Page 1

Instruction Manual

IQ-MAN-PERpH-X

L

April 2017

Rosemount™3300HT/3300HTVP/3400HT/

3400HTVP/3500P/3500VP

PERpH-X High Performance pH/ORP Sensors

Rev. J

Page 2

asgkas

h

Page 3

Essential Instructions

Read this page before proceeding!

Emerson designs, manufactures and tests its products to meet many national and international stan-

dards. Because these sensors are sophisticated technical products, you MUST properly install, use,

nd maintain them to ensure they continue to operate within their normal specifications. The

a

following instructions MUST be adhered to and integrated into your safety program when installing,

using, and maintaining Rosemount products. Failure to follow the proper instructions may cause

any one of the following situations to occur: loss of life; personal injury; property damage; damage

to this sensor; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson representative for

clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance

of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate

Instruction Manual and per applicable local and national codes. Connect all products to

the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update,

program, and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Emerson. Unauthorized parts and procedures can affect the product's

performance, place the safe operation of your process at risk, and VOID YOUR WARRANTY.

Third-party substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when

maintenance is being performed by qualified persons, to prevent electrical shock and

personal injury.

The information contained in this document is subject to change without notice.

CAUTION

Sensor/Process Application Compatibility

The wetted sensor materials may not be compatible with process composition and operating

conditions. Application compatibility is entirely the responsibility of the user.

WARNING

Before removing the sensor, be absolutely certain that the process pressure is reduced to 0 psig and

the process temperature is lowered to a safe level!

CAUTION

Special Conditions for Safe Use

1. All pH/ORP sensors have a plastic enclosure which must only be cleaned with a damp cloth to avoid

the danger due to a build up of an electrostatic charge.

2. All pH/ORP sensor models are intended to be in contact with the process fluid and may not meet the

500V r.m.s. a.c. test to earth.

This must be taken into consideration at installation.

Page 4

About This Document

This manual contains instructions for installation and operation of the Rosemount 3300HT/3300HTVP/

3400HT/3400HTVP/3500P/3500VP.

The following list provides concerning all revisions of this document.

Rev. Level Date Notes

J 04/2017 Updated information with new Emerson Style Guidelines, Updated

Ordering Information, Specifications, and Wiring Diagrams. Added

Accessories Information, EC Declaration of Conformity and

FM Installation Drawings.

Page 5

Instruction Manual Table of Contents

LIQ-MAN-PERpH-X April 2017

Contents

Section 1: Specifications

1.1 Specifications ......................................................................................................1

1.2 Product Certifications ..........................................................................................3

1.3 Ordering Information...........................................................................................4

Section 2: Installation

2.1 Storage................................................................................................................7

2.2 Installation...........................................................................................................7

2.3 Retraction with Kit P/N 23240-00 ......................................................................16

2.4 Electrical Installation..........................................................................................17

Section 3: Startup and Calibration

3.1 Electrode Preparation .......................................................................................21

3.2 pH Sensor Calibration ........................................................................................21

3.3 Recommended pH Sensor Standardization ........................................................21

Section 4: Maintenance

4.1 Electrode Cleaning.............................................................................................23

4.2 Reference Junction Replacement and Sensor Electrolyte Recharge.....................23

Section 5: Accessories

5.1 Accessories........................................................................................................25

EC Declaration of Conformity.............................................................................27

Intrisicallly Safe Sensor Installation Drawing - FM ................................29

Table of Contents i

Page 6

Table of Contents Instruction Manual

April 2017 LIQ-MAN-PERpH-X

ii Table of Contents

Page 7

Instruction Manual Specifications

LIQ-MAN-PERpH-X April 2017

Section 1: Specifications

1.1 Specifications

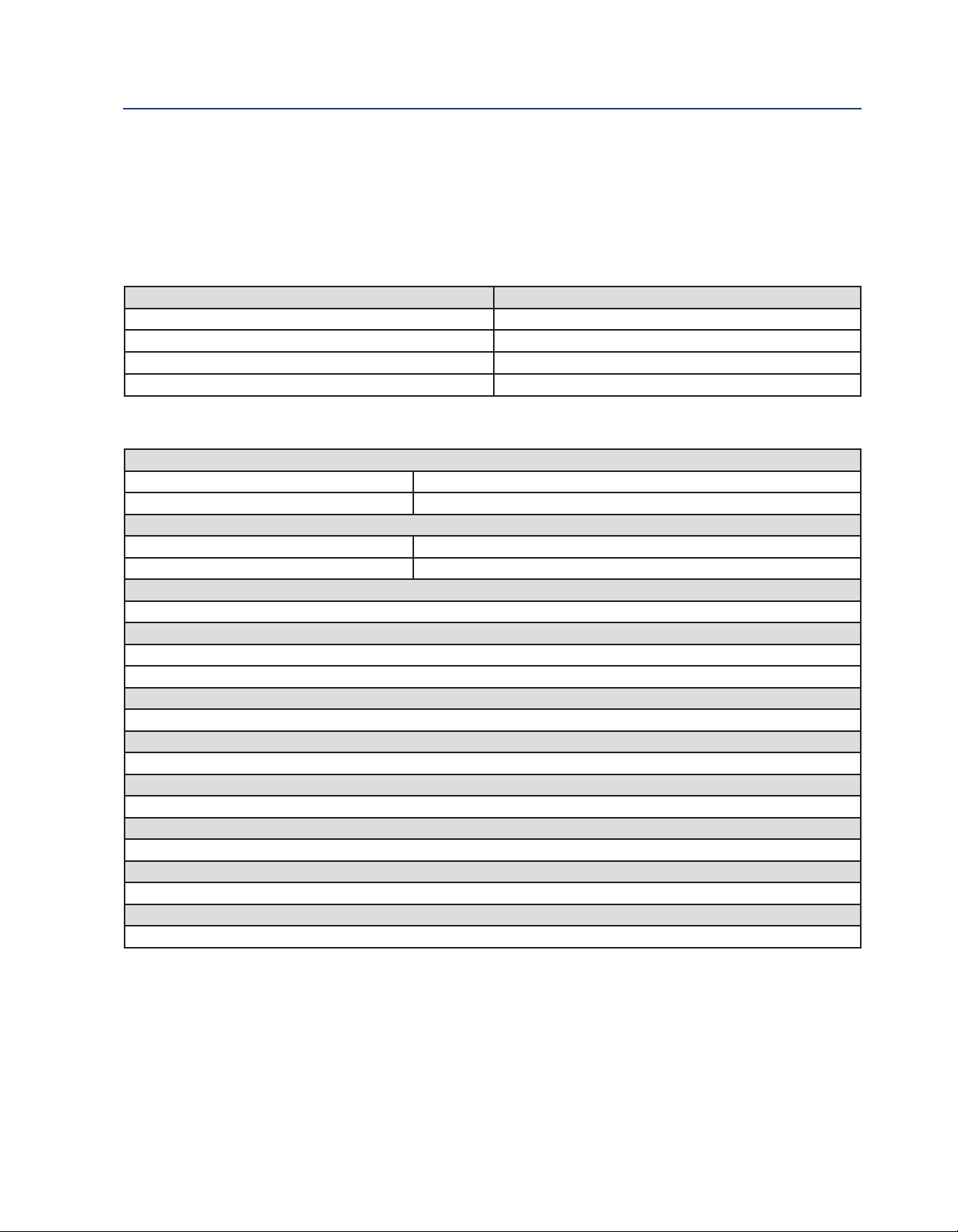

Table 1-1: Percent linearity over pH

pH Range HT Series

0-2 pH 94%

2-12 pH 99%

12-13 pH 97%

13-14 pH 92%

Table 1-2: Rosemount 3300HT/3300HTVP sensor specifications

Measured Range

pH range 0 to 14 pH

ORP range -1500 mV to 1500 mV

Operating Temperature

Without Preamplifier 41 to 311 °F (5 to 155 °C)

