Rosemount X-STREAM X1 Flameproof Addendum for Hazardous Area Applications-3rd Ed. Manuals & Guides

Page 1

Instruction Manual

HASADE-IM-Ex

07/2007

Flameproof Gas Analyzer

Instruction Manual Addendum for

Hazardous Area Applications

www.EmersonProcess.com

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and

tests its products to meet many national and international standards. Because these

instruments are sophisticated technical products, you MUST properly install, use, and

maintain them to ensure they continue to operate within their normal speci.cations.

The following instructions MUST be adhered to and integrated into your safety program

when installing, using and maintaining Emerson Process Management (Rosemount

Analytical) products. Failure to follow the proper instructions may cause any one of the

following situations to occur: Loss of life; personal injury; property damage; damage to

this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarication.

• Follow all warnings, cautions, and instructions marked on and supplied with the

product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as speci.ed in the Installation Instructions of the

appropriate Instruction Manual and per applicable local and national codes.

Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualied personnel to install, operate, update,

program, and maintain the product.

• When replacement parts are required, ensure that qualied people use replacement

parts specied by Emerson Process Management (Rosemount Analytical).

Unauthorized parts and procedures can affect the product’s performance, place the

safe operation of your process at risk, and VOID YOUR WARRANTY. Look-alike

substitutions may result in re, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place,

except when maintenance is being performed by qualied persons, to prevent

electrical shock and personal injury.

The information contained in this document is subject to change without notice.

3rd edition 2007-07

2nd edition 2007-04

1st edition 2006-07

Emerson Process Management GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Germany

T +49 (0) 6055 884-0

F +49 (0) 6055 884-209

Internet: www.EmersonProcess.com

Page 3

Instruction Manual

HASDE-IM-Ex

04/2007

X-STREAM FD

PREAMBLE

This instruction manual provides information about installing, operating and maintaining/

servicing X-STREAM series gas analyzers in hazardous (classied) areas and shall be read

in conjunction with the standard analyzer instruction manual only!

This instruction manual covers several X-STREAM series analyzer variations and therefore

may describe congurations and/or options not part of your specic analyzer.

DEFINITIONS

The following denitions apply to WARNINGS, CAUTIONS and NOTES found throughout

this publication.

Highlights an operation or maintenance procedure, practice, condition,

statement, etc.

If not strictly observed, could result in injury, death, or long-term health

hazards of personnel.

Highlights an operation or maintenance procedure, practice, condition,

statement, etc.

Safety Instructions

If not strictly observed, could result in damage to or destruction of equipment,

or loss of effectiveness.

NOTE

Highlights an essential operating procedure, condition or statement.

Emerson Process Management GmbH & Co. OHG S-1

Page 4

Instruction Manual

HASDE-IM-Ex

04/2007

Emerson Process Management GmbH & Co. OHGS-2

X-STREAM FD

Symbols

SYMBOLS USED IN THIS MANUAL

1. Where equipment or covers are marked with the symbol to the right, hazardous voltages are likely to be present beneath. These covers should only be

removed when power is removed from the equipment — and then by trained

service personnel only.

2. Where equipment or covers are marked with the symbol to the right, there is a

danger from hot surfaces beneath. These covers should only be removed by

trained service personnel when power is removed from the equipment. Certain

surfaces may remain hot to the touch.

3. Where equipment or covers are marked with the symbol to the right, refer to

the Instruction Manual for instructions.

4. Further graphical symbols possibly used in this product:

Elektrostatic discharge (ESD)

Harmful (to Health)!

Explosion Hazard!

Toxic!

Heavy Instrument!

Disconnect from Power!

Page 5

Instruction Manual

HASDE-IM-Ex

04/2007

TERMS USED IN THIS MANUAL

ATEX

Directive 94/9/EC, commonly called the

ATEX („Atmosphères Explosibles“) directive,

dealing with equipment intended to be used

in potentially explosive atmospheres.

This directive is valid for equipment to be

sold into and/or installed and operated in the

European Union (EU).

Area Classication

X-STREAM FD

Terms

Safety Instructions

Zone 1

Where ignitable concentrations of ammable

gases can exist some of the time under normal operating conditions.

(A guideline value [not part of a standard ] is

10 to 1.000 hours per year.)

Flammable Gas(es)

Gases and gas mixtures are assigned to be

ammable if they might become ignitable

when in a mixture with air.

Lower Explosion Limit (LEL)

Volume ratio of ammable gas in air below

which an explosive gas atmosphere will not

be formed: the mixture of gas and air lacks

sufcient fuel (gas) to burn.

Zone 2

Where ignitable concentrations of ammable

gases are not likely to exist under normal

operating conditions.

(A guideline value [not part of a standard ] is

less than 10 hours per year.)

Upper Explosion Limit (UEL)

Volume ratio of ammable gas in air above

which an explosive gas atmosphere will not

be formed: the mixture of gas and air is too

rich in fuel (decient in oxygen) to burn.

Emerson Process Management GmbH & Co. OHG S-3

Page 6

Instruction Manual

HASDE-IM-Ex

04/2007

Emerson Process Management GmbH & Co. OHGS-4

X-STREAM FD

Safety Instructions

SAFETY INSTRUCTIONS

INTENDED USE STATEMENT

X-Stream series gas analyzers are intended to be used as analyzers for industrial purposes. They must not be used in medical, diagnostic or life support applications nor as

safety devices, and no independent agency certications or approvals are to be implied

as covering such applications!

SAFETY SUMMARY

If this equipment is used in a manner not specied in these instructions, protective systems may be impaired.

AUTHORIZED PERSONNEL

To avoid explosions, loss of life, personal injury and damage to this equipment and on-site

property, do not operate or service this instrument before reading and understanding this

instruction manual and receiving appropriate training.

ADDITIONAL LITERATURE

This manual covers aspects specic for using ameproof X-STREAM FD analyzers in

hazardous (classied) areas, only.

To install, start-up, operate and maintain/service the instrument in a safe manner it is

MANDATORY to read all additional instruction manuals shipped together with the instrument!

The following instruction manuals are available and/or referenced within this manual at

hand:

HASAxE-IM-HS X-STREAM series instruction manual

HASFAE-IM-H Flame arrestors series instruction manual

The original manufacturer´s cable gland or conduit instruction manual, depending on

what is used.

Contact your local service center or sales ofce when missing documents.

Save all instructions for future use!

Page 7

Instruction Manual

HASDE-IM-Ex

04/2007

X-STREAM FD

Safety Instructions

EXPLOSION HAZARD BY MODIFICATION

Any addition, substitution, or replacement of components installed on or

in this device, must be certied to meet the hazardous area classication

that the device was certied to prior to any such component addition,

substitution, or replacement. In addition, the installation of such device or

devices must meet the requirements specied and dened by the hazardous

area classication of the unmodied device.

Any modications to the device not meeting these requirements, will void

the product certication(s).

Contact Emerson Process Management‘s customer service center for return

authorization.

POSSIBLE EXPLOSION HAZARD

Do not open instrument when energized.

Ensure that external circuitry is disconnected or de-energized before

opening the instrument.

Safety Instructions

Ensure that all gas connections are made as labeled and are leak free.

Improper gas connections could result in explosion and death.

POSSIBLE EXPLOSION HAZARD

The X-STREAM analyzer may utilize not only sample gas but one or more

pressurized carrier gases and/or calibration gases.

If an external owmeter is required for ow control, legislative requirements

and instructions for installation in hazardous (classied) areas must be

considered.

Emerson Process Management GmbH & Co. OHG S-5

Page 8

Instruction Manual

HASDE-IM-Ex

04/2007

Emerson Process Management GmbH & Co. OHGS-6

X-STREAM FD

The analyzer model X-STREAM FD, to which this manual relates, intended

to be wall mounted and/or outdoor installed, weighs up to approx. 63 kg

(139 lbs), depending on included options!

Use two people and/or suitable tools for transportation and lifting these

instruments!

Take care to use anchors and bolts specied to be used for the weight of

the units!

Safety Instructions

HEAVY INSTRUMENT

Take care the wall or stand the unit is intended to be installed at is solid and

stable to hold the units!

HOW TO STAY IN COMPLIANCE WITH THE

EUROPEAN DIRECTIVE 94/9/EC ("ATEX") WHEN PERFORMING GAS

ANALYSIS WITHIN A FLAMEPROOF ENCLOSURE.

