Page 1

Model 226

Submersion/Insertion Toroidal Sensor

Instruction Sheet

PN 51A-226/rev.D

December 2010

For additional information, visit our website

at www.emersonprocess.com/raihome/liquid/.

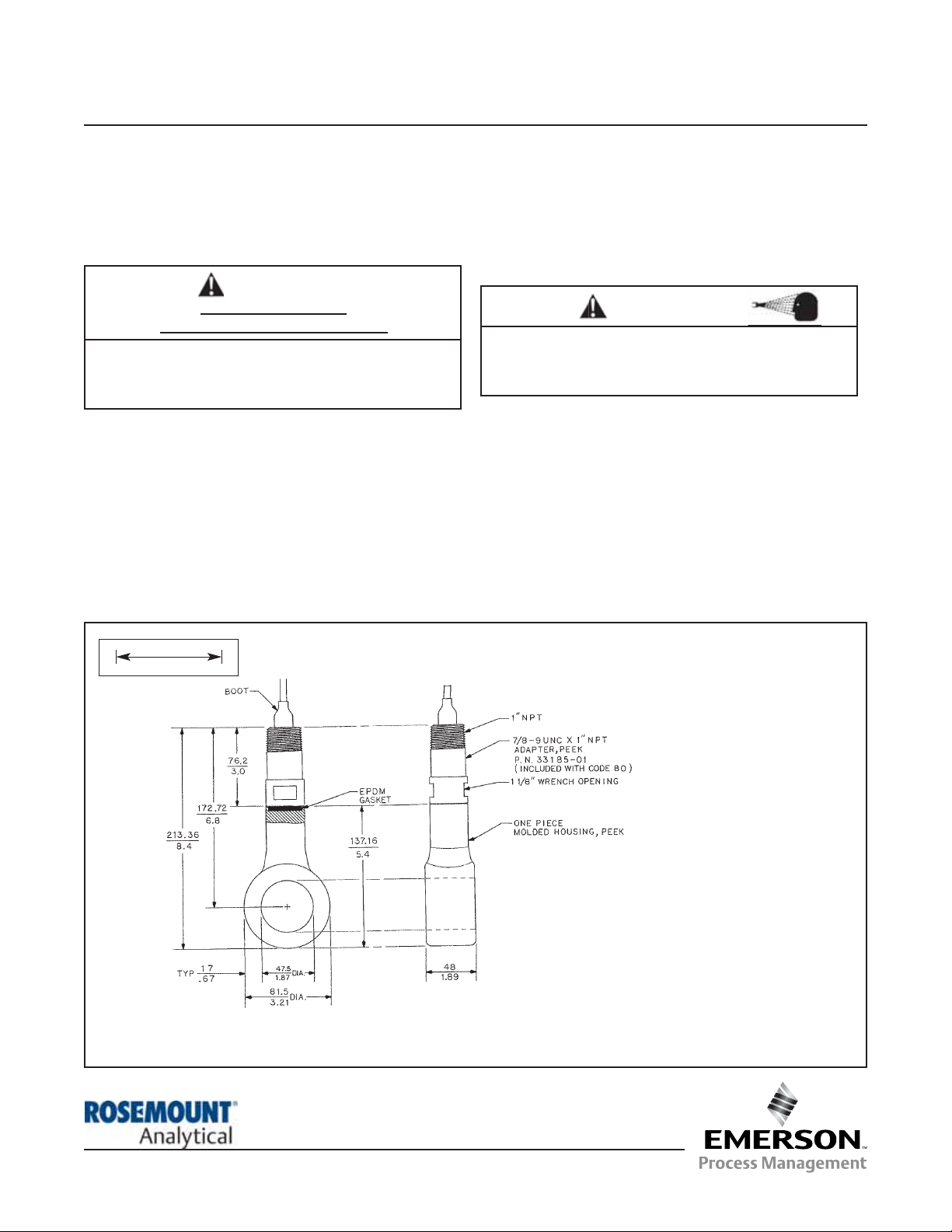

SUBMERSION

CODE - 80

FIGURE 1. Submersion Installation Showing Mounting Hardware

Screw the rear facing thread of the PEEK adapter into the pipe. Do not let the back end of the sensor get wet.

SPECIFICATIONS

Wetted Material: PEEK (glass-filled), EPDM gasket

Temperature: 248°F (120°C) maximum

Pressure: 295 psig (2135 kPa abs)

INSTALLATION

Keep at least 1.5 in. (40 mm) between the sensor and pipe walls. If the clearance is too small, calibrate the sensor

in place. Ensure that the sensor is completely submerged in the liquid. Mounting the sensor in a vertical pipe run

with the flow from bottom to top is best. If the sensor must be installed in a horizontal pipe run, mount the sensor in

the 3 o’clock or 9 o’clock position.

