Reference Manual

00809-0100-4889, Rev AA

Rosemount™ Xi

Advanced Electronics for Zirconium Oxide Flue Gas O2 Probes

July 2018

Essential Instructions

Read this page before proceeding!

Emerson designs, manufactures, and tests its products to meet many national and international standards. Because these

instruments are sophisticated technical products, you must properly install, use, and maintain them to ensure they continue to

operate within their normal specifications. The following instructions must be adhered to and integrated into your safety program

when installing, using, and maintaining Emerson's Rosemount products. Failure to follow the proper instructions may cause any one

of the following situations to occur: loss of life, personal injury, property damage, damage to this instrument, and warranty

invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of the product.

• Install your equipment as specified in the installation instructions of the appropriate instruction manual and per applicable

local and national codes. Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts specified by Emerson.

Unauthorized parts and procedures can affect the product's performance, place the safe operation of your process at risk,

and VOID YOUR WARRANTY. Look-alike substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when maintenance is being performed

by qualified people, to prevent electrical shock and personal injury.

The information contained in this document is subject to change without notice.

NOTICE

The 375 Field Communicator must be upgraded to System Software 2.0 with Graphic License for operation with Xi Electronics. The

AMS software must be upgraded to AMS 8.0 or above.

Contact Emerson's Global Service Center (GSC) at 1-800-833-8314 to upgrade the 375 Field Communicator software to System

Software 2.0 with Graphic License.

Preface

The purpose of this manual is to provide information concerning the components,

functions, installation, and maintenance of the Xi Electronics.

Some sections may describe equipment not used in your configuration. You should become thoroughly familiar with the operation

of this module before operating it. Read this instruction manual completely.

Definitions

The following definitions apply to WARNINGS, CAUTIONS, and NOTICES found throughout

this publication.

WARNING!

Highlights an operation or maintenance procedure, condition, statement, etc. that if not strictly observed, could result in injury,

death, or long-term health hazards of personnel.

CAUTION!

Highlights an operation or maintenance procedure, practice, condition, statement, etc. that if not strictly observed, could result in

damage to or destruction of equipment or loss of effectiveness.

NOTICE

Highlights an essential operating procedure, condition, or statement.

Symbols

Earth (ground) terminal

:

Protective conduit or terminal

:

Risk of electrical shock

:

Warning: Refer to Instruction Manual

:

NOTICE

The number in the lower right corner of each illustration in this publication is a manual illustration number. It is not a part number

and is not related to the illustration in any technical manner.

Overview

The Xi is specifically designed to control a zirconium oxide probe for measuring oxygen,

usually the O2 remaining from a combustion process. Call the Rosemount Customer

Support Center (CSC) to get recommendations for other oxygen probes: 800 854 8257 (US

and Canada).

The Xi electronics has several main functions:

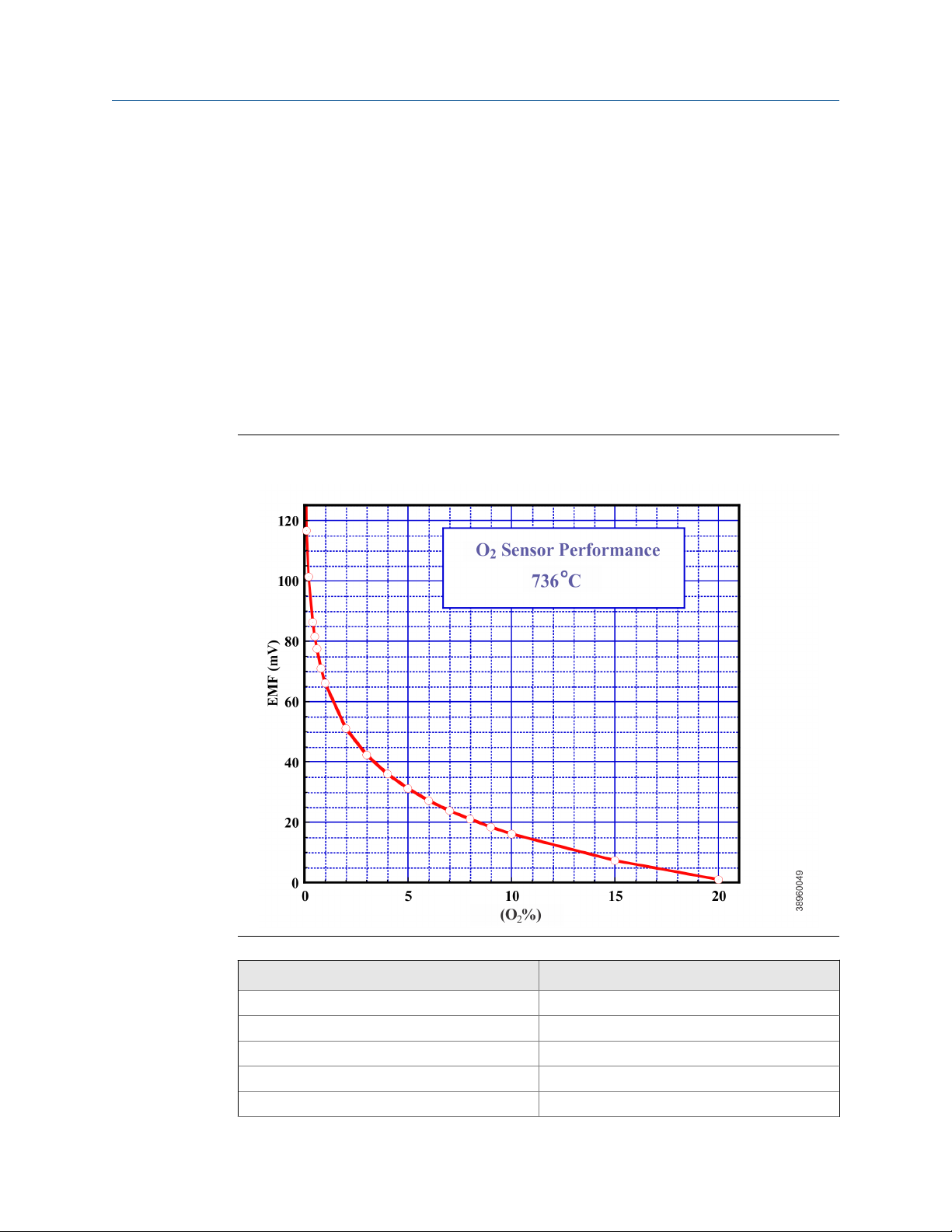

1. Heater Control: The electronics receives a type K thermocouple input from an O2 probe and switches power on and off to

the probe's heater in order to maintain a temperature setpoint of 1357 °F (736 °C).