Special conditions apply to using a ameproof enclosure analyzer under the scope of the

"European Directive for Equipment used in Explosive Atmosphere" (Directive 94/9/EC;

ATEX). To stay compliant to the directive please consider the following clarication sheet

released by the European ATEX Notied Body Group (see next page):

Page 9

Instruction Manual

HASDE-IM-Ex

04/2007

X-STREAM FD

Safety Instructions

Safety Instructions

Emerson Process Management GmbH & Co. OHG S-7

Page 10

X-STREAM FD

Instruction Manual

HASDE-IM-Ex

04/2007

Emerson Process Management GmbH & Co. OHGS-8

Page 11

Instruction Manual

HASDE-IM-Ex

04/2007

X-STREAM FD

Table of ConTenTs

Preamble S-1

Denitions S-1

Symbols used in this manual .............................................................................................S-2

Terms used in this manual .................................................................................................S-3

Safety instructions ..............................................................................................................S-4

Chapter 1 Technical Description 1-1

1-1 Overview ................................................................................................................. 1-1

1-2 Design Features ..................................................................................................... 1-1

1-3 Protective Measures in Detail ............................................................................... 1-1

1-4 Explosion Protection Compliances......................................................................1-3

1-5 Technical Data ........................................................................................................1-4

Table of Contents

Chapter 2 Installation 2-1

2-1 Installing the Analyzer ...........................................................................................2-2

2-2 Connecting Gas Lines ........................................................................................... 2-3

2-3 Electrical Installation ............................................................................................. 2-5

Chapter 3 Startup 3-1

Chapter 4 Service and Maintenance 4-1

4-1 Verications and Tests after Service or Maintenance ........................................4-3

4-1-1 Routine Tests ......................................................................................................4-3

4-1-1-1 Visual Inspection ............................................................................................4-3

4-1-1-2 Tests on Flame Arrestors .............................................................................. 4-3

4-2 Replacement of Parts ............................................................................................4-4

Appendix A-1

A-1 EC Declaration of Conformity ...............................................................................A-2

A-2 ATEX EC Type Examination Certicate ...............................................................A-3

A-3 Cable gland ADL 1F installation instruction ........................................................A-7

A-4 Block diagram X-STREAM FD ...............................................................................A-8

A-5 Assignment of Terminals and Socket .................................................................A-9

TOC-1Emerson Process Management GmbH & Co. OHG

Page 12

Instruction Manual

X-STREAM FD

HASDE-IM-Ex

04/2007

Table of Contents

Table of figures

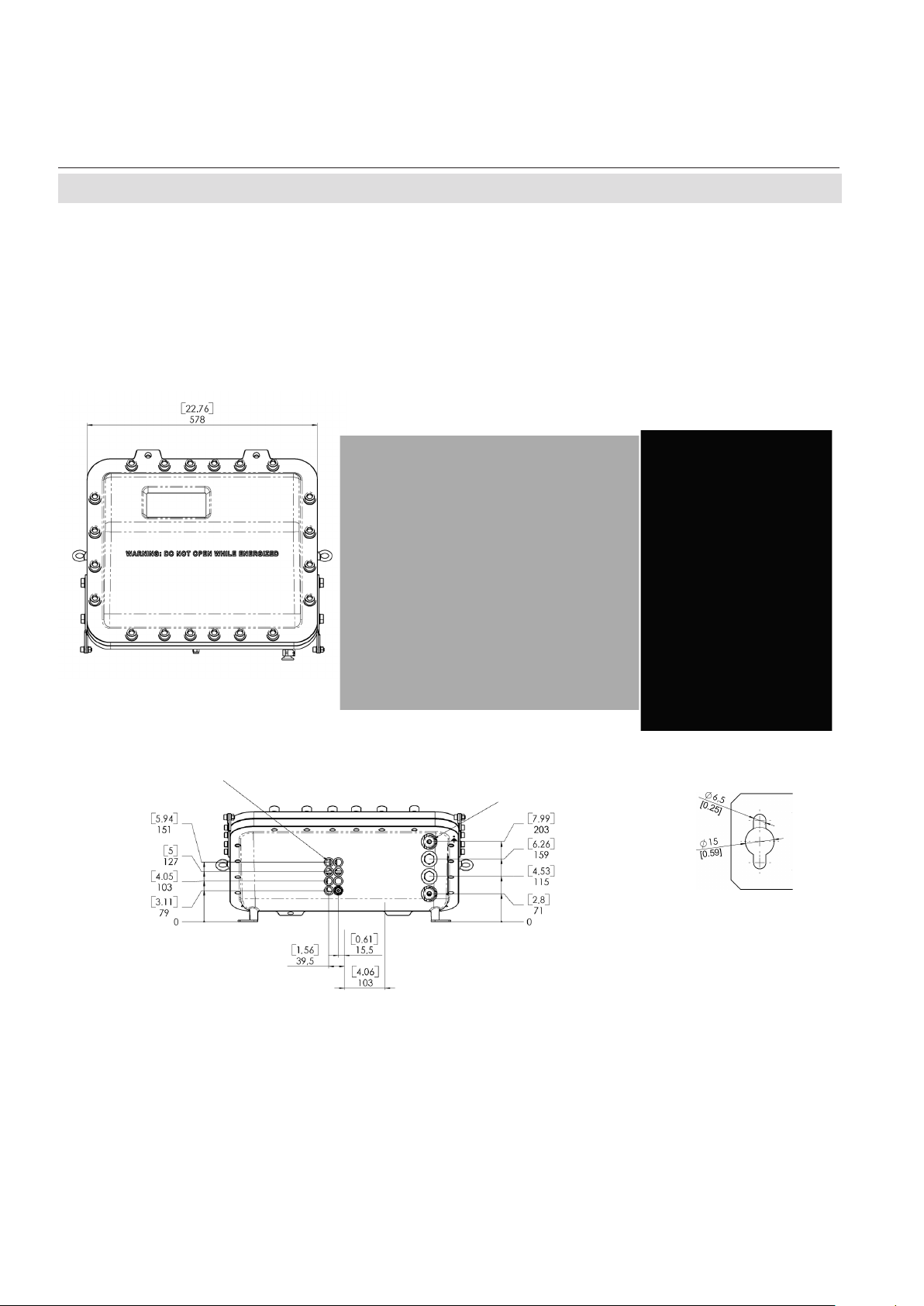

Fig. 1-1: X-STREAM FD .....................................................................................................................................1-1

Fig. 1-2: X-STREAM FD, bottom view ..............................................................................................................1-2

Fig. 1-3: X-STREAM FD - dimensions .............................................................................................................1-4

Fig. 1-4: X-STREAM FD - power terminals / fuse holders ..............................................................................1-7

Fig. 1-5: X-STREAM FD - signals terminals ....................................................................................................1-8

Fig. 2-1: X-STREAM FD dimensions ................................................................................................................2-2

Fig. 2-2: Flame arrestor installed into instrument enclosure ........................................................................2-3

Fig. 2-3: Flame arrestor elements, considering as example FA 01 ...............................................................2-3

Fig. 2-4: X-STREAM FD - allocation of terminals ..........................................................................................2-10

Fig. 2-5: X-STREAM FD - Analog output terminals .......................................................................................2-12

Fig. 2-6: X-STREAM FD - Modbus interface terminals .................................................................................2-13

Fig. 2-7: X-STREAM F - Modbus over ethernet connector ...........................................................................2-14

Fig. 2-9: X-STREAM FD - Relay Status Terminals ........................................................................................2-15

Fig. 2-8: Relay status signals, block diagram ..............................................................................................2-15

Fig. 2-10: Digital Inputs & Outputs Terminals ...............................................................................................2-16

Fig. 2-11: Power terminals ..............................................................................................................................2-17

Fig. 2-12: Equipotential bonding conductor terminal ..................................................................................2-18

Fig. A-1: Terminals strip 1 ................................................................................................................................A-9

Fig. A-2: Terminals strip 2 ................................................................................................................................A-9

Fig. A-3: Power terminals ................................................................................................................................A-9

Fig. A-4: Ethernet connector for Modbus ....................................................................................................... A-9

TOC-2 Emerson Process Management GmbH & Co. OHG

Page 13

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

Chapter 1

Technical Description

1-1 Overview

The new X-STREAM FD gas analyzer is designed to be used in hazardous areas. Its ameproof enclosure can be installed at Zone 1

locations without the need of any additional

protective measures, e.g. purge gas supply.