MILLIMETER

INCH

WARNING

Before removing the sensor, be absolutely certain

that the process pressure is reduced to 0 psig and

the process temperature is lowered to a safe level!

CAUTION

The wetted sensor materials may not be compatible

with process com position and operating conditions.

Application compat ibility is entirely the

responsi-

bility of the user.

CAUTION

SENSOR/PROCESS

APPLICATION COMPATIBILITY

Page 2

MODEL 226 INSTALLATION

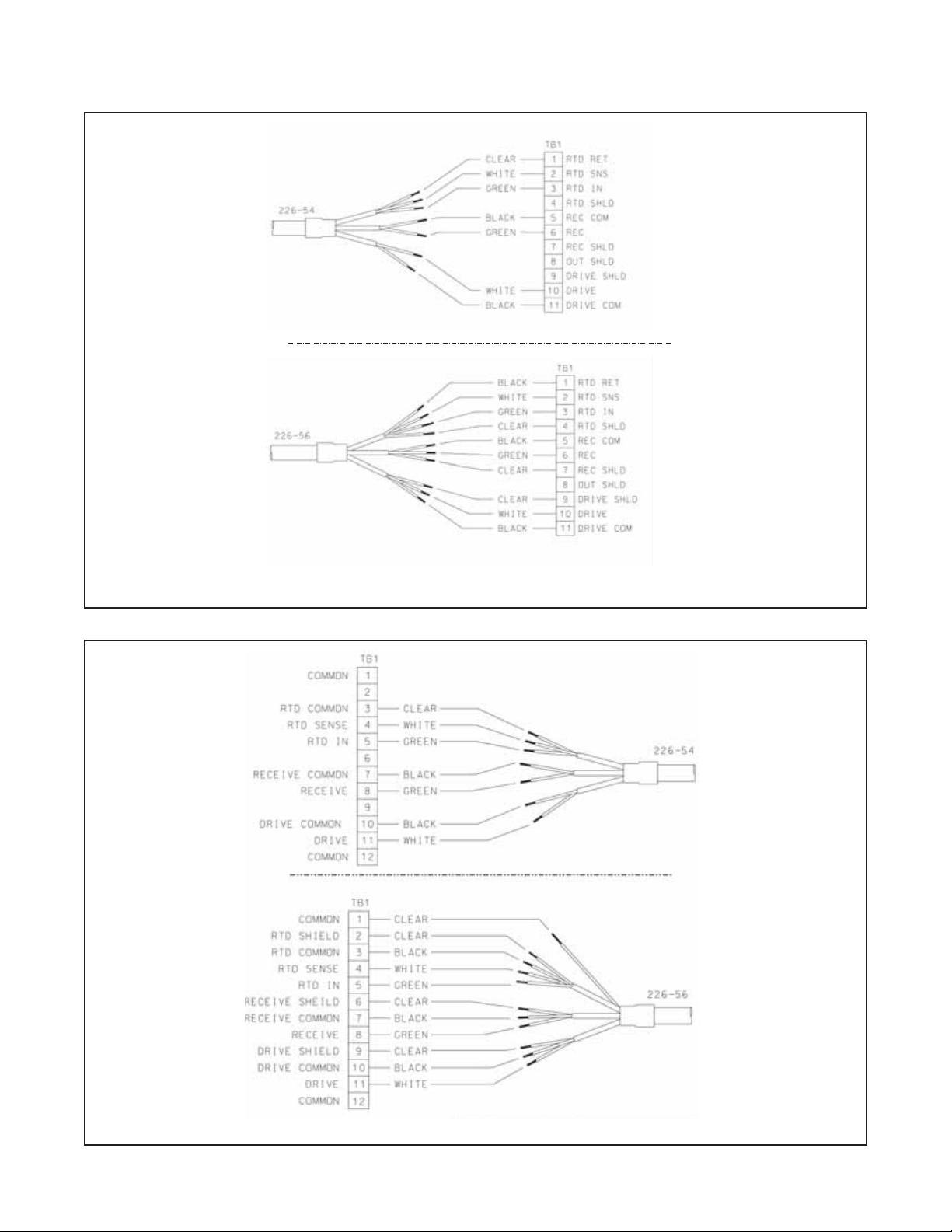

WIRING

Keep sensor wiring away from ac conductors and high current demanding equipment. Do not cut cable.

Cutting the cable may void the warranty.