2. Signal Conditioning: The electronics receives the raw millivolt signal from the O2 sensing cell and then linearizes and

amplifies the signal to provide a linear 4-20 mA output signal used for recording or as in input into a DCS system for control

purposes.

3. Calibration: A bottled calibration gas of known value is typically flowed into the probe's sensor to verify that it is reading

correctly. If the signal is out of calibration, the calibration gas is used to adjust the 4-20 mA output signal. During calibration,

the Xi prompts the technician to flow two calibration gases into the probe and, with the calibration gases flowing,

automatically adjusts the O2 signal. With the addition of a Single Probe Sequencer (SPS), the Xi electronics can also switch

the calibration gases on and off.

4. Diagnostics: Multiple alarms are available for display. The alarm displays are intended to assist a technician in locating where

an instrument problem may reside.

The electronics has been verified to operate the following probes:

• Westinghouse 218 and World Class

• Rosemount Oxymitter

• Yokogawa

Technical Support Hotline

For assistance with technical problems, please call the Customer Support Center (CSC).

The CSC is staffed 24 hours a day, 7 days a week.

Phone: 1-800-433-6076, 1-440-914-1261

In addition to the CSC, you may also contact Field Watch. Field Watch coordinates Emerson's field service throughout the U.S. and

abroad.

Phone: 1-800-654-RSMT (1-800-654-7768)

Emerson may also be reached via the Internet through email and the World Wide Web:

Email: GAS.CSC@emerson.com

World Wide Web: www.Emerson.com/RosemountGasAnalysis

Warranty

RosemountTM warrants that the equipment manufactured and sold by it will, upon

shipment, be free of defects in workmanship or material. Should any failure to conform to

this warranty become apparent during a period of one year after the date of shipment,

Rosemount shall, upon prompt written notice from the purchaser, correct such

nonconformity by repair or replacement, F.O.B. factory of the defective part or parts.

Correction in the manner provided above shall constitute a fulfillment of all liabilities of

Rosemount with respect to the quality of the equipment.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES OF QUALITY WHETHER WRITTEN, ORAL, OR

IMPLIED (INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR PURPOSE).

The remedy(ies) provided above shall be purchase'rs sole remedy(ies) for any failure of Rosemount to comply with the warranty

provisions, whether claims by the purchaser are based in contract or in tort (including negligence).

Rosemount does not warrant equipment against normal deterioration due to environment. Factors such as corrosive gases and

solid particulates can be detrimental and can create the need for repair or replacement as part of normal wear and tear during the

warranty period.

Equipment supplied by Rosemount but not manufactured by it will be subject to the same warranty as is extended to Rosemount by

the original manufacturer.

At the time of installation, it is important that the required services are supplied to the system and that the electronic controller is

set up at least to the point where it is controlling the sensor heater. This will ensure that, should there be a delay between

installation and full commissioning, the sensor being supplied with ac power and reference air will not be subjected to component

deterioration.

Contents

Contents

Chapter 1 Description and specifications ........................................................................................1

1.1 Component checklist ...................................................................................................................1

1.2 System overview ..........................................................................................................................2

1.2.1 Scope ............................................................................................................................2

1.2.2 System configurations .................................................................................................. 3

1.2.3 Automatic calibration ....................................................................................................4

1.2.4 Communication options ............................................................................................... 4

1.3 Specifications .............................................................................................................................. 6

Chapter 2 Install .............................................................................................................................9

2.1 System considerations ...............................................................................................................10

2.2 Mechanical installation .............................................................................................................. 10

2.2.1 Mount .........................................................................................................................10

2.3 Electrical installation ..................................................................................................................13

2.3.1 Optional flame safety interlock ................................................................................... 16

2.3.2 Wire the traditional architecture cable connections .................................................... 17

Chapter 3 Configure .....................................................................................................................19

3.1 Verify installation .......................................................................................................................19

3.1.1 Xi configuration .......................................................................................................... 19

3.2 Set test gas values ......................................................................................................................20

3.2.1 Setting test gas values using Field Communicator .......................................................20

3.3 Alarm relay output configuration ...............................................................................................20

3.3.1 Configuring alarm relays with the Xi keypad/display ....................................................21

3.3.2 Configuring autocalibration with the Field Communicator ..........................................21

3.4 Configure analog output ............................................................................................................22

3.4.1 Configuring the analog output with the Xi keypad/display .......................................... 22

3.4.2 Configuring alarm relays with the Field Communicator ...............................................23

3.5 Autocalibration setup ................................................................................................................ 23

3.6 Optional advanced features inside the Xi ................................................................................... 23

3.6.1 Extended process temperature range to 1472 °F (800 °C) ............................................24

3.6.2 Stoichiometer ............................................................................................................. 24

3.6.3 Programmable reference ............................................................................................ 24

Chapter 4 Startup and operation .................................................................................................. 27

4.1 Overview ................................................................................................................................... 27

4.2 Startup ...................................................................................................................................... 27

4.2.1 Operation via Xi ...........................................................................................................28

4.2.2 Error conditions ...........................................................................................................28

4.2.3 Xi Controls .................................................................................................................. 28

4.2.4 Password protection ................................................................................................... 32

4.3 System parameter descriptions ................................................................................................. 33

4.4 Probe parameter descriptions ....................................................................................................36

4.5 Operation via HART/AMS ........................................................................................................... 41

4.5.1 Field communicator signal line connections ................................................................41

4.5.2 Field Communicator menu trees .................................................................................42

4.6 Offline and online operations .....................................................................................................44

4.7 Calibration - general .................................................................................................................. 45

Reference Manual i

Contents

4.8 O2 calibration ............................................................................................................................ 45

4.8.1 O2 calibration with Xi .................................................................................................. 46

4.8.2 O2 calibration with Xi and Field Communicator ........................................................... 47

4.9 D/A trim .....................................................................................................................................48

4.9.1 D/A trim with Xi ...........................................................................................................48

Chapter 5 Troubleshooting .......................................................................................................... 49

5.1 Overview of operating principles ............................................................................................... 49

5.2 General ......................................................................................................................................50