1-2 Design Features

Packaged into a cast aluminum enclosure, the

X-STREAM FD gas analyzer provides all the

measurement options available for general

purpose instruments, but for installation at locations where explosive atmosphere might be

present frequently and classied as Zone 1.

The basic concept used is to protect the surrounding atmosphere from being ignited if an

internal failure results in high temperatures,

ames or even an explosion.

To provide adequate explosion protection

the X-STREAM FD analyzer features several

protection methods:

•

The cast aluminum enclosure is designed to

• withstand an internal explosion,

• extinguish the ames resulting from an

internal explosion (thus preventing a

sur-rounding explosive atmoshere from

being ignited).

• Flame arrestors avoide ame transmission

from the gas paths into the surrounding

atmosphere.

• Approved cable glands (option: conduits)

protect the cable inlets and outlets.

1-3 Protective Measures in Detail

The cast aluminum enclosure consists of

two parts: base and cover, connected by

hinges.

The area where the two parts are in contact

is designed to work as a ange, quenching

ames entering the small path between them.

When operated, the analyzer enclosure has to

be closed and secured by 20 screws evenly

arranged all over the ange.

6

3

1: Enclosure base

2: Screws

3: Enclosure cover

4: Flange

5: Eyebolts for lifting

6: Eyebolts for installation

7: Hinges

Fig. 1-1: X-STREAM FD

Emerson Process Management GmbH & Co. OHG 1-1

2

7

4

5

1

1 Technical Description

Page 14

X-STREAM FD

Emerson Process Management GmbH & Co. OHG1-2

Instruction Manual

HASADE-IM-EX

07/2007

1-3 Protective Measures in Detail

The only openings penetrating the enclosure

are threads, to be used for gas and cable inand outlets:

Depending on the measurement application

the instrument provides up to 8 gas in- and

outlets, each protected by an approved ame

arrestor. These arrestors are installed into

threads at the bottom side of the enclosure

base. Two tting sizes are available for external connection of gas pipes with 3.18 mm

(1/8“) or 6.35 mm (1/4“) outer diameter (OD).

Optionally a clamping ring for 6 mm OD may

be used, replacing the 6.35 mm version.

Cables are fed into the enclosure utilizing up

to 4 cable glands, located at the enclosure`s

bottom right side. The approved glands accept

3 different internal elastomeric sealing rings

with different internal diameters, supporting

a wide range of cables.

For installation in North-America cable glands

are replaced by a combination of conduits and

metric-to-NPT thread adapters.

All threads provide a ame path of a length

ensuring that possibly entering ames are

extin-guished before reaching the external

atmos-phere.

Unused threads must be closed with plugs

when the instrument is operated to ensure

explosion protection.

Note!

See the X-STREAM series instruction manual

for more information about common X-STREAM

series gas analyzers features and special

features of the X-STREAM FD.

1: Plugged when not used

2: Gas tting (part of ame arrestor)

3: Plug

4: Cable gland (or conduits)

1 2 3 4

Fig. 1-2: X-STREAM FD, bottom view

Page 15

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

1-4 Compliances

1-4 Explosion Protection Compliances

This product is available in two different variations, separately certied by agencies for the use

in hazardous (classied) areas:

The one version, to be equipped with metric-to-NPT adapters and conduits (these components

are not part of the instrument certication), is certied by the Canadian Standards Association,

an „OSHA Nationally Recognized Testing Labor tory“ (NRTL), for Canada and USA and conforms

to the provisions of CAN/CSA-E60079-0:02 (R2006), CAN/CSA-E60079-1:02 (R2006), ANSI/ISA-

12.00.01-2002 (IEC 60079-0 Mod), ANSI/ISA-12.22.01-2002 (IEC 60079-1 Mod).

The second variation, to be equipped with cable glands, is certied by Fyzikálně technický

zkušební ústav, s.p (FTZÚ), an European Notied Body under the Directive 94/9/EC („ATEX“)

and conforms to the provisions of EN 60079-0 and EN 60079-1. See appendix for a copy of the

CE type examination certicate.

Depending on the variation, the following certication markings apply to the product:

Class I, Zone 1, AEx d IIB + H2 T3

USA

Canada Class I, Zone 1, Ex d IIB + H2 T3

European Union (EU) ATEX, category 2, Zone 1, Ex d IIB + H2 T4

EC ATEX Type Examination Certicate: FTZU 06 ATEX 0186.

Conforms with the provisions of the „Equipment intended for use in Potentially Explosive Atmospheres (ATEX)“ Directive 94/9/EC, EMC Directive 89/336/EEC and CE Directive 93/68/EEC.

1 Technical Description

Emerson Process Management GmbH & Co. OHG 1-3

Page 16

X-STREAM FD

Emerson Process Management GmbH & Co. OHG1-4

Instruction Manual

HASADE-IM-EX

07/2007

1-5 Technical Data

1-5 Technical Data

Flame arrestors with gas ttings

(enclosure threads: M18 x 1.5)

(enclosure threads; M20 x 1.5)

Cable inlets

Eyebolt detail

approx. in mm [inches]

Fig. 1-3: X-STREAM FD - dimensions

Housing

Permissible ambient temperature range -22 F to 122 F ( -30 °C to +50 °C)

Weight: approx. up to 139 lbs (63 kg)

(depending on analyzer conguration)

Protection class: IP 66 (EN 60529) / NEMA 4X

for outdoor installation

Analyzer must not be exposed to direct

sun light

Gas ttings: quantity: max. 8

specication: ame arrestors with ttings

6/4 mm or 1/4“, stainless steel

Page 17

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

1-5 Technical Data

Site of installation

Humidity (non condensing) < 90 % r. h. at 68 F (+20 °C)

< 70 % r. h. at 104 F (+40 °C)

Pollution degree 2

Installation category I I

Altitude 0 to 6560 ft (2000 m) above sea level

Sourrounding atmosphere Analyzers must not be operated in

corrosive atmosphere.

General Purpose Compliances

Electrical safety CAN / USA CSA-C/US, based on

CAN/CSA-C22.2 No. 61010-1-04 /

UL 61010-1, 2nd Edition

Europe CE, based on EN 61010-1

Electromagnetic compatibility

Europe CE, based on EN 61326

other NAMUR

Power supply

Rated input voltageated input voltage

100 - 240 V 50/60 Hz, wide range input

Power supply voltage uctuations are

not to exceed +/- 10 % of the nominal

supply voltage!

Input voltage range 85 - 264 V , 47 - 63 Hz

Rated input current

standard 0,75 - 0,35 A max.

with thermostated physics 2 - 1 A max.

1 Technical Description

Emerson Process Management GmbH & Co. OHG 1-5

Page 18

X-STREAM FD

Emerson Process Management GmbH & Co. OHG1-6

Instruction Manual

HASADE-IM-EX

07/2007

1-5 Technical Data

Interfaces, signal inputs / outputs

2 analog outputs channel 4 (0) - 20 mA (RB < 500 Ω)

(optically isolated; congurable by keypad

start and end concentration user congurable)

Modbus interface RS 485 (2- or 4-wire)

optional:

RS 232 with or without optical isolation

Ethernet (RJ45 socket)

3 relay outputs (option „status signals“) “Failure”

according NAMUR NE 107 “Maintenance required / Off specication“

“Function check”

dry contacts, max. 30 V; 1 A; 30 W resistive

Digital Inputs and Outputs (option)