With Preamplifier up to 212 °F (100 °C)

Storage Temperature

14 to 138 °F (-10 to 70 °C)

Maximum Process Pressure

400 psig (2859 kPa [abs])

CRN Rating: 200 psig at room temperature

Wetted Materials

Titanium, Ryton, Teflon, Glass, and User Specified O-ring Material (EPDM, Viton or Kalrez)

Reference Electrode

Double junction with replaceable process side electrolyte and Teflon junction

Temperature Sensor

Pt-100 RTD

Process Connections

Must use 1 in. compression process connector (P/N 23166-00 or 23166-01)

Weight/Shipping Weight

1 lb/2 lb (0.5 kg/0.9 kg)

Cable Length

15 ft. integral cable (Rosemount 3300HT) or VP8 Cable for Rosemount 3300HTVP (sold separately)

Specifications 1

Page 8

Specifications Instruction Manual

April 2017 LIQ-MAN-PERpH-X

Table 1-3: Rosemount 3400HT/3400HTVP sensor specifications

Measured Range

pH range 0 to 14 pH

ORP range -1500 mV to 1500 mV

perating Temperature

O

Without Preamplifier 41 to 311 °F (5 to 155 °C)

ith Preamplifier

W

Storage Temperature

14 to 138 °F (-10 to 70 °C)

Maximum Process Pressure

400 psig (2859 kPa [abs])

CRN Rating: 200 psig at room temperature

Wetted Materials

Titanium, Ryton, Teflon, Glass, and User Specified O-ring Material (EPDM, Viton or Kalrez)

Reference Electrode

Double junction with replaceable process side electrolyte and Teflon junction

Temperature Sensor

Pt-100 RTD

Process Connections

Must use 1 in. compression process connector (P/N 23166-00 or 23166-01)

Can be inserted through a ball valve

Weight/Shipping Weight

21 inch Sensor 2 lbs/3 lbs (0.9 kg/1.4 kg)

36 inch Sensor 3 lbs/4 lbs (1.4 kg/1.8 kg)

p to 293 °F (145 °C)

u

Table 1-4: Rosemount 3500P/3500VP sensor specifications

Measured Range

pH range 0 to 14 pH

ORP range -1500 mV to 1500 mV

Operating Temperature

41 to 248 °F (5 to 120 °C)

Storage Temperature

14 to 122 °F (-10 to 50 °C)

Maximum Process Pressure

100 psig (790 kPa [abs])

CRN Rating: 40 psig at room temperature

Wetted Materials

Titanium, Ryton, Teflon, Glass, and User Specified O-ring Material (EPDM, Viton or Kalrez)

Reference Electrode

Double junction with replaceable process side electrolyte and Teflon junction

Temperature Sensor

Pt-100 RTD

Process Connections

1in. MNPT Front and Rear facing threads

Weight/Shipping Weight

21 inch Sensor 2 lbs/3 lbs (0.9 kg/1.4 kg)

2 Specifications

Page 9

Instruction Manual Specifications

LIQ-MAN-PERpH-X April 2017

1.2 Product Certifications

lease see online certificates for further details.

P

IECEx

Sensors without preamp – Ex ia IIC T4 Ga (-20 °C ≤ Ta ≤ +60°C)

Sensors with SMART preamp (pH only) – Ex ia IIC T4 Ga (-20°C ≤ Ta ≤ +60°C)

Sensors with standard preamp (ORP only) – Ex ia IIC T4 Ga (-20°C ≤ Ta ≤ +80°C) or

Ex ia IIC T5 Ga (-20°C ≤ Ta ≤ +40°C)

Per standards IEC60079-0 : 2011, IEC 60079-11 : 2011

ATEX

Sensors without preamp – II 1 G Ex ia IIC T4 Ga (-20˚C ≤ Ta ≤ +60˚C)

Sensors with SMART preamp (pH only) – II 1 G Ex ia IIC T4 Ga (-20˚C ≤ Ta ≤ +60˚C)

Sensors with standard preamp (ORP only) – II 1 G Ex ia IIC T4 Ga (-20˚C ≤ Ta ≤ +80˚C) or

II 1 G Ex ia IIC T5 Ga (-20˚C ≤ Ta ≤ +40˚C)

Per standards EN 60079-0: 2012+A11:2013, EN 60079-11:2012

FM

See online FM Certificate of Compliance for applicable sensor options:

Intrinsically Safe for use in Class I, II, and III, Division 1, Groups A, B, C, D, E, F, and G; Temperature

Class T6 Ta = -20˚C to +60˚C

Intrinsically Safe for use in Class I, Zone 0, AEx ia IIC T6 Ta = -20˚C to +60˚C

Nonincendive for use in Class I, Division 2, Groups A, B, C, and D; Temperature Class T6 Ta = -20˚C

to +60˚C

Suitable for use in Class II and III, Division 2, Groups E, F, and G; Temperature Class T6 Ta = -20˚C

to +60˚C Hazardous (Classified) Locations

IS/I,II,III/1/ABCDEFG/T6 Ta = 60°C - 1400332; Entity; I/0/AEx ia IIC/T6 Ta = 60°C - 1400332; Entity;

NI/I/2/ABCD/T6 Ta = 60°C; S/II,III/2/EFG/T6 Ta = 60°C

Per standards 3600:1998, 3610:2010, 3611:2004, 3810:2005

CSA

See online CSA Certificate of Compliance for applicable sensor options:

Sensors with preamp – Intrinsically Safe:

Class I, Division 1, Groups ABCD; Class II, Division 1, Groups EFG; Class III; Class I, Division 2, Groups

ABCD; Ambient temperature rating -20˚C to +60˚C; Ex ia IIC; T6

Sensors without preamp – Intrinsically Safe and Non-Incendive:

Class I, Division 1, Groups ABCD; Class II, Division 1, Groups EFG; Class III; Class I, Division 2, Groups

ABCD; Ex ia IIC; T6; Ambient temperature rating -20˚C to +60˚C: (Simple Apparatus)

Per standards C22.2 No. 0-10, C22.2 No. 0.4-M2004, C22.2 No. 94-M1991, C22.2 No. 142 – M1987,

