Page 1

pH/ORP Sensor

Instruction Manual

PN 51-381+/rev.G

March 2012

Model 381+

Page 2

CAUTION

SENSOR/PROCESS

APPLICATION COMPATIBILITY

The wetted sensor materials may not be

compatible with process com position

and operating conditions. Application

compat ibility is entirely the responsibility of the user.

DANGER

HAZARDOUS AREA INSTALLATION

Installations near flammable liquids or in hazardous

area locations must be carefully evaluated by qualified on site safety personnel. This sensor is not

Intrinsically Safe or Explosion Proof.

To secure and maintain an intrinsically safe installation, the certified safety barrier, transmitter, and

sensor combi nation must be used. The installation system must comply with the governing

approval agency (FM, CSA or BASEEFA/CENELEC) hazardous area classification requirements. Consult your analyzer/transmitter instruc tion manual for details.

Proper installation, operation and servicing of this

sensor in a Hazardous Area Instal lation is entirely

the responsibility of the user.

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures, and tests its products to meet

many national and international standards. Because these instruments are

sophisticated technical products, you must properly install, use, and maintain them to ensure they continue to operate within their normal specifications. The following instructions must be adhered to and integrated into your

safety program when installing, using, and maintaining Rosemount

Analytical products. Failure to follow the proper instructions may cause any

one of the following situations to occur: Loss of life; personal injury; property damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product. If this Instruction Manual is not the correct manual, telephone 1-800654-7768 and the requested manual will be provided. Save this

Instruction Manual for future reference.

• If you do not understand any of the instructions, contact your Rosemount

representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied

with the product.

• Inform and educate your personnel in the proper installation, operation,

and maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the

appropriate Instruction Manual and per applicable local and national

codes. Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate,

update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people use

replacement parts specified by Rosemount. Unauthorized parts and procedures can affect the product’s performance and place the safe operation of your process at risk. Look alike substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in

place, except when maintenance is being performed by qualified persons,

to prevent electrical shock and personal injury.

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.rosemountanalytical.com

© Rosemount Analytical Inc. 2012

About This Document

This manual contains instructions for installation and operation of the Model 381+ High pH/ORP Sensor. The following

list provides notes concerning all revisions of this document.

Rev. Level Date Notes

0 5/01 This is the initial release of the product manual. The manual has been refor-

matted to reflect the Emerson documentation style and updated to reflect any

changes in the product offering.

A 6/02 Updated multiple drawings throughout.

B 7/02 Added 1055 wiring drawing and updated kPa references.

C 9/02 Revised drawing captions on page 9.

D 9/04 Add Xmt wiring drawings and delete Ultrasonic cleaner.

E 11/07 Added M certs on back page.

G 3/12 Update addresses - mail and web

Page 3

MODEL 381+ pH/ORP TABLE OF CONTENTS

MODEL 381+ pH/ORP SENSOR

TABLE OF CONTENTS

Section Title Page

1.0 DESCRIPTION AND SPECIFICATIONS........................................................... 1

1.1 Features and Applications................................................................................. 1

1.2 Specifications .................................................................................................... 2

1.3 Ordering Information ......................................................................................... 3

2.0 INSTALLATION ................................................................................................. 4

2.1 Installation ......................................................................................................... 4

2.2 Submersion Installation .................................................................................... 4

2.3 Insertion Installation ......................................................................................... 4

2.4 Flow Through Installation ................................................................................. 7

2.5 Flow Powered Cleaner Installation ................................................................... 7

2.6 Wiring ................................................................................................................ 7

3.0 START-UP......................................................................................................... 14

3.1 Start-Up............................................................................................................. 14

3.2 pH Calibration ................................................................................................... 14

3.3 ORP Standardization......................................................................................... 14

4.0 MAINTENANCE ................................................................................................ 16

4.1 General ............................................................................................................. 16

4.2 Sensor Removal................................................................................................ 16

4.3 Monthly Maintenance ........................................................................................ 16

4.4 Annual Maintenance ......................................................................................... 16

4.5 Electrode Checking and Standardization .......................................................... 17

5.0 TROUBLESHOOTING ...................................................................................... 18

5.1 Sensor Troubleshooting .................................................................................... 18

5.2 T.C. Element Evaluation.................................................................................... 19

5.3 Ultrasonic Cleaner/Generator Troubleshooting................................................. 19

6.0 RETURN OF MATERIAL................................................................................... 20

i

Page 4

MODEL 381+ pH/ORP TABLE OF CONTENTS

MODEL 381+ pH/ORP SENSOR

LIST OF FIGURES

Figure No. Title Page

2-1 Sensor Component Locator Diagram................................................................ 5

2-2 Submersion Installation Diagram ...................................................................... 6

2-3 Insertion Installation Diagram............................................................................ 6

2-4 Flow Through Installation Diagram.................................................................... 7

2-5 Installation Details Low Flow Conditions (Code -03 and -04)............................ 8

2-6 Flow Powered Cleaner Component Locator (Code -04)................................... 8

2-7 Wiring Model 381+ to Models 54, 3081, and 81................................................ 9

2-8 Wiring through J-Box with Extension Board to Models 54, 3081, and 81 ......... 9

2-9 Wiring Model 381+-52 through J-Box with Preamp to Models 54, 3081, & 81 . 10

2-10 Wiring to Solu Cube Junction Box (PN 23054-03) ............................................ 11

2-11 Wiring Model 381+-31-41/43-55 to Model 1055-10-22-32 ................................ 11

2-12 Wiring Model 381+-31-42-55 to Model 1055-22-32 .......................................... 12

2-13 Wiring Model 381+-52-62 to Model 1055-22-32 through Remote J-Box .......... 12

2-14 Wiring Model 381+-41-52 to Model Xmt-P........................................................ 13

2-15 Wiring Model 381+-55 to Model Xmt-P ............................................................. 13

LIST OF TABLES

Table No. Title Page

1-1 Recommended Accessories and Spare Parts................................................... 2

3-1 ORP of Saturated Quinhydrone Solutions ........................................................ 14

5-1 Troubleshooting................................................................................................. 18

5-2 T.C. Element Resistance................................................................................... 19

ii

Page 5

at temperatures greater than 80°C, the preamplifier

must be located in a remote junction box or in the

instrument.

A double junction, gel-filled reference cell, a standard

feature of the Model 381+, improves sensor life when

unknown reference cell contaminants, such as sulfides, may exist. The gel solution maintains its viscosity at high temperatures, and resists the effect of pumping and dilution, resulting in an extended service life. A

choice of wood or ceramic liquid junction allows the

user to optimize performance by emphasizing reference lifetime (wood) or chemical resistance (ceramic).

