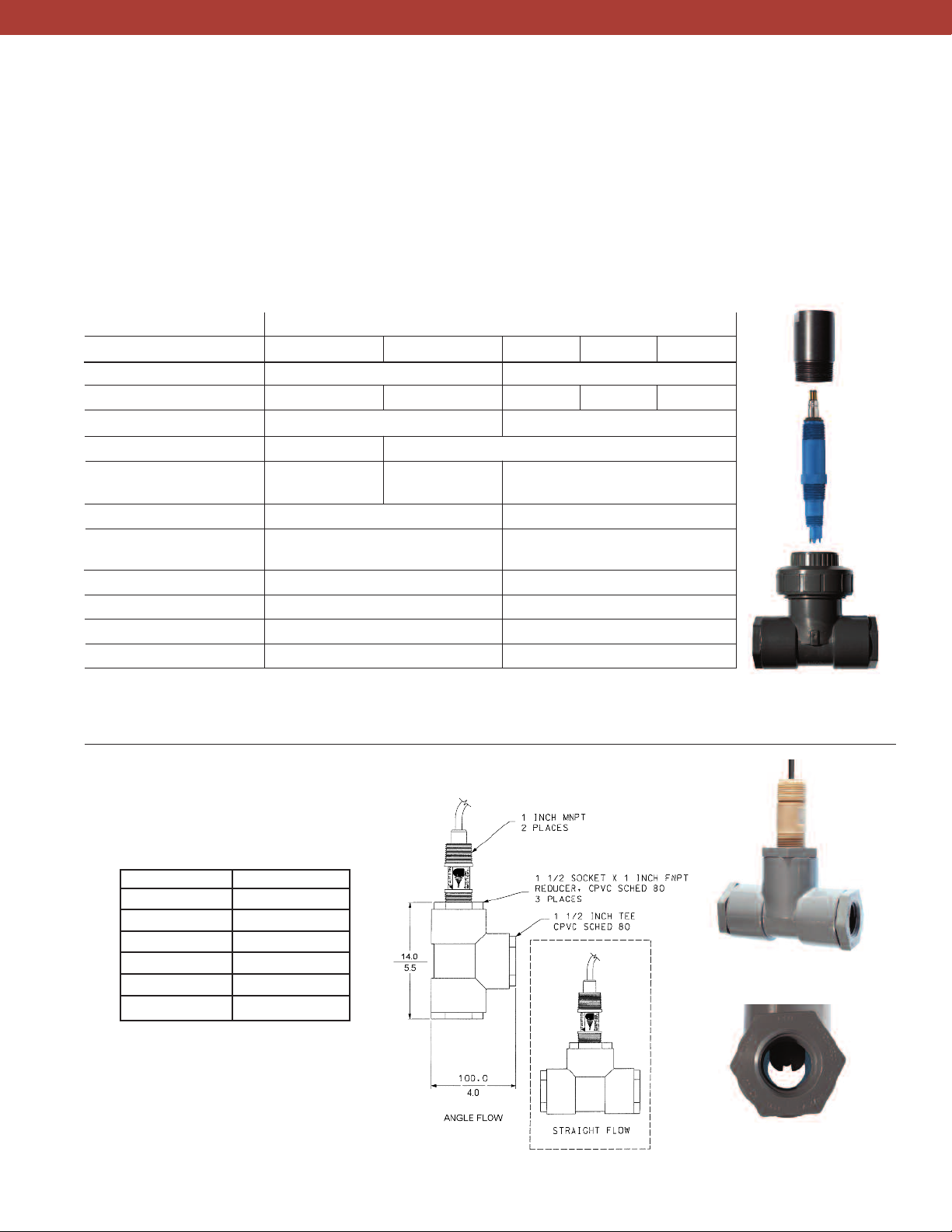

The pipe insertion depth is adjustable. The HRMS

consists of a 1½ inch pipe clamp held by a clevis and

pin assembly, which can be attached to a railing. The

user supplies the 1 ½ inch pipe. The clamp can be

rotated from side to side and up and down and locked

in place once the pipe is in the desired position. The

sensor attaches to the pipe using either a threaded

adapter (HRMS-02) or a union coupling (HRMS-01).

HINT: Using a sensor with a VP connector and

cable will allow for easier access to the sensor

when cleaning or calibration is necessary.

Figure 26. Photo on left shows sensor being dangled into the pond, an incorrect installation. Photo on

right shows correct sensor mounting – sensor is threaded into a pipe conduit while cable is run through the

pipe of the Handrail Mounting Assembly.

10

Figure 27. HRMS-01 shown with usersupplied 1-1/2" pipe (top) and assembled (bottom).

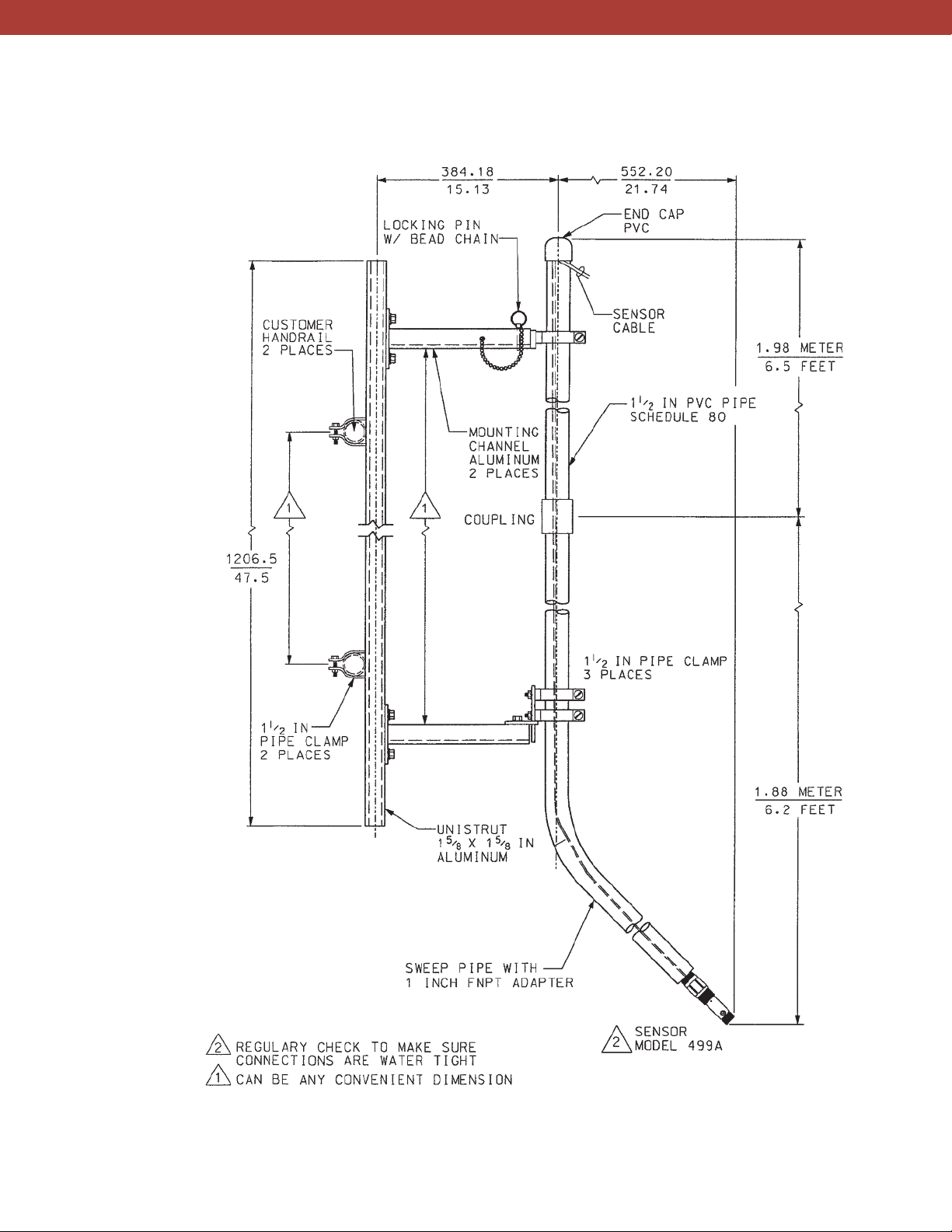

Page 11

HANDRAIL MOUNTING ASSEMBLY

Figure 28. Handrail Mounting Assembly (PN 11275-01) shown with Model 499A Dissolved Oxygen Sensor.

