Page 1

www.emerson.com

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 1 of 264

00809-0100-3975. Rev AB Instruction Manual Page 1 of 264

April 2021

04/2021

Page 2

Emerson Automation Solutions

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 2 of 264

Rosemount

Process Gas Analyzer Center

Industriestrasse 1

63594 Hasselroth

Germany

Telephone: +49 6055 884 0

Fax: +49 6055 884 209

E-mail: gas.csc@emerson.com

Internet: www.emerson.com 3

edition, 04/2021

Original document

Emer-43755-DE, 1, en_US

rd

© 2021

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer2

Page 3

Supplemental directives

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 3 of 264

00809-0100-3975. Rev AB Instruction Manual Page 3 of 264

April 2021

Essential instructions

Emerson Rosemount designs, manufactures and

tests its products to meet national and international standards. Because the products are

sophisticated technical products, you MUST

properly install, use, and maintain them to ensure

they continue to operate within their normal specifications. The following instructions MUST be

adhered to and integrated into your safety program when installing, using and maintaining

Emerson Process Management (Rosemount

Analytical) products. Failure to follow the proper

instructions and operating the Analyzer outside

the boundries specified in this manual may cause

any one of the following situations to occur: Loss

of life; personal injury; property damage; damage

to this instrument; and warranty invalidation.

n Read all instructions prior to installing, oper-

ating, and servicing the product.

n If you do not understand any of the instruc-

tions, contact your Emerson Automation Solutions (Rosemount) representative for clarification.

n Follow all warnings, cautions, and instructions

marked on and supplied with the product.

n Inform and educate your personnel in the

proper installation, operation, and maintenance of the product.

n Install your equipment as specified in the

Installation Instructions of the appropriate

Instruction Manual and per applicable local

and national codes.

n Connect all products to the proper electrical

power and gas supplies.

n To ensure proper performance, use qualified

personnel to install, operate, update, program,

and maintain the product.

n When replacement parts are required, ensure

that qualified personnel use replacement parts

specified by Emerson Process Management

(Rosemount Analytical). Unauthorized parts

and procedures can affect the product’s performance, place the safe operation of your

process at risk, and VOID YOUR WARRANTY.

Non-original substitutions may result in fire,

electrical hazards, or improper operation.

n Ensure that all equipment doors are closed

and protective covers are in place, except

when maintenance is being performed by

qualified persons, to prevent electrical shock

and personal injury.

The information contained in this document is

subject to change without notice.

X-STREAM and IntrinzX are trademarks of one of

the Emerson group of companies.

All other trademarks are property of their respective owners.

Copyright

The contents of this manual are protected by

copyright. Use of these contents is permissible

within the framework of use of the device. Any

other use is not permitted without the written

per-mission of the manufacturer.

Use of open source software

This product firmware includes open-source

software components, distributed under various

licenses, such as the GNU General Public

License and the GNU Lesser General Public

License. The source code of these components,

along with their licensing and copyright

information, as well as configuration and

compilation scripts and instructions is delivered

in a data medium alongside the product.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 3

Page 4

Table of contents

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 4 of 264

Table of contents

1 Safety Instructions................................................................................................................................ 8

1.1 Symbols Used On and Inside the Unit............................................................................................ 8

1.1.1 Housing Signage.......................................................................................................................... 8

1.1.2 Signage Below Covers............................................................................................................... 11

1.2 Symbols Used in this Manual........................................................................................................ 12

1.3 Intended Use Statement............................................................................................................... 13

1.4 Authorized Personnel.................................................................................................................... 14

1.5 Personal Protective Gear.............................................................................................................. 15

1.6 Residual Risks.............................................................................................................................. 15

1.6.1 Unspecified Hazard.................................................................................................................... 15

1.6.2 Electrical Hazard........................................................................................................................ 16

1.6.3 Chemical Hazard........................................................................................................................ 16

1.6.4 Fire and Burns Hazards............................................................................................................. 17

1.6.5 Mechanical Hazards................................................................................................................... 17

1.7 On the use of figures..................................................................................................................... 18

2 Technical Description......................................................................................................................... 19

2.1 Tools and Consumable Materials.................................................................................................. 19

2.2 Inputs and Outputs........................................................................................................................ 20

2.2.1 Inputs and Outputs: General Information................................................................................... 20

2.2.2 Inputs and Outputs: Data Connectors........................................................................................ 20

2.2.3 Inputs and Outputs: Gas Connectors......................................................................................... 35

2.2.4 Electrical connectors.................................................................................................................. 36

2.3 Controls, Signals and Display....................................................................................................... 36

3 Technical Data..................................................................................................................................... 42

3.1 Housing Data, Connection Data, Environmental Conditions and Emissions................................ 43

3.1.1 Housing Data............................................................................................................................. 43

3.1.2 Performance Specifications....................................................................................................... 44

3.1.3 Power Connection Data............................................................................................................. 45

3.1.4 Gas Supply Data........................................................................................................................ 46

3.1.5 Interface Data............................................................................................................................. 48

3.1.6 Enviromental Conditions............................................................................................................ 49

3.1.7 Emissions................................................................................................................................... 49

3.2 Spare parts Data........................................................................................................................... 51

3.2.1 Storage Battery Data.................................................................................................................. 51

3.2.2 Electrical Fuse Data................................................................................................................... 52

4 Measuring Principles.......................................................................................................................... 53

5 Startup.................................................................................................................................................. 55

5.1 Introduction................................................................................................................................... 55

5.2 Front Panel Elements.................................................................................................................... 56

5.2.1 Display....................................................................................................................................... 56

5.2.2 Status Line and Text Message Line........................................................................................... 56

5.2.3 Keys........................................................................................................................................... 57

5.3 Software........................................................................................................................................ 59

5.3.1 Access Levels and Codes.......................................................................................................... 60

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer4

Page 5

Table of contents

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 5 of 264

5.3.2 Special Messages...................................................................................................................... 61

5.4 Powering Up.................................................................................................................................. 62

5.4.1 Boot Sequence........................................................................................................................... 63

5.4.2 Measurement Display................................................................................................................ 63

5.5 Selecting the Language................................................................................................................ 63

5.6 Checking the Settings................................................................................................................... 64

5.6.1 Installed Options........................................................................................................................ 65

5.6.2 Configuring the Display.............................................................................................................. 65

5.6.3 Calibration/Validation Setup....................................................................................................... 66

5.6.4 Setting the Analog Outputs........................................................................................................ 68

5.6.5 Setting Concentration Alarms.................................................................................................... 72

5.6.6 Backup the Settings................................................................................................................... 73

5.7 Performing a Calibration............................................................................................................... 74

6 User Interface and Software Menus.................................................................................................. 75

6.1 Symbols and Typographical Conventions..................................................................................... 75

6.2 Menu System................................................................................................................................ 76

6.2.1 Switching On.............................................................................................................................. 79

6.2.2 Control Menu.............................................................................................................................. 80

6.2.3 Setup Menu................................................................................................................................ 92

6.2.4 Status Menu............................................................................................................................. 149

