Page 1

Instruction Manual

IQ-MAN-140

L

Rev. F

May 2017

Rosemount

™

140/141/142

Contacting Conductivity Sensors

Page 2

asgkas

h

Page 3

Essential Instructions

Read this page before proceeding!

Emerson designs, manufactures and tests its products to meet many national and international stan-

dards. Because these sensors are sophisticated technical products, you MUST properly install, use,

nd maintain them to ensure they continue to operate within their normal specifications. The

a

following instructions MUST be adhered to and integrated into your safety program when installing,

using, and maintaining Rosemount products. Failure to follow the proper instructions may cause

any one of the following situations to occur: loss of life; personal injury; property damage; damage

to this sensor; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson representative for

clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance

of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate

Instruction Manual and per applicable local and national codes. Connect all products to

the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update,

program, and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Emerson. Unauthorized parts and procedures can affect the product's

performance, place the safe operation of your process at risk, and VOID YOUR WARRANTY.

Third-party substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when

maintenance is being performed by qualified persons, to prevent electrical shock and

personal injury.

The information contained in this document is subject to change without notice.

CAUTION

Sensor/Process Application Compatibility

The wetted sensor materials may not be compatible with process composition and operating

conditions. Application compatibility is entirely the responsibility of the user.

CAUTION

Before removing the sensor, be absolutely certain the process pressure is reduced to 0 psig and the

process temperature is at safe level.

Page 4

About This Document

his manual contains instructions for installation and operation of the Rosemount

T

140/141/142 Contacting Conductivity Sensor

The following list provides concerning all revisions of this document.

Rev. Level Date Notes

F 05/17 Reformatted to reflect the latest Emerson documentation style

Specifications and Wiring Diagrams.

Page 5

Instruction Manual Table of Contents

LIQ-MAN-140 May 2017

Contents

Section 1: Specifications

1.1 Specifications ......................................................................................................1

Section 2: Installation

2.1 Unpacking and Inspection ...................................................................................5

2.2 Sensor Installation ...............................................................................................5

2.3 Installation - Rosemount 140 Sensor with Ball Valve Kit (PN 23724-00) ................5

2.4 Installation - Rosemount 141 Sensor ....................................................................6

2.5 Installation - Rosemount 142 Sensor ....................................................................7

Section 3: Wiring

3.1 Wiring for Rosemount 140/141/142 ....................................................................9

Section 4: Retracting and Inserting the Rosemount 140 Sensor

4.1 Retracting the Sensor ........................................................................................13

4.2 Inserting the Sensor...........................................................................................13

Section 5: Removing and Reinstalling the Rosemount 142 Sensor

5.1 Removing the Sensor .........................................................................................15

5.2 Reinstalling the Sensor.......................................................................................15

Section 6: Calibration and Maintenance

6.1 Calibrating the sensor........................................................................................17

6.2 Cleaning the Sensor ...........................................................................................21

6.3 Checking the Rosemount 140 Retraction Restraint ............................................21

6.4 Replacing Rosemount 140 Sensor Seal ...............................................................21

Section 7: Accessories

7.1 Accessories........................................................................................................23

Section 8: Troubleshooting

8.1 Troubleshooting ................................................................................................25

Table of Contents i

Page 6

Table of Contents Instruction Manual

May 2017 LIQ-MAN-140

ii Table of Contents

Page 7

Instruction Manual Specifications

LIQ-MAN-140 May 2017

Section 1: Specifications

1.1 Specifications

Table 1-1: Rosemount 140 contacting conductivity sensor specifications

Wetted Materials

Electrodes 316 stainless steel

Body 316 stainless steel

Insulator PEEK

O-rings Viton

Temperature range

Standard 32 °F to 302 °F (0 °C to 150 °C) maximum

High temperature 32 °F to 392 °F (0 °C to 200 °C) maximum

Pressure

100 psig (791 kPa abs) maximum

Maximum retraction pressure

100 psig (791 kPa abs)

Vacuum

At 1.6 in. Hg (5.2 kPa) air leakage is less than 0.005 SCFM (0.00014 m3/min)

Junction box

cast aluminum

Process connection

1 in. MPT through 1inch full port ball valve (retractable)

Weight/Shipping Weight

5 lb /6 lb (2.5 kg / 3.0 kg)

