Rosemount X-STREAM X1 FN Addendum for Non-Incendive Analyzers in Zone 2 Hazardous Area Applications-2nd Ed. Manuals & Guides

Instruction Manual

HASANE-IM-ATEX

04/2008

Addendum for Non-Incendive Analyzers

intended to be used in Hazardous Areas of Zone 2

X-STREAM® FN

www.EmersonProcess.com

X-STREAM® FN

Emerson Process Management (Rosemount Analytical) designs, manufactures and tests

its products to meet many national and international standards. Because these instruments

are sophisticated technical products, you MUST properly install, use, and maintain

them to ensure they continue to operate within their normal specications. The following

instructions MUST be adhered to and integrated into your safety program when installing,

using and maintaining Emerson Process Management (Rosemount Analytical) products.

Failure to follow the proper instructions may cause any one of the following situations

to occur: Loss of life; personal injury; property damage; damage to this instrument; and

warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarication.

• Follow all warnings, cautions, and instructions marked on and supplied with the

product.

Instruction Manual

HASANE-IM-ATEX

08/2007

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specied in the Installation Instructions of the

appropriate Instruction Manual and per applicable local and national codes.

Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualied personnel to install, operate, update,

program, and maintain the product.

• When replacement parts are required, ensure that qualied people use replacement

parts specied by Emerson Process Management (Rosemount Analytical).

Unauthorized parts and procedures can affect the product’s performance, place the

safe operation of your process at risk, and VOID YOUR WARRANTY. Look-alike

substitutions may result in re, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place,

except when maintenance is being performed by qualied persons, to prevent

electrical shock and personal injury.

The information contained in this document is subject to change without notice.

2nd Edition 04/2008

Emerson Process Management

GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Germany

T +49 (0) 6055 884-0

F +49 (0) 6055 884-209

Internet: www.EmersonProcess.com

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FN

PREAMBLE

This instruction manual provides information about installing, operating and maintaining/

servicing Non-Incendive X-STREAM FN series gas analyzers in hazardous (classied) areas

and shall be read in conjunction with the standard analyzer instruction manual only!

This instruction manual covers all X-STREAM FN series analyzer variations and therefore

may describe congurations and/or options not relevant for your specic analyzer.

DEFINITIONS

The following denitions apply to WARNINGS, CAUTIONS and NOTES found throughout

this publication.

Highlights an operation or maintenance procedure, practice, condition,

statement, etc.

If not strictly observed, could result in injury, death, or long-term health

hazards of personnel.

Highlights an operation or maintenance procedure, practice, condition,

statement, etc.

Safety Instructions

If not strictly observed, could result in damage to or destruction of equipment,

or loss of effectiveness.

NOTE!

Highlights an essential operating procedure, condition or statement.

Emerson Process Management GmbH & Co. OHG S-1

Emerson Process Management GmbH & Co. OHGS-2

X-STREAM® FN

Instruction Manual

HASANE-IM-ATEX

08/2007

Symbols

SYMBOLS USED IN THIS MANUAL

1. Where equipment or covers are marked with the symbol to the right, hazardous voltages are likely to be present beneath. These covers should only be

removed when power is removed from the equipment — and then by trained

service personnel only.

2. Where equipment or covers are marked with the symbol to the right, there is

a danger from hot surfaces beneath. These covers should only be removed

by trained service personnel when power is removed from the equipment.

3. Where equipment or covers are marked with the symbol to the right, refer to

the Instruction Manual for instructions.

4. Further graphical symbols possibly used in this product:

Elektrostatic discharge (ESD)

Harmful (to Health)!

Explosion Hazard!

Toxic!

Heavy Instrument!

Disconnect from Mains!

Instruction Manual

HASANE-IM-ATEX

08/2007

TERMS USED IN THIS MANUAL

ATEX

Directive 94/9/EC, commonly called the

ATEX („Atmosphères Explosibles“) directive,

dealing with equipment intended to be used

in potentially explosive atmosphere.

This directive is valid for equipment to be

sold into and/or installed and operated in the

European Union (EU).

Area Classication

X-STREAM® FN

Terms

Safety Instructions

Zone 2

In Zone 2 ignitable concentrations of ammable gases are not likely to exist under

normal operating conditions.

(A guideline value [not part of a standard]:

less than 10 hours per year.)

Flammable Gas(es)

Gases and gas mixtures are assigned to be

ammable if they might become ignitable

when in a mixture with air.

Lower Explosion Limit (LEL)

Volume ratio of ammable gas in air below

which an explosive gas atmosphere will not

be formed: the mixture of gas and air lacks

sufcient fuel (gas) to burn.

Upper Explosion Limit (UEL)

Volume ratio of ammable gas in air above

which an explosive gas atmosphere will not

be formed: the mixture of gas and air is too

rich in fuel (decient in oxygen) to burn.

Emerson Process Management GmbH & Co. OHG S-3

Emerson Process Management GmbH & Co. OHGS-4

X-STREAM® FN

Instruction Manual

HASANE-IM-ATEX

08/2007

Safety Instructions

SAFETY INSTRUCTIONS

INTENDED USE STATEMENT

X-STREAM FN series gas analyzers are intended to be used as analyzers for industrial

purposes. They must not be used in medical, diagnostic or life support applications nor

as safety devices, and no independent agency certications or approvals are to be implied

as covering such applications!

SAFETY SUMMARY

If this equipment is used in a manner not specied in these instructions, protective systems may be impaired.

AUTHORIZED PERSONNEL

To avoid personal injury and loss of property, do not operate or service this instrument

before reading and understanding this instruction manual and receiving appropriate training. Save all instructions!

ADDITIONAL LITERATURE

This manual covers aspects specic for using Non-Incendive X-STREAM FN analyzers in

hazardous (classied) areas, only.

To install, start-up, operate and maintain/service the instrument in a safe manner it is

MANDATORY to read ALL additional instruction manuals shipped together with the instrument!

The following instruction manuals are available and/or referenced within this manual at

hand:

HASAxE-IM-HS X-STREAM series instruction manual

Contact your local service center or sales ofce when missing documents.

Save all instructions for future use!

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FN

Safety Instructions

EXPLOSION HAZARD BY MODIFICATION

Any addition, substitution, or replacement of components installed on or

in this device, must be certied to meet the hazardous area classication

that the device was certied to prior to any such component addition,

substitution, or replacement. In addition, the installation of such device or

devices must meet the requirements specied and dened by the hazardous

area classication of the unmodied device.

Any modications to the device not meeting these requirements, will void

the product certication(s).

Contact Emerson Process Management‘s customer service center for return

authorization.

POSSIBLE EXPLOSION HAZARD

Do not open instrument when energized.

Ensure that external circuitry is disconnected or de-energized before

opening the instrument.

Safety Instructions

Before opening the instrument ensure the waiting time, as specied on the

label at the analyzer´s enclosure, has elapsed!

Ensure that all gas connections are made as labeled and are leak free.

Improper gas connections could result in explosion and death.