11

Page 12

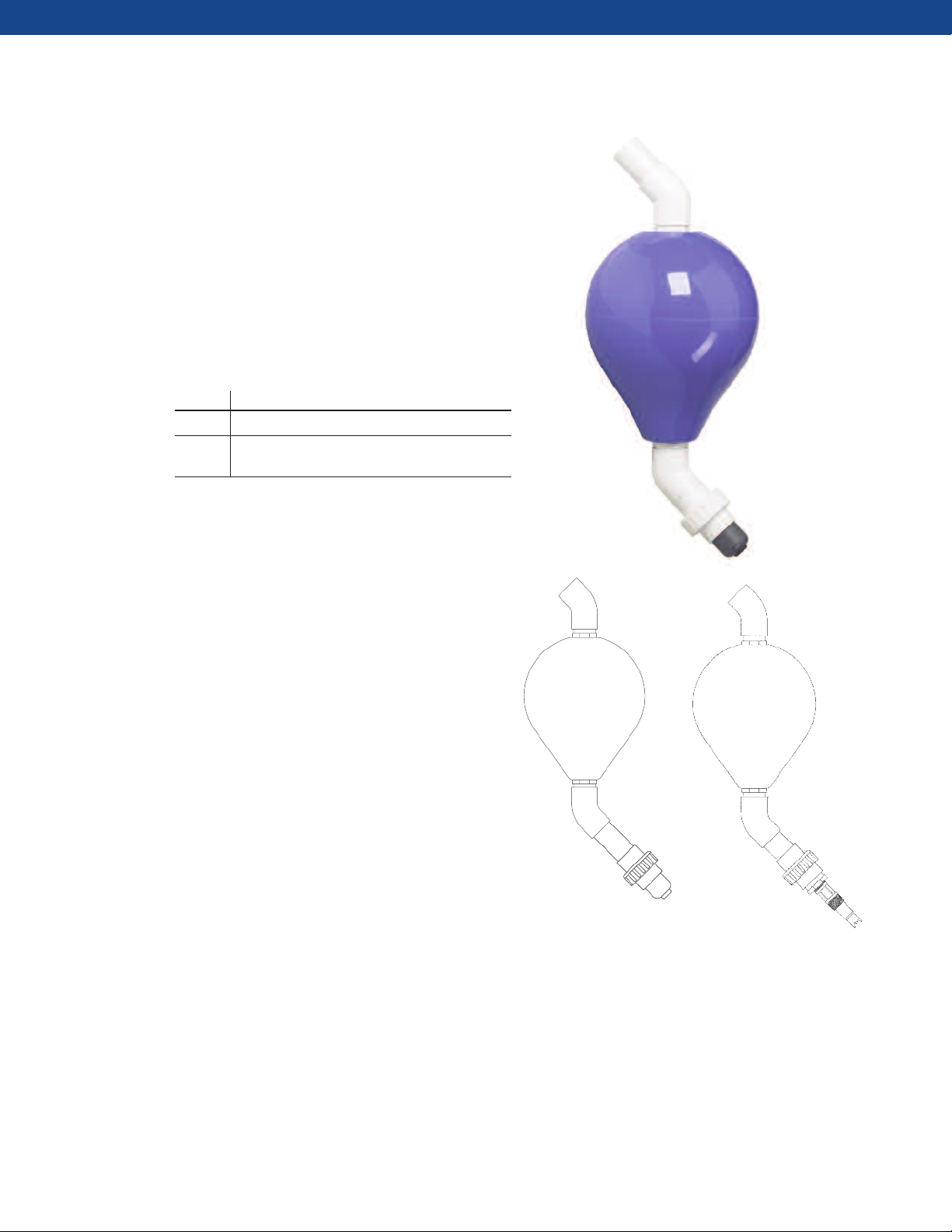

FLOATING BALL SYSTEM

The floating ball system when used with the HRMS

provides a convenient way of keeping the sensor a fixed

distance below the surface of a pond or basin

independent of the water level. The system

accommodates any sensor having 1-inch back facing

threads. The sensor attaches to the bottom of the float

through a union coupling, and the sensor is held a 45°

angle allows air bubbles to side off the sensor. The float

can be readily inflated using a hand pump.

Floating Ball System

Part No. Description

BB11-01 For Model 499ADO; includes sensor union adapter

BB11-03 For any sensor with a 1 inch rear-facing MNPT

connection; includes union adapter

Wetted Material: Flexible PVC, rigid PVC

Temperature Range: 32°F to 140°F (0°C to 60°C)

Size (Diameter x Length): 11 x 13 inches (28 x 33 cm)

Maximum Inflation Pressure: 2.1 psig (0.15 bar)

Maximum Circumference: 34-1/2 inches (88.0 cm)

Buoyancy: 27lbs (12 kg)

Minimum Sensor Insertion Depth Into Process:

BB11-01 with 499ADO sensor: 13 inches (33 cm)

BB11-03 with standard 1 inch sensor: 17 inches (43 cm)

Pipe Boom Support Arm: 1-1/2 inch Sch 80 PVC pipe

(by others)

Sensor Compatibility: 1 inch MNPT on sensor cable end

12

Figure 29. Assembled

Floating Ball BB11-01 for

the 499ADO dissolved

oxygen sensor

Figure 30. Floating Ball and

Sensor with 1 inch Rear Facing

MNPT Connection

Page 13

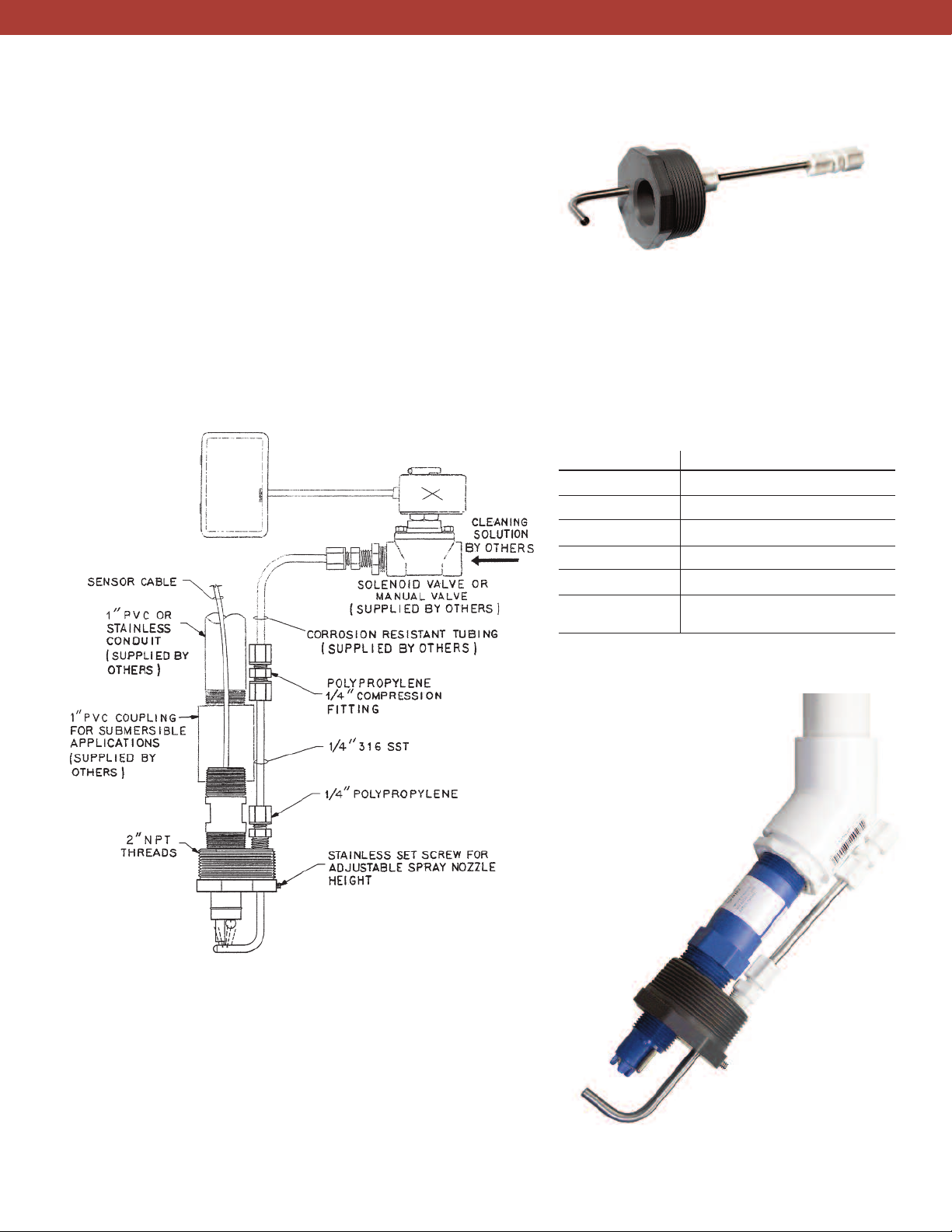

JET SPRAY CLEANER

The jet spray cleaner is intended for use with pH, ORP, or

oxygen sensors. It directs a spray of air, water, or other

cleaning fluid at the end of the sensor flushing away

suspended solids that have accumulated there. The

cleaner can be used only if the sensor is installed in a

tank or basin. It is not suitable for in-pipe installations.

Cleaning frequency and spray duration is controlled by

n interval timer in the analyzer. During cleaning the

a

analyzer can be programmed to hold the last reading,

thus avoiding spurious outputs and relay actions. Hold

can be continued beyond the end of the cleaning

Timer: supplied By

user or uTilize

imer funcTion

T

inside rosemounT

AnAlyTicAl

nsTrumenTs

i

period, allowing the sensor time to stabilize before the

analyzer returns to normal operation.

Cleaning intervals and frequency as well as the best

cleaning agent can be determined only by experience.

Several trials will likely be necessary to determine the

best program.

Jet Spray Cleaner

Part Number 12707-00

Process Connection 2" NPT threads OR use sensor/conduit

Wetted Materials 316 SST, polypropylene, PVC

Maximum Pressure 50 psig (446 Kpa)

Compatible sensors*

pH and ORP 396P, 389, 3900, 3500

Chlorine, dissolved 499ACL, 499ADO, 499AOZ

oxygen, and ozone

*Note: All sensor models noted in this graph are listed with integral

cables. The sensor models with the “VP” designation can also be used.