In flow applications where crystalline or viscous coatings, such as calcium carbonate or petroleum oils, may

coat the electrode surfaces and impede the sensor’s

performance, the flow-powered cleaning option may be

used. A specially designed flow chamber directs the

process fluid in a circular path carrying four Teflon

1

balls which clean the electrode surface, physically

preventing accumulation of coating materials. Flowpowered cleaning is suitable for all hazardous area

applications.

The Model 381+ comes with Pt100 temperature compensation and is compatible with the Models 54e

pH/ORP and 1055 Analyzers, and 81, 3081, 4081,

5081-P, and Xmt-P pH/ORP Transmitters.

* Patent pending

1

Teflon is a registered trademark of E.I. du Pont de Nemours & Co.

1

Model 381+ pH/ORP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

• ADVANCED ON-LINE SENSOR DIAGNOSTICS* of the Model 381+ when used with the

Models 54e pH/ORP and 1055 Analyzers, or 81, 3081, 4081, 5081-P, and Xmt-P pH/ORP

Transmitters.

• MOLDED POLYETHERSULFONE (PES) BODY provides compatibility with a variety of processes.

• MODULAR DESIGN facilitates maintenance by eliminating mounting brackets and extrane-

ous hardware.

• INTEGRAL PREAMPLIFIER provides reliable signal transmission.

• DOUBLE JUNCTION, GEL-FILLED, REFERENCE CELL provides high temperature performance,

extended service life, and resists the effects of pumping, dilution and contamination.

1.1 FEATURES AND APPLICATIONS

The Rosemount Analytical Model 381+ Sensor measures the pH or the Oxidation Reduction Potential (ORP)

of aqueous solutions in pipelines, open tanks or ponds.

The sensor is used in most indus trial applications including water and waste treatment plants.

The Model 381+pH Sensor features continuous on-line

advanced diagnostics that allow the user to identify sensor failures such as coated reference junction or broken

glass. Sensor diagnostics result in time and money savings by reducing the guesswork in sensor maintenance

and replacement requirements. On-line sensor diagnostics are made possible by calculation of the temperature

corrected glass electrode impedance and by characterizing failure modes.

The sensor is housed in a molded PES body and has two

O-ring seals with breach lock threads which secure the

PES cover. This provides a waterproof union for long

operating life and easy removal for routine maintenance.

The modular body design eliminates the need for internal mounting brackets, terminal brackets and screws.

All components are screw-type or plug-in-place, allowing for fast simple service.

The integral preamplifier conditions the high impedance glass elec trode signal at the sensor, providing a

transmission capability of up to 1000 feet (304.8

meters). The Rosemount Analytical method of

preampli fication has become the industry standard for

reliable pH measurement. In submersion applications

Page 6

2

Model 381+ pH/ORP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.2 SPECIFICATIONS

Materials of Construction:

Body, Cover and Flow Cell: Polyethersulfone (PES)

O-Rings: Viton1.

Measuring Electrode: Glass (platinum for ORP)

Liquid Junction: PVDF/wood (Code 20) or

PVDF/ceramic (Code 21)

Solution Ground/Temperature Compensator: 316

Stainless steel/EPDM

Process Connections: Submersion: 3/4-inch MNPT

Insertion: 2 “ MNPT, Flow Through: 3/4 ” MNPT

Measuring Range: pH: 0-14

ORP: –1400 to +1400 mV

Temperature Compensation: Automatic, 0 to 100°C

(32 to 212°F)

Maximum Pressure/Temperature Rating:

790 kPa abs at 100°C (100 psig at 212°F)

Cable: Prepped (P/N 23646-01)/unprepped

(P/N 9200273)

Weight/Shipping Weight: 1.0 kg/1.7 kg (2.2 lbs/3.7lbs)

1

Viton is a registered trademark of E.I. duPont de Nemours & Co.

TABLE 1-1 Recommended Accessories and Spare Parts

P/N DESCRIPTION QUANTITY

2000734 Liquid Junction, Kynar/Wood 2

2000735 Liquid Junction, Kynar/Ceramic 2

22694-00 Electrode, pH, GP 2

22694-01 Electrode, High pH 2

22694-02 Electrode, pH, Ruggedized 2

22694-03 Electrode, pH, HF Resistant 4

22697-00 Electrode, pH Combination

22697-01 Electrode, High pH, Combination 4

22723-00 Flow Powered Cleaner Balls (Qty 9) 1

22731-00 ORP Electrode, Platinum 2

22751-00 O-Ring Kit (Qty 5), Upper Body 1

22751-01 O-Ring Kit (Qty 5), Lower Body 1

22811-01 Flow Powered Cleaner Retrofit Kit for Code -00,-02

22892-00 Flow Powered Cleaner Retrofit Kit for Code -03

23018-00 Reference Electrode, Microjunction 2

23561-00 Preamplifier, Integral to 381+ 1

23550-00 Junction Box, remote, with Extension Board, 54, 54e, 1055, 81, 3081, 4081, 5081, Xmt Compatible

23551-00 Sensor Body complete, Pt 100 TC, 1

23552-00 Sensor Cover with 15 ft. Cable 1

23552-01 Sensor Cover with 15 ft. Coax Cable, without BNC 1

23552-02 Sensor Cover with 50 ft. Cable 1

23646-01 Cable extension, 11 conductor, Shielded, Prepped, Price/Foot

23555-00 Junction Box, with Models 54, 54e, 1055, 81, 3081, 4081, 5081, Xmt Preamplifier

23557-00 Preamplifier for Remote Junction Box, 54, 54e, 1055, 81, 3081, 4081, 5081, Xmt Compatible 1

32602-00 Flow Cell, PES 1

32605-00 Electrode Shroud, PES

32606-00 Flow Cell Coupling Nut, PES

32793-00 Flow Powered Cleaner, Ring

32794-00 Flow Powered Cleaner Chamber

9200273 Cable extension, 11 conductor, Shielded, Unprepped Price/Foot

9210012 Buffer Solution, 4.01pH, 16 oz 4

9210013 Buffer Solution, 6.86pH, 16 oz 4

9210014 Buffer Solution, 9.18pH, 16 oz 4

R508-160Z ORP Standard 500ml (460 mV± 10 at 20°C) 2

9210342 Reference Cell Recharge, KCl Gel, 250 ml 2

9550146 O-Ring, 2-229, Viton, Shroud 2

9550147 O-ring, 2-232, Viton, Flow Cell 2

11275-00 Handrail Mounting Bracket for Submersion Service

1000857 Handrail Mounting Bracket for Submersion Service, for use with Remote Junction Box

Page 7

3

Model 381+ pH/ORP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.3 ORDERING INFORMATION

