Page 1

Short Form Manual

HASAxE-SFM-HS

07/2006

Gas Analyzer Series

Short Form Manual

www.EmersonProcess.com

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and tests

its products to meet many national and international standards. Because these

instruments are sophisticated technical products, you MUST properly install, use, and

maintain them to ensure they continue to operate within their normal specifications. The

following instructions MUST be adhered to and integrated into your safety program when

installing, using and maintaining Emerson Process Management (Rosemount Analytical)

products. Failure to follow the proper instructions may cause any one of the following

situations to occur: Loss of life; personal injury; property damage; damage to this

instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the

product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the

appropriate Instruction Manual and per applicable local and national codes.

Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update,

program, and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement

parts specified by Emerson Process Management (Rosemount Analytical).

Unauthorized parts and procedures can affect the product’s performance, place the

safe operation of your process at risk, and VOID YOUR WARRANTY. Look-alike

substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place,

except when maintenance is being performed by qualified persons, to prevent

electrical shock and personal injury.

The information contained in this document is subject to change without notice.

Edition 2006-07

Emerson Process Management GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Germany

T +49 (0) 6055 884-0

F +49 (0) 6055 884-209

Internet: www.EmersonProcess.com

Page 3

Short Form Manual

HASAxE-SFM-HS

05/2006

X-STREAM

PREAMBLE

This quick start guide provides BRIEF INFORMATION about X-STREAM series gas

analyzers concerning installation and operation. For more detailled information about these

topics as well as subassemblies, functions, procedures and maintenance refer to the related

sections of the X-STREAM gas analyzer instruction manual.

This guide covers several X-STREAM series analyzer variations and therefore may describe

configurations and/or options not part of your specific analyzer.

For more detailled safety instructions and precautions refer to the related sections of the

X-STREAM gas analyzer instruction manual.

DEFINITIONS

The following definitions apply to WARNINGS, CAUTIONS and NOTES found throughout

this publication.

Highlights an operation or maintenance procedure, practice, condition, statement, etc.

If not strictly observed, could result in injury, death, or long-term health

hazards of personnel.

Safety Instructions

Highlights an operation or maintenance procedure, practice, condition, statement, etc.

If not strictly observed, could result in damage to or destruction of equipment,

or loss of effectiveness.

NOTE!

Highlights an essential operating procedure, condition or statement.

Emerson Process Management GmbH & Co. OHG S-1

Page 4

Short Form Manual

X-STREAM

HASAxE-SFM-HS

05/2006

IMPORTANT

Safety Instructions

Wiring and Installation of this Apparatus

The following safety instructions apply specifically to all EU member states. They should be strictly

adhered to in order to assure compliance with the Low Voltage Directive. Non-EU st ates should also

comply with the following unless superseded by local or National Standards.

1. Adequate earth connections should be made to all earthing points, internal and external, where

provided.

2. After installation or troubleshooting, all safety covers and safety grounds must be replaced. The

integrity of all earth terminals must be maintained at all times.

3. To ensure safe operation of this equipment, connection to the mains supply should only be

made through a circuit breaker which will disconnect all circuits carrying conductors during a

fault situation. The circuit breaker may also include a mechanically operated isolating switch.

Circuit breakers or switches must comply with a recognized standard such as IEC947. All wiring

must conform with any local standards.

4. Where equipment or covers are marked with the symbol to the right, hazardous

voltages are likely to be present beneath. These covers should only be removed

when power is removed from the equipment — and then by trained service

personnel only .

5. Where equipment or covers are marked with the symbol to the right, there is a

danger from hot surfaces beneath. These covers should only be removed by

trained service personnel when power is removed from the equipment. Certain

surfaces may remain hot to the touch.

6. Where equipment or covers are marked with the symbol to the right, refer to the

Instruction Manual for instructions.

7. Further graphical symbols used in this product:

Electrostatic discharge (ESD)

Harmful (to Health)!

Explosion Hazard!

Toxic!

Heavy Instrument!

Disconnect from Mains!

All graphical symbols used in this product are from one or more of the following standards:

EN61010-1, IEC417, and ISO3864.

Emerson Process Management GmbH & Co. OHGS-2

Page 5

Short Form Manual

HASAxE-SFM-HS

05/2006

X-STREAM

Safety Instructions

Operating and Maintaining this Apparatus

This instrument has left the factory in compliance with all applicable safety regulations.

To maintain this operating condition, the user

must strictly follow the instructions and consider

the warnings in this manual or provided on the

instrument.

Before switching on the instrument, verify that

the electrical supply voltage matches the

instrument´s operating voltage as set in the

factory .

Any interruption in the instrument´s ground line,

whether inside or outside the instrument, or

removal or interruption of its ground line

connection, could result in hazardous operating

conditions. Intentionally interrupting the

instrument´s protective ground is strictly prohibited.

Opening cover panels could expose voltagecarrying components. Connectors may also be

under voltage. The instrument must be

disconnected from all electrical supplies before

attempting any calibrations, maintenance

operations, repairs or component

replacements requiring opening of the

instrument. Any calibrations, maintenance

operations, or repairs that need the instrument

to be opened while connected to electrical

supplies should be subject to qualified

technicians familiar with the hazards involved

only!

Observe all applicable regulations when

operating the instrument from an autotransformer or variac.

Substances hazardous to health may emerge

from the instrument‘s exhaust.

Please pay attention to the safety of your

operation personnel. Protective measures

must be taken, if required.

Safety Instructions

Use only fuses of the correct type and current

ratings as replacements. Using repaired fuses

and short circuiting of fuse holders is prohibited.

