Page 1

• ADVANCED ON-LINE SENSOR DIAGNOSTICS

(Model 381+ only), for use with the Models 54e

pH/ORP and 1055 Analyzers and 81, 3081, 4081,

5081-P, and Xmt-P pH/ORP Transmitters, predict

and identify process-related sensor failures.

• MODULAR DESIGN facilitates maintenance by

eliminating terminal and mounting brackets and

extraneous hardware.

• DOUBLE-JUNCTION, GEL-FILLED REFERENCE

CELL provides high temperature performance,

extended service life, and resistance to the effects

of pumping, dilution, and contamination.

• MOLDED POLYETHERSULFONE (PES) BODY

provides compatibility with a variety of processes.

• OPTIONAL FLOW-POWERED CLEANING provides

trouble-free service in difficult applications.

Model 381 pH/ORP

Insertion/Submersion Flow Through Sensor

Product Data Sheet

PDS 71-381/rev.E

October 2010

Continued on page 2

FEATURES AND APPLICATIONS

The Rosemount Analytical Model 381 Sensor measures the pH or the Oxidation Reduction Potential

(ORP) of aqueous solutions in pipelines, open tanks, or

ponds. The sensor is suitable for use in most indus trial

applications, including water and waste treatment

plants.

The Model 381+ features a stainless steel solution

ground. The solution ground provides advanced sensor diagnostics for preventative maintenance when

used with the Models 54e pH/ORP and 1055 analyzers and 81, 3081, 4081, 5081-P, and Xmt-P pH/ORP

transmitters. Sensor diagnostics result in time and

money savings by reducing the guesswork in sensor

maintenance and replacement requirements.

The sensor is housed in a molded PES body and has

two O-ring seals with breach lock threads that secure

the PES cover. This provides a waterproof union for

long operating life and easy removal for routine maintenance.

The modular body design eliminates the need for

internal mounting brackets, terminal brackets, and

screws. All components are screw-type or plug-inplace, allowing for fast simple service.

The integral preamplifier conditions the high impedance glass elec trode signal at the sensor, providing a

transmission capability of up to 1000 ft (304.8 m). The

Rosemount Analytical method of preampli fication has

become the industry standard for reliable pH measurement. In submersion applications at temperatures

greater than 80°C, the preamplifier must be located in

a remote junction box or in the instrument.

A double-junction, gel-filled reference cell, a standard feature of the Model 381, improves sensor life

when unknown reference cell contaminants, such

as sulfides, may exist. The gel solution maintains its

viscosity at high temperatures, and resists the effect

of pumping and dilution, resulting in an extended

Page 2

2 Rosemount Analytical

FEATURES AND APPLICATIONS

Continued from page 1

service life. A choice of a wood or ceramic liquid junction allows the user to optimize performance by

emphasizing reference life (wood) or chemical resistance (ceramic).

In many flow applications, crystalline or viscous coatings are present, such as calcium carbonate or petroleum oils, which may coat the electrode surfaces and

impede the sensor’s performance. The flow-powered

cleaning option may be used in these instances. A

specially designed flow chamber directs the process

fluid in a circular path carrying three Teflon1balls that

clean the electrode surface, physically preventing

accumulation of coating materials. Flow-powered

cleaning is suitable for all hazardous area applications.

The Model 381 is available with 3K Balco or Pt 100

temperature compensation and is compatible with all

Rosemount Analytical pH/ORP Analyzers.

1

Teflon is a registered trademark of E.I. du Pont de Nemours & Company.

