Page 1

Rosemount™ 228

Toroidal Conductivity Sensors

Reference Manual

LIQ-MAN-228, Rev V

April 2018

Page 2

Page 3

Safety Information

WARNING!

HIGH PRESSURE AND TEMPERATURE HAZARD

Before removing the senosr, reduce the process pressure to 0 psig and cool down the process temperature.

Failure to reduce the pressure and temperature may cause serious injury to personnel.

CAUTION!

EQUIPMENT DAMAGE

The wetted sensor materials may not be compatible with process composition and operating conditions. Application compatibility is

entirely your responsibility.

Page 4

Page 5

Contents

Contents

Chapter 1 Description and specifications ..........................................................................................1

1.1 Description .................................................................................................................................... 1

1.2 Unpacking and inspection .............................................................................................................. 1

1.3 Sensor Specifications ......................................................................................................................1

1.4 Ordering information ..................................................................................................................... 4

Chapter 2 Install ...............................................................................................................................5

2.1 Installing the sensor ....................................................................................................................... 5

2.2 Insertion/Retraction Assembly Installation Requirements .............................................................. 8

2.2.1 Manual Retraction Assembly ............................................................................................9

2.2.2 Mechanical Retraction Assembly (PN 23311-00) ............................................................12

2.2.3 Replacing Seals in Manual and Mechanical Retraction Assemblies ................................. 15

Chapter 3 Wiring ........................................................................................................................... 19

3.1 Wiring the Sensor .........................................................................................................................19

Chapter 4 Calibration ..................................................................................................................... 23

4.1 Sensor calibration .........................................................................................................................23

4.2 Calibrating against a Standard Solution ........................................................................................23

4.3 Calibrating against a Referee - in-Process ..................................................................................... 25

4.4 Calibrating against a Referee - Grab Sample ................................................................................. 26

Chapter 5 Maintaining and Troubleshooting .................................................................................. 29

5.1 Maintaining the sensor .................................................................................................................29

5.2 Troubleshooting .......................................................................................................................... 29

Chapter 6 Accessories .................................................................................................................... 31

Chapter 7 Return of Materials .........................................................................................................33

Rosemount 228 Sensor i

Page 6

Contents

ii Reference Manual

Page 7

Description and specifications

1 Description and specifications

1.1 Description

The Rosemount 222 toroidal flow through conductivity sensor measures conductivity in

highly conductive liquids up to 2 S/cm (2,000,000 μS/cm). A noninvasive flow through

design allows for in-line installations without any obstruction to sample and makes these

sensors ideal for use with viscous or fibrous liquids.

1.2 Unpacking and inspection

Complete the following steps when you unpack your instrument.

1. Inspect the shipping container. If there is damage, contact the shipper immediately

for instructions.

2. If there is no apparent damage, and remove the sensor.

3. Ensure that all items shown on the packing list are present. If items are missing,

contact your local Customer Care representative.

4. Save the shipping container and packaging.

They can be reused to return the sensor to the factory in case of damage.