Emerson Process Management GmbH & Co. OHG S-3

Page 6

Short Form Manual

X-STREAM

Safety Instructions

HASAxE-SFM-HS

05/2006

INTENDED USE STATEMENT

X-Stream series gas analyzers are intended to be used as analyzers for industrial purposes.

They must not be used in medical, diagnostic or life support applications nor as safety

devices, and no independent agency certifications or approvals are to be implied as

covering such applications!

AUTHORIZED PERSONNEL

If this equipment is used in a manner not specified in these instructions, protective systems

may be impaired.

SAFETY SUMMARY

T o avoid loss of life, personal injury and damage to this equipment and on-site property , do

not operate or service this instrument before reading and understanding this quick start

guide.

The analyzer‘s instruction manual gives more detailled instructions. Save these documents.

ELECTRICAL SHOCK HAZARD !

Do not operate without covers secure. Do not open while energized.

Installation requires access to live parts which can cause death or serious

injury.

For safety and proper performace this instrument must be connected to a

properly grounded three-wire source of power.

TOXIC GASES !

This unit’s exhaust may contain toxic gases such as sulfur dioxide.

These gases can cause serious injuries.

Aviod inhalation of the exhaust gases at the exhaust fitting.

Connect exhaust outlet to a safe vent. Check vent line and connections for

leakage.

Keep all fittings tight to avoid leaks. See section 7-2, page 7-2 for leak test

instructions.

Emerson Process Management GmbH & Co. OHGS-4

Page 7

Short Form Manual

HASAxE-SFM-HS

05/2006

X-STREAM

Safety Instructions

EXPLOSION HAZARD !

Do not operate nor install these instruments in hazardous areas without additional measures!

HEAVY INSTRUMENTS !

The analyzer variation X-STREAM F, intended to be wall mounted and/or

outdoor installed, weighs up to approx. 26 kg (57 lbs), depending on

included options!

Use two people and/or suitable tools for transportation and lifting these

instruments!

Take care to use anchors and bolts specified to be used for the weight of

the units!

T ake care the wall or stand the unit is intended to be inst alled at is solid and

stable to hold the units!

Safety Instructions

HIGH TEMPERATURES !

While working with photometers and/or thermostated components inside

the analyzers hot components may be accessible!

Emerson Process Management GmbH & Co. OHG S-5

Page 8

X-STREAM

Magnetically Operated Front Panel

Magnetically Operated Front Panel

Persons with cardiac pacemakers should absolutely avoid magnetic

fields !

Negative effects on persons beyond those described above caused by

magnetic fields are not known. It is presumed that persons showing allergic

reaction on contact with ceramic or metallic material show the same

behavior on contact with magnetic material.

Short Form Manual

HASAxE-SFM-HS

05/2006

DANGER TO LIFE !

Permanent magnets are surrounded by magnetic fields. These magnetic

fields can disturb and even destroy sensitive electronic measuring devices,

but also mechanical watches, credit cards, etc.

Usually a distance of 20 inch (0.5 m) is enough to avoid damages. All sintered

permanent magnets are hard and brittle. Hitting of sintered permanent

magnets by the magnetic attraction causes splitting into fragments with many

sharp edges. This especially occurs with high energy magnets, and can

also cause skin bruises by high attraction.

High energy magnets made of rare-earth materials have to be stored dry,

otherwise the surfaces would oxidise. Unprotected operation in a humid

environment may cause corrosion. A void damaging the protective galvanic

coating.

A storage in a hydrogen atmosphere destroys these magnets. A

demagnetisation is caused when permanent magnet materials have been

exposed in a radioactive radiation for a long time.

For air transportation of magnetic material the IATA instructions have to be

observed:

Magnetic fields are not allowed to penetrate the package, if necessary the

magnets have to be shorted using a metal plate.

Emerson Process Management GmbH & Co. OHGS-6

Page 9

Short Form Manual

HASAxE-SFM-HS

05/2006

X-STREAM

TABLE OF CONTENTS

Preamble S-1

Definitions S-1

Safety Instructions S-2

Magnetically Operated Front Panel...................................................................................... S-6

Chapter 1 Installation 1-1

1-1 Abstract.......................................................................................................................1-1

1-2 Gas Conditioning .......................................................................................................1-2

1-3 Electrical Connections .............................................................................................. 1-5

1-4 Installation Instructions.............................................................................................1-6

1-4-1 X-STREAM GP, X-STREAM GPS...........................................................................1-6

1-4-1-1 Plugs & Sockets Version .................................................................................. 1-7

1-4-1-2 Terminals Version..............................................................................................1-9

1-4-2 X-STREAM F.........................................................................................................1-13

Chapter 2 Startup 2-1

2-1 Abstract.......................................................................................................................2-1

2-2 The User Interface......................................................................................................2-1

2-3 The Keys .....................................................................................................................2-2

2-4 Power-On Sequence .................................................................................................. 2-3

2-4-1 Measuring Screen .................................................................................................. 2-3

2-5 Menu structure ........................................................................................................... 2-4

2-6 Calibration ..................................................................................................................2-5

Table of Contents

Table of Figures

Fig. 1-0: Example of Gas Fittings Label ................................................................................................................1-3

Fig. 1-1: Bypass Mode Installation.........................................................................................................................1-5

Fig. 1-2: Frontal View .............................................................................................................................................1-6

Fig. 1-3: Rear Panel - Plugs & Sockets Version ....................................................................................................1-7

Fig. 1-4: Socket X1 - Pin Assignment ...................................................................................................................1-8

Fig. 1-5: IEC Mains Input Plug ...............................................................................................................................1-8