7 digital inputs zero calibration ch1 & ch2,

(common ground) span calibration ch1,

span calibration ch2,

open valve V4

open valve V1

open valve V2

open sample gas valve V3 /

switch off sample pump

max. 30 V, internally limited to 2.3 mA

H level: min. 4 V; L level: max. 3 V

8 digital outputs 2 thresholds per channel,

(optically isolated, common ground) sample gas valve,

zero gas valve V4,

span gas valve V1,

span gas valve V2

“Open Collector”, max. 30 V / 30 mA

Gas parameters

X-STREAM Instruction Manual, chapter 3 Measuring Principles

Page 19

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

1-5 Technical Data

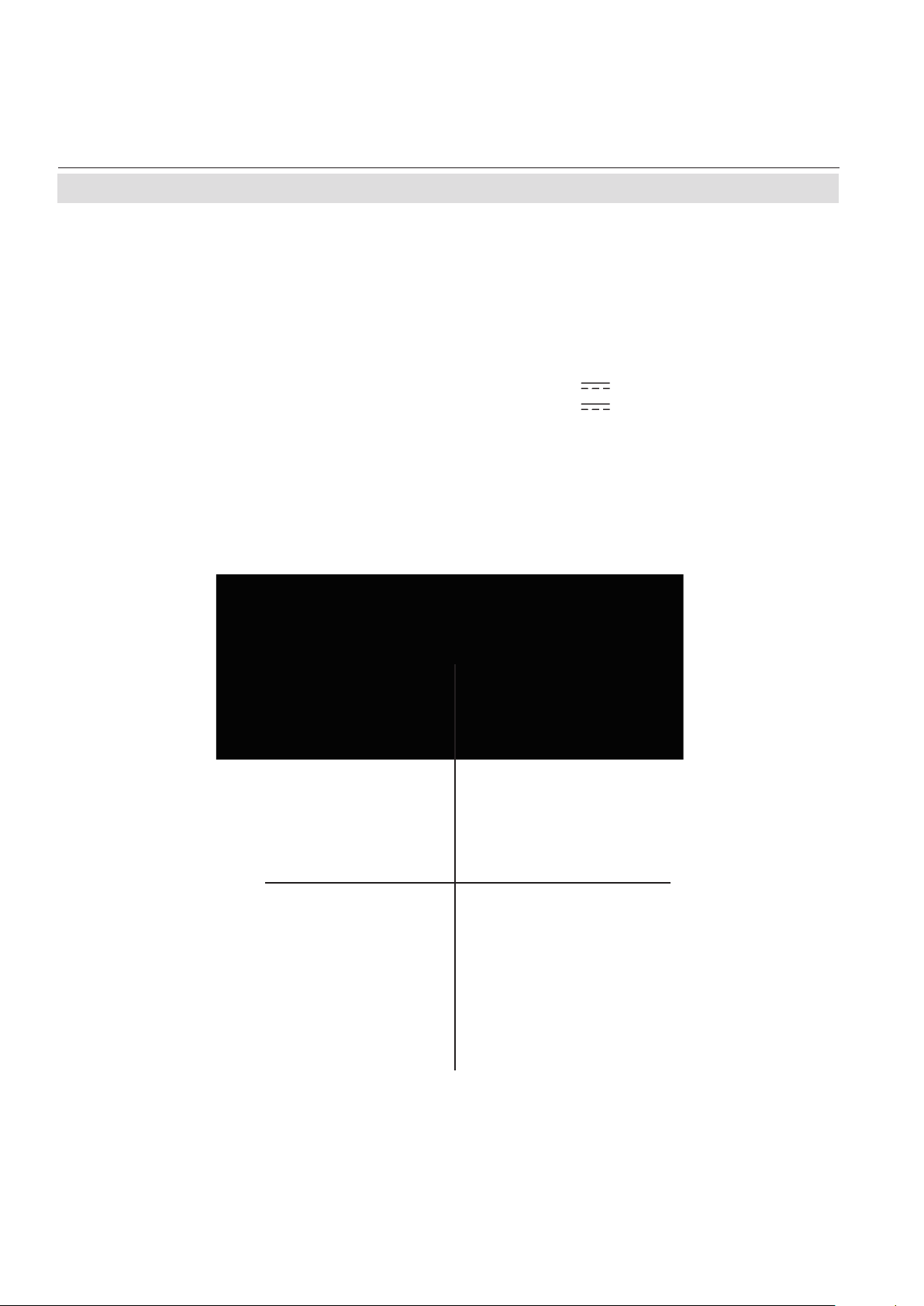

Power Connection

Connection via internal screw terminals near

cable entries, (g. 2-8).

Cross section: max. 10 AWG (4 mm2), using conductor

sleeves is not required

Cable entry via 1 cable gland, classied IP 68 or suitable

conduit with metric-to-NPT adaptor

Permissible outer cable diameter for power

cord when provided with cable glands: 0.11 to 0.5 inch (3-13 mm),

depending on used cable gland sealing ring

Power fuses

The power terminals integrate fuse holders.

Fuse ratings: AC 230 V, 3.15 A, 5x20 mm

324 1

1 Technical Description

1 Power terminals with integrated

fuse holders

2 Protective earth terminal (PE)

Fig. 1-4: X-STREAM FD - power terminals / fuse holders

Emerson Process Management GmbH & Co. OHG 1-7

3 Power cable entry

4 EMI power lter

Page 20

Instruction Manual

X-STREAM FD

HASADE-IM-EX

07/2007

1-5 Technical Data

Signal inputs / outputs

All signal lines need to be connected to internal

screw terminals (g. 1-5), except the optional RJ45 ethernet connector.

Cross section: max. 12 AWG (2.5 mm2), using conductor

sleeves is not required

Cable entry via

3 cable glands, classied IP 68 or suitable

conduits with metric-to-NPT adaptors

Permissible outer cable diameter for signal

cables when provided with cable glands: 0.11 to 0.5 inch (3-13 mm)

depending on used cable gland sealing rings

Available signals: standard: Analog signal outputs

Relay status signals

Modbus interface (RS232; RS 485)

optional: Digital inputs/outputs

Modbus RJ45 ethernet connector

Detailed pin assignment 2 Installation

The optional ethernet connector (RJ45),

Fig. 1-5: X-STREAM FD - signals terminals

Emerson Process Management GmbH & Co. OHG1-8

located on the electronics

main board BKS

Page 21

Instruction Manual

HASADE-IM-EX

07/2007

Installing and wiring this instrument must comply with all relevant national

legislative requirements and regulations.

Consider all safety instructions within this on hand manual and all associated analyzer instruction manuals!

X-STREAM FD

Chapter 2

Installation

POSSIBLE EXPLOSION HAZARD

POSSIBLE EXPLOSION HAZARD

Installing this instrument requires opening the enclosure and working at

the open instrument. This is permitted only when both no hazardous atmosphere is present and the instrument and connected external circuitry are

de-energized!

Depending on the local regulation, this may require a competent hot work

supervisor to issue a hot work permit.

HEAVY INSTRUMENT

The analyzer model X-STREAM FD, to which this manual relates, intended

to be wall mounted and/or outdoor installed, weighs up to approx. 63 kg

(139 lbs), depending on included options!

Use two people and/or suitable tools for transportation and lifting these

instruments!

Take care to use anchors and bolts specied to be used for the weight of

the units!

Take care the wall or stand the unit is intended to be installed at is solid and

stable to hold the units!