POSSIBLE EXPLOSION HAZARD

The X-STREAM analyzer may utilize not only sample gas but one or more

pressurized carrier gases and/or calibration gases.

If an external owmeter is required for ow control, legislative requirements

and instructions for installation in hazardous (classied) areas must be

considered.

Emerson Process Management GmbH & Co. OHG S-5

X-STREAM® FN

The analyzer model X-STREAM FN, to which this manual relates, intended

to be wall mounted and/or outdoor installed, weighs up to approx. 26 kg

(58 lbs), depending on included options!

Use two people and/or suitable tools for transportation and lifting these

instruments!

Take care to use anchors and bolts specied to be used for the weight of

the units!

Instruction Manual

HASANE-IM-ATEX

08/2007

Safety Instructions

HEAVY INSTRUMENT

Take care the wall or stand the unit is intended to be installed at is solid and

stable to hold the units!

POSSIBLE EXPLOSION HAZARD

Flammable Gases must be intoduced in INFALLIBLE CONTAINMENTS ONLY,

to avoid leakage into internal Analyzer Housing!

Emerson Process Management GmbH & Co. OHGS-6

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FN

Table of ConTenTs

Preamble S-1

Denitions S-1

Symbols used in this manual .............................................................................................S-2

Terms used in this manual .................................................................................................S-3

Safety instructions ..............................................................................................................S-4

Chapter 1 Technical Description 1-1

1-1 Application and Principle of Operation ............................................................... 1-1

1-2 Technical Data ........................................................................................................1-2

1-2-1 Installation Site and Protection Method ........................................................... 1-2

1-2-2 General Technical Data ...................................................................................... 1-3

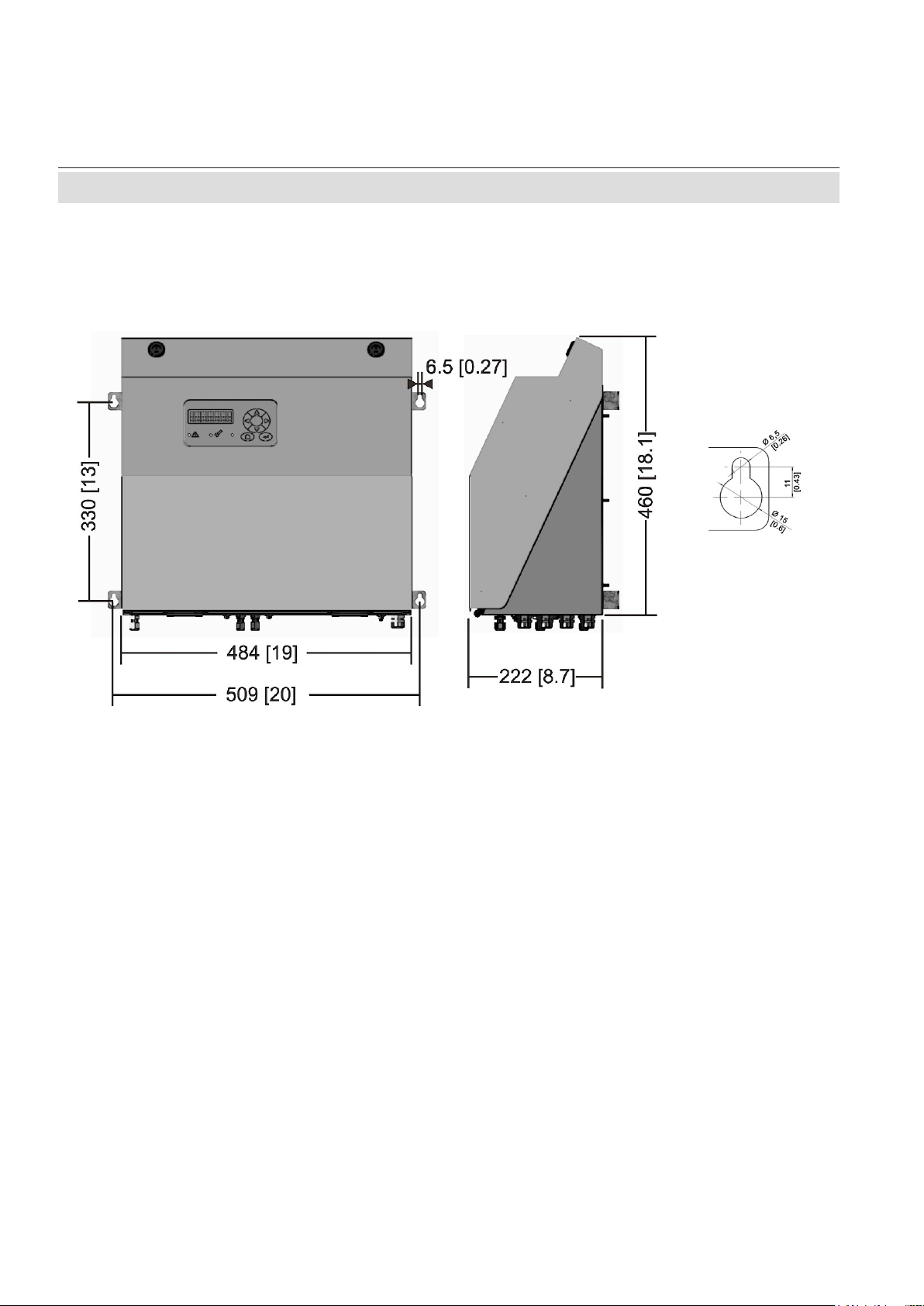

1-3 X-STREAM Dimensions .........................................................................................1-4

1-4 MeasurementSpecications ................................................................................1-5

1-5 Infallible Containments .........................................................................................1-5

1-6 Additional Safety Measures .................................................................................. 1-5

Table of Contents

Chapter 2 Installation 2-1

2-1 Abstract ..................................................................................................................2-1

2-2 Installation of the Instrument ................................................................................2-1

2-3 X-STREAM Dimensions .........................................................................................2-2

2-4 Connections of Gas Pipes ....................................................................................2-3

2-5 Wiring ......................................................................................................................2-4

2-5-1 Cable Gland Assembly Instruction for Shielded Cables ................................ 2-6

Chapter 3 Startup 3-1

3-1 Final Check .............................................................................................................3-1

3-2 Switching On .......................................................................................................... 3-1

Chapter 4 Maintenance 4-1

4-1 Maintenance Instructions......................................................................................4-2

4-2 Gas Paths ...............................................................................................................4-2

4-3 CheckModiedorRepairedAnalyzers .............................................................. 4-3

IHV-1Emerson Process Management GmbH & Co. OHG

Instruction Manual

X-STREAM® FN

HASANE-IM-ATEX

08/2007

Table of Contents

4-4 Enclosure Leakage Test ....................................................................................... 4-3

4-4-1 Preparation..........................................................................................................4-3

4-4-2 Run Leakage Test ..............................................................................................4-4

4-4-3 Startup after Test Procedure ............................................................................. 4-4

4-5 Replacement of Components ............................................................................... 4-5