Model 381+ pH/ORP Sensor is housed in a PES body suitable for insertion, submersion or flow through installa-

tion. The sensor includes an integral preamplifier, measuring electrode, double junction gel filled reference cell,

automatic temperature compensation, and a choice of two cable lengths, 15 ft. or 50 ft. (4.5 or 15.2 m). The Model

381+ sensor provides on line advanced diagnostic capabilities and is compatible with the Modeld 54e pH/ORP and

1055 Analyzers and Models 81, 3081, 4081, 5081, and Xmt pH/ORP Two-Wire Transmitters.

381+ – 00 – 10 – 20 – 31 – 40 – 55 EXAMPLE

MODEL 381+ INSERTION, SUBMERSION, FLOW THROUGH SENSOR

CODE LIQUID JUNCTION

20 Wood/PVDF Liquid Junction

21 Ceramic/PVDF Liquid Junction

CODE INSTALLATION

00 Insertion

02 Submersion

03 Flow Through

04 Flow Through with Flow Powered Cleaner (not available with ORP).

CODE MEASURING ELECTRODE

10 General purpose pH

11 High pH Electrode, requires Code 21. For sodium concentrations

grea

ter than 1% or

continuous

measurement above 11 pH.

12 Ruggedized pH Electrode. For abrasive solutions.

13 Platinum ORP Electrode

14 Gold ORP Electrode

15 HF pH Electrode. For HF concentrations less than 100 ppm.

CODE TEMPERATURE COMPENSATION

31 Automatic T.C., 100 ohm RTD.

CODE INTEGRAL PREAMPLIFIER

52 Preamp NOT REQUIRED

55 Preamp for Model 54, 54e, 1055, 81, 3081, 4081, 5081-P, and Xmt-P

CODE CABLE

40 15 ft. (4.5 m) cable for integral sensor preamp

41 15 ft. (4.5 m) coax cable for remote preamp (requires Code 52)

43 50 ft. (15.2 m) cable for integral sensor preamp

Page 8

4

MODEL 381+pH/ORP SECTION 2.0

INSTALLATION

SECTION 2.0

INSTALLATION

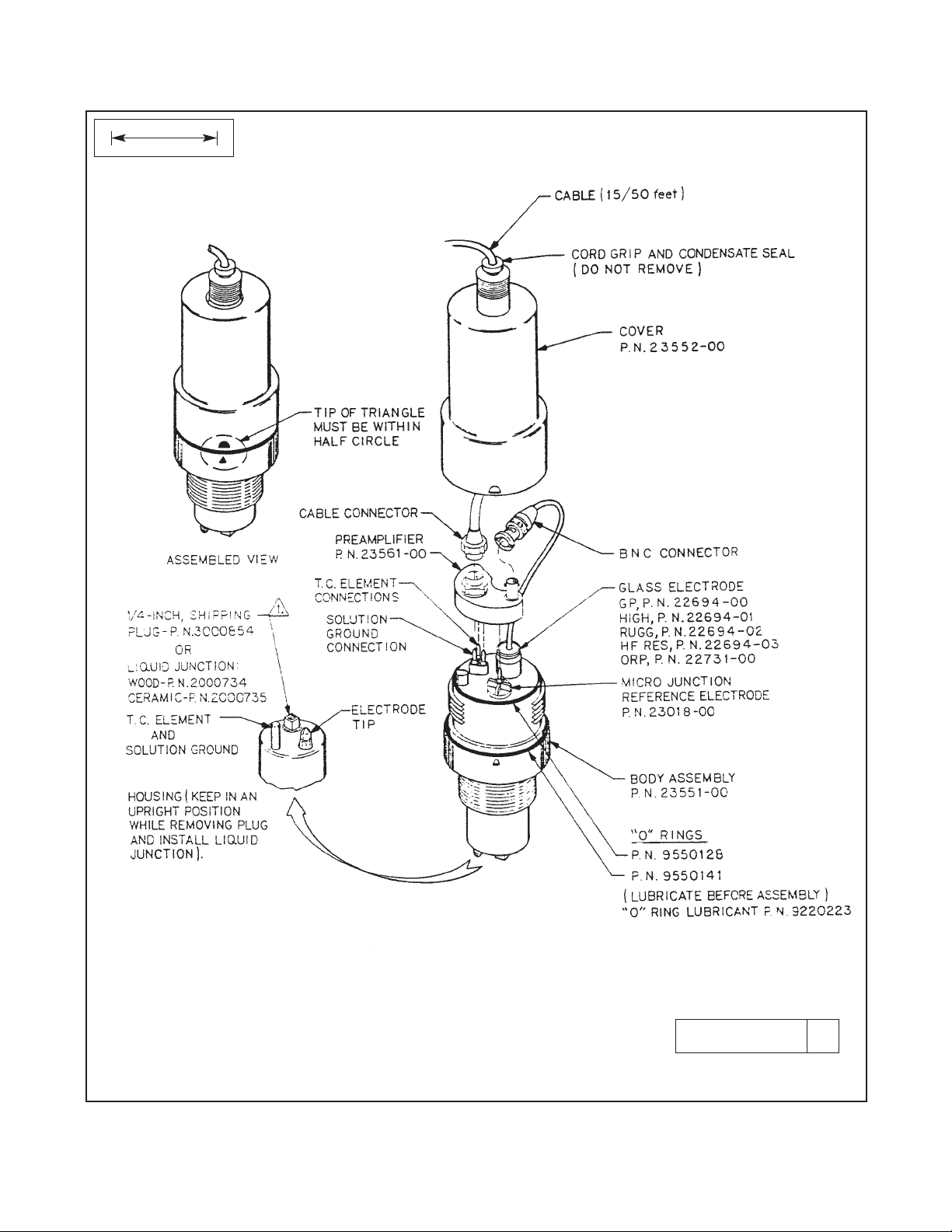

2.1 INSTALLATION. Prepare the sensor for instal la tion

as follows (see Figure 2-1):

1. Remove the cover from the body by grasping the

body and rotating the cover 1/4-turn counter

clockwise.