Figure 31. Example of Jet Spray Cleaner with timer and

solenoid valve for interval timed cleaning

Figure 32. Jet Spray Cleaner shown

with Model 3900 pH sensor using the

front threads to connect to the

cleaner and the back threads to

connect to a watertight pipe conduit

Typical install uses

these threads

13

Page 14

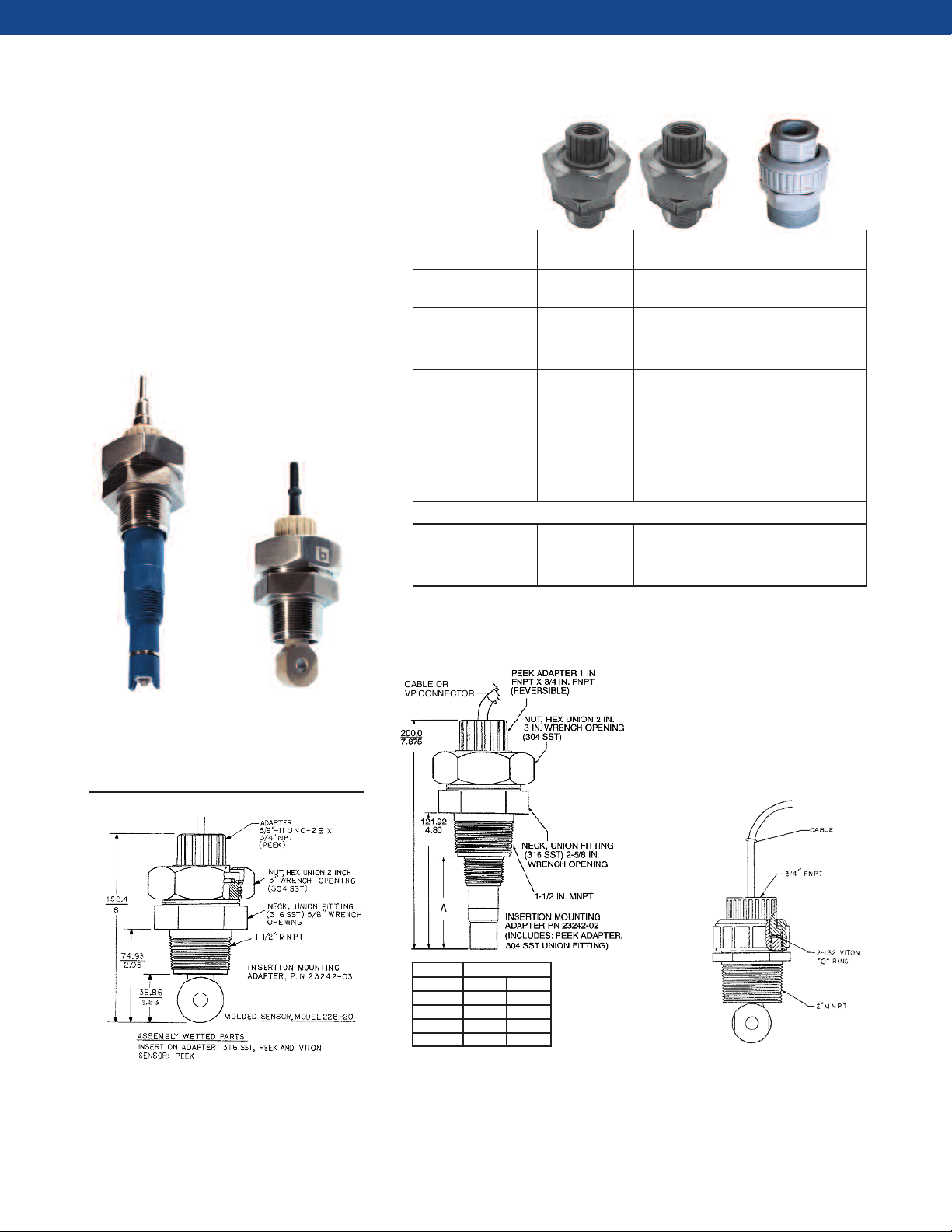

MOUNTING ADAPTERS – THREADED CONNECTIONS

Use these adapters to install sensors

with back facing threads into

process piping or sample tees. The

sensor screws into a plastic adapter

that is held in the process connector

by a union nut. The rear of the

adapter is threaded for a conduit

connection, if required. The union

connection allows the sensor to be

removed without the danger of

twisting and damaging the cable.

Mounting

Adapters

ADAPTER 23242-02 23242-03 2001990

Materials of 316 SST, 316 SST, CPVC, PEEK,

Construction PEEK, Viton PEEK, Viton Viton

Process Connection 1-1/2" MNPT 1-1/2" MNPT 2" MNPT

Sensor Adapter/ 1" x 3/4" FPT 3/4" x 5/8 - 3/4" x 3/4" FPT

Union Thread Size 11 UNC

Temperature, 392F (200C) 392F (200C) 100F(38C) at

Maximum

Pressure, 295 psig 295 psig 100 psig

Maximum (2135 kPa abs) (2135 kPa abs) (791 kPa abs)

Compatible Sensor Models*

pH and ORP 389, 396P

3500, 3900 --

Conductivity 228-21 228-20 228-21

*Note: Most sensor models noted in this graph are listed with integral cables. The

sensor models with the “VP” designation can also be used.

100 psig (791 kPa abs)

OR

185F (85C) at

45 psig (412 kPa abs)

Figure 33. 3500

PERpH-X pH sensor

with adapter

PN 23242-02

Figure 35. The 228 Toroidal Conductivity

Sensor with Adapter PN 23242-03

Figure 34. 228

Toroidal Conductivity

sensor with adapter

PN 23242-02 (or -03)

A “A” Dimension

Sensor* inches mm

396P 3.5 88.9

389 3.75 95.2

3900 4.5 114.3

3500 5.5 139.7

Figure 36. The 396P pH Sensor with Adapter

PN 23242-02. Can also be used for connection

to a 228-21 toroidal conductivity sensor using

the reversible PEEK adapter.

*The VP connector

versions can also

be used.

Figure 37. Adapter

PN 2001990 with 228-21

Toroidal Conductivity sensor

14

Page 15

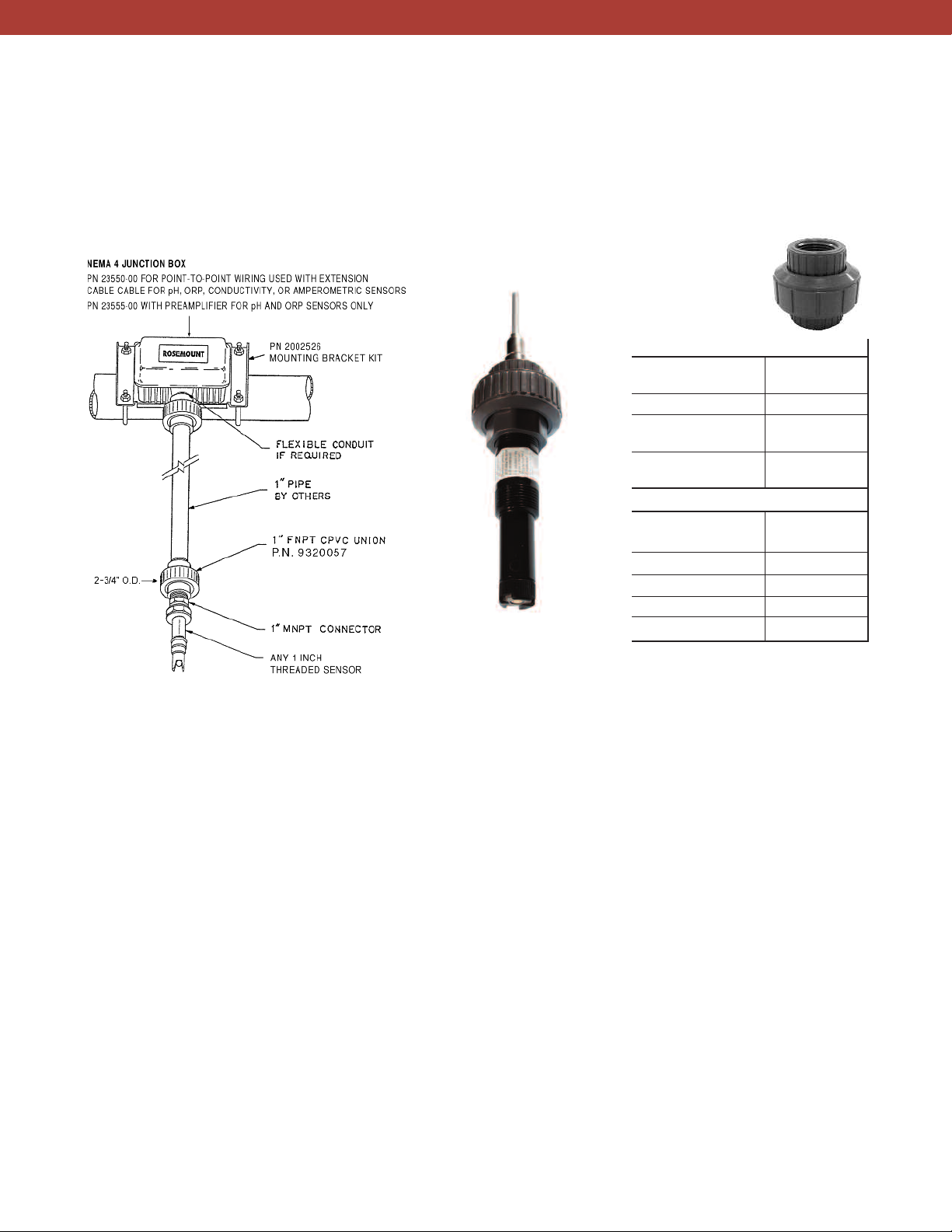

MOUNTING ADAPTERS – SUBMERSION

Use this adapter to connect sensors with 1 inch back

facing threads to standpipes for installation in tanks

and basins.

Figure 38. Example of pipe mounting sensor with mounting

adapter PN 9320057.

