Page 1

TM

Rosemount

242

Toroidal Flow-Through Conductivity Sensor

Instruction Manual

LIQ-MAN-242

Rev. F

June 2017

Page 2

Installations near flammable liquids or in hazardous

not

transmitter, and

sensor combination must be used. The installation

system must comply with the governing approval

hazardous area classification requirements.

any

agency

Proper installation, operation and servicing of this

sensor in a Hazardous Ar ea Installation is entirely

ESSENTIAL INSTRUCTIONS

install,

e within their

and

life; perso nal

Read all instructions prior to installing, operating, and servicing the

7768 and the requested manual will be provided.

If you do not understand any of the instructions, contact your

ow all warnings, cautions, and instructions marked on and

ions of

the appropriate Instruction Manual and per applicable local and

the

ensure proper performance, qualified personnel should install,

people

Replacement of

original components with those constructed from alternative

ELEC

agency approvals that were applicable to the original device.

original

process

an affect the

performance, place the safe operation of your process at

are

is being performed by qualified

READ THIS PAGE BEFORE PROCEEDING!

Rosemount designs, manufactures, and tests its products to meet

many national and international standards. Because these instruments are sophisticated technical products, you must properly

use, and maintain them to ensure they continue to operat

normal specifications. The following instructions must be adhered to

integrated into your safety program when installing, using, and maintaining Rosemount products. Failure to follow the proper/ instructions may

cause any one of the following situations to occur: Loss of

injury; property damage; damage to this instrument; and warranty

invalidation.

•

product. If this Instruction Manual is not the correct manual, telephone 1-800-654Save this Instruction Manual for future reference.

•

Rosemount representative for clarification.

• Foll

supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of the product.

• Install your equipment as specified in the Installation Instruct

national codes, for example, ANSI B16.5. Connect all products to

proper electrical and pressure sources.

• To

operate, and maintain the product.

• When repla cement parts are required, ensure that qualified

use replacement parts specified by Rosemount.

materials will void any CSA, FM, and BASEEFA/CENFurthermore, replacement of original components with those con-

structed from alternative materials might change the pressure, temperature, and/or performance specifications from those of the

configuration. Ensure replacement parts are compatible with

requirements. Unauthorized parts and procedures c

product’s

risk, and may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers

in place, except when maintenance

persons, to prevent electrical shock and personal injury.

DANGER

HAZARDOUS AREA INSTALLATION

area locations mus t be caref ully evaluated by qualified on site safety personnel. This sensor is

Intrinsically Safe or Explosion Proof.

To secure and maintain an intrinsically safe installation, the certified safety barrier,

agency (FM, CSA, BASEEFA/CENELEC, or ATEX)

Consult your anal yzer/trans mitter instruction m anu-

al for details.

Replacement of original components with those con-

structed from alternative materials will void

CSA, FM, and BASEEFA/CENELEC

approvals that were applicable to the original device.

the responsibility of the user.

APPLICATION COMPATIBILITY

The wetted sensor materials may not be compatible

with process com pos iti on a nd oper a tin g co nditions.

Replacement of original components with those constructed from alternative materials might change the

pressure, temperatur e, and/or perform ance spec ifications from thos e of the origin al sensor configur ation. Application compat ibi li t y is entirely the responsibility of the user.

CAUTION

SENSOR/PROCESS

Page 3

MODEL 242

TABLE OF CONTENTS

Rosemount 242

TOROIDAL CONDUCTIVITY SENSOR

TABLE OF CONTENTS

Section Title Page

1.0 MODEL 242 SENSOR ............................................................................................. 1

1.1 Features and Applications........................................................................................ 1

1.2 Specifications ........................................................................................................... 2

1.3 Ordering Information ................................................................................................ 5

1.4 Installation ................................................................................................................ 7

1.5 Calibration ................................................................................................................ 10

1.6 Maintenance ............................................................................................................ 13

2.0 Troubleshooting ..................................................................................................... 14

3.0 Replacement Parts................................................................................................. 16

3.1 General .................................................................................................................... 16

3.2 Remove the Sensor From the Process .................................................................... 16

3.3 Disassemble the Sensor .......................................................................................... 16

3.4 Re-assemble the Sensor ......................................................................................... 19

3.5 Re-install the Sensor into the Process ..................................................................... 19

4.0 Return of Materials ................................................................................................ 20

LIST OF TABLES

Table No. Title Page

1-1 Nominal Cell Constants for 242 Sensors................................................................. 10

2-1 Resistance vs. Temperature for RTD (Resistance Temperature Detector) ............. 14

2-2 Sensor Resistance Check........................................................................................ 14

3-1 Replacement Parts and Accessories ....................................................................... 17

3-2 Sensor Bolt Removal & Installation Guide............................................................... 18

i

Page 4

MODEL 242

Rev. Level

Date

Notes

E

03/12

Update addresses pages 22 and 24

TABLE OF CONTENTS

MODEL 242

TOROIDAL CONDUCTIVITY SENSOR

LIST OF FIGURES

Figure No. Title Page

1-1 Pressure-Temperature Specs for 1”, 1.5”, & 2” Sensors: Models 242-02/03/04 .... 3

1-2 Pressure-Temperature Specs for 3” & 4” Sensors: Models 242-06/08 ................... 3

1-3 Pressure-Temperature Specs for 1” & 2” Sensors: Alumina Liner .......................... 4

1-4 Pressure-Temperature Specs for 3” & 4” Sensors: Alumina Liner .......................... 4

1-5 Dimensional Drawing ............................................................................................... 7

1-6 Installation and Torque Guidelines........................................................................... 8

1-7 Sensor to Junction Box Wiring ................................................................................ 9

1-8 Sensor/Junction Box/RTD Assembly ....................................................................... 9

1-9 Extension Cable ...................................................................................................... 10

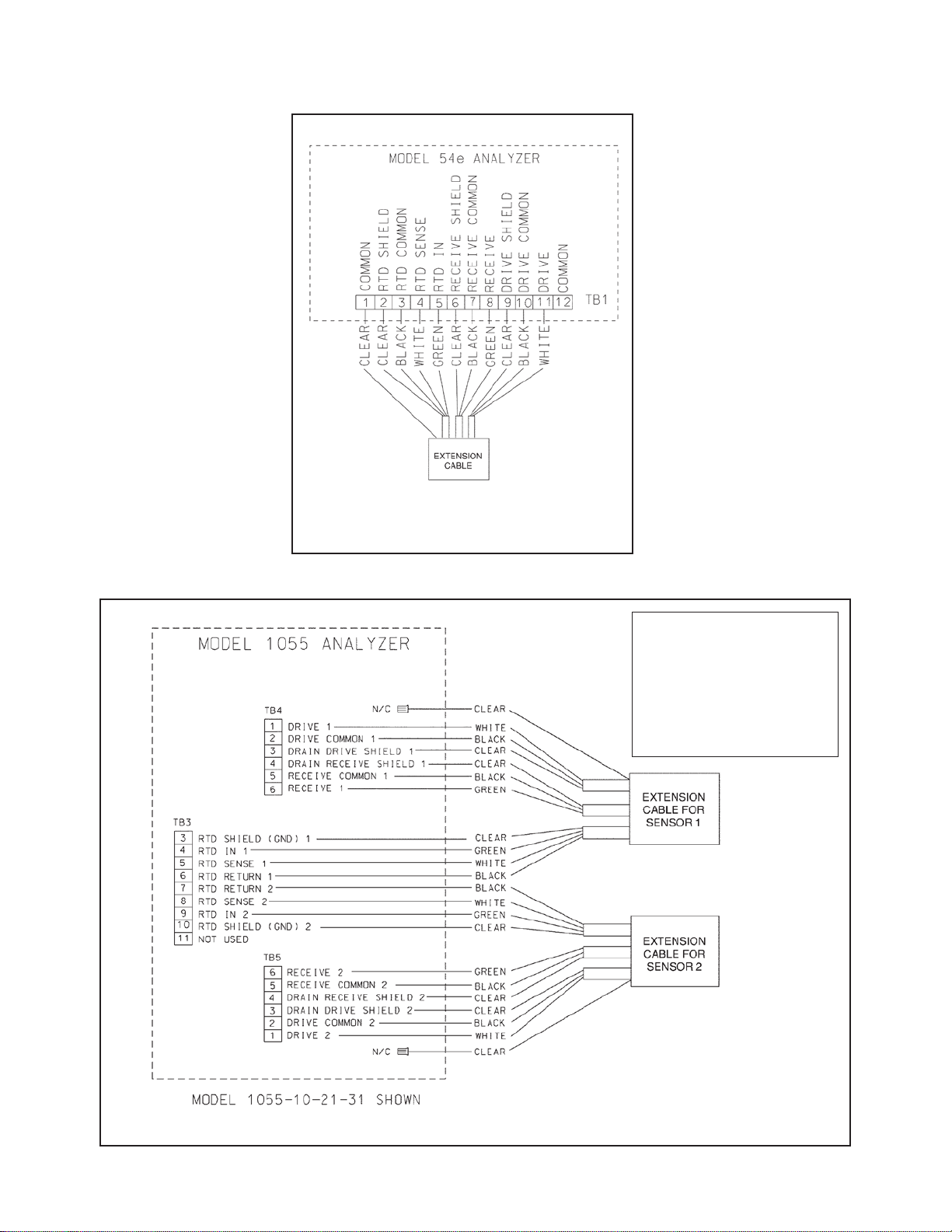

1-10 Extension Cable to Instrument Model 54eC Wiring................................................ 11

1-11 Extension Cable to Instrument Model 1055 Wiring ................................................. 11

