Page 1

Product Data Sheet

Model 242

LIQ-PDS-242

June 2017

Flow Through Toroidal C onductivity Sensor

•

FLOW THROUGH DESIGN is ideal for use with viscous,

abrasive, or fibrous process liquids.

• OVER 250 CONFIGURATIONS to meet customers' needs.

• REPLACEABLE LINER in glass-filled PEEK, TEFLON, or

ALUMINA reduces long-term operating costs.

•

DIN and ANSI FLANGES compatible with all piping installations.

•

LINE SIZES of 1 through 4 inches (DN 25, 40, 50, 80 and

100).

• IN-LINE CALIBRATION saves money by reducing labor

and down-time.

• TEMPERATURE SENSOR and JUNCTION-BOX included.

FE AT URE S AND APPL ICAT IONS

Rosemount Analytical Toroidal Conductivity Sensors

are ideal for use in processes where contacting sensors -- those with electr odes exposed to th e m easur ed

solution -- would corrode or become fouled.

The Model 242 Flow Through Toroidal conductivity

sensor consists of two toroids surrounding a pipe

through which the proc ess liqu id flo ws. O ne t or oi d acts

as a transmitter and the other as a receiver.

Energizing the transmitter toroid induces an electric

current in the proc ess solution which induces a n electric current in t he receiver toroid. The strengt h of the

induced current is direct ly proportional to the conductivity of the solution.

The Model 242 sensor is available in over two hundred fifty configurations to meet the needs of many

applications and installations. Line sizes of 1, 1.5, 2, 3,

and 4 inches (25, 40, 50, 80, and 1 00 mm) are available with both ANSI and DIN compatible flanges. A

variety of liner m aterials and O-rings are available to

ensure compatibility with most process liquids.

The Model 242 sensor is e asy to install. It fits in th e

process piping between mounting flanges. Special

grounding rings are not needed because the senso r

has contact rings built into it. Recessed bolts hold the

sensor together to ensure all internal parts stay in

perfect alignment. A junction box and a Pt 100 RTD

are included. The RTD slips easily into one of the

sensor contact rings. There is no need to install a

separate thermowell, and temperature measurements are made at th e sam e point as the con ductivity measurements.

The Model 242 is n ot sensitive to flow r ate or direction. It does not obstruc t the process flow. The sensor is rugged and constructed from chemically

resistant materials. All these features m ake the sensor ideal for applications in mining and metals processing, pulp and paper processing, and the

chemical processing industry.

The Model 242 Flo w Through C onductivit y Sensor is

compatible with instrument Models 54eC, 1055,

3081T, 4081T, 5081-T, and Xmt-T.

Page 2

SPECIFICATIONS

Installation Type

Flow Through

Conductivity Range

Process Connections

Maximum Temperature

Maximum Pressure

Wetted Materials:

O-rings

Shipping Weight

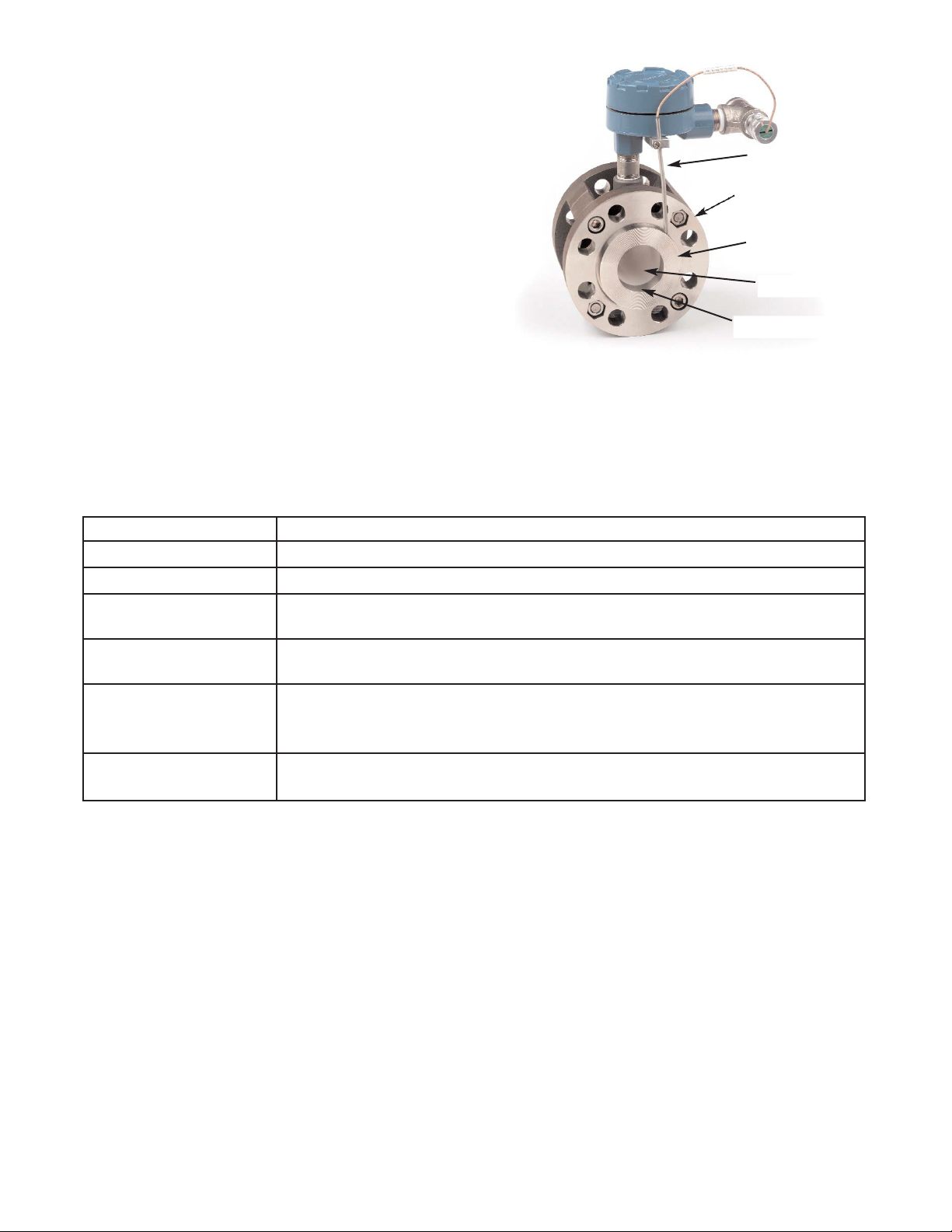

The Model 242 Flow Through Sensor comprises a toroid

housing constructed from 316 stainless steel and polyethyleneterephthalate, process connection flanges of 316

stainless steel, two metal c ontact rings (available in choice

of three materials), an insulating liner (choice of three

materials), O-rings (choice of three materials), a Pt 100

RTD, and a sensor-mounted junction box. Only the liner,

contact rings, and O-rings are wetted b y the process. The

Pt 100 RTD is designed for insertion into one pre-drilled

contact ring. The NEMA 7D junction box is constructed of

heavy duty epoxy-painted cast aluminum . The conductivity

range is user-selectable with the tappe d toroid windings. Inline calibration can be perform ed with resistors connect- ed

to an integral wire around the toroids that is terminated in

the junction box.

Liners are available in T eflon, glass-filled Polyetheretherk etone (PEEK), and alumina. These mater ials provide

excellent chem ical resistance. P EEK is recom mended for high pressure or high tem perature appl ications. Tef lon

is recommended when the process solution contains hydrofluoric acid or other strong oxidizing agents. Alumina is

recommended if the process solution is abrasive, such as in alumina/caustic ratio applications.

Pt 100 RTD

Flange

Contact Ring

Liner

O-ring (not visible)

Teflon is a registered trademark of E.I. du Pont de Nemours & Co.

Viton is a registered trademark of Du Pont Dow Elastomers.

Carpenter 20Cb-3 is a registered trademark of Carpenter Technologies.

Hastelloy is a registered trademark of Haynes International.

Chemraz is a registered trademark of Greene, Tweed, & Co.

2

Liner

Contact Rings

100 μS/cm to 2 S/cm

150# ANSI, 300# ANSI, PN16 DIN 2501 compatible flanges

Depends on configuration. For plastic-lined sensors, see charts on facing page.

For alumina-lined sensors, see charts on page 4.

Depends on configuration. For plastic-lined sensors, see charts on facing page.

For alumina-lined sensors, see charts on page 4.