Figure 39. 499ADOVP

Dissolved Oxygen Sensor

with adapter PN 9320057

ADAPTER 9320057

Materials of PVC, Sch 80

Construction

Process Connection 1" FNPT

Sensor Adapter/ 1" FNPT

Union Thread Size

Temperature, Ambient

Maximum

Compatible Sensor Models*

pH and ORP 389, 396P,

3500, 3900

Conductivity -

Dissolved Oxygen 499ADO

Ozone 499AOZ

Chlorine 499ACL

*Note: Most sensor models noted in this

graph are listed with integral cables. The

sensor models with the “VP” designation

can also be used.

15

Page 16

MOUNTING ADAPTERS – TRI-CLAMP®CONNECTIONS

Use these adapters to install threaded sensors into 1 ½

inch or 2 inch Tri-Clamp

®

process connections

Mounting Adapters

ADAPTER S10021 (SQ8940) SQP-10098-LQD* SQ 10904A & B

Materials of Construction 316 SST, 16 Ra finish 316 SST 304 SST

Process Connection 1.5" Tri-Clamp 2" Tri-Clamp

Sensor Adapter/Union Thread Size PG 13.5 1" 1" FNPT

Compatible Sensor Models**

pH and ORP 3800, Hx338 385+, 396, 396R, 398R, 389, 396P, 3500, 3900

TF396, 398, 3300HT, 3400HT

Conductivity –– –

Dissolved Oxygen Hx438 ––

* Formerly PN 23513-00

**Note: Most sensor models noted in this graph are listed with integral cables.

The sensor models with the “VP” connection can also be used.

2" (A) or 1.5" (B) Tri-Clamp

Figure 40. SQ10904 1.5" Tri-Clamp

adapter (bottom) and 2" adapter (top)

Figure 41. 396P TUpH sensors shown with

1 inch threaded, 1.5 and 2 inch Tri-Clamp

adapters

Figure 42. PN SQP-10098-LQD Compression fitting with

Tri-Clamp Flange shown on TF396 sensor

16

Page 17

PROCESS CONNECTORS FOR 1 INCH SENSOR TUBES

Certain models of pH and ORP sensors lack threads and

must be installed in the process piping using one of the

fittings shown below. The sensor slides into the fitting,

and a nut and ferrule tightened against the sensor tube

holds the sensor in place. The insertion depth is

adjustable. A collar on the tube prevents the sensor from

being ejected by the process pressure if the nut is not

sufficiently tightened. The fittings are available with 1-in

MPT and 2-in Tri-Clamp process connections. To prevent

the sensor from turning and twisting the cable while a

threaded fitting is being installed or removed, loosen the

nut to free the sensor.

Process Connectors

ADAPTER PN 23166-00 PN 23166-01 PN 9510066 SQP-10098-LQD**

Materials of Construction 316 Stainless Steel Titanium Nylon 316 Stainless Steel

O-Ring Material EPDM EPDM Polyethylene Viton

Process Connection 1" MNPT 1" MNPT 1" MNPT 2" Tri-Clamp

Sensor Tube OD 1" (25.4 mm) 1" (25.4 mm) 1" (25.4 mm) 1" (25.4 mm)

Compatible pH and 385+, 396, 398, 396R, 385+, 396, 398, 396R, 396, 398, 3300HT 385+, 396, TF396, 398,

ORP Sensors 398R, 3300HT, 3400HT 398R, 3300HT, 3400HT

*Note: Most sensor models noted in this graph are listed with integral cables. The sensor models with the “VP” designation can also be used.

**Formerly PN 23513-00

396R, 398R, 3300HT, 3400HT

17

Page 18

PROCESS CONNECTORS FOR 1 INCH SENSOR TUBES

Figure 43. Metal process connector (PN 23166-00 [316 SST] or PN 23166-01 [titanium]) shown with

TUpH Model 396 pH sensor. This process connector can be used for all 396, 398, and 3300HT sensor

installations. Also, it must be used for 396R, 398R, and 3400HT installations with or without a ball valve. See

ball valve section for more information.

Figure 44. The 23166-00 (or -01) metal

process connector, shown with the

3300HT PERpH-X sensor, allows various

insertions depths, depending on where

the user locates the compression fitting.

Also the threads can be switched to face

the top end of the sensor (right) for

connection to submersion pipes.

Figure 45. Nylon Process Connector PN 9150066 can be

installed with threads facing up or down. NOTE: This

connector should be used for low pressure, non-aggressive

chemical processes only.

Figure 46. 398 TUpH pH

Sensor with SQP-10098LQD Tri-Clamp flange

adapter

18

Figure 47. PN SQP-10098-LQD Compression fitting

with Tri-Clamp Flange shown here with TF396. Can

also be used with the 396, 398, and 3300HT sensors.

Page 19

RETRACTION ASSEMBLIES

Retraction assemblies allow a pH, ORP, or conductivity

sensor (both contacting and toroidal) to be inserted or

removed from a vessel or pipe without the need for

depressurizing or draining it. Insertion depth is

adjustable. Five retraction assemblies are available. Two

S

e

nsor

M

o

d

e

l

N

um

b

ME

A

S

UR

E

T

Y

PE

p

H

a

nd

O

R

Conductivit

MEN

P

y

T

385+, 396, 396P

228, 402

e

, 396R, 398, 398R, 3300HT

include the ball valve needed to close off the process

line before the sensor is removed. Two require the ball

valve to be purchased separately. The fifth assembly is a

rotary retraction valve.

r

s

, 3400HT

See following pages for retractable mounting options.

19

Page 20

RETRACTION ASSEMBLIES – BALL VALVE INCLUDED

Two retraction assemblies are available. PN 23240-00

has a 1 ½ inch full port ball valve and PN 23765-00 has a

1 ¼ inch ball valve. Both assemblies can be used with

the pH sensors listed in the table below. Model 402 and

402VP sensors can be used only with PN 23765-00.

PN 23765-00 includes a retraction chamber, 1 ¼ inch

ball valve, and close nipple for attaching the retraction

Ball Valve

Kits

1 1/2 in. Ball Valve Kit 1 1/4 in. Ball Valve Kit

Process Connections 1 1/2" FNPT 1 1/4" MNPT

Wetted Materials 316 SST 316 SST

Temperature Rating 32-212°F(0-100°C) 32-212°F(0-100°C)

Pressure Rating 100 psig (790 kPa) 200 psig (1481 kPa)

Maximum Retraction For 21 inch pH sensors: 64 psig (542 kPa)

Pressure 64 psig (542 kPa)

For 36 inch pH sensors:

35 psig (343 kPa)

Compatible

Sensor Models*

pH and ORP 396R, 398R, 385, 385+, 3400HT, RB-547

Conductivity – 402

Other information Use PN 23166-00 or -01 If ball valve is already

sensor to ball valve.** alone is available (PN 23796-00)

Use 1-1/2" close nipple (PN 93101-02)

to attach ball valve to FTP

process connection.

assembly to an FPT process connection. PN 23240-00

includes only the ball valve and retraction chamber. A

fitting (PN 23166-00 or 23166-01) is required to

connect the sensor to the retraction chamber, and a 1 ½

inch close nipple (PN 9310102) is needed to attach the

ball valve to a FPT process connection.

PN 23240-00 PN 23765-00

to connect available, the retraction assembly

* All sensor models noted in this graph are listed with integral cables. The sensor models with the

“VP” connector can also be used.

**Process connector is included with the 385 and 385+ sensors

Short insertion

Long insertion

Figure 48. Retractable sensors have the distinct advantage of having an adjustable

insertion depth. Sensor tubes can be installed with a short (top photo) or a longer

(bottom) insertion. See sensor model information for more about sensor tube lengths.

20

Page 21

RETRACTION ASSEMBLIES – BALL VALVE INCLUDED

pH sensors should be mounted at

least 10 degrees above horizontal

Conductivity sensors

should be mounted

between 0 and -30

degrees from the

horizontal

Figure 49. Examples of sensor mounting using a ball valve

retraction kit connected to a standard pipe tee, pipe “Y”, or

pipe weldolet.

To retract a sensor:

1) Loosen the retraction chamber or process connector

nut.

2) Slide the sensor into the retraction chamber. The

stop collar on the sensor prevents the sensor from

sliding out of the retraction chamber.

0

0

-

5

6

7

3

2

PN

Kit

lve

Va

ll

a

B

¼”

1

Figure 50. Observe the above mounting angles to obtain

best measuring results.

3) Close the ball valve.

4) Remove the process connector or retraction

chamber and sensor from the ball valve.

1.

” Ball Valve Kit PN 23240-00

½

1

Figure 51. Follow these four steps to easily remove the sensor from a pressurized system.

2

sensor out of process

e

Slid

.

retraction chamber

to

in

Close ball valve

3 .

4 .

t

u

n

n

Loose

21

Remove retraction

chamber plus sensor

Sensor stop collar

Page 22

RETRACTION ASSEMBLIES – BALL VALVE INCLUDED

BASENSOR TUBE

mm/in mm/in

LENGTH

327.7/12.9 586.2/23.1 21 in.

660.0/27.4 954.5/37.58 36 in.

Figure 52. 1½ in. FNPT Ball Valve Kit (PN 23240-00) shown with process connector (sold separately) and TUpH Model 396R

pH sensor. Ball valve kit includes a 1½ in. full port ball valve, a 1½ in. FTP to 1 in. FTP reducer (which serves as the retraction

chamber) and a 1½ in. close nipple that connects the reducer to the ball valve. A connector (PN 23166-00 or 23166-01) is required

to connect sensor to the reducer.

ro

P

PN

o

(s

q

re

sens

va

c

1

0

-

r

o

0

0

-

6

6

1

3

2

epar

s

ld

d

e

ir

u

r tub

o

it .

e k

lv

t

a

o

e to

tel

co

is

)

y

ct

e

n

n

the bal

e

th

l

Ball valve kit PN 23240-00 includes

1

inch ball valve, a close nipple

⁄2

a 1

o connect the reducer to the ball

t

1

lo

h c

inc

2

⁄

1

lu

inc

(not

ble fo

a

l

vai

a

an M

the 1

co

T

P

N

1

inch FNPT threads.