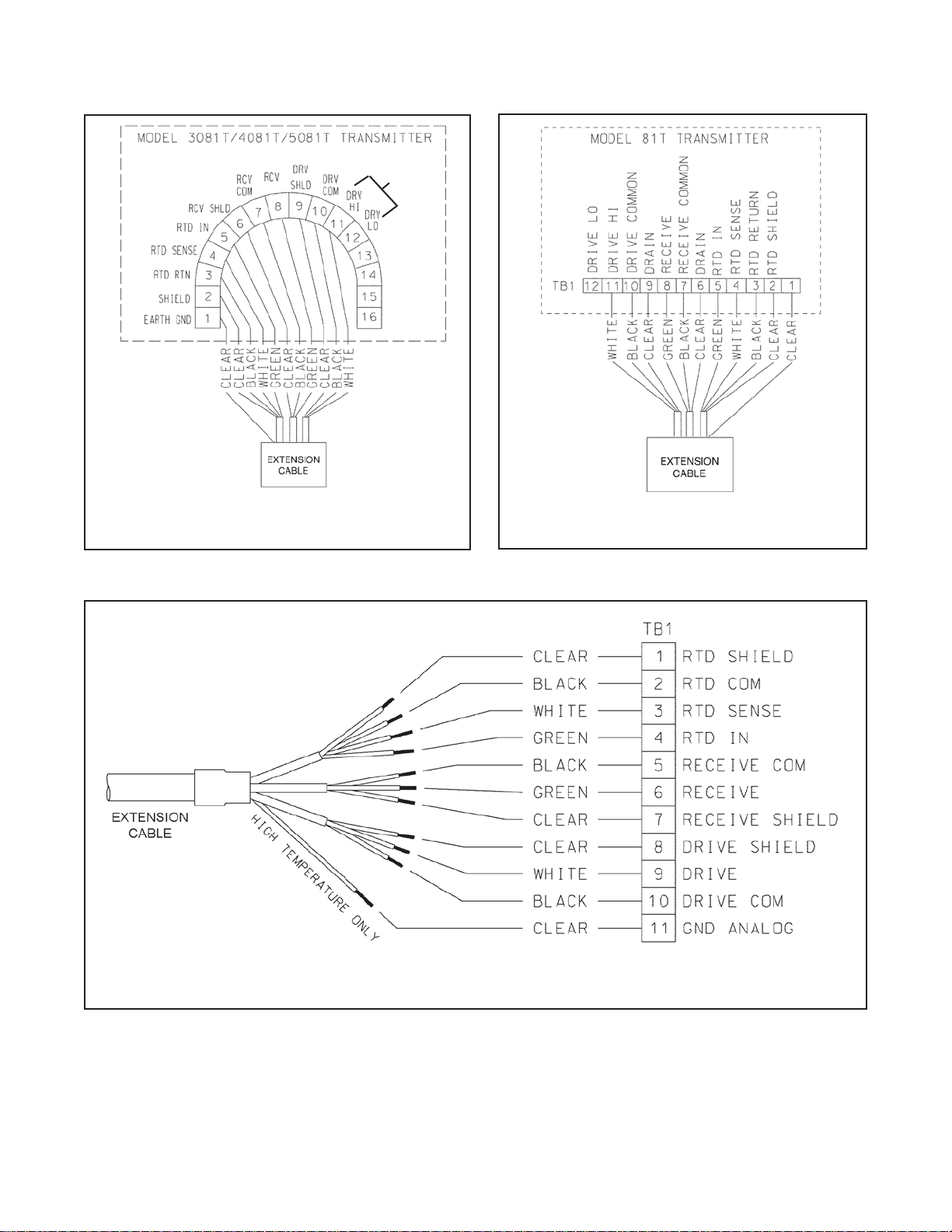

1-12 Extension Cable to Instrument Models 3081T & 4081T Wiring............................... 12

1-13 Extension Cable to Instrument Model 81T Wiring ................................................... 12

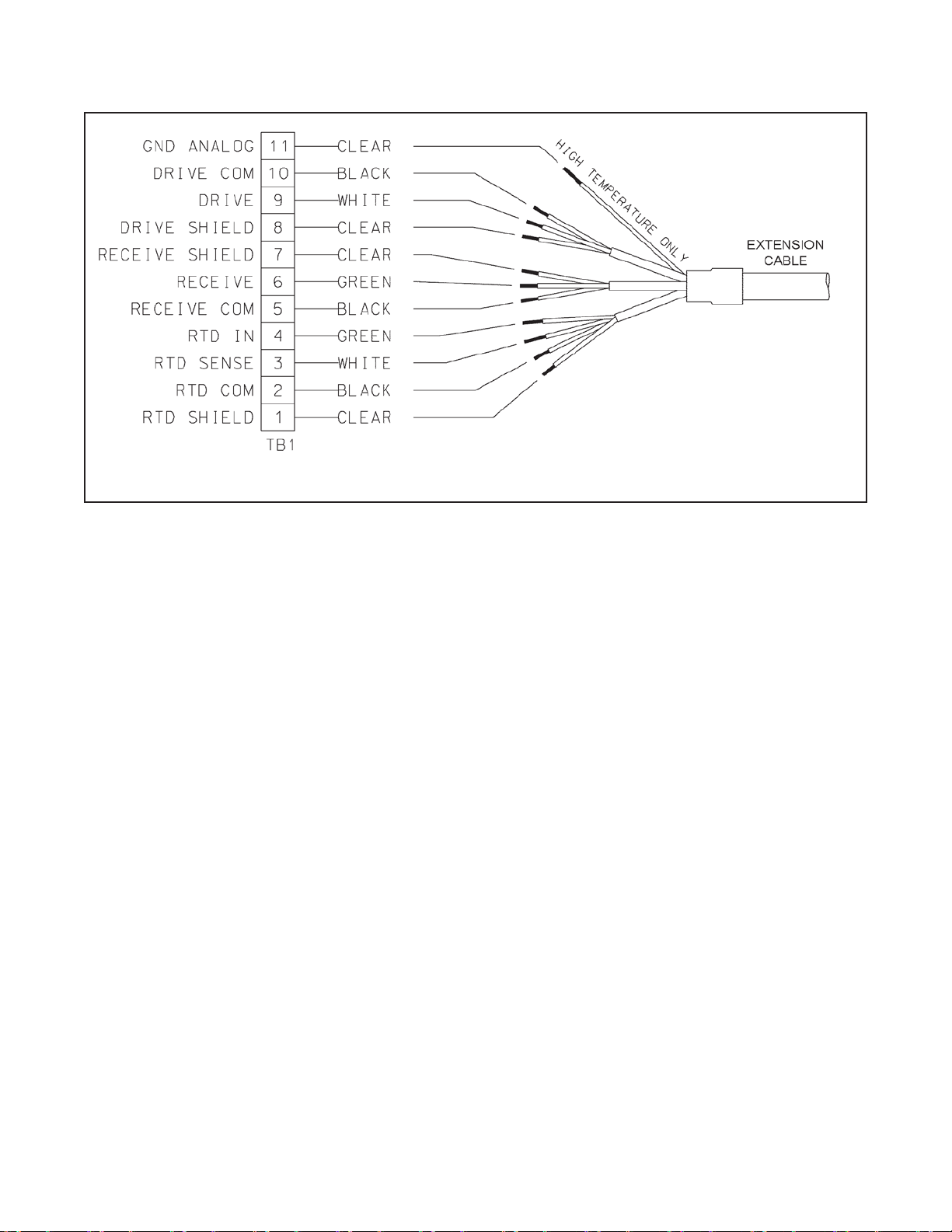

1-14 Extension Cable to Instrument Model Xmt Pipe/Wall Mount Enclosure.................. 12

1-15 Extension Cable to Instrument Model Xmt Panel Mount Enclosure........................ 13

2-1 Sensor Circuit for Troubleshooting .......................................................................... 15

3-1 Model 242 Sensor - Exploded View ........................................................................ 18

3-2 Flange Assembly...................................................................................................... 19

About This Document

This manual contains ins tructions for installation and operation of the Model 242 Flow-Through

Toroidal Conductivit y Sensor. The following list provides notes concerning all revisions of this document.

A 11/02 This is the initial release of the product manual. The manual has been

reformatted to reflect the Emerson documentation style and updated to reflect

any changes in the product offering.

B 8/03 Corrected wiring references in text and drawings. Added information regarding

ATEX approvals with Model 5081T.

C 5/04 Added information regarding the alumina liner, and updated wiring diagrams.

D

ii

Page 5

MODEL 242

SECTION 1.0 242 SENSOR

•

FLOW THROUGH DESIGN is ideal for use with viscous,

abrasive, or fibrous process liquids.

SECTION 1.0

242 SENSOR

• OVER 250 CONFIGURATIONS to meet customers' needs.

• REPLACEABLE LINER in glass-filled PEEK, TEFLON, or

ALUMINA reduces long-term operating costs.

•

DIN and ANSI FLANGES compatible with all piping installations.

•

LINE SIZES of 1 through 4 inches (DN 25, 40, 50, 80 and

100).

• IN-LINE CALIBRATION saves money by reducing labor

and down-time.

• TEMPERATURE SENSOR and JUNCTI ON-BOX included.

1.1 FEATURES AND APPLICATIONS

Rosemount Toroidal Conductivity Sensors are ideal

for use in processes where contacting sen- sors -those with electrodes exposed to the measured

solution -- would corrode or become fouled.

The 242 Flow Through Toroidal conductivity sensor

consists of two toroids surrounding a pipe through

which the process liquid flows. One toroid acts as a

transmitter and the other as a rec eiver. Energi zing the

transmitter toroid induces an electric current in the

process solution which induces an electric current in

the receiver toroid. T he s tr engt h of th e i nduc e d c urr en t

is directly proport ional to the conductivity of the solution.