C22.2 No 157 – M1992, CAN/CSA E60079-0:07, CAN/CSA E60079 - 11:02, UL50 11th Ed, UL508

17th Ed, UL913 7th Ed, UL 60079-0: 2005, UL 60079-11: 2002

Specifications 3

Page 10

Specifications Instruction Manual

April 2017 LIQ-MAN-PERpH-X

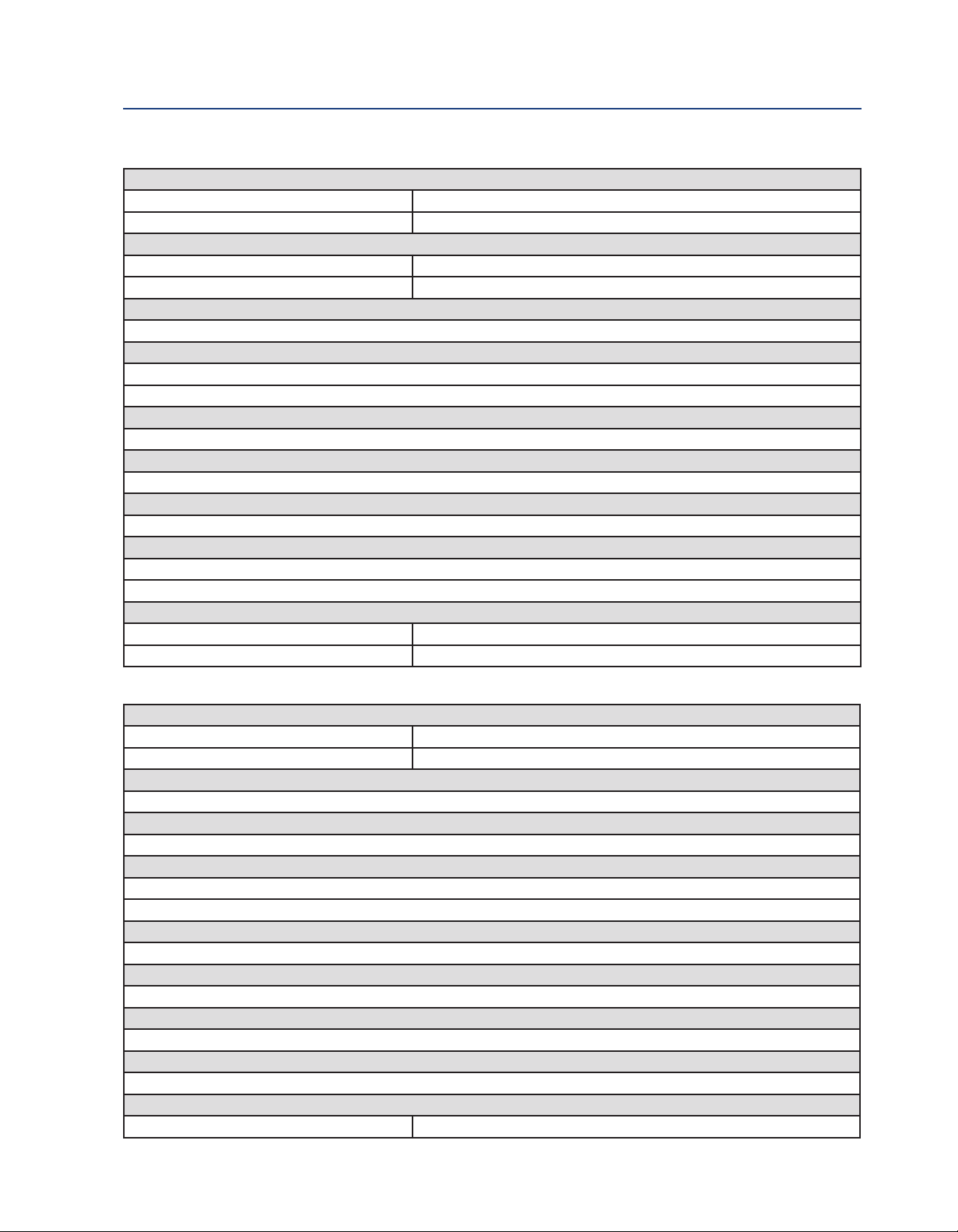

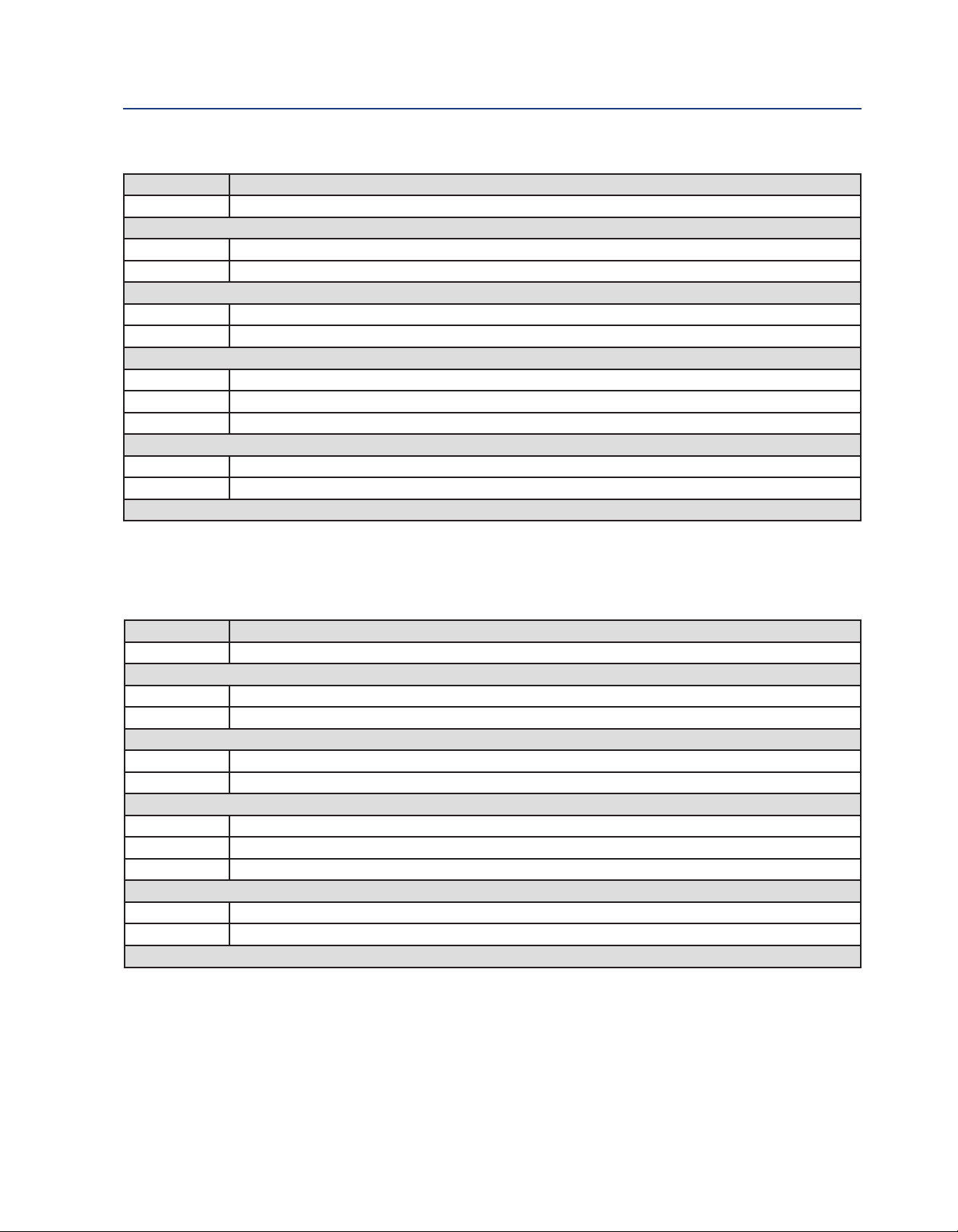

1.3 Ordering Information

able 1-5: Rosemount 3300HT sensor ordering information

T

Model Sensor type

3300HT pH/ORP Sensor

Measuring Electrode

10 pH - GPHT Glass

12 ORP

O-ring Material

30 EPDM

31 Viton

32 Kalrez

Typical Model Number: 3300HT-10-30

Table 1-6: Rosemount 3300HTVP sensor ordering information

Model Sensor type

3300HTVP pH/ORP Sensor

Measuring Electrode

10 pH - GPHT Glass

12 ORP

O-ring Material

30 EPDM

31 Viton

32 Kalrez

Preamplifier Option

_ No selection

70 SMART Preamplifier

Typical Model Number: 3300HTVP-10-30-70

(1)