5.2.1 Grounding ...................................................................................................................50

5.2.2 Electrical noise ............................................................................................................ 50

5.2.3 Electrostatic discharge ................................................................................................51

5.3 Alarm indications .......................................................................................................................51

5.4 Identifying and correcting fault indications ................................................................................52

5.5 Calibration passes, but still reads incorrectly ..............................................................................54

5.5.1 Probe passes calibration, O2 still reads high .................................................................54

5.5.2 Probe passes calibration, O2 still reads low .................................................................. 55

5.5.3 How do I detect a plugged diffuser? ............................................................................ 55

5.5.4 Can I calibrate a badly plugged diffuser? ......................................................................55

Chapter 6 Maintenance and service ..............................................................................................57

6.1 Overview ................................................................................................................................... 57

6.2 Maintenance intervals ................................................................................................................57

6.3 Calibration .................................................................................................................................58

6.3.1 Automatic calibration ................................................................................................. 58

6.3.2 Manual calibration ...................................................................................................... 58

6.4 Replacement parts .....................................................................................................................58

6.5 Xi components replacement ......................................................................................................58

6.5.1 I/O board replacement ................................................................................................60

6.5.2 AC relay board replacement ........................................................................................64

6.5.3 Power supply board replacement ................................................................................65

6.5.4 Xi front panel replacement ..........................................................................................67

6.5.5 DR board replacement ................................................................................................ 69

Chapter 7 Replacement parts ....................................................................................................... 73

7.1 Xi electronics ............................................................................................................................. 73

7.2 Calibration components ............................................................................................................ 74

Chapter 8 Optional accessories .................................................................................................... 75

8.1 HART handheld 375/475 Field Communicator ...........................................................................75

8.2 Asset Management Solutions (AMS) .......................................................................................... 76

8.3 By-Pass Packages ....................................................................................................................... 76

8.4 Rosemount SPS 4001B Single Probe Autocalibration Sequencer ................................................77

8.5 Rosemount IMPS 4000 Intelligent Multiprobe Test Gas Sequencer ............................................ 78

8.6 O2 calibration gas ...................................................................................................................... 79

8.7 OxyBalance Display and Averaging System ................................................................................ 80

Appendices and reference

Appendix A XPS information ...........................................................................................................81

A.1 XPS equipment description ........................................................................................................81

A.1.1 Remote XPS for 44 V probes - 6A00358G01 ................................................................ 81

A.1.2 Remote XPS for 115 V probes - 6A00358G03 .............................................................. 82

ii Xi

Contents

A.1.3 Integral XPS 6A00365G01 with Xi (for 44 V probes) .................................................... 83

A.1.4 Other XPS uses ............................................................................................................83

A.2 Specifications ............................................................................................................................ 90

A.3 Recommended spare parts ........................................................................................................ 90

Appendix B Service support ............................................................................................................ 91

Reference Manual iii

Contents

iv Xi

Description and specifications

1 Description and specifications

1.1 Component checklist

A typical Rosemount O2 Combustion Flue Gas Transmitter should contain all the items

shown in Figure 1-1. A complete Oxygen Analyzer system will include some or all of the

equipment shown. However, this manual describes item H only.

Use the product matrix (Table 1-1) at the end of this section to compare your order number

against your unit. The first part of the matrix defines the model. The last part defines your

options and features. Ensure the features and options specified by your order number are

on or included with the unit.

Reference Manual 1

Description and specifications

Typical system packageFigure 1-1:

A. Quick Start Guide

B. Weld plate

C. Traditional architecture cable

D. O2 probe

E. Reference Air Set (not used if SPS 4001B or IMPS 4000 is used)

F. HART® 375/475 Field Communicator package (optional)

G. Optional SPS 4001B or IMPS 4000 Autocalibration Sequencer

H. Xi Advanced Electronics

1.2

System overview

1.2.1 Scope

This Instruction Manual supplies details needed to install, start up, operate, and maintain

the Xi Electronics. Signal conditioning electronics output a 4-20 mA signal representing

the O2 value. This information, plus additional details, can be accessed with the HART

Model 375/475 Field Communicator or Asset Management Solutions (AMS) software..

2 Xi

1.2.2 System configurations

Traditional architecture, HART ,and Xi communications

Some customers prefer not to mount electronics onto the probe, so a traditional

architecture version is offered. This probe sends raw millivolt signals via a 7-conductor

cable to the Xi electronics, Figure 1-2, which does all heater control and signal conditioning

in addition to its display/keypad functions. The Xi Advanced Electronics is offered to

support direct replacement probes with either 120 volt or 44 volt heaters.

Direct replacement probe with traditional architecture electronicsFigure 1-2:

Description and specifications

O2 probe with Xi Electronics and autocalibration sequencerFigure 1-3:

Reference Manual 3

Description and specifications

1.2.3 Automatic calibration

Calibrations consist of introducing bottled gases of known value into the probe so the

electronics can make automatic adjustments to the O2 readings to match the bottled gas

value. 0.4% O2 and 8% O2 (balance nitrogen) gases are recommended. Never use nitrogen

or instrument air as calibration gases.

Flowmeters (for calibration gases) and regulators and flowmeters (for reference air) are

available as loose components, mounted into an optional manual calibration switching

panel or as a fully automated calibration system, Figure 1-3, where calibration solenoids are

switched from the Xi Electronics. See IM-106-340AC, SPS 4000B Single Probe

Autocalibration Sequencer or IM-106-400IMPS, IMPS 4000 Intelligent Multiprobe Test Gas

Sequencer, for additional details.

1.2.4 Communication options

Data communications

An operator can configure and troubleshoot the O2 probe system in one of two ways:

1. Using the Xi Advanced Electronics; the Xi carries the following optional advanced

features:

• Fully automatic calibration

• Flame safety interface

• High temperature operation [above 1292 °F (700 °C) standard temperature]

• Stoichiometer feature provides the ability to indicate O2 efficiency when the

combustion process goes into reducing conditions (0% O2).

• Programming reference provides advanced accuracy when measuring at or near

O2 level (20.95% O2).

2. Using the HART interface, the Xi's 4-20 mA output line transmits an analog signal

proportional to the oxygen level. The HART output is superimposed on the 4-20 mA

output line. This information can be accessed through the following:

• Rosemount 375/475 Field Communicator - The handheld communicator

requires Device Description (DD) software specific to the Xi. The DD software will

be supplied with many 375/475 units, but can also be programmed into existing

units at most Emerson service offices. See Chapter 4 for additional information.