Fig. 1-6: Rear Panel - Terminals Version...............................................................................................................1-8

Fig. 1-7: Analog Signal Output Terminals ..........................................................................................................1-10

Fig. 1-8: Mains Terminals.....................................................................................................................................1-10

Fig. 1-9: X-STREAM F ..........................................................................................................................................1-12

Fig. 1-10: X-STREAM F -Allocation of Terminals and Gas Fittings .................................................................. 1-14

Fig. 1-11: X-STREAM F - Analog Output Terminals...........................................................................................1-16

Fig. 1-12: Mains Terminals...................................................................................................................................1-17

Fig. 2-1: X-STREAM User Interface........................................................................................................................2- 1

Fig. 2-2: X-STREAM Software Menu Structure ....................................................................................................2-4

Emerson Process Management GmbH & Co. OHG

T-1

Page 10

X-STREAM

Short Form Manual

HASAxE-SFM-HS

05/2006

Table of Contents

T-2

Emerson Process Management GmbH & Co. OHG

Page 11

Short Form Manual

HASAxE-SFM-HS

07/2006

X-STREAM

Chapter 1

Installation

This chapter describes in a brief manner how

to safely install the different analyzer models.

For more detailled instructions see the

X-STREAM instruction manual.

1-1 Abstract Carefully examine the shipping carton and contents for signs of damage.

Immediately notify the shipping carrier if the carton or its contents are damaged.

Retain the carton and packing material until the instrument is operational.

ELECTRICAL SHOCK HAZARD!

Prior to connecting the analyzer to mains ensure all safety instructions

as given in the appropriate chapters of this manualand the X-STREAM

instruction manual!

Installation area has to be clean, free from

moisture, excessive vibration and frostprotected. T ake care to meet the permissible

ambient temperatures as given in the technical data section!

Instruments must not be exposed to direct

sunlight nor sources of heat.

1 Installation

For outdoor installation it is recommended

to mount the instruments into a cabinet. At

least sheltering against rain is recommended.

1-1Emerson Process Management GmbH & Co. OHG

Page 12

X-STREAM

1-2 Gas Conditioning

Short Form Manual

HASAxE-SFM-HS

07/2006

1-1 Installation - Abstract

To ensure trouble-free analyzer operation

one has to attach great importance to gas

conditioning:

All gases must be conditioned

before supplying!

When supplying corrosive

gases ensure that gas path

components are not affected!

Flammable gases must not

supplied without additional

protective measures!

It is prohibited to supply explosive gases!

Furthermore the gases must be

- dry

- free of dust

- free of aggressive components affecting

gas path materials (e.g. by corrosion).

If moisture can not be avoided take care that

the gas‘ dew point is at least 18 F (10 °C) below

ambient temperature to avoid condensation

within the gas path.

Pressure and flow must be within the limits given

by the measurement specifications table 3-7

X-STREAM instruction manual, page 3-17).

(

1-2 Emerson Process Management GmbH & Co. OHG

Page 13

Short Form Manual

HASAxE-SFM-HS

07/2006

Take care that all external gas lines are connected as described and are

tight to avoid leaks!

Improperly connected gas lines may cause explosion or death!

Exhaust may contain hydrocarbon and other toxic components (e.g. carbon

monoxide)! Carbon monoxide is highly toxic and can cause headache,

nausea, loss of consciousness, and death. Avoid inhalation of exhaust!

X-STREAM

1-2 Installation - Gas Conditioning

TOXIC GAS HAZARDS!

Do not interchange gas inlet and outlet! All gases must be conditioned before

supplying! When supplying corrosive gases ensure that gas path components

are not affected!

Max. permissible gas pressure: 21.7 psi (1,500 hPa), except instruments with

integrated valve blocks (7.25 psi; 500 hPa) and/or paramagnetic oxygen sensor

table 3-7, page 3-17)!

(

Exhaust lines must be installed in a descending way, need to be pressureless,

frost-protected and in compliance with applicable legislative requirements!

The number of gas fittings as well as their

assignment vary depending on analyzer model

and selected options.

All gas fittings are labeled and are located at

• the analyzer's rear panel (X-STREAM GP ,

X-STREAM GPS)

• the analyzer's bottom side (X-STREAM F)

When it is necessary to open gas paths seal

the analyzer‘s gas fittings using PVC caps to

Fig. 1-0: Example of Gas Fittings Label

avoid pollution of the internal gas path by

moisture, dust, etc.