Weights rounded up to nearest whole lb or 0.5 kg

Specifications 1

Page 8

Specifications Instruction Manual

May 2017 LIQ-MAN-140

Table 1-2: Rosemount 141 contacting conductivity sensor specifications

Wetted Materials

Electrodes 316 stainless steel

ody

B

Insulator PEEK

O-rings Viton

Temperature and pressure

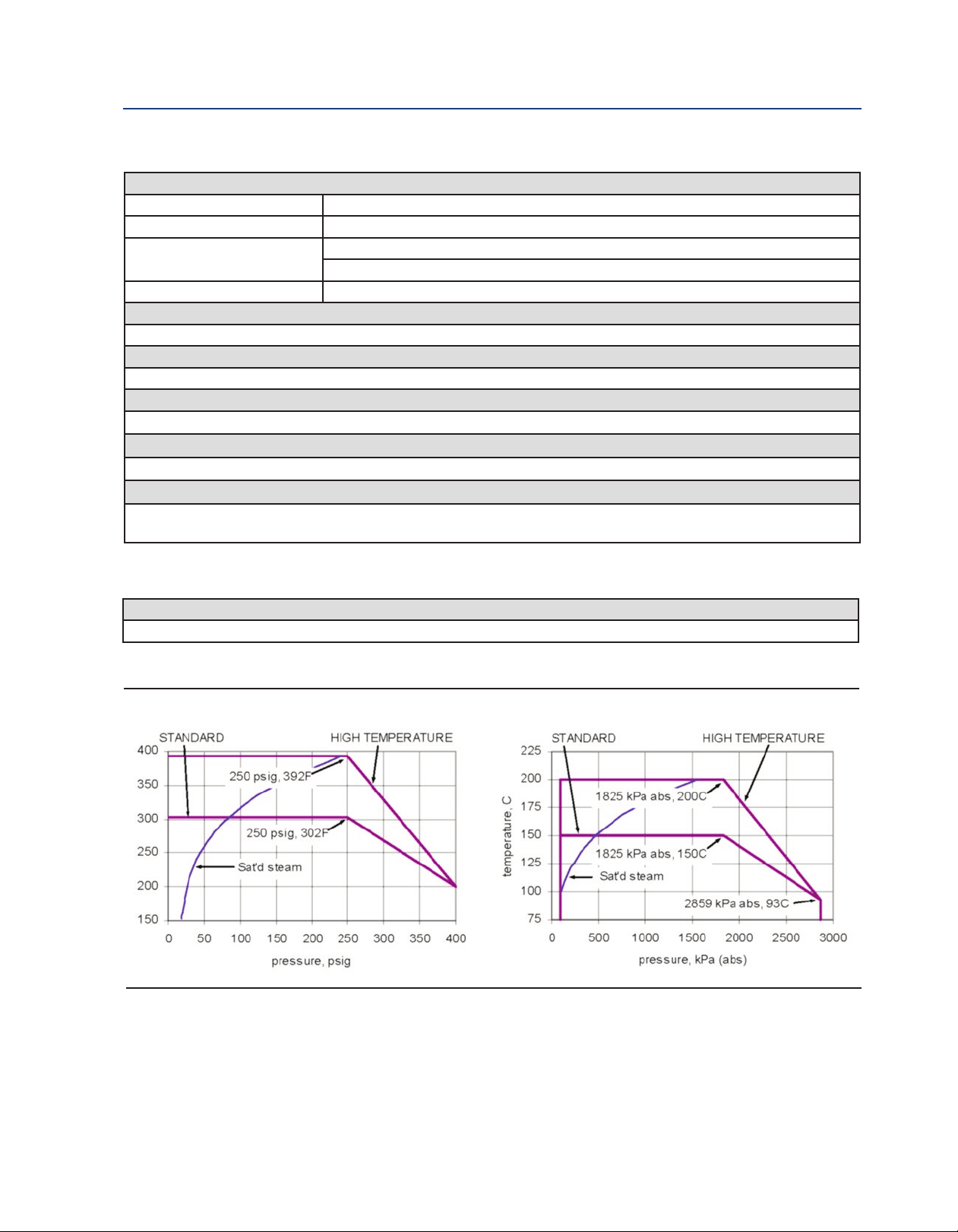

See Figure 1-1

Vacuum

At 1.6 in. Hg (5.2 kPa) air leakage is less than 0.005 SCFM (0.00014 m3/min)

Junction box

cast aluminum

Process connection

¾ in. MPT

Weight/Shipping Weight

2 lb / 3 lb (1.0 kg / 1.5 kg)

Weights rounded up to nearest whole lb or 0.5 kg

16 stainless steel

3

2 Specifications

Page 9

Instruction Manual Specifications

LIQ-MAN-140 May 2017

Table 1-3: Rosemount 142 contacting conductivity sensor specifications

Wetted Materials

Electrodes 316 stainless steel

ody

B

Insulator PEEK (high temperature option)

O-rings Viton

Temperature and Pressure

See Figure 1-1

Vacuum

At 1.6 in. Hg (5.2 kPa) air leakage is less than 0.005 SCFM (0.00014 m3/min)

Junction box

cast aluminum

Process connection

¾ in. MPT

Weight/Shipping Weight

2 lb/3 lb (1.0 kg / 1.5 kg)

Weights rounded up to nearest whole lb or 0.5 kg

16 stainless steel

3

PCTFE (low temperature option)

Table 1-4: Specifications for PN 23724-00 ball valve kit

Wetted Materials

316 stainless steel except Teflon® seat and seals in ball valve

Figure 1-1 Rosemount 141 and 142 sensor pressure/temperature graphs

Heading title 3

Page 10

Specifications Instruction Manual

May 2017 LIQ-MAN-140

4 Specifications

Page 11

Instruction Manual Installation

LIQ-MAN-140 May 2017

Section 2: Installation

2.1 Unpacking and Inspection

Inspect the outside of the carton for any damage. If damage is detected, contact the carrier

immediately. Inspect the instrument and hardware. Make sure all items in the packing list are

present and in good condition. Notify the factory if any part is missing.

2.2 Sensor Installation

Keep 1/4 in. (6 mm) clearance between electrodes and piping. The electrodes must be completely