The 242 sensor is availab le in over two hundred fifty

configurations to meet the needs of m any applications

and installations. Line sizes of 1, 1.5, 2, 3, and 4 inch-

es (25, 40, 50, 80, and 100 mm) are available with

both ANSI and DIN compatible flanges. A variety of

liner materials and O-rings are available to ensure

compatibility with most process liquids.

The 242 sensor is easy to install. It fits in the process

piping between mounting flanges. Spec ial grounding

rings are not needed because the sensor has contact rings built into it. Rec es sed bo lts hold the s ensor

together to ensure all internal parts stay in perfect

alignment. A junction box and a Pt 100 RTD are

included. The RTD slips ea sil y into on e of the sens or

contact rings. T here is no need to insta ll a separate

thermowell, and temperature measurements are

made at the sam e po int as the c o nductivity measurements.

The sensor is not sensit ive to flow rate or direction.

It does not obstruct t he process flow. The sensor is

rugged and constructed from chemically resistant

materials. All these features make the sensor ideal

for applications in mining and metals processing,

pulp and paper processing, and the chemical processing industry.

The 242 Flow Throug h Conductivity Sensor is com patible with instrument instumentsL 54eC, 1055,

3081T, 4081T, 5081-T, and Xmt-T.

1

Page 6

MODEL 242

MODEL 242 SENSOR

Installation Type

Flow Through

Conductivity Range

Process Connections

150# ANSI, 300# ANSI, PN16 DIN 2501 compatible flanges

Maximum Temperature

Maximum Pressure

Wetted Materials:

Shipping Weight

SECTION 1.0

1.2 SPECIFICATIONS

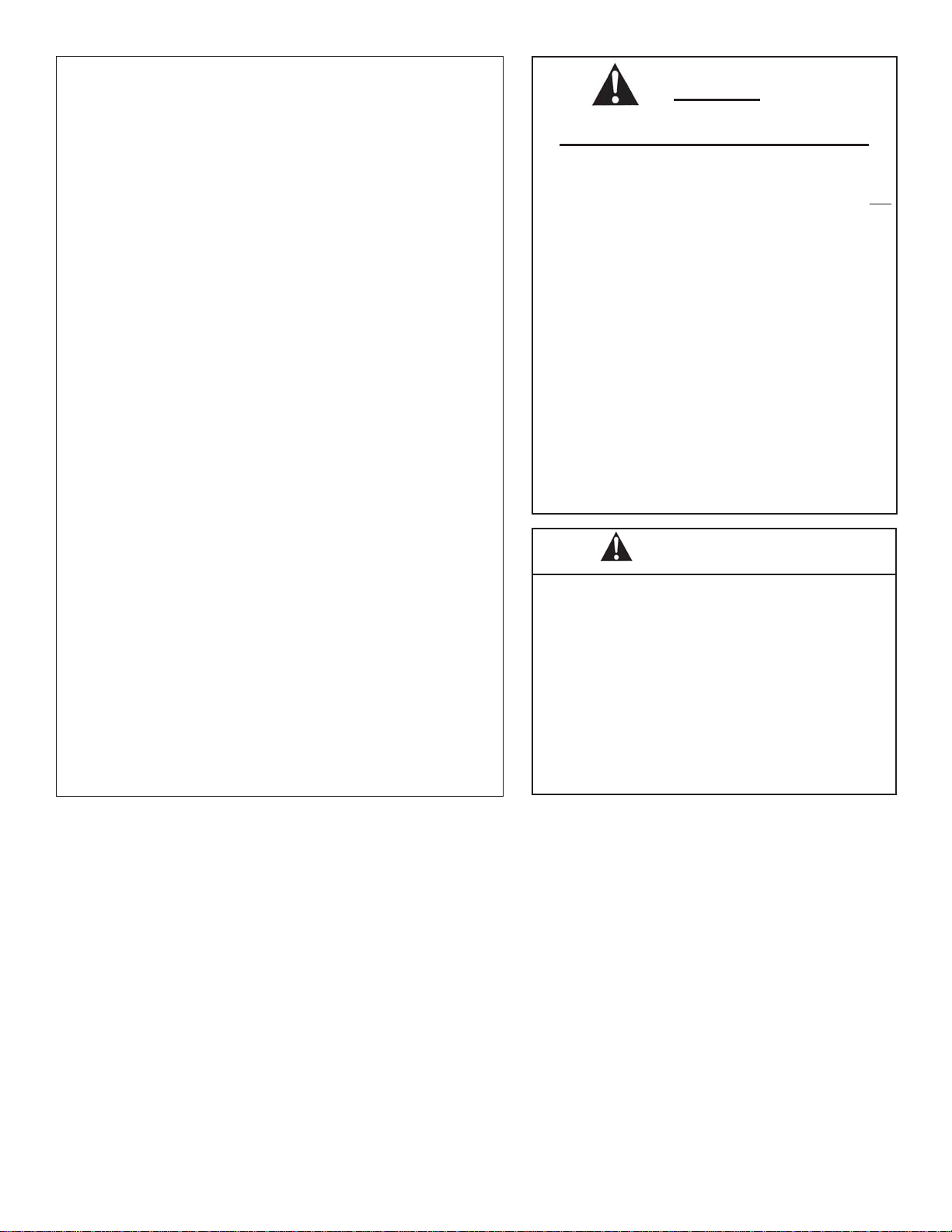

The Model 242 Flow Through Sensor comprises a toroid

housing constructed from 316 stainless steel and polyethyleneterephthalate, process connection flanges of 316

stainless steel, two metal c ontact rings (available in choice

of three materials), an insulating liner (choice of three

materials), O-rings (choice of three materials), a Pt 100

RTD, and a sensor-mounted junction box. Only the liner,

contact rings, and O-rings are wetted b y the process. The

Pt 100 RTD is designed for insertion into one pre-drilled

contact ring. The NEMA 7D junction box is constructed of

heavy duty epoxy-painted cast aluminum . The conductivity

range is user-selectable with the tappe d toroid windings. Inline calibration can be perform ed with resistors connect- ed

to an integral wire around the toroids that is terminated in

the junction box.

Liners are available in T eflon, glass-filled Polyetherether ketone (PEEK), and alumina. These m aterials provide

excellent chem ical resistance. P EEK is recom mended for high pressure or high tem perature appl ications. Tef lon

is recommended when the process solution contains hydrofluoric acid or other strong oxidizing agents. Alumina is

recommended if the process solution is abrasive, such as in alumina/caustic ratio applications.

Pt 100 RTD

Flange

Contact Ring

Liner

O-ring (not visible)