2 Installation

Emerson Process Management GmbH & Co. OHG 2-1

Page 22

Emerson Process Management GmbH & Co. OHG2-2

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

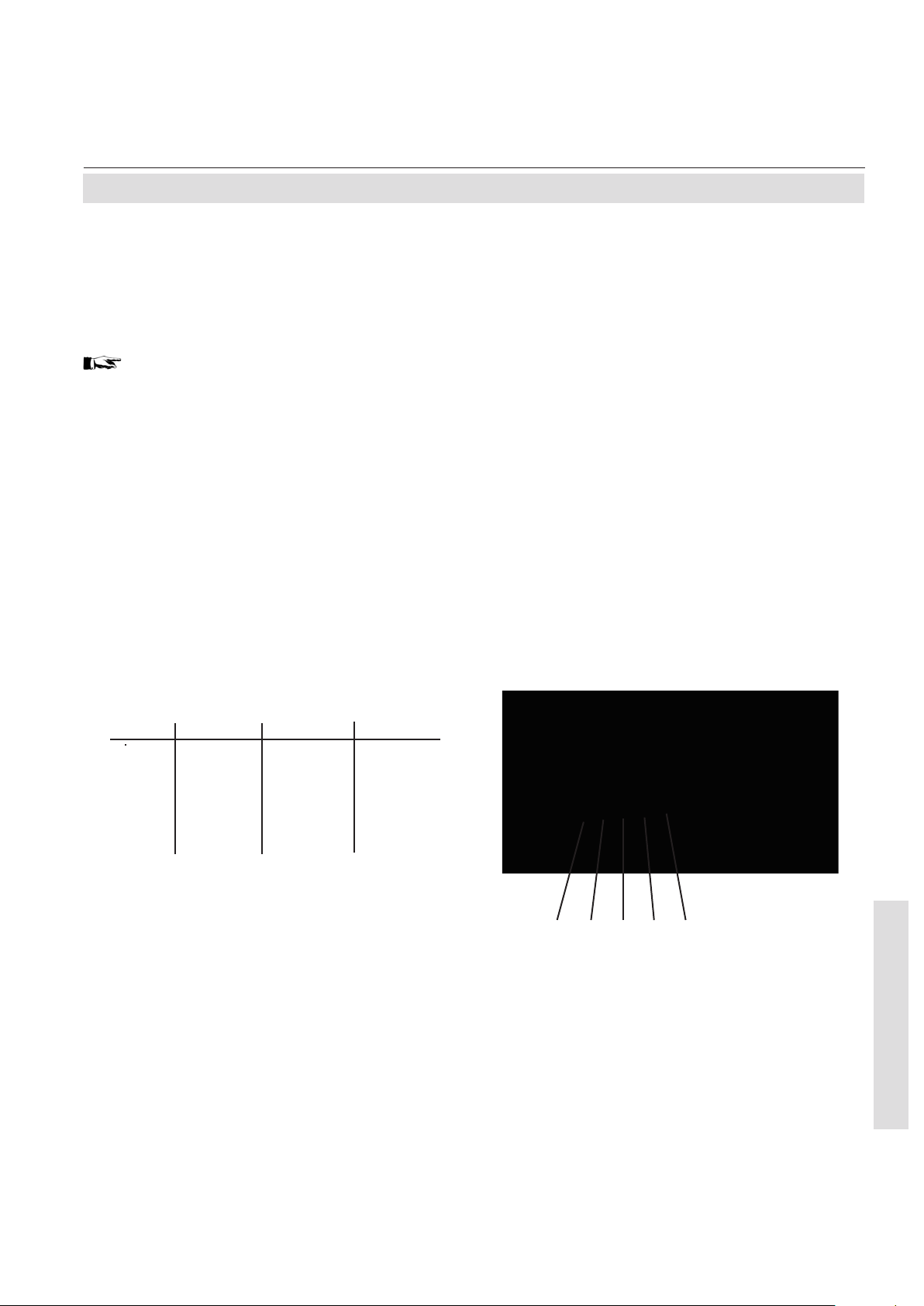

2-1 Installing the Analyzer

2-1 Installation - Analyzer

Install the analyzer to a stand or a wall by

means of 4 eyebolts, provided at the instruments rear side.

It is recommended to install the analyzer in an

Note!

Add 15 [0.59] to left and right side to include

hinges.

upright (vertical) position; other orientations

may affect the measuring results.

Flame arrestors with gas ttings

Fig. 2-1: X-STREAM FD dimensions

Electrical connections

Eyebolt detail

All dimensions in mm

[inches in brackets]

Page 23

Instruction Manual

HASADE-IM-EX

07/2007

2-2 Connecting Gas Lines

X-STREAM FD

2-2 Installation - Gas Lines

Gas inlets and outlets are protected by certied ame arrestors (FTZU 06 ATEX 0164),

suppor-ting stainless steel pipes of either 3,18

mm (1/8“) or 6,35 mm (1/4“) outer diameter

(OD). The 1/4“ tting may optionally be supplied

with a clamping ring for 6 mm OD pipes.

POSSIBLE EXPLOSION HAZARD

Take care not to damage the threats, this may void the instrument´s safety

and cause hazards!

Take care to follow the instructions of the separate ame arrestor instruction

manual (HASFAE-IM-H)!

Ensure unused entries remain sealed with approved plugs!

When thightening the tting, counterhold the

ame arrestor with a wrench placed at the

hexagon (items 5 of g. 2) next to the cap

nut (items 1, 4) to be tightened.

Always counterhold the ame

arrestor while thightening ttings; otherwise the ame arrestor may be damaged!

The instrument provides up to 8 gas inlets and

outlets, depending on the ordered conguration. Unused entries are closed by approved

plugs.

1

5

2

3

6

5

7

4

1: Gas tting 1/8“ (inside instrument) *

2: M18 male threat (inside enclosure wall)

3: O-ring

4: Gas tting 1/4“ or 1/8“ (outside instrument) *

5: Hexagon for counter holding while thightening

6: Hexagon for wrench when mounting into a M18 threat

7: O-ring shoulder

*) FA 01 with 1/4“ (outside instrument) and 1/8“ (inside)

FA 02 with 1/4“ at both ends

FA 03 with 1/8“ at both ends

Fig. 2-2: Flame arrestor installed

into instrument enclosure

Emerson Process Management GmbH & Co. OHG 2-3

Fig. 2-3: Flame arrestor elements,

considering as example FA 01

)

)

2 Installation

Page 24

Emerson Process Management GmbH & Co. OHG2-4

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

2-2 Installation - Gas Lines

Gas ttings are accessible at the instrument‘s

outer bottom side.The number and assignment of gas inlet and outlet ttings depends

on the application and is given on a label attached to the analyzer‘s bottom side adjacent

to the ttings.

For simple installation we recommend to mark

the gas lines according to the marking on the

analyzer label. This avoids confusion during

re-installation when the analyzer had to be

disconnected for whatever reason.

Page 25

Instruction Manual

HASADE-IM-EX

07/2007

2-3 Installation - Electrical

2-3 Electrical Installation

ELECTRICAL SHOCk H AZARD

Installation and connecting power and signal cables are subject to qualied

personnel only taking into account all applicable standards and legislative

requirements!

Failure to follow may cause warranty invalidation, property damage and/or

personal injury or death!

Installation of these instruments is subject to qualied personnel only,

familiar with the resulting potential risks! Instruments providing screw

terminals for electrical connections may require working near live part!

X-STREAM FD

X-STREAM FD gas analyzers do not provide a power switch!

A power switch or circuit breaker (complying with IEC 60947-1/-3) has to be

provided in the building installation. This switch has to be installed near

by analyzer, must be easily operator accessible and has to be assigned as

disconnector for the analyzer.

Disconnect instruments with screw terminals from power when working at

power terminals (pull power plug or operate power switch/ circuit breaker

in building installation)!

The analyzers provide a protective earth terminal. To prevent electrical shock

hazards the instruments must be connected to a protective earth. Therefore

the instruments must be connected to power by using a three wire power

cable with earth conductor!

Any interruption of the earth connector inside or outside the instrument

or disconnecting the earth terminal may cause potential electrical shock

hazzard!

The analyzers do not provide a power switch and are operable when connected to power.

Emerson Process Management GmbH & Co. OHG 2-5

2 Installation

Page 26

Emerson Process Management GmbH & Co. OHG2-6

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

Do not open instrument when energized.

Ensure that external circuitry is disconnected or de-energized before

opening the instrument.

All cables (power and signal) must end (be connected) in either a safe (non-

hazardous) area or in a protecting enclosure (e.g. Ex e junction box)!

2-3 Installation - Electrical

POSSIBLE EXPLOSION HAZARD

SELECT THE CORRECT TYPE OF CABLE ENTRY

Before starting to install the analyzer, verify what type of cable entry is required at your

site of installation:

X-STREAM FD gas analyzers may be equipped with cable glands (regulated e.g. for installations covered by ATEX) or may be installed with conduits (e.g. in North-America).

INSTALLATION USING CONDUITS

X-STREAM FD analyzers provide metric threads for installing cable entries.

Installing conduits requires using metric-to-NPT adaptors!

To stay compliant with the North-American certication use only ameproof

certied adaptors, e.g. the following type:

Redapt AD-U series, stainless steel with captive o-ring seals,

size male M20 x 1.5 to female 3/4-NPT or 1/2-NPT.

Select a type of conduit according the local code, suitable for above

mentioned adaptors and the site of installation.

During installation follow the instructions provided by the manufacturer of

the conduits!

Unused entries must be provided with ameproof plugs, secured in place

with thread locking compound!