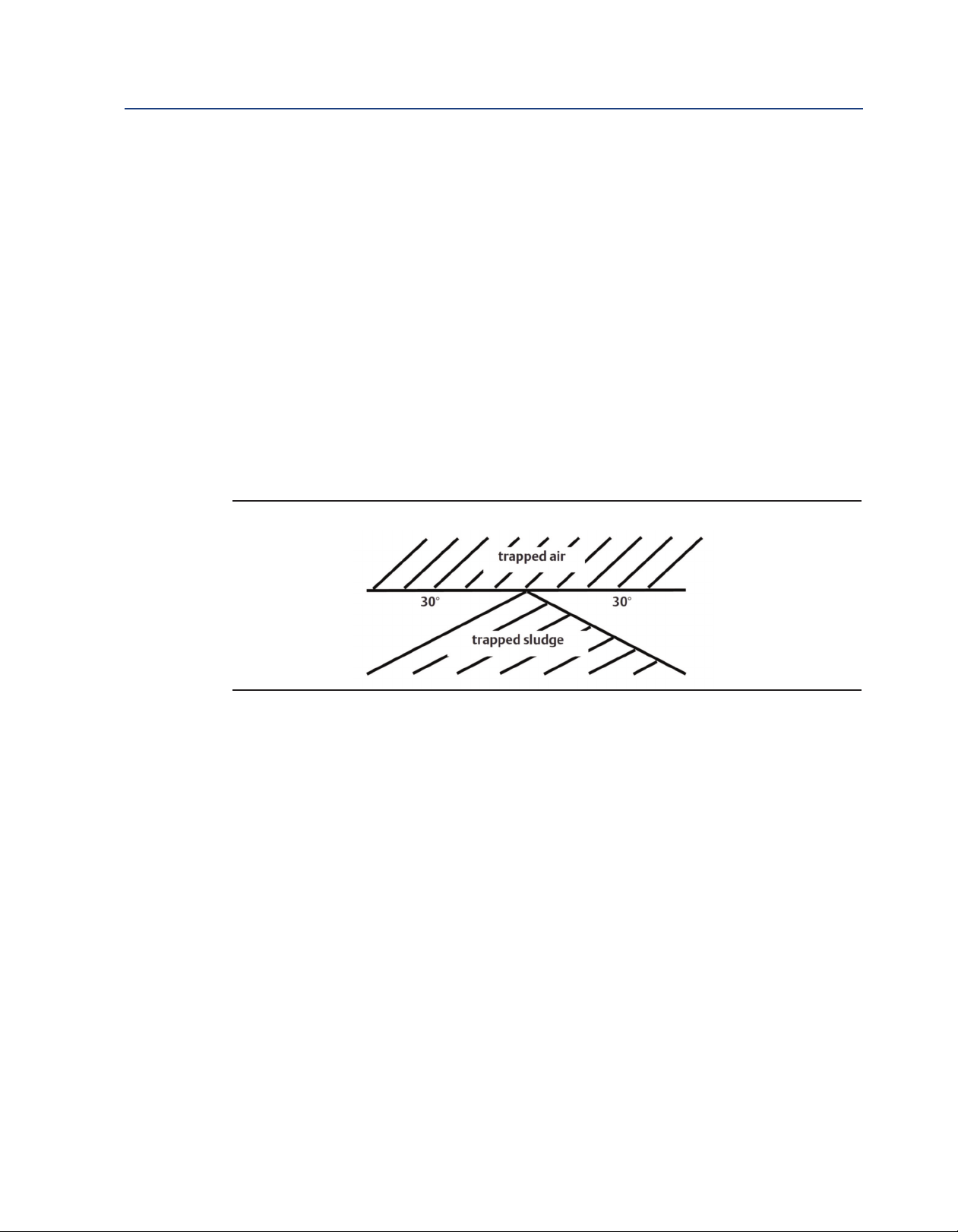

submerged in the process liquid, i.e., to the level of the threaded connection. See Figure 2-1 for

recommended orientation.

If the sensor is installed in a side stream with the sample draining to open atmosphere, bubbles

may accumulate on the electrodes. Trapped bubbles will cause errors. As bubbles accumulate, the

conductivity reading drops. To control bubble formation, apply a small amount of back pressure to

the drain.