1. Only available if selected with option 10.

4 Installation

Page 11

Instruction Manual Specifications

LIQ-MAN-PERpH-X April 2017

able 1-7: Rosemount 3400HT sensor ordering information

T

Model Sensor type

3300HTVP pH/ORP Sensor

easuring Electrode

M

10 pH - GPHT Glass

12 ORP

Sensor Length

21 21 in. Titanium Tube

22 36 in. Titanium Tube

O-ring Material

30 EPDM

31 Viton

32 Kalrez

Cable Length

61 9.5 in. cable without BNC

62 15 ft. cable without BNC

Typical Model Number: 3400HT-10-21-30-62

(1)

(2)

1. For use with sensor head junction boxes.

2. For wiring directly to transmitter or junction box.

Table 1-7: Rosemount 3400HTVP sensor ordering information

Model Sensor type

3400HT pH/ORP Sensor

Measuring Electrode

10 pH - GPHT Glass

12 ORP

Sensor Length

21 21 in. Titanium Tube

22 36 in. Titanium Tube

O-ring Material

30 EPDM

31 Viton

32 Kalrez

Preamplifier Option

_ No Selection

70 SMART Preamplifier

Typical Model Number: 3400HTVP-10-21-30-70

(1)

1. Only available if selected with option 10.

Installation 5

Page 12

Specifications Instruction Manual

April 2017 LIQ-MAN-PERpH-X

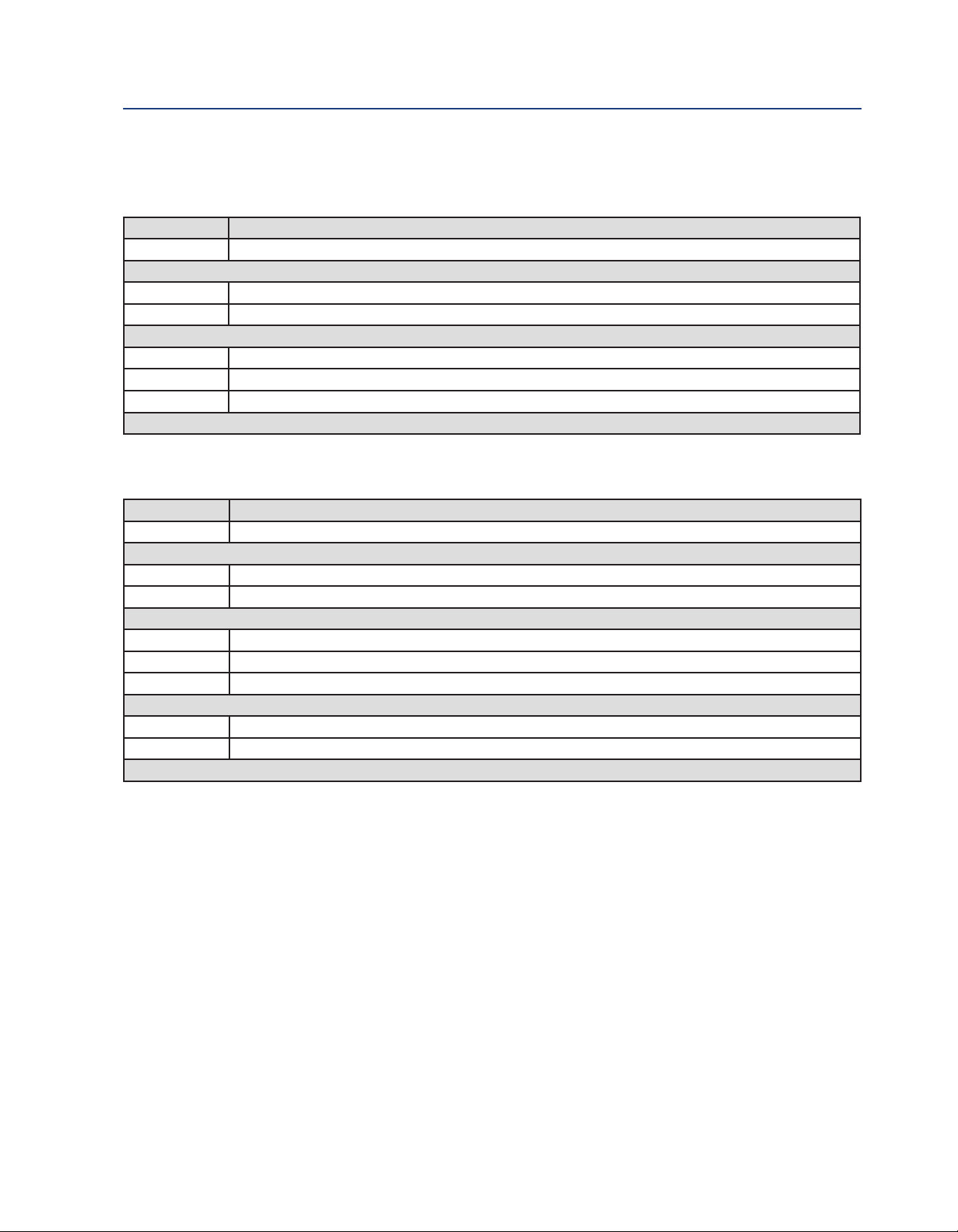

able 1-7: Rosemount 3500P sensor ordering information

T

Model Sensor type

3500P pH/ORP Sensor

lectrolyte Selection

E

BF Bio-Film Resistant

HT High Temperature

MR Metal Resistant

OR Oil Resistant

PR Poisoning Resistant

R

S

Preamplifier/Cable

01 Preamplifier with 25 ft.

02 No Preamplifier with 15 ft. Cable

Measuring Electrode Type

10 pH – GPHT Glass

12 ORP

Reference Type

21 Double Junction Reference

O-ring Material

30 EPDM

31 Viton

32 Kalrez

Typical Model Number: 3500P-HT-01-10-21-30

caling Resistant

S

(1)

1. Preamplifier is SMART if selected with option 10. Preamplifier is standard if selected with option 12.

Table 1-7: Rosemount 3500VP sensor ordering information

Model Sensor type

3500VP pH/ORP Sensor

Electrolyte Selection

BF Bio-Film Resistant

HT High Temperature

MR Metal Resistant

OR Oil Resistant

PR Poisoning Resistant

SR Scaling Resistant

Preamplifier/Cable

01 Preamplifier

02 No Preamplifier

(1)

Measuring Electrode Type

10 pH – GPHT Glass

12 ORP

Reference Type

21 Double Junction Reference

O-ring Material

30 EPDM

31 Viton

32 Kalrez

Typical Model Number: 3500VP-HT-01-10-21-30

1. Preamplifier is SMART if selected with option 10. Preamplifier is standard if selected with option 12.

6 Installation

Page 13

Instruction Manual Installation

LIQ-MAN-PERpH-X April 2017

Section 2: Installation

2.1 Storage

1. It is recommended that electrodes be stored in their original shipping containers

until needed.