Page 27

Instruction Manual

HASADE-IM-EX

07/2007

When installing the analyzer in a Hydrogen environment and/or applying

Hydrogen to the analyzer, do not use the standard ADL type cable glands!

Use suitable compound barrier cable glands to stay compliant to EN 60079-14.

During installation follow the instructions provided by the manufacturer of

the glands!

When using the ADL type cable glands: Take care to use the correct cable

gland internal elastomeric ring with an internal diameter supporting the cable

to be used! The supported cable diameters are noted on the sealing ring.

X-STREAM FD

2-3 Installation - Electrical

INSTALLATION USING CABLE GLANDS

Use only cables as specied in the cable glands installation instruction, and

carefully follow the installation instructions!

The next two pages show

• the English section of the ADL type cable

gland installation instructions, reprinted with

the permission of

Cooper Industries

Cooper Menvier Division

CAPRI-CODEC sas .

and

• the English installation instructions for type

AD-U adapters, reprinted with the permission of

Redapt Ltd

Note!

See appendix of this manual for a complete

reprint, and the documentation delivered

together with your analyzer for an original

version of the cable gland or adapter installation instructions, where applicable !

2 Installation

Emerson Process Management GmbH & Co. OHG 2-7

Page 28

Emerson Process Management GmbH & Co. OHG2-8

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

2-3 Installation - Electrical

Type AD-U adapter installation instructions

Page 29

Instruction Manual

HASADE-IM-EX

07/2007

ADL type cable gland installation instructions

X-STREAM FD

2-3 Installation - Electrical

The elastomeric sealing

rings, provided together

with the cable gland,

are designed to cover

the diameter ranges

3 to 8 mm

6,5 to 10.5 mm

or

10 to 13 mm.

Emerson Process Management GmbH & Co. OHG 2-9

2 Installation

Page 30

Emerson Process Management GmbH & Co. OHG2-10

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

2-3 Installation - Electrical

The analyzer provides 4 cable entries and

is shipped with selected sets of plugs and

glands or adaptors, depending on the ordered

analyzer conguration:

The default set consists of

• 1 gland/adaptor for the power cord

• 1 gland/adaptor for one signal cable

• 3 plugs for unused entries, taking into

account an installation without even one

signal cable.

Unused entries during installation have to be

provided with plugs, secured in place with

thread locking compound.

Installation under CSA certication requires

the use of approved conduits and suitable

metric-to-NPT adaptors. .

The instrument provides internal screw terminals for connecting power and signal cables.

This requires opening the instrument during

installation:

• Unsrew the 20 screws located on the

enclosure ange.

• Flap down the cover part to gain access

to the analyzer inside.

1 42 35

1 Terminals for signal cables

2 Power EMI lter

3 4 cable entries for power and signal cables

4 Power terminals with integrated fuses

5 Ethernet connector (option)

Fig. 2-4: X-STREAM FD - allocation of terminals

Page 31

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

2-3 Installation - Electrical

Installation with conduits

Ensure all required parts are available:

Adaptors, suitable conduits, plugs for not used

entries and compound (see accessory kit).

Place some locking compound onto the male

thread of the required number of adaptors and

install them into the related cable entries:The

3 rear entries are reserved for signal cables,

the rst one is for the power cord.

Ensure the explosionproof seal is placed

at the analyzer enclosure or within 2“ from

enclosure.

All cables need to be fed properly through

conduits when entering the instrument and

connected to the terminals (

warning

notes, page 2-5).

To seal the cable entries proceed according to

the installation instruction given in the related

conduits manufacturer documentation.

Seal unused entries utilizing ameproof certi-

ed plugs, also provided with some compound

on their threads.

Installation with cable glands

Ensure all required parts are available:

Cable glands, plugs for not used entries and

compound (see accessory kit).

Place some locking compound onto the male

thread of the required number of cable glands

body parts and install them according the

manufacturers instruction into the related

cable entry:The 3 rear entries are reserved

for signal cables, the rst one is for the power

cord.

All cables need to be fed properly through the

cable glands when entering the instrument

and connected to the terminals (

warning

notes, page 2-5).

To seal the cable entries proceed according to

the installation instruction given in the related

cable glands manufacturer documentation.

Seal unused entries utilizing the plugs, also

provided with some compound on their threads.

Preparation of signal cables

All signal cables are to be connected via

screw terminals, except the optional ethernet

connector, located inside the analyzer.

Supported wire cross sections: 24 to 14 AWG (0,2 to 2,5 mm2),

no need to use wire end sleeves

Cable skinning length: 0.354 inch (9 mm)

Hole diameter: 0.05 inch (1,2 mm)

Screw thread: M 2,5

Tightening torque, min: 3.5 in.lb (0,4 Nm)

Emerson Process Management GmbH & Co. OHG 2-11

2 Installation

Page 32

Emerson Process Management GmbH & Co. OHG2-12

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

2-3 Installation - Electrical

Signal inputs / outputs

Analog signal outputs

The rightmost 4 terminals (# 1 - 4) of the terminals row next to the power terminals are

reserved for analog signal outputs.

Burden: RB ≤ 500 Ω

Note!

Take care of the special installation instructions in section 4-5 of the X-STREAM gas

analyzer series manual!

(-) 4 (0) - 20 mA, channel 2

(+) 4 (0) - 20 mA, channel 2

(-) 4 (0) - 20 mA, channel 1

(+) 4 (0) - 20 mA, channel 1

Fig. 2-5: X-STREAM FD - Analog output terminals

Page 33

Instruction Manual

HASADE-IM-EX

07/2007

2-3 Installation - Electrical

Modbus interface

Specication and driving the interface:

X-STREAM gas analyzer series manual,

chapter 7.

Note 1!

Take care of the special installation instructions in section 4-5 of the X-STREAM gas

analyzer series manual!

The leftmost 5 terminals (# 11 - 15) of the

terminals row next to the power terminals are

reserved for the Modbus interface, which can

be either of type RS 232 or RS 485.

X-STREAM FD

Terminal RS 232 RS 485/2w RS 485/4w

11 Common Common Common

12 RXD not used RXD0

13 TXD not used RXD1

14 not used D1 TXD1

15 Common D0 TXD0

Note 2!

X-STREAM analyzers are to be considered

a DTE (Data Terminal Equipment).

Fig. 2-6: X-STREAM FD - Modbus interface terminals

1112131415

2 Installation

Emerson Process Management GmbH & Co. OHG 2-13

Page 34

Emerson Process Management GmbH & Co. OHG2-14

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

2-3 Installation - Electrical

Optional Modbus RJ45 connection

If installed, the optional RJ45 connector is

located on the BKS main board, in the upper

part of the instrument.

To install this connection one has to insert

a cable without connetor through the cable

inlet.

Once the open end is inside the instrument,

the plug connector can be installed:

We recommend using a VARIOSUB RJ45

QUICKON plug connector (PHOENIX CONTACT), as supplied together with the instrument, not requiring special tools. See the

separate installation instruction, provided

together with the plug connector for information on how to install it.

Note!

Notice, that the modbus screw terminals

( page 2-12) are installed, too, but without function!

Pin 1 Pin 8

Fig. 2-7: X-STREAM F - Modbus over ethernet connector

Pin Signal

1 TX+

2 TX 3 RX+

6 RX other not used

RJ45 connector on

main board BKS

Page 35

Instruction Manual

HASADE-IM-EX

07/2007

Relay status Signals

X-STREAM FD

2-3 Installation - Electrical

Design: dry relay contacts

Electrical specication: max. 30 V , 1 A,

30 W

Note!

Take care of the special installation instructions in section 4-5 of the X-STREAM gas

analyzer series manual!

The middle 6 terminals (# 5 - 10) of the terminals row next to the power terminals are

reserved for the relay status signals.

Signal output

(NC); conguration on request

Signal output

(NO); factory

standard conguration

Fig. 2-8: Relay status signals, block diagram

Terminal Signal

5 Failure COM

6 Failure NO

7 Maintenance, off-spec COM

8 Maintenance, off-spec NO

9 Function check COM

10 Function check NO

10

9

Fig. 2-9: X-STREAM FD - Relay Status Terminals

Emerson Process Management GmbH & Co. OHG 2-15

5678

2 Installation

Page 36

Emerson Process Management GmbH & Co. OHG2-16

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

2-3 Installation - Electrical

Digital Inputs & Outputs

Design: Open collector (outputs)

Electrical specication:

outputs: max. 30 V , 30 mA

inputs: max. 30 V , internally limited to 2,3 mA

H level: min. 4 V; L level: max. 3 V

Note!