Teflon® (PTFE), glass-filled PEEK, or alumina

316 SST, Carpenter 20Cb-3

EPDM, Viton

1” to 2”: 22 lbs. (10kg)

3” to 4”: 86 lbs. (39 kg)

®

(FKM), or Chemraz® (FFKM)

®

SST, or Hastelloy® C-276

Page 3

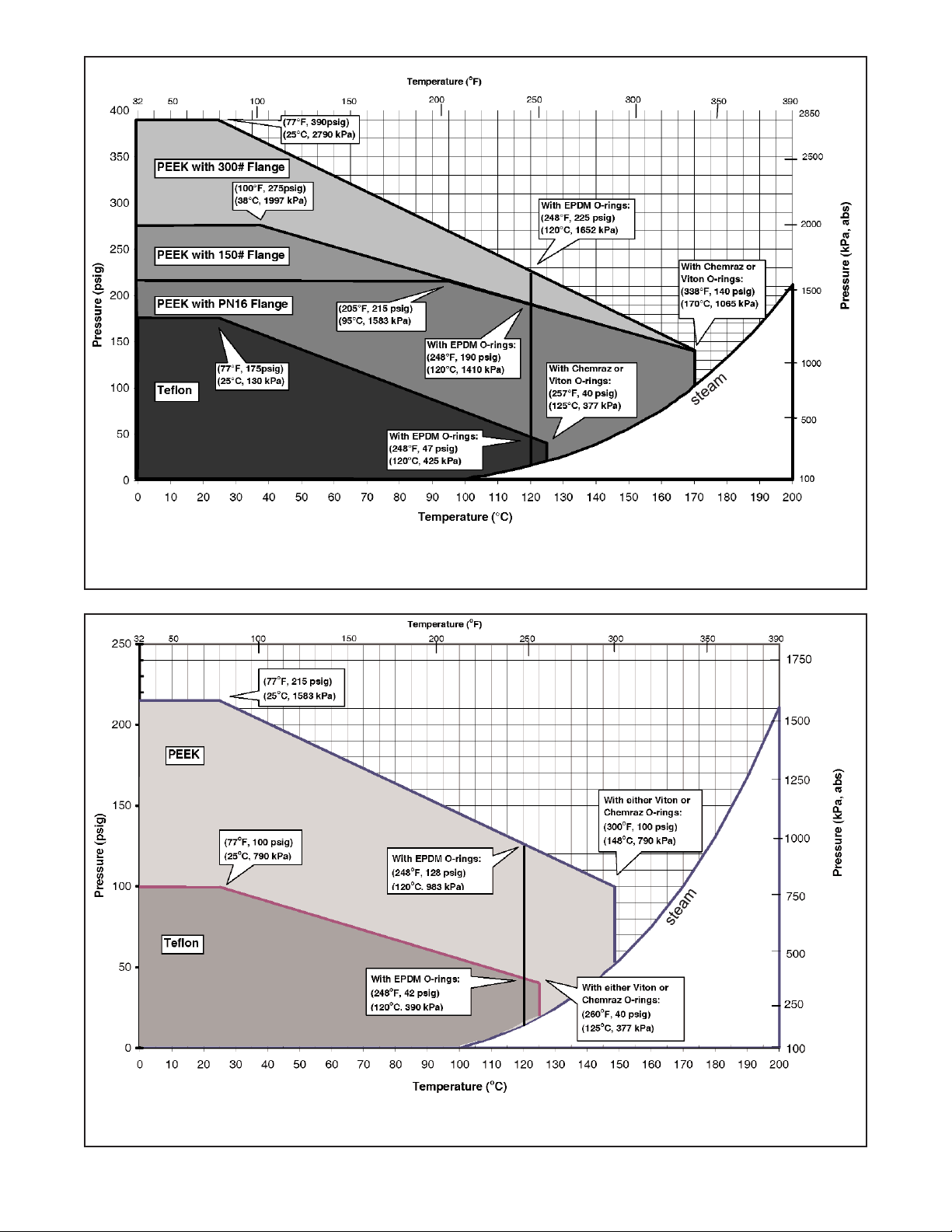

Pressure - Temperature Specifications for 1”, 1.5”, and 2” (25, 40, and 50 mm) Sensors:

Models 242-02, 242-03, and 242-04

Pressure - Temperature Specifications for 3” and 4” (80 and 100 mm) Sensors:

Models 242-06 and 242-08

3

Page 4

Pressure - Temperature Specifications for 1” and 2” Sensors: Alumina Liner

4

Pressure - Temperature Specifications for 3” and 4” Sensors: Alumina Liner

Page 5

DIMENSIONAL DRAWING

The dimensions of the Model 242 sensor depend on the selected line size and the flange option. Please refer to

the dimensional drawing for the appropriate sensor dimensions.