6.2.5 Info Menu................................................................................................................................. 158

6.2.6 Service Menu........................................................................................................................... 159

7 Installation......................................................................................................................................... 161

7.1 Safety on Installation................................................................................................................... 161

7.2 Assembly, Location and Mounting Requirements....................................................................... 161

7.3 Transport..................................................................................................................................... 162

7.4 Unpacking................................................................................................................................... 162

7.4.1 Scope of Delivery..................................................................................................................... 162

7.4.2 Disposing of Packaging............................................................................................................ 163

7.5 Mechanical installation................................................................................................................ 163

7.5.1 Connecting Rack Mount Brackets............................................................................................ 163

7.5.2 Connecting Housing Feet......................................................................................................... 164

7.6 Gas Conditioning......................................................................................................................... 165

7.7 Connecting gas lines................................................................................................................... 166

7.8 Establishing Electrical Connection.............................................................................................. 166

7.9 Notes on Wiring........................................................................................................................... 167

7.9.1 Connecting Shields.................................................................................................................. 167

7.9.2 Wiring different types of loads.................................................................................................. 169

8 Continuous operation....................................................................................................................... 171

8.1 How to measure NO.................................................................................................................... 171

8.2 How to measure NOx.................................................................................................................. 171

9 Maintenance and Other Procedures................................................................................................ 174

9.1 Safety on Maintenance............................................................................................................... 174

9.2 Maintenance Overview................................................................................................................ 174

9.3 Preparing Maintenance............................................................................................................... 175

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 5

Page 6

Table of contents

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 6 of 264

9.3.1 Purging Gas Lines.................................................................................................................... 175

9.3.2 Making Measuring Unit Accessible.......................................................................................... 176

9.4 Cleaning the analyzer................................................................................................................. 177

9.5 Exchanging Converter................................................................................................................. 178

9.6 Exchanging Power Connector Fuse............................................................................................ 184

9.7 Exchanging Power Supply Fuses............................................................................................... 185

9.8 Exchanging Housing Filter.......................................................................................................... 186

9.9 Performing a Leakage Test......................................................................................................... 187

9.10 Fine Adjusting Pressure Measurements................................................................................... 188

9.11 Saving and Restoring Configuration Data Sets......................................................................... 189

9.12 Handling Log Files.................................................................................................................... 192

9.12.1 Configuring Log Files............................................................................................................. 193

9.12.2 Exporting log files................................................................................................................... 193

9.13 Accessing via Web Browser...................................................................................................... 194

9.13.1 Connecting via Network......................................................................................................... 194

9.13.2 Connecting via Crossover Cable............................................................................................ 194

10 Calibration and Validation Procedures........................................................................................... 196

10.1 Safety on Calibration and Validation......................................................................................... 196

10.2 Information on Calibration and Validation................................................................................. 196

10.3 Preparing Calibration or Validation............................................................................................ 197

10.4 Performing Manual Calibration and Validation.......................................................................... 199

10.4.1 Performing Manual Calibration............................................................................................... 199

10.4.2 Performing Manual Validation................................................................................................ 201

10.5 Performing Non-Manual Calibration.......................................................................................... 202

10.5.1 Supplying Calibration and Validation Gases.......................................................................... 202

10.5.2 Assigning Digital Outputs to External Valves......................................................................... 203

10.5.3 Valve Assignment for Valve Supported Calibrations and Validations..................................... 205

10.5.4 Performing Advanced Calibration.......................................................................................... 205

10.5.5 Performing Remote Calibration/Validation............................................................................. 207

10.5.6 Performing Unattended Calibration/Validation....................................................................... 208

10.6 Performing NO- and NOX Calibration........................................................................................ 210

11 Troubleshooting................................................................................................................................ 212

11.1 Troubleshooting Safety.............................................................................................................. 212

11.2 Possible Wear-Related Replacements...................................................................................... 213

12 Service Information........................................................................................................................... 214

12.1 Customer Service...................................................................................................................... 214

13 Glossary............................................................................................................................................. 215

14 Index................................................................................................................................................... 216

Appendix............................................................................................................................................ 217

A Potentially Poisonous Substances ................................................................................................ 218

B PLC Quick Reference Card ............................................................................................................. 219

C

Spare Parts List .................................................................................................................................

D

Safety Data Sheets ............................................................................................................................

E

Troubleshooting .................................................................................................................................

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer6

Page 7

Table of contents

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 7 of 264

E.1

XE-related Troubleshooting ........................................................................................................

E.2

CLD-related Troubleshooting ......................................................................................................

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 7

Page 8

Safety Instructions

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 8 of 264

1 Safety Instructions

1.1 Symbols Used On and Inside the Unit

1.1.1 Housing Signage

Nameplate

All configurations

Fig. 1: Nameplate

1 Product type

2 Channel 1: Measurement range (ppm)

The nameplate (Fig. 1) is located on the rear panel. It contains information about the exact configuration of

the analyzer.

Back panel

All configurations

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer8

3 Channel 1: Maximum measurement range (ppm)

4 Serial number

Page 9

Safety Instructions

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 9 of 264

Fig. 2: Signage (backpanel)

On the back panel the signage shown in (Fig. 2) indicates dangerously hot surfaces, rotating fans and a separate connector for protective earth.

Sign Meaning

Hot Surfaces!

First turn off the device and let it cool down for

approx. 30 min before touching the marked parts.

Possible contact with Electrictity!

Never touch live parts (e. g. damaged cables) and

only remove any covers on the backpanel as

described in this manual.

A

Rotating Fan!

Never insert body parts or other objects into the

marked fan-openings.

B

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 9

Page 10

Safety Instructions

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 10 of 264

Sign Meaning

Equipotential bonding connector.

On-site equipotential bonding should be connected

at the marked position.

Top Cover

All configurations

Fig. 3: Signage (top cover)

On the backside of the top cover a sign with a warning regarding a potential electrical hazard (Fig. 3, top

right) is attached.

Sign Meaning

Electrical Shock!

Always disconnect power before opening the

housing.

Never open the top cover or any panel with power

plugged in.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer10

Page 11

1.1.2 Signage Below Covers

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 11 of 264

Module Cover

All configurations

The module cover is only visible after removing the top cover.

Safety Instructions

Fig. 4: Signage (module cover)

On the module cover, a sign showing a schematic drawing of the XECLD Personality Board at the front end

of the module with marked connectors is attached.

The upper part of the displayed circuit board is accessible after removing the module cover.

Converter Cover and Ozonator

All configurations

Converter cover and ozonator are only visible after removing the module cover.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 11

Page 12

Safety Instructions

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 12 of 264

Fig. 5: Signage (converter cover)

After removing the module cover, the converter cover becomes accessible.

Signage on the ozonator indicates high voltage (Fig. 5/left). Signage on the converter cover indicates hot

surfaces (Fig. 5/right).

Sign Meaning in product context

High Voltage!

The ozonator works with high voltage which can

result in electric shocks.

Never open housing with analyzer connected to

power supply.

Hot Surfaces!

Converter case may heat up to 75 °C (170 °F).