2. When the cover breaks loose from the body, pull

the cover straight out.

3. Lubricate the seals of the glass electrode with Oring lubricant, Rosemount Analytical P/N 2001928,

and install the glass electrode in the body. Tighten

the electrode nut by hand. DO NOT use tools.

CAUTION

Do not get lubricant on tip of glass or metal

electrode. It will disrupt the electrical circuit

path.

4. Make sure the double junction electrode is threaded tightly.

5. Plug the preamplifier (or remote connector) onto

the T.C. solution ground and microjunction reference electrode pins.

6. Connect the BNC connector from the glass elec trode to the preamplifier (or remote connector).

7. Install the body O-rings. Make sure they are clean,

and not twisted. Make sure the covers mating surfaces faces are clean.

8. Lubricate the body O-rings with O-ring lubricant,

P/N 2001928.

9. Plug the cable connector to the preamplifier, making

sure the cable is toward the center of the body.

10. Install the cover on the body so that the threads

will engage.

11. Rotate the cover until the triangle on the body

aligns with (or falls within) the adjacent mark on

the cover.

12. While holding the sensor in an upright position

(see Figure 2-1), remove the 1/4-inch shipping

plug from the electrode tip end of the sensor.

13. Install the liquid junction in place of the 1/4-inch plug,

using TEFLON tape on the liquid junction threads.

CAUTION

DO NOT use pipe joint compound or pipe

dope on the threads of the liquid junction.

The electrical circuit will be disrupted if the

liquid junction is contaminated.

2.2 SUBMERSION INSTALLATION (Code 02). To

install the sensor in process proceed as follows (see

Figure 2-2):

1. Wrap TEFLON tape on 3/4-inch MNPT threads of

cover and on standpipe threads.

CAUTION

Do not use a pipe wrench on the plastic

parts. Severe damage could result.

2. Attach a 3/4-inch coupling to the sensor.

3. Attach electrode shroud to 2 inch MNPT.

4. Feed cable through the rigid standpipe.

5. Attach the rigid standpipe to the coupling.

CAUTION

Rigid standpipe should be water-tight.

6. Tighten all fittings and secure the standpipe to

minimize sensor movement. Use flexible conduit

at the top of the rigid standpipe to permit removal

of the sensor for periodic maintenance.

7. Refer to Section 2.6 and wire the sensor to the

transmitter as described.

2.3 INSERTION INSTALLATION (Code 00). To install

the sensor in the side of a tank, in a pipeline, or in a

pipe “tee”, proceed as follows (see Figure 2-3):

CAUTION

Sensor must be installed within 80° of the

vertical plane.

1. Use TEFLON tape on pipe joint, and install sensor

as shown in Figure 2-3.

CAUTION

Do not use a pipe wrench on the plastic

sensor parts. Severe damage could result.

2. Tighten all fittings and sensor.

3. Refer to Section 2.6 for wiring instructions.

4. If desired, the cable may be installed in a con-duit.

Flexible conduit MUST be used at the sensor for a

short distance to permit removal for periodic maintenance. Use the 3/4-inch MNPT threads on the

cover to attach the conduit to the sensor.

Page 9

5

MODEL 381+pH/ORP SECTION 2.0

INSTALLATION

FIGURE 2-1. Sensor Component Locator Diagram

DWG. NO. REV.

40381+04 B

MILLIMETER

INCH

Page 10

6

FIGURE 2-2. Submersion Installation Diagram

MODEL 381+pH/ORP SECTION 2.0

INSTALLATION

DWG. NO. REV.

40038160 B

MILLIMETER

INCH

FIGURE 2-3. Insertion Installation Diagram

Page 11

7

2.4 FLOW THROUGH INSTALLATION (Code 03). To install

the sensor in the flow cell proceed as follows (see Figure 2-4):

1. Attach the flow cell’s ‹-inch MNPT to the sample or

process line. (Note flow direction on side of flow cell.)

2. Holding the sensor with the electrode pointing up, seat

the upper O-ring (PN 9550146) flush with the sensor

body above the 2-inch MNPT. Lubricate with O-ring lubricant (PN 2001928).

3. With the coupling nut thread in place, thread the electrode shroud onto the sensor body (see Figure 2-4),

insuring that the O-ring is properly seated and does not

become pinched or twisted.

NOTE

The coupling nut must be inserted between the

lower body assembly of the sensor and electrode

shroud (see Figure 2-4).

4. Next, place the lower O-ring (PN 9550147) in the flow cell

and lubricate with O-ring lubricant (PN 2001928).

5. Place sensor, coupling nut and electrode shroud in the

flow cell. Insure that the O-ring is seated properly.

6. Rotate sensor until the key on electrode shroud drops

into either the “open-flow” or “guarded” flow* position.

7. Tighten the coupling nut and the flow cell fittings.

NOTE

Electrode shroud and coupling nut should be hand

tightened only. Do not use a wrench. When tightening process or sample line connectors to the flow

cell do not use a pipe wrench on the flow cell.

Severe damage may result.

* In "guarded" flow position, solid particles in the flow stream

are diverted from electrode.

2.4.1 Installation Procedures For Low Flow Conditions. It

is extremely important that the measuring electrode and liquid junction of any pH/ORP sensor remain in contact with the

process fluid at all times.

Under low flow conditions or where flow fluctuations are common, sensor contact with the process fluid may be interrupted unless piping procedures are followed to prevent it.

A customer supplied valve should be installed to eliminate

head pressure when the sensor is being removed from the

process. This valve may also serve as a grab sample takeoff point.

The installation drawing (Figure 2-5) shows the recommended piping procedures for the Model 381+ pH/ORP sensor in

low flow conditions.

2.5 FLOW POWERED CLEANER INSTALLATION (Code

04). To install the sensor in a flow cell with flow powered

cleaner, proceed as follows (see Figure 2-6);

1. Attach the flow cell’s ‹-inch MNPT to sample or process

line. Note flow direction shown on the side of the flow cell.

2. Insert the ring as shown in Figure 2-6. It should snap in

place.

3. Place the chamber into the flow cell. Notch must be

aligned for the chamber to go in place. Place the

TEFLON balls (4 each) in the chamber.

4. Follow Steps 2 through 7 in Section 2.4 for sensor installation into flow assembly (see Figure 2-4).

2.6 WIRING. Connect the sensor wire to the trans mitter ter-

minals as shown in Figures 2-7 through 2-13.