100 μS/cm to 2 S/cm

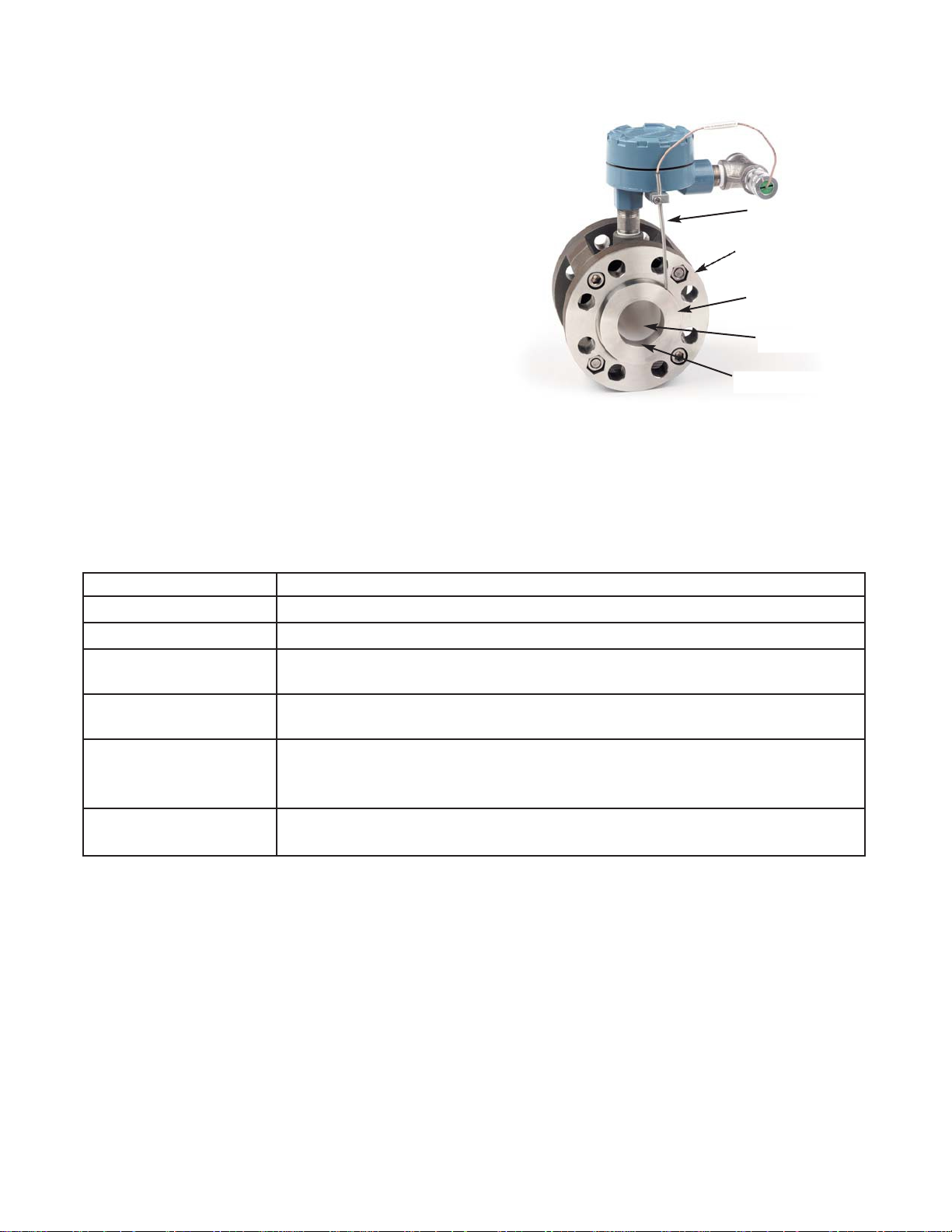

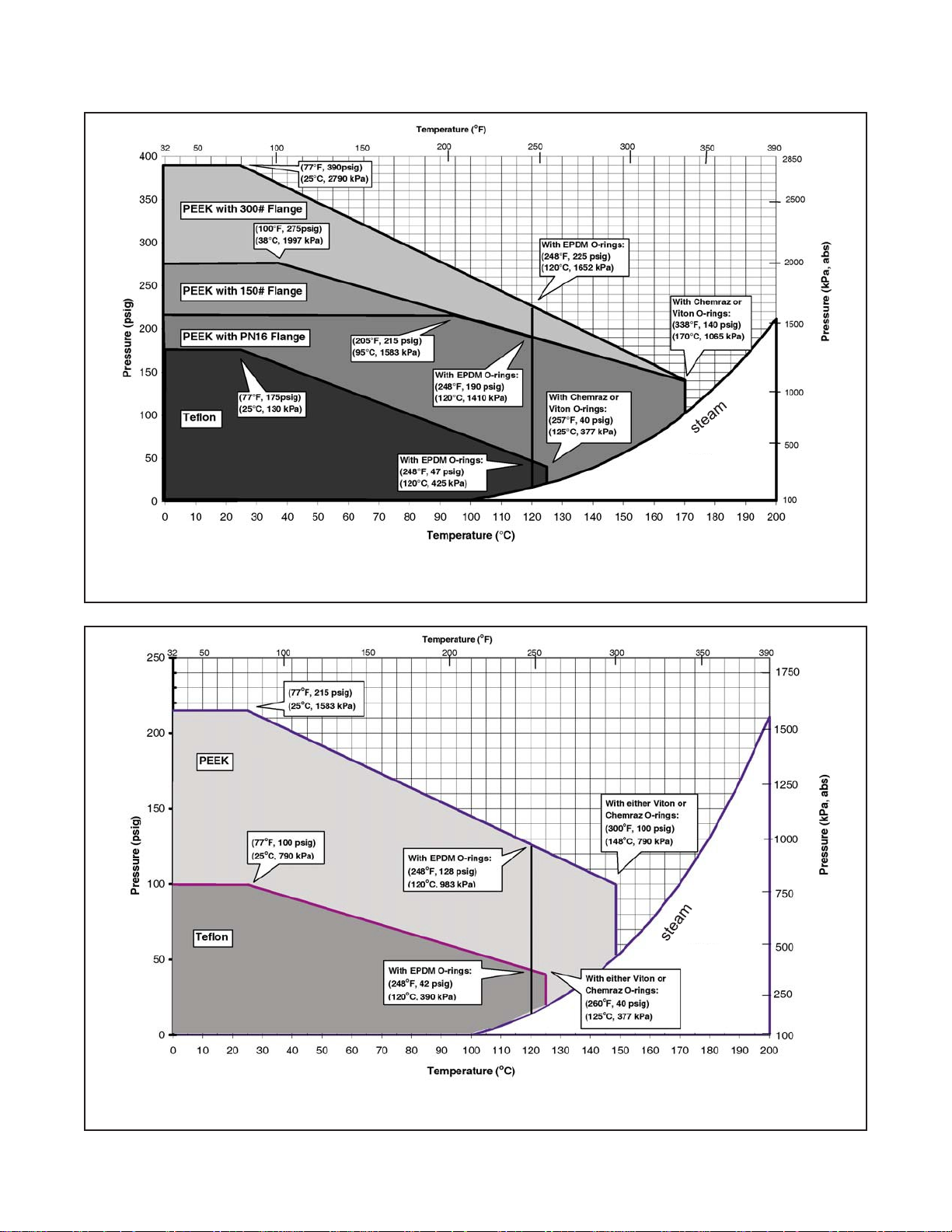

Depends on configuration. For plastic-lined sensors, see charts on facing page.

For alumina-lined sensors, see charts on page 4.

Depends on configuration. For plastic-lined sensors, see charts on facing page.

For alumina-lined sensors, see charts on page 4.

Liner

Contact Rings

O-rings

®

Teflon

(PTFE), glass-filled PEEK, or alumina

316 SST, Carpenter 20Cb-3

EPDM, Viton

1” to 2”: 22 lbs. (10kg)

3” to 4”: 86 lbs. (39 kg)

Teflon is a registered trademark of E.I. du Pont de Nemours & Co.

Viton is a registered trademark of Du Pont Dow Elastomers.

Carpenter 20Cb-3 is a registered trademark of Carpenter Technologies.

Hastelloy is a registered trademark of Haynes International.

Chemraz is a registered trademark of Greene, Tweed, & Co.

2

®

SST, or Hastelloy® C-276

®

(FKM), or Chemraz® (FFKM)

Page 7

MODEL 242

MODEL 242 SENSOR

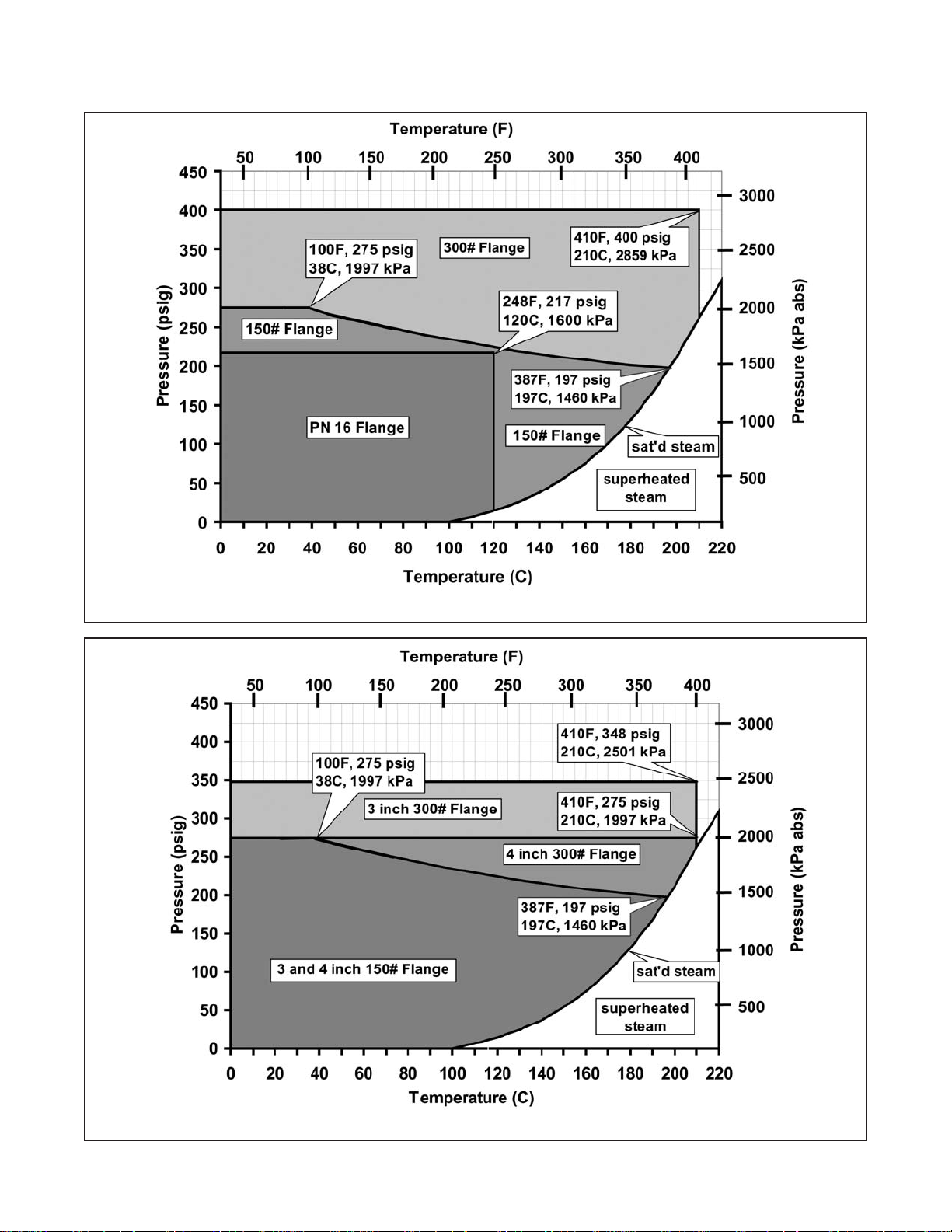

FIGURE 1-1. Pressure - Temperature Specifications for 1”, 1.5”, and 2” (25, 40, and 50 mm) Sensors:

SECTION 1.0

Models 242-02, 242-03, and 242-04

FIGURE 1-2. Pressure - Temperature Specifications for 3” and 4” (80 and 100 mm) Sensors:

Models 242-06 and 242-08

3

Page 8

MODEL 242

MODEL 242 SENSOR

FIGURE 1-4. Pressure - Temperature Specifications for 3” and 4” Sensors: Alumina Liner

SECTION 1.0

4

FIGURE 1-3. Pressure - Temperature Specifications for 1” and 2” Sensors: Alumina Liner

Page 9

MODEL 242

MODEL 242 SENSOR

242

FLOW THROUGH TOROIDAL CONDUCTIVITY SENSOR

CODE

LINE SIZE (Required Selection)

02

1”

DN 25 03

1-1/2”