SPECIFICATIONS

Materials of Construction:

Body, Cover and Flow Cell: Polyethersulfone (PES)

O-Rings: Viton

2

Measuring Electrode: Glass (and platinum or gold

for Model 381 ORP)

Liquid Junction: Kynar3/wood (Code 20) or

Kynar/ceramic (Code 21)

Solution Ground: 316 Stainless steel (Code + only)

Sensor Process Connections:

Submersion: 3/4 in. MNPT

Insertion: 2 in. MNPT

Flow Through Cell: 3/4 in. MNPT inlet and outlet

Measuring Ranges:

ORP; -1500 to +1500 mV

pH; ACCUGLASS

™

4

0-14

Minimum Conductivity: 75 μS/cm, nominal 100 μS/cm

Temperature Compensation: Automatic, 0 to 100°C

(32 to 212°F)

Maximum Pressure/Temperature Rating:

790 kPa (abs) at 100°C (100 psig at 212°F)

Cable: For Code pH, pHE, ORP: 4 conductor, 22 GA

with common shield. Code +: 10 conductor,

shielded cable

Weight/Shipping Weight: 1.0 kg/1.7 kg (2.2 lb/3.7lb)

2

Viton is a registered trademark of E.I. du Pont de Nemours & Co.

3

Kynar is a trademark of Elf Atochem North America, Inc.

4

ACCUG LASS is a trademark of Rosemount Analytical.

Percent Linearity Over pH Range

General Purpose and Ruggedized glass (codes -10 &-12) High pH glass (code -11)

0-2 pH 97% 94%

2-12 pH 99% 97%

12-13 pH 96% 98%

13-14 pH 92% 98%

* Note: Ruggedized glass electrodes are ideal for abrasive applications, but response times are typically slower than other glass

formulas.