NOTE

For maximum EMI/RFI protection when wiring from

the sensor to the junction box, the outer braid of the

sensor should be connected to the outer braided

shield of the extension cable. The outer braid of the

extension cable to the instrument must be terminated at earth ground or by using an appropriate metal

cable gland fitting that provides a secure connection

to the instrument case.

MODEL 381+pH/ORP SECTION 2.0

INSTALLATION

FIGURE 2-4. Flow Through Installation Diagram (Code 03 or 04)

DWG. NO. REV.

40038159 B

Page 12

8

MODEL 381+pH/ORP SECTION 2.0

INSTALLATION

FIGURE 2-5. Installation Details Low Flow Conditions (Code 03 and 04)

DWG. NO. REV.

40038107 C

DWG. NO. REV.

40038108 C

FIGURE 2-6. Flow Powered Cleaner Component Locator (Code -04)

Page 13

9

MODEL 381+pH/ORP SECTION 2.0

INSTALLATION

FIGURE 2-7. Wiring Model 381+ to Models 54, 54e, 81, 3081, 4081, 5081-P

DWG. NO. REV.

40396P07 F

FIGURE 2-8. Wiring Model 381+ through Junction Box with

Extension Board (PN 23550-00) to Models 54, 54e, 81, 3081, 4081, 5081-P

DWG. NO. REV.

40396P08 B

NOTE: Junction Box Specs in Fig.2-8.

Page 14

10

FIGURE 2-9. Wiring Model 381+ -52 through Junction Box

with Preamp (PN 23557-00) to Models 54, 54e, 81, 3081, 4081, 5081-P

MODEL 381+pH/ORP SECTION 2.0

INSTALLATION

DWG. NO. REV.

40396P09 B

MILLIMETER

INCH

Page 15

11

FIGURE 2-10. Wiring to Solu Cube Junction Box (PN 23054-03)

MODEL 381+pH/ORP SECTION 2.0

INSTALLATION

DWG. NO. REV.

40381+10 A

FIGURE 2-11. Wiring Model 381+-31-40/43-55 Sensor to Model 1055-10-22-32 Analyzer

DWG. NO. REV.

40105540 D

NOTE: BETWEEN PREAMP AND MODEL 2700 ANALYZER GROUND SHIELD

OF CABLE (PN 661-898695) TO SECOND GROUNDING RING/QUICK

CONNECT LUG ON INSIDE OF PREAMP BOX.

Page 16

MODEL 381+pH/ORP SECTION 2.0

INSTALLATION

FIGURE 2-12. Wiring Model 381+-52 Sensor to Model 1055-22-32 Analyzer

FIGURE 2-13. Wiring Model 381+-55 Sensor to Model 1055-22-32 Analyzer

through Remote Junction Box PN 23555-00

12

Page 17

13

MODEL 381+pH/ORP SECTION 2.0

INSTALLATION

FIGURE 2-14. Wiring Model 381+-41-52 Sensor to Model Xmt-P Transmitter

FIGURE 2-15. Wiring Model 381+-55 Sensor to Model Xmt-P Transmitter

Page 18

14

Model 381+ pH/ORP SECTION 3.0

START-UP

SECTION 3.0

START-UP

3.1 START-UP. Greater measurement accuracy may

be obtained by calibrating the Model 381+ sensor and

instrument as a loop. Please refer to the applicable

analyzer/transmitter instruction manual for calibration

procedures.

3.2 pH CALIBRATION

3.2.1 Buffer Solution Method. The Model 381+ pH

sensor and analyzer/transmitter may be calibrated by

immersing the sensor's measuring tip into two pH

buffer solutions of different pH values (two point calibration). This is the preferred method because the

analyzer can calculate the slope (efficiency) of the pH

sensor.

NOTE

Thin film coatings on the glass electrode

may cause a slight shift in calibration.

Since some coating will be encountered

under normal operating conditions, permit

the electrode to condition itself, and perform the procedure described in Section

3.2.2, grab sample method.

3.2.2 Grab Sample Method. This method does not

require the sensor to be removed from the process.

The grab sample method is recommended immediately after and in between scheduled two point calibration

procedures.

1. Take a sample of the process as close to the sensor as possible.

2. Check the sample with a calibrated portable or

laboratory analyzer. This analyzer should be automatically or manually temperature compensated

to the temperature of the sample being measured.

3. Refer to the analyzer/transmitter instruction manual for process standardization after buffer calibration.

3.3 ORP STANDARDIZATION. An ORP loop is best

calibrated using an ORP standard solution method.

3.3.1 Quinhydrone Solution.

CAUTION

The solution used during the following

check is an acid and should be handled

with care. Follow the directions of the acid

manufacturer. Wear the proper equip ment.

Do not let the solution come in contact with

skin or clothing. If contact with skin is made,

immediately rinse with clean water.

A commonly used ORP standard solution is a saturated quinhydrone solution (PN R508-160Z). This can be

made by simply adding a few quinhydrone crystals to

either a 4 pH or a 7 pH buffer. Quinhydrone is only

sightly soluble so only a few crystals will be required.

The solution will have a yellow color. The resulting

potentials should be within ±20 millivolts of the value

shown in Table 3-1. The ORP value of saturated quinhydrone solution is not stable over long periods of time

and therefore new solutions should be made each time

they are used.

TABLE 3-1. ORP of Saturated Quinhydrone Solutions (in Millivolts)

pH 4 pH 7

Temp. °C 20 25 30 20 25 30

Millivolt Potential 268 264 260 94 87 80

Page 19

15

Model 381+ pH/ORP SECTION 3.0

START-UP

3.3.2 Ferric-Ferrous Ammonium Sulfate Solution. This solution offers a much more stable solution which will

maintain its millivolt value for approximately one year when stored in a glass container. Rosemount Analytical offers

this ORP standard as spare part number R508 for your convience. Otherwise you can prepare the solution with

the formula below.

CAUTION

The solution used during the following check is an acid and should be handled with care. Follow the

directions of the acid manu facturer. Wear the proper equip ment. Do not let the solution come in contact

with skin or clothing. If contact with skin is made, immediately rinse with clean water.

To prepare solution, dissolve 39.2 grams of reagent grade ferrous ammonium sulfate [Fe(SO

4

) • (NH)2SO4 • 6H20]

and 48.2 grams of reagent grade ferric ammonium sulfate [FeNH4(SO)2 • 12H20] in approximately 700 milliliters of

water (distilled water is preferred, but tap water is acceptable). Slowly and carefully add 56.2 milliliters of concentrated sulfuric acid. Add sufficient water to bring the total solution volume up to 1,000 milliliters. This solution (ferric-ferrous ammonium sulfate) will produce a nominal ORP of 476 ±20 mV at 25 C. Some tolerance in mV values

is to be expected due to the rather large liquid reference junction potentials which can arise when measuring this

strongly acidic and concentrated solution. However, if the measuring electrodes are kept clean and in good operating condition, consistent repeatable calibrations can be achieved.