FIGURE 3. Wire Functions

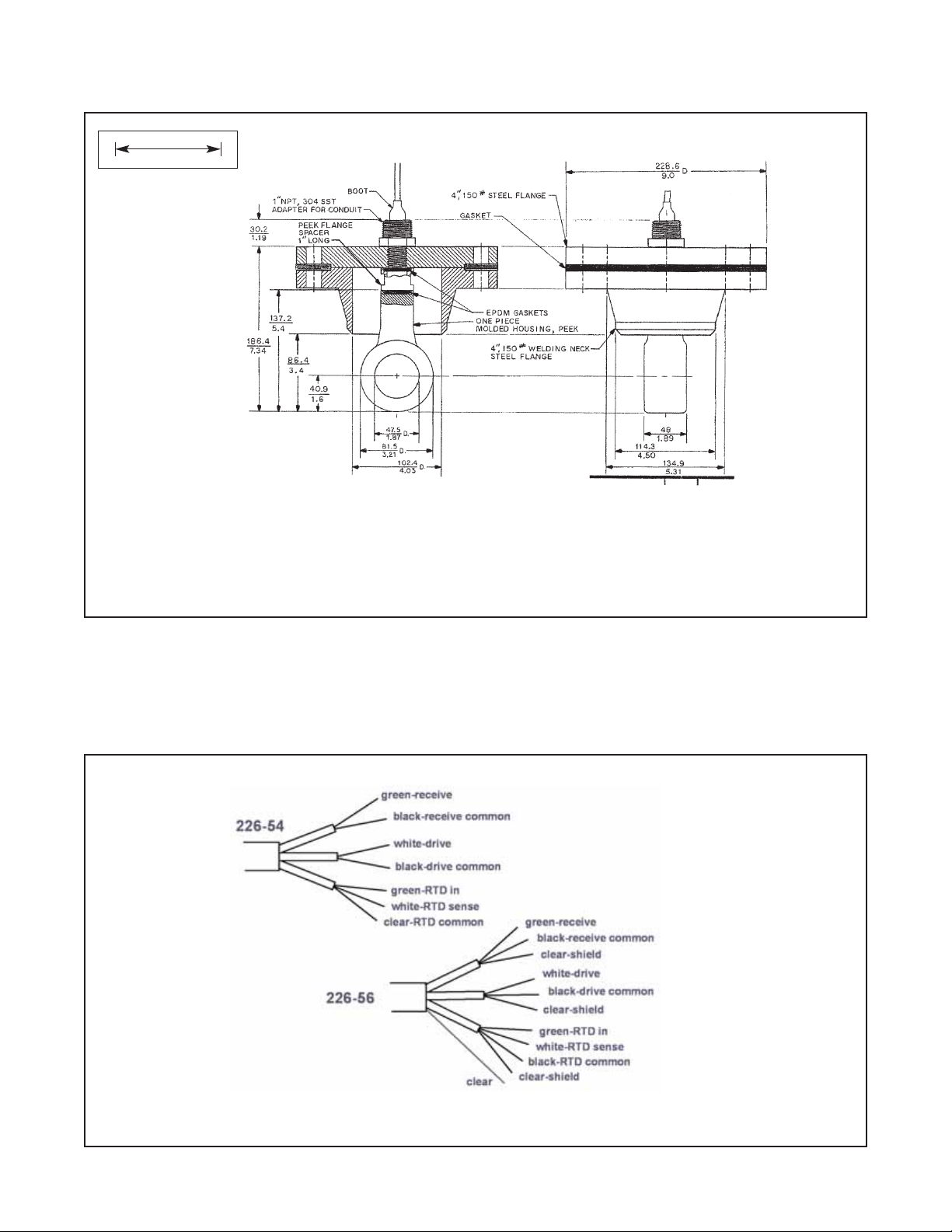

INSERTION

CODE - 81

MILLIMETER

INCH

FIGURE 2. Insertion Installation Showing Mounting Hardware

2

Page 3

3

MODEL 226 WIRING

FIGURE 4. Wiring 226-54 and 226-56 sensors to Model 1056 and 56 analyzers

FIGURE 5. Wiring 226-54 and 226-56 sensors to Model 54eC analyzer

Page 4

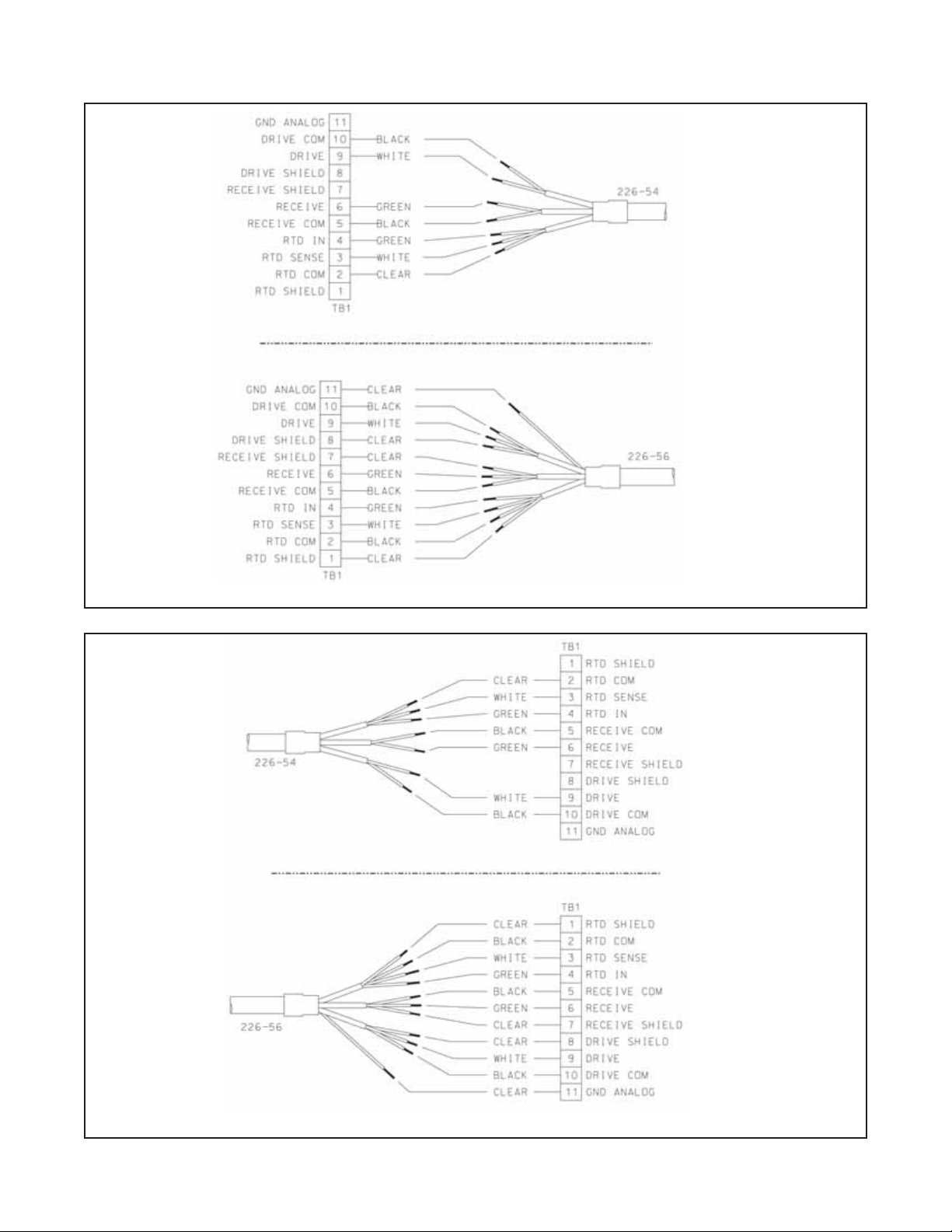

MODEL 226 WIRING

FIGURE 6. Wiring 226-54 and 226-56 sensors to Model Xmt-T panel mount transmitter

FIGURE 7. Wiring 226-54 and 226-56 sensors to Model Xmt-T pipe/wall mount transmitter

4

Page 5

5

MODEL 226 WIRING

FIGURE 8. Wiring 226-54 and 226-56 sensors to Model 1066 transmitter

RCV B

RCV A

RSHLD

DRV B

226-54

RTN

SENSE

RTD IN

SHLD

CLEAR

WHITE

GREEN

BLACK

GREEN

BLACK

WHITE

DRV A

DSHLD

TB1TB2

FIGURE 9. Wiring 226-54 and 226-56 sensors to Model 5081-T transmitter

RCV B

RCV A

RSHLD

DRV B

226-56

RTN

SENSE

RTD IN

SHLD

BLACK

GREEN

WHITE

CLEAR

DRV A

DSHLD

CLEAR

BLACK

CLEAR

WHITE

GREEN

BLACK

TB1TB2

Page 6

MODEL 226 WIRING

FIGURE 10. Wiring sensors through a remote junction box

Wire sensors point to point. For wiring at the analyzer end, refer to the appropriate analyzer wiring diagram. For interconnecting

cable 23294-00, use the 2265-54 wiring diagram. For interconnecting cable 23294-04 and 23294-05, use the 226-56 wiring diagram.