Page 3

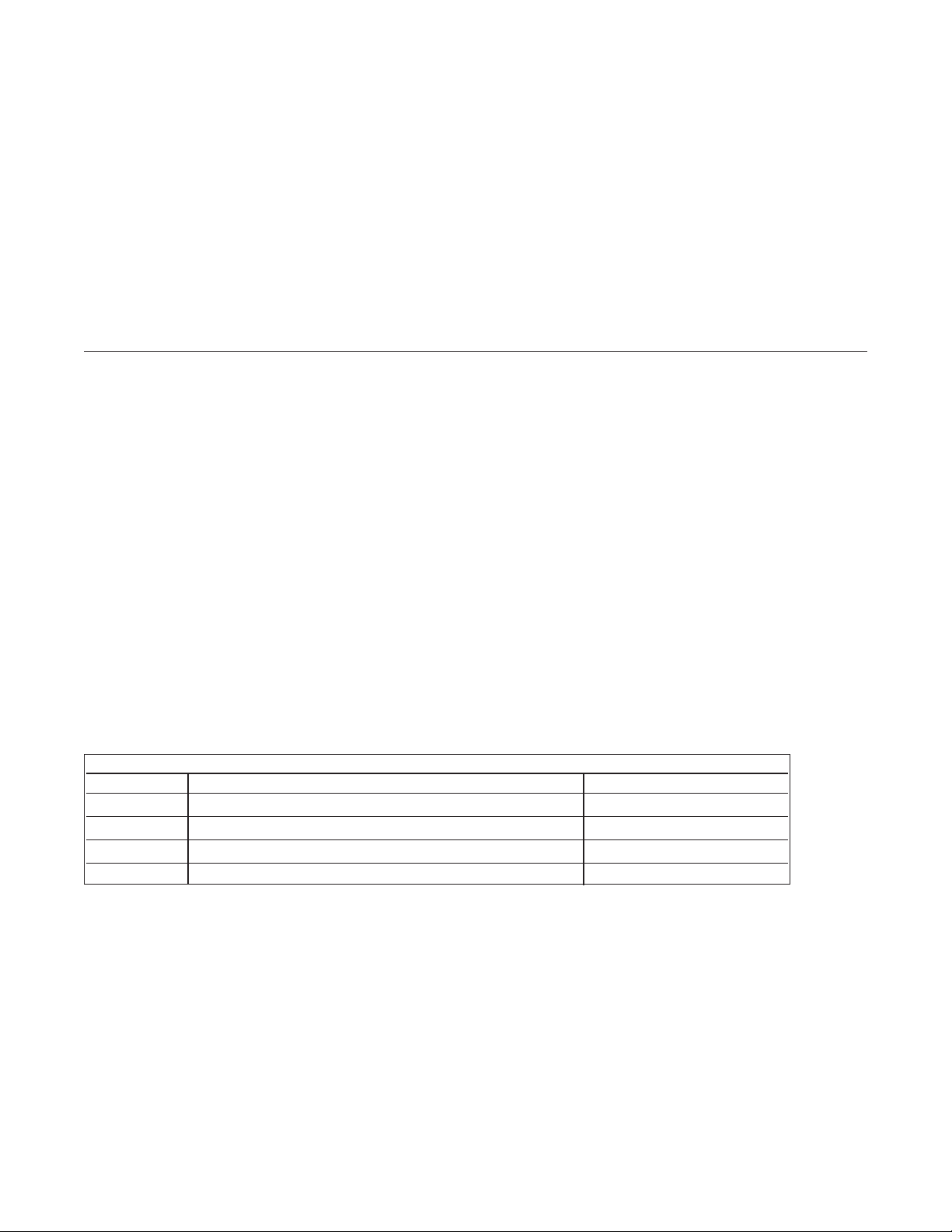

MOUNTING AND DIMENSIONAL DRAWING

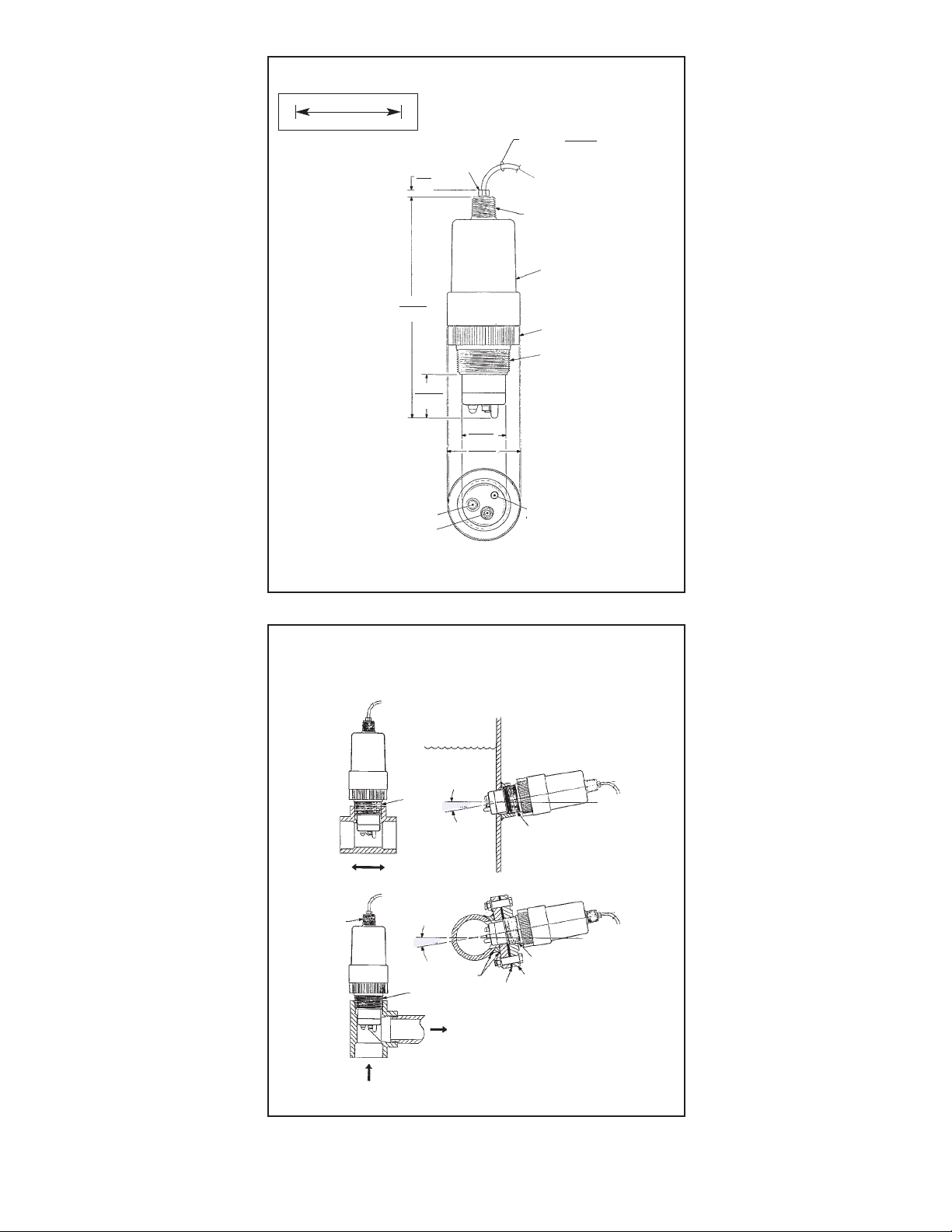

INSERTION AND FLOW THROUGH INSTALLATION

PIPE TEE

INSTALLATION

STRAIGHT

FLOW

SIDE OF TANK

INSTALLATION

PIPE TEE INSTALLATION

ELBOW FLOW

GASKET

WELD

150 LBS. RAISED

FACE FLANGE

PIPE LINE

INSTALLATION

2 IN. MNPT

2 IN. MNPT

2 IN.

MNPT

2 IN.

MNPT

3/4 IN.

MNPT

10°

MIN

FLOW

FLOW

FLOW

10°

MIN

CABLE

3/4” MNPT

COVER

BODY

2 IN. MNPT

(FOR INSERTION

INSTALLATION)

4.5 IN.

15 FT.

249.2

8-13/16

48.4

1-28/32

47.6

1-7/8 DIA

81.7

3-7/32 DIA

CORD GRIP

(DO NOT REMOVE)

MEASURING

ELECTRODE

TEMPERATURE

COMPENSATOR

1

LIQUID JUNCTION

9.5

3/8

1

ALSO SERVES AS SOLUTION GROUND FOR 381+

Rosemount Analytical 3

MILLIMETER

INCH

Page 4

SUBMERSION INSTALLATION: HANDRAIL MOUNTING ACCESSORY (P/N 1000857)

4 Rosemount Analytical

Page 5

SUBMERSION INSTALLATION: HANDRAIL MOUNTING ACCESSORY (P/N 11275-00)

MILLIMETER

INCH

Rosemount Analytical 5

Page 6

6 Rosemount Analytical

MODEL 381 SENSOR WITH FLOW

POWERED CLEANER, MINIMUM FLOW

RATE REQUIRED IS 2 gpm;

DO NOT

EXCEED 6 gpm AS THIS

COULD CAUSE ELECTRODE DAMAGE.

MILLIMETER

INCH

MODEL 381 SENSOR IN

FLOW THROUGH ASSEMBLY

Page 7

ORDERING INFORMATION

Model 381 pH/ORP Sensor is housed in a PES body suitable for insertion, submersion, or flow through

installation. The sensor is offered with an integral preamplifier, measuring electrode, double-junction gel-filled

reference cell, automatic temperature compensation for pH, and a choice of two cable lengths of either

15 ft or 50 ft (4.5 or 15.2 m).