1 Installation

1-3Emerson Process Management GmbH & Co. OHG

Page 14

X-STREAM

Short Form Manual

HASAxE-SFM-HS

07/2006

1-2 Installation - Gas Conditioning

The analyzer should be mounted near the

sample source to minimize sample transport

time. A sample pump may be used to decrease

response time, whereat the analyzer is either

Overpressure valve

Filter

Sample pump

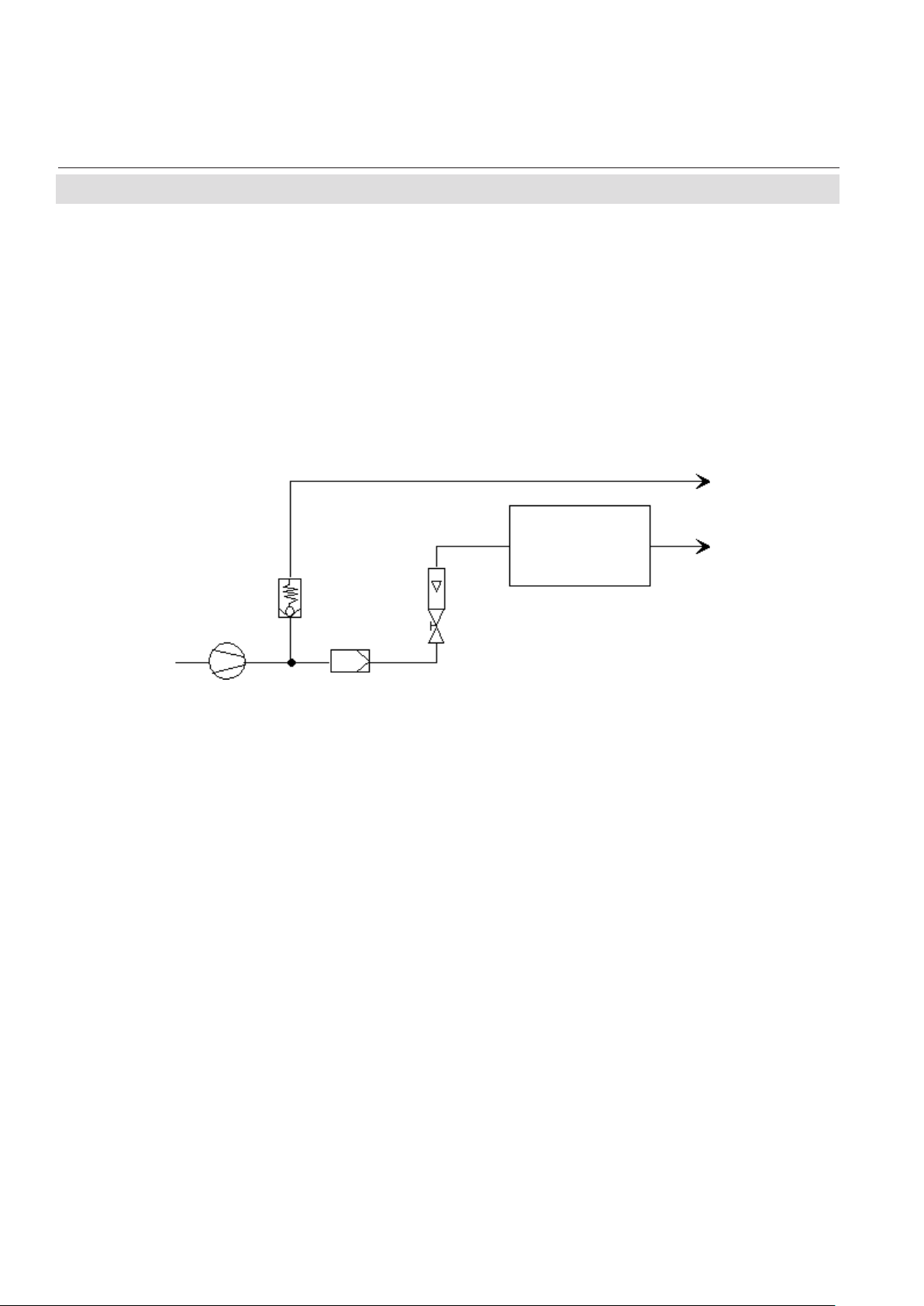

Fig. 1-1: Bypass Mode Installation

operated in bypass mode or protected by an

overpressure valve against too high flow and

pressure (fig. 1-1).

Output

Analyzer

Flowmeter

Output

Internal Solenoid Valve Block

Supply overpressure for all gases is limited to

0.7 to 7.2 psi (50 to 500 hPa) when the analyzer

is equipped with an internal solenoid valve

block.

1-4 Emerson Process Management GmbH & Co. OHG

Page 15

Short Form Manual

HASAxE-SFM-HS

07/2006

1-3 Installation - Electrical Connections

1-3 Electrical Connections

Installation and connecting mains and signal cables are subject to qualified

personnel only taking into account all applicable standards and legislative

requirements! V erify the mains volt age at site of inst allation corresponds to

the analyzer´s rated voltage as given on the nameplate label!

Failure to follow may cause warranty invalidation, property damage and/or

personal injury or death!

Installation of these instruments is subject to qualified personnel only,

familiar with the resulting potential risks! Instruments providing screw

terminals for electrical connections may require working near live part!

X-STREAM

ELECTRICAL SHOCK HAZARD!

X-STREAM gas analyzers do not provide a mains switch!

For X-STREAM F analyzers a mains switch or circuit breaker (complying

with IEC 60947-1/-3) has to be provided in the building installation. This switch

has to be installed near by analyzer , must be easily operator accessible and

has to be assigned as disconnector for the analyzer.

Disconnect instruments with screw terminals from mains when working at

mains terminals (pull mains plug or operate mains switch/ circuit breaker in

building installation)!

The analyzers provide a protective earth terminal. T o prevent electrical shock

hazards the instruments must be connected to a protective earth. Therefore

the instruments must be connected to mains by using a three wire mains

cable with earth conductor!

Any interruption of the earth connector inside or outside the instrument or

disconnecting the earth terminal may cause potential electrical shock

hazzard!

The analyzers do not provide a mains switch and are operable when connected to power.

Installation instructions for

1 Installation

X-STREAM GP, X-STREAM GPS Page 1-6

X-STREAM F Page 1-13

1-5Emerson Process Management GmbH & Co. OHG

Page 16

X-STREAM

1-4-1 Installation - X-STREAM GP, X-STREAM GPS

1-4 Installation Instructions 1-4-1 X-STREAM GP, X-STREAM GPS

Short Form Manual

HASAxE-SFM-HS

07/2006

The analyzer variations X-STREAM GP and

GPS are intended for horizontal orientation

during operation.