2. Do not store Rosemount 3500P at temperatures below 14 °F (-10 °C). Rosemount 3300HT,

3300HTVP, 3400HT, and 3400HTVP below 23 °F (-5 °C).

3. Electrodes should be stored with a protective cap containing KCl solution.

4. For overnight storage, immerse the sensor in tap water or 4 pH buffer solution.

5. A pH glass electrode has a limited shelf life of one year.

2.2 Installation

For sensor dimensions, see Figure 2-1 to Figure 2-3.

For sensor orientation and installation, see Figure 2-4 to Figure 2-13.

For wiring, see Figure 2-14 to Figure 2-17.

Figure 2-1: Example of sensor tube replacement

Installation 7

Page 14

Installation Instruction Manual

April 2016 LIQ-MAN-PERpH-X

Figure 2-2: Rosemount 3300HT and 3300HTVP sensor dimensional drawing

8 Installation

Page 15

Instruction Manual Installation

LIQ-MAN-PERpH-X April 2017

Figure 2-3: Rosemount 3400HT and 3400HTVP sensor dimensions with optional Ball

Valve PN 23240-00

Installation 9

Page 16

Installation Instruction Manual

April 2017 LIQ-MAN-PERpH-X

Figure 2-4: Rosemount 3400HT and 3400HTVP sensor dimensions with optional Ball

Valve PN 23765-00

10 Calibration and Maintenance

Page 17

Instruction Manual Installation

LIQ-MAN-PERpH-X April 2017

igure 2-5: Rosemount 3300HT and 3300HTVP flow through and insertion installation.

F

1½ in. pipe Tee (PN 2002011) with 1 in. threaded connections.

Note: The sensor must be mounted at least 10° above the horizon.

Figure 2-6: Rosemount 3500P and 3500VP sensor dimensional drawing

Calibration and Maintenance 11

Page 18

Installation Instruction Manual

April 2017 LIQ-MAN-PERpH-X

Figure 2-7: Rosemount 3500P AND 3500VP Jet Spray Cleaner (PN 12707-00) for

Submersion Installation.

This accessory is especially useful for keeping the sensor clean in dirty ponds or tanks. It can

be mounted using the Handrail Mounting Assembly or a similar submersion accessory.

Figure 2-8: Rosemount 3500P and 3500VP flow through installation

12 Installation

Page 19

Instruction Manual Installation

LIQ-MAN-PERpH-X April 2017

Figure 2-9: Rosemount 3500P or 3500VP for Submersion Installation using the

Handrail Mounting Assembly (PN 11275-01)

All parts shown are supplied. Sensor sold separately.

Installation 13

Page 20

Installation Instruction Manual

April 2017 LIQ-MAN-PERpH-X

igure 2-10: Rosemount 3400HT and 3400HTVP mounting details – retraction version

F

Figure 2-11: Exploded view of 1½ in. ball valve kit PN 23240-00 used with process connector

PN 23166-00 (or PN 23166-01).

Ball valve kit includes 11/2" x 1" reducer, 11/2" close nipple, and 11/2" ball valve.

Figure 2-12: Exploded view of 1¼ in. ball valve kit (PN 23765-00)

14 Installation

Page 21

Instruction Manual Installation

LIQ-MAN-PERpH-X April 2017

igure 2-13: Rosemount 3300HT or 3300HTVP typical submersion installation

F

Installation 15

Page 22

Installation Instruction Manual

April 2017 LIQ-MAN-PERpH-X

2.3 Retraction with Kit P/N 23240-00

WARNING

ystem pressure may cause the sensor to blow out with great force unless care is taken during removal.

S

2.3.1 Rosemount 3400HT/3400HTVP-21 (21 in. Tube)

Be certain system pressure at the sensor is below 64 psig (542 kPa) before proceeding with the

retraction. It is also recommended that the personnel wear a face shield and have a stable footing.

Refer to Figure 2-1. Push in on the sensor end or the top of the J-box and slowly loosen the hex nut

(B) of the process end male connector (A).

2.3.2 Rosemount 3400HT/3400HTVP-25 (36 in. Tube)

1. Be certain that pressure at the sensor is below 35 psig (343 KPa) before proceeding with

the retraction. It is also recommended that the personnel wear a face shield and have a

stable footing. Refer to Figure 2-1. Push in on the sensor end or the top of the J-box and

slowly loosen the hex nut (B) of the process end male connector (A).

CAUTION

Do not remove nut at this time.

2. When the hex nut is loose enough, slowly ease the sensor back completely until the

retraction stop collar is reached.

NOTICE

Failure to withdraw the sensor completely may result in damage to the sensor when the valve is closed.

3. Close the ball valve slowly. If there is resistance, the valve may be hitting the sensor. Double

check that the sensor has been retracted to the retraction stop collar.

WARNING

Before removing the sensor from the ball valve, be absolutely certain that the ball valve is fully closed.

Leakage from the male connector threads may indicate that the male connector is still under pressure.

Leakage through a partially open valve could be hazardous, however with the ball valve closed, some

residual process fluid may leak from the connector's pipe threads.

4. The male connector body (A) may now be completely unthreaded from the reducing

coupling and the sensor removed for servicing.

NOTICE

If the male connector leaks during insertion or retraction, replace the O-ring (PN 23594-01) in the male

connector A.

16 Installation

Page 23

Instruction Manual Installation

Gre

en

W

h

ite

/Red

Whi

t

e

R

ed

W

h

it

e/

G

r

a

y

G

ray

Bl

u

e

C

l

ear

O

ran

g

e

54ep

H

/O

RP

5081

C

l

e

a

r

(

m

V/p

H

Sh

iel

d)

Bl

u

e

(S

o

lu

t

io

n

G

r

o

un

d

)

G

r

ay (R

e

fer

e

n

ce

i

n)

W

h

it

e

/G

r

a

y

(Re

f

ere

n

ce

Shi

eld

)

R

ed

(R

TD

in)

White/R

e

d (RTD Se

n

se

)

W

h

it

e

(RTD

R

et

u

r

n

)

O

ra

n

g

e

(

m

V

/pH

in

)

X

M

T

+

5

V

D

C /

+

V

S

NSR

R

TD S

E

N

S

E

/

SN

S

R

TD

I

N

p

H

/pH in

-

5

V

D

C / -V SNSR

RT

D RT

N

/

RT

N

Ref

SHLD

/

SHLD /GU

A

RD

p

H

S

HL

D

/

SHLD / GUARD

REF / REF IN

GN

D

/

SOL GND

1

2

1

4

5

1

0

1

1

3

6

9

7

2

8

1

4

5

10

3

6

9

7

2

8

C

o

n

n

e

ct

t

o

ins

t

r

um

e

n

t

g

ro

u

n

d

or

a

s

s

h

ow

n

ID

(i

n

n

e

r d

rai

n)

(N

o

Co

n

n

ect

i

o

n

Ro

s

emount

i

ntr

uments:

56 / 105

6

/ 105

7

/

1066

•

F

or

3300

H

T

,

3

30

0

H

T

V

P,

3

4

0

0H

T

, 34

0

0

H

TVP

,

35

0

0P

-

02,

&

35

00V

P-0

2

s

e

ns

o

rs

•

N

o

n

-

pr

e

a

mp

se

nsor

s

•

B

lue

Cab

le

PERp

H

-X

S

e

n

s

or

s,

Pr

e

am

pl

i

f

ie

r

i

n

Instr

u

m

e

n

t

G

r

een

Rosemount

LIQ-MAN-PERpH-X April 2017

2.4 Electrical Installation

For additional wiring information on this product, including sensor combinations not shown here,

lease refer to Transmitter Wiring Diagrams

p

Figure 2-14: PERpH-X sensors, preamplifier in instrument

.