Figure 2-1 Sensor orientation

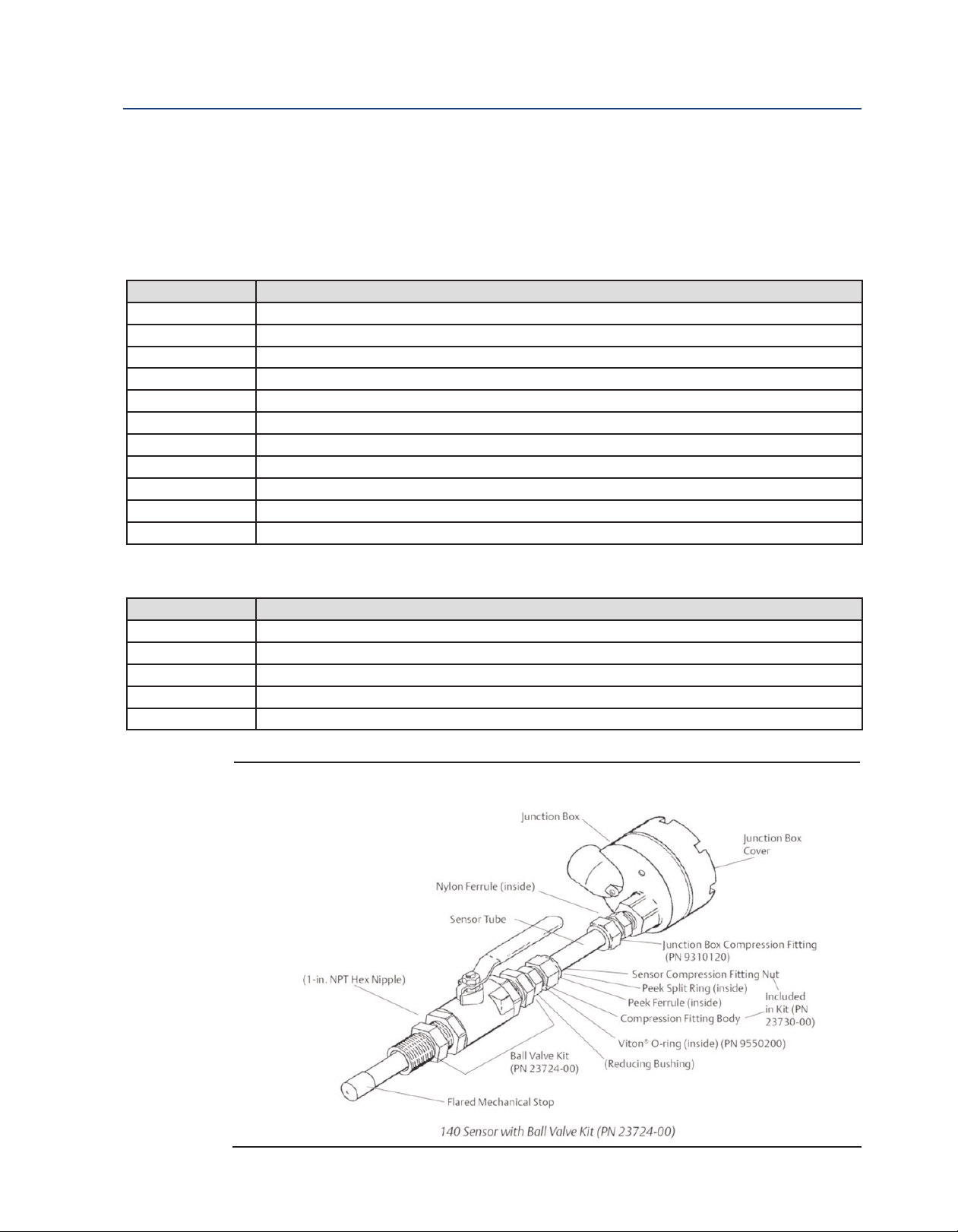

2.3 Installation - Rosemount 140 Sensor with Ball Valve

Kit (PN 23724-00) *

1. Install the sensor in either a 1 in. NPT weldalet or in a 1 in. pipe tee.

2. Remove the plastic shipping cap from the sensor.

3. Screw the 1 in. hex nipple into the weldalet or pipe tee. See Figure 2-2. Use pipe tape on

the threads.

4. Position the sensor for easy access to the ball valve handle, sensor compression fitting nut,

and junction box.

5. Make sure the ball valve is in the fully open position.

6. Finger tighten the sensor compression fitting nut. Do not over tighten because the next

step is to press the sensor into the process pipe.

7. Insert the sensor tube until the sensor tip is no closer than 1 in. (25 mm) from the far wall

of the process pipe. See Figure 2-2.

8. Tighten the sensor compression fitting nut to hold the sensor tip in position.

* If the ball valve assembly is already in place and the process line is pressurized, refer to

Inserting the Sensor.

Installation 5

Page 12

Installation Instruction Manual

May 2017 LIQ-MAN-140

Figure 2-2 Installing the Rosemount 140 sensor with ball valve kit (PN 23724-00)

2.4 Installation - Rosemount 141 Sensor

1. Install the sensor in a 3/4 in. NPT weldalet or in a 1 in. pipe tee.

2. Remove the plastic shipping cap from the sensor.

3. Screw the sensor into the fitting. Use pipe tape on the threads. See Figure 2-3.

Figure 2-3 Installing Rosemount 141 sensor

6 Installation

Page 13

Instruction Manual Installation

LIQ-MAN-140 May 2017

2.5 Installation - Rosemount 142 Sensor

1. Install the sensor in a 3/4 in. NPT weldalet or in a 1 in.pipe tee. See Figure 2-4.

2. Remove the plastic shipping cap from the sensor.

3. Screw the sensor into the fitting. Use pipe tape on the threads. DO NOT tighten the sensor

compression fitting until the sensor is correctly positioned.

4. If necessary, loosen the sensor compression fitting and position the sensor so that the tip

of the sensor is at least 1 in. (25 mm) from the far wall of the pipe.

5. Tighten the compression fitting using the procedure shown in Figure 2-2.

Figure 2-4 Installing Rosemount 142 sensor

Installation 7

Page 14

Installation Instruction Manual

May 2017 LIQ-MAN-140

8 Installation

Page 15

Instruction Manual Wiring

LIQ-MAN-140 May 2017

Section 3: Wiring

3.1 Wiring for Rosemount 140/141/142

For other wiring diagrams not shown below, please refer to the Liquid Transmitter Wiring Diagrams.

All Rosemount 140 series sensors have a junction box mounted on the back of the sensor. Wiring

connections in the junction box are shown in Figure 3-1.

Rosemount 141 and 142 sensors have one gray wire (shown). The Rosemount 140 sensor has two

gray wires attached to the terminal.

Figure 3-1: Sensor junction box wiring. Terminals in the junction box are not numbered.

Figure 3-2: Wire color and connections in sensor

Wiring 9

Page 16

Wiring Instruction Manual

May 2017 LIQ-MAN-140

Figure 3-3: Rosemount 140/141/142 Sensor Wiring to Rosemount 1056, 56, and 1057

Transmitters

Figure 3-4: Rosemount 140/141/142 Sensor Wiring to Rosemount 1066 Transmitter

10 Wiring

Page 17

Instruction Manual Wiring

LIQ-MAN-140 May 2017

Figure 3-5: Rosemount 140/141/142 Sensor Wiring to Rosemount 5081 Transmitter

Wiring 11

Page 18

Wiring Instruction Manual

May 2017 LIQ-MAN-140

12 Wiring

Page 19

Instruction Manual Retracting and Inserting the Rosemount 140 Sensor

LIQ-MAN-140 May 2017

Section 4: Retracting and Inserting the

Rosemount 140 Sensor

CAUTION

Rosemount 140 sensors are retractable. Before retracting the sensor, be absolutely certain the process

pressure is less than 100 psig (791 kPa abs) and the process temperature is at a safe level!