X-STREAM GP / GPS with mounting frames

beside the front panel may be mounted into a

rack (rack mount version). Use four screws to

fix the analyzer in the rack (fig. 1-2).

Depending on which variation was ordered

either screw terminals or plugs and sockets are

provided for electrical connections, accessible

at the rear panel (fig. 1-3 and 1-6).

The analyzers do not provide a

power switch and are operable

when connected to power.

Fixing holes for rack mounting (rack mount version only)

(0.3 x 0.4 inches / 7.5 x 10.5 mm)

Fig. 1-2:Frontal view

1-6 Emerson Process Management GmbH & Co. OHG

Page 17

Short Form Manual

HASAxE-SFM-HS

07/2006

1-4-1 Installation - X-STREAM GP, X-STREAM GPS

1-4-1-1 Plugs & Sockets Version

1

2

Gas inlets

Gas outlets

X-STREAM

Modbus interface

Analog outputs

Digital inputs /

Relays

outputs

3

4

(option)

Mains fuses

Purge gas inlet

Fig. 1-3: Rear panel - plugs & sockets version (GPS)

Mains appliance

The number and assignment of gas inlet and outlet fittings depends on the application and is given

on a label attached to the analyzer's rear panel adjacent to the fittings.

For simple installation we recommend to mark the gas lines according to fig. 1-3 (In1, Out1, In2,

Out2, ...). This avoids confusion during rae-installation when the analyzer had to be disconnected for

whatever reason.

Gas inlets and outlets

Quantity: max. 8 (+ 1 optional purge gas fitting)

Specification: 6/4 mm PVDF

optional 6/4 mm or 1/4", stainles steel,

other on request

1 Installation

1-7Emerson Process Management GmbH & Co. OHG

Page 18

X-STREAM

1-4-1 Installation - X-STREAM GP, X-STREAM GPS

Preparing the analog output signal cable

The signal cable is to be connected via a

submin-d connector at the analyzer's rear panel:

Short Form Manual

HASAxE-SFM-HS

07/2006

1 / not used

2 / not used

3 / (+) 4 (0) - 20 mA, channel 1

4 / not used

5 / (+) 4 (0) - 20 mA, channel 2

Burden: RB ≤ 500 Ω

Legend: Pin # / Signal

Fig. 1-4: Socket X1 - pin assignment

Note!

For information on how to connect other signal

cables check the related section of the

X-STREAM instruction manual!

Preparation of mains cable

6 / not used

7 / (-) 4 (0) - 20 mA channel 1

8 / not used

9 / (-) 4 (0) - 20 mA channel 2

The mains power inlet appliance is of type IEC.

Use a standard mains cable with IEC connector

complying with your local requirements to

supply the instrument with power.

Fig. 1-5: IEC mains input plug

1-8 Emerson Process Management GmbH & Co. OHG

Protective

Earth (PE)

Page 19

Short Form Manual

HASAxE-SFM-HS

07/2006

1-4-1 Installation - X-STREAM GP, X-STREAM GPS

1-4-1-2 Terminals Version

Gas inlets

Gas outlets

1

2

3

4

Strain-reliefs

Edge protection

}

X-STREAM

Analog outputs / relays /

Digital inputs / outputs

Modbus interface

Mains fuse

Mains

terminals

Mains fuse

Cover

(illustrated transparent)

Fig. 1-6: Rear panel - terminals version (GP)

4 screws for

fixing the cover

The number and assignment of gas inlet and outlet fittings depends on the application and is given

on a label attached to the analyzer's rear panel adjacent to the fittings.

For simple installation we recommend to mark the gas lines according to fig. 1-3 (In1, Out1, In2,

Out2, ...). This avoids confusion during re-installation when the analyzer had to be disconnected for

whatever reason.

A label fixed to the inner side of the terminals cover shows how the terminals are assigned.

Gas inlets and outlets

Quantity: max. 8 (+ 1 optional purge gas fitting)

Specification: 6/4 mm PVDF

optional 6/4 mm or 1/4", stainles steel,

other on request

1 Installation

1-9Emerson Process Management GmbH & Co. OHG

Page 20

X-STREAM

1-4-1 Installation - X-STREAM GP, X-STREAM GPS

Connecting the analog output signal cable

Short Form Manual

HASAxE-SFM-HS

07/2006

The signal cable is to be connected via screw

terminals, located at the analyzer's rear panel.

to the cable shield after the cable's outer

insulation is stripped.

The strain reliefs provide a metal strip to connect

Maximum outer cable diameter: 0.6 inch (15 mm)

Supported wire cross sections: 24 to 14 A WG (0.2 to 2.5 mm

no need to use wire end sleeves

Cable skinning length: 0.354 inch (9 mm)

Screw thread: M 2.5

Tightening torque, min: 3.5 in.lb (0.4 Nm)

To connect the terminals remove the cover at

the analyzer's rear panel (4 screws). Feed the

analog signals cable through the uppermost

edge protection, and through the upper strainrelief.

The upper 4 terminals (# 1 - 4) of the terminals

row next to the mains terminals are reserved

for analog signal outputs.

Note!

For information on how to connect other signal

cables check the related section of the

X-STREAM instruction manual!

2

),

(+) 4 (0) - 20 mA, channel 1

(-) 4 (0) - 20 mA, channel 1

(+) 4 (0) - 20 mA, channel 2

(-) 4 (0) - 20 mA, channel 2

Burden: RB ≤ 500 Ω

Fig. 1-7: Analog Signal Output Terminals

1-10 Emerson Process Management GmbH & Co. OHG

Page 21

Short Form Manual

HASAxE-SFM-HS

07/2006

1-4-1 Installation - X-STREAM GP, X-STREAM GPS

Connecting the mains cable

The mains cable is connected by screw terminals, located at the analyzer's rear panel.