Always wear safety gloves when handling converter

case or surrounding parts.

Measure temperature and let the surface cool down

before touching.

1.2 Symbols Used in this Manual

Safety Instructions

Safety instructions in this manual are identified by

symbols. The safety instructions are introduced

by signal words which express the extent of the

hazard.

DANGER!

DANGER indicates a hazardous situation

which, if not avoided, will result in death or

serious injury.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer12

Page 13

WARNING!

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 13 of 264

WARNING indicates a hazardous situation

which, if not avoided, could result in death

or serious injury.

CAUTION!

CAUTION indicates a hazardous situation

which, if not avoided, could result in minor

or moderate injury.

NOTICE!

NOTICE indicates important, non-safetyrelated information, such as property and

environmental damage.

Safety Instructions

To highlight procedural instructions, results, lists,

references, and other elements, the following

identifiers are used in this manual:

Identifier Explanation

Step-by-step procedural

instructions

ð

[Button] Controls or signals (e.g., dis-

“Display” Screen elements (e.g., buttons,

Results of procedural steps

References to sections of this

manual and to other applicable

documents

Lists without a defined

sequence

play elements or signal lamps)

assignment of function keys)

Safety Instructions in Procedural Instructions

Safety instructions can refer to specific, individual

procedural instructions. Such safety instructions

are embedded in the procedural instructions so

that they do not interrupt the reading flow when

performing the activity. The signal words

described above are used.

Example:

WARNING!

Check temperature before

touching heater jacket. If too hot

let it cool down!

Carefully pull out heater jacket in the direction of the rear panel.

Tips and Recommendations

This symbol highlights useful tips and recommendations, as well as useful information for efficient and fault-free operation.

1.3 Intended Use Statement

Intended Use

The X-STREAM Enhanced Chemiluminescence

Detector (XECLD) is an analyzer intended for

measurement of NO/NO2/NOx concentrations in

exhaust fumes and clean gas mixtures.

The analyzed exhaust fumes may come from all

possible types of power plants with burning processes or from combustion engines.

Furthermore, the XECLD can be used for gas

purity measurements.

In principle, the XECLD is fit for analyzing nonflammable gases and can be set up as a tabletop

unit or as a rackmount device.

The XECLD may only be supplied with power

and gases and be operated in surroundings as

specified in this manual (Ä Chapter 3.1 “Housing

Data, Connection Data, Environmental Conditions and Emissions” on page 43).

The Analyzer is intended for commercial use in

industrial or non-industrial sectors. The intended

use is limited to measuring and testing where

usage in laboratories is included.

Identifiers in this Manual

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 13

Page 14

Safety Instructions

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 14 of 264

Dangerous Misuse

WARNING!

Danger of injury and material damage

due to misuse!

If the device is not used as intended, dangerous situations may occur. Material

assets may be damaged.

– Never use in unventilated locations.

– Only supply Analyzer with gases as

Ä

described in this manual

Chapter

3.1.4 “Gas Supply Data” on page 46.

– Make sure that gas connections are

never unintentionally swapped.

– Always check gas connections and tub-

ings for leakage as described in this

manual Ä Chapter 9.9 “Performing a

Leakage Test” on page 187.

– Only operate the Analyzer within the

boundaries specified in this manual

Ä

Chapter 3 “Technical Data”

on page 42.

– Always check additional operating

boundary restrictions due to individually

ordered configurations.

– The Analyzer may only be operated

indoors in water and dust-protected

environments. Use only in explosionprotected areas.

1.4 Authorized Personnel

Special Training

Authorized personnel who install, operate,

service and maintain the analyzer need to be fully

instructed and trained. Authorized personnel who

install, operate, service and maintain the analyzer

need to be fully instructed and trained by the

qualified personnel of the operating company and

the manufacturer.

Analyzer operator

The Analyzer operator is qualified to perform

basic tasks that do not require the opening of the

Analyzer housing or the use of tools.

The Analyzer operator is trained in safety matters, on-site special features, regulations on-site

and basics of gas measuring in a way that meets

legal and other official requirements to work with

the Analyzer.

Due to personality, experience and education, the

Analyzer operator is capable of working in such a

way as to keep all personnel in the industrial or

laboratory environment safe.

Authorized service personnel

Authorized service personnel are trained and

authorized by Emerson Rosemount to perform

specific service related tasks on the Analyzer.

Authorized service personnel have been extensively trained to understand the Emerson exhaust

measuring product lines and have acquired deep

knowledge about local safety regulations and

technical standards during previous roles or

training. The knowledge and experience gained

enables these authorized service personnel to

identify and avoid potential danger for themselves and others.

Laboratory researchers

Laboratory researchers have a locally recognized

university diploma (Bachelor’s degree equivalent

or higher) qualifying them to analyze automotive

and industrial exhausts. Laboratory researchers

have, in the scope of their activities, already

gained experience in working with technical laboratory equipment (measuring and monitoring

devices). Laboratory researchers are familiar with

locally applicable safety regulations and guidelines for working in a laboratory setting.

Due to their professional experience and their

analytical, methodological and technical knowledge gained through their studies, laboratory

researchers are able to safely perform the following tasks with valid results:

Required Qualifications

TThe following job titles will appear in this manual

allocated to procedures for which they are qualified:

Always make sure that only personnel that meet

the special requirements as described in the following paragraphs are assigned to the described

tasks.

n Erecting safe measurement setups with regard

to the state-of-the-art.

n Designing, evaluating and interpreting a series

of tests.

n Adapting parameters of the measurement

setup in a targeted manner.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer14

Page 15

Safety Instructions

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 15 of 264

The Analyzer-specific knowledge and skills of the

laboratory researcher exceed or at least match

those of an on-site service technician. Therefore

Laboratory researchers may perform all Analyzer-related tasks, an on-site service technician

is required for.

On-site service technician

The on-site service technician is assigned by the

operator to perform service tasks that may

involve opening the Analyzer housing.

On-site service technicians are also capable of

performing comprehensive repair work which

demands manual dexterity and a high level of

mechanical or technical qualification. This qualification enables the on-site service technician to

for example handle fasteners, sheet metal parts,

electrical components and fragile components.

On-site service technicians are trained, have the

expertise, and have familiarity with all applicable

regulations to be able to complete the tasks

entrusted to them. They are also able to independently, detect and avoid any possible hazards

at the Analyzer itself or operation site.

System integrator

Systems integrators are trained specialists, who

are familiar with the interfaces provided by the

Analyzer and its specification. System integrators

are allowed to perform each and every action on

the device in this manual and are able to connect

the device to appropriate external systems for

processing the counting data.

System integrators are familiar with the locally

applicable safety regulations and guidelines for

working in an industrial environment (for example

a power plant or incineration facility) setting.

1.5 Personal Protective Gear

Mandatory Protective Gear on Site

Only Analyzer-specific stipulations can be given

in this manual regarding the protective equipment, since specific regulations on site are not

known.