Installation 17

Page 24

Installation Instruction Manual

1

4

5

12

10

11

3

6 9 7

2

8

1

4

5

10

11

3

6 9 7 2 8

1

4

5

10

3

6 9 7

2

8

1

4

5

10

3

6 9 7 2 8

BNC

No Connection

TB 2

TB 1

Green

White/Red

White

Red

White/Gray

Gray

Blue

Clear

Orange

)C

D

V 5

+

(

n

eerG

Brown (-5VDC)

54epH/ORP

5081

White/Black ( mV/pH Shield)

)

dn

uo

rG

no

i

t

u

l

o

S(

eulB

Gray (Reference in)

White/Gray (Reference Shield)

)n

i

DTR(

d

eR

White (RTD Return)

)

nia

r

d

r

en

n

i

(

D

I

Black ( mV/pH in)

XMT

+5VDC / +V SNSR

RTD SENSE /SNS

RTD IN

pH/pH in

-5VDC / -V SNSR

RTD RTN /RTN

Ref SHLD / SHLD /GUARD

pH SHLD / SHLD / GUARD

REF / REF IN

GND/SOL GND

12

1

4

5

10

11

3

6 9 7 2 8

1

4

5

10

3

6

9

7

2

8

White/Red (RTD Sense)

ID (inner drain)

(No Connection

Rosemount

intruments:

56/1056/1057/

1066

• For Rosemount 3300HT, 3300HTVP, 3400HT, 3400HTVP, 3500P-02, & 3500VP-02 sensors

• Non-preamp sensors

• Blue Cable

PERpH-X Sensors, Preamplifier in Junction Box

Remote Junction Box PN 23555-00 or Sensor Head Junction Box PN 23709-00

(Both J-boxes include Preamplifier Board PN 23557-00)

Extension Cable PN 23646-01 or

9200273 shown

Extension Cable PN 9200348 can also

be used; extend color scheme from

sensor or VP8 cable instead of using

shown wiring scheme.

Connect to instrument

ground or as shown

April 2017 LIQ-MAN-PERpH-X

Figure 2-15: PERpH-X sensors, preamplifier in junction box

18 Installation

Page 25

Instruction Manual Installation

G

r

e

e

n

W

h

i

te

/

Re

d

W

h

i

te

Re

d

White/

G

ray

G

ra

y

Bl

ue

Cl

ea

r

O

r

ang

e

54epH/

OR

P

5081

C

l

e

a

r

(

mV

/

p

H

S

h

i

e

l

d

)

Bl

ue

(

S

o

luti

on Gr

oun

d

)

G

r

ay (

R

ef

e

r

en

ce

i

n

)

W

hi

te/

G

r

a

y

(

-5

V)

Red

(

R

TD in)

Whi

t

e/

R

e

d

(

R

T

D

Se

n

s

e

)

Wh

i

t

e

(

R

T

D

R

e

t

u

rn)

G

r

e

e

n

O

ran

ge

(

m

V

/p

H

in)

XMT

12

1

4 5

10

1

1

3

6

9

7

2

8

1

4 5

1

0

3

6 9 7 2 8

Co

n

n

e

c

t

t

o

i

nst

ru

me

n

t

g

r

o

u

nd

or

a

s

sho

w

n

I

D

(inne

r

d

r

a

in) (+

5

V)

+5VDC / +V SNSR

R

T

D

S

E

NS

E

/S

N

S

RTD

IN

pH/pH in

-5

VD

C /

-

V

S

N

SR

R

TD

R

TN

/R

T

N

Re

f

SHLD / SHLD /GUARD

p

H

SHL

D

/ S

H

LD

/

G

UA

R

D

REF

/ REF IN

G

N

D/SOL GN

D

Rosemount

intruments:

56 / 1056 / 1057 /

1

0

66

•

For

3

30

0HTVP

-

70,

34

00

HT

V

P

-

70,

3

500P

-01

,

&

3

5

0

0

VP

-

0

1

s

e

n

s

ors

•

P

re

amp

l

i

fi

e

r

in

s

en

s

o

r

•

B

l

u

e

Ca

ble

PERp

H-

X

S

e

nsor

s, Pr

e

a

mpli

f

i

e

r

i

n

Se

n

s

o

r

Rosemount

LIQ-MAN-PERpH-X April 2017

Figure 2-16: PERpH-X sensors, preamplifier in sensor

Installation 19

Page 26

Installation Instruction Manual

1

4

5

1

2

10 1

1

3

6 9 7 2 8

1

4

5

1

0

11

3

6

9

7

2

8

1

4 5

10

3

6

9

7

2

8

1

4

5

1

0

3

6

9

7

2

8

Rem

o

t

e

Ju

nc

ti

o

n

Bo

x PN

2

35

50

-0

0

(

wi

th

Ex

te

n

s

io

n

b

o

ard

for

p

o

int-

to

-po

i

n

t

wiring

)

TB

2

TB

1

Gr

e

e

n

W

h

i

t

e/R

ed

Wh

it

e

R

e

d

Whi

te

/Gra

y

Gray

Bl

ue

C

l

ear

(

O

r

a

n

ge s

hie

ld)

Or

a

n

g

e

Ex

t

e

n

sion Cable PN 2

3

646

-

01

o

r

9

2

0

0

2

73

sh

o

wn

.

Exten

sio

n C

a

b

l

e PN 920034

8

can also be used; White/gray

is

rep

laceme

n

t wi

r

e

colo

r

fo

r

Brow

n

wir

e

.

Gr

e

e

n (+

5 VD

C)

54

epH

/

O

R

P

5081

Wh

i

te/

Bl

ack (mV/pH Sheild)

B

l

ue

(

Solu

tio

n

Gro

u

nd)

G

r

a

y

(

R

e

f

e

r

e

nc

e

i

n)

W

hi

te/

Gr

a

y

(No

co

nn

ec

ti

o

n

)

Red

(R

T

D in)

W

h

ite

(

R

T

D Re

t

u

r

n)

I

n

ne

r

D

rain

Bl

a

ck ( mV/

p

H

in)

XMT

12

1

4

5

10

11

3

6 9 7 2 8

1

4

5

10

3

6 9 7

2

8

12

1

1

ID

(

i

nn

e

r

drain

)

C

o

nn

e

c

t

to

ins

t

ru

m

e

nt

g

r

ound

or

as

s

h

own

W

hi

te

/

Re

d

(

R

T

D

S

e

n

se

)

+5VDC / +V SNSR

RT

D

SENSE

/S

N

S

RTD IN

pH

/

pH in

-5V

D

C

/

-

V

SNSR

R

TD RTN /R

T

N

R

e

f

SH

LD / S

H

L

D /

G

UAR

D

p

H

SHL

D /

SH

LD

/

GUA

R

D

REF / REF IN

GND/SOL GND

B

r

own

(-

5VDC)