4.1 Retracting the Sensor

1. Push in on the sensor junction box and slowly loosen the sensor compression fitting nut by

reversing the sensor tightening procedure illustrated in Figure 2-2.

2. When the sensor compression nut is completely unscrewed, slowly ease the sensor out

until the flared tip of the electrode rests firmly within the body of the compression fitting

body.

3. Close the ball valve completely.

CAUTION

Before removing the sensor be sure the ball valve is completely closed.

4. Unscrew the compression fitting body from the reducing bushing and remove the sensor

from the ball valve assembly.

4.2 Inserting the Sensor

CAUTION

Make sure process O-ring is clean, lubricated, and in place before installing sensor. Replace if worn.

1. Do not open the ball valve.

CAUTION

The system pressure must be less than 100 psig (791 kPa).

2. Thread the sensor compression fitting body into the reducing bushing in the rear of the

ball valve and tighten.

Note: Do not push past this point. Damage to the sensor could result.

WARNING

If the sensor comes free of the valve, refer to Figures 2-2 and 7-1 and verify that the valve and

associated fittings are as shown. Do not proceed until the sensor is correctly restrained.

3. Slowly open the valve.

WARNING

Stand clear of the sensor.

Retracting and Inserting the Rosemount 140 Sensor

13

Page 20

Retracting and Inserting the Rosemount 140 Sensor Instruction Manual

May 2017 LIQ-MAN-140

1. Insert the sensor up to the desired insertion depth and turn the sensor compression fitting

nut until it is finger tight.

2. Position the entire sensor for easy access to the ball valve handle, sensor compression

fitting nut and J-box terminal block.

3. Tighten sensor compression fitting nut.

CAUTION

For initial installation of the sensor, tighten the compression fitting nut 1-1/4 turns after finger tight. If

it is a reinstallation, turn no more than 1/4 to 1/2 additional turns.

14 Retracting and Inserting the Rosemount 140 Sensor

Page 21

Instruction Manual Removing and Reinstalling the Rosemount 142 Sensor

LIQ-MAN-140 May 2017

Section 5: Removing and Reinstalling the

Rosemount 142 Sensor

5.1 Removing the Sensor

WARNING

efore removing the sensor, be absolutely certain that the process pressure is reduced to 0 psig and

B

the process temperature is lowered to a safe level!

1. Reduce process temperature and pressure to a safe level. If necessary drain the process

line.

2. Loosen the sensor compression fitting and slowly slide the sensor from the pipe fitting or

weldalet.

5.2 Reinstalling the Sensor

1. Slide the sensor into the process fitting and position the sensor the way it was originally

installed.

CAUTION

Be sure the sensor is in the original position. The sensor tube takes a permanent set and could become

weakened if the new set is adjacent to the original set.

2. Tighten the sensor compression fitting 1/4 to 1/2 turn after it is finger tight.

Removing and Reinstalling the Rosemount 142 Sensor 15

Page 22

Retracting and Inserting the Rosemount 140 Sensor Instruction Manual

May 2017 LIQ-MAN-140

16 Removing and Reinstalling the Rosemount 142 Sensor

Page 23

Instruction Manual Calibration and Maintenance

LIQ-MAN-140 May 2017

Section 6: Calibration and Maintenance

6.1 Calibrating the sensor

osemount 140/141/142 sensors are not calibrated at the factory. The cell constant on the label is

R

a nominal value only. The true cell constant can differ from the nominal value by as much as ±5%.

For improved accuracy, calibrate the sensor using either a solution of known conductivity or a

referee meter and sensor. If using a standard solution, choose one having conductivity in the

recommended operating range for the sensor cell constant.

Do not use standard solutions having conductivity less than about 100 µS/cm for calibration. They

are susceptible to contamination by atmospheric carbon dioxide, which can alter the conductivity

by a variable amount as great as 1.2 µS/cm (at 25 °C). Because 0.01/cm sensors must be calibrated

in low conductivity solutions, they are best calibrated against a referee meter and sensor in a closed

system. For more information about calibrating refer to

6.1.1 Calibrating using a standard solution

Application Data Sheet.

If using a standard solution, choose one having conductivity in the recommended operating range

for the sensor cell constant.

1. Immerse the rinsed sensor in the standard solution and adjust the transmitter reading to

match the conductivity of the standard.

2. For an accurate calibration:

a. Choose a calibration standard near the midpoint of the recommended conductivity

range for the sensor.

b. Do not use calibration standards having conductivity less than 100 µS/cm.

c. Turn off automatic temperature compensation in the transmitter.

d. Use a standard for which the conductivity as a function of temperature is known.

e. Use a good quality calibrated thermometer with an error rate less than ±0.1 °C to

measure the temperature of the standard.

f. Follow good laboratory practice. Rinse the beaker and sensor at least twice with

standard. Be sure the rinse solution reaches between the inner and outer electrodes by

tapping and swirling the sensor while it is immersed in the standard.

g. Be sure air bubbles are not trapped between the electrodes. Place the sensor in the

standard and tap and swirl to release bubbles. Note the reading and repeat. If readings

agree, no trapped bubbles are present. Repeat until two subsequent readings agree.

Calibration and Maintenance 17

Page 24

Calibration and Maintenance Instruction Manual

May 2017 LIQ-MAN-140

6.1.2 Calibrating using a reference meter and sensor

1. Connect the process sensors and reference sensor in series and allow the process liquid

to flow through all sensors.

2. Calibrate the process sensor by adjusting the process transmitter reading to match the

conductivity measured by the reference meter. See Figure 3-1 for the calibration setup.