FIGURE 11. Remote Junction Box (PN 23550-00)

WIRING THROUGH A REMOTE JUNCTION BOX

6

Page 7

7

MODEL 226 CALIBRATION

CALIBRATION

The nominal cell constant of the Model 226 sensor is

1.2/cm. The error in the cell constant is about ±10%, so

conductivity readings made using the nominal cell constant will have an error of at least ±10%. Wall effects,

discussed below, will likely make the error greater. For

higher accuracy, the sensor must be calibrated.

Wall effects arise from the interaction between the current induced in the sample by the sensor and nearby

pipe or vessel walls. As Figure 12 shows, the measured conductivity can either increase or decrease

depending on the wall material. Because wall effects

do not disappear until the Model 226 sensor is at least

1.5 inch (40 mm) away from the nearest wall, wall

effects are present in most installations. Correcting for

them is an important part of calibration.

Conductivity sensors are calibrated against a solution

of known conductivity (a standard) or against a previously calibrated referee sensor and analyzer. If wall

effects are present, calibrating a toroidal sensor with

a standard solution is possible only if the vessel holding the standard has exactly the same dimensions as

the process piping. If the Model 226 sensor is installed

in a tee, duplicating the process environment in the

laboratory or shop might be possible. Otherwise, cali-

bration against a standard solution is probably impractical. The alternative is to calibrate the sensor in place

against a referee sensor and analyzer, ideally while

both sensors are simultaneously measuring the same

process liquid. If this is not practical, calibrate the

process sensor against the results of a measurement

made on a grab sample.

For more information about calibrating toroidal conductivity sensors, refer to application sheet ADS 43-025

available on the Rosemount Analytical website.

MAINTENANCE

Generally, the only maintenance required is to keep

the opening of the sensor clear of deposits. Cleaning

frequency is best determined by experience.

FIGURE 12. Measured conductivity as a function

of clearance between sensor and walls

WARNING

Be sure sensor has been cleaned of process liquid

before handling.

CAUTION

Page 8

8

MODEL 226 MAINTENANCE

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE SOLUTION

Off-scale reading Wiring is wrong. Verify and correct wiring.

RTD is open or shorted. Check the RTD for open or short circuits.

See Figure 13.

Sensor is not in process stream. Confirm that the sensor is fully submerged in

the process stream. See installation section.

Sensor is damaged. Perform isolation checks. See Figure 13.

Noisy reading Sensor is improperly installed in the Confirm that the sensor is fully submerged

process stream. in the process stream. See installation section.

Sensor cable is run near high voltage Move cable away from high voltage conductors.

conductors.

Sensor cable is moving. Keep sensor cable stationary.

Reading seems wrong (lower Bubbles are trapped in the sensor, Install the sensor in a vertical pipe run with the

or higher than expected) particularly in the toroid opening. flow against the toroid opening. Increase flow

if possible.

Sensor is not completely submerged in the Confirm that the sensor is fully submerged

process stream. in the process stream. See installation section.

Cell constant is wrong. Wall effects are Calibrate the sensor in place in the process

present. piping. See calibration section.

Wrong temperature correction algorithm Check that the temperature correction is

is being used. appropriate for the sample. See analyzer

manual for more information.

Temperature reading is inaccurate. Disconnect the RTD leads (Figure 13) and

measure the resistance between the in and

common leads. Resistance should be close

to the value in Table 1.

Slow temperature response to sudden Use an RTD in a metal thermowell for

changes in temperature. temperature compensation.

Sluggish response Sensor is installed in a dead area in the Move sensor to a location more representative

piping. of the process liquid.

Slow temperature response to sudden Use an RTD in a metal thermowell for

changes in temperature. temperature compensation.

Page 9

MODEL 226 MAINTENANCE

FIGURE 13. Resistance check. Disconnect leads from analyzer before measuring resistances.

TABLE 1.

Temperature Resistance

10°C 103.9 Ω

20°C 107.8 Ω

25°C 109.7 Ω

30°C 111.7 Ω

40°C 115.5 Ω

50°C 119.4 Ω

9

Page 10

NOTES:

10

Page 11

11

NOTES:

Page 12

Credit Cards for U.S. Purchases Only.

The right people,

the right answers,

right now.

ON-LINE ORDERING NOW AVAILABLE ON OUR WEB SITE

http://www.raihome.com

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2010

8

Loading...

Loading...