PE

R

p

H

-X Se

n

so

r

s

,

P

re

am

p

l

i

f

i

er

i

n

S

e

n

s

o

r

,

Ju

n

c

t

i

o

n

Bo

x

u

se

d

f

o

r

e

x

te

n

d

i

n

g

c

ab

l

e

R

ose

mount

i

nt

rument

s

:

56

/

10

56 /

1

05

7

/

1

0

6

6

•

F

o

r

33

0

0

H

T

V

P

-

70,

3

40

0H

T

VP

-

70,

3

5

0

0P-

02

,

&

35

00VP-

02

s

ens

o

rs

• Pre

a

m

p

l

i

fi

e

r

i

n

s

e

n

s

o

r

• Bl

u

e

Cabl

e

Rosemount

April 2017 LIQ-MAN-PERpH-X

Figure 2-17: PERpH-X sensors, preamplifier in sensor – junction box used for

extending cable

20 Installation

Page 27

Instruction Manual Startup and Calibration

LIQ-MAN-PERpH-X April 2017

Section 3: Startup and Calibration

3.1 Electrode Preparation

1. Remove electrode from shipping container.

2. Remove the protective boot covering the electrode bulb.

3. Rinse away salt film with clean water, then gently shake the electrode so that the internal

solution fills the bulb, thus removing any air trapped there.

CAUTION

The buffer in the protective boot may cause skin or eye irritation.

3.2 pH Sensor Calibration

3.2.1 Two Point pH Buffer Calibration

Select two stable buffer solutions, preferably pH 4.0 and 7.0 (pH buffers other than pH 4.0 and

pH 7.0 can be used as long as the pH values are at least two pH units apart).

Note: A pH 7 buffer solution reads a mV value of approx. zero, and pH buffers read

approximately ± 59.1 mV for each pH unit above or below pH 7. Check the pH buffer

manufacturer specifications for millivolt values at various temperatures since it may affect

the actual value of the buffer solution mV/pH value.

1. Immerse the sensor in buffer solution. The buffer solution must contact the metal housing

of the sensor which acts as the solution ground contact. Allow sensor to equilibrate to the

buffer temperature and wait for reading to stabilize. Value of buffer can now be

acknowledged by the transmitter.

2. Once the first buffer has been acknowledged by the transmitter, rinse the buffer solution

off of the sensor with distilled or deionized water.

3. Repeat steps 1 and 2 using the second buffer solution.

4. The theoretical slope value, according to the Nernst equation for calculating pH, is

approximately 59.17 mV/pH. Over time the sensor will age, both in the process and in

storage, and will result in reduced slope values. To ensure accurate readings, it is

recommended that the electrode be replaced when the slope value falls below

47 to 49 mV/pH.

3.3 Recommended pH Sensor Standardization

For maximum accuracy, the sensor can be standardized on-line or with a process grab sample after

a buffer calibration has been performed and the sensor has been conditioned to the process.

Standardization accounts for the sensor junction potential and other interferences.

Standardization will not change the sensor’s slope but will simply adjust the analyzer’s reading to

match that of the known process pH.

Startup and Calibration 21

Page 28

Starup and Calibration Instruction Manual

April 2017 LIQ-MAN-PERpH-X

22 Startup and Calibration

Page 29

Instruction Manual Maintenance

LIQ-MAN-PERpH-X April 2017

Section 4: Maintenance

4.1 Electrode Cleaning

lectrodes should respond rapidly. Sluggishness, offsets, and erratic readings are indicators that

E

the electrodes may need cleaning or replacement.

1. To remove oil deposit, clean the electrode with a mild non-abrasive detergent.

2. To remove scale deposits, soak electrodes for 30 to 60 minutes in a 5% hydrochloric acid

solution.

4.2 Reference Junction Replacement and Sensor

Electrolyte Recharge

The reference junction and reference fill gelled solution is replaceable to facilitate longer sensor life

due to electrolyte depletion and junction plugging and contamination. Use the junction

replacement kit and reference fill gel to accomplish this procedure.

1. Remove the junction cap by turning counter clockwise.

2. Remove the liquid junction by pulling the junction straight out.

CAUTION

The reference electrolyte may cause skin or eye irritation.

3. Remove the old reference fill gel by rinsing with water.

4. Fill the reference fill chamber with the reference fill gel using the syringe and remove any

air bubbles. Top off the reference fill chamber until it is completely filled.

5. Replace the junction O-ring and liquid junction by sliding over the glass electrode.

Excess reference gel should flow out.

6. Replace junction cap by turning clockwise. Hand tighten the junction cap only do not use

pliers to tighten the cap.

7. Buffer check and calibrate the sensor as described in the previous section.

Maintenance 23

Page 30

Maintenance Instruction Manual

April 2017 LIQ-MAN-PERpH-X

24 Maintenance

Page 31

Instruction Manual Accessories

IQ-MAN-PERpH-X April 2017

L

Section 5: Accessories

5.1 Accessories

Table 5-1: Rosemount 3300HT/3300HTVP/3400HT/3400HTVP/3500P/3500PVP sensors accessories

Part Number Description

Rosemount 3300HT/3300HTVP/3400HT/3400HTVP Sensors

23166-00 1 in. MNPT process connector, stainless steel with EPDM O-ring

23166-01 1 in. MNPT process connector, titanium with EPDM O-ring

23796-00

9550220 Process connector O-ring, Kalrez, 2-214

23594-01 Process connector O-ring, EPDM, 2-214

23555-00 Remote junction box with preamplifier

2002565 Mounting bracket kit (for remote junction box)

23709-00

23646-01 Extension cable, 11 conductor, shielded, prepped (for use with junction box)

9200273 Extension cable, 11 conductor, shielded, unprepped (for use with junction box)

23555-00 Remote junction box with preamplifier

23646-01 Extension cable, 11 conductor, shielded, prepped (for use with junction box)

9200273 Extension cable, 11 conductor, shielded, unprepped (for use with junction box)

915240-03 PVC flow through Tee, ¾ in. NPT process connection

915240-04 PVC flow through Tee, 1 in. NPT process connection

915240-05 PVC flow through Tee, 1-½ in. NPT process connection

2002011 CPVC flow through Tee, 1-1/2” NPT process connection

11275-01 Handrail mounting assembly

24091-00 Low flow cell, 1 in. NPT adapter

12707-00 Jet spray cleaner

24281-00 15 ft. cable with mating VP8 connector

24281-01 25 ft. cable with mating VP8 connector

24281-02 2.5 ft. cable with mating VP8 connector

24281-03 50 ft. cable with mating VP8 connector

24281-04 100 ft. cable with mating VP8 connector

24281-05 4 ft. cable with mating VP8 connector

24281-06 10 ft. cable with mating VP8 connector

24281-07 20 ft. cable with mating VP8 connector

24281-08 30 ft. cable with mating VP8 connector

9210012 Buffer Solution, 4.01 pH, 16 oz

9210013 Buffer Solution, 6.86 pH, 16 oz

9210014 Buffer Solution, 9.18 pH, 16 oz

R508-8OZ ORP Solution, 475 mV, 8 oz

(1)

(

316 SST retraction kit for use with a 1-¼ in. full port ball valve

1)