DN 40 04

2”

DN 50 06

3”

DN 80

(no ATEX approval with 5081T)

08

4”

DN 100

(no ATEX approval with 5081T)

CODE

PROCESS CONNECTION (Required Selection)

10

150# ANSI Flange (Line sizes 1", 1-1/2", 2”, 3”, 4”)

11

300# ANSI Flange (Line sizes 1", 1-1/2", 2”, 3”, 4”)

14

PN 16 Metric Flange (Line sizes DN 25, 40, 50, 80, 100)

CODE

CONTACT RING MATERIAL (Required Selection)

SS

316 Stainless Steel

H4

Hastelloy C-276 (Line Sizes 1", 1-1/2", 2”, 25mm, 40mm, 50mm)

H8

Hastelloy C-276 (Line Sizes 3", 4", 80mm, 100mm)

C4

Carpenter 20-Cb3 (Line Sizes 1", 1-1/2", 2”, 25mm, 40mm, 50mm)

CODE

LINER MATERIAL (Required Selection)

TE

PTFE (Teflon®)

G4

PEEK, 30% Glass-Filled (Line Sizes 1", 1-1/2", 2”, 25mm, 40mm, 50mm)

G8

PEEK, 30% Glass-Filled (Line Sizes 3", 4", 80mm, 100mm)

A4

Alumina (Line sizes 1”, 2”, 25 mm, 50 mm); available only with option F4

A8

Alumina (Line sizes 3”, 4”, 80 mm, 100 mm); available only with option F8

CODE

PROCESS O-RING MATERIAL (Required Selection)

EP

Ethylene Propylene Rubber

VT

Fluorocarbon Rubber (Viton

®

)

F4

High Temp. Perfluoroelastomer (Chemraz

)

(Line Sizes 1", 1-1/2", 2”, 25mm, 40mm, 50mm)

1.3

ORDERING INFORMATION

SECTION 1.0

The 242 Flow-T hrough Sensor is configurable to meet the needs of many applications an d installations (both

ANSI and DIN). After specifying line size and flange type, the customer selects the wetted materials most compatible with the process stream. A NEMA 7D junction box and Pt 100 RTD are also included. Compatible instruments

include Rosemount Models 54eC, 1055, 3081T, 4081T, 5081-T, and Xmt-T.

The extension cable requ ired for wiring from the junction box to th e instrument m ust be ordered separatel y. The

customer supplies the gaskets, mating flanges, and flange bolts.

C8 Carpenter 20-Cb3 (Line Sizes 3", 4", 80mm, 100mm)

F8

242 -0611SSG8VT EXAMPLE

High Temp. Perfluoroelastomer (Chemraz

®

®

) (Line Sizes 3", 4",

80mm, 100mm

)

5

Page 10

MODEL 242

MODEL 242 SENSOR

PART NUMBER

DESCRIPTION

4081T, 5081-T, and Xmt-T (Specify length)

KIT PN

DESCRIPTION

FOR SENSOR MODELS

24005-00

Kit, Liner, 1” DN 25, Teflon PTFE

242-02[ ]TE[ ]

24005-01

Kit, Liner, 1” DN 25, glass-filled PEEK

242-02[ ]G4[ ]

24005-02

Kit, Liner, 1” DN 25, Alumina

242-02[ ]A4[ ]

24006-00

Kit, Liner, 1-1/2” DN 40, Teflon PTFE

242-03[ ]TE[ ]

24006-01

Kit, Liner, 1-1/2” DN 40, glass-filled PEEK

242-03[ ]G4[ ]

24007-00

Kit, Liner, 2” DN 50, Teflon PTFE

242-04[ ]TE[ ]

24007-01

Kit, Liner, 2” DN 50, glass-filled PEEK

242-04[ ]G4[ ]

24007-02

Kit, Liner, 2” DN 50, Alumina

242-04[ ]A4[ ]

24008-00

Kit, Liner, 3” DN 80, Teflon PTFE

242-06[ ]TE[ ]

24008-01

Kit, Liner, 3” DN 80, glass-filled PEEK

242-06[ ]G8[ ]

24008-02

Kit, Liner, 3” DN 80, Alumina

242-06[ ]A8[ ]

24009-00

Kit, Liner, 4” DN 100, Teflon PTFE

242-08[ ]TE[ ]

24009-01

Kit, Liner, 4” DN 100, glass-filled PEEK

242-08[ ]G8[ ]

24009-02

Kit, Liner, 4” DN 100, Alumina

242-08[ ]A8[ ]

KIT PN

DESCRIPTION

FOR SENSOR MODELS

24010-00

Kit, O-Ring, 1” DN 25, EPDM

242-02[ ]EP[ ]

24010-01

Kit, O-Ring, 1” DN 25, Viton

242-02[ ]VT[ ]

24010-02

Kit, O-Ring, 1” DN 25, Chemraz

242-02[ ]F4[ ]

24010-03

Kit, O-Ring, 1” DN 25, Chemraz for use with Alumina liner

242-02[ ]A4-F4

24011-00

Kit, O-Ring, 1-1/2” DN 40, EPDM

242-03[ ]EP[ ]

24011-01

Kit, O-Ring, 1-1/2” DN 40, Viton

242-03[ ]VT[ ]

24011-02

Kit, O-Ring, 1-1/2” DN 40, Chemraz

242-03[ ]F4[ ]

24012-00

Kit, O-Ring, 2” DN 50, EPDM

242-04[ ]EP[ ]

24012-01

Kit, O-Ring, 2” DN 50, Viton

242-04[ ]VT[ ]

24012-02

Kit, O-Ring, 2” DN 50, Chemraz

242-04[ ]F4[ ]

24012-03

Kit, O-Ring, 2” DN 50, Chemraz for use with Alumina liner

242-04[ ]A4-F4

24013-00

Kit, O-Ring, 3” DN 80, EPDM

242-06[ ]EP[ ]

24013-01

Kit, O-Ring, 3” DN 80, Viton

242-06[ ]VT[ ]

24013-02

Kit, O-Ring, 3” DN 80, Chemraz

242-06[ ]F8[ ]

24013-03

Kit, O-Ring, 3” DN 80, Chemraz for use with Alumina liner

242-06[ ]A8-F8

24014-00

Kit, O-Ring, 4” DN 100, EPDM

242-08[ ]EP[ ]

24014-01

Kit, O-Ring, 4” DN 100, Viton

242-08[ ]VT[ ]

24014-02

Kit, O-Ring, 4” DN 100, Chemraz

242-08[ ]F8[ ]

ACCESSORIES

23909-00 Extension cable, Pre-prepped, for connection to Instrument Models 54eC, 1055, 3081T,

SECTION 1.0

24014-03 Kit, O-Ring, 4” DN 100, Chemraz for use with Alumina liner 242-08[ ]A8-F8

6

Page 11

MODEL 242

handled. Do NOT place any object through the liner for

Support structures sho uld be installed as appropriate on

ly support the weight of the sensor during insta llation and

1.4 INSTALLATION

In the instructions below, the Junction Box is installed

after the sensor is bo lted into the process line. If appr opriate for the site and final mounting configuration, the

Junction Box can be installed prior to bolting the sensor

into the process line.

CAUTION

The liner of the Model 242 sensor can be damaged if misthe purpose of lifting the Model 242 sensor.

CAUTION

or around process p ipes and s ensor locat ion to suf ficientminimize strain on adjacent process pipes during the

operational life of the sensor.