1.3 Sensor Specifications

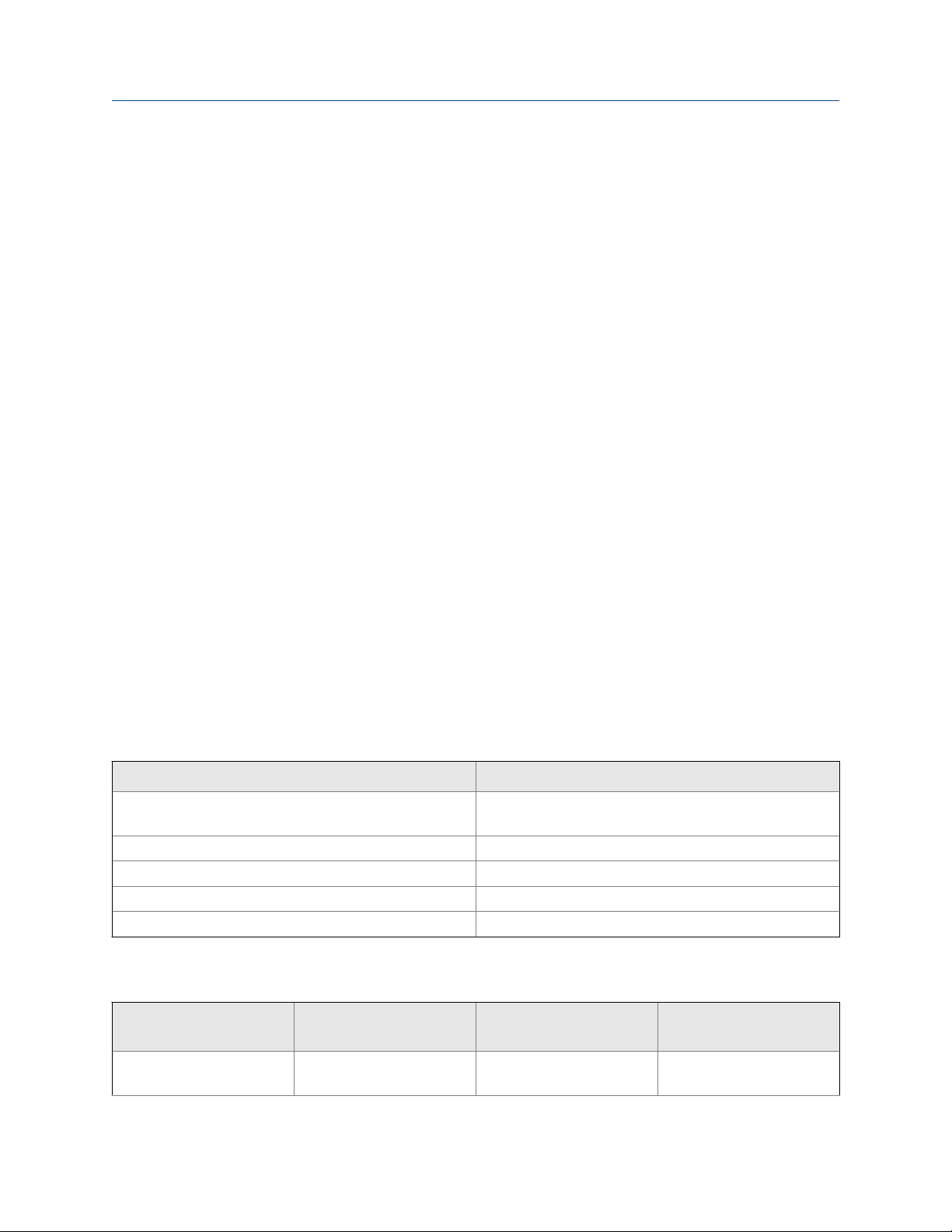

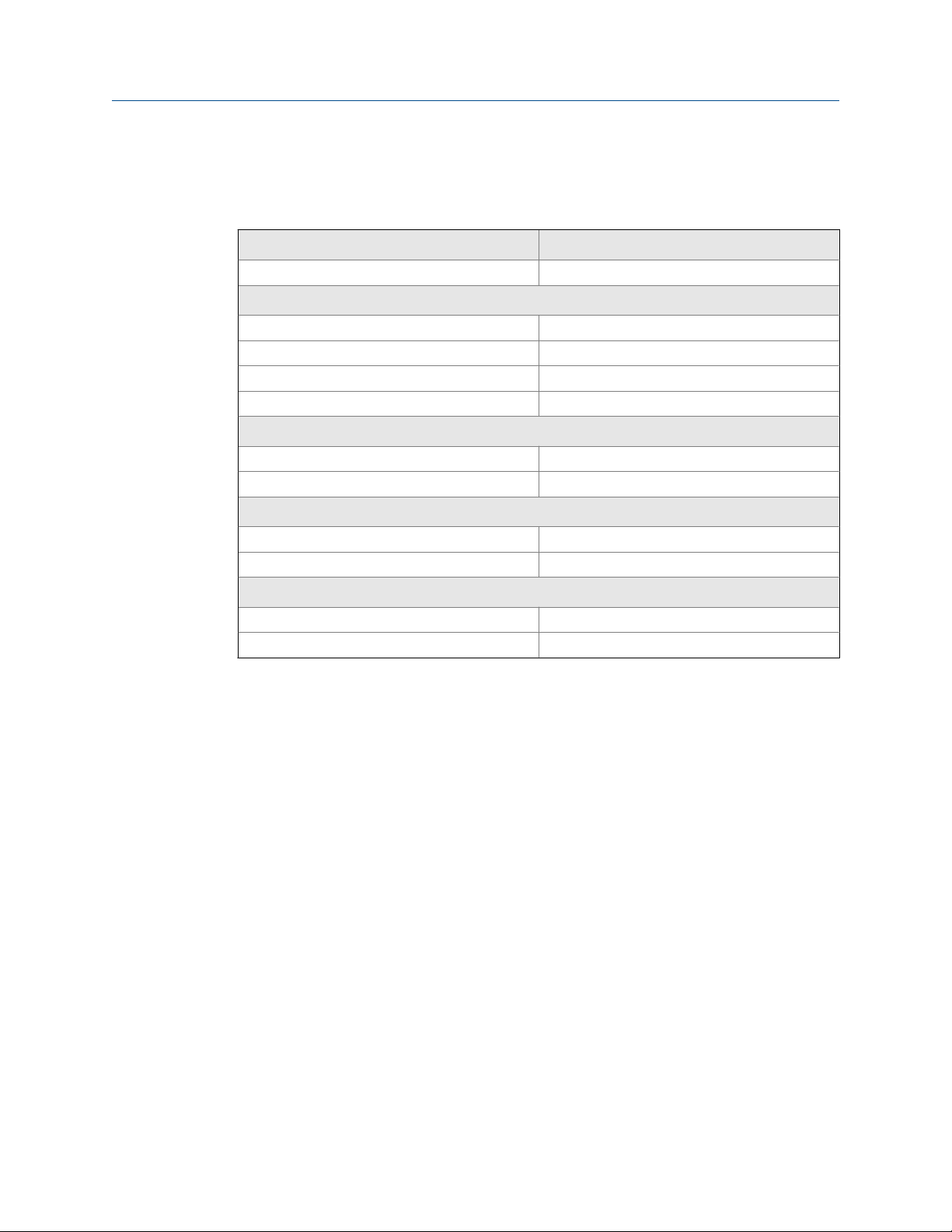

Sensor specificationsTable 1-1:

Sensor specification Description

Wetted materials Body materials either glass-filled PEEK, glass-filled Tefzel,

or unfilled Tefzel. Option -20 has EPDM gasket

Process connection -20: 5/8 in. 11 UNC, -21: 3/4 in. MNPT

Cable length 20 ft (6.1 m)

Maximum cable length 200 ft (61.0 m)

Weight/shipping weight 2 lb / 3 lb (1.0 kg / 1.5 kg)

Maximum operating temperature and pressureTable 1-2:

Maximum pressure (for

Body material option Maximum temperature Maximum pressure

-02 (Glass-filled PEEK

(standard temperature))

248 °F (120 °C) 295 psig (2135 kPa) 220 psig (1618 kPa [abs])

CRN registration only)