5

Page 6

ORDERING INFORMATION

MODEL

242

FLOW THROUGH TOROIDAL CONDUCTIVITY SENSOR

CODE

LINE SIZE (Required Selection)

02

1”

DN 25 03

1-1/2”

DN 40 04

2”

DN 50 06

3”

DN 80

(no ATEX approval with 5081T)

08

4”

DN 100

(no ATEX approval with 5081T)

CODE

PROCESS CONNECTION (Required Selection)

10

150# ANSI Flange (Line sizes 1", 1-1/2", 2”, 3”, 4”)

11

300# ANSI Flange (Line sizes 1", 1-1/2", 2”, 3”, 4”)

14

PN 16 Metric Flange (Line sizes DN 25, 40, 50, 80, 100)

CODE

CONTACT RING MATERIAL (Required Selection)

SS

316 Stainless Steel

H4

Hastelloy C-276 (Line Sizes 1", 1-1/2", 2”, 25mm, 40mm, 50mm)

H8

Hastelloy C-276 (Line Sizes 3", 4", 80mm, 100mm)

C4

Carpenter 20-Cb3 (Line Sizes 1", 1-1/2", 2”, 25mm, 40mm, 50mm)

C8

Carpenter 20-Cb3 (Line Sizes 3", 4", 80mm, 100mm)

CODE

LINER MATERIAL (Required Selection)

TE

PTFE (Teflon®)

G4

PEEK, 30% Glass-Filled (Line Sizes 1", 1-1/2", 2”, 25mm, 40mm, 50mm)

G8

PEEK, 30% Glass-Filled (Line Sizes 3", 4", 80mm, 100mm)

A4

Alumina (Line sizes 1”, 2”, 25 mm, 50 mm); available only with option F4

A8

Alumina (Line sizes 3”, 4”, 80 mm, 100 mm); available only with option F8

CODE

PROCESS O-RING MATERIAL (Required Selection)

EP

Ethylene Propylene Rubber

VT

Fluorocarbon Rubber (Viton

)

F4

High Temp. Perfluoroelastomer (Chemraz

)

(Line Sizes 1", 1-1/2", 2”, 25mm, 40mm, 50mm)

The Model 242 Flow -Through Sensor is configurable to meet the needs of many applicat ions and instal lations

(both ANSI and DIN). After specifying line size and flange t ype, the custom er selects the wetted m aterials most

compatible with the pr ocess stream. A NEMA 7D jun ction box and Pt 100 RTD are a lso included. Compatible

instruments include Rosemount Models 54eC, 1055, 3081T, 4081T, 5081-T, and Xmt-T.

The extension cable requ ired for wiring from the junction box to th e instrument m ust be ordered separatel y. The

customer supplies the gaskets, mating flanges, and flange bolts.

F8

242 -0611SSG8VT EXAMPLE

High Temp. Perfluoroelastomer (Chemraz

®

®

®

) (Line Sizes 3", 4",

80mm, 100mm

)

6

Page 7

ACCESSORIES

PART NUMBER

DESCRIPTION

4081T, 5081-T, and Xmt-T (Specify length)

KIT PN

DESCRIPTION

FOR SENSOR MODELS

24005-00

Kit, Liner, 1” DN 25, Teflon PTFE

242-02[ ]TE[ ]

24005-01

Kit, Liner, 1” DN 25, glass-filled PEEK

242-02[ ]G4[ ]

24005-02

Kit, Liner, 1” DN 25, Alumina

242-02[ ]A4[ ]

24006-00

Kit, Liner, 1-1/2” DN 40, Teflon PTFE

242-03[ ]TE[ ]

24006-01

Kit, Liner, 1-1/2” DN 40, glass-filled PEEK

242-03[ ]G4[ ]