NOTE

Most industrial applications have a number of ORP reactions occurring in sequence or simultaneously. There can be several components that are oxidized or reduced by the reagents that are used.

Theoretically, the ORP potential is absolute because it is the result of the oxidation-reduction equilibrium. However, the actual measured potential is dependent on many factors, including the condition of

the surface of the ORP platinum electrode. Therefore, the sensor should be allowed 1-2 hours to

become “conditioned” to the stream to be measured when first setting up or after being cleaned.

Page 20

16

MODEL 381+pH/ORP SECTION 4.0

MAINTENANCE

SECTION 4.0

MAINTENANCE

4.1 GENERAL. The Model 381+ sensor requires peri-

odic cleaning and calibration. Since this sensor is

rebuildable, components may be replaced as required.

4.2 SENSOR REMOVAL.

! WARNING !

BEFORE REMOVING THE SENSOR, be

absolutely certain that the process pressure

is reduced to 0 psig and the process temperature is lowered to a safe level!

Remove the sensor from the process for cleaning, calibration or component replacement.

4.3 MONTHLY MAINTENANCE.

4.3.1 pH Electrode Cleaning. If the electrode is coat-

ed or dirty, it may be cleaned as follows:

1. Remove the sensor from process as instructed in

Section 4.2.

2. Wipe the glass bulb with a soft, clean, lint free

cloth or tissue. If this does not remove the dirt or

coating, proceed to step 3. If the sensor appears

to be clean, go to step 5.

3. Wash the glass bulb in a strong detergent solution

and thoroughly rinse with tap water. If the bulb still

appears to have a coating, proceed to step 4.

CAUTION

The solution used in the following step is

an acid and should be handled with care.

Follow the directions of the acid manufacturer. Wear the proper protective equipment. Do not let the solution come in contact with skin or clothing. If contact with the

skin is made, immediately rinse with clean

water.

4. If step 3 does not clean the electrode tip, remove the

glass electrode from the sensor body. Following the

caution above, wash the glass electrode bulb in

dilute 5% hydrochloric acid solution and then rinse it

thoroughly in tap water. Replace the glass electrode

if it cannot be cleaned. Install the clean or new glass

electrode into the Model 381+ sensor body and proceed to step 5.

5. Buffer calibrate the sensor (Refer to Section 3.0). If

the sensor appears to respond sluggishly to pH

change, soaking it overnight in a weak acid solution

(5% hydrochloric acid) may improve its response. Be

sure to follow the CAUTION above and to rinse the

sensor’s tip thoroughly with tap water. If the sensor

will not calibrate, it must be replaced.

4.3.2 Cleaning Platinum Electrode. The electrode can

be restored to normal operation by simply cleaning the

platinum electrode with baking soda. Polish it by rubbing

it with a damp paper towel and baking soda until a bright,

shiny appearance is attained.

4.4 ANNUAL MAINTENANCE.

1. Remove the sensor from the process.

2. While holding the sensor in an upright position,

remove and discard the liquid junction.

3. Drain the solution from the sensor body and rinse

the inside of the body with clean, warm water.

4. Remove the cover from the body by grasping the

body and rotating the cover ¤-turn in the counterclockwise direction.

5. When the cover breaks loose from the body, pull

straight out on the cover and disconnect the cable

connector from the preamplifier.

6. Disconnect the electrode BNC connector from the

preamplifier or remote connector and then unplug

the preamplifier or remote connector from the sensor body.

7. Remove and discard the microjunction reference

electrode.

Page 21

17

MODEL 381+pH/ORP SECTION 4.0

MAINTENANCE

8. Remove and discard the O-rings on the body.

9. Install a new microjunction reference electrode in the body.

10. Make sure the upper and lower body O-ring sealing surfaces are clean, and lubricate the new O-rings with Oring lubricant (PN 2001928). Install the O-rings making sure they are not twisted.

11. Install the preamplifier or remote connector on the sensor body and make sure all connections are secure

and that both O-rings are in place.

12. Install the cover on the sensor body so the threads will engage.

13. Rotate the cover until the triangle on the sensor body aligns with (or falls within) the adjacent mark on the

cover.

CAUTION

DO NOT use a pipe wrench on the body or cover. Severe damage could result.

14. While holding the sensor in an upside down position, fill the reference chamber in the body (through the liquid junction opening) with gel solution (PN 9210342). Care must be taken to remove as much air as possible

from the reference cell.

CAUTION

DO NOT use pipe joint compound or pipe dope on the threads of the liquid junction. The electrical circuit will be disrupted if the liquid junction is contaminated

15. Wrap TEFLON tape on a new liquid junction and install the liquid junction in the body.

16. Calibrate the sensor per Section 3.0. Install the sensor as described in Section 2.0.

NOTE

Flow-through sensor (Codes 03 & 04). Upper and lower flow cell O-rings should be replaced at this

time. Lubricate new O-rings with O-ring lubricant (PN 2001928) and reinstall sensor as described in

Section 2.4 and Section 2.5.

4.5 ELECTRODE CHECKING AND STANDARDI ZATION. Refer to Section 3.2 or Section 3.3 for pH or ORP elec-

trode checking, start-up and standardization.

Page 22

18

Model 381+ pH/ORP SECTION 5.0

TROUBLESHOOTING

SECTION 5.0

TROUBLESHOOTING

5.1 SENSOR TROUBLESHOOTING. In the event of a malfunction, refer to Table 5-1 below. This table lists the

Models 54, 54e, 81, 3081, 4081, 5081, and Xmt diagnostic messages, description of the problem and remedy for

the Model 381+ pH/ORP sensor. Refer to instrument’s instruction manual for screen displays.