2

⁄

pple PN

e ni

s

ded in ball val

io

at

all

inst

r

n to

io

nnect

9310102

) is

e kit

v

ns requirin

e to

at

m

g

r

o

ct

e

n

n

Co

s

es

valve. The reducer is also the

retraction chamber.

Figure 53. Ball valve kit PN 23240-00 with other accessories (sold separately).

22

Page 23

RETRACTION ASSEMBLIES – BALL VALVE INCLUDED

Figure 54. 1¼ in. MNPT Ball Valve Kit (PN 23765-00 or 23765-01) shown with retraction kit and Endurance Model 402

conductivity sensor. Ball valve kit includes a 1¼ in. full port ball valve, a 1¼ in. nipple, and a retraction chamber.

Model A Dimensions B Dimensions C Dimensions

Minimum* Maximum

inches mm inches mm inches mm inches mm

402-11 3.21 82 5.34 136 18.13 460.5 1.19 30.2

402-12 2.34 59 4.47 114 17.33 440.2 1.19 30.2

402-13 2.36 60 4.49 114 17.33 440.2 1.19 30.2

402-14 3.89 99 4.91 125 18.83 478.3 1.19 30.2

396R-21 2.0 50.8 12.12 307.85 21 533.4 1.0 25.4

398R-21 2.0 50.8 12.12 307.85 21 533.4 1.0 25.4

3400HT-21 2.0 50.8 12.12 307.85 21 533.4 1.0 25.4

396R-25 2.0 50.8 26.62 676.15 36 914.4 1.0 25.4

398R-25 2.0 50.8 26.62 676.15 36 914.4 1.0 25.4

3400HT-25 2.0 50.8 26.62 676.15 36 914.4 1.0 25.4

*Minimum dimension must be met in order for sensor to measure correctly

Retraction

Chamber

1

" Full port ball valve

4

⁄

1

1

" nipple

4

⁄

1

Figure 55. The ball valve kit (PN 23765-00 or -01) has all parts needed to install the sensor. The retraction chamber

(PN 23796-00) can be purchased separately.

23

Page 24

RETRACTION ASSEMBLIES (BALL VALVES NOT INCLUDED)

These retraction assemblies are primarily intended for

use with Model 228 toroidal conductivity sensors.

owever, they can be modified for use with certain pH

H

and contacting conductivity sensors. Consult the

factory for information.

A mechanical (PN 23311-00) and manual (PN 23311-

01) retraction assembly are available. The mechanical

Shown with Model

28 Toroidal Sensor

2

retraction assembly, which uses a drive screw to insert

and retract the sensor, can be operated against a

ressure as high as 295 psig (2036 kPa abs). Both

p

retraction assemblies are fitted with 1/8" flush ports on

the retraction chamber to allow the sensor to be

ashed clean of sample before it is removed. Both

w

assemblies were designed to be used with a 1-1/2" full

port ball valve (purchased separately – PN 9340065).

hown with Model

S

228 Toroidal Sensor

PART NUMBER 23311-00 PART NUMBER 23311-01

Mechanical Retraction Assembly Manual Retraction Assembly

Process Connection 1.5" MNPT 1.5" MNPT

Wetted Materials 316 SST, Teflon, EP 316 SST, Teflon, EP

Maximum Operating Temperature 392°F (200°C) 392°F (200°C)

Maximum Operating Pressure 295 psig (2036 kPa) 295 psig (2036 kPa)

Max. Insertion/Retraction Conditions 392°F (200°C) 266°F (130°C)

295 psig (2036 kPa) 35 psig (241 kPa)

Maximum Insertion Travel 8.5" (21.6 cm) 12" (30 cm)

Maximum Insertion Travel 6.25" (15.9 cm) 7.0" (17.8 cm)

using PN 9340065 Ball Valve

Compatible Toroidal Model 228 Model 228

Conductivity Sensors

Compatible Contacting Consult factory for information Consult factory for information

Conductivity Sensors

Compatible pH & ORP Sensors Consult factory for information Consult factory for information

24

Page 25

RETRACTION ASSEMBLIES (BALL VALVES NOT INCLUDED)

Figure 56. Mechanical Retraction/Insertion Assembly

(PN 23311-00). To remove the sensor, use a socket

wrench to turn the drive screw until the sensor is inside

the retraction chamber. Close the ball valve (not shown)

and flush the retraction chamber. Loosen the hex union

nut. Remove the stop collar and the front half of the

guide clamp. Remove the sensor.

25

Figure 57. Manual Retraction/Insertion Assembly

(PN 23311-01). To remove the sensor, loosen the

collet nut and pull the sensor into the retraction

chamber. Close the ball valve (not shown) and flush

the chamber. Loosen the hex union nut and remove

the sensor.

Page 26

PASVE ROTARY RETRACTION VALVE

The PASVE is a mounting/service valve for pH sensors. It

allows the cleaning and calibration of pH sensors

without stopping the process. When required, this can

be done automatically.

hen using the sensor in abrasive processes, it can be

W

rotated to the measuring position only for the duration

of the actual measurement.

The PASVE valve is available in a manually operated type

or equipped with a pneumatic or electric actuator. It is

offered in a version for welding directly onto the pipe or

tank. It is also available with flanged connections.

Contact factory for more details.

Figure 58. PASVE valve, shown in welded on tank, manual

operation configuration

PASVE Specifications

Process Connections Code B: Welded on Tank at 15° angle

Code C: Welded on Tank

Code P: Welded on Pipe

Code F: Flange

Code D: Flow through with flanged connection

Wetted Materials (Valve) AISI 316LSST or Titanium

Wetted Materials (Seals) PTFE (Teflon) or PTFE (With carbon graphite filling)

Maximum Operating 482°F (250°C)

Temperature

Maximum Operating Pressure 570 psig (4000 kPa)

Cleaning Port Connections ¼ inch

Compatible pH Sensors 396, 396P, 389, 398, and 3300HT (with SQ9608)

385+, 396PVP, 3300HTVP (SQ 9608) and no others

26

Page 27

PASVE ROTARY RETRACTION VALVE

Figure 59. Operating PASVE Measuring Position Figure 60. Operating PASVE Servicing and Calibration

Position

Figure 61. Pasve valve with spring return, double action,

and pneumatic (left) or electric (right) actuator

Flush ports to connect cleaning liquid

or air to spray directly onto the sensor.

Spray tube from cleaning port.

Sensing end of the pH sensor.

Figure 63. PASVE Example of Flush Water Set-Up

Figure 62. Close-up of PASVE valve

with cleaning ports

27

Page 28

INSTRUMENT MOUNTING

The instrument mounting accessories found in this

section include instrument mounting kits for pipe or

wall mounting. These can be used with the following

Rosemount Analytical Instruments:

TWO-WIRE INSTRUMENTS

5081 Transmitter

Features a rugged, weatherproof,

corrosion-resistant enclosure.

> Meets NEMA 7B explosion proof

standards.

> Digital communication protocols:

®

HART

and FOUNDATION®fieldbus, allowing access to

AMS (Asset Management Systems)

1066

Tr

ansmit

Br

oad

r

ange

a

dv

anced

c

ap

a

b

i

lity,

>

U

ses

HA

F

O

UN

DA

T

comm

unic

>

U

se

r-

defina

WIRELESS INSTRUMENTATION

6081

Remote locations and installation

costs are no longer barriers to getting

information you require for critical

applications.

> 6081-C measures conductivity

> 6081-P measures pH

> Self-organizing network for

high data reliability and

network stability

> Industry leading wireless

security

of

comm

and

R

T

ve

IO

N

fie

ation

ble

te

mea

unic

uni

rs

ldbus

mea

que

io

pr

r

s

ur

ations

n

7

o

s

e

me

ea

se-

and

di

gital

tocols

ur

e

nts

me

F

OUR-WI

5

6

>

H

c

p

>

E

>

P

t

> Pr

to a

,

of

-

use

.

.

nt

dia

gnos

tic

p

ar

amet

e

> Pr

De

> T

Wid

1056

>

Sin

rs

.

>

L

allo

g

allo

>

E

1057

>

T

>

C

Contacting Conductivity/

Resistivity, in any combination.

A

n

ig

h

o

lo

a

r

a

x

t

e

r

o

c

r

e

n

ocess

op

r

ivat

P

C (Du

g

a

rg

w

l

ance

wable

a

s

y to ins

hr

e

hoo

a

ly

r

eso

r

f

o

r

met

n

s

iv

e

ess

d

din

g

d

USB d

or

t

ional,

ive

t

t

h Mod

A

n

aly

le

or

e,

e

a

s

op

if

A

n

aly

e-in

se

f

R

E

ze

r

lu

imme

e

r

.

h

e

is

r

g

r

aphs

ata c

r

ive.

(PID

y Cy

zer

d

ual in

s

y

-to-r

e

r

t

he

par

tall an

zer

pu

t

r

om p

I

t

io

lp

u

ul

ators

pr

a

NS

T

R

UM

n

sc

r

e

e

n

d

i

a

t

e

r

e

sc

r

e

e

n

s

p

t

io

n

s

c

a

n

.

an b

e

do

Inte

g

r

a

l an

) c

ont

r

ol.

cle

C

ont

r

ol/Pulse

a

t

ion).

pu

t

ana

e

ad

displ

kno

w

ocess

is

amete

rs

.

d

w

ir

e.

naly

ze

r.