Appendix A-1

A-1 EC Declaration of Conformity ...............................................................................A-2

A-2 Manufacturer‘s Declaration ..................................................................................A-3

A-3 Certicate ...............................................................................................................A-4

A-4 Block diagram ........................................................................................................A-5

A-5 Assignment of Plugs and Terminals ....................................................................A-6

Index of fIgures

Fig. 1-1: X-STREAM FN - Dimensions ..............................................................................................................1-4

Fig. 2-1: X-STREAM FN - Dimensions ..............................................................................................................2-2

Fig. 2-2: Marking of the gas ttings (example) ...............................................................................................2-3

Fig. 2-3: Terminal block X1 - Analog outputs .................................................................................................2-8

Fig. 2-4: Terminal block X2 - Modbus interface ..............................................................................................2-9

Fig. 2-5: X-STREAM FN - Modbus over ethernet connector ........................................................................2-10

Fig. 2-6: Relay status signals ......................................................................................................................... 2-11

Fig. 2-7: Terminal block X3 - Relay Status Terminals ..................................................................................2-11

Fig. 2-8: Terminal block X4 - Digital Inputs & Outputs .................................................................................2-12

Fig. 2-9: Power terminals ................................................................................................................................2-13

Fig. 3-1: Sealing Plug for Cable Connections .................................................................................................3-1

Fig. 3-2: Hexagon Socket Screw used as Sealing Plug .................................................................................3-1

Fig. 4-1: Assembly for check routines .............................................................................................................4-4

Fig. A-1: Terminals strip 1 ................................................................................................................................ A-6

Fig. A-2: Terminals strip 2 ................................................................................................................................ A-6

Fig. A-3: Power terminals ................................................................................................................................A-6

Fig. A-4: Ethernet connector for Modbus .......................................................................................................A-6

IHV-2 Emerson Process Management GmbH & Co. OHG

Instruction Manual

HASANE-IM-ATEX

08/2007

Chapter 1

Technical Description

1-1 Application and Principle of Operation

X-STREAM® FNX-STREAM

The Gas Analyzer model X-STREAM FN has

been developed to enable the measurement

of gas components in hazardous areas (Ex

zones):

X-STREAM FN is assembeled with selected

components (method of protection: „Non- incendive“ Ex n) to be installed and operated in

hazardous (classied) area of ex zone 2.

X-STREAM FN Analyzers which are certied

according to EN 60079-15, protection method

Ex n „Non-Incendive“, do not include components by design which may create arcs,

sparks or hot spots under normal operation

conditions. That is why they cannot ignite

an explosive atmosphere being eventually

present.

The advantage of the Non-Incendive protection type versus other protection methods is

that no other means need to be provided such

as purge gas for pressurized systems.

The used method of protection is suitable for

Zone 2 applications only. According to this

ammable/explosive gases are not allowed or

just for a short while in the ambient of these

components.

This is especially true for the measurement

of ammable gases:

Measuring ammables gases with standard

tubings (containments) would enable those

gases to pass off into the housing in case of

leakages. Together with the air being present

an explosive mixture would be built. As a

result of the tight enclosure and the missing

exchange with the surrounding atmosphere

the explosive mixture would be available for

a long time. The categorization of the internal

compartment of the X-STREAM FN analyzer would be no more according to zone 2

but zone 0 requiring special protection methods!

Nevertheless Emerson Process Management has designed infallible containments to

enable the measurement of ammable gases

in X-STREAM FN Analyzers:

These are gas paths designed as „technically

tight“ due to the construction ( 1-5, Page

1-5). Using those infallible containments in

a proper way enables the use to avoid the

leakage of ammable gases into the analyzer

and the formation of explosive atmosphere.

1 Technical Description

EXPLOSION DANGER MEASURING FLAMMABLE GASES

Flammable Gases must be introcuced into INFALLIBLE CONTAINMENTS

ONLY thus avoiding internal leakages!

Such Containments are available on request.

Emerson Process Management GmbH & Co. OHG 1-1

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

®

FN

Instruction manual

HASANE-IM-ATEX

08/2007

1-2 Technical Data

1-2 Technical Data 1-2-1 Installation Site and Protection Method

Permissible ambient temperature -20 °C (-4 °F) to +50 °C (122 °F), other

on request

Permissible storage temperature -20 °C (68 °F) to +70 °C (158 °F)

Permissible humidity (non-condensing) < 90 % r. F. at +20 °C (68 °F)

< 70 % r. F. at +40 °C (104 °F)

Pollution degree 2

Installation category I I

Altitude 0 to 2000 m (6560 ft.) Höhe über N.N.

Ambient atmosphere The Analyzer may not be

used in corro-

sive atmosphere

Protection concept:

Wall-mount eld housing for outdoor installa-

tion with protection method Ex n

Hazardous zone: Zone 2, Gas

Underlying standard:

IEC 60079-0:2004 (4th Edition)

DIN EN 60079-0:2004

IEC 60079-15:2005 (3

rd

Edition)