• Personal computer (PC) - The use of a personal computer requires AMS software

available from Emerson.

• Delta V and Ovation Distributed Control System (DCS) with AMS-inside

capability.

NOTICE

The 375 Field Communicator must be upgraded to System Software 2.0 with Graphic

License for operation with the Xi. The AMS software must be upgraded to AMS 8.0 or

above.

Contact Emerson's Global Service Center (GSC) at 1-800-833-814 to upgrade the 375

Field Communicator software to System Software 2.0 with Graphic License.

4 Xi

Description and specifications

3. The Xi can also transmit HART information wirelessly via a wireless THUM Adapter,

Figure 1-4. The THUM Adapter threads into the Xi conduit ports and converts the

4-20 mA O2 signal to a wireless protocol. All other HART information is also

transmitted.

In addition to the wireless THUM Adapter, a hard-wire connection of the 4-20 mA

signal to the DCS may be used at the same time. More detailed information

regarding the application of the THUM Adapter is available in Product Data Sheet

00813-0100-4075. Note that the THUM Adapter may also be used with the

Oxymitter, mounted integral to the probe, or to the Oxymitter remote electronics.

Wireless THUM AdapterFigure 1-4:

Optional OxyBalance display and averaging system

Receives up to eight 4-20 mA signals from individual Xi units. Trends individual outputs

and calculates four programmable averages as additional 4-20 mA outputs. OxyBalance

graphic displays are shown in Figure 1-5. See IM-106-4050, OxyBalance Oxygen Display and

Averaging System, for additional details.

Reference Manual 5

Description and specifications

OxyBalance displaysFigure 1-5:

1.3 Specifications

SpecificationsTable 1-1:

Measurement specifications

Net O2 range 0 to 50% O2 user scalable

-2 to 50% O2 user scalable with stoichiometer

Lowest detectable limit 0.01% O

Signal stability ±0.03% O

Accuracy in reducing conditions ±10% of reading or 0.1% O

System responses in reducing conditions Going from oxidizing to reducing -T90 in 120 seconds

Going from reducing to oxidizing -T90 in 30 seconds

Ambient temperature effect on Xi 4-20 mA signal Less than 0.0025% O2 per degree Celsius

Environmental specifications

Xi Advanced Electronics Type 4X/IP66 polycarbonate material

Ambient temperature limits -4 to 122 °F (-20 to 50 °C)

-4 to 158 °F (-20 to 70 °C) as measured by electronics

Xi LCD display: ambient temperature limits -4 to 131 °F (-20 to 55 °C)

2

2

2

6 Xi

Description and specifications

Specifications (continued)Table 1-1:

General purpose certifications

Installation specifications

Mounting Panel, wall, or pipe

Reference air 0.5 scfh (0.25 l/min), clean, dry, instrument-quality air

(20.95% O2), regulated to 5 psi (34 kPa)

Calibration Semi-automatic or automatic

Cal gases 0.4% O2 and 8% O2, balance N

Traditional architecture cable 200 ft (61 m) maximum length

Transmitter electrical power 12 - 24 Vdc (loop-powered from control room or Xi)

Electrical power for Xi 100 - 240 Vac ±10%, 50/60 Hz

Power consumption of Xi 12 VA maximum or 776 VA maximum with traditional arch-

tecture, 120 V probes

450 VA maximum with traditional architecture, 44 V

probes

Alarm relay outputs Two provided - 2 Amperes, 30 Vdc, Form-C

Optional loss of flame input Internally powered input to remove heater power actuated

via dry contact output from user's flame scanner

Emerson has satisfied all obligations from the European legislation to harmonize the product requirements in Europe.

All static performance characteristics are with operating

variables constant. Specifications subject to change without notice.