The leftmost terminal strip is reserved for the

digital inputs and outputs.

Take care of the special installation instructions in section 4-5 of the X-STREAM gas

analyzer series manual!

Digital Inputs DigitalOutputs

Terminal 13

Terminal 14

Terminal 15

Terminal 16

Terminal 17

Open V4

Open V1

Open V2

Open sample valve or close all

DIG In GND

Fig. 2-10: Digital Inputs & Outputs Terminals

Terminal 10

Terminal 11

Terminal 12

Zero cal. Ch1 & Ch2

Span cal. Ch1

Span cal. Ch2

Terminal 7

Terminal 8

Terminal 9

Valve V1

Valve V2

DIG Out GND

Terminal 4

Terminal 5

Terminal 6

Ch2: threshold 2

Sample valve

Valve V4

Terminal 1

Terminal 2

Terminal 3

Ch1: threshold 1

Ch1: threshold 2

Ch2: threshold 1

Page 37

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

2-3 Installation - Electrical

Connecting the power cord

The power cord is connected by screw terminals, located inside analyzer.

Supported wire cross sections: 24 to 12 AWG (0,2 to 4 mm2),

no need to use wire end sleeves

Cable skinning length: 0.315 inch (8 mm)

Hole diameter: 0.05 inch (1,2 mm)

Screw thread: M 3

Tightening torque, min: 4.4 in.lb (0,5 Nm)

To install the cable proceed according to the

installation instructions for either conduits or

cable glands, given on page 2-11.

Insert the power cord through the foremost

entry, strip the outer insulation, skin and

connect the conductors to the terminals (a

descriptive label is xed to the lter‘s housing

nearby the terminals), by inserting them from

the bottom sides.

ELECTRICAL SHOCk HAZARD

Verify the power supply at installation site meets the specication given on

the analyzer´s nameplate label, before installing the instrument!

Location

for label

L

N

PE

L= Line

N=Neutral

PE=Protective Earth

Power cord

entry

Fig. 2-11: Power terminals

Verify power cables are disconnected and/or instrument is de-energized

prior to working at the terminals!

Verify the power cord is layed with a distance of at least 1 cm (0.5“) to any

signal cable to ensure proper insulation from signal circuits!

Emerson Process Management GmbH & Co. OHG 2-17

2 Installation

Page 38

Emerson Process Management GmbH & Co. OHG2-18

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

2-3 Installation - Electrical

Connecting an optional equipotential

bonding conductor

The X-STREAM FD enclosure provides an

additional terminal for connecting an equipotential conductor, located at the base part

ange´s rear side (see g. 2-6), near the

nameplate label.

Screw thread: M5

Fig. 2-12: Equipotential bonding conductor terminal

Page 39

Instruction Manual

HASADE-IM-EX

07/2007

2-3 Installation - Electrical

ELECTRICAL SHOCk HAZARD

Before completing the electrical connection of the instrument, verify cables

are inserted and connected in correct manner!

Ensure the earthing conductor (protective earth; PE) is connected!

After all connections are established in correct

manner and veried,

• x the cables according to the installati-

on instruction given in the cable glands/

conduits manufacturer documentation.

• Install the analyzer´s cover by means of

ALL 20 screws!

Tightening torque: min. 354 in.lb (40 Nm)

X-STREAM FD

POSSIBLE EXPLOSION HAZARD

Do NOT operate the instrument with doors or covers open! This is permitted

only when no hazardous atmosphere is present!

Depending on the local regulation, this may require a competent hot work

supervisor to issue a hot work permit.

Use ALL 20 screws to x the cover! Violation may cause an explosion

hazard!

Emerson Process Management GmbH & Co. OHG 2-19

2 Installation

Page 40

X-STREAM FD

Instruction Manual

HASADE-IM-EX

07/2007

2-3 Installation - Electrical

Emerson Process Management GmbH & Co. OHG2-20

Page 41

Instruction Manual

HASADE-IM-EX

04/2007

X-STREAM FD

Chapter 3

Startup

Once the X-STREAM FD analyzer is installed

correctly and in accordance to the instructions given in chapter2 „Installation“ it is

prepared for startup.

POSSIBLE EXPLOSION HAZARD

Ensure all covers, plugs and housing parts are in place and secured properly

before supplying power and signal voltages!

Ensure all requirements given

by the clarication sheet for

performing gas analysis within

a ameproof enclosure are

considered BEFORE supplying

gases (see page S-5)!

The sheet also gives instructions for the sequence of supplying gases during process and

analyzer startup .

3 Startup

After all safety aspects are followed and

checked, the instrument may be powered and

operated according the instructions given in

the X-STREAM series instruction manual.

Read this manual for detailled information

about software, parameter settings and

more.

Emerson Process Management GmbH & Co. OHG 3-1

Page 42

X-STREAM FD

Instruction Manual

HASADE-IM-EX

04/2007

3 Startup

Emerson Process Management GmbH & Co. OHG3-2

Page 43

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

Chapter 4

Service and Maintenance

Note!

This chapter deals with service and maintenance procedures related to explosion protection only!

More detailled instructions about servicing and maintaining general purpose components of

X-STREAM gas analyzers are subject of the X-STREAM analyzer instruction manual.

POSSIBLE EXPLOSION HAZARD

Inspection, maintenance and service must be carried out considering all

related standards (e.g. EN 60079-17 „Inspection and maintenance of

electrical installations in hazardous areas (other than mines)“ ).

POSSIBLE EXPLOSION HAZARD

Service or replacement of safety related components or requiring to open

the instrument are permitted only if no hazardous atmosphere is present

and both the instrument and connected circuitry are de-energized!

Depending on the local regulation this may require a competent hot work

supervisor to issue a hot work permit.

POSSIBLE EXPLOSION HAZARD

After maintenance or replacement of parts concerning explosion protection

an authority on explosion protection has to verify that the analyzer still meets

the requirements for explosion protection before it is switched on again.

Parts essential for explosion protection must not be repaired, they must be

replaced if defective!

4 Maintenance

The authority has to issue a certicate for this and/or attach a test label to

the equipment before startup after maintenance or replacement of parts.

Emerson Process Management GmbH & Co. OHG 4-1

Page 44

Emerson Process Management GmbH & Co. OHG4-2

X-STREAM FD

Instruction Manual

HASADE-IM-EX

07/2007

FLAMMABLE GASES - POSSIBLE EXPLOSION HAZARD

Leaks may cause explosion when measuring ammable gases!

When measuring ammable gases it is recommended to perform a leak test

on all gas paths, connections and components before startup or applying

power. Leak tests should be carried out on a 2 month‘s regular basis and

after repair/maintenance.

See the analyzer instruction manual for instructions on how to carry out

leak tests.

4 Service and Maintenance

HAZARDOUS GASES

When measuring ammableand/or toxic gases it is recommended to purge

the system with air or an inert gas, e.g. nitrogen, prior to opening the gas

paths.

Violation may cause an explosion and/or personal injury or death!

POSSIBLE EXPLOSION HAZARD

Modications affecting the integrity of type of protection (e.g. afxing

addtional threads, replacing the ame arrestors by other model) are NOT

PERMITTED!

Violation may cause an explosion and/or personal injury or death!

Page 45

Instruction Manual

HASADE-IM-EX

07/2007

4-1 Verications and Tests after Service or Maintenance

4-1 Verications and Tests after Service or Maintenance

Modications made on the electrical apparatus affecting the integrity of the type of protection or the temperature of the apparatus shall

be permitted only if the modied apparatus is

resubmitted to a testing station.

In the case of repairs affecting the type of

protection, the parts which have been repaired should be subjected to new routine

verications and tests. These tests need not

necessarily be made by the manufacturer.

4-1-1 Routine Tests

X-STREAM FD

The following tests shall be performed on a

regular basis:

4-1-1-1 Visual Inspection

The instrument shall be visually checked for

damages to the enclosure and external analyzer components.

4-1-1-2 Tests on Flame Arrestors

Depending on the application ame arrestors

should be checked periodically according

the information given in the ame arrestors

instruction manual.