24007-00

Kit, Liner, 2” DN 50, Teflon PTFE

242-04[ ]TE[ ]

24007-01

Kit, Liner, 2” DN 50, glass-filled PEEK

242-04[ ]G4[ ]

24007-02

Kit, Liner, 2” DN 50, Alumina

242-04[ ]A4[ ]

24008-00

Kit, Liner, 3” DN 80, Teflon PTFE

242-06[ ]TE[ ]

24008-01

Kit, Liner, 3” DN 80, glass-filled PEEK

242-06[ ]G8[ ]

24008-02

Kit, Liner, 3” DN 80, Alumina

242-06[ ]A8[ ]

24009-00

Kit, Liner, 4” DN 100, Teflon PTFE

242-08[ ]TE[ ]

24009-01

Kit, Liner, 4” DN 100, glass-filled PEE K

242-08[ ]G8[ ]

24009-02

Kit, Liner, 4” DN 100, Alumina

242-08[ ]A8[ ]

KIT PN

DESCRIPTION

FOR SENSOR MODELS

24010-00

Kit, O-Ring, 1” DN 25, EPDM

242-02[ ]EP[ ]

24010-01

Kit, O-Ring, 1” DN 25, Viton

242-02[ ]VT[ ]

24010-02

Kit, O-Ring, 1” DN 25, Chemraz

242-02[ ]F4[ ]

24010-03

Kit, O-Ring, 1” DN 25, Chemraz for use with Alumina liner

242-02[ ]A4-F4

24011-00

Kit, O-Ring, 1-1/2” DN 40, EPDM

242-03[ ]EP[ ]

24011-01

Kit, O-Ring, 1-1/2” DN 40, Viton

242-03[ ]VT[ ]

24011-02

Kit, O-Ring, 1-1/2” DN 40, Chemraz

242-03[ ]F4[ ]

24012-00

Kit, O-Ring, 2” DN 50, EPDM

242-04[ ]EP[ ]

24012-01

Kit, O-Ring, 2” DN 50, Viton

242-04[ ]VT[ ]

24012-02

Kit, O-Ring, 2” DN 50, Chemraz

242-04[ ]F4[ ]

24012-03

Kit, O-Ring, 2” DN 50, Chemraz for use with Alumina liner

242-04[ ]A4-F4

24013-00

Kit, O-Ring, 3” DN 80, EPDM

242-06[ ]EP[ ]

24013-01

Kit, O-Ring, 3” DN 80, Viton

242-06[ ]VT[ ]

24013-02

Kit, O-Ring, 3” DN 80, Chemraz

242-06[ ]F8[ ]

24013-03

Kit, O-Ring, 3” DN 80, Chemraz for use with Alumina liner

242-06[ ]A8-F8

24014-00

Kit, O-Ring, 4” DN 100, EPDM

242-08[ ]EP[ ]

24014-01

Kit, O-Ring, 4” DN 100, Viton

242-08[ ]VT[ ]

24014-02

Kit, O-Ring, 4” DN 100, Chemraz

242-08[ ]F8[ ]

23909-00 Extension cable, Pre-prepped, for connection to Instrument Models 54eC, 1055, 3081T,

24014-03 Kit, O-Ring, 4” DN 100, Chemraz for use with Alumina liner 242-08[ ]A8-F8

7

Page 8

* REPLACEMENT PARTS AVAILABLE.

EXPLODED VIEW OF MODEL 242

Page 9

Notes:

7www.Emerson.com/RosemountLiquidAnalysis

Page 10

Rosemount 242 Sensor

LIQ-PDS-242

Global Headquarters

Emerson Automation Solutions

8200 Market Blvd

Chanhassen, MN 55317

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

Liquid.CSC@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 700

R

MT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

1

Product Data Sheet

June 2017

Europe Regional Office

Emerson Automation Solutions GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 76

R

FQ.RMD-RCC@Emerson.com

8 6300

Asia Pacific Regional Office

Emerson Automation Solutions Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 094

E

nquiries@AP.Emerson.com

7

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033,

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 88654

R

FQ.RMTMEA@Emerson.com

65

Analyticexpert.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

Google.com/+RosemountMeasurement

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

Rosemount and Rosemount logotype are trademarks of Emerson.

All other marks are the property of their respective owners.

© 2017 Emerson. All rights reserved.

Loading...

Loading...