Figure 3-1 In process calibration setup

NOTICE

The above figure shows two process sensors connected in series with a reference sensor. The horizontal

sensor orientation ensures good circulation of the process liquid past the electrodes. The staircase

orientatation provides an escape path for bubbles.

3. The method is ideal for calibrating the sensors used in low conductivity water (0.01/cm

cell constants) because the calibration system is closed and cannot be contaminated by

atmospheric carbon dioxide.

Following precautions are necessary for successful calibration:

1. If the normal conductivity of the process liquid is less than about 1.0 µS/cm, adjust the

conductivity so that it is near the upper end of the operating range.

The difference between the conductivity measured by the process and reference meter

usually has both a fixed (constant error) and relative (proportional error) component.

Because the cell constant calibration assumes the error is proportional only, calibration at

low conductivity allows the fixed component to have an outsized influence on the result.

For example, assume the only difference between reference meter and process sensor is

fixed and the process sensor always reads 0.002 µS/cm high. If the process sensor is

calibrated at 0.100 µS/cm, the new cell constant will be changed by 0.100/0.102 or 2%. If

the sensor is calibrated at 0.500 µS/cm, the change will be only 0.500/0.502 or 0.4%.

Calibration at higher conductivity produces a better result because it minimizes the effect

of the offset.

18 Calibration and Maintenance

Page 25

Instruction Manual Calibration and Maintenance

LIQ-MAN-140 May 2017

. Orient the sensors so that air bubbles always have an easy escape path and cannot get

2

trapped between the electrodes.

3. Turn off automatic temperature compensation in the transmitter.

Almost all process conductivity transmitter feature automatic temperature compensation

in which the transmitter applies one of several temperature correction algorithms to

convert the measured conductivity to the value at a reference temperature, typically 25 °C.

Although temperature correction algorithms are useful for routine measurements, they

should not be used during calibration.

There are two following reasons:

a. No temperature correction is perfect. If the assumptions behind the algorithm do not

perfectly fit the solution being measured, the temperature-corrected conductivity will

be in error.

b. If the temperature measurement itself is in error, the corrected conductivity will be in

error.

The purpose of calibrating the sensor is to determine the cell constant. To minimize the

error in the cell constant, all sources of avoidable error, e.g., temperature compensation

should be eliminated.

4. Keep tubing runs between the sensors short and adjust the sample flow as high as possible.

Short tubing runs and high flow ensure the temperature of the liquid does not change as

it flows from one sensor to another.

If the process temperature is appreciably different from ambient, high flow may not be

enough to keep the temperature constant. In this case, pumping sample at room

temperature from a reservoir through the sensors might be necessary. Because such a

system is likely to be open to atmosphere, saturate the liquid with air to prevent drift

caused by absorption of atmospheric carbon dioxide.

5. To prevent contamination of low conductivity (<1 µS/cm) process liquids, use clean tubing

to connect the sensors. To prevent drift caused desorption of ionic contaminants from

tube walls, keep the sample flow greater than 6 ft/sec (1.8 m/sec).

6.1.3 Calibrating using a grab sample

1. Use the grab sample method when it is impractical to remove the sensor for calibration or

to connect a reference sensor to the process line.

2. Take a sample of the process liquid, measuring its conductivity using a reference

instrument, and adjusting the reading from the process transmitter to match the measured

conductivity.

3. Take the sample from a point as close to the process sensor as possible.

4. Keep temperature compensation turned on. There is likely to be a lag time between

5. Be sure the reference and process instruments are using the same temperature correction

Calibration and Maintenance

sampling and analysis, so temperature is likely to change.

algorithm.

19

Page 26

Calibration and Maintenance Instruction Manual

May 2017 LIQ-MAN-140

. Grab sample calibration should be used only when the conductivity is fairly high.

6

a. The temperature compensation algorithm will most likely be linear slope.

b. Confirm that both instruments are using the same temperature coefficient in the linear

slope calculation.

c. If the reference meter does not have automatic temperature correction, calculate

the conductivity at 25 °C using the equation:

Where: C25 = the conductivity at 25 °C

Ct = the conductivity at t °C

α = the temperature co-efficient expressed as a decimal fraction.

d. Confirm the temperature measurements in both the process and reference instruments

are accurate, ideally to within ±0.5 °C.

e. Follow good laboratory practice when measuring the conductivity of the grab sample.

- Rinse the beaker and sensor at least twice with sample. Be sure the rinse solution

reaches between the inner and outer electrodes by tapping and swirling the

sensor while it is immersed in the sample.

- Be sure air bubbles are not trapped in the sensor. Place the sensor in the sample

and tap and swirl to release bubbles. Note the reading. Then, remove the sensor

and return it to the sample. Tap and swirl again and note the reading. If the two

readings agree, trapped bubbles are absent. If they do not agree, bubbles are

present . Continue the process until two subsequent readings agree.

- While making the measurement, do not allow the sensor to touch the sides and,

particularly, the bottom of the beaker. Keep at least 1/4 in. (6 mm) clearance.

f. Be sure to compensate for process conductivity changes that might have occurred

while the grab sample was being tested. Rosemount conductivity transmitters

(Rosemount transmitter models 1056, 1066, and 56) do this automatically. They save

the value of the process conductivity at the time the sample was taken and use that

value to calculate the new cell constant when the user enters the result of the grab

sample test. Older transmitters do not remember the process conductivity value.

Therefore, the user must enter a value adjusted by an amount proportional to the change

in the process conductivity. For example, suppose the process conductivity is 810 µS/cm

when the sample is taken and 815 µS/cm when the test result is entered. If the grab

sample conductivity is 819 µS/cm, the user should enter (815/810) × 819 or 824 µS/cm.