2

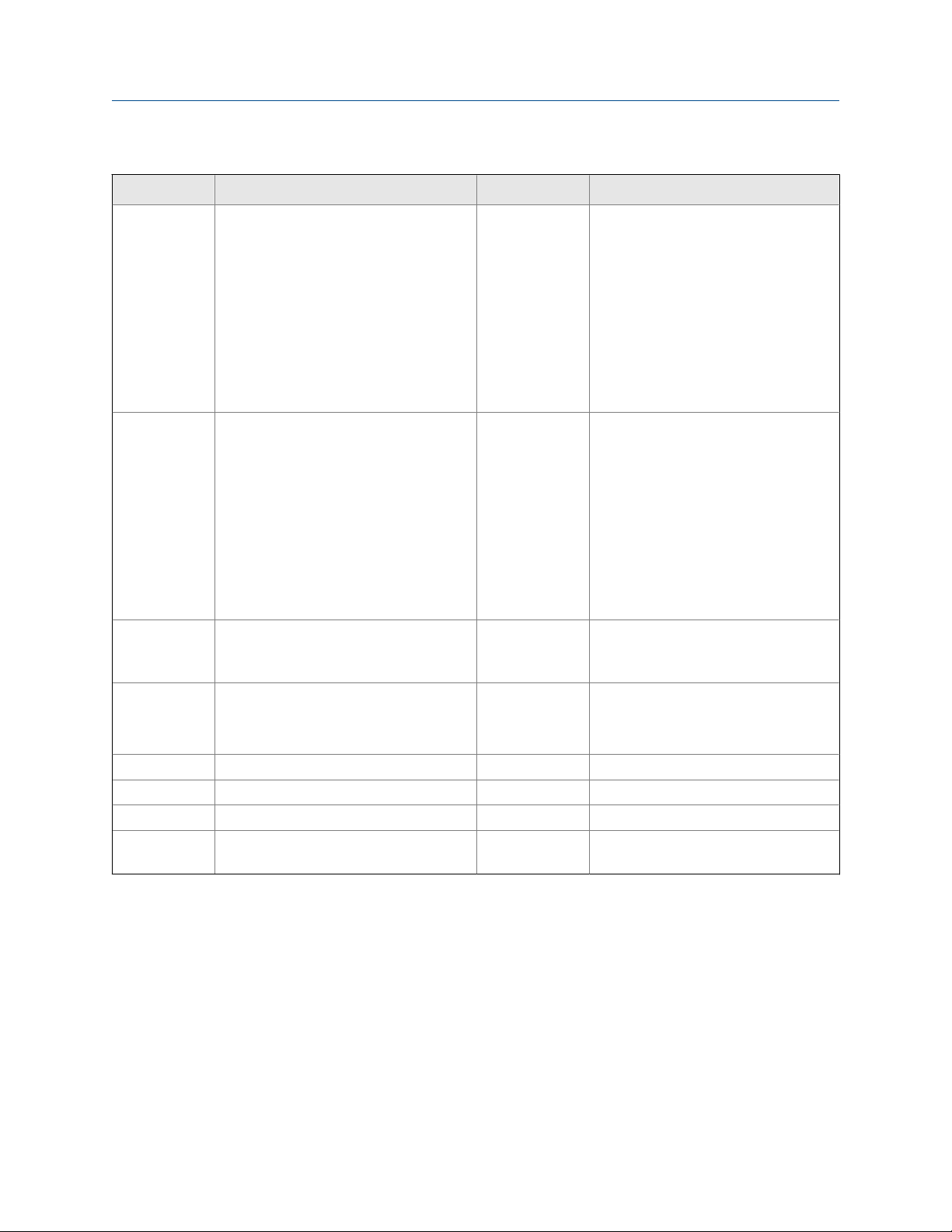

Product matrix, Xi advanced electronicsTable 1-2:

Xi Xi Advanced Electronics

Code Remote type

01 Single channel

(1)

02 Single channel, accepting a loss-of-flame input to remove heater power with flame

status relay

03 Dual channel

(1)

(1)

04 Single channel traditional architecture for 120 V probes

05 Single channel traditional architecture for 44 V probes

Code Mounting

00 No hardware

01 Panel mount kit with gasket

02 2 in. pipe/wall mount kit

Reference Manual 7

Description and specifications

Code Cable

00 No cable

10 20 ft (6 m) cable

11 40 ft (12 m) cable

12 60 ft (18 m cable)

13 80 ft (24 m cable)

14 100 ft (30 m) cable

15 150 ft (45 m) cable

16 200 ft (60 m) cable

Code Stoichiometer function

00 None

01 Single channel (stoichiometer cell also required in probe)

02 Dual channel (stoichiometer cell also required in probe)

Code Programmable reference function

00 None

01 Single channel

02 Dual channel

Product matrix, Xi advanced electronics (continued)Table 1-2:

Code 800 deg C process function

00 None

01 Single channel

02 Dual channel

1. Requires XPS transmitter, P/N 6A00358G03

Note

All static performance characteristics are with operating variables constant. Specifications subject to

change without notice.

8 Xi

2 Install

WARNING!

Before installing this equipment, read Safety Instructions. Failure to follow safety instructions

could result in serious injury or death.

WARNING!

ELECTRICAL HAZARD

Install all protective equipment covers and safety ground leads after installation. Failure to

install covers and ground leads could result in serious injury or death.

WARNING!

HAZARDOUS AREAS

The Xi Advanced Electronics can be installed in general purpose areas only. Do not install the Xi

in hazardous areas or in the vicinity of flammable liquids.

Install

WARNING!

ELECTRICAL HAZARD

If external loop power is used, the power supply must be a safety extra low voltage (SELV)

type.

NOTICE

All unused ports on the probe housing and Xi enclosure should be plugged with a suitable

filling.

Reference Manual 9

Install

2.1 System considerations

A typical system installation for an Xi or O2 probe is shown in Figure 2-1.

Typical system installationFigure 2-1:

A. Gases

B. Duct

C. Adapter plate and flange

D. Instrument air supply (reference air)

E. Pressure regulator

F. Flowmeter

G. Calibration gas

H. Line voltage

I. 4 to 20 mA signal

J. Rosemount 6888Xi Advanced Electronics (optional)

K. Stack

2.2

Mechanical installation

2.2.1 Mount

The Xi Advanced Electronics is available in a panel mounting, wall mounting, or pipe

mounting configuration.

10 Xi

Install

Refer to Figure 2-2 or Figure 2-3 for the panel, wall, or pipe mounting details.

Procedure

1. Ensure all components are available to install the Xi.

2. Select a mounting location near or removed from the O2 probe.

Consider the temperature limitations of the Xi (see Section 1.3) when selecting the

mounting location.

3. Mount the Xi at a height convenient for viewing and operating the interface.

Approximately 5 ft (1.5 m) is recommended.

4. The keypad window on the Xi may have interior and exterior protective membranes.

Remove the protective membranes prior to use of the Xi enclosure.

NOTICE

Failure to remove the protective membranes may cause the display to appear distorted.

The membrane may be difficult or impossible to remove after extended use at elevated

temperatures.

Reference Manual 11

Install

Xi Advanced Electronics - panel mounting detailsFigure 2-2:

12 Xi

Install

Xi Advanced Electronics - wall/surface and pipe mounting detailsFigure 2-3:

2.3 Electrical installation

All wiring must conform to local and national codes. Multiple wiring diagrams are shown in

this section. Always refer to the diagrams that apply to your transmitter configuration and

disregard all other wiring diagrams.

Reference Manual 13

Install

WARNING!

ELECTRIC SHOCK

Disconnect and lock out power before connecting the power supply. Failure to lock out power

could result in serious injury or death.

WARNING!

ELECTRIC SHOCK

Install all protective covers and safety ground leads after installation. Failure to install covers

and ground leads could result in serious injury or death.

WARNING!

ELECTRIC SHOCK

To meet the safety requirements of IEC 1010 (EC requirement) and ensure safe operation of this

equipment, connection to the main electrical power supply must be made through a circuit

breaker (min 10 A) which will disconnect all current-carrying conductors during a fault

situation. This circuit breaker should also include a mechanically operated isolating switch. If it

does not, locate another external means of disconnecting the power supply close by. Circuit

breakers or switches must comply with a recognized standard such as IEC 947.

Note

Line, voltage, signal, and relay wiring must be rated for at least 105 °C (221 °F).

NOTICE

If a metal conduit is used with the Xi, the conduit should be reliably bonded to protective earth.

The grounding plate inside the Xi is not bounded to PE and does not provide adequate

grounding.

1. Remove cover screws from the front cover of the Xi. Swing down the front cover of

the interface box.

2. Pull out the I/O board on the right-hand side of the card rack inside the Xi. If your

system is configured to operate two transmitter probes, there are two I/O interface

boards.

3. See Figure 2-4. Connect the 4-20 mA signal wires at J4 of the I/O board. Attach the

supplied ferrite clamp over the 4-20 mA OUT wires that extend past the shield.