Level 4 LIQUID JUNCTION

20 Wood/Kynar Liquid Junction

21 Ceramic/Kynar Liquid Junction

Level 6 INSTALLATION

_ No Selection

02 Submersion

03 Flow Through

04 Flow Through with Flow Powered Cleaner

Level 1 TEMPERATURE COMPENSATOR

31 Automatic TC, 100 ohm RTD

Level 3 MEASURING ELECTRODE

10 General purpose pH, GPHT (0-14), not available with Code OR

11 High pH Electrode, requires Code 21. For sodium concentrations greater than 1 or continuous

measurement above 11 pH; not available with Code OR

12 Ruggedized pH Electrode. For abrasive solutions, not available with Code OR

13 Platinum ORP Electrode, not available with Code pH

14 Gold ORP Electrode, not available with Code pH

15 HF pH Electrode. For HF concentrations less than 300 ppm, not available with Code OR

Level 5 PREAMPLIFIER

52 Preamp NOT REQUIRED

55 Preamp for Models 54/e, 81, 3081, 4081, 5081-P, and Xmt-P (for Code+ only)

Level 7 SPECIAL

_ No Selection

99 Special (consult factory)

Level 2 CABLE

40 15 ft (4.5 m) cable for integral sensor preamp (see below for preamp choices)

41 15 ft (4.5 m) coax cable w/BNC connector for remote sensor preamp and integral analyzer preamp

(Models 1054A-54, 1054B-54, 2054-54 and 54e, 1055, 81, 3081, 4081, 5081-P, and Xmt-P)

43 50 ft (15.2 m) cable for integral sensor preamp (see below for preamp choices)

Level 0 FUNCTION

pH pH assembly for Models 1003, 1023, 1050, 1060, and 1181pH; requires Code 30

PE pH or ORP assembly for Models 1054, 1054A, 1054B, 2054, and 2081; requires Code 31

+ pH or ORP assembly for Models 54/54e, 1055, 81, 3081, 4081, 5081-P, Xmt-P; requires Code 31

OR ORP assembly for Models 1003, 1023, 1050, 1060, and 1181ORP; requires Code 32

MODEL

381 INSERTION, SUBMERSION, FLOW THROUGH SENSOR

Rosemount Analytical 7

Page 8

PART # DESCRIPTION

23550-00 Junction Box, with extension board 54, 81, 3081, and 4081 compatible

23555-00 Remote junction box with preamp for 54/e, 5081-P, and Xmt-P compatible

23557-00 Preamplifier for junction box, 54/e, 5081-P, and Xmt-P compatible

9210012 Buffer Solution, pH 4.01, 16 oz.

9210013 Buffer Solution, pH 6.86, 16 oz.

ACCESSORIES

PART # DESCRIPTION

2000734 Liquid Junction, KYNAR/wood

2000735 Liquid Junction, KYNAR/Ceramic

22694-00 Electrode, pH, GP

22694-01 Electrode, High pH

22694-02 Electrode,pH, Rugged

22694-03 Electrode, pH, HF Resistant

22697-00 Electrode, Combination pH

22697-01 Electrode, HIgh pH, Combination

22723-00 Flow Powered Cleaner Balls (quantity 9)

22731-00 ORP Electrode, Platinum

22751-00 O-ring Kit (quantity 5), Upper Body

22751-01 O-ring Kit (quanity 5), Lower Body

22811-01 Flow Powered Cleaner - Retrofit Kit, code -00, -02

22892-00 Flow powered cleaner retrofit kit (for use with Option -03 sensors)

23018-00 Reference element (formerly 22688-00)

23551-00 Sensor Body, complete, Pt-100

23552-00 Sensor Cover with 15’ Cable

23552-01 Sensor Cover with 15’ Coax Cable

23552-02 Sensor Dover with 50’ Cable

32602-00 Flow Cell, PES

32605-00 Electrode, Shroud, Protective

32606-00 Flow Cell Coupling Nut, PES

32793-00 Flow Powered Cleaner, Ring

SPARE PARTS

Credit Cards for U.S. Purchases Only.

The right people,

the right answers,

right now.

ON-LINE ORDERING NOW AVAILABLE ON OUR WEB SITE

http://www.raihome.com

Specifications subject to change without notice.

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2010

8

Loading...

Loading...