Rosemount 228 Sensor 1

Page 8

Description and specifications

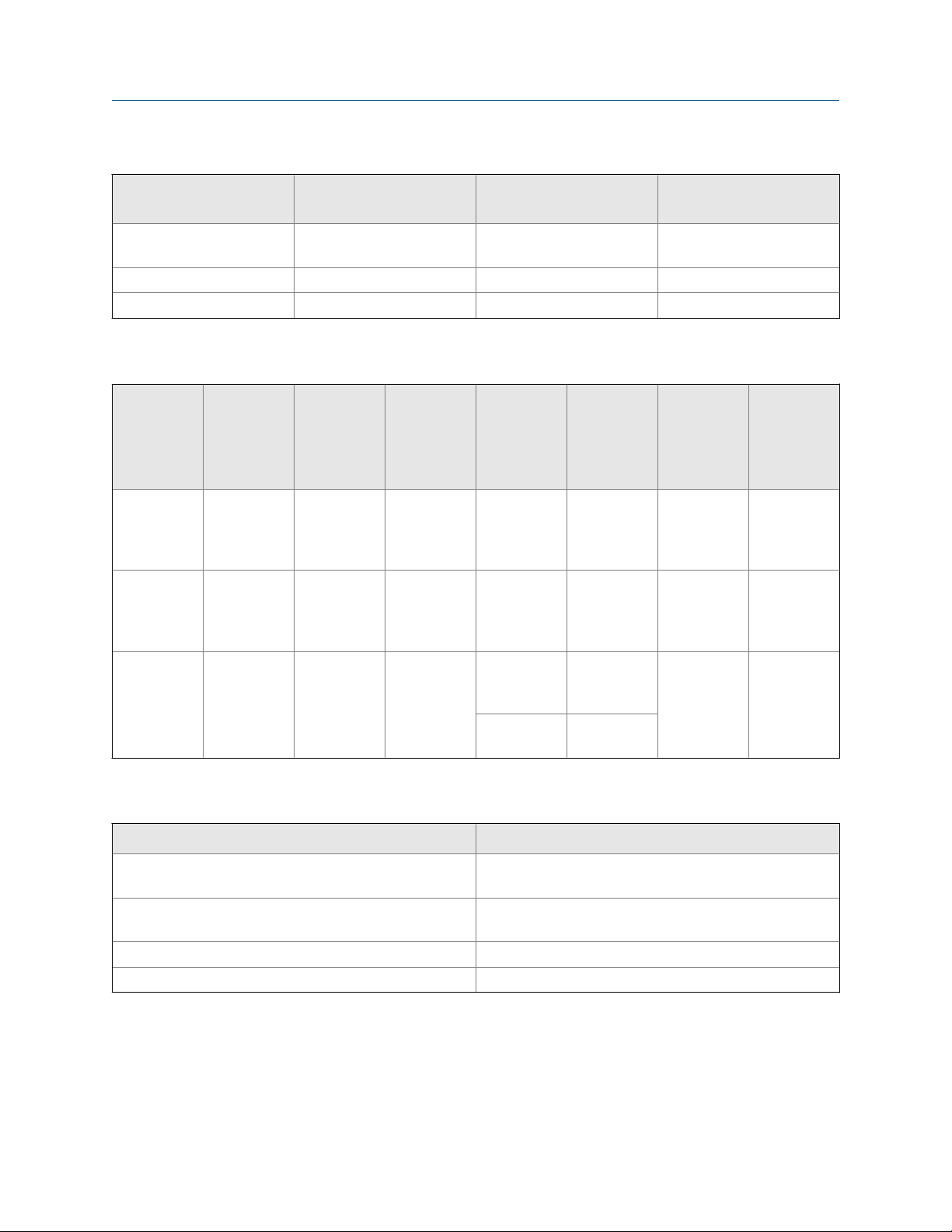

Maximum operating temperature and pressure (continued)Table 1-2:

Maximum pressure (for

Body material option Maximum temperature Maximum pressure

-03 (Glass-filled PEEK (high

temperature))

-04 (Glass-filled Tefzel) 248 °F (120 °C) 200 psig (1480 kPa) 150 psig (1135 kPa [abs])

-05 (Unfilled Tefzel) 248 °F (120 °C) 200 psig (1480 kPa) 150 psig (1135 kPa [abs])

392 °F (200 °C) 295 psig (2135 kPa) 220 psig (1618 kPa [abs])

CRN registration only)

Insertion adapter specificationsTable 1-3:

Maximum

pressure

Adapter

part number

23242-02 For use with

23242-03 For use with

2001990 For use with

Sensor compatibility

option -21

option -20

option -21

Process connection

1-1/2 in.

MNPT

1-1/2 in.

MNPT

2 in. MNPT CPVC

Wetted materials

316 stainless

steel, glassfilled PEEK,

Viton

316 stainless

steel, glassfilled PEEK,

Viton

Viton

Maximum

temperature

392 ° F

(200 °C)

392 °F

(200 °C)

100 °F

(38 °C)

185 °F (85 °C)45 psig (412

Maximum

pressure

295 psig

(2135 kPa)

295 psig

(2135 kPa)

100 psig

(791 kPa

[abs])

kPa [abs])

(for CRN

registration

only)

220 psig

(1618 kPa

[abs])

220 psig

(1618 kPa

[abs])

N/A 1 lb / 2 lb

Weight /

shipping

weight

3 lb / 4 lb

(1.5 kg / 2.0

kg)

3 lb / 4 lb

(1.5 kg / 2.0

kg)

(0.5 kg / 1.0

kg)

Retraction assembly specficationsTable 1-4:

Specification Description

Sensor compatibility The retraction assemblies are used with 228 - [ ]-20-54-62

only

Wetted materials 315 stainless steel, ethylene polypropylene (EP), unfilled

Teflon, carbon-filled Teflon

Process connection 1 - 1/2 in. MNPT

Maximum operating condition 392 °F (200 °C), 295 psig (2135 kPa [abs])

2 Reference Manual

Page 9

Description and specifications

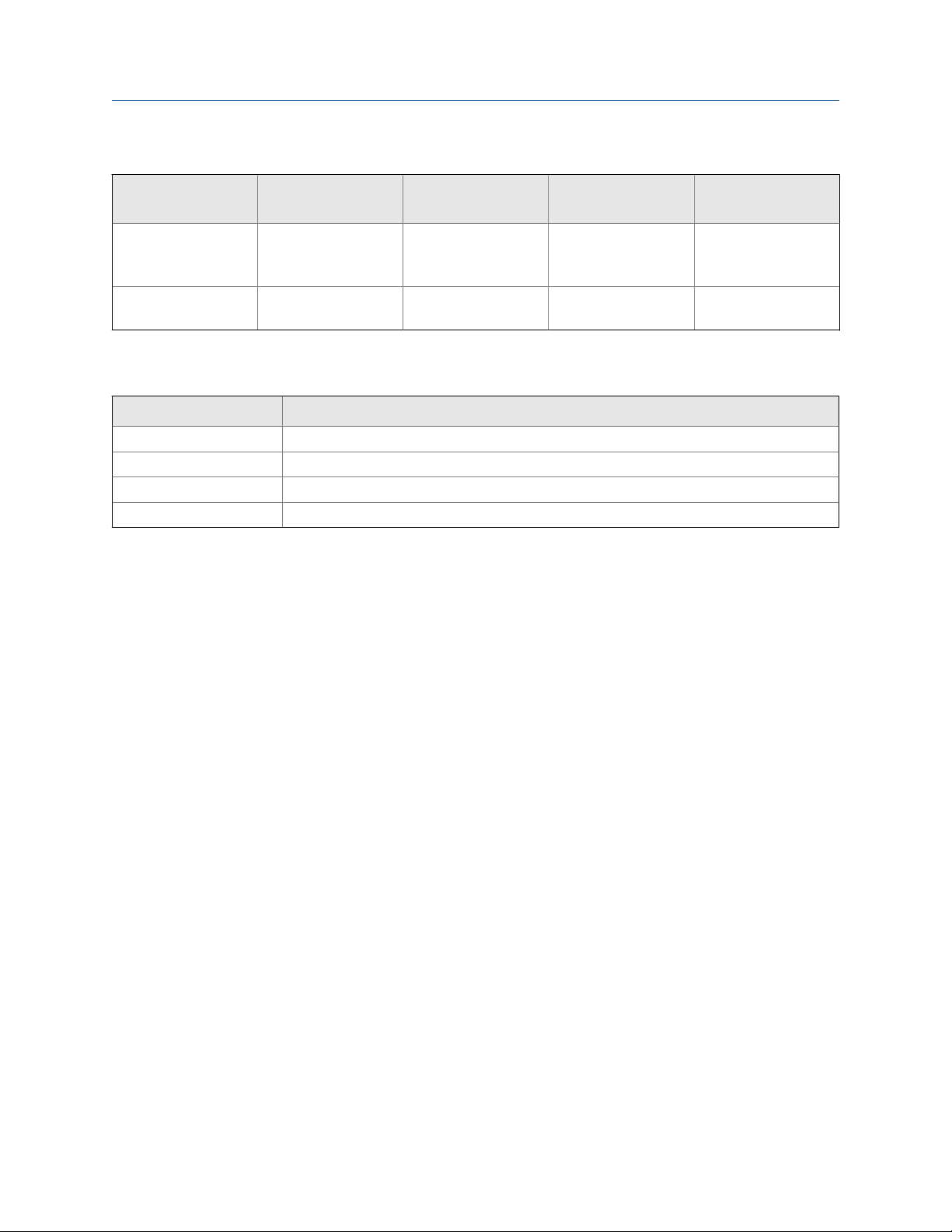

Maximum retraction/insertion conditionsTable 1-5:

Description Temperature Pressure

23311-00, mechanical retraction assembly

23311-01, manual retraction assembly

392 °F (200 °C) 295 psig (2135 kPa

[abs])

266 °F (130 °C) 35 psig (343 kPa

[abs])

Ball valve specifications (sold separately)Table 1-6:

Specification Description

Part number 9340065

Wetted materials 316 stainless steel, Teflon TFE

Process connection 1-1/2 in. FNPT

Weight / shipping weight 4 lb / 5 lb (2.0 kg / 2.5 kg)

Ball valve pressure and temperature

Maximum insertion

travel

10.5 in. (267 mm) 12 lb / 15 lb (5.5 kg /

12.0 in. (305 mm) 9 lb / 12 lb (4.5 kg /

Weight / shipping

weight

7.0 kg)

5.5 kg)

Rosemount 228 Sensor 3

Page 10

Description and specifications

1.4 Ordering information

Rosemount 228 Toroidal Conductivity Sensor Ordering InformationTable 1-7:

Model Sensor type

228 Toroidal Conductivity Sensor

Materials of construction

02 Glass-filled PEEK (standard temperature)

03 Glass-filled PEEK (high temperature)

04 Glass-filled Tefzel

05 Unfilled Tefzel

Process connection

20 5/8 in. 11 UNC

21 3/4 in. MNPT

Cable type

54 Unshielded cable

56 EMI/RFI shielded cable

(5)

(1)

(2)

(3)

(4)

(6)

(7)

Cable length

61 6.1 m (20 ft)

62 457 mm (18 in.)

(1) Not available with options -50-62 and -54-62.

(2) Not available with option -54-62.

(3) This option requires a mounting adapter. This option comes standard with an EPDM gasket (Viton® and

Kalrez® gaskets are also available).

(4) Not available with option -62.

(5) Cable may be extended using the remote junction box PN 23550-00 (sold separately) and extension cables..

(6) Recommended for use with transmitter models 1054 and 2054. May be used with transmitter models 1055,

1056, 1066, 54C, 54eC, 81T, 2081T, 3081T, 4081T, 5081, and XMT, but not recommended.

(7) Recommended for use with transmitter models 1055, 1056, 1066, 56, 54C, 54eC, 5081, and XMT.

(8) For use with option -54 only. Connects sensor used in valve insertion assembly to junction box. Requires

interconnecting cable to connect junction box to transmitter. Use either cable 23294-00 (unshielded) or

23294-05 (shielded).

(8)

4 Reference Manual

Page 11

2 Install

2.1 Installing the sensor

Keep at least 1 in. (25 cm) between the sensor and the pipe wall. If clearance is too small,

calibrate the sensor in place. Ensure that the sensor is completely submerged in liquid.

Mounting the sensor in a vertical pipe run with the flow from bottom to top is best. If the

sensor must be mounted in a horizontal pipe run, orient the sensor in the 3 o-clock or 9

o'clock position.

Rosemount 228 dimensional drawingFigure 2-1:

Install

Rosemount 228 Sensor 5

Page 12

Install

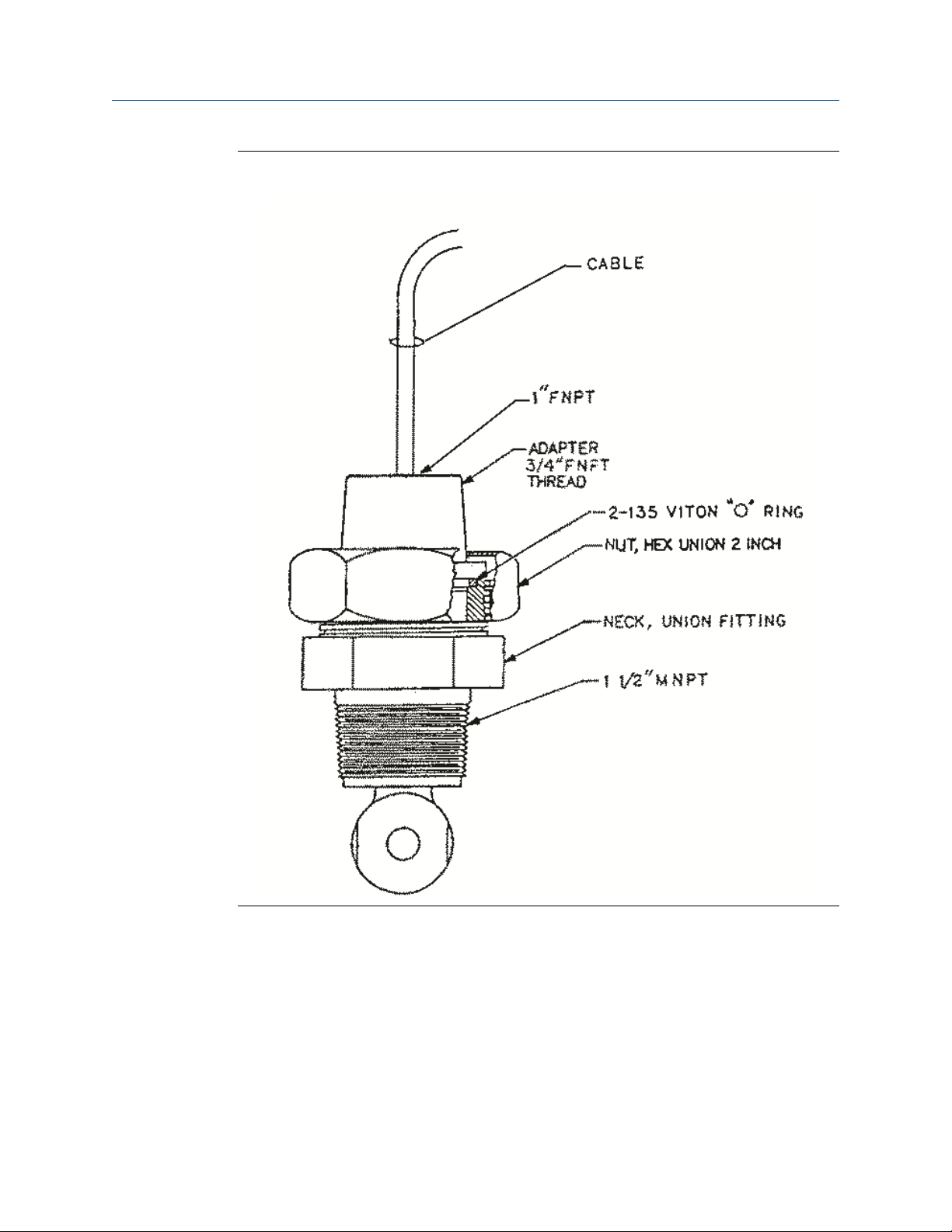

Figure 2-2:

Insertion adapter 23242-02 for use with 3/4 in. MNPT threaded process

connection (-21 option)

6 Reference Manual

Page 13

Install

Figure 2-3:

Insertion adapter 23242-03 for use with 5/8 in. 11 UNC threaded process

connection (-20 option)

Rosemount 228 Sensor 7

Page 14

Install

Figure 2-4:

Procedure

1.

2. Keep at least 1 in. (2.5 cm) between the sensor and pipe walls.

3. Mount the sensor in a vertical pipe run with flow from top to bottom.

Insertion adapter 2001990 for use with 3/4 in. MNPT threaded process

connection (-21 option)

Mount the sensor in the pipe.

If the clearance is too small, calibrate the sensor in place.

If the sensor must be mounted in a horizontal pipe run, orient the sensor in the

3 o'clock or 9 o'clock position.

4. Ensure that the sensor is completely submerged in liquid.

2.2 Insertion/Retraction Assembly Installation

Requirements

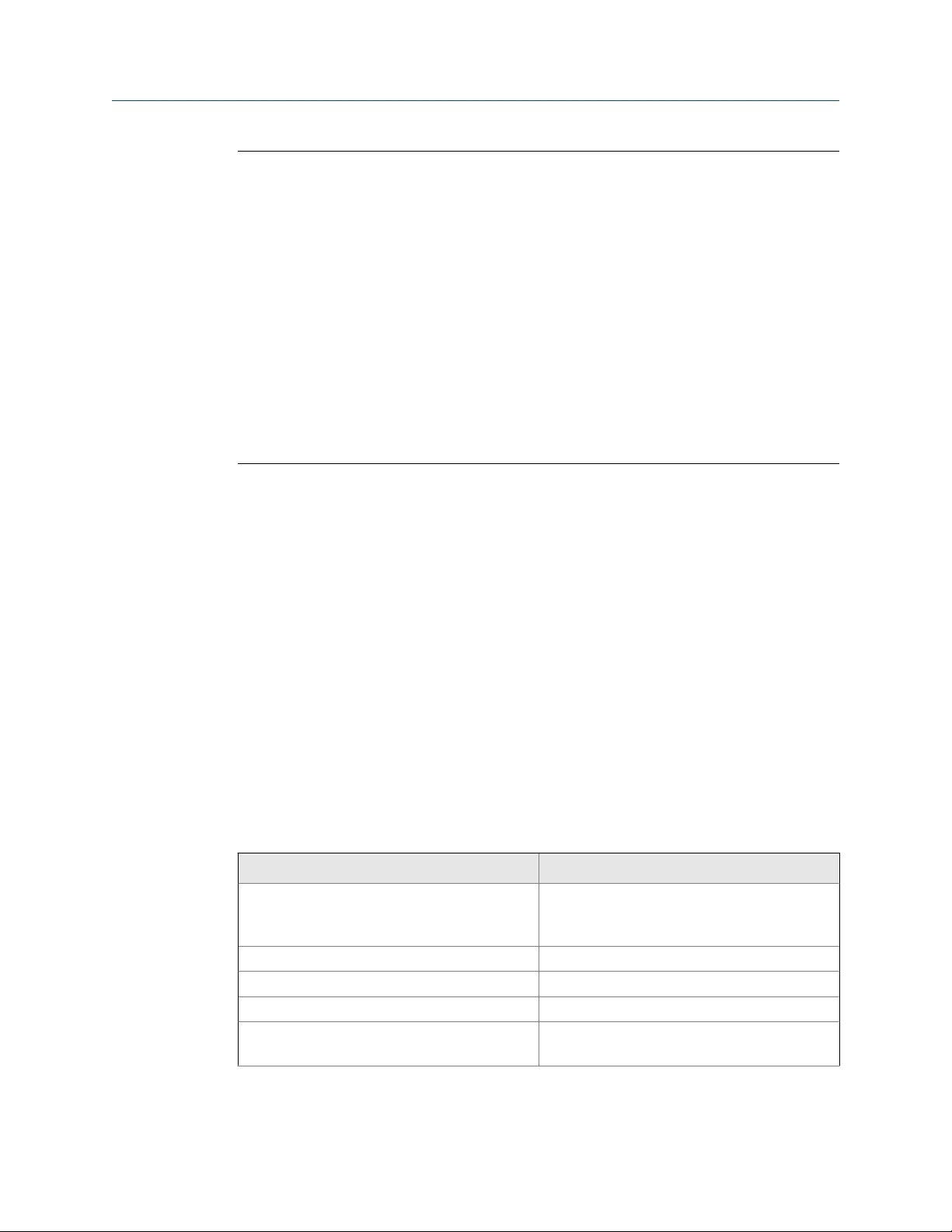

Insertion/Retraction Assembly Installation RequirementsTable 2-1:

Requirement Description

Process connection 1-1/2 in. Larger openings may keep the sensor

from inserting far enough into the process liquid.

Line size 3 in.; 2 in. line requires in-place calibration.

Valve 1-1/2 in. NPT full port valve (PN 9340065)

Retraction clearance 2 ft (0.6 m)

Excess vibration Provide mechanical support if excess vibration is

expected.

8 Reference Manual

Page 15

Insertion/Retraction Assembly Installation Requirements (continued)Table 2-1:

Requirement Description

Flush water Provide 1/8 in. valves in inlet and outlet flush

2.2.1 Manual Retraction Assembly

Installing a Manual Retraction Assembly

1. Loosen the collet nut and retract the sensor tube into the retraction chamber.

See Figure 2-5.

Install

ports. Position flush ports so that the retraction

chamber can be drained.