The required special protective equipment for

working on site must be worn in addition to the

protective equipment described in this manual. If

the protective equipment described in this

manual (for example safety gloves) is the same

as in the operating instructions of other manufacturers, always wear the version which guarantees

the higher standard of safety.

Description of Protective Equipment

The following list describes all protective equipment that must be worn for working with the Analyzer. At the introduction of every step-by-step

instruction, the specific protective equipment that

is to be worn is listed.

Safety gloves

Safety gloves are designed to protect the hands

from friction, abrasions, puncture wounds or

deeper wounds as well as coming into contact

with hot surfaces.

Safety shoes

Safety shoes protect against injuries of the feet

due to falling or pointed objects, as well as

against slipping.

Safety shoes exhibit the following characteristics:

n High skid resistance

n Steel caps as toe protection

n Strong upper material

n Puncture-resistant soles

Safety shoes must satisfy at least the applicable

requirements of protection class 3 according to

ISO 20345 or the requirements of other local regulations such as ASTM F2413-1

1.

1.6 Residual Risks

1.6.1 Unspecified Hazard

Unsuitable spare parts

WARNING!

Danger of injuries when using unsuitable spare parts!

If unsuitable spare parts are used, unforseeable risks may arise. Fire, electrical

shocks, gas poisonings, cuts or other injuries may be the result if unsuitable spare

parts are used.

– Only purchase original spare parts from

the manufacturer.

– Order only and exactly the spare parts

listed on the spare parts list in this

manual or a spare parts list provided by

the manufacturer.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 15

Page 16

Safety Instructions

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 16 of 264

1.6.2 Electrical Hazard

Electrical Shock

DANGER!

Risk of death due to electric voltage!

The Analyzer works from a mains voltage.

Incorrectly handling the Analyzer or connecting cables can result in a fatal electrical shock.

– Do not operate Analyzer without secure

covers.

– Do not open Analyzer whilst Analyzer is

energized.

– Do not operate with damaged cables.

Replace damaged cables immediately.

– Do not perform any tasks on mains-

voltage-components. Use licensed electricians only!

– Never operate without a protective

earth.

– Do not replace cables or other electrical

components of the Analyzer on your

own. Contact manufacturer.

– Never connect the power supply to any

voltage other than that specified within

Ä

the technical data

“Power Connection Data” on page 45.

High Voltage Components

WARNING!

Risk of electrical shock on high voltage

components!

The Ozonator works with high voltages.

Touching the energized ozonator may

result in an electric shock.

– Do not operate Ozonator without secure

covers.

– Only allow authorized service personnel

to perform tasks on the ozonator.

– Never open any cover while the Ana-

lyzer is connected to a power supply.

Chapter 3.1.3

Wrong Supply Voltage

NOTICE!

Risk of damaged Analyzer when using

wrong supply voltage!

If the Analyzer is supplied with a voltage

other than specified in this manual

(Ä Chapter 3.1.3 “Power Connection Data”

on page 45) it may be damaged irreparably.

– Only connect supply voltages as speci-

fied in technical data.

1.6.3 Chemical Hazard

Harmful Gases

WARNING!

Risk of poisoning by inhalation of

ozone or exhaust fumes!

The Analyzer is supplied with exhaust

fumes and generates Ozone. Ozone is

harmful to health and should not be

inhaled in concentrations above the officially specified limits. Exhaust fumes may

be poisonous.

– Only use the Analyzer in locations that

have adequate ventilation that meet the

local legal requirements.

– Test the gas tightness as described in

this manual.

– Do not operate the Analyzer with a

defective housing fans. Replace defective fan immediately.

– Treat exhaust gases only according to

local regulations.

– Purge analyzer with nitrogen (N2) before

opening housing and gas connections.

– Only open unpressurized Analyzers.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer16

Page 17

Safety Instructions

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 17 of 264

1.6.4 Fire and Burns Hazards

Electrical Fire

WARNING!

Fire hazard due to use of unsuitable

fuses!

If unsuitable fuses are used or fuses are

bridged, electrical fires may occur.

– Only use fuses as described in this

manual.

– Never bridge fuses. Never operate

without fuses.

Flammable Gases

WARNING!

Risk of fire and explosion injuries!

If the Analyzer is supplied with flammable

gases fire and explosions may occur.

– Never supply the Analyzer with flam-

mable gases.

– Always purge gas paths as described in

this manual.

Heated Components

WARNING!

Risk of burns due to temperatures

exceeding specification!

Certain components can reach very high

temperatures on their surfaces. Contact

with these surfaces may cause burns:

Converter (Inner parts): 500 °C (930 °F)

Converter (Housing): 80 °C (176 °F)

Gas-Connectors: 75 °C (170 °F)

Module cover (top side): 90 °C (195 °F)

– Never operate with housing open.

– Never operate with a defective housing

fan.

– Always switch off first and allow to cool

for 60 minutes. Only when the Analyzer

has cooled down:

– Touch top cover.

– Open housing.

– Carry out work on the gas connec-

tions

– Follow the instructions in this manual

exactly for activities inside the housing.

– Observe signage indications of hot sur-

faces.

1.6.5 Mechanical Hazards

Falling Objects

WARNING!

Risk of injuries caused by falling

objects!

If the Analyzer or any components fall (for

example caused by mishandling), injuries

may result.

– Always wear additional protective gear

as described in this manual.

– Handle Analyzer and components with

care.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 17

Page 18

Safety Instructions

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 18 of 264

Sharp Edges and Corners

CAUTION!

Risk of injuries at edges and corners!

The rack mounting brackets protrude and

bumping them may cause injuries; especially in transit. During activities inside the

housing, contact with sharp-edged components is possible.

– When in transit, remove the mounting

brackets.

– Only carry out activities within the

housing in accordance with the instructions in this manual.

Finger Injuries Caused by Fan

CAUTION!

Risk of injury to fingers on the housing

fan!

If the finger protection is not reinstalled

after working on the housing fan, crushing

and impact injuries may result if fan is

reached into.

– Always install finger protection as

described.

– Never reach into the fan.

1.7 On the use of figures

Product variants

The Analyzer is available in different variants and

configurations. In this manual, a distinct configuration is shown which illustrates all tasks or information provided. In some sections however, the

Analyzer configuration may differ. This will be

more common in gas connector illustrations (for

example, the existence of a purge connector or

the connector type), the usage of optional I/Ocards and screw terminals, and in the distinction

between rack mounting or the use of stand feet.

Please contact customer service if unsure some

information does not apply to your configuration.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer18

Page 19

2 Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 19 of 264

Technical Description

2.1 Tools and Consumable Materials

Tools

To work with the Analyzer, use a set of standard

tools (for example, screwdrivers (cross-head and

flat-head) and wrenches.

Additionally the following special tools are

needed:

External hexagon nut with extension (5.5 mm)

The external hexagon nut with extension enables

to unscrew hexagon socket nuts in an distance of

approx. 20 cm (8 in).

The width across flat-head screwdrivers must be

approx. 5.5 mm (0.22 in).

Consumable Materials

The following consumable materials are needed.