DIN EN 60079-15:2005

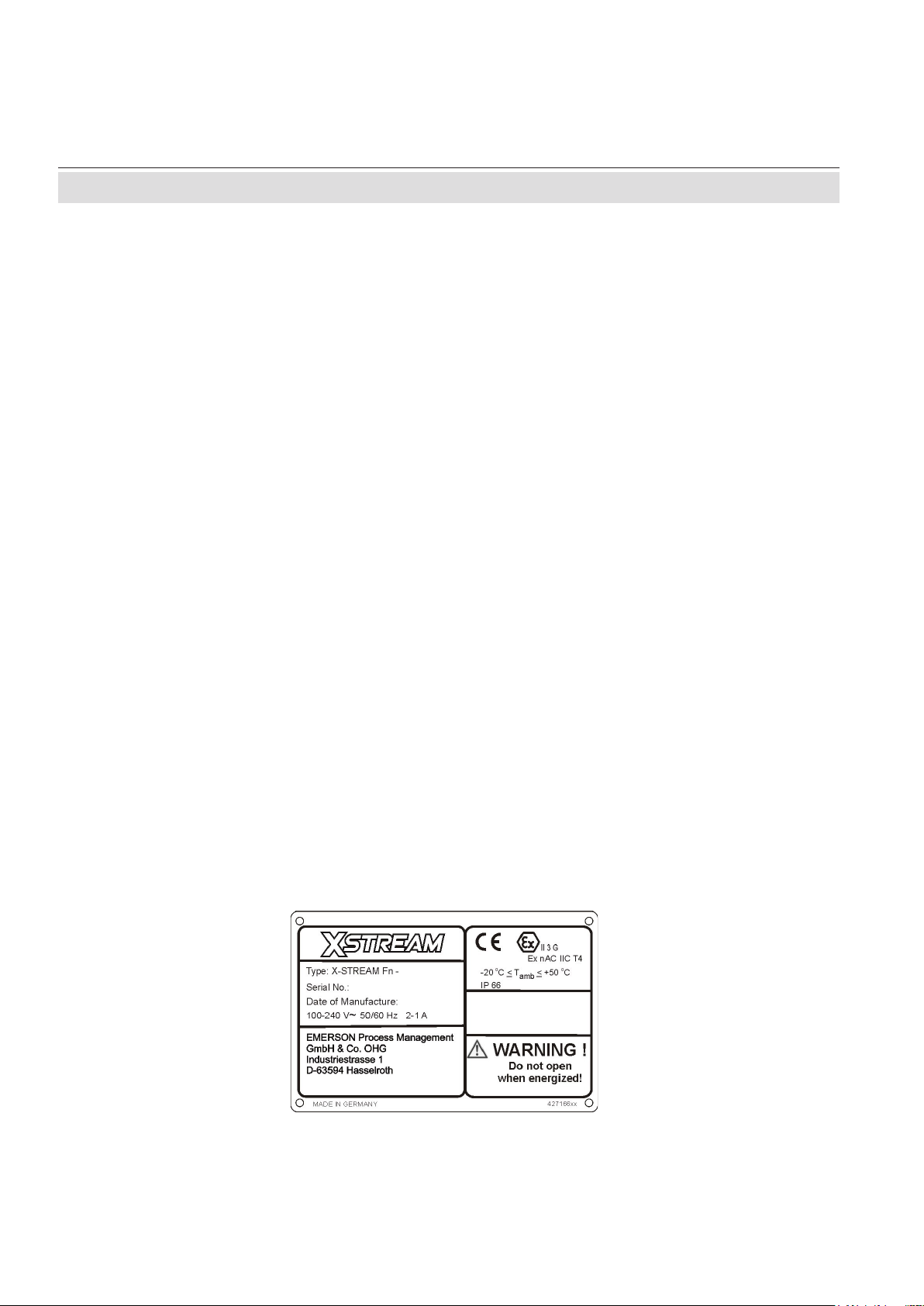

Classication:

ATEX Group II, Category 3, Gas,

Ex nAC IIC T4

Temperature class: T4

A test sample was approved by an independant test institute according to Guideline (Directive)

94/9/EG („ATEX“) and fullls the corresponding standard.

Identication Mark (Labeling)

Emerson Process Management GmbH & Co. OHG 1-2

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

Instruction Manual

HASANE-IM-ATEX

08/2007

1-2 Technical data

1-2-2 General Technical Data

For further technical data consult X-STREAM general instruction manual.

Voltage supply

Rated input voltage 100 - 240 V 50/60 Hz,

Wide range input

Power supply voltage uctation must

not exceed

voltage

Input voltage range 85 - 264 V , 47 - 63 Hz

!

X-STREAM® FNX-STREAM

+/- 10 % of the nominal

Rated input current

standard 0,75 - 0,35 A max.

with thermostatically controlled physics 2 - 1 A max.

Housing

Weight: up to 26 kg

(depending on analyzer conguration)

Protection class: IP 66 (EN 60529) / NEMA 4X

for outdoor installation analyzer must be

protected against direct sun

Gas ttings: Number: max. 8

Specication: 6/4 mm or 1/4“, stainless

steel, other on request

General Certications (Compliances)

Electrical safety

Europe CE, based on EN 61010-1

Elektromagnetic compatibility

Europe CE, based upon EN 61326

other NAMUR

1 Technical Description

Emerson Process Management GmbH & Co. OHG 1-3

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

®

FN

1-3 X-STREAM Dimensions

1-3 X-STREAM Dimensions

Instruction manual

HASANE-IM-ATEX

Eyebolt detail

08/2007

approx. mm [inch]

Fig. 1-1: X-STREAM FN - Dimensions

Emerson Process Management GmbH & Co. OHG 1-4

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

Instruction Manual

HASANE-IM-ATEX

08/2007

1-4 Measurement Specications

1-4 Measurement Specications

X-STREAM® FNX-STREAM

Gas components

Maximal sample

gas pressure

Sample gas ow Depending on measuring principle (see X-STREAM general instruction

Gas components

Flammable Gases must be introduced with INFALLIBLE CONTAINMENTS

only!

1-5 Infallible Containments

Infallible Containments are based on connections being velded, soldered or designed

as glass-to-metal connections resp. eutectic

or similar methods. The function test for infallible containments is performed according

to the legislation guidline EN 60079-2. Thus

it makes sure that no leakage may occur in

the gas paths enabling gas to enter the inner

compartment of the analyzer housing.

Non-ammable gases resp. gas mixtures; concentration does not exceed LEL

(lower explosion limit)

Atmospheric pressure or <1500 hPa at normal ambient pressure depen-

ding on used measuring principle (see X-STREAM general instruction

manual)

manual)

Flammable gases

POSSIBLE EXPLOSION HAZARD

The X-STREAM FN Analyzer can be used for

measurement of ammable gases if the gas

paths for sample gas (and ammable cal gas)

are designed as infallible containment.

Infallible containments are availble for thermal

conductivity while Infrared/Ultraviolet method

is under construction. Consult factory or

EMERSON sales ofce for further information.

1 Technical Description

1-6 Additional Safety Measures

• Gas outlets need to be located at a safe

location ouside hazard area. Sample gas

tubings may be connected to the sample

inlet.

• If sample gas oulets are located inside

hazardous areas ame arrestors have

to be provided for gas inlet and outlet.

Emerson Process Management GmbH & Co. OHG 1-5

• Signal lines need to end in safe or pro-

tected areas (e.g. in a suitable housing

type Ex e).

®

FN

Instruction manual

HASANE-IM-ATEX

08/2007

Emerson Process Management GmbH & Co. OHG 1-6

Instruction Manual

HASANE-IM-ATEX

08/2007

POSSIBLE EXPLOSION HAZARD AND MORTAL DANGER

Read the corresponding sections of the Analyzer Instruction Manual and

all Addendum Manuals before performing the Installation !

Disregarding of the Security Advices can lead to explosion, physical injury

or death!

X-STREAM® FNX-STREAM

Chapter 2

Installation

2-1 Abstract

Save operation of Emerson Process Management gas analyzers requires a proper

installation. Therefor all procedures that are

described in this section as well as those of

the analogous sections of the X-STREAM

analyzor family general instruction manual

need to be followed strictly.

HEAVY INSTRUMENT

X-STREAM FN Analyzers intended to be wall mounted and/or outdoor

installed weigh up to 26 kg (58 lbs), depending on the chosen options!

Use two persons and/or suitable tools for transportation and lifting these

instruments!

Take care to use anchors and bolts specied to be used for the weight of

the instruments!

2-2 Installation of the Instrument

For installation of the instrument use the descriptions of the X-STREAM analyzor family

general instruction manual. Verify that the

installation site of the instrument is determined adequately by means of the Figures (see

Fig. 2-1).

Assure that the wall/device for installation is sufciently attached and stable

to carry the instrument!