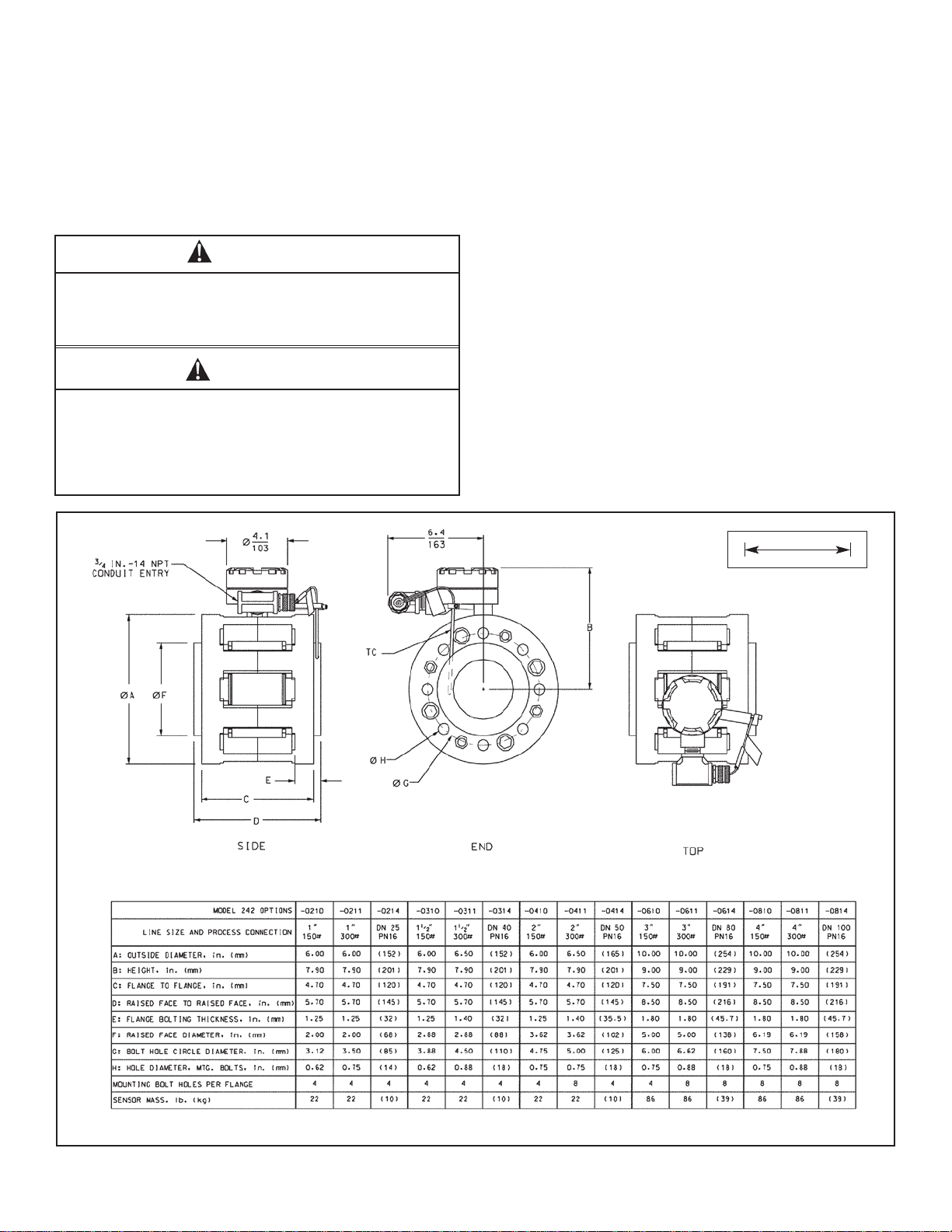

FIGURE 1-5. DIMENSIONAL DRAWING

MODEL 242 SENSOR

SECTION 1.0

Installation of the Mod el 24 2 F lo w Through Sensor is s imilar to installation of a section of pipe. Consequently, be

prepared to use tools, supplies, equipment, and techniques sim ilar to those used to instal l process pipes. Use

common piping practices t o minimize torque and bendin g

loads on process connections. Observe all applicable

safety standards. Dimensional information is shown in

Figure 1-5 below. Refer to Figures 1-6 t o 1-8 for as sembly

and installation diagrams.

NOTES

1. Allow at least f our pipe diameters of straight pip e run

on either side of the sensor.

2. Install the sensor so that it is filled with proces s liquid

at all times when measurements are being made.

Avoid downward flow as such a configuration might

leave the sensor partially empty.

3. Use a sling and hoist to lift and position the sensor.

INCH

MILLIMETER

7

Page 12

MODEL 242

MODEL 242 SENSOR

SECTION 1.0

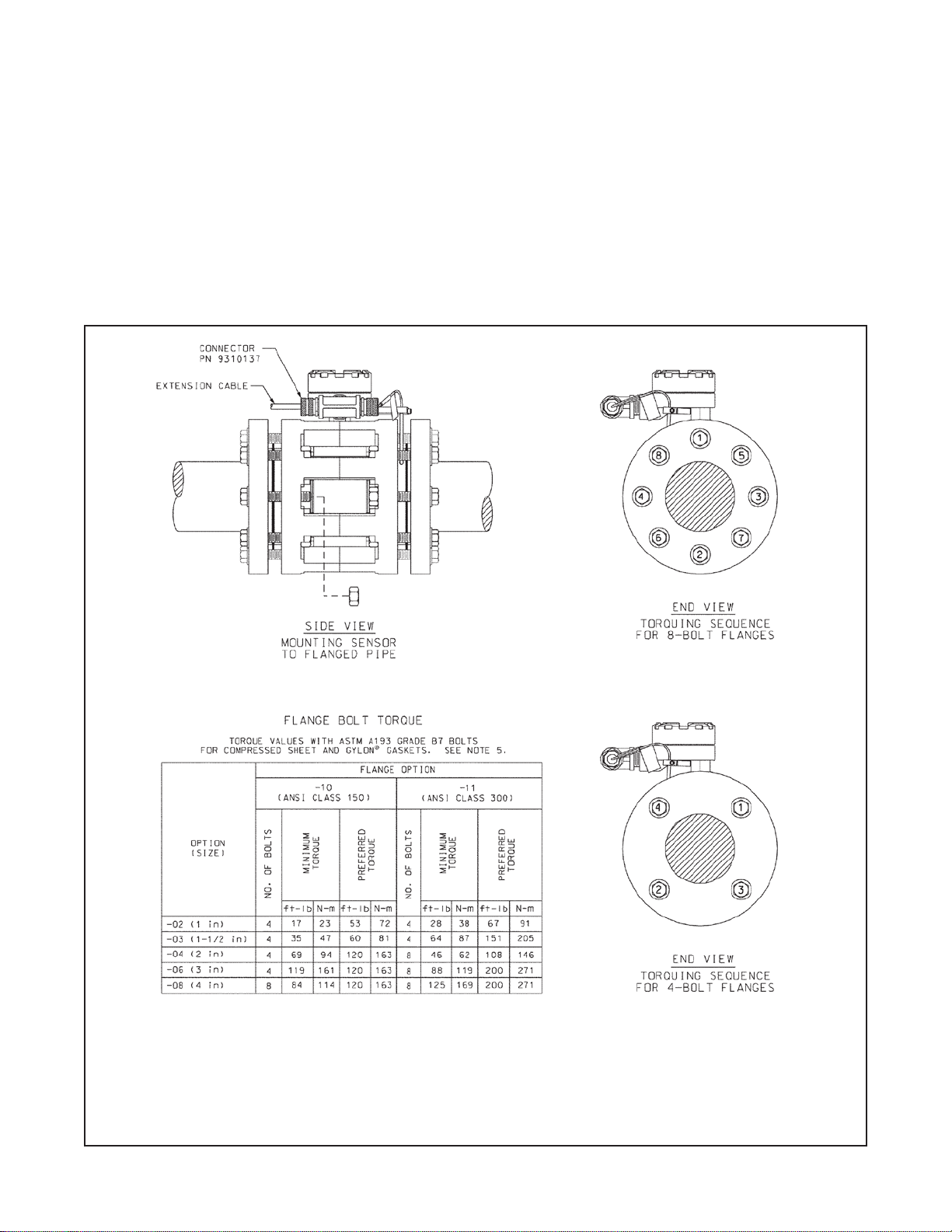

INSTALLING THE SENSOR IN THE PROCESS LINE

1. Install process flanges in accordance with applicable instructions, standards, and local regulations.

2. Position the sensor bet ween the process mating flanges with flange gaskets inserted betwee n each set of

flanges. Ensure that the lo cations of the juncti on box connection a nd the RTD hole in the cont act ring are in

the correct position for easy wiring and use.

3. Align the bolt holes in the sensor and process flanges.

4. Lubricate the bolt threa ds. Using a torque wrench, bol t the sensor into place. Tight en the bolts in 1/3 increments of the final desire d torque. Follow the bolt-tightening sequence and torque suggestions provided in

Figure 1-6.

5. Re-torque the bolts 12 to 2 4 hours after installation . Mak e a final check of torque values b y moving consec utively from bolt to bolt.

Torque values in the table above are from Garlock Sealing Technologies. Other values might apply

when using different bolt and gasket materials.

®

Gylon

is a registered Trademark of Garlock Sealing Technologies.

FIGURE 1-6. Installation and Torque Guidelines

8

Page 13

MODEL 242

MODEL 242 SENSOR

ATTACHING THE JUNCTION BOX

1. Pull the sensor wires up into the junction box.

2. Screw the junction box onto the threaded male connection on

the sensor. Use of pipe sealing tape or other compound is at the

discretion of the customer.

3. Connect the sensor wires to the junction box terminal as indicated in Figure 1-7.

INSTALLING THE Pt100 RTD

1. Use of the included Pt100 RTD is recommended. Use of a customer-supplied Pt100 or Pt1000 TC mounted in a separate thermowell is also acceptable. The accuracy specifications provided

by Rosemount apply only to situations wherein the Pt100 RTD

supplied with the sensor is used.

2. Refer to Figure 1-8. Screw the threaded nipple onto the conduit

connector of the junction box. Screw the tee onto the nipple, and

screw the RTD cable connector onto the tee.

3. Attach the bracket to the shaft of the RTD using the #10 washer

and small screw enclosed in the RTD kit. The purpose of the

bracket is to retain the RTD in the contact ring after installation.

4. Slide the Pt100 RTD into the pre-drilled hole in the contact ring.

Rotate the bracket to a position beneath the junction box, and

tighten the set screw.

5. Thread the RTD wires through cable connector, tee, nipple, and into junction box. Wire the RTD to the junction box terminals as

indicated in Figure 1-7. Install the white jumper wire between terminal s 1 and 2.

*For optimal performance below 10,000 µS/cm, connect

green wire from extension cable to terminal indicated by *

FIGURE 1-7. Sensor to Junction Box Wiring

SECTION 1.0

Items 1-9 are included with the Model 242

sensor. Items 3-9, the white jumper wire,

and Teflon tape are included in the TC kit.

Items 10 and 11 are sold separately as

accessories.

FIGURE 1-8. Sensor/J-bo x/RTD Assembly

9

Page 14

MODEL 242

MODEL 242 SENSOR

Sensor Size

Cell Constant (/cm)*

Black Orange

* The table gives the cell constant when the green receive

Figures 1-7 and 2-1.

1”, DN 25

20

2.0

1.5”, DN 40

9.0

0.90

2”, DN 50

5.0

0.50

3”, DN 80

4.0

0.40

4”, DN 100

2.3

0.23

SECTION 1.0

EXTENSION CABLE HOOK UP

1. Do not run sensor cab le in conduit or open trays

with A.C. power wiri ng. Do not rout e sensor cable

near heavy electrical equipment.

2. For best sensor/instrument loop performance, use

factory-terminated ex te nsio n c abl e (PN 23909-00).

(Using a different cable can introduce noise into

the signal and/or reduce loop accuracy.)