H/ORP/ISE or

c

f

w

at

w

E

s

h

o

o

b

ly

NT

o

w

g

n

it

r

r

a

e

p

nload

d

ze

r.

a

y

a

it

hin

S

s

fa

u

lt

s

a

n

d

w

a

r

n

in

g

s

in

io

n

o

f

a

n

o

u

t

o

f

r

a

n

g

e

p

id

s

ta

r

t

u

p.

in

p

o

int

e

d

in

t

h

e

c

o

lo

r

e

d

28

Page 29

INSTRUMENT MOUNTING ACCESSORIES

R

os

e

m

o

u

n

t

A

na

l

y

ti

c

a

l

in

s

tru

m

e

n

ts

c

a

n

b

e

m

o

p

i

p

e,

in

a

p

a

n

e

l

,

or

on

a

w

a

ll

u

s

in

g

the

v

a

r

i

o

u

s

m

o

u

n

tin

g

a

c

c

e

s

s

or

i

e

s

.

T

he

s

e

k

its

c

on

t

a

in

a

ll

p

n

eed

ed

for

a

s

u

c

c

e

s

s

f

u

l

in

s

tru

m

e

n

t

in

s

t

a

ll

a

ti

on

Mounting part 23820-00 23820-01

Bracket Carbon Steel, blue epoxy coating 316 SST

Bracket Dimensions 7.5" x 4.0" x 1.2"

U-Bolt SST

U-Bolt Dimensions for 2" pipe maximum

Screws and washers SST

Compatible Instruments 56, 1056, 1057, 1066, 5081, 6081

u

n

t

ed

v

e

rsa

ti

a

r

ts

.

PN 23820-00 and 23820-01 are Mounting Bracket Kits

on

a

for Pipe, Surface or Wall Mounting. Kit includes one

le

bracket and two u-bolts with washers and screws. Use

for mounting Rosemount 56, 1056, 1057, 1066, 5081,

and 6081 instruments.

Figure 64. These two graphics are examples of pipe or wall mounting a 6081 instrument using

either of the mounting bracket kits. On the left is an example of the instrument mounting onto a

pipe. On the right, the instrument uses the kit to mount onto a wall. Other Rosemount Analytical

instruments can be mounted similarly.

29

Page 30

INSTRUMENT MOUNTING ACCESSORIES

165

6.5

130

5.1

33.5

1.3

232

9.1

2 INCH PI PE SUPPLIED

BY CUSTOMER

SIDE VIEW

0.85”

22 mm

4.0”

102 mm

1.2”

30.5 mm

1.2”

30.5 mm

0.85”

22 mm

3.0”

76 mm

6.5”

1

65 mm

2

.8”

7

1 mm

3.0”

76 mm

Figure 65. 5081 pipe mounted with the

PN 23820-01 SST Kit.

Figure 67. 1056 shown mounted on a pipe using either pipe

mount kit, side view.

30

Figure 66. Dimensions of the mounting bracket found in

kits PN 23820-00 and 23820-01

Figure 68. The 1056 is shown mounted on a wall/surface

using either pipe mount kit, side view.

Page 31

WIRING ACCESSORIES

This section features junction boxes and cables compatible with

Rosemount Analytical sensors and instruments.

Cable Extensions through Junction Boxes

Use a junction box when the analyzer must be installed

urther from the sensor than the standard cable length

f

allows. To replace the sensor, disconnect the cable at

the junction box. The cable between the junction box

and the analyzer never needs to be disturbed.

> The distances between the sensor and instrument are

recommendations only.

> Long cable distances may degrade the signal; for best

performance, install long cable runs in a noise-free

environment.

> For contacting conductivity sensors, long cable runs

will result in some loss of linearity.

> Consider an Emerson Wireless solution instead.

Mount the analyzer within standard cable length of

the sensor and send the signal wirelessly to the

control room. Emerson offers wireless pH and conductivity instruments as well as the THUM, which

converts any Rosemount Analytical HART instrument

into a wireless device. All wireless instruments require

a Model 1420 Gateway to receive the signal.

Best Practice Tip

The best practice for extended distances are recommended below to assist with the easiest sensor replacement. Follow this guideline when installing sensors at a

long distance from the instrument:

1. Install the junction box closest to the sensor.

2. Use an extension cable to run the signal from the

junction box to the instrument. The use of factory

prepared cable is strongly recommended. The cables

designated as “prepped” are prepared with the cable

jacket and all of the wires stripped and ready for a

quick installation.

3. Distances between the sensor and instrument are

cumulative and include the sensor cable plus the

extension cable. For instance, if the maximum cable

required is 200 ft (61.0 m) and the sensor cable is 15

ft (4.6 m), the extension cable maximum length is

185 ft (56.4m).

Chlorine, Dissolved Oxygen, and Ozone Sensors

Sensor to Analyzer Separation Distances

Sensor Cable Length

Measurement Sensor Standard Junction Box Prepped Unprepped

Dissolved Oxygen 499ADO 25 ft (7.6m) 200 ft (61.0m) 23550-00 23747-00 9200275

Chlorine 498CL or 499ACL 25 ft (7.6m) 200 ft (61.0m) 23550-00 23747-00 9200275

Ozone 499AOZ 25 ft (7.6m) 200 ft (61.0m) 23550-00 23747-00 9200275

Chlorine, Dissolved

Oxygen or Ozone

Sensor

Standard sensor

cable or VP cable

(50 ft (15m) max)

Maximum recommended distance between sensor and instrument is 200 ft (61.0m)

Recommended maximum distance

between sensor and instrument*

Junction box

PN 23550-00

31

Extension cable

Extension Cable

Analyzer

Page 32

WIRING ACCESSORIES

Conductivity Sensors

Sensor to Analyzer Separation Distances

Sensor Cable Length

Recommended

maximum distance

etween sensor and

Measurement Sensor Standard Optional Junction Box Prepped Unprepped

b

instrument*

140, 141, 142 No Cable; use extension cable 200 ft (61.0m) Included 23747-00 9200275

Contacting 150 10 ft (3.1m) 200 ft (61.0m) 23550-00 23747-00 9200275

Conductivity 400, 401, 403, 404 10 ft (3.1m) 50 ft (15.2m) 200 ft (61.0m) 23550-00 23747-00 9200275

402 10 ft (3.1 m) 200 ft (61.0m) Included 23747-00 9200275

225, 226, 228 20 ft (6.1m) 200 ft (61.0m) 23550-00 23294-04 9200276

Toroidal 222 20 ft (6.1m) 100 ft (30.5m) 23550-00 23294-04 9200276

Conductivity 242, 245 Use extension 200 ft (61.0m) Included 23909-00

(flow through) cable

Extension Cable

Contacting

Conductivity

Sensors

Toroidal

Conductivity

Sensors

Standard sensor

cable or VP cable

(50 ft (15m) max)

J

unctio

P

N

n

23550-

b

o

x

00

Extension cable

Maximum recommended distance between sensor and instrument is 200 ft (61.0m)

Standard sensor

cable or VP cable

(50 ft (15m) max)

Junction box

PN 23550-00

Extension cable

Maximum recommended distance between sensor and instrument is 100 ft (30.5m) to 200 ft

(61.0m) depending on the sensor model. See chart for more information.

Analyzer

Contacting or Toroidal

Conductivity Sensors with

sensor mounted junction box

Maximum recommended distance between sensor and instrument is 200 ft (61.0m)

Extension cable

32

Page 33

WIRING ACCESSORIES

pH and ORP Sensors

Sensor to Analyzer Separation Distances

Sensor Cable Length

Recommended

maximum distance

etween sensor and

Measurement Sensor Standard Optional Junction Box Prepped Unprepped

b

instrument*

No preamp 15 ft (4.6m) 200 ft (61.0m) 23555-00 23646-01 9200273

pH Sensors in the sensor (contains preamp)

Preamp in the sensor 25 ft (7.6m) 200 ft (61.0m) 23550-00 23646-01 9200273

Preamplifier in Sensor No Cable; 200 ft (61.0m) - 23646-01 9200273

Mounted Junction Box use extension cable

pH or ORP Sensor NON preamplified

version

Extension Cable

pH or ORP Sensor with

integral preamplifier

pH or ORP Sensor with

integral preamplifier

Standard sensor

cable or VP cable

(50 ft (15m) max)

Junction box PN 23555-00

WITH preamplifier

Extension cable

Maximum recommended distance between sensor and instrument is 200 ft (61.0m)

Standard sensor

cable or VP cable

(50 ft (15m) max)

Junction box PN 23550-00

with extension board

Extension cable

Maximum recommended distance between sensor and instrument is 200 ft (61.0m)

Extension cable

Maximum recommended distance between sensor and instrument is 200 ft (61.0m)

33

Page 34

REMOTE JUNCTION BOXES

Use remote junction boxes to extend the sensor cable

for longer runs. Two captive screws allow easy access to

the board inside the box. There are two ports for cable;

the bottom port is for the sensor cable and the side port

is for the extension cable. These weatherproof junction

boxes are also ideal for indoor mounting.

> PN 23550-00 can be used to extend the cable of

lmost any Rosemount Analytical sensor. The terminal

a

board allows point-to-point wiring between the

sensor and extension cable.

> PN 23555-00 has an integral preamplifier (PN 23557-

00) and is used for pH and ORP sensors only. The

preamplifier has FM, CSA and ATEX approval for use in

hazardous locations. Any non-preamplified

Rosemount Analytical pH or ORP sensor can be used

with this junction box. The preamplified signal is

compatible with Rosemount Analytical 56, 1056,

1057, 1066, 5081, and 6081 instruments.

> Both junction boxes have identical dimensions.

Figure 69. Junction Box PN 23550-00.

Figure 70. Junction Box PN 23550-00 is used for extending

any Rosemount Analytical sensor’s cable by connecting the

sensor cable to an internal extension board. Extension cable

sold separately.