Rosemount 228 Sensor 9

Page 16

Install

Manual retraction assembly dimensional drawingFigure 2-5:

2. Loosen the union nut and separate the retraction chamber from the assembly.

Install the retraction chamber on the 1-1/2 in. NPT full port valve mounted on the

3.

process line or vessel.

4. Thread the sensor cable through the tube into the junction box. Screw the sensor

into the tube. Hand-tighten the sensor an additional half turn once the gasket is

seated.

5. Connect the sensor and interconnecting cable leads to the terminal strip in the

junction box.

See Figure 2-6.

10 Reference Manual

Page 17

Install

Sensor-mounted junction box wiringFigure 2-6:

Note

The wiring diagram shown is for the cable PN 23294-00, which has three RTD (TC) leads. If you are

useing cable PN 23294-05, which has four RTD (TC) leads, connect the green, white, and clear

wires in the RTD bundle as shown in the drawing. Do not disconnect the black wire. When you

reconnect the RTD wires in PN 23294-05 to the transmitter, make the connections as described in

Step 6 (this section) or Step 3 (Installing the Mechanical Retraction Assembly.

6. Connect the other end of the cable to the transmitter. See the wiring diagrams in

Figure 3-2, Figure 3-3, and Figure 3-4. For cable PN 23294-00, follow the wiring for the

228-54 sensor. For cable PN 23294-05, follow the wiring for the 228-56 sensor with

the following exception:

Refer to the wire function diagram for the 228-56 option in Figure 3-1 and identify

the RTD wire bundle. Connect the RTD wires to the transmitter as follows:

• Green - RTD in

• Black - No connection

• Clear - RTD common or RTD return

• White - RTD sense

Wrap the bare end of the black wire to prevent accidental connections.

7.

Insert the sensor and tube assembly into the retraction chamber.

8. Tighten the union nut.

9. Open the ball valve, check for leaks, and manually insert the sensor into the process.

10. Position the sensor at least 1/2 in. (13 mm) away from any wall of the vessel or pipe.

11. Tighten the collet nut.

Rosemount 228 Sensor 11

Page 18

Install

Retracting the Manual Retraction Assembly

Prerequisites

Make certain that the system pressure is less than 35 psig (342 kPa [abs]).

Procedure

1. Push in on the sensor using the top of the junction box. Slowly loosen the collet nut.

WARNING!

HIGH PRESSURE

Reduce pressure to 0 psig. Do not loosen collet nut until pressure is 0 psig.

Failure to reduce pressure may cause a loose collet nut to disengage and cause injury to

personnel.

2. When the collet nut is loose enough, slowly ease the sensor back so that it clears the

ball valve. Close the valve to the process line.

3. Drain the retraction chamber contents using the 1/8 in. flush ports.

4. Loosen the 3 in. hex union nut. Removt the sensor and tube assembly.

5. Replace the 3 in. hex nut O-ring. Place the sensor and tube assembly back in the

retraction assembly. Tighten the 3 in. hex union nut. Verify that the 1/8 in. flush

ports are closed.

NOTICE

With the ball valve closed and the retraction chamber 1/8 in. flush ports open, some

residual process fluid may leak from the 3 in. hex union nut female ACME threads. This

leakage is normal and to be expected.

WARNING!

HIGH PRESSURE

Retraction chamber contents may be under pressure. Before opening the ball valve,

make sure that the process pressure is less than 35 psig (342 kPa [abs]).

Failure to reduce pressure may cause a loose collet nut to disengage and cause injury to

personnel.

6. Open the ball valve and check for leaks. Insert the sensor into the process. Tighten

the collet nut.

2.2.2 Mechanical Retraction Assembly (PN 23311-00)

Installing the Mechanical Retraction Assembly

1.

Tighten the sensor cable through the tube into the junction box. Screw the sensor

into the tube. Hand-tighten the sensor an additional half turn once the gasket is

seated.

12 Reference Manual

Page 19

See Figure 2-7.

Install

Mechanical retraction assemblyFigure 2-7:

2. Terminate the sensor wiring in the junction box.

See Figure 2-6 for wiring details.

3.

Connect the other end of the cable to the transmitter.

Rosemount 228 Sensor 13

Page 20

Install

See the wiring diagrams in Figure 3-2, Figure 3-3, and Figure 3-4. For cable PN

23294-00, follow the wiring for the 228-54 sensor. For cable PN 23294-05, follow

the wiring for the 228-56 sensor with the following exception:

Refer to the wire function diagram for the 228-56 option in Figure 3-1 and identify

the RTD wire bundle. Connect the RTD wires to the transmitter as follows:

• Green - RTD in

• Black - no connection

• Clear - RTD common or RTD return

• White - RTD sense

Wrap the bare end of the black wire to prevent accidental connections.

4. Using a 1/2 in. (13 mm) socket wrench, retract the sensor into the retraction

chamber.

5. Install the assembly on the 1-1/2 in. NPT full port ball valve mounted in the process

line or vessel.

6. Tighten the union nut.

7. Open the ball valve and check for leaks.

8. Using a 1/2 in. (13 mm) socket wrench, inser the sensor into the process line or

vessel.

9. Position the sensor at least 1/2 in. (13 mm) away from any wall of the vessel or pipe.

Set the travel stop collar A net to the nut housing.

WARNING!

HIGH PRESSURE

Do not loosen cap screws or collar when pressurized.

Failure to reduce pressure may cause a loose part to disengage and cause injury to

personnel.

Retracting a Mechanical Retraction Assembly

Prerequisites

Make sure that the system pressure is less than 295 psig (2135 kPa [abs]) before retracting

the sensor.

Procedure

1.

Retract the sensor using a 1/2 in. (13 mm) socket wrench. When the sensor clears

the ball valve, close the valve.

WARNING!

HIGH PRESSURE

Retraction chamber contents may be under pressure.

Failure to reduce pressure may cause a loose part to disengage and cause injury to

personnel.

14 Reference Manual

Page 21

2. Drain the retraction chamber using 1/8 in. flush ports.

3. Loosen the 3 in. hex union nut and remove the retraction stop collar and orange

clamp top. Remove the sensor and tube assembly.

4. Replace the 3 in. hex nut O-ring. Place the sensor and tube assembly back in the

retraction assembly. Replace the retraction stop collar about 1/2 in. in front of the

clamp. Tighten the clamp screws, retraction stop collar, and 3 in. hex union nut.

Verify that the 1/8 in. flush ports are closed.

NOTICE

With the ball valve fully closed and the retraciton chamber 1/8 in. flush ports open,

some residual process fluid maay leak from the 3 in. hex union female ACME threads.

This leakage is normal and to be expected.