Do not use other materials than these described:

Materials:

Converter test gas supply

n

Detergents

n

Leakage test gas supply (N2 or He)

n

Replacement fuse

n

Replacement housing filter

n

Span gas supply

n

USB storage device

n

Zero gas supply (N2)

n

Air-supply gas

n

Air-supply gas

Air-supply gas is pressurized or synthetic air and

meets the technical requirements Ä Chapter

3.1.4 “Gas Supply Data” on page 46.

Do not use pure oxygen as air-supply gas.

Converter test gas supply

Converter test gas has a known concentration of

NO2 (< 500 ppm) and meets the technical

requirements.

A supply of converter test gas can be connected

to the sample-in-line independently from sample

gas or air supply.

Detergents

The detergent is not chemically aggressive, is

free of solvents and does not contain any hydrocarbons.

Leakage test gas supply (N2 or He)

A supply of test gas (N2 or He) which can be connected to the exhaust line independently from

sample gas or air supply (e. g. gas bottle).

The leakage test gas supply must be able to at

least build up pressure of 1,034 hPa (15 psig)

and must provide an option to shut down so that

connected gas lines remain under pressure.

Replacement fuse

The replacement fuse matches the description

and the technical data stated in the spare parts

Ä

list in this manual

Replacement housing filter

The replacement housing filter is available at

Emerson Rosemount.

The filter fits into the seat at the air inlet at the

rear of the housing and meets the requirements

e. g. considering filtered particulate size.

Use replacement filters as listed on the spare

parts list only.

Span gas supply

Span gas has a known concentration of NO and

meets the technical requirements Ä Chapter

3.1.4 “Gas Supply Data” on page 46.

A supply of span gas can be connected to the

sample-in-line independently from sample gas.

Span gas should have a concentration of 80 % to

110 % of the upper measuring range limit to the

gas path. Using lower concentrations may

decrease accuracy when measuring above the

span gas concentration!

USB storage device

The USB-Storage Device is used for external

data backups and must meet the specifications of

USB 1.0 or higher. The device plug must be a

USB male connector (type A).

It is recommended to use storage devices manufactured by renowned brands such as SANDISK,

KINGSTON, TOSHIBA etc..

Always test functionality of USB-Storage Device

before using it for (important) backups.

“Fuses” on page 227.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 19

Page 20

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 20 of 264

Zero gas supply (N2)

The zero gas supply is N2 of high purity.

The nitrogen should, as a minimum, be of quality

of 5.0, which means nitrogen of purity ≥

99.999 %. If such gas is not available, the substitute must be dry, clean and free of corrosives or

components containing solvents. It has to be free

of components to be measured, to minimize

cross interferences.

The supply of zero gas (N2) can be connected to

the sample gas connector independently from

sample gas or air supply.

The zero gas supply must also meet the technical

Ä

requirements

on page 46.

Chapter 3.1.4 “Gas Supply Data”

2.2 Inputs and Outputs

2.2.1 Inputs and Outputs: General Information

Limits and SELV

All external inputs shall provide reinforced or

double insulation for protection against electric

shock and with output voltages below the limits of

6.3.1 of 61010-1 or 30 V RMS and 42.4 V peak

or 60 V DC.

Connect only secondary circuits that are

designed in a way that under normal and single

fault conditions, the voltage between any two

parts of the SELV circuit does not exceed safe

values.

2.2.2 Inputs and Outputs: Data Connectors

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer20

Page 21

2.2.2.1 Overview of Backpanel Configurations

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 21 of 264

Available Configurations

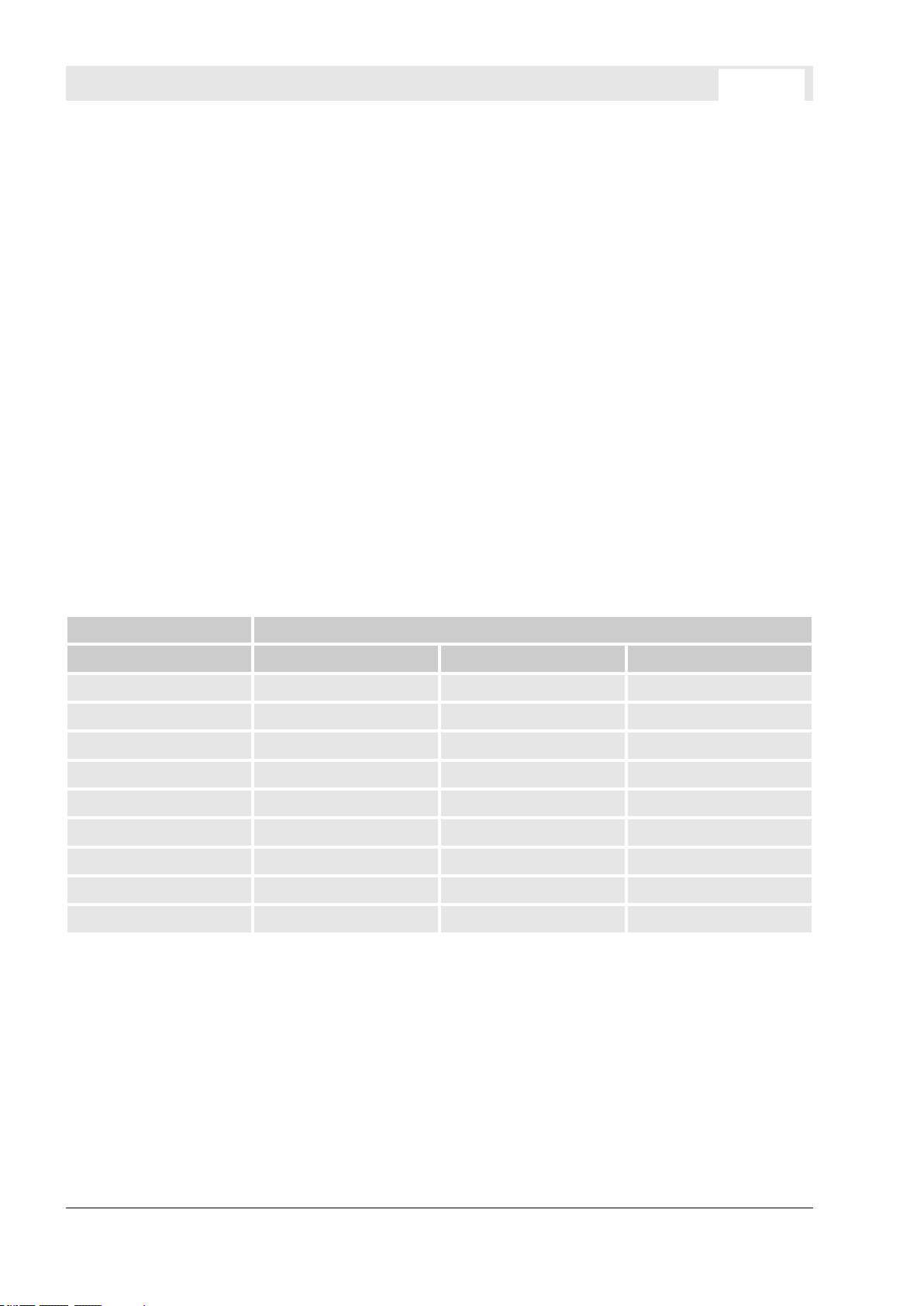

The Following configurations are available for the Analyzer:

Technical Description

Option

no.