Emerson Process Management GmbH & Co. OHG 2-1

2 Installation

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

®

FN

2-3 X-STREAM Dimensions

2-3 X-STREAM Dimensions

Instruction Manual

HASANE-IM-ATEX

Eyebolt detail

08/2007

approx. mm [inch]

Figure 2-1: X-STREAM FN - Dimensions

Emerson Process Management GmbH & Co. OHG 2-2

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

Instruction Manual

HASANE-IM-ATEX

08/2007

2-4 Connections of Gas Pipes

2-4 Connections of Gas Pipes

TOXIC GAS HAZARDS

Take care that all external gas pipes are connected in the described way

and that they are gastight to avoid leakages!

Faulty connected gas pipes lead to explosion hazard or even to mortal

danger!

Emissions may contain hydrocarbon or other toxic components (e.g.

carbon monoxide)! Carbon monoxide may cause headache, sickness,

unconsciousness and death. Don‘t take a breathe of the emissions!

X-STREAM® FNX-STREAM

Don‘t confuse gas inlet and outlet! All introduced gases need to be previously

conditioned! If aggressive gases are introduced into the instrument it needs

to be assured that the gas paths don‘t get damaged!

More information is available in the X-STREAM general instruction

manual, page 4-2 ff.

The number of the gas ttings and their allocation may vary depending on the installated

options.

All gas ttings are marked and located at the

rear side of the analyzer.

If it‘s necessary to open the gas paths, the

gas ttings need to be tightened with PVC-

caps to prevent contamination through moisture, dust etc..

Figure. 2-2: Marking of the gas ttings

(example)

2 Installation

Emerson Process Management GmbH & Co. OHG 2-3

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

®

FN

Instruction Manual

HASANE-IM-ATEX

2-5 Wiring

2-5 Wiring

EXPLOSION DANGER / ELECTRICAL SHOCK HAZARD

Installation and connecting power and signal cables are subject to qualied

personnel only taking into account all applicable standards and legislative

requirements!

The standard EN 60079-14 „Electrical installations in [gas explosion]

hazardous areas“ und all corresponding standards must be taken into

account.

Failure to follow may cause warranty invalidation, property damage and/or

personal injury or death!

08/2007

Installation of these instruments is subject to qualied personnel only,

familiar with the resulting potential risks! Instruments providing screw

terminals for electrical connections may require working near live part!

X-STREAM FN gas analyzers do not provide a power switch!

A power switch or circuit breaker (complying with IEC 60947-1/-3) has to be

provided in the building installation. This switch has to be installed near

by analyzer, must be easily operator accessible and has to be assigned as

disconnector for the analyzer.

Disconnect instruments with screw terminals from power when working at

power terminals (pull power plug or operate power switch/ circuit breaker

in building installation)!

The analyzers provide a protective earth terminal. To prevent electrical

shock hazards the instruments must be connected to a protective earth.

Therefore the instruments must be connected to power by using a three

wire power cable with earth conductor!

Any interruption of the earth connector inside or outside the instrument

or disconnecting the earth terminal may cause potential electrical shock

hazzard!

The analyzers do not provide a power switch and are operable when connected to power.

Emerson Process Management GmbH & Co. OHG 2-4

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

Instruction Manual

HASANE-IM-ATEX

08/2007

Do NOT open instrument during operation before having made sure that

ambient atmosphere is not hazardous (explosive)!explosive)!

2-5 Wiring

POSSIBLE EXPLOSION HAZARD

X-STREAM® FNX-STREAM

POSSIBLE EXPLOSION HAZARD

If the analyzer is powered and shall be opened (e.g. for troubleshooting)

make sure that ambient atmosphere is not hazardous (explosive) beforeexplosive) before

servicing internal components (this is valid also for example for the

exchange of fuses!)

Terminal tags and screwed connections with signals being not intrinsically

safe may be disconnected when energized!

Emerson Process Management GmbH & Co. OHG 2-5

2 Installation

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

®

FN

2-5 Wiring

Instruction Manual

HASANE-IM-ATEX

08/2007

• All gas ttings have to be executed according to the circuit diagrams handed over

with the instrument.

• A mains switches or circuit breakers have

to be provided at the installation site.

• The housing needs to be connected to a

ground or a potential equalization conductor.

• All cabels that are introduced into the

housing need to be kept as short as possible.

• The cable connectors are intended for se-

• Use shielded cables only for signal lines! To ensure electromagnetic compatibility (EMC) we recommend attending

the installation commands in section

2-5-1.

• Cables for intrinsically safe (Ex i) signals

need to get marked adequately. For passing

the cables take care of the requirements

of the corresponding standards (minimum

distance to cables being not intrinsically

safe etc.). If the minimum distance can‘t be

hold a sufciently thick rm isolation needs

to be applied.

veral cables with a diameter of 7 to 12 mm.

Special adapters that allow the mounting of

thinner or multiple cables in one connection

can be delivered on request.

• Supply terminals are intended for cables

with a cross section of up to 2,5 mm2.

2-5-1 Cable Gland Assembly Instruction for Shielded Cables

1. Strip the cabel insulation

2. Uncover the shiel-

ding

3. Feed cable through

gland nut and into

xing element

4. Put the shielding net

over the element

the way that it covers the o-ring 2 mm

(0.08 in).

5. Stick the fixing element into the neck

and x the gland

Emerson Process Management GmbH & Co. OHG 2-6

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

Instruction Manual

HASANE-IM-ATEX

08/2007

2-5 Wiring

Preparation of signal cables

All signal cables are to be connected via

screw terminals, located inside the analyzer. The instruments inner components are

Supported wire cross sections: 24 to 14 AWG (0.2 bis 2.5 mm2),

no need to use wire end sleeves

Cable skinning lenght: 0.354 inch (9 mm)

Hole diameter: 0.05 inch (1.2 mm)

Screw thread: M2.5

accessible after loosening the two fasteners

at it‘s upper end and opening the front door

downwards.

X-STREAM® FNX-STREAM

Tightening torque, min: 3.5 in.lb (0.4 Nm)

All cables need to be fed through cable glands

when entering the instrument and xed by the

gland nut when connected to the terminals.

The cable glands provide strain-relief and

protection against EMI (Electro Magnetic Interference) when installed properly.

Emerson Process Management GmbH & Co. OHG 2-7

2 Installation

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

®

FN

Signal inputs / outputs

Analog signal outputs

2-5 Wiring

Instruction Manual

HASANE-IM-ATEX

08/2007

For access to the terminals open the

instrument‘s front door.

Burden: RB ≤ 500 Ω

The rightmost 4 terminals (# 1-4) of the terminals row next to the power terminals are

reserved for analog signal outputs.

Note!

Take care of the special installation instructions in section 4-5 and the cable gland assembly instruction on page 2-6!

(-) 4 (0) - 20 mA, channel 2

(+) 4 (0) - 20 mA, channel 2

(-) 4 (0) - 20 mA, channel 1

(+) 4 (0) - 20 mA, channel 1

Fig. 2-3: Terminal block X1 - Analog outputs

ELECTRICAL SHOCK HAZARD

Take care that electricity cables are not connected and/or the analyzer is

not energized during operation!