Use a mains cable with plug for wall outlet socket.

ELECTRICAL SHOCK HAZARD!

Verify cables are disconnected from mains

prior to working at the mains terminals!

Maximum outer cable diameter: 0.6 inch (15 mm)

X-STREAM

Supported wire cross sections: 24 to 14 A WG (0.2 to 2.5 mm2),

no need to use wire end sleeves

Cable skinning length: 0.354 inch (9 mm)

Screw thread: M 2.5

Tightening torque, min: 3.5 in.lb (0.4 Nm)

To connect the terminals remove the cover at

the analyzer's rear panel (4 screws). Feed the

The 3 rightmost terminals (between the fuse

holders) are reserved for mains.

mains cable through the lower edge protection,

through the lower strain-relief and around the

separation between mains terminals and next

terminals row.

Line (L)

Protective

Earth (PE)

Neutral (N)

1 Installation

Fig. 1-8: Mains terminals

1-11Emerson Process Management GmbH & Co. OHG

Page 22

X-STREAM

Short Form Manual

HASAxE-SFM-HS

07/2006

1-4-1 Installation - X-STREAM GP, X-STREAM GPS

ELECTRICAL SHOCK HAZARD!

Before completing the electrical

connection of the instrumen verify

screws are tight and cables are

inserted correctly!

Ensure the earthing conductor is

connected!

After all connections are established in correct

manner and verified,

• place the edge protection rubbers into the

associated openings of the cover

and finally

• attach the terminals cover to the instrument's rear panel utilizing all 4 torx screws.

1-12 Emerson Process Management GmbH & Co. OHG

Page 23

Short Form Manual

HASAxE-SFM-HS

07/2006

1-4-2 Installation - X-STREAM F

1-4-2 X-STREAM F

The X-STREAM F analyzer variation is

intended for outdoor installation and wall

mounting, utilizing 4 supports:

X-STREAM

4 supports for bolts with

diameters 6 mm / 0.23 inch

Eyebolts detail

509 [20]

sash fasteners (2 pcs)

330 [13]

Dimensions: mm [inch]

Fig. 1-9: X-STREAM F

1 Installation

HEAVY INSTRUMENTS !

The analyzer variation X-STREAM F , intended to be wall mounted and/or

outdoor installed, weighs up to approx. 26 kg / 57 lbs), depending on

included options!

Use two people and/or suitable tools for transportation and lifting these

instruments!

Take care to use anchors and bolts specified to be used for the weight of

the units!

T ake care the wall or stand the unit is intended to be inst alled at is solid and

stable to hold the units!

1-13Emerson Process Management GmbH & Co. OHG

Page 24

X-STREAM

Short Form Manual

HASAxE-SFM-HS

07/2006

1-4-2 Installation - X-STREAM F

The instrument provides internal screw terminals for connecting mains and electrical signal

cables. This requires opening the instrument

during installation utilizing the sash fasteners.

Gas fittings are accessible at the instrument‘s

outer bottom side.

The number and assignment of gas inlet and

outlet fittings depends on the application and

is given on a label attached to the analyzer's

bottom side adjacent to the fittings.

For simple installation we recommend to mark

the gas lines according to the marking. This

avoids confusion during re-installation when the

analyzer had to be disconnected for whatever

reason.

1

4

1423

1 T erminals for signal cables

2 Mains EMI filter

3 4 cable glands for mains and signal cables

4 Mains terminals with integrated fuses

Fig. 1-10: X-STREAM F -Allocation of terminals and gas fittings

7

5 Cable glands for mains and signal cables

6 Gas inlet and outlet fittings

7 Purge gas inlet fitting (option)

6

Gas inlets

Gas outlets

5

Gas inlets and outlets

Quantity: max. 8 (+ 1 optional purge gas fitting)

Specification: 6/4 mm PVDF

optional 6/4 mm or 1/4", stainles steel;other on request

1-14 Emerson Process Management GmbH & Co. OHG

Page 25

Short Form Manual

HASAxE-SFM-HS

07/2006

1-4-2 Installation - X-STREAM F

ELECTRICAL SHOCK HAZARD!

V erify mains cables are disconnected and/or instrument is de-energized prior

to working at the terminals!

Preparation of signal cables

All signal cables are to be connected via screw

terminals, located inside the analyzer. The

instruments inner components are accessible

X-STREAM

after loosening the two fasteners at it‘s upper

end and opening the front door downwards.

Supported outer cable diameter: 0.27 to 0.47 inch (7 to 12 mm)

Supported wire cross sections: 24 to 14 A WG (0.2 to 2.5 mm

no need to use wire end sleeves

Cable skinning length: 0.354 inch (9 mm)

Screw thread: M 2.5

Tightening torque, min: 3.5 in.lb (0.4 Nm)

All cables need to be fed through cable glands

when entering the instrument and fixed by the

gland nut when connected to the terminals.

The cable glands provide strain-relief and

protection against EMI (Electro Magnetic

Interference) when installed in a proper way:

Cable Gland Assembly Instruction for Shielded Cables

1. Strip the cable

insulation

2. Uncover the shielding

5. Stick the fixing element

into the neck and fix the

gland.

3. Feed cable through

gland nut and into fixing

element

2

),

1 Installation

4. Put the shielding net

over the element the

way that it covers the

o-ring 2 mm.

1-15Emerson Process Management GmbH & Co. OHG

Page 26

X-STREAM

1-4-2 Installation - X-STREAM F

Connecting the analog output signal cable

For access to the terminals open the instrument's front door.