1 - -

Optional I/Os Screw Terminal Exten-

sion

Description

Ä

“Data Connectors - Without Optional

I/Os - Without Screw Terminal Extensions”

on page 21

2 Digital I/Os -

Ä

“Data Connectors - With Optional Digital

I/Os - Without Screw Terminal Extensions”

on page 22

3 Analog Input -

Ä

“Data Connectors - With Optional Analog

Inputs - Without Screw Terminal Extensions” on page 22

4 Digital I/Os yes

Ä

“Data Connectors - With Optional Digital

I/Os - With Screw Terminal Extensions”

on page 23

5 Analog Input yes

Ä

“Data Connectors - With Analog Input With Screw Terminal Extensions”

on page 23

Data Connectors - Without Optional I/Os - Without Screw Terminal Extensions

Fig. 6: Option 1

1 USB-port 1 (USB-A)

2 USB-port 2 (mini-USB)

3 RJ45 Ethernet connector (2)

4 RJ45 Ethernet connector (1, process port)

5 CAN interface (reserved for future use)

7 Service port

8 Analog outputs / relay outputs

9 Serial interface (RS 232 / Modbus 485)

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 21

Page 22

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 22 of 264

Data Connectors - With Optional Digital I/Os - Without Screw Terminal Extensions

Fig. 7: Option 2

1 USB-port 1 (USB-A)

2 USB-port 2 (mini-USB)

3 RJ45 Ethernet connector (2)

4 RJ45 Ethernet connector (1, process port)

5 CAN interface (reserved for future use)

6 Digital in- / outputs

7 Service port

8 Analog outputs / relay outputs

9 Serial interface (RS 232 / Modbus 485)

Data Connectors - With Optional Analog Inputs - Without Screw Terminal Extensions

Fig. 8: Option 3

1 USB-port 1 (USB-A)

2 USB-port 2 (mini-USB)

3 RJ45 Ethernet connector (2)

4 RJ45 Ethernet connector (1, process port)

6 9-pin Analog input

7 Service port

8 Analog outputs / relay outputs

9 Serial interface (RS 232 / Modbus 485)

5 CAN interface (reserved for future use)

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer22

Page 23

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 23 of 264

Data Connectors - With Optional Digital I/Os - With Screw Terminal Extensions

Fig. 9: Option 4

1 USB-port 1 (USB-A)

2 USB-port 2 (mini-USB)

3 RJ45 Ethernet connector (2)

4 RJ45 Ethernet connector (1, process port)

5 CAN interface (reserved for future use)

6 Screw terminal extension XSTD

7 Screw terminal extension XSTA

8 Ribbon cable connector (XPSA)

9 Ribbon cable connector (XSTA)

Data Connectors - With Analog Input - With Screw Terminal Extensions

Fig. 10: Option 5

1 USB-port 1 (USB-A)

2 USB-port 2 (mini-USB)

3 RJ45 Ethernet connector (2)

4 RJ45 Ethernet connector (1, process port)

5 CAN interface (reserved for future use)

6 Ribbon cable connector (XSTI)

7 Screw terminal extension XSTI)

8 Screw terminal extension (XSTA)

9 Ribbon cable connector (XPSA)

10 Ribbon cable connector (XSTA)

2.2.2.2 Description of Data Connectors

USB connectors

(Fig. 6/1 + 2)

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 23

Page 24

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 24 of 264

Fig. 11: USB-ports

The device is equipped with two USB-connectors. Only one connector can be used at any one

time. The active USB-connector is selected via

software settings.

External data storage devices can be connected

to the USB-A connector (Fig. 11/1). The miniUSB port (Fig. 11/3) is designed to connect

measurement devices (computers).

Ethernet1 can be used to connect the analyzer to

a network.

Ethernet2 can be used to connect a PC directly

via crossover cable.

Fig. 12: RJ45 connector

# Signal

1 TX +

2 TX -

Overview of LED-states: Ä “Status LED”

on page 38

RJ45 Ethernet Connectors

(Fig. 6/3 + 4)

The Ethernet (Modbus) interface offers the same

form of communication with a data acquisition

system as a serial interface. Furthermore, this

interface enables to connect the analyzer to a

network, providing webbrowser access. This

interface is electrically isolated from the unit’s

electronic components and enables the construction of a network of several analyzers.

3 RX +

4 not used

5 not used

6 RX -

7 not used

8 not used

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer24

Page 25

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 25 of 264

Option: Analog inputs

(Fig. 8/6)

Instead of having analog inputs the analyzer is optionally available with digital in/outputs.

Optionally, the Analyzer can be equipped with a 9-pin analog input. The pinout is as follows:

Fig. 13: Passive Analog Interface (X5-connector,

option 2)

# Signals Note

A1 BR1 fit a wire bridge here to apply analog signal

A2 BR1

A3 not used -

A4 BR2 fit a wire bridge here to apply analog signal

A5 BR2

in current mode to input 2**

A6 Input 1 high (+) -

A7 Input 1 low (-) -

A8 Input 2 low (-) -

A9 Input 2 high (+) -

*alternatively set jumper P2 on electronics board XASI.

**alternatively set jumper P1 on electronics board XASI.

Electrical specifications of two analog inputs:

n 0–1 (10) V, software selectable; Rin = 100 kΩ

n Optional (requires to fit wire bridges, see figures): 0–20 mA ; Rin = 50 Ω

n Protected against overload up to ± 15 V or ± 20 mA

in current mode to input 1*

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 25

Page 26

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 26 of 264

Fig. 14: Passive Analog Input

1 Passive Analyzer input

2 Input signal, high

3 Wire bridge (optional)

4 Input signal, low

The optional wire bridge is used for current mode selection.

If the Analyzer is equipped with analog inputs, a terminal extension is available Ä “XSTI adapter”

on page 34.

Option: Digital In/Outputs

(Fig. 7/6)

Instead of having digital in/outputs the analyzer is optionally available with an analog inputs.

Optionally, the Analyzer can be equipped with a 37-pin digital in/output interface. The pinout is as follows:

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer26

Page 27

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 27 of 264

Fig. 15: Digital in- / outputs (optional)

If the Analyzer is equipped with a digital in/output, a terminal extension is available Ä “XSTD adapter”

on page 34.

Service Port

(Fig. 6/7)

The Service port connector is configured as an

RS 232 connector with pinout as shown here:

Fig. 16: Service port

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 27

Page 28

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 28 of 264

# Signals

1 Common

2 RSD

3 TXD

4 not used

5 Common

# Signals

6 not used

7 not used

8 not used

9 not used

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer28

Page 29

Analog Outputs / Relay Output (X1)

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 29 of 264

(Fig. 6/8)

Technical Description

Fig. 17: Analog Outputs / Relay outputs

The X1-Interface is by default configured as shown in Fig. 17.