3. One end of extension cabl e (PN 23909-00) has 8

wires, and the other end has 11 wires. Refer to

Figure 1-9. The end with 8 wires goes into the junction box. The end with 11 wires goes to the instrument. The extension cab le enters the j unction box

through the open sid e of the fem ale threaded tee.

Use of conduit, th e optional cable connector (PN

9310137), or other strain relief device to protect the

cable is at the discretion of the customer and

should comply with applicable agency guidelines.

NOTE

If starting with unprepped cable (PN 9200276), remove

only as much insulation as is necessary. The instrument end needs 11 leads: four leads from the greenwhite-black-drain bundle, three from each of the two

coaxial cable bundles (the inner conductor, the insulating braid, and the drain wir e), and one f rom the out ermost overall braided-copper shield. For the junction

box end, only 8 leads are used: t he wh ite coaxi al conductor, its braided shield, the green coaxial cond uctor,

its braided shield, its dr ain wire, and the gre en, white,

and black conductor s f r om the green-white-black-drain

bundle. The rem aining shields a nd drain wires ar e not

used on the junction box end and should be removed -

- they should NOT be connected.

4. Connect the 8 wires of the extension cable t o the

terminal block inside the sensor junction box as

indicated in Figur e 1-7. Note: If all process m easurements will be less than 10,000 µS/cm, connec t

the green wire from the black-green-clear wire bundle of the extension ca ble t o the terminal receiving

the orange sensor wire. See Figure 1-7.

5. Connect the 11 wires of the i nstrument-end of the

extension cable according to the applicable diagram from Figures 1-10 through 1-15.

1.5 CALIBRATION

After sensor and transmitter/analyzer wiring is completed, calibrate the sensor.

NOTE

Most analyzers require the input of the approximate

sensor cell constant bef ore the ana lyzer c alcul ates th e

true cell constant. The nominal cell constant of the

Model 242 sensor dep ends on the size of the se nsor

and the terminal to which the rec eive wire of the inter connecting cable is attached. Refer to Table 1-1 for

the appropriate nominal cell constant value.

TABLE 1-1: Nominal Cell Constants for 242 Sensors

wire (from black-green-clear bundle) of the interconnecting cable is attached to either the black wire terminal or

the orange wire terminal in the sensor junction box. See

10

FIGURE 1-9. Extension Cable

Page 15

MODEL 242

MODEL 242 SENSOR

NOTE: If wiring to a single

21 or to a dual

31, the toroidal sensor is

Blocks

3 and 4. If wiring 2 sensors to

use

SECTION 1.0

FIGURE 1-10. Extension Cable to

Model 54eC Wiring

FIGURE1-11. Extension Cable to Model 1055 Wiring

channel 1055channel 1055-21-xx or 1055xxwired only to Terminal

a dual toroidal 1055-21-31,

TB 3, 4, and 5 as shown.

11

Page 16

MODEL 242

MODEL 242 SENSOR

SELECT

*

HI OR

* Applies only to 3081T

and 4081T.

FIGURE 1-12. Extension Cable to Models 3081T,

4081T, and 5081T Wiring

LO

SECTION 1.0

12

FIGURE 1-14. Extension Cable to Model Xmt Pipe/Wall Mount Enclosure

FIGURE 1-13. Extension Cable to Model 81T

Wiring

Page 17

MODEL 242

MODEL 242 SENSOR

SECTION 1.0

A. To perform liquid calibratio n prior to instal ling the sens or in the process li ne, first seal one e nd of the sens or,

and then proceed with the following steps.

1. Stand the sensor on the sealed end.

2. Fill the sensor completely with a standard conductivity solution.

3. Insert the Pt100 RTD into the contact ring.

4. Adjust the analyzer reading so that it matches the conductivity of the standard solution at the solution tem-

B. Use of the Integral Calibration Loop Wire: This internal wire can be used to facilitate future in-process loop cal-

ibration and to p erf orm a quick verificatio n that the loo p is f unctionin g properly. Performing this ad ditio nal (b ut

optional) step is highly recommended.

1. The sensor must be empty of all fluids, reasonably clean, and preferably completely dry.

2. Attach a variable resistance decade box to the sensor yellow “Cal Loop” wires (in the junction box).

3. Adjust the applied resistan ce until the instrum ent reads the s ame conductivit y value that it did dur ing the

4. To recalibrate the loop at a later d ate, o ptim al res ults will be ach ieve d if the s ensor is retur ned to a cond i-

1.6 MAINTENANCE

The only routine m aintenance required during the operational life of the sensor is to ensure that there are n o

deposits plugging the sens or or coating the inside of the contac t rings. Some custom ers find it advantageous t o

periodically replace process gaskets and/or re-tighten the flange bolts to ensure adequate process seals. Refer to

Figure 1-6 for flange bolting sequence and torque recommendations.

FIGURE 1-15. Extension Cable to Model Xmt Panel Mount Enclosure

perature. Refer to the analyzer/ transmitter instruction manual for complete calibration procedures.

liquid calibration process. Record the conductivity, applied resistance value, and temperature for future reference.

tion approximating its condition d ur in g t he in it ial p er f or mance of steps C.1 to C.3 above. If this is no t possible, the sensor mus t at least be empty of process f luids. Reapply the sam e resistance to the Cal Loop

and adjust the instrument reading.

13

Page 18

MODEL 242

SECTION 2.0

Connection

TABLE 2-2 Sensor Wire Resistance Values

Resistance

(Wire colors are for sensor wires unless indicated)

GREEN

GREEN

GREEN to GROUND screw in J

MegOhms

GREEN

GREEN

WHITE

WHITE to

MegOhms

WHITE

WHITE

YELLOW

YELLOW to GROUND screw in J-box (GRAY wire) > 20 MegOhms

TABLE 2-1 Resistance Values for Pt100 RTD

C = Celsius / F = Fahrenheit

Temperature

Resistance

(°C/°F)

(Ohms)

27 / 80.6

110.4

SECTION 2.0

TROUBLESHOOTING

2.1 TROUBLESHOOTING. The simplest method of trou-

bleshooting is to run a r esistance test on the inducti ve

sensing device. It is also recommended to check the

resistance of the RT D and resistance between vari ous

pairs of the sensor wires.

To perform a quick resistance check of the sensor, recall

the data obtained during Part C of the Calibration

Process (Refer to Sect ion 1. 5) With the sensor empty of

process fluids (preferably also clean and dry), reapply

the resistance to the sensor yellow Cal Loop wires in the

junction box. The reading should be with ±20% of the

original value.

To check the RTD, measure the resistance across th e

RTD wires. See Figure 1-4. The resistance value should

be close to the value shown in Table 2-1.

TROUBLESHOOTING

18 / 64.4 106.9

19 / 66.2 107.3

20 / 68.0 107.7

21 / 69.8 108.1

22 / 71.6 108.4

23 / 73.4 108.9

24 / 75.2 109.2

25 / 77.0 109.6

26 / 78.8 110.0

Refer to Figure 2-1 for a circuit d iagram of the sensor to

use as an aid when perform ing the resistance checks.

Use Table 2-2 to determ ine the resistance values that

should be found across various pairs of sensor wires.

to ORANGE < 1 Ohm

to BLACK 1 to 5 Ohms

-box (GRAY wire) > 20

to WHITE > 20 MegOhms

to YELLOW > 20 MegOhms

to GRAY < 1 Ohm

GROUND screw in J-box (GRAY wire) > 20

to YELLOW > 20 MegOhms

to RED > 20 MegOhms

to YELLOW < 1 Ohm

14

Page 19

MODEL 242

MODEL 242 SENSOR

SECTION 2.0

*The green wire from the extension cable’s black-green-clear bundle might be connected opposite the

sensor’s orange wire, as indicated by

* to utilize the sensor’s alternative cell constant.

FIGURE 2-1. Sensor Circuit for Troubleshooting

15

Page 20

SECTION 3.0

Before removing the s enso r from the process piping,

rings inside the sensor:

ring replacement kits

To distinguish the

ring is less than

ring. The size difference is

rings are

rings have the

ring is less than

ring. The size difference is

rings are

MODEL 242

REPLACEMENT PARTS

SECTION 3.0

REPLACEMENT PARTS

3.1 GENERAL

When replacement parts are required, ensure that

qualified people install the parts specified by

Rosemount. Replacem ent of original com ponents with

those constructed from alternative materials might

change the temperature, pressure, and/or performance

specifications from those of the original configuration

and will void an y CSA, FM, and BASEEFA/CENELEC

agency approvals th at were applicable to the origin al

device. Table 3-1 lists the replacement parts kits for the

Model 242 Sensor. An instruction manual is included

with each kit.

3.2 REMOVE THE SENSOR

CAUTION

ensure that the process ha s been shut do wn and liquid drained from the sensor line. For personal safety,

The RTD can be removed either before or after the

sensor is rem oved from the proc ess. T he junction bo x

should be left attached to the toroid subassembly. After

ensuring that it is s afe to remove the s ensor from the

process line, loosen the flange bolts in 1/ 3 increm ents

in the same order in which they were tightened as

shown in Figure1-4. Remove the bolts and sensor.

3.3 DISASSEMBLE THE SENSOR

NOTE REGARDING O-RINGS

There are two pairs of Oprocess O-rings (item 6) and secondary or backup

O-rings (item 7). Ref er to Figure 3-1 to i dentif y these

items. The two pairs of O -rings are not interchangeable.

Older O-ring replacement kits contained onl y the pai r

of process O-rings. New Ocon- tain both pairs of O-rings.

process O-ring from the backup O-ring:

For sensors with plastic liners:

1. The process O-ring has a much smaller cross sectional area than the sec ondar y O-ring. The c rosssection diameter of the process O-ring is 0.07 in.

The cross-section diameter of the secondary O-ring

is 0.139 in.