NOTICE

Installation of the ferrite clamp over the 4-20 mA OUT wires is required for compliance

with the European EMC directive.

14 Xi

Install

Signal connections at I/O boardFigure 2-4:

Alarm indicator relay terminalsFigure 2-5:

4. Terminate the shield of the 4-20 mA signal wires at the designated ground terminal

of the Xi. Do not allow bare shield wires to contact the circuit boards. Insulate the

shield wires prior to termination.

5. Connect the signal wires from the SPS or IMPS (if used) to the applicable terminals of

J3. Refer to the SPS or IMPS instruction manual for wiring details.

6. Connect the signal wires for the flame status input (if used) to the applicable

terminals of J2. The flame status sensing device is supplied by the customer. Refer to

the applicable OEM documents for signal wiring details.

7. Connect the customer's alarm indicator devices to the alarm indicator relay

terminals. See Figure 2-5 for the alarm indicator relay terminals.

8. Reinstall the I/O board in the card rack of the Xi.

Reference Manual 15

Install

Power connections - Xi Advanced ElectronicsFigure 2-6:

2.3.1

9. If your system is configured for two channel operation, repeat steps 2 through 7 to

connect the other signal wires.

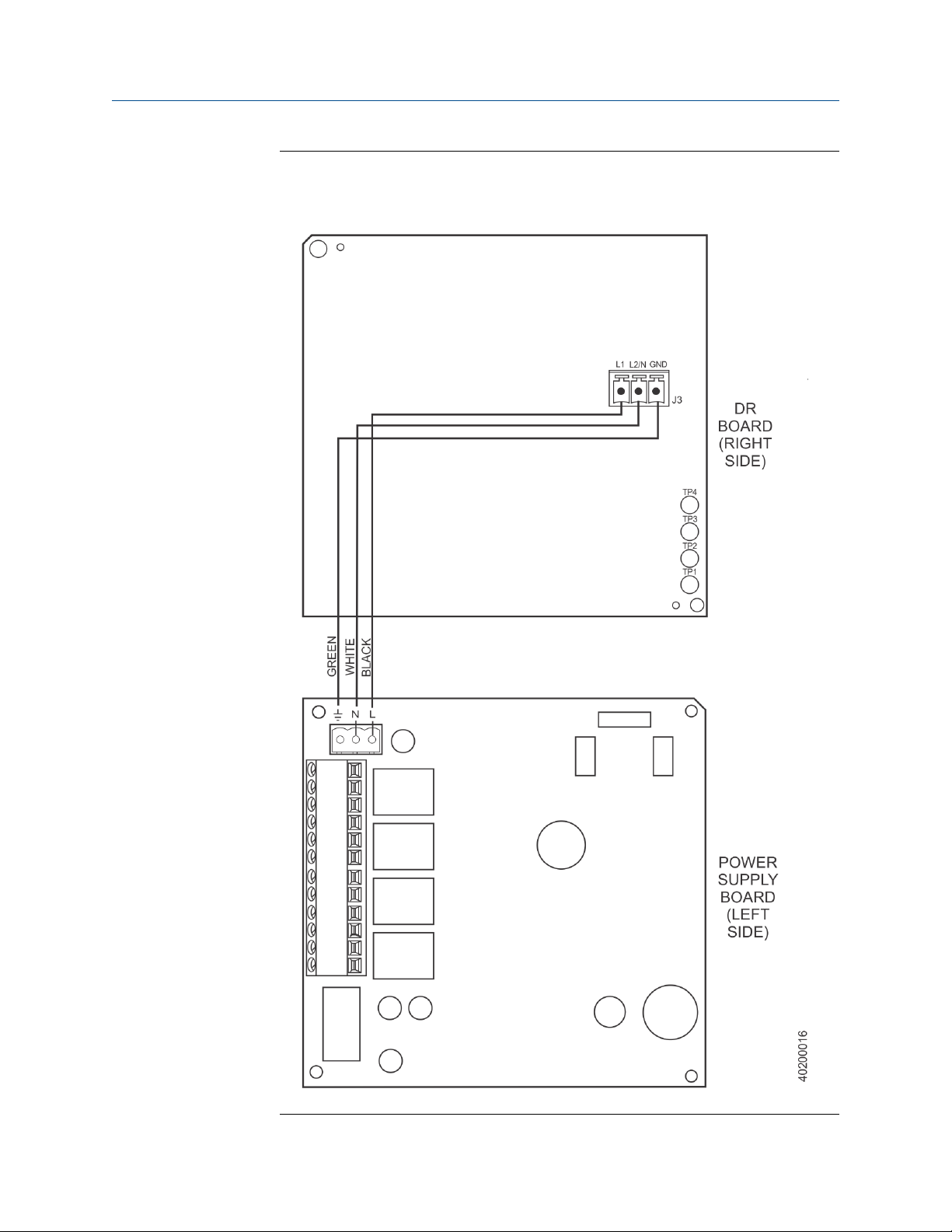

10. Remove the connector from the power supply board located on the left-hand side of

the card rack inside the Xi.

11. See Figure 2-6. Connect the line, or L1, wire to the L1 terminal and the neutral, or L2,

wire to the N terminal.