Five software-configurable analog outputs can be used to supply external devices with analog signals.

The 4 relay-outputs are by default assigned according to NAMUR-specification NE 107 (status signals).

The technical data of analog outputs and relay outputs is as follows:

Data Value Unit

Current, analog output 4 (0)–20 mA

Burden (RB), analog output < 500

Ω

Current, relay output 1 A

Voltage, relay output 30 VDC

Load, relay output 30 W

By default, the Analyzer is fitted with one output, which can transmit data on concentration levels to an

external data acquisition system. Up to five analog outputs can be installed.

The analog outputs support several operation modes, such as 4-20 mA, 0-20 mA, as well as the NAMUR NE

43 specifications (incl. Live Zero). Operation modes can be set in a software menu (6-76).

The factory setting for analog outputs is 4-20 mA.

X-STREAM analyzers support up to five analog outputs that do not always have to be assigned to measurement channels which are physically present.

If a unit features less than five channels, the remaining analog outputs can be used to transmit concentration

levels with a different resolution. For example, the XECLD could be set up as follows:

Output 1: 0 … 10 ppm NO = 4 … 20 mA

Output 2: 0 … 100 ppm NO = 4 … 20 mA

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 29

Page 30

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 30 of 264

Serial Interface (X2)

(Fig. 6/9)

A serial interface with the Modbus protocol allows communication with external data acquisition systems.

The interface enables the exchange and modification of measurement and analyzer signals, analyzer status

monitoring as well as remote activation of procedures.

The serial Interface (X2) may have different signal configurations:

Fig. 18: Serial interface

Signals

# MOD 485/2 wire MOD 485/4 wire RS232

1 Common Common Common

2 not used not used RSD

3 not used not used TXD

4 not used RXD1 (+) not used

5 D1 (+) TXD1 (+) Common

6 not used not used not used

7 not used not used not used

8 not used RXD1 (-) not used

9 D0 (-) TXD1 (-) not used

The active configuration is indicated by a marking on a table below the Serial interface:

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer30

Page 31

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 31 of 264

Fig. 19: Configuration table

In the example shown, the X2 connector is configured as an RS 232 interface (Fig. 19).

2.2.2.3 Screw Terminal Extensions (Optional)

Terminal Extensions

Fig. 20: Screw terminal extensions

Screw terminals are available optionally and allow the user to establish individual configurations.

Screw terminal extensions are available for the optional 37-pin connector (Fig. 20/1, alternatively for a 9-pin

analog input and for the 25-pin analog / relay output (Fig. 20/3). Via flat cable the serial interface X2

(Fig. 20/2) can also be connected to the lower part of the right screw terminal extension (Fig. 20/4).

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 31

Page 32

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 32 of 264

Equipotential Bonding

Fig. 21: Cable leads

The shield of cables connected to terminal extensions must be routed through the shield connection

(Fig. 21/2) to establish equipotential bonding. Screw terminals (Fig. 21/1) are described in the following sections.

Connection Data

All screw terminal extensions share the following

technical properties:

Property Value

Stripping length 0.2" (5 mm)

Thread M2

Property Value

Wire gauge, recommended

AWG 26 – AWG 16

(0.14 – 1.5 mm²)

Tightening torque, min 2.21 in lb (0.25 Nm)

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer32

Page 33

XSTA adapter

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 33 of 264

Technical Description

Fig. 22: XSTA adapter (Terminal extension)

The Terminal extension for the XSTA adapter allows to individually wire analog outputs and relay outputs (X1

connector). It also offers a possiblilty to connect the X2 connector via flat cable.

The Analog Outputs (Fig. 22/P2.1 – 2.10) can be indiviually configured via software settings.

The configuration of Relay Outputs (Fig. 22/P3.3 – P4.2) is set per factory setting and represents standard

NAMUR status signals. The signals set may also be adapted via software settings.

The Serial Interface (Fig. 22/P4.4 – P4.12) may be set to different modes of operation. For a description of

the possible configurations see Ä Serial Interface (X2) on page 28.

In default configuration, the connectors 2.11 – P3.2 and P4.3 are not used.

When wiring individually, make sure the cable shielding is properly connected to the equipotential

bonding Ä “Equipotential Bonding” on page 32.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 33

Page 34

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 34 of 264

XSTD adapter

An XSTD adapter can optionally be used to connect digital I/O cables to screw-type terminals instead of

Submin-D plugs and sockets; it is plugged into the digital I/O Submin-D connectors on the unit.

Fig. 23: XSTD adapter (Terminal extension)

XSTI adapter

An XSTI adapter can optionally be used to connect analog input cables to screw-type terminals instead of

Submin-D plugs and sockets; it is plugged into the optional analog input connector on the unit.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer34

Page 35

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 35 of 264

Fig. 24: XSTI adapter (Terminal extension)

2.2.3 Inputs and Outputs: Gas Connectors

Fig. 25: Gas connections

1 EXHAUST

2 SAMPLE IN

3 AIR IN

4 PURGE (optional)

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 35

Page 36

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 36 of 264

Three gas connectors and an optional fourth are located on the back panel of the Analyzer (Fig. 25/1 – 4).

The PURGE gas connector is only available for direct connection of PTFE (e. g. Teflon®) or FKM (e. g. Viton

®

) tubings. EXHAUST, SAMPLE IN and AIR IN connectors can be ordered in two different versions:

n 6 or 10 mm fitting

n 1/4" or 3/8" fitting

Sample gas must be supplied at the SAMPLE IN connector (Fig. 25/2). Pressurized Air as specified within

this manual (Ä Chapter 2.2.3 “Inputs and Outputs: Gas Connectors” on page 35) that can be used to supply

the Ozonator is connected to the AIR IN connector (Fig. 25/3). The exhaust's gas line must be connected to

the EXHAUST connector (Fig. 25/1). Optionally, a PURGE connector (Fig. 25/4) which may be used as a

purge gas inlet can be installed.

Technical specifications on connected gases and systems: Ä Chapter 3.1.4 “Gas Supply Data”

on page 46

2.2.4 Electrical connectors

Power Connector

Fig. 26: Power connector

The Power connector (Fig. 26/1) is located at the

lower left of the backpanel.

Only connect the supplied IEC C13 connector

cable!

Equipotential Bonding Connector

Fig. 27: Equipotential Bonding Connector

The equipotential bonding connector (Fig. 27/1)

is located at the lower left of the backpanel,

directly below the power connector. Use the equipotential bonding connector for grounding the

Analyzer.

2.3 Controls, Signals and Display

ON/OFF switch

Fig. 28: ON/OFF switch

The ON/OFF switch (Fig. 28/1) is located on the

left side of the rear panel, adjacent to the IEC

connector.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer36

Page 37

The ON/OFF switch connects or disconnects the

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 37 of 264

power supply to the Analyzer.