Emerson Process Management GmbH & Co. OHG 2-8

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

Instruction Manual

HASANE-IM-ATEX

08/2007

Modbus interface

Specication and driving the interface:

X-STREAM general instruction manual

Chapter 9

2-5 Wiring

X-STREAM® FNX-STREAM

Note 1!

Take care of the special installation instructions in section 4-5 of X-STREAM general

instruction manual and of the cable gland

assembly instruction on page 2-6!

For accessing the terminals open the

instrument‘s front door.

Terminal RS 232 RS 485/2w RS 485/4w

11 Common Common Common

12 RXD not used RXD0

13 TXD not used RXD1

14 not used D1 TXD1

15 Common D0 TXD0

Note 2!

X-STREAM analyzers are to be considered

a DTE (Data Terminal Equipment).

The leftmost 5 terminals (# 11 - 15) of the

terminals row next to the power terminals are

reserved for the Modbus interface.

1112131415

Fig. 2-4: Terminal block X2 - Modbus interface

Emerson Process Management GmbH & Co. OHG 2-9

2 Installation

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

®

FN

2-5 Wiring

Optional RJ45 connection

If installed, the optional RJ45 connector is

located on the BKS main board, in the upper

part of the instrument.

To install this connection one has to insert a

cable without connector through the cable

inlet.

Once the open end is inside the instrument,

the plug connector can be attached:

We recommend using a VARIOSUB RJ45

QUICK-ON plug connector (PHOENIX

CONTACT), as supplied together with the

instrument, not requiring special tools. See

the separate installation instruction, provided

together with the plug connector for information on how to install it.

Instruction Manual

HASANE-IM-ATEX

08/2007

Note!

Notice, that the modbus screw terminals

( page 4-25) are installed, too, but without

function!

Pin 1 Pin 8

Fig. 2-5: X-STREAM FN - Modbus over ethernet connector

Pin Signal

1 TX+

2 TX 3 RX+

6 RX other not used

RJ45 connector on

main board BKS

Emerson Process Management GmbH & Co. OHG 2-10

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

Instruction Manual

HASANE-IM-ATEX

08/2007

Relay Status Signals

2-5 Wiring

X-STREAM® FNX-STREAM

Design: potential-free relay contact

Electrical specication: max. 30 V , 1 A,

30 W

Note!

Take care of the special installation instructions in section 4-5 and of the cable gland

assembly instruction on page 2-6!

For accessing the terminals open the

instrument‘s front door.

The middle 6 terminals (# 5–10) of the terminals row next to the power terminals are

reserved for the relay status signals.

Signal output

(NC); conguration on request

Signal output

(NO); standard

conguration

Fig. 2-6: Relay status signals

Terminal Signal

5 Failure COM

6 Failure NO

7 Maintenance, off-spec COM

8 Maintenance, off-spec NO

9 Function check COM

10 Function check NO

10

9

Fig. 2-7: Terminal block X3 - Relay Status Terminals

Emerson Process Management GmbH & Co. OHG 2-11

5678

2 Installation

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

®

FN

Instruction Manual

HASANE-IM-ATEX

08/2007

2-5 Wiring

Digital Inputs & Outputs (option)

Design: Open collector (outputs)

Electrical specication:

outputs: max. 30 V , 30 mA

inputs: max. 30 V , internally limited to 2.3 mA

H level: min. 4 V; L level: max. 3 V

For accessing the terminals open the instruments front door. The leftmost terminal strip is

reserved for the digital inputs and outputs.

Terminal 9

Terminal 10

Terminal 11

Terminal 12

Terminal 13

Terminal 14

Terminal 15

Terminal 16

Terminal 17

DIG Out GND

Zero cal. Ch1 & Ch2

Span cal. Ch1

Span cal, Ch2

Valve V4

Valve V1

Valve V2

Sample valve or pump

DIG In GND

Terminal 6

Terminal 7

Terminal 8

Valve V4

Valve V1

Valve V2

Note!

Take care of the special installation instructions in section 4-5 of the X-STREAM Basis

Instruction Manual and of the cable gland

assembly instruction on page 2-6!

Terminal 1

Terminal 2

Terminal 3

Terminal 4

Terminal 5

*)

When making use of the

Ch1 -threshold 1

Ch1 -threshold 2

Ch2 -threshold 1

Ch2 -threshold 2

Sample valve

*)

range switching option, this

output is assigned a range

indicator

( X-STREAM general

instruction manual, section

7-7-5, page 7-57)

Digital Inputs Digital Outputs

Fig. 2-8: Terminal block X4 - Digital Inputs & Outputs

Emerson Process Management GmbH & Co. OHG 2-12

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

2-5 Wiring

Connecting the power cable

The power cable is connected by screw terminals, located inside the analyzer.

Supported wire cross section: 24 to 12 AWG (0.2 to 4 mm2),

no need to use wire end sleeves

Cable skinning lenght: 8 mm (0.315 inch)

hole diameter: 1.2 mm (0.05 inch)

Screw thread: M 3

Tightening torque, min: 0.5 Nm (4.4 in.lb)

ELECTRICAL SHOCK HAZARDELECTRICAL SHOCK HAZARD

Take care that the power cable is not connected and/or the analyzer is not

energized during operation!

The distance between power and signal cables must exceed 1 cm

(0.4 in)!

Insert the power cable through the foremost

cable gland, strip the outer insulation, skin

and connect the conductors to the terminals (a

descriptive label is xed to the lter‘s housing

nearby the terminals).

When done, x the power cable by tightening

the outer cable gland nut.

L

Location for label

N

PE

Power cable gland

2 Installation

Fig. 2-9: Power terminals

Emerson Process Management GmbH & Co. OHG 2-13

®

FN

Instruction Manual

HASANE-IM-ATEX

08/2007

Emerson Process Management GmbH & Co. OHG 2-14

Instruction Manual

HASANE-IM-ATEX

08/2007

Chapter 3

Startup

POSSIBLE EXPLOSION HAZARD

Startup, operation and service must not be performed before reading and

understanding all instructions!

Especially all warnings in the manual have to be taken into account!

3-1 Final Check

Ensure that the analyzer has been installed

according to the descriptions in section 2

and that all covers and doors are closed and

fastened.

All unused cable connections need to be closed

with the provided permissible sealing plug

(part no. ETC00791; Fig. 3-1)

Unused openings for cable connections in

the housing need to be closed with a special

screw (part no. ETC00790; Fig. 3-2).

X-STREAM® FNX-STREAM

3 Startup

Fig. 3-1: Sealing Plug for Cable Connections

POSSIBLE EXPLOSION HAZARD

Use these above mentioned

ATEX-approved components only!

Fig. 3-2: Hexagon Socket Screw as Sealing

Plug for unused Cable Connection Openings

3-2 Switching On

Now the analyzer can be switched on.

Emerson Process Management GmbH & Co. OHG 3-1

®

FN

Instruction Manual

HASANE-IM-ATEX

08/2007

Emerson Process Management GmbH & Co. OHG 3-2

Instruction Manual

HASANE-IM-ATEX

08/2007

Inspection, maintenance and service must be carried out by qualied personnel

only considering all related standards and legal requirements!