Sensor head junction box with preamplifier

Rosemount 3500P/3500VP Sensors

Common Accessories

Accessories 25

Page 32

Accessories Instruction Manual

April 2017 LIQ-MAN-PERpH-X

Part Number Description

Solution Kits

24231-00 High temperature solution kit (0 to 145 °C) with EPDM O-rings

24231-01 Bio-film resistant solution kit (0 to 60 °C) with EPDM O-rings

24231-02 Poisoning resistant solution kit (0 to 100 °C) with viton O-rings

4231-03

2

il resistant solution kit (0 to 100 °C) with viton O-rings

O

24231-04 Scaling resistant solution kit (0 to 100 °C) with EPDM O-rings

4231-05

2

etals resistant solution kit (0 to 145 °C) with EPDM O-rings

M

Reference Junction Kits

24238-00 High temperature porous teflon liquid junction (EPDM O-rings)

24239-00 High temperature porous teflon liquid junction (Viton O-rings)

24240-00 High temperature porous teflon liquid junction (Kalrez O-rings)

24238-01 Bio-film resistant porous teflon liquid junction (EPDM O-rings)

24238-02 Poisoning resistant porous teflon liquid junction (Viton O-rings)

24238-03 Oil resistant porous teflon liquid junction (Viton O-rings)

24238-04 Scaling resistant porous teflon liquid junction (EPDM O-rings)

24238-05 Metals resistant porous teflon liquid junction (EPDM O-rings)

Refill Kits

9210392 High temperature refill kit (0 to 145 °C)

9210426 Bio-film resistant refill kit (0 to 60 °C)

9210425 Poisoning resistant refill kit (0 to 100 °C)

9210423 Oil resistant refill kit (0 to 100 °C)

9210424 Scaling resistant refill kit (0 to 100 °C)

9210422 Metals resistant refill kit (0 to 145 °C)

Replacement O-rings for Teflon Junction

24250-00 Viton O-ring kit

24251-00 Kalrez O-ring kit

24270-00 EPDM O-ring kit

(2)

(3)

4)

(

1. For 21 in. and 36 in. extended length sensors only.

2. Solution kits contain one Teflon junction, replacement O-rings, and a syringe with reference electrolyte.

3. Reference junction kits include one Teflon junction and listed O-rings.

4. Refill kits include one syringe with 30 cc of electrolyte refill. (Approximately 4 to 5 refills per syringe).

26 Accessories

Page 33

Instruction Manual EC Declaration of Conformity

LIQ-MAN-PERpH-X April 2017

EC Declaration of Conformity

Note: Please see website for most recent Declaration.

EC Declaration of Conformity 27

Page 34

EC Declaration of Conformity Instruction Manual

April 2017 LIQ-MAN-PERpH-X

28 EC Declaration of Conformity

Page 35

Instruction Manual FM Installation

ANY FM APPROVED

ASSOCIATED APPARATUS

HAVING ENTITY PARAMETERS

NO

N-

H

AZARDOUS

(UNCLASSIFIED)

AREA

CLASS I, II, III, DIVISION 1, GROUPS A-G

T6 Ta = 60°C

SENSOR

ENTITY PARAMETERS

Ui = 13.1U, Ii = 358mA

Pi = 698 mW

Ci = 0.967 µF, Li = 0.1mH

1. NO REVISION TO THIS DRAWING IS PERMITTED WI THOUT

FM APPROVAL.

2. U

max

> U

t

; I

max

> I

t

; (C

i

OF ALL LOOPS + C CABLE) < C

a

;

(L

i

OF ALL LOOPS + L CABLE) < L

a

, P

max

OR P

i

> P

0.

3. SINGLE MULTI-CHANNEL

IS BARRIER OR APPARATUS MUST BE FM APPROVED,

4. SINGLE MULTI-CHANNEL

IS BARRIER OR APPARATUS MANUFACTURE'S

CONTROL DRAWI NGS MUST BE FOLLOWED WHEN INSTALLING THE SYSTEM.

IS BARRIER OR EQUI PMENT MAY BE INSTALLED WITHIN THE HAZARDOUS

(CLASSIFIED) LOCATION FOR WHICH IT IS APPROVED

.

5. INSTALLATION MUST BE IN ACCORDANCE WITH ARTICL

E 500 OF THE NEC

(ANSI/NFPA 70) AND ANSI/ISA RP 12.6.

WARNING: SUBSTITUTION OF COMPONENTS MAY IMPA

IR INTRINSIC SAFETY.

6. pH & AMPEROMETRIC SENSORS WITHOUT PREAMPS ARE SIMPLE APPARATUS.

ZON E

ZONE 0

7. CONTROL EQUIPMENT CONNECTED TO THE ASSOCIATED APPARATUS MUST

NOT USE OR GENERATE MORE THAN 250V.

RESISTANCE BETWEEN INTRINSICALLY SAFE GROUND AND EARTH GROUND

MUST BE LESS THAN OR EQUAL TO 1 OHM.

ANY

FM APPROVED TRANSMITTER FOR

DIVISION 1 WI TH INTRINSICALLY SAFE

OUTPUT PARAMETERS. THIS

FM

APPROVED DEVICE MUST BE INSTALLED

PER ITS INSTALLATION DRAWING.

FM

APPROVED EQUIPMENT (MAY BE

MULTIPLE DEVICES, NUMBER IS LIMITED

BY REQUIREMENTS TO MEET ALL OTHER

IS REQUIREMENTS FOR THE NETWORK)

WITH EQUIVALENT HAZARDOUS AREA

APPROVALS.

H

AZA RDOUS

(CL ASSI

F

IED)

AREA

INTRISICALLY SA FE

9. pH/ORP SENSOR MODELS THAT MAY CONTAIN THE PREAMPLIFIER:

3900/VP

3500/VP

3300HT/VP

3400HT/VP

396/VP

396R/VP

396P/VP

398R/VP

399/VP

389/VP

385/385+

10. WARNING: TO PREVENT IGNITION OF FLAMMABLE OR COMBUSTIBLE

ATM OSPHERES, DISCONNECT POWER BEFORE SERVIC

ING.

11. THE ENTI TY CONCEPT ALLOWS INTECONNECTION OF INTRINSICALLY SAFE

APPARATUS WITH ASSOCIATED APPARATUS WHEN THE FOLLOWING IS TRUE:

U

i

> U

o;

I

i

> I

o;

P

i

> P

o;

C

o

> C

i

+ C CABLE; L

o

> L

i

+ L CABLE.

12. COPY REVI SIONS TO 1400332 TO pH/ORP SHIPPING MANUALS.

13 Ci INCLUDES THE CAPACITANCE OF 500 FEET OF SENSOR CABLE.

13

DWG NO.

1400332

8.

LIQ-MAN-PERpH-X April 2017

Intrisicallly Safe Sensor Installation Drawing - FM

FM Installation 29

Page 36

LIQ-MAN-PERpH-X

Rev. J

April 2017

www.Emerson.com/RosemountLiquidAnalysis

Youtube.com/user/Rosemount

Twitter.com/Rosemount_News

Emerson

8200 Market Blvd.

Chanhassen, MN 55317,

USA

Tel +1 800 999 9307

Fax +1 952 949 7001

Liquid.CSC@Emerson.com

Analyticexpert.com

facebook.com/Rosemount

©2017 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount is a mark of

one of the Emerson family of companies. All other marks are the property of their respective

owners.

The contents of this publication are presented for information purposes only, and while effort has

been made to ensure their accuracy, they are not to be construed as warranties or guarantees,

express or implied, regarding the products or services described herein or their use or applicability.

All sales are governed by our terms and conditions, which are available on request. We reserve the

right to modify or improve the designs or specifications of our products at any time without notice.

Loading...

Loading...