5. Before opening the ball valve, make sure that the process pressure is less than 295

psig (3135 kPa [abs]). Open the valve, check for leaks, and insert the sensor into the

process.

2.2.3 Replacing Seals in Manual and Mechanical Retraction

Install

Assemblies

1. Retract the sensor into the retraction chamber and fully close the ball valve.

2. Drain the retraction chamber contents using the 1/8 in. flush ports.

WARNING!

HIGH PRESSURE

Retraction chamber contents may be under pressure. Reduce pressure to 0 psig before

opening the retraction chamber.

Failure to reduce pressure may cause a loose part to disengage and cause injury to

personnel.

3. For mechanical retraction assemblies, mark the location of the nut housing cap and

retraction collar on the sensor tube. Remove both socket head cup screws from the

nut housing and loosent the retraction stop collar.

4. Remove the 3 in. hex union nut.

5. Withdraw the sensor from the retraction chamber.

6. Open the junction box and disconnect the sensor wires from the terminal block.

7. Remove the compression fitting just below the junction box and remove the

junction box from the sensor tube.

8. For manual retraction assemblies, pull down the nut guard and remove the collet

nut from the bushing housing.

9. Slide all hardware, including the bushing housing, off the sensor tube.

10. Remove the retaining ring from the bottom of the bushing housing.

11. Remove the Teflon guard.

Rosemount 228 Sensor 15

Page 22

Install

12. From the top of the bushing housing, press out the Teflon bushing.

This will also push out the Teflon cup seal.

13. Replace all damaged parts with replacement parts from Figure 2-8 or Figure 2-9.

Replace the sensor tube if the surface is damaged.

A rough or uneven surface will prevent the Teflon cup from sealing.

Mechanical retraction assembly replacement partsFigure 2-8:

16 Reference Manual

Page 23

Install

Manual retraction assembly replacement partsFigure 2-9:

14. Rebuild the bushing housing.

The open end of the cup seal (spring visible) faces the process.

15.

Carefully slide the bushing housing onto the sensor tube.

Do not damage the Teflon bushing or the Teflon cup seal.

16. For manual retraction assemblies, slide the 3 in. hex union nut, collet nut with nut

guard, junction box compression nut, and plastic ferrules onto the sensor tubee.

17. For mechanical retraction assemblies, slide the 3 in. hex union nut, retraction stop

collar, junction box compression nut, and plastic ferrules onto the sensor tube.

18. Connect the junction box to the sensor tube and wire the sensor leads to the

appropriate terminals.

Rosemount 228 Sensor 17

Page 24

Install

19. For mechanical retraction assemblies, lock the retraction stop collar into position.

See Figure 2-8 or previously marked position for proper location.

20. Place the union nut O-ring at the bottom of the bushing housing. Insert the sensor

assembly into the retraction chamber and tighten the 3 in. hex union nut.

21. For mechanical retraction assemblies, install the nut housing cap.

See Figure 2-8 or previously marked position for proper location.

18 Reference Manual

Page 25

3 Wiring

3.1 Wiring the Sensor

Keep sensor wiring away from ac conductors and high current demanding equipment. Do

not cut the cable.

NOTICE

For additional wiring information on this product, please refer to the

Liquid Transmitter Wiring Diagrams.

Wire functionsFigure 3-1:

Wiring

Rosemount 228 Sensor 19

Page 26

Wiring

Wiring diagram for Rosemount 1056 and 56 TransmittersFigure 3-2:

20 Reference Manual

Page 27

Wiring

Wiring diagram for Rosemount 1066 TransmittersFigure 3-3:

Wiring diagram for Rosemount 5081 TransmittersFigure 3-4:

Rosemount 228 Sensor 21

Page 28

Wiring

Wiring sensors through a remote junction boxFigure 3-5:

Wire sensors point to point. For wiring at the transmitter end, refer to the appropriate transmitter wiring

diagram. For interconnecting cable 23294-00, use the 228-54 wiring diagram. For interconnecting cable

23294-04 and 23294-05, use the 228-54 wiring diagram.

Remote Junction Box (PN 23550-00) dimensionsFigure 3-6:

22 Reference Manual

Page 29

4 Calibration

4.1 Sensor calibration

The nominal cell constant of the Rosemount 228 sensor is 2.7/cm. The error in cell

constant is about ±10%, so conductivity readings made the using the nominal cell constant

will have an error of at least ±10%. Wall effects,as shown in Figure 4-1, will likely make the

error greater.

For more detailed information on calibration methods, please reference application data

sheet ADS-43-025 available on the Emerson Liquid Analysis website.

Calibration

Figure 4-1:

Measured Conductivity as a Function of Clearance between Sensor and

Walls

4.2 Calibrating against a Standard Solution

Calibration against a standard solution requires removing the sensor from process piping.

This calibration method is practical only if wall effects are absent or if the sensor can be

calibrated in a container identical to the process piping. Ideally, the conductivity of the

standard used should be close to the middle of the range that the sensor will be used in.

Generally, toroidal conductivity sensors have good linearity, and so standards greater than

5000 µS/cm at 77 °F (25 °C) may also be used.

1.

Remove the sensor from the pipe.

2. Fill a container with the standard solution.

Rosemount 228 Sensor 23

Page 30

Calibration

If wall effects are absent in the process installation, use a sufficiently large container

for calibration to ensure that wall effects are absent. To check for wall effects, fill the

container with solution and place the sensor in the center, submerged at least 3/4 of

the way up the stem. Note the reading. Then move the sensor small distances from

the center and note the reading in each position. The readings should not change.

If wall effects are present, be sure the vessel used for calibration has exactly the

same dimensions as the process piping. Also ensure that the orientation of the

sensor with respect to the piping is exactly the same in the process and calibration

vessels. See Figure 4-2.

Calibration installation orientationFigure 4-2:

3. Rinse the sensor with water.

4.

Immerse the rinsed sensor in the standard solution.

Use a good quality calibrated thermometer to measure the temperature of the

standard solution. The thermometer error should be less than ±1 °C. Allow adequate

time for the solution and sensor to reach thermal equilibrium. If the sensor is being

calibrated in an open beaker, keep the thermometer far enough away from the

sensor so it does not introduce wall effects. If the sensor is being calibrated in a pipe

tee or similar vessel, it is impractical to place the thermometer in the standard

solution. Instead, put the thermometer in a beaker of water placed next to the

callibration vessel. Let both come to thermal equilibrium with the ambient air before

continuing calibration. See Figure 4-3.

24 Reference Manual

Page 31

Calibration

Measuring standard temperatureFigure 4-3:

Be sure air bubbles are not adhering to the sensor. An air bubble trapped in the

toroid opening has a particularly severe effect on the reading.

5.

Turn off automatic temperature compensation in the transmitter.