20 Calibration and Maintenance

Page 27

Instruction Manual Calibration and Maintenance

LIQ-MAN-140 May 2017

6.2 Cleaning the Sensor

Use a warm detergent solution and a soft brush or pipe cleaner to remove oil and scale. Isopropyl

alcohol can also be used to remove oily films. Avoid using strong mineral acids to clean

onductivity sensors.

c

6.3 Checking the Rosemount 140 Retraction Restraint

The integrity of the Rosemount 140 will become compromised is the flared tip of the electrode is

allowed to blow out against the compression fitting body. In the even a blowout occurs, replace

the sensor.

6.4 Replacing Rosemount 140 Sensor Seal

If the process seal is leaking owing to a pitted or uneven sensor tube, a replacement sensor is

required. If the sensor tube surface is smooth and clean yet the process seal is leaking, the process

O-ring is damaged and requires replacement according to the following procedure. Replacement

parts can be obtained from the Process Fitting Rebuild Kit (PN 23731-00).

1. The junction box with attached compression fitting body, nut and compression fitting must

be recovered from the sensor for reuse. Unscrew the junction box cover and set aside. Mark

and disconnect the electrical connections from the terminal block. Remove the junction

box compression fitting nut from the compression fitting body and separate the junction

box from the sensor tube.

2. Remove the nylon ferrule and snap ring (discard both). Remove and save the junction box

compression fitting nut.

3. Slide off the sensor compression fitting nut and set aside for reuse. Slide off the remaining

PEEK ferrule and split ring (discard both).

4. Remove the sensor compression fitting body and replace the Viton O-ring. Lubricate the

O-ring with the barium based lubricant provided.

5. Wrap the threads of the sensor compression fitting body with pipe tape and slide the body

on to the sensor tube.

6. Slide on a new PEEK ferrule, beveled side facing the electrode tip, and a new PEEK split ring,

flared end towards electrode tip. Slide on the sensor compression fitting nut and thread it

onto the compression fitting body. Finger tighten.

7. Reinstall the J-box on the sensor tube. Finger tighten the J-box compression fitting nut.

Use a wrench to turn the nut a 1/4 to 1/2 additional turn.

Calibration and Maintenance 21

Page 28

Calibration and Maintenance Instruction Manual

May 2017 LIQ-MAN-140

22 Calibration and Maintenance

Page 29

Instruction Manual Accessories

LIQ-MAN-140 May 2017

Section 7: Accessories

7.1 Accessories

Table 7-1 Rosemount 140/141/142 Sensor accessories information

Part Number Description

3550-00

2

9200275 Connecting cable, unterminated, specify length

23747-00 Connecting cable, terminated, specify length

05010781899

05010797875

05010782468

05010783002

05000705464

05000709672

05010782147

05010782026

unction box for remote cable connection

J

Conductivity standard SS-6, 200 µS/cm, 32 oz. (0.95 L)

Conductivity standard SS-6A, 200 µS/cm, 1 gal (3.78 L)

Conductivity standard SS-5, 1000 µS/cm, 32 oz (0.95 L)

Conductivity standard SS-5A, 1000 µS/cm, 1 gal (3.78 L)

Conductivity standard SS-1, 1409 µS/cm, 32 oz (0.95 L)

Conductivity standard SS-1A, 1409 µS/cm, 1 gal (3.78 L)

Conductivity standard SS-7, 5000 µS/cm, 32 oz (0.95 L)

Conductivity standard SS-7A, 5000 µS/cm, 1 gal (3.78 L)

Table 7-2 Rosemount 140 Sensor accessories information

Part Number Description

23724-00 Ball valve kit

23730-00 Process compression fitting, ¾ inch NPT

23731-00 Process fitting rebuild kit

9310120 Junction box compression fitting

9550200 O-ring® 2-116, Viton®

Figure 7-1: Rosemount 140 with Ball Valve Kit (PN 23724-00)

Accessories 23

Page 30

Accessories Instruction Manual

May 2017 LIQ-MAN-140

Table 7-2 Rosemount 142 Sensor accessories information

Part Number Description

33107-01 Compression fitting, ¾ in.