12. Reinstall the power supply connector in the power supply board.

13. Close and fasten the Xi cover.

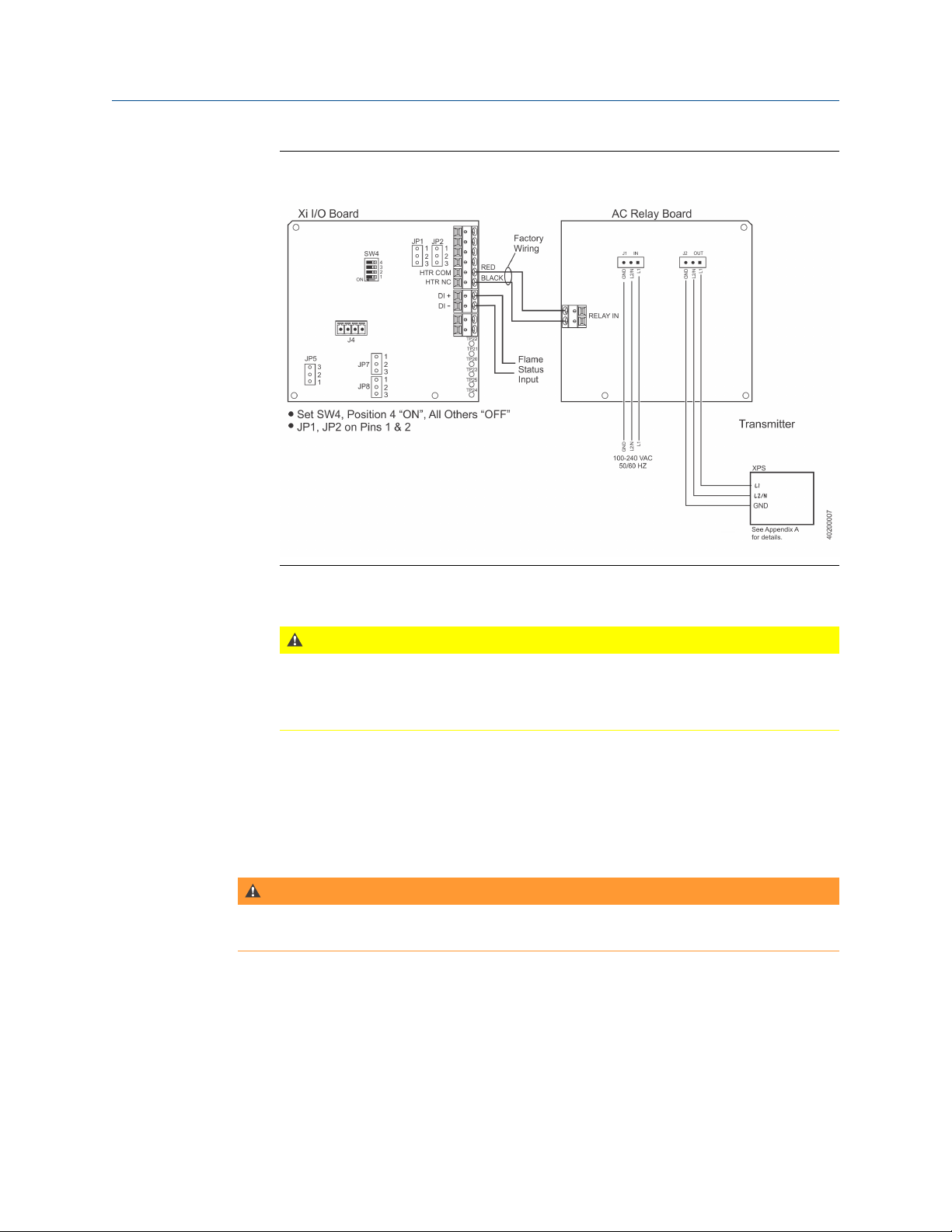

Optional flame safety interlock

A flame safety interlock by Emerson is available for the heater power disconnect whenever

there is a loss of the process flame or a heater runaway condition (heater overtemperature) in the O2 probe. A simplified wiring diagram for the flame safety interlock is

shown in Figure 2-7. The input is internally powered by the Xi and is actuated via a dry

contact output from the user's flame scanner. A closed contact indicates a flame is

present. An open contact indicates a loss of flame.

16 Xi

Install

Flame safety interlock - wiring diagramFigure 2-7:

2.3.2 Wire the traditional architecture cable connections

A traditional architecture configuration is used to provide for remote location of the

transmitter electronics. All electronics are housed inside the Rosemount 6888Xi. A multiconductor power/signal cable connects between the probe and the Rosemount 6888Xi.

Use the following procedure to connect the traditional architecture probe to the

Rosemount 6888Xi.

NOTICE

The traditional architecture cable is provided at the specified length and is ready for

installation. The cable glands must be properly terminated to maintain EMC/EMI noise

protection.

Procedure

1. Run the 7-conductor cable between the traditional architecture probe and the

installation site for the Rosemount 6888Xi. Use new cable conduit or trough as

needed.

2. Install the cable and lead wires to the probe per manufacturer's instructions.

3. Install the cable at the probe housing and at the Rosemount 6888Xi enclosure

according to the following procedure:

a. Unscrew the locking nut from the gland assembly and slide the locking nut back

along the cable.

b. Pull the gland body away from the plastic insert.

Use care not to damage the cable shield braid.

Reference Manual 17

Install

c. Insert the cable wires into the proper entry port in either the probe housing or

the Rosemount 6888Xi enclosure.

d. At the probe housing, apply Teflon® tape or similar sealing compound to the

tapered pipe threads. Thread the gland body into the probe housing until

properly seated.

e. At the Rosemount 6888Xi enclosure, insert the gland body into the left front

cable port from the inside of the enclosure. Use the rubber O-ring provided to

seal the cable port.

f. Ensure the cable shield braid is evenly formed over the gray insert.

When properly formed, the braid should be evenly spaced around the

circumference of the insert and not extend beyond the narrow diameter portion.

g. Carefully press the gray insert into the gland body. The grooves on the insert

should align with similar grooves inside the gland body. Press the insert in until it

bottoms out in the gland body.

h. Slide the locking nut up and thread it onto the gland body. Tighten the locking

nut so the rubber grommet inside the plastic insert compresses against the cable

wall to provide an environmental seal.

4. At the Rosemount 6888Xi, connect the cable leads to the connectors on the

transmitter I/O board.

18 Xi

3 Configure

3.1 Verify installation

WARNING!

ELECTRIC SHOCK

Install all protective equipment covers and safety ground leads before equipment startup.

Failure to install covers and ground leads could result in serious injury or death.

WARNING!

ELECTRIC SHOCK

If external loop power is used, the power supply must be a safety extra low voltage (SELV)

type.

Configure

3.1.1 Xi configuration

Refer to Figure 3-1 for the configuration of jumpers JP1 through JP8. The jumper

configuration for your I/O board depends on the system design and system components

used in your installation.

The setting of switch SW4 and the configuration of jumpers JP1 through JP8 must be

verified on the I/O board in the Xi. All four dip switches on switch SW4 must be set to the

Off position, as shown.

I/O board jumper configurationFigure 3-1:

Reference Manual 19

Configure

3.2 Set test gas values

Use a Field Communicator or the Xi to set test gas values for calibration.

An Xi shipped from the factory has test gas values for low and high set to 0.4% and 8%

respectively. This same process must be performed any time a replacement transmitter

board, I/O board, or DR board is installed.