This eliminates error in the cell constant.

6. Adjust the transmitter reading to match the conductivity of the standard.

4.3 Calibrating against a Referee - in-Process

Prerequisites

If possible, adjust the conductivity of the process liquid so that it is near the midpoint of

the operating range. If this is not possible, adjust the conductivity so that it is at least 5000

µS/cm.

Turn off automatic temperature compensation in the transmitter. This eliminates error in

the cell constant.

Procedure

Connect the process and referee sensors in a series.

1.

Keep tubing runs between the sensors short and adjust the sample flow to as high a

rate as possible. Short tubing runs and high flow ensure that the temperature of the

liquid does not change as it flows from one sensor to another.

2. Allow the process liquid to flow through both sensors.

Orient the referee sensor so that the air bubbles always have an easy escape path

and cannot get trapped. Tap and hold the flow cell in different positions to allow

bubbles to escape.

Wait for readings to stabilize before starting the calibration.

Rosemount 228 Sensor 25

Page 32

Calibration

3. Adjust the process sensor to match the conductivity measured by the referee

instrument.

Figure 4-4 shows the arrangement.

Calibration with a referee instrument exampleFigure 4-4:

4.4 Calibrating against a Referee - Grab Sample

This method is useful when calibration against a standard is impractical or when in-process

calibration is not feasible, because the sample is hot, corrosive, or dirty, making handling

the waste stream from the referee sensor difficult.

1.

Take a sample of the process liquid.

Take the sample from a point as close to the process sensor as possible. Be sure the

sample is representative of what the sensor is measuring. If possible, adjust the

conductivity of the process liquid so that it is near the midpoint of the operating

range. If that is not possible, adjust the conductivity so that it is at least 5000 µS/cm.

2. Connect the process and referee sensors.

26 Reference Manual

Page 33

Calibration

Keep temperature compensation with the transmitter turned on. Confirm that the

temperature measurements in both process and referee instruments are accurate,

ideally to within ±0.5 °C.

3. Place the sensors in the grab sample.

Wait until the readings are stable before starting the calibration.

4. Adjust the reading from the process analyzer to match the conductivity measured

by the referee sensor.

Rosemount 228 Sensor 27

Page 34

Calibration

28 Reference Manual

Page 35

Maintaining and Troubleshooting

5 Maintaining and Troubleshooting

5.1 Maintaining the sensor

WARNING!

HIGH PRESSURE

Retraction chamber contents may be under pressure. Reduce the pressure to 0 psig before

opening the retraction chamber.

Failure to reduce pressure may cause a loose part to disengage and cause injury to personnel.

WARNING!

TOXIC LIQUIDS

Be sure the sensor has been cleaned of process liquid before handling.

Generally, the only maintenance required is to keep the opening of the sensor clear of

deposits. Cleaning frequency is best determined by experience.

5.2 Troubleshooting

Resistance vs. Temperature for Temperature Compensation (PT-100 RTD)Table 5-1:

Temperature Resistance

10 °C (50 °F) 103.9 Ω

20 °C (68 °F) 107.8 Ω

25 °C (77 °F) 109.7 Ω

30 °C (86 °F) 111.7 Ω

40 °C (104 °F) 115.5 Ω

50 °C (122 °F) 119.4 Ω

Rosemount 228 Sensor 29

Page 36

Maintaining and Troubleshooting

30 Reference Manual

Page 37

6 Accessories

Part number Description

23550-00 Remote junction box

23294-00 Interconnecting extension cable, unshielded, prepped (for use with re-

mote junction box)

23294-05 Interconnecting extension cable, shielded, prepped (for use with remote

junction box)

23311-00 Mechanical valve insertion assembly

23311-01 Manual valve insertion assembly

2001990 Mounting adapter, 2 in. MNPT, CPVC

9550179 O-ring, EP rubber, for 20011990

23242-02 Mounting adapter, 1-1/2-in. MNPT insertion, 1-in. FNPT conduit connec-

tion, PEEK

33081-00-99SQ7091AAdapter insert, Tefzel, for 23242-02

Accessories

33081-00 Adapter insert, PEEK, for 23242-02

23242-03 Mounting adapter, 1-1/2-in. MNPT insertion, 3/4-in. FNPT conduit connec-

tion, PEEK

33080-01-99SQ7091BAdapter insert, Tefzel, for 23242-03

23277-01 Mounting adapter, Foxboro, PEEK, 5/8 11 UNC

23277-01-99SQ7182 Mounting adapter, Foxboro, Tefzel, 5/8 11 UNC

33075-00 Viton gasket for option 20

33075-03 Kalrez gasket for option 20

9200276 Interconnecting extension cable, shielded, unprepped

9340065 1-1/2 in. FNPT full port ball valve for use with retraction assemblies

Rosemount 228 Sensor 31

Page 38

Accessories

32 Reference Manual

Page 39

7 Return of Materials

For repair and warranty inquiries, please contact Rosemount Customer Care to obtain a

Return Material Authorization (RMA) number. Drain the sensor of fluids before shipping it

back to Rosemount.

Return of Materials

Rosemount 228 Sensor 33

Page 40

Return of Materials

34 Reference Manual

Page 41

Return of Materials

Rosemount 228 Sensor 35

Page 42

Return of Materials

36 Reference Manual

Page 43

Return of Materials

Rosemount 228 Sensor 37

Page 44

GLOBAL HEADQUARTERS

Emerson Automation Solutions

6021 Innovation Blvd

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

F +1 952 949 7001

liquid.csc@emerson.com

NORTH AMERICA

Emerson Automation Solutions

8200 Market Blvd

Chanhassen, MN 55317

Toll Free +1 800 999 9307

F +1 952 949 7001

liquid.csc@emerson.com

LIQ-MAN-228

Rev V

2018

EUROPE

Emerson Automation Solutions

Neuhofstrasse 19a P.O. Box 1046

CH-6340 Baar

Switzerland

T + 41 (0) 41 768 6111

F + 41 (0) 41 768 6300

liquid.csc@emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

twitter.com/rosemount_news

Facebook.com/Rosemount

youtube.com/RosemountMeasurement

google.com/+RosemountMeasurement

AnalyticExpert.com

MIDDLE EAST AND AFRICA

Emerson Automation Solutions

Emerson FZE

Jebel Ali Free Zone

Dubai, United Arab Emirates, P.O. Box 17033

T +971 4 811 8100

F +971 4 886 5465

liquid.csc@emerson.com

©

2018 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount is a

mark of one of the Emerson family of companies. All other marks are the property of their

respective owners.

ASIA-PACIFIC

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

Singapore

T +65 777 8211

F +65 777 0947

liquid.csc@emerson.com

Loading...

Loading...