Insert the cable into the housing utilizing one of

the three rear cable glands. Strip the outer

insulation, skin and connect the conductors to

the terminals (a descriptive label is fixed nearby

the terminals).

When done, fix the cable by tightening the outer

cable gland nut.

Short Form Manual

HASAxE-SFM-HS

07/2006

Note!

For information on how to connect other signal

cables check the related section of the

X-STREAM instruction manual!

The rightmost 4 terminals (# 1 - 4) of the

terminals row next to the mains terminals are

reserved for analog signal outputs.

Burden: RB ≤ 500 Ω

(-) 4 (0) - 20 mA, channel 2

(+) 4 (0) - 20 mA, channel 2

(-) 4 (0) - 20 mA, channel 1

(+) 4 (0) - 20 mA, channel 1

Fig. 1-11: X-STREAM F - Analog output terminals

1-16 Emerson Process Management GmbH & Co. OHG

Page 27

Short Form Manual

HASAxE-SFM-HS

07/2006

X-STREAM

1-4-2 Installation - X-STREAM F

Connecting the mains cable

The mains cable is connected by screw

terminals, located inside analyzer.

Supported outer cable diameter: 0.27 to 0.47 inch (7 to 12 mm)

Supported wire cross sections: 24 to 12 A WG (0.2 to 4 mm2),

no need to use wire end sleeves

Cable skinning length: 0.315 inch (8 mm)

Screw thread: M 3

Tightening torque, min: 4.4 in.lb (0.5 Nm)

ELECTRICAL SHOCK HAZARD!

V erify mains cables are disconnected and/or instrument is de-energized prior

to working at the terminals!

Verify the mains cable has a distance of at least 1 cm (0.5“) to any signal

cable to ensure proper insulation from signal circuits!

Insert the mains cable through the foremost

cable gland, strip the outer insulation, skin and

connect the conductors to the terminals (a

descriptive label is fixed to the filter‘s housing

nearby the terminals).

When done, fix the mains cable by tightening

the outer cable gland nut.

L=Line

N=Neutral

PE=Protective Earth

for label

PE

N

Fig. 1-12: Mains terminals

Mains cable glandLocation

L

1 Installation

1-17Emerson Process Management GmbH & Co. OHG

Page 28

X-STREAM

Before completing the electrical connection of the instrument verify cables

are inserted correctly!

Ensure the earthing conductor is connected!

Short Form Manual

HASAxE-SFM-HS

07/2006

1-4-2 Installation - X-STREAM F

ELECTRICAL SHOCK HAZARD!

After all connections are established in correct

manner and verified,

• close the front door and secure it utilizing

the two sash fasteners.

1-18 Emerson Process Management GmbH & Co. OHG

Page 29

Short Form Manual

HASAxE-SFM-HS

05/2006

Chapter 2

2-1 Abstract

Once the analyzer has been istalled successfully just ensure all gases are applied and power on the instrument to operate it.

2-2 The User Interface

The X-STREAM gas analyzer‘s user interface

consists of a 4x20 character alphanumeric LC

display (fieldhousing:optional VF display),

providing all the necessary information to

operate, calibrate and function check the

instrument.

X-STREAM

Startup

The underlying software is operated by six keys.

Additional status information is provided utilizing three LEDs right below the display .

In case of X-STREAM F the display, LEDs and

keys are located behind a protective glass and

the keys (sensors) are operated by a magnetic

tool.

12345678

1 Display

2 Failure LED

3 Maintenance / Check requests / Off spec LED

4 Power LED

Fig. 2-1: X-STREAM user interface

Emerson Process Management GmbH & Co. OHG 2-1

5 HOME key

6 UP / DOWN keys

7 ENTER key

8 LEFT / RIGHT keys

2 Startup

Page 30

X-STREAM

2-3 The Keys

Short Form Manual

HASAxE-SFM-HS

05/2006

2-3 The Keys

Six keys are provided to operate the menu

system. Depending on the three operation

modes (measure-browse-edit) they have the

following functionality:

ENTER key:

Mode Function

Measure Exit measuring screen

Browse Select menu (..) or function (!)

Edit Submit new input

HOME key:

Mode Function

Measure (without function)

Browse Return to measuring screen

Edit Abort editing

UP / DOWN keys:

Mode Function

Measure Exit measuring screen

Browse - Select a menu line

- Open previous/next menu page if

placed in a line starting with /

Edit increase /decrease the input value

LEFT key:

Mode Function

Measure Exit measuring screen

Browse One page/level back in menu tree

Edit - Shift cursor on the input field

- Leave Component Selection

menu

- Abort editing an enumerated

variable

RIGHT key:

Mode Function

Measure Exit measuring screen

Browse - Enter submenu in lines ending ..

- show next menu page for menu

pages with in the 4th line

Edit Shift cursor on the input field

Emerson Process Management GmbH & Co. OHG2-2

Page 31

Short Form Manual

HASAxE-SFM-HS

05/2006

2-4 Power-On Sequence

2-4 Power-On Sequence

After Power-On a sequence of start-up messages is displayed. During this time all keys are

disabled. The sequence takes a few seconds

(a counter shows the remaining time) until the

measuring screen shows up.

2-4-1 Measuring Screen

X-STREAM

The measuring screen shows up

• automatically after the start-up sequence

has finished

• when pressing the HOME key

• when a programmable time has elapsed

without user interaction (without pressing

a key).

The information shown on the upper three lines

is (within limits) user configurable and by default

are setup to as follows:

• The upper line shows the channel 1 data.

• For dual channel instruments the second

line gives the data for the second

measuring channel.