TABLE 5-1. Troubleshooting

DIAGNOSTIC MESSAGE DESCRIPTION OF PROBLEM REMEDY

“Calibration Warning” 1. Aged glass 1. Perform buffer calibration

2. Sensor not immersed 2. Be sure electrode measuring tip is in

process

“Cracked glass failure” Broken or cracked glass Replace Sensor

“High reference impede” 1. Liquid junction coated 1. Clean sensor; replace if necessary

2. Reference Cell gel depleted 2. Replace sensor

3. Sensor not immersed 3. Be sure electrode measuring tip is in

process

“Input voltage high” pH input shorted or sensor Check wiring. Replace sensor if

“Input voltage low” miswired necessary

“Old glass warning” 1. Glass electrode worn out 1. Replace sensor

2. Sensor not immersed 2. Be sure electrode measuring tip is in

process

“Reference offset err” Reference electrode poisoned Replace sensor

(offline only)

“Ref voltage high” Reference shorted or sensor Check wiring. Replace sensor if

“Ref voltage low” miswired necessary

“Sensor line open” 1.

Open wire between sensor and analyzer

1. Check sensor wiring

2. Interconnecting cable greater than 2. Relocate analyzer

1000 ft.

“Sensor miswired” 1.

Open wire between sensor and analyzer

1. Check wiring

2. Bad preamplifier 2. Replace preamplifier

“Temp error high” 1. Open or shorted RTD 1. Replace sensor

Page 23

19

Model 381+ pH/ORP SECTION 5.0

TROUBLESHOOTING

5.2 T.C. ELEMENT EVALUATION. Table 5-2, below, is a ready reference of RTD resistance values at various tem-

peratures. These values may be used for test and evaluation of the sensor.

To check the 100 ohm T.C. element, proceed as follows:

1. Using an ohmmeter, check the resistance at the body or between the red and white wires of the sensor cable

with the transmitter disconnected.

2. The resistance shall agree with the resistance shown in Table 5-2.

3. The T.C. element resistance for other temperatures may be calculated as follows: Each degree difference

equals 0.385 ohm.

NOTE

0hmic values are read across the RTD element and are based on the manufacturers stated value of

±1%. Allow enough time for the RTD element to stabilize to the surrounding temperature.

TABLE 5-2. T.C. Element Resistance

Temp °C Resistance (±1%)

100 ohm

0 100.00 ohms

10 103.90 ohms

20 107.79 ohms

25 109.73 ohms

30 111.67 ohms

40 115.54 ohms

50 119.40 ohms

60 123.24 ohms

70 127.07 ohms

80 130.89 ohms

90 134.70 ohms

100 138.50 ohms

Page 24

20

Model 381+ pH/ORP SECTION 6.0

RETURN OF MATERIAL

SECTION 6.0

RETURN OF MATERIAL

6.1 GENERAL. To expedite the repair and return of

instruments, proper communication between the customer and the factory is important. A return material

authorization number is required. Call 1-800-6547768 or (949) 757-8500. The “Return of Materials

Request” form is provided for you to copy and use in

case the situation arises. The accuracy and completeness of this form will affect the processing time of your

materials.

6.2 WARRANTY REPAIR. The following is the procedure for returning products still under warranty.

1. Contact the factory for authorization.

2. Complete a copy of the “Return of Materials

Request” form as completely and accurately as

possible.

3. To verify warranty, supply the factory sales order

number or the original purchase order number. In

the case of individual parts or sub-assemblies, the

serial number on the unit must be supplied.

4. Carefully package the materials and enclose your

“Letter of Transmittal” and the completed copy of

the “Return of Materials Request” form. If possible, pack the materials in the same manner as it

was received.

IMPORTANT

Please see second section of “Return of

Materials Request Form”. Compliance to

the OSHA requirements is mandatory for

the safety of all personnel. MSDS forms

and a certification that the instruments

have been disinfected or detoxified are

required.

5. Send the package prepaid to:

Rosemount Analytical Inc.

2400 Barranca Parkway

Irvine, CA 92606

Attn: Factory Repair

Mark the package: Returned for

Repair RMA No. __________

Model No. _________

6.3 NON-WARRANTY REPAIR.

1. Contact the factory for authorization.

2. Fill out a copy of the “Return of Materials Request”

form as completely and accurately as possible.

3. Include a purchase order number and make sure

to include the name and telephone number of the

right individual to be contacted should additional

information be needed.

4. Do Steps 4 and 5 of Section 6.2.

NOTE

Consult the factory for additional infor mation regarding service or repair.

Page 25

FROM: RETURN BILL TO:

_____________________________ _____________________________ _____________________________

_____________________________ _____________________________ _____________________________

_____________________________ _____________________________ _____________________________

CUSTOMER/USER MUST SUBMIT MATERIAL SAFETY SHEET (MSDS) OR COMPLETE STREAM COMPOSITION, AND/OR

LETTER CERTIFYING THE MATERIALS HAVE BEEN DISINFECTED AND/OR DETOXIFIED WHEN RETURNING ANY PRODUCT, SAMPLE OR MATERIAL THAT HAVE BEEN EXPOSED TO OR USED IN AN ENVIRONMENT OR PROCESS THAT CONTAINS A HAZARDOUS MATERIAL ANY OF THE ABOVE THAT IS SUBMITTED TO ROSEMOUNT ANALYTICAL WITHOUT

THE MSDS WILL BE RETURNED TO SENDER C.O.D. FOR THE SAFETY AND HEALTH OF OUR EMPLOYEES. WE THANK

YOU IN ADVANCE FOR COMPLIANCE TO THIS SUBJECT.

SENSOR OR CIRCUIT BOARD ONLY:

(Please reference where from in MODEL / SER. NO. Column)

1. PART NO.__________________________1. MODEL_________________________________1. SER. NO. ________________

2. PART NO.__________________________2. MODEL_________________________________2. SER. NO. ________________

3. PART NO.__________________________3. MODEL_________________________________3. SER. NO. ________________

4. PART NO.__________________________4. MODEL_________________________________4. SER. NO. ________________

PLEASE CHECK ONE:

nn REPAIR AND CALIBRATE nn DEMO EQUIPMENT NO. __________________________

nn EVALUATION nn OTHER (EXPLAIN) _______________________________

nn REPLACEMENT REQUIRED? nn YES nn NO _________________________________________________

DESCRIPTION OF MALFUNCTION:

______________________________________________________________________________________________________

______________________________________________________________________________________________________

______________________________________________________________________________________________________

WARRANTY REPAIR REQUESTED:

nn YES-REFERENCE ORIGINAL ROSEMOUNT ANALYTICAL ORDER NO. ________________________________________

CUSTOMER PURCHASE ORDER NO. _________________________________________________

nn NO-PROCEED WITH REPAIRS-INVOICE AGAINST P.O. NO. _________________________________________________

nn NO-CONTACT WITH ESTIMATE OF REPAIR CHARGES: LETTER nn __________________________________________

PHONE nn ___________________________________________

NAME ____________________________________________________ PHONE _________________________________________

ADDRESS ___________________________________________________________________________________________________

______________________________________________________________ ZIP _________________________________________

RETURN AUTHORITY FOR CREDIT ADJUSTMENT [Please check appropriate box(s)]

nn WRONG PART RECEIVED nn REPLACEMENT RECEIVED

nn DUPLICATE SHIPMENT REFERENCE ROSEMOUNT ANALYTICAL SALES ORDER NO.__________

nn RETURN FOR CREDIT RETURN AUTHORIZED BY: ______________________________________

WARRANTY DEFECT____________________________________________________________________________________

_____________________________________________________________________________________________________

24-6047

RETURN OF MATERIALS REQUEST

•IMPORTANT!