2. The diameter of the process Othe secondary Oimmediately obvious when the two Oallowed to dangle from a pencil.

For sensors with alumina liners:

1. The process and secondary Osame cross sectional area. (0.139 in).

2. The diameter of the process Othe secondary Oimmediately obvious when the two Oallowed to dangle from a pencil.

Using the tool indicated in Table 3-2, remove the

Sensor Bolts (Item 2). Note that these bolts were

installed using a thre ad-locking adhesive. Any use of

heat to loosen the adhesive should not exceed the temperature ratings of the s ensor. Figure 3-1 is an ex p loded view of the all the parts of the Model 242 sensor.

16

Page 21

MODEL 242

PART NUMBER

DESCRIPTION

4081T, 5081-T, and Xmt-T (Specify length)

KIT PN

DESCRIPTION

FOR SENSOR MODELS

24005-00

Kit, Liner, 1” DN 25, Teflon PTFE

242-02[ ]TE[ ]

24005-01

Kit, Liner, 1” DN 25, glass-filled PEEK

242-02[ ]G4[ ]

24005-02

Kit, Liner, 1” DN 25, Alumina

242-02[ ]A4[ ]

24006-00

Kit, Liner, 1-1/2” DN 40, Teflon PTFE

242-03[ ]TE[ ]

24006-01

Kit, Liner, 1-1/2” DN 40, glass-filled PEEK

242-03[ ]G4[ ]

24007-00

Kit, Liner, 2” DN 50, Teflon PTFE

242-04[ ]TE[ ]

24007-01

Kit, Liner, 2” DN 50, glass-filled PEEK

242-04[ ]G4[ ]

24007-02

Kit, Liner, 2” DN 50, Alumina

242-04[ ]A4[ ]

24008-00

Kit, Liner, 3” DN 80, Teflon PTFE

242-06[ ]TE[ ]

24008-01

Kit, Liner, 3” DN 80, glass-filled PEEK

242-06[ ]G8[ ]

24008-02

Kit, Liner, 3” DN 80, Alumina

242-06[ ]A8[ ]

24009-00

Kit, Liner, 4” DN 100, Teflon PTFE

242-08[ ]TE[ ]

24009-01

Kit, Liner, 4” DN 100, glass-filled PEEK

242-08[ ]G8[ ]

24009-02

Kit, Liner, 4” DN 100, Alumina

242-08[ ]A8[ ]

KIT PN

DESCRIPTION

FOR SENSOR MODELS

24010-00

Kit, O-Ring, 1” DN 25, EPDM

242-02[ ]EP[ ]

24010-01

Kit, O-Ring, 1” DN 25, Viton

242-02[ ]VT[ ]

24010-02

Kit, O-Ring, 1” DN 25, Chemraz

242-02[ ]F4[ ]

24010-03

Kit, O-Ring, 1” DN 25, Chemraz for use with Alumina liner

242-02[ ]A4-F4

24011-00

Kit, O-Ring, 1-1/2” DN 40, EPDM

242-03[ ]EP[ ]

24011-01

Kit, O-Ring, 1-1/2” DN 40, Viton

242-03[ ]VT[ ]

24011-02

Kit, O-Ring, 1-1/2” DN 40, Chemraz

242-03[ ]F4[ ]

24012-00

Kit, O-Ring, 2” DN 50, EPDM

242-04[ ]EP[ ]

24012-01

Kit, O-Ring, 2” DN 50, Viton

242-04[ ]VT[ ]

24012-02

Kit, O-Ring, 2” DN 50, Chemraz

242-04[ ]F4[ ]

24012-03

Kit, O-Ring, 2” DN 50, Chemraz for use with Alumina liner

242-04[ ]A4-F4

24013-00

Kit, O-Ring, 3” DN 80, EPDM

242-06[ ]EP[ ]

24013-01

Kit, O-Ring, 3” DN 80, Viton

242-06[ ]VT[ ]

24013-02

Kit, O-Ring, 3” DN 80, Chemraz

242-06[ ]F8[ ]

24013-03

Kit, O-Ring, 3” DN 80, Chemraz for use with Alumina liner

242-06[ ]A8-F8

24014-00

Kit, O-Ring, 4” DN 100, EPDM

242-08[ ]EP[ ]

24014-01

Kit, O-Ring, 4” DN 100, Viton

242-08[ ]VT[ ]

24014-02

Kit, O-Ring, 4” DN 100, Chemraz

242-08[ ]F8[ ]

MODEL 242 SENSOR

TABLE 3-1. Replacement Parts and Accessories

23909-00 Extension cable, Pre-prepped, for connection to Instrument Models 54eC, 1055, 3081T,

SECTION 3.0

24014-03 Kit, O-Ring, 4” DN 100, Chemraz for use with Alumina liner 242-08[ ]A8-F8

17

Page 22

MODEL 242

Sensor Type

Model

Wrench

Torque (ft-lbs)

Torque (N-m)

1", 150# flange

242-02-10

5/16" Hex Allen

18 ft-lbs

24 Nm

1", 300# flange

242-02-11

5/16" Hex Allen

18 ft-lbs

24 Nm

DN 25, PN 16

242-02-14

5/16" Hex Allen

18 ft-lbs

24 Nm

1.5", 150# flange

242-03-10

5/16" Hex Allen

18 ft-lbs

24 Nm

1.5", 300# flange

242-03-11

3/8" Hex Allen

42 ft-lbs

57 Nm

DN 40, PN 16

242-03-14

5/16" Hex Allen

18 ft-lbs

24 Nm

2", 150# flange

242-04-10

5/16" Hex Allen

18 ft-lbs

24 Nm

2", 300 # flange

242-04-11

3/8" Hex Allen

42 ft-lbs

57 Nm

DN 50, PN 16

242-04-14

3/8" Hex Allen

42 ft-lbs

57 Nm

3", 150# flange

242-06-10

3/4" Socket

42 ft-lbs

57 Nm

3", 300 # flange

242-06-11

3/4" Socket

42 ft-lbs

57 Nm

DN 80, PN 16

242-06-14

3/4" Socket

42 ft-lbs

57 Nm

4", 150# flange

242-08-10

3/4" Socket

42 ft-lbs

57 Nm

4", 300 # flange

242-08-11

3/4" Socket

42 ft-lbs

57 Nm

DN 100, PN 16

242-08-14

3/4" Socket

42 ft-lbs

57 Nm

Table 3-2. Sensor Bolt Removal & Installation Guide

SECTION 3.0

MODEL 242 SENSOR

* REPLACEMENT PARTS AVAILABLE.

FIGURE 3-1. Exploded View of Model 242

18

Page 23

MODEL 242

MODEL 242 SENSOR

SECTION 3.0

3.4 RE-ASSEMBLE THE SENSOR

It is recommended that a press be used during the assembly process to ensure tight seals between components.

Locate the part to be changed o n the diagram and substitute the new par t from the kit. Complete disassem bly

of the sensor might no t be necessary and in that case is not rec ommended. If new O-rings are to be used, the y

should be lubricated prior to installation.

Assuming the sensor has been completely disass embled, begin by placing bot h Contact Rings (Item 1) side by

side on their flat f aces. Set a Flange (Item 4) on eac h Contact Ring (Item 1). Install a Retainer Ring (Item 5)

onto the step on the outs ide of each Contact Ring (Item 1) . Insert a lubricated Process O-ring (Item 6) in the

lower groove (closest to the flat fac e) located inside each Contact R ing (Item 1). Place a lubr icated Secondary

Back-up O-ring (Item 7) on the upper step insid e each Contact Ring (Item 1). The flange-assem bly should look

like Figure 3-2.

Place one of these flange-assemblies onto a press a nd install the Liner (Item 8). It is advisabl e to place a flat

surface between the pr es s and the liner to protect the l iner f r om damage during pressing. Be c ar ef ul t o ensure Orings do not slip or twist. Slip the Toroid Housing (Item 9) over the Liner (Item 8) to nest inside the flangeassembly. The pins on the toroid hous ing m ust seat into the sm all hol es in the f langes. Place the s econd flangeassembly on top of the first flange assembly with the Liner (Item 8) and Toroid Housing (Item 9) in between.

Check for pin alignm ent, pinched O-rings, and straight, e ven insertion. The Sensor Bolts (Item 2) can be temporarily preplaced in t he bolt holes to align the two Flanges . Press the entire sensor together to begin assem-

bly of all the com ponents. Install and tighten the Sensor Bolts and Nuts (Items 2 and 3), using thread-locking

compound. Using th e torquing sequence shown in Figure 1-6, t ighten the bolts in 1/3 increm ents of their final

torque values as listed in Table 3-2.

Back-up O-ring

Contact Ring

Process O-ring

Retainer Ring

Flange

FIGURE 3-2. Flange Assembly: Contact Ring, Flange, and O-rings.

3.5 RE-INSTALL THE SENSOR INTO THE PROCESS

Please see Section 1.4 of this manual for instructions.

Page 24

LIQ-MAN-242

Rev. F

June 2017

www.Emerson.com/RosemountLiquidAnalysis

Youtube.com/user/Rosemount

Twitter.com/Rosemount_News

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317,

USA

Tel +1 800 999 9307

Fax +1 952 949 7001

Liquid.CSC@Emerson.com

Analyticexpert.com

facebook.com/Rosemount

©2017 Emerson Automation Solutions. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount is a mark of

one of the Emerson family of companies. All other marks are the property of their respective

owners.

The contents of this publication are presented for information purposes only, and while effort has

been made to ensure their accuracy, they are not to be construed as warranties or guarantees,

express or implied, regarding the products or services described herein or their use or applicability.

All sales are governed by our terms and conditions, which are available on request. We reserve the

right to modify or improve the designs or specifications of our products at any time without notice.

Loading...

Loading...