• The 3rd line may show an additional

parameter (e.g. internal temperature).

• The 4th line is used for cleartext status infor-

mation like failures, calibration events etc.

Messages are stored in an internal

message buffer and then put onto the line.

If there is more than one message in the

buffer the content of the message line will

change every 1-2 seconds.

Any failure, maintenance, function check or outof-spec message appearing in this line

activates the related front panel LED and the

NAMUR relay , too.

CO2.1 135.1 ppm

O2.2 201952 ppm

Temp-1 58.8 °C

(Messages)

MEASURING SCREEN

Refer to fig. 2-2 for an overview about the

software menu structure.

2 Startup

Emerson Process Management GmbH & Co. OHG 2-3

Page 32

X-STREAM

2-5 Menu structure

Short Form Manual

HASAxE-SFM-HS

05/2006

2-5 Menu Structure

Fig. 2-2: X-STREAM Software menu structure

Emerson Process Management GmbH & Co. OHG2-4

Page 33

Short Form Manual

HASAxE-SFM-HS

05/2006

2-6 Set User Interface Language

2-6 Set User Interface Language

X-STREAM

Sequence of keys to be entered for changing the language of an analyzer, if the

operator is not competent in the currently

setup language

(Sequence starting from the measuring screen)

Note!

After pressing the ENTER key the 4th time

within this sequence you entered the

LANGUAGE parameter line.

The DOWN key changes the language. A f ter

pressing the ENTER key this language is

set and the menu's language is updated

immediately.

If the selected language is not the one desired,

repeat the sequence of last three keys multiple

times until the desired language is set.

Emerson Process Management GmbH & Co. OHG 2-5

2 Startup

Page 34

X-STREAM

2-7 Calibration

Short Form Manual

HASAxE-SFM-HS

05/2006

2-7 Calibration

To achieve valid measuring results it is

recommended to perform a calibration. This

section describes in short form how to perform

a manual calibration procedure.

Setup..

Calibration..

Calibration gases..

Calibration gases

ZeroGas: 0.0 ppm

SpanGas: 500.0 ppm

For more detailled information about calibration

and available calibration procedures refer to

the X-STREAM instruction manual.

Within the measuring screen press the DOWN

key and then enter the CALIBRATION setup

menu for specifying the calibration gas

concentrations.

Within this screen enter the values for the listed

gases: Take the correct values from your gas

supplier's certificate. Proper values only assure

faultless measuring results.

For multichannel instruments enter the values

for each channel separately .

Zero calibration..

Span calibration..

Next enter the CONTROL menu to start a zero

calibration.

Make sure the required calibration gas is applied and flowing!

Supply all calibration gases with

the same flow as the sample gas

(recommeded approx. 1 l/min),

pressureless and utilizing the

right gas fitting.

Ensure the warm-up time after

switching on has elapsed!

Warm-up time is 15 to 50 minutes

depending on installed measuring system and configuration!

Emerson Process Management GmbH & Co. OHG2-6

Page 35

Short Form Manual

HASAxE-SFM-HS

05/2006

X-STREAM

2-7 Calibration

CANCEL calibration!

START calibration!

ZeroGas 0.000 ppm

CO2.1 0.200 ppm

CANCEL calibration!

START calibration!

SpanGas 20.000 ppm

CO2.1 16.200 ppm

Select the second line to start the calibration.

Line 3 shows the calibration gas setup (here:

required zero gas concentration is 0.000 ppm),

while line 4 shows the currently measured gas

concentration.

When finished press the LEFT key two times

to return to the controls menu, which allows you

to start a span calibration. The procedure and

screens look similiar to those of a zero

calibration:

Before selecting any further line

make sure the required calibration gas is applied and flowing!

Select the second line to start the calibration.

Line 3 shows the calibration gas setup (here:

required span gas concentration is 20 ppm),

while line 4 shows the currently measured gas

concentration.

When finished press the HOME key to return

to the measurement screen to finish the manual

calibration procedures.

Emerson Process Management GmbH & Co. OHG 2-7

2 Startup

Page 36

X-STREAM

Short Form Manual

HASAxE-SFM-HS

05/2006

Emerson Process Management GmbH & Co. OHG2-8

Page 37

Short Form Manual

HASAxE-SFM-HS

05/2006

X-STREAM

Page 38

X-STREAM

EUROPE

Emerson Process Management GmbH & Co. OHG

Industriestrasse 1

63594 Hasselroth

Germany

T +49 (6055) 884-0

F +49 (6055) 884-209

Internet: www.emersonprocess.de

EUROPE, MIDDLE EAST , AFRICA

Emerson Process Management Shared Services Limited

Heath Place

Bognor Regis

West Sussex PO22 9SH

England

T +44-1243-863121

F +44-1243-845354

Internet: www.emersonprocess.co.uk

Short Form Manual

HASAxE-SFM-HS

05/2006

NORTH AMERICA

Emerson Process Management

Rosemount Analytical Inc.

6565P Davis Industrial Parkway

Solon, OH 44139-3922

USA

T +1 (440) 914-1261

F +1 (440) 914-1271

Internet: www.emersonprocess.com

LATIN AMERICA

Emerson Process Management

Rosemount Analytical Inc.

Latin America Headquarters

11100 Brittmoore Park Drive

Houston, TX 77041

USA

T +1 (713) 467-6000

F +1 (713) 827-3329

ASIA - P ACIFIC

Emerson Process Management Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

T +65 6777 8211

F +65 6777 0947

Internet: www.ap.emersonprocess.com

© 2006 Emerson Process Management GmbH & Co. OHG

Loading...

Loading...