4 Maintenance

Emerson Process Management GmbH & Co. OHG 4-3

Page 46

Emerson Process Management GmbH & Co. OHG4-4

X-STREAM FD

Instruction Manual

HASADE-IM-EX

07/2007

4-2 Replacement of Parts

4-2 Replacement of Parts

POSSIBLE EXPLOSION HAZARD !

Replacement of parts found defective is permitted only by using original

parts!

Violation voids the approvals and may cause explosions!

Parts beside the cast enclosure, the safety of the X-STREAM FD relies on:

Cable glands, standard

for ATEX approved analyzers

Type: ADL 1F ISO 20 No. 05 by CAPRI

LCIE 97 ATEX 6006 X

Compound Cable glands (optional)

for ATEX approved analyzers

Type: to be selected for the installed cable

and with ATEX (EU) or suitable local approval

(outside EU)

Male thread: M20 x 1.5

Available from several manufacturers, e.g.

type CR-X by PeppersCable Glands Limited

Cable entries stopping plugs

for ATEX approved analyzers

Type: 120209 by CAPRI

Male thread: M20 x 1.5

98 ATEX 0001U

Metric-to-NPT adapters

for CSA approved analyzers

Any ameproof certied type

Male thread: M20 x 1.5

Female thread: 1/2“ or 3/4“ per request

e.g.

Type: AD-U series by Redapt Ltd.

CSA certicate 1248014

Page 47

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

4-2 Replacement of Parts

Cable entries stopping plugs

for CSA approved analyzers

Any ameproof certifed type

Male thread: M20 x 1.5

e.g.

Type: PD-U by Redapt Ltd.

CSA certicate 1248014

Flame arrestors

Type: FA 01, FA 02, FA 03

by EMERSON PROCESS MANAGEMENT

FTZU 06 ATEX 0164

Enclosure screws

Material: stainless steel A2-70

Thread: M16 x 45 ISO 4762 A2

Thread locking adhesive

Type: ML® 5249 by DELO

Internal battery (soldered to electronics board,

not user replaceable)

Type: SL 750 by Tadiran Batteries GmbH

System: SOCl2 / Li

Nom. voltage: 3.6 VNom. voltage: 3.6 V

IEC 60086-1 type E cell

4 Maintenance

Emerson Process Management GmbH & Co. OHG 4-5

Page 48

X-STREAM FD

Instruction Manual

HASADE-IM-EX

07/2007

4-2 Replacement of Parts

Emerson Process Management GmbH & Co. OHG4-6

Page 49

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

Appendix

This chapter contains

EC Declaration of Conformity A-1, page A-2

ATEXECTypeExaminationCerti.cate A-2, page A-3

Cable gland ADL 1F installation instruction A-3, page A-7

Block diagram A-4, page A-8

Assignment of Terminals and Socket A-5, page A-9

Appendix

Emerson Process Management GmbH & Co. OHG A-1

Page 50

Emerson Process Management GmbH & Co. OHGA-2

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

A-1 EC Declaration of Conformity

A-1 EC Declaration of Conformity

Page 51

Instruction Manual

HASADE-IM-EX

07/2007

A-2ATEXECTypeExaminationCerticate

A-2 ATEXECTypeExaminationCerti.cate

X-STREAM FD

Appendix

Emerson Process Management GmbH & Co. OHG A-3

Page 52

Emerson Process Management GmbH & Co. OHGA-4

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

A-2ATEXECTypeExaminationCerticate

Page 53

Instruction Manual

HASADE-IM-EX

07/2007

X-STREAM FD

A-2ATEXECTypeExaminationCerticate

Appendix

Emerson Process Management GmbH & Co. OHG A-5

Page 54

X-STREAM FD

Instruction Manual

HASADE-IM-EX

07/2007

Emerson Process Management GmbH & Co. OHGA-6

Page 55

Instruction Manual

HASADE-IM-EX

07/2007

A-3 Cable gland ADL 1F installation instruction

X-STREAM FD

A-3 Cable Gland Installation Instruction

(reprinted with the

permission of

Cooper Industries

Cooper Menvier Division

CAPRI-CODEC sas. )

Appendix

Emerson Process Management GmbH & Co. OHG A-7

Page 56

X-STREAM FD

A-4 Block diagram X-STREAM FD

Instruction Manual

HASADE-IM-EX

07/2007

A-4 Block Diagram

Emerson Process Management GmbH & Co. OHGA-8

Page 57

Instruction Manual

HASADE-IM-EX

07/2007

A-5 Assignment of Terminals and Socket

56789101112131415 1234

A-5 Assignment of Terminals and Socket

Terminal 16

Terminal 17

Terminal 14

Terminal 15

Terminal 12

Terminal 13

Terminal 11

Terminal 9

Terminal 10

Terminal 7

Terminal 8

Terminal 5

Terminal 6

Terminal 3

Terminal 4

Terminal 1

Terminal 2

X-STREAM FD

Appendix

Terminal RS 232 RS 485/2d RS 485/4d

11 Common Common Common

12 RXD not used RXD0

13 TXD not used RXD1

14 not used D1 TXD1

15 Common D0 TXD0

Modbus interface

Fig. A-1: Terminals strip 1

Pin 1 Pin 8

Fig. A-4: Ethernet connector for Modbus

Terminal Signal

5

6

7

8

9

10

Failure COM

Failure NO

Maintenance, off-spec COMMON

Maintenance, off-spec NO

Function check COMMON

Function check NO

Relay outputs

Pin Signal

1 TX+

2 TX 3 RX+

6 RX andere nicht

verwendet

Terminal Signal

1 (+) 4 (0) - 20 mA, ch 1

2 (-) 4 (0) - 20 mA, ch 1

3 (+) 4 (0) - 20 mA, ch 2

4 (-) 4 (0) - 20 mA, ch 2

Burden: RB ≤ 500 Ω

Analog outputs

DIG inputs COMMON

Fig. A-2: Terminals strip 2

Fig. A-3: Power terminals

Valve V2

DIG outputs COMMON

Ch1 & Ch2: Zero cal.

Ch1: Span cal.

Ch2: Span cal.

Valve V4

Valve V1

Valve V2

Open sample valve, close all, or pump on/off

Digital Inputs Digital Outputs

Protective Earth PE

Valve V4

Valve V1

Ch2: threshold 1

Ch2: threshold 2

Sample valve

Ch1: threshold 1

Ch1: threshold 2

*)

*)

With optional range switching this

output is used as range indicator

( X-STREAM series instruction

manual, section 7-7-5, page 7-58)

Line L

Neutral N

Note!

Line and neutral terminals with builtin fuse holders

Emerson Process Management GmbH & Co. OHG A-9

Page 58

X-STREAM FD

Instruction Manual

HASADE-IM-EX

07/2007

Emerson Process Management GmbH & Co. OHGA-10

Page 59

Instruction Manual

HASADE-IM-Ex

04/2007

X-STREAM FD

Page 60

X-STREAM FD

WORLD HEADQUARTERS

ROSEMOUNT ANALYTICAL EUROPE

Emerson Process Management

GmbH & Co. OHG

Industriestrasse 1

63594 Hasselroth

Germany

T 49 6055 884 0

F 49 6055 884209

Emerson Process Management

Rosemount Analytical Inc.

6565 P Davis Industrial Parkway

Solon, OH 44139 USA

T 440.914.1261

Toll Free in US and Canada 800.433.6076

F 440.914.1271

e-mail: gas.csc@EmersonProcess.com

www.raihome.com

Instruction Manual

HASADE-IM-Ex

04/2007

GAS CHROMATOGRAPHY CENTER

AND LATIN AMERICA

Emerson Process Management

Rosemount Analytical Inc.

11100 Brittmoore Park Drive

Houston, TX 77041

T 713 467 6000

F 713 827 3329

EUROPE, MIDDLE EAST AND AFRICA

Emerson Process Management

Shared Services Limited

Heath Place

Bognor Regis

West Sussex PO22 9SH

England

T 44 1243 863121

F 44 1243 845354

ASIA-PACIFIC

Emerson Process Management

Asia Pacic Private Limited

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T 65 6 777 8211

F 65 6 777 0947

e-mail: analytical@ap.emersonprocess.com

© 2007 Emerson Process Management GmbH & Co. OHG

Loading...

Loading...