Technical Description

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 37

Page 38

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 38 of 264

Status LED

Fig. 29: Status LEDs

1 LED 1

2 LED 2

The Status LEDs are located on the left side of the backpanel, next to the air inlet of case ventilation and

above the RJ45 connectors. The Status LEDs indicate the Analyzer's status considering software and operational readiness. LED 1 (Fig. 29/1) is labeled "L1" and LED 2 (Fig. 29/2) "L2".

LED state Meaning Recommended action

LED 1: Blinking (green)

Regular state of operation.

LED 2: constantly ON (green)

LED 1: Blinking (red) NAMUR "Failure" state. Check displayed failure descrip-

tion and consult troubleshooting in

the appendix

Ä

Appendix “Trou-

bleshooting” on page 241.

LED 1: constantly ON (green)

LED 2: constantly ON (green)

Analyzer not properly programmed.

Inform customer services.

Let authorized service personnel

program analyzer.

LED 1 and LED 2 : blinking alternately (green)

New program version has just

been loaded. User input is

expected.

Mind displayed messages or let

authorized service personell login

via TELNET.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer38

Page 39

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 39 of 264

POWER LED

Fig. 30: Power LED

1 POWER LED

The POWER LED (Fig. 30/1) is located in the

upper part of the back panel above the X1-Interface. When the Analyzer is connected to the

power grid and the ON/OFF switch is switched to

postition [I] the POWER LED is lit.

Softkeys

WARNING!

Only open housing, when POWER LED

is not lit!

Fig. 31: Softkeys

The softkeys are located in the center of the front

panel. The main function of the soft keys is navigating through the software menu.

Via softkeys the software menu can be accessed,

tasks can be executed and status messages can

be displayed.

Softkey Function (s)

UP Key

n Navigate

up within a

menu

DOWN Key

n Navigate

down within

a menu

RIGHT Key

n Enter the

highlighted

sub menu

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 39

Page 40

Technical Description

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 40 of 264

Softkey Function (s)

LEFT Key

n Return from

a sub-menu

to the

higher level

menu.

Softkey Function (s)

HOME Key

n Return to

home

screen

ENTER Key

n Execute a

function

n Enter a

value

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer40

Page 41

Display

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 41 of 264

Technical Description

Fig. 32: Display

The display is located at the center of the front panel (Fig. 32).

The contents displayed are divided in four sections:

In the status symbol section (Fig. 32/1) a selection of symbols describes the states of operation. The menu

title line (Fig. 32/2) indicates the current active menu and – if applicable – the number of the sub-menu

pages. In the Menu sections, menu entries (Fig. 32/3) and their associated values or settings are shown. On

the bottom of the display, the status message line (Fig. 32/4) displays date and time or any pending error

messages.

Refer to Ä Chapter 5.3 “Software” on page 59 for a detailed description.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 41

Page 42

Technical Data

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 42 of 264

3 Technical Data

Units Rounded

The values in imperal units given in the following are calculated from metric units.

The calculated values are rounded. This

can produce small deviations from the

actual values.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer42

Page 43

Technical Data

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 43 of 264

3.1 Housing Data, Connection Data, Environmental Conditions and Emissions

3.1.1 Housing Data

Dimensions (without screw extensions)

Fig. 33: Dimensions

Data Value Unit

Dimension* (length) 369.6 (14.55) mm (in)

Dimension* (width) 440 (17.32) mm (in)

Dimension* (height) 132 (5.2) mm (in)

Weight 12.3 (27.12) kg (lb)

Mounting, Type A 19" rack mount -

Mounting, Type B Table top -

Ingress protection rating IP20 -

Safety clearance** 1 RU

Air flow, housing fan 0.88 (1.15) m³/min (yd³/min)

*Dimensions without housing feet or rack mounting brackets.

**Make sure there is at least one unoccupied Rack Unit (RU) above and underneath the designated

mounting location.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 43

Page 44

Technical Data

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 44 of 264

Dimensions (with screw extensions)

Fig. 34: Dimensions

Data Value Unit

Dimension* (length) 411,7 (16.21) mm (in)

Dimension* (width) 440 (17.32) mm (in)

Dimension* (height) 132 (5.2) mm (in)

Weight 12.3 (27.12) kg (lb)

Mounting, Type A 19" rack mount -

Mounting, Type B Table top -

Ingress protection rating IP20 -

Safety clearance** 1 RU

Air flow, housing fan 0.88 (1.15) m³/min (yd³/min)

*Dimensions without housing feet or rack mounting brackets attached.

**Make sure there is at least one unoccupied Rack Unit (RU) above and underneath the designated

mounting location.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer44

Page 45

3.1.2 Performance Specifications

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 45 of 264

Technical Data

Detection limit (4σ)

Linearity

Repeatability

1, 2

1, 2

Response time (t90)

Zero-point drift

1, 2

Span (sensivity) drift

1, 2

3

≤ 2 s for range > 25 ppm

1, 2

≤ 1.0 %

≤ 1.0 %

≤ 0.5 %

4

≤ 4 s for range ≤ 25 ppm

≤ 0.5 % per 24 h

≤ 1.0 % per 24 h

Permissible ambient temperature +5 – +40 °C (+41 – +104 °F)

Zero-point temperature effect

Span (sensitivity) temp. effect

1, 6

1, 6

≤ 2.0 % per 10 K

≤ 3.0 % per 10 K

Maximum gas pressure ≤ 1500 hPa gauge (≤ 21 psig)

Warm-up time

1

Related to full scale.

2

Constant pressure and temperature.

3

From gas analyzer inlet.

4

Electronic damping = 0s.

5

Electronic damping = 3s.

6

Temperature variation: ≤ 10K per hour.

7

Depending on ambient temperature.

7

30 – 60 minutes

5

3.1.3 Power Connection Data

Data Value Unit

Mains overvoltage category, transient II -

Mains connection IEC Connector (C13) -

Mains voltage 100...240 V AC

Net frequency 50 / 60 Hz

Mains cartridge fuse* 5 x 20 (0.2 x 0.79) mm (in)

Power consumption approx. 120 W

Nominal input current, max. 2...1 A

Mains supply voltage fluctuations ± 10 %

Mains Fuse, trip current 4 A

Mains Fuse, nominal voltage 250 V

Mains Fuse, breaking capacity 1500 A @ 250 V AC -

Ä

*Fuses are available from Emerson. Only use fuses listed in the spare parts list

“Fuses” on page 227.

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer 45

Page 46

Technical Data

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 46 of 264

3.1.4 Gas Supply Data

Chemical components

NOTICE!

Never apply highly corrosive gases (e. g.

Chlorine or H2S) in concentrations of

approximately 1 % or higher!

X-STREAM Enhanced XECLD - Chemiluminescence Detection Gas Analyzer46

Page 47

Technical Data

00809-0100-3975. Rev AB

April 2021

Instruction Manual

Page 47 of 264

Technical Data

Ä

Only use conditioned gases

Data Value Unit

Sample gas connection, type A 6 mm

Sample gas connection, type B 1/4 in

Air supply connection (ozonator), type A 6 mm

Air supply connection (ozonator), type B 1/4 in

Exhaust outlet, type A 10 mm