Figure 71. Junction Box PN 23555-00 is used for pH and ORP

sensors only. A preamplifier board is mounted internally.

Figure 72. Junction Box PN 23555-00 dimensions.

Junction Box PN 23550-00 has identical dimensions.

34

Page 35

MOUNTING BRACKET FOR REMOTE JUNCTION BOXES

Remote mount junction boxes can be mounted on a

wall or pipe using the Mounting Bracket PN 2002526.

Mounting Bracket Specifications

Mounting part 2002526

U-Bolt SST

U-Bolt Dimensions for 2" pipe maximum

Screws and washers SST

Compatible Junction Boxes 23550-00 and 23555-00

SENSOR HEAD JUNCTION BOX

Sensor Head Junction box PN 23709-00 is for use with

all Rosemount Analytical retractable style pH and ORP

sensors. It is mounted on the back end of the sensor

using a compression fitting. The junction box contains

an integral preamplifier (PN 23557-00) and has terminals to connect an extension cable (sold separately)

directly to an instrument.

11.5 inches

292 mm

.4 inches

4

—————

—

12 mm

1

> Dimensions: 5"D x 5

3

⁄8" H x 4"W

> Materials: Aluminum Alloy

> Preamplifier: FM, CSA, ATEX

> Compatible Sensors: 396R, 398R, 3400HT and RB547

35

Figure 72. Sesor Head Junction Box PN PN 23709-00.

Page 36

VP CONNECTOR CABLES, EXTENSION CABLES, AND CABLE GLANDS

Rosemount Analytical offers various extension and

connector cables for the best EMI protection in the

industry. VP connector cables are used with sensors

VP Connector Cables

pH and ORP Sensor Cables

The VP8 connector cable is compatible with the

following sensors: 3300HTVP, 3400HTVP, 3500VP,

3900VP, 389VP, 396VP, 396PVP, 396RVP, 398VP,

398RVP, HX338, 3800VP.

Part Number VP8 Cable for pH & ORP sensors

Feet Meters

24281-02 2.5 0.8

24281-05 4 1.2

24281-06 10 3.0

24281-00 15 5

24281-07 20 6.1

24281-01 25 7.6

24281-08 30 9.1

24281-03 50 15.2

24281-04 100 30.5

having VP quick disconnect fittings. Extension cables are

used with sensor mounted or remote junction boxes.

Follow this simple guide to select the appropriate cable.

The VP8 Cable PN 24281-XX is a 6 conductor cable with

1 coax and 3 shields.

Jacket Material: PVC

Jacket Maximum Diameter: 0.31 inches

Temperature Range: -40C to 105C; sunlight resistant

Figure 73. VP8 connector cables (bottom) can be used with

all pH and ORP sensors with a VP designation. 3500VP (top)

and 396PVP shown.

Conductivity, DO, OZ, and Chlorine Sensor Cables

VP6 cable PN 23747-XX is compatible with the following

sensors: 400VP, 402 VP, 403VP, 499ACL-VP, 499ADO-VP,

400ATrDO-VP, and 499AOZ-VP. For 410VP (four-electrode

contacting sensor) use PN 24287-00 or -01.

VP6 Cable

for conductivity,

dissolved oxygen, ozone

& chlorine sensors

Part Number Feet Meters

23747-02 10 3.0

23747-03 50 15.2

23747-04 4 1.2

23747-05 2.25 0.7

23747-06 2.5 0.8

23747-07 15 4.6

23747-08 20 6.1

23747-09 25 7.6

23747-10 30 9.1

23747-11 100 30.5

24287-00 10 3.0

24287-01 20 15.2

The VP6 Cable PN 23747-XX is a 3 conductor cable with

2 coax and 3 shields.

Jacket Material: PVC

Jacket Maximum Diameter: 0.31 inches

Temperature Range: -40C to 105C; sunlight resistant

The VP6 cable PN 24287-XX is a cable with 2 twisted

pairs and 1 triad.

Jacket Material: PVC

Jacket Maximum Diameter: 0.31 inches

Temperature Range: 0C to 105C; sunlight resistant

Figure 74. VP6 connector cables can be used with conductivity and amperometric sensors with a VP designation.

499ADO-VP and 400VP (bottom) shown.

36

Page 37

EXTENSION CABLES

Rosemount Analytical offers two types of cables; prepped

and unprepped. The unprepped cables are raw cables;

user must cut the cable jacket and strip all of the wires

before use. The cables designated as prepped are

prepared with the cable jacket and all of the wires stripped

and ready for quick installation. The use of factoryprepped cables is strongly recommended. All extension

cables can be ordered at user specified length.

pH and ORP Sensor

Extension Cables

3300HT/HTVP

3400HT/HTVP

3500/VP

3900/VP

385+

389/VP

396/VP / 398/VP

396P/VP

396R/VP 398R/VP

398R/VP

Cable Part No. Cable Description

9200273 Gray Ext Cable, 11-cond, shielded, unprepped XXX XXXXXXX

23646-01 Extension Cable, 11-cond, shielded, XXX X XX XXX

prepped (raw cable PN 9200273)

Conductivity

Amperometric*

Conductivity and Amperometric

Sensor Extension Cables

Cable Part Extension Cable Description

Number

9200275 Shielded 9-cond, unprepped XX X

9200276 Unprepped XXX

9200334 For 410VP sensor X

23294-00 Unshielded, Prepped XX

23294-04 Shielded for improved EMI/RFI protection. XX

Prepped

23294-05 Shielded with additional shield wire for -03 option. XX

Prepped

23747-00 Prepped XX X X

23909-00 Prepped XXX

24289-00 For 410VP sensor X

9200275 is the raw cable for prepped cable 23747-00

9200276 is the raw cable for prepped cables 23909-00, 23294-00, 23294-04, 23294-05

* Amperometric sensors measure dissolved oxygen, ozone, and/or chlorine

140, 141, 142

150

222

225, 226, 228

242

245

400 & 400VP, 401,

402 & 402VP, 403

& 403VP, 404

410VP

499ACl, 499ADO

499AOZ,

499ATRDO

Cable Glands

Use cable glands to seal the cable where it enters the

analyzer or junction box. Cable glands also prevent the

weight of the cable from pulling on and dislodging

wiring connections in the analyzer. Cable gland kit PN

23554-00 provides 5 cable glands that fit all Rosemount

Analytical instruments and junction boxes.

37

Figure 75. Cable gland found in kit PN 23554-00

Page 38

CALIBRATION ACCESSORIES

Portable Conductivity Validation Unit

he conductivity validation unit (CVU) consists of a

T

factory-calibrated Model 1056 conductivity analyzer

and Model 404 flow-through conductivity sensor

oused in a rugged carrying case. The CVU is ideal for

h

applications where calibrating a conductivity sensor

against a standard solution is impractical. This includes

ensors that cannot easily be removed from the process

s

piping and sensors having 0.01/cm cell constants for

which stable low conductivity calibration standards are

not available. The CVU is widely used for calibrating

conductivity sensors in water for injection applications.

Using the CVU is easy. Connect the Model 404 sensor in

series with the process sensor using the tubing provided

with the CVU. Allow the sample to flow past both

sensors. Once readings are stable, adjust the process

analyzer reading to match the CVU reading.

The calibration system is completely enclosed. The solution never contacts atmospheric carbon dioxide, which

can contaminate low conductivity standards, leading to

erroneous calibration. Thus, the CVU is ideal for calibrating 0.01/cm cell constant sensors.

Figure 76. The 1056 conductivity instrument and 404

conductivity sensor are hard mounted into a protective

case. Each unit includes all cabling and tubing needed for

connection to a water system.

The CVU is available in two versions:

> CVU-01: One 404-11-17 Stainless Steel Sensor with a

0.01 cell constant pre-wired to the 1056-01-20-38-AN

analyzer.

> CVU-02: Two sensors, one 404-11-17 Stainless Steel

Sensor with a 0.01 cell constant and one 404-12-17

Stainless Steel Sensor with a 0.1 cell constant prewired to the model 1056-01-20-30-AN analyzer.

See Product Data Sheet PDS 71-CONDVALII for more

information.

38

Page 39

CALIBRATION STANDARDS

pH Buffer Solutions

Emerson offers pH 4.01, pH 6.86, and pH 9.18 NIST

buffer solutions that meet most pH calibration requirements. Accuracy is ±0.02 pH at 25°C (77°F). A chart listing

the pH of the buffer at other temperatures is provided on

the label.

Other buffer solutions, pH 4.00, pH 7.00, and pH 10.00,

are available. These solutions are color-coded for easy

recognition. They are available as single bottles or in

packages of six.

All Rosemount Analytical pH instruments have an auto-

matic buffer calibration features that recognizes the pH of

the buffer and uses the temperature-adjusted pH value

during calibration.

A 475 mV ORP (redox) standard solution is also available.

Part Number Description Size Color Code

9210012 Rosemount Analytical pH 4.01 buffer solution 16 oz (473 ml) Pink

9210013 Rosemount Analytical pH 6.86 buffer solution 16 oz (473 ml) Clear

9210014 Rosemount Analytical pH 9.18 buffer solution 16 oz (473 ml) Clear

905-3506 pH 4 buffer solution 16 oz (473 ml) Red

905-582517 6 pack of pH 4 buffer solution (PN 905- 3506) Box of 6 16 oz (473 ml) bottles Red

905- 3501 pH 7 buffer solution 16 oz (473 ml) Green

905- 582521 6 pack of pH 7 buffer solution (PN 905- 3501) Box of 6 16 oz (473 ml) bottles Green

905- 3505 pH 10 buffer solution 16 oz (473 ml) Blue

905- 582525 6 pack of pH 10 buffer solution (PN 905- 3505) Box of 6 16 oz (473 ml) bottles Blue

R508- 8oz ORP Standard, 475mV, 8oz 8 oz (237 ml) NA

Conductivity Standards

Emerson offers a variety of conductivity standards in

both 16 oz (473 mL) and 1 gal (3.8 L) sizes. To determine

the best standard to use, consult the analyzer product

data sheet and choose a standard whose conductivity is

in the recommended range for the cell constant.