This form must be completed to ensure expedient factory service.

R

E

P

A

I

R

S

T

A

T

U

S

R

E

A

S

O

N

F

O

R

R

E

T

U

R

N

C

U

S

T

O

M

E

R

N

O

T

I

C

E

T

O

S

E

N

D

E

R

Emerson Process Management

Liquid Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2004

Page 26

Immediate, Reliable Analytical Support

Now there’s a way to quickly get the right answers for your liquid analytical instrumentation questions: the Analytical

Customer Support Center.

Our staff of trained professionals is ready to provide the information you need. If you are placing an order, verifying delivery,

requesting application information, or just want to contact an Emerson Process Management representative, a call to the

Customer Support Center will provide you with the right people, the right answers, right now.

The right people, the right answers, right now.

THE AMERICAS HEADQUARTERS

Emerson Process Management

Rosemount Analytical Inc.

Liquid Center of Excellence

2400 Barranca Parkway

Irvine, CA 92606

Phone: +1.949.757.8500

Toll Free: +1.800.854.8257

Fax: +1.949.474.7250

ASIA-PACIFIC

Emerson Process Management

Asia Pacific Private Ltd.

1 Pandan Crescent

Singapore 0512

Republic of Singapore

Phone: 65.777.8211

Fax: 65.777.0947

EUROPE

Emerson Process Management

Heath Place

Bognor Regis

West Sussex PO22 9SH

England

Phone: 44.1243.863121

Fax: 44.1243.845354

VISIT OUR WEBSITE AT

www.rosemountalaytical.com

GERMANY

Emerson Process Management

Process Gas Analyzer Center of

Excellence

GmbH & Co. OHG

Industriestrasse 1

63594 Hasselroth

Germany

T 49.6055.884.0

F 49.6055.884.20

LATIN AMERICA

Emerson Process Management

Rosemount Analytical

10241 West Little York, Suite

#200 Houston, TX 77040 USA

T 713.467.6000

F 713.827.3328

MIDDLE EAST AND AFRICA

Emerson Process Management

EPM Building

P. O. Box 17033

Jebe Ali Free Zone

Dubai, United Arab Emirates

T 971.4.8835235

F 971.4.8835312

Page 27

WARRANTY

Seller warrants that the firmware will execute the programming instructions provided by Seller, and that the Goods manufactured

or Services provided by Seller will be free from defects in materials or workmanship under normal use and care until the expiration of the applicable warranty period. Goods are warranted for twelve (12) months from the date of initial installation or eighteen

(18) months from the date of shipment by Seller, whichever period expires first. Consumables, such as glass electrodes,

membranes, liquid junctions, electrolyte, o-rings, catalytic beads, etc., and Services are warranted for a period of 90

days from the date of shipment or provision.

Products purchased by Seller from a third party for resale to Buyer ("Resale Products") shall carry only the warranty extended by

the original manufacturer. Buyer agrees that Seller has no liability for Resale Products beyond making a reasonable commercial

effort to arrange for procurement and shipping of the Resale Products.

If Buyer discovers any warranty defects and notifies Seller thereof in writing during the applicable warranty period, Seller shall, at

its option, promptly correct any errors that are found by Seller in the firmware or Services, or repair or replace F.O.B. point of manufacture that portion of the Goods or firmware found by Seller to be defective, or refund the purchase price of the defective portion of the Goods/Services.

All replacements or repairs necessitated by inadequate maintenance, normal wear and usage, unsuitable power sources, unsuitable environmental conditions, accident, misuse, improper installation, modification, repair, storage or handling, or any other

cause not the fault of Seller are not covered by this limited warranty, and shall be at Buyer's expense. Seller shall not be obligated to pay any costs or charges incurred by Buyer or any other party except as may be agreed upon in writing in advance by

an authorized Seller representative. All costs of dismantling, reinstallation and freight and the time and expenses of Seller's personnel for site travel and diagnosis under this warranty clause shall be borne by Buyer unless accepted in writing by Seller.

Goods repaired and parts replaced during the warranty period shall be in warranty for the remainder of the original warranty period or ninety (90) days, whichever is longer. This limited warranty is the only warranty made by Seller and can be amended only

in a writing signed by an authorized representative of Seller. Except as otherwise expressly provided in the Agreement, THERE

ARE NO REPRESENTATIONS OR WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, AS TO MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, OR ANY OTHER MATTER WITH RESPECT TO ANY OF THE GOODS OR SERVICES.

RETURN OF MATERIAL

Material returned for repair, whether in or out of warranty, should be shipped prepaid to:

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606

The shipping container should be marked:

Return for Repair

Model

_______________________________

The returned material should be accompanied by a letter of transmittal which should include the following information (make a

copy of the "Return of Materials Request" found on the last page of the Manual and provide the following thereon):

1. Location type of service, and length of time of service of the device.

2. Description of the faulty operation of the device and the circumstances of the failure.

3. Name and telephone number of the person to contact if there are questions about the returned material.

4. Statement as to whether warranty or non-warranty service is requested.

5. Complete shipping instructions for return of the material.

Adherence to these procedures will expedite handling of the returned material and will prevent unnecessary additional charges

for inspection and testing to determine the problem with the device.

If the material is returned for out-of-warranty repairs, a purchase order for repairs should be enclosed.

Page 28

Credit Cards for U.S. Purchases Only.

The right people,

the right answers,

right now.

ON-LINE ORDERING NOW AVAILABLE ON OUR WEB SITE

http://www.rosemountanalytical.com

Specifications subject to change without notice.

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.rosemountanalytical.com

© Rosemount Analytical Inc. 2012

Sira MC070110/00

8

Loading...

Loading...