Especially the standard EN 60079-17 „Inspection and maintenance

of electrical installations in [gas explosion] hazardous areas“ and all

corresponding standards have to be taken into account.

After maintenance or replacement of parts concerning explosion protection

an authority on explosion protection has to verify that the analyzer still

meets the requirements for explosion protection before it is switched on

again. If parts being essential for explosion protection are repaired, they

must undergo a routine test!

X-STREAM® FNX-STREAM

Chapter 4

Maintenance

POSSIBLE EXPLOSION HAZARDPOSSIBLE EXPLOSION HAZARD

4 Maintenance

The authority for explosion protection has to issue a certicate and/or

attach a label to the equipment/analyzer before startup after maintenance

or replacement of parts.

Emerson Process Management GmbH & Co. OHG 4-1

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

®

FN

4-1 Maintenance Instructions

4 Maintenance

Instruction Manual

HASANE-IM-ATEX

08/2007

To assure instrument performance and safety

the analyzer has to be checked regularly but

at least once a year.

During maintenance especially those part

being relevant for explosion protection have

to be taken into account.

For X-STREAM FN this does include particularly the enclosure and the corresponding

sealings. The sealings have to be checked

on damage and they need to show sufcient

effectiveness ( Leakage test, 4-4).

During maintenance the optional gas sampling

pump has to be evaluated that moving parts

do not grind or hook on creating sparks

thereby.

Internal connectors have to be regarded ac-

cordingly. They need to be xed to draw no

sparks during operation.

Due to visual inspection of the internal part of

the analyzer especially the electrical compo-

nents it must be veried that no components

are overloaded. Otherwise they may become

hot and thus become a danger of ignition (an

indication for overloaded components is for

example discoloration).

The user/owner has to take

responsibility to modify the

maintenance interval regarding

the conditions at site

(inuence

of gases or ambient atmosphere

on material being in contact with

sample/cal gas or which are relevant for

explosion protection

[e.g. enclosure sealing]).

POSSIBLE EXPLOSION HAZARD

Replacement of defective parts being relevant for explosion protection

must be done with original

The use

of not suitable parts or procedures may reduce performance or

jeopardize the safe process operation and affect Explosion Protection!

Section 4-5 of this manual includes a listing of parts being relevant for Explo-

sion Protection.

4-2 Gas Paths

Detailled Information about maintenance, replacement of components and accomplishment

of a gas paths leakage test are available in

Emerson Process Management

the X-STREAM gas analyzer series general

instruction manual.

Emerson Process Management GmbH & Co. OHG 4-2

parts only!

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

Instruction Manual

HASANE-IM-ATEX

08/2007

4 Maintenance

4-3 Check Modied or Repaired Analyzers

X-STREAM® FNX-STREAM

Modications on X-STREAM FN analyzers

which inuence the integrity of protection type

or analyzer temperature are permissible only

if the modied analyzer are inspected by a

licensed test laboratory or if an authorized

expert has evaluated the modications.

4-4 Enclosure Leakage Test 4-4-1 Preparation Required Tools:

• Pressure gauge with a measuring range

of 50 und 100 mbar (0.7 to 1.5 psig; resolution of 0.1 mbar/ 0.0015 psig).

•

Flow meter with a measuring range of 5 to

10 l/min;

• Span gas: Instrumental air or nitrogen;

pressure reduced to 1.500 mbar

(22 psig).

To run the test procedure the following preparations have to be encountered:

• Disconnect or de-ernergize the analy-

zer.

• Disconnect containment system ttings

from external gas pipes.

• Disconnect one containment system gas

tting inside the analyzer and close the

other tting.

(Remark: Now it need to be possible

to pressurize the housing supplying an

external gas (e.g. compressed air) to the

gas inlet.)

• Supply compressed air from an external

source as described on sketch of the

following page, (Fig. 4-1).

resolution of

0.1 l/min.

In case of repair inuencing the protection

type, the repaired parts should be drawn to

suitable check routines and must be controlled. These inspections need not to be

carried out from the supplier necessarily.

• Pressure regulator to reduce pressure to

25 mbar (0.4 psig)

• Equipment for ow control

• 1 plug to shut off the gas outlet

(size: 6 mm/ 1/4“)

The compressed air must be

dry and free from dust, oil and

corrosive components!

4 Maintenance

Emerson Process Management GmbH & Co. OHG 4-3

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

®

FN

4 Maintenance

Instruction Manual

HASANE-IM-ATEX

08/2007

Fig. 4-1: Assembly for check routines

4-4-2 Run Leakage Test

The housing needs to be controlled on leakages with a pressure of 25 mbar (0.4 psig). The

following steps have to be provided:

• Modify like described on chapter 4-4-1.

• Supply a pressure of 25 mbar to the ana-

lyzer housing and take care of the ow

meter display.

The test is conrmed if the measured value

does not exceed the following max. value:

Permissible ow: 3 l/min max.

4-4-3 Startup after Test Procedure

All in section 4-4-1 described modications

have to be cancelled.

Especially the gas ttings‘ tight assemblies

need to be checked.

Emerson Process Management GmbH & Co. OHG 4-4

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FNX-STREAM

Instruction Manual

HASANE-IM-ATEX

08/2007

4 Maintenance

4-5 Replacement of Components

POSSIBLE EXPLOSION HAZARDPOSSIBLE EXPLOSION HAZARD

Replacement of defective parts must be carried out with original parts

only!

Neglection may cause Explosion Hazard!

Components which are important for X-STREAM FN safety:

X-STREAM® FNX-STREAM

Internal Battery (soldered on circuit board,

not to be replaced by the user)

Type: SL 750Type: SL 750

Supplier: Tadiran Batteries GmbH

System: SOCl2 / Li

Rated voltage: 3,6 V

Classied to IEC 60086-1: Typ E

Optional internal Gas Sampling Pump

Type: 113.095.103.1, 113.095.100.0

Supplier: ASF Thomas, WISA

Relays (soldered on circuit board,

not to be replaced by the user.

These components must not be exchanged

individually!)