9310063 Ferrule, ¾ in.

9310066 Compression nut, ¾ in.

24 Accessories

Page 31

Instruction Manual Troubleshooting

LIQ-MAN-402 May 2017

Section 8: Troubleshooting

8.1 Troubleshooting

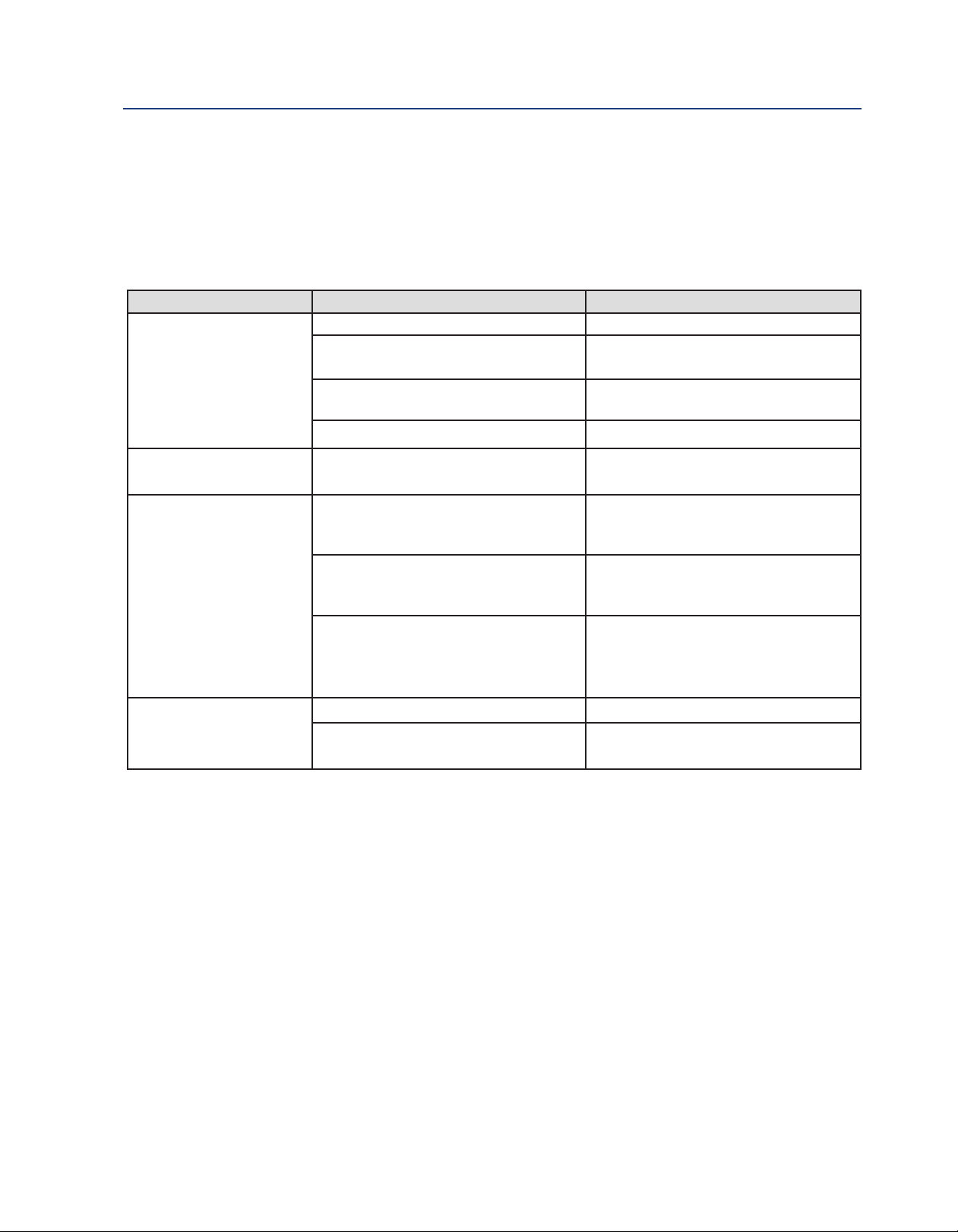

Table 8-1: Troubleshooting

Trouble Probable Cause Remedy

Wiring is incorrect. Verify wiring.

Temperature element is open or shorted. Check temperature element for open or short

Off-scale reading

Sensor is not in process stream. Be sure sensor is completely submerged in

Sensor has failed. Perform isolation checks. See Figure 8-2

circuits. See Figure 8-1

process stream.

Sensor is improperly installed in process

Noisy reading

Reading seems wrong (lower

or higher than expected)

Sluggish response Electrodes are fouled. Clean electrodes.

stream.

Bubbles trapped in sensor. Be sure sensor is properly oriented in pipe or

Wrong temperature correction algorithm. Check that temperature correction is appro-

Wrong cell constant. Verify that the correct cell constant has been

Sensor is installed in dead area in piping Move sensor to a location more representative

Be sure sensor is completely submerged in

process stream.

flow cell. See

to flow cell.

priate for the sample. See transmitter manual

for more information.

entered in the analyzer and that the cell

constant is appropriate for the conductivity of

the sample. See transmitter manual.

of the process liquid.

Figure 2-1. Apply back pressure

Note: For any repair or warranty inquiries please contact our Customer Care group.

Troubleshooting 25

Page 32

Troubleshooting Instruction Manual

May 2017 LIQ-MAN-402

8.1.1 Checking the temperature element

Disconnect leads and measure resistance shown. The measured resistance should be close to the

value in the table.

Figure 8-1 Checking the temperature element

8.1.2 Checking the continuity and leakage

Disconnect electrode leads and measure resistance and continuity as shown. Sensor must be dry

when checking resistance between electrode leads.

Figure 5-2 Checking the continuity and leakage

Temperature

(°C)

0 100.0 29.49k 351K

10 103.9 18.79k 208K

20 107.8 12.26K 127K

30 111.7 8194 79.4K

40 115.5 5592 51.0K

50 119.4 3893 33.6K

Resistance in ohms

Pt 100 10K NTC 100K NTC

26 Troubleshooting

Page 33

Instruction Manual Accessories

LIQ-MAN-402 May 2017

Accessories 27

Page 34

LIQ-MAN-140

Rev. M

May 2017

www.Emerson.com/RosemountLiquidAnalysis

Youtube.com/user/Rosemount

Twitter.com/Rosemount_News

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317,

USA

Tel +1 800 999 9307

Fax +1 952 949 7001

Liquid.CSC@Emerson.com

Analyticexpert.com

facebook.com/Rosemount

©2017 Emerson Automation Solutions. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount is a mark of

one of the Emerson family of companies. All other marks are the property of their respective

owners.

The contents of this publication are presented for information purposes only, and while effort has

been made to ensure their accuracy, they are not to be construed as warranties or guarantees,

express or implied, regarding the products or services described herein or their use or applicability.

All sales are governed by our terms and conditions, which are available on request. We reserve the

right to modify or improve the designs or specifications of our products at any time without notice.

Loading...

Loading...