Part Number Standard Solution Value Size Color Code

05010781899 (SS- 6) 200 μS/cm 16 oz (473 ml) Red

05000705464 (SS-1) 1409 μS/cm 16 oz (473 ml) Blue

05010782468 (SS-5) 1000 μS/cm 16 oz (473 ml) Yellow

05010782147 (SS-7) 5000 μS/cm 16 oz (473 ml) Violet

05010797875 (SS- 6A) 200 μS/cm 1 gallon (3.8 L) Red

05000709672 (SS-1A) 1409 μS/cm 1 gallon (3.8 L) Blue

05010783002 (SS-5A) 1000 μS/cm 1 gallon (3.8 L) Yellow

05010782026 (SS-7A) 5000 μS/cm 1 gallon (3.8 L) Violet

39

Page 40

CALIBRATION ACCESSORIES

Bench Top Calibrator

he bench top calibrator lets you take full advan-

T

tage of the power of Emerson’s SMART pH

sensors. Instead of carrying buffer solutions,

eakers, a waste container, and a wash bottle

b

into the plant to calibrate the sensor, just discon-

nect the SMART sensor and bring it to the

hop or laboratory. Connect the sensor to

s

the bench top calibrator and complete

the calibration. The results are auto-

matically stored in the sensor. When

the sensor is reconnected to the field

analyzer, it transfers the stored calibration data to the field instrument.

The calibrator has a pre-wired VP cable

and pre-wired spring-loaded push connec-

ors, so it can be used with both VP and integral cable

t

sensors. Although the calibrator is most convenient for

use with SMART sensors, it can also be used with non-

MART pH sensors. In the latter instance, the user notes

S

the calibration data and enters it manually in the field

instrument.

The bench top calibrator (PN S10119) consists of a dual

channel Model 1056 pH analyzer—one channel

connected to the VP cable, the other to the push

connectors—mounted on a stand with openings in front

to accommodate three 250 mL beakers for buffers and

rinse water. Beakers are not provided.

pH sensors and buffers solutions are sold separately. See

product data sheet PDS 71-BTC for more information.

Handheld pH Simulator

The handheld pH simulator PN S10104 (SQ7428)

supplies switch-selectable pH 4, 7, and 10 inputs to an

analyzer. Two other switches allow the user to simulate

a cracked glass membrane and a coated reference junction. The simulator is compatible with any Rosemount

Analytical pH instrument. The unit is battery operated.

Consult the factory for more information.

pH and Conductivity Simulator Module with VP plug

Simulator modules, when connected to a VP cable,

simulate either a pH or contacting conductivity sensor.

They are used for checking the proper working of the

cable and analyzer.

PN SQ8705 simulates pH 7.00, 25°C, 100 MΩ glass

impedance, and 5 kΩ reference impedance. Use it with

any VP pH cable having part number 24281-XX.

PN 23979-00 contains two modules for checking VP

conductivity cables and conductivity analyzers. One

module puts a 20 kΩ resistor across the electrode

terminals; the other puts a 100 kΩ

resistor across the terminals. The

expected conductivity or resistivity

depends on the cell constant stored

in the analyzer. Both modules simulate 25°C. Use the module with any

VP conductivity cable having part

number 23747-XX

Consult the factory for more information.

40

Page 41

FLOW ACCESSORIES

Rosemount Analytical offers a variety of rotameters with

integral valves to help measure and control flow in

sidestream samples. A constant head flow controller is

also available.

Rotameters – Sensor Recommendations

Sensor Model Flow Recommended

Rate* Valve Rotameter

All pH Sensor Models 2-5 g/hr (7.6 - 19 L/hr) PN 9390004 or PN 196-898754

499A CL 8-15 g/hr (30-57 L/hr) PN 196-898754

499A DO 2-5 g/hr (7.6-19 L/hr) PN 9390004

499A OZ 2-5 g/hr (7.6-19 L/hr) PN 9390004

When used with low flow cells (see page 9)

*

Rotameter Specifications

PN 9390004 PN 196-898754

Range of Flow Required 0.4 - 5.0 g/hr (1.5 - 19.0 L/hr) 2.0 - 20.0 g/hr (7.6 - 76.0 L/hr)

Wetted Parts Acrylic, 316 SST, Viton polycarbonate, 316 SST, brass, Buna N

Process Connection 1/4 inch FNPT (316 SST) 1/8 inch FNPT (brass)

Maximum Pressure 100 psig (790 kPa) 100 psig (790 kPa)

Maximum Temperature 130°F (54°C) 130°F (54°C)

41

Page 42

CONSTANT HEAD FLOW CONTROLLER

The constant head flow controller SQP-10077-LQD

(SQ10957) uses gravity to control flow in sidestream

samples, eliminating the need for pressure regulators,

valves, and rotameters. The overflow sampler consists

of two concentric tubes with the annular space closed at

the bottom. The sample enters through a fitting at the

bottom of the outside tube and fills the space between

the tubes, eventually overflowing the inside tube and

running to drain. A second fitting on the outside tube

connects to a low flow cell, which holds the sensor. The

outlet from the low flow cell joins the drain from the

overflow sampler. The flow of sample to the sensor is

controlled by the difference between the height of the

overflow tube and the outlet from the low flow cell as

well as by an orifice in the flow cell inlet. The flow

controller provides a steady flow of 2 gph (126 mL/min)

Flow Controller Specifications

Inlet flow 3 – 80 gph (0.2 – 30 L/hr)

Inlet pressure 3 – 65 psig (122 – 549 kPa abs)*

Temperature 32 - 122°F (0 - 50°C)

*The minimum inlet pressure is required to open a check valve, which

prevents the flow cell from draining if sample flow is lost. Removing the check

valve lowers the inlet pressure requirement to a few feet of water head.

as long as the inlet flow is enough to cause the sample

to overflow the center tube of the flow controller.

The flow controller is part of the FCL, FCLi, and MCL

systems for measuring free chlorine and monochlo-

amine. The system shown can also be used with pH and

r

ORP sensors. It is not recommended for ENDURANCE

conductivity sensors because the orientation of the flow

ell does not allow the sensor to be completely

c

submerged in the sample. The flow controller may not

be suitable for ozone or oxygen sensors. Consult the

factory for these applications.

The flow controller is mounted on a plastic back plate

for ease of installation.

Figure 78. Example of a panel using a specially design

constant head flow controller designed to control the

flow to three flow cells. Panels with choice of one, two,

or three flow cells and choice of one or two instruments

(shown with the 56 are offered under SQ 11102. Consult

factory for more information

Figure 77. Example of Overflow Sampler with Low flow cell

PN 24091-00 (see page 9).

42

Page 43

TAGS FOR SENSORS AND INSTRUMENTS

It is common for most facilities to tag their sensors and

instruments. It is especially critical in large facilities so that

all instruments and sensors are correctly located.

Rosemount Analytical makes it simple to tag all of your

Figure 79. PN 2001492 SST Tag

Used for sensors, commonly

installed on sensor with wire

Dimensions: 3.125"W x 1.31"H

SAMPLE COOLERS

new equipment before it gets installed into your facility.

Tags are also useful for large projects and OEM users. Up

to three lines of information can be added with 13 characters per line including spaces.

Figure 80. PN 9240048-00 SST Tag

Used for most instruments

Dimensions: 3.125"W x 1.31"H

Figure 81. PN 9241178-00 SST Tag

Used for 5081 and 6081 instruments only

Dimensions: 2.56"W x 1.28"H

Rosemount Analytical offers a pre-packaged sample

cooler suitable for cooling high temperature and pressure liquid samples, such as boiler and boiler feedwater.

The cooler is not recommended for steam. The cooler

consists of a sediment trap to remove suspended solids,

a coil-in-shell heat exchanger, a needle valve for control-

Figure 82. Sample Cooler example

ling flow and pressure, a pressure relief valve set to 75

psig (618 kPa abs), and a bimetal thermometer for local

display of temperature. The entire system is mounted

on a strut channel frame. The system is available in two

versions: the sample cooler alone (Model BSA), or the

sample cooler with a Model 141-06 conductivity sensor

(Model 99-14).

Uncooled sample

Temperature: 600 F (315C) max

Pressure: 1500 psig (10,440 Kpa abs)

Cooled sample

Operating Temperature Range: 32 F to 203 F (0C to 95C)

Preferred: 70F to 90 F (21 C to 32 C)

Cooling Water

Temperature: 122F (50C) maximum

Pressure: 200 psig (1480 Kpa abs) maximum

Contact factory for more information.

43

Page 44

SPECIAL PARTS AND ASSEMBLIES

Need a small modification to a standard product? Want a

small sampling system but don’t have the facilities or

personnel to design and build it yourself? Whether your

requirement is as simple as increasing the insertion

length of a retractable sensor or building a special

sample panel, our Special Request Department can help.

Figure 82 shows an example of a sample cooling system

uilt to customer specifications. It includes a sample

b

cooler, throttle valve, bimetal thermometer, stainless

steel flow cell, and pressure relief valve. The entire

sample system is mounted on a stainless steel back

plate along with a Model 5081 transmitter.

Figure 83 shows a stainless steel enclosure with air

purge. A 5081 transmitter and flow cell is visible inside

the enclosure.

Figure 84 is an example of a customer specified special

system with an air purge system located on the outside