Diverse types and suppliers

4 Maintenance

All internal Connections and

Screw Terminals Diverse types and suppliers

Emerson Process Management GmbH & Co. OHG 4-5

Instruction Manual

®

FN

HASANE-IM-ATEX

4 Maintenance

Fuses Data: 3,15 AT; 250V

Type: 215 (5x20 mm)

Supplier: Wickmann / Littlefuse

Safety holder

Type: UK 5 - HESI

Supplier: Phoenix

Mini fuse (on circuit board BKS)

Data: 4 AT; 250 V

Type: 372

Supplier: Wickmann / Littlefuse

08/2007

Fuse holder with cap

Type: 571 with 575

Supplier: Wickmann / Littlefuse

Emerson Process Management GmbH & Co. OHG 4-6

Instruction Manual

HASANE-IM-ATEX

04/2008

This chapter includes:

X-STREAM® FN

Appendix

EC Declaration of Conformity

Manufacturer‘s Declaration

Certicate

Block diagram

Assignment of Terminals and Sockets

A-1, page A-2

A-2, page A-3

A-3, page A-4

A-4, page A-5

A-5, page A-6

A Appendix

Emerson Process Management GmbH & Co. OHG A-1

Emerson Process Management GmbH & Co. OHG A-2

X-STREAM® FN

Instruction Manual

HASANE-IM-ATEX

04/2008

A-1 EC Declaration of Conformity

A-1 EC Declaration of Conformity

Emerson Process Management GmbH & Co. OHG A-3

Instruction Manual

HASANE-IM-ATEX

04/2008

X-STREAM® FN

A Appendix

A-2 Manufacturer‘s Declaration

A-2 Manufacturer‘s Declaration

X-STREAM® FN

Gewerbestr. 28

87600 Kaufbeuren

Germany

PrüfbescheinigungPrüfbescheinigung

Certificate Certificate

Antragsteller: Emerson Process Management GmbH & Co. OHGAntragsteller: Emerson Process Management GmbH & Co. OHG

Applicant: Industriestraße 1, 63594 Hasselroth – Germany Applicant: Industriestraße 1, 63594 Hasselroth – Germany

Produkt Typ: Gas AnalyzerProdukt Typ: Gas Analyzer

Product type: Product type:

Modell: X-STREAM FN Modell: X-STREAM FN

Model:Model:

Ein repräsentatives Testmuster des o.g Models bestand die Prüfung nach Ein repräsentatives Testmuster des o.g Models bestand die Prüfung nach

A representative Test Sample of above stated model passed the tests according to A representative Test Sample of above stated model passed the tests according to

Norm: IEC 60079-15:2005 (3

rd

Edition) and DIN EN 60079-15:2005Norm: IEC 60079-15:2005 (3

Standard: and IEC 60079-0:2004 (4

th

Edition) and DIN EN 60079-0:2004 Standard: and IEC 60079-0:2004 (4

rd

Edition) and DIN EN 60079-15:2005

th

Edition) and DIN EN 60079-0:2004

II 3 GATEX Kennzeichnung: ATEX Kennzeichnung:

ATEX marking: Ex nAC IIC T4

Technische Daten: 100 – 240Vac; 50/60Hz; 2A

Ratings:

Bericht Nr: 05KFS106

Report No.:

Zertifikat Nr. 06 – 088 – 2

Certificate No.

Datum: 12. Juli 2006

Issued:

Zertifizierstelle: Horst Haug

Certificate Placement: Horst Haug

Dieses Zertifikat hat eine Gültigkeit von 3 Jahren ab Ausstellungsdatum.

This Certificate is valid for 3 years from date of issue.

A-3Certicate

A-3 Certicate

Instruction Manual

HASANE-IM-ATEX

04/2008

Emerson Process Management GmbH & Co. OHG A-4

Instruction Manual

HASANE-IM-ATEX

08/2007

A-4 Block diagram

X-STREAM® FN

A-4 Block diagram

Appendix

Emerson Process Management GmbH & Co. OHG

A-5

X-STREAM® FN

A-5 Assignment of Plugs and Terminals

56789101112131415 1234

A-5 Assignment of Plugs and TerminalsAssignment of Plugs and Terminals

Terminal 16

Terminal 17

Terminal 14

Terminal 15

Terminal 12

Terminal 13

Terminal 11

Terminal 9

Terminal 10

Terminal 7

Terminal 8

Terminal 5

Terminal 6

Terminal 3

Terminal 4

Terminal 1

Terminal 2

Instruction Manual

HASANE-IM-ATEX

08/2007

Terminal RS 232 RS 485/2d RS 485/4d

11 Common Common Common

12 RXD not used RXD0

13 TXD not used RXD1

14 not used D1 TXD1

15 Common D0 TXD0

Fig. A-1: Terminals strip 1Terminals strip 1

Modbus interface

Pin 1 Pin 8

Terminal Signal

5

6

7

8

9

10

Failure COM

Failure NO

Maintenance, off-spec COMMON

Maintenance, off-spec NO

Function check COMMON

Function check NO

Relay outputs

Terminal Signal

1 (+) 4 (0) - 20 mA, ch 1

2 (-) 4 (0) - 20 mA, ch 1

3 (+) 4 (0) - 20 mA, ch 2

4 (-) 4 (0) - 20 mA, ch 2

Burden: RB ≤ 500 Ω

Analog outputs

Pin Signal

1 TX+

2 TX 3 RX+

6 RX other not used

Fig. A-2: Terminals strip 2

Valve V4

Valve V1

Valve V2

Open sample valve, close all, or pump on/off

DIG inputs COMMON

Digital Inputs Digital Outputs

Protective Earth PE

Ch1 & Ch2: Zero cal.

Ch1: Span cal.

Ch2: Span cal.

Valve V2

DIG outputs COMMON

Valve V4

Valve V1

Ch2: threshold 1

Ch2: threshold 2

Sample valve

Ch1: threshold 1

Ch1: threshold 2

*)

*)

With optional range

switching this output is

used as range indicator.

Line L

Neutral N

Note:

Line and neutral terminals with builtin fuse holders

Fig. A-4: Ethernet connector for ModbusEthernet connector for Modbus

Fig. A-3: Power terminals

Emerson Process Management GmbH & Co. OHGA-6

Instruction Manual

HASANE-IM-ATEX

08/2007

X-STREAM® FN

X-STREAM® FN

WORLD HEADQUARTERS

ROSEMOUNT ANALYTICAL EUROPE

Emerson Process Management GmbH & Co. OHG

Industriestrasse 1

63594 Hasselroth

Germany

T +49 (6055) 884-0

F +49 (6055) 884-209

Internet: www.emersonprocess.de

NORTH AMERICA

Emerson Process Management

Rosemount Analytical Inc.

6565P Davis Industrial Parkway

Solon, OH 44139 USA

T +1 (440) 914-1261

Toll Free in US and Canada (800) 433-6076

F +1 (440) 914-1271

e-mail: gas.csc@EmersonProcess.com

Internet: www.raihome.com

Instruction Manual

HASANE-IM-ATEX

08/2007

GAS CHROMATOGRAPHY CENTER

and LATIN AMERICA

Emerson Process Management

Rosemount Analytical Inc.

11100 Brittmoore Park Drive

Houston, TX 77041 USA

T +1 (713) 467-6000

F +1 (713) 827-3329

EUROPE, MIDDLE EAST, AFRICA

Emerson Process Management Shared Services Limited

Heath Place

Bognor Regis

West Sussex PO22 9SH England

T +44 (1243) 863121

F +44 (1243) 845354

Internet: www.emersonprocess.co.uk

ASIA - PACIFIC

Emerson Process Management Asia Pacic Pte Ltd

1 Pandan Crescent

Singapore 128461

T +65 (6777) 8211

F +65 (6777) 0947

e-mail: analytical@ap.emerson.com

Internet: www.ap.emersonprocess.com

© Emerson Process Management GmbH & Co. OHG 2007

Loading...

Loading...