Setting test gas values using Xi display/keypad

Procedure

1. Press the MENU button once.

2. From the main menu, select PROBE 1.

3. From PROBE 1, select DETAILED SETUP.

4. From the DETAILED SETUP menu, select CAL SETUP.

5. From CAL SETUP, select Cal Gas 1. Enter the percent O2 used for the low O2 test gas.

6. From CAL SETUP, select Cal Gas 2. Enter the percent O2 used for the high O2 test gas.

7. Press the Left arrow key several times to return to the main menu.

8. Repeat steps 2 through 6 for PROBE 2 if configured for dual channel.

3.2.1 Setting test gas values using Field Communicator

1. Use the Field Communicator software to access the HART menu.

2. From the DEVICE SETUP menu, select DETAILED SETUP.

3. From the DETAILED SETUP menu, select CAL SETUP.

4. From CAL SETUP, select Cal Gas 1. Enter the percent O2 used for the low O2 test gas.

5. From CAL SETUP, select Cal Gas 2. Enter the percent O2 used for the high O2 test gas.

3.3

Alarm relay output configuration

The Xi has two dry contact Form-C alarm relay output signals that can be configured in

eight different modes through the Xi keypad display or the 375/475 Field Communicator.

A list of possible configurations is shown in Table 3-1. Each alarm relay can be configured

separately.

If the Xi is configured with the optional flame safety interlock, Alarm 2 is configured with

Heater Relay and prewired to the AC relay board. In this condition, the relay configuration

cannot be changed to any other setting. If the Xi is not configured with the optional flame

safety interlock, Heater Relay is not valid and cannot be chosen for Alarm 2.

20 Xi

Configure

Alarm relay output configurationsTable 3-1:

Mode Configuration

No alarm

Unit alarm The output is configured for a unit alarm.

Low O2 alarm The output is configured for a low O2 alarm.

Low O2/unit alm The output is configured for a unit alarm and a low O2 alarm.

Cal recommended The output is configured for a calibration recommended display.

Cal rec/unit alm

Low O2/cal rec The output is configured for a low O2 alarm and a calibration recom-

Low O2/unit/cal rec The output is configured for a low O2 alarm, a unit alarm, and a cali-

Heater relay The output is configured for flame safety interlock.

(1) The default configuration for Alarm 2

(2) The default configuration for Alarm 1

(1)

(2)

The output is not configured for any alarm condition.

The output is configured for a unit alarm and a calibration recommended display.

mended display.

bration recommended display.

3.3.1 Configuring alarm relays with the Xi keypad/display

1. Press the MENU button once.

2. From the main menu, select PROBE 1.

3. From PROBE 1, select DETAILED SETUP.

4. From the DETAILED SETUP menu, select ALARM RELAY.

5. From ALARM RELAY, select as follows:

• Alm Relay1 - Alarm 1 mode

• Alm Relay2 - Alarm 2 mode

• Low O2 Alm SP - Low O2 alarm setpoint

• High Temp Alm SP - High temperature alarm setpoint

6. Press the Left arrow key several times to return to the main menu.

7. Repeat steps 2 through 6 for PROBE 2 if configured for dual channel.

3.3.2

Configuring autocalibration with the Field Communicator

1. Use the 375/475 Field Communicator software to access the HART menu.

2. From the DEVICE SETUP menu, select DETAILED SETUP.

3. From the DETAILED SETUP menu, select CAL SETUP.

4. From CAL SETUP, select Auto Cal.

5. Press the Right arrow key to change the state from NO to YES.

Reference Manual 21

Configure

3.4 Configure analog output

The analog output signal from the Rosemount 6888A can be configured for the 4-20 mA

range and fault condition. A separate configuration is set up when the Rosemount 6888A

is used with the optional Rosemount 6888Xi Advanced Electronics. When the Rosemount

6888A is used without the Rosemount 6888Xi, this parameter must be set to NO. If it is set

to YES and a Rosemount 6888Xi is not connected, the Rosemount 6888A triggers an alarm

and forces the analog output to the fault level. If the Rosemount 6888A is used later with a

Rosemount 6888Xi, the Rosemount 6888Xi automatically sets this parameter to YES.

An Rosemount 6888A shipped from the output has the analog outputs set to 4 to 20 mA

range with a 3.5 mA alarm level. You must complete the same process any time

transmitter board is replaced.

1. Use the 375/475 Field Communicator to access the main HART menu.

2. From the main menu, select CONFIGURE.

3. From the CONFIGURE menu, select MANUAL SETUP.

4. From the MANUAL SETUP menu, select ANALOG OUTPUT.

5. From the ANALOG OUTPUT menu, select from the following parameters; then press

ENTER.

• O2 LRV: O2 value at lower analog output value (0% at 4 mA, non-configurable)

• O2 URV: O2 value at upper analog output value (50% max at 20 mA)

• Output Range: Range of analog output (4-20 mA, non-configurable)

• Alarm level: O2 alarm level (3.5 mA or 21.1 mA)

• Xi Mode: Selects whether or not the Rosemount 6888A is used with a Rosemount

6888Xi (should always be set to NO for a stand-alone Rosemount 6888A)

3.4.1

6. Use the stylus to enter the value; then press ENTER when finished.

7. Use the stylus to select SEND to update the Rosemount 6888A.

Configuring the analog output with the Xi keypad/ display

1. Press the MENU button once.

2. From the main menu, select PROBE 1.

3. From PROBE 1, select DETAILED SETUP.

4. From the DETAILED SETUP menu, select ANALOG OUTPUT.

5. From ANALOG OUTPUT, select the following parameters:

• O2 LRV - O2 value at the lower analog output value (0 mA or 4 mA)

• O2 URV - O2 value at the upper analog output value (20 mA)

• AO Range - Range of the analog output (0-20 mA or 4-20 mA)

• Signal Alarm Level - O2 alarm level (3.5 mA or 21.1 mA)

22 Xi

Configure

3.4.2 Configuring alarm relays with the Field Communicator

1. Use the 375/475 Field Communicator software to access the HART menu.

2. From the DEVICE SETUP menu, select DETAILED SETUP.

3. From the DETAILED SETUP menu, select ALARM RELAY.

4. From ALARM RELAY, select as follows:

• Alm Relay1 - Alarm 1 mode

• Alm Relay2 - Alarm 2 mode

• Low O2 Alm SP - Low O2 alarm setpoint

• High Temp Alm SP - High temperature alarm setpoint

5. From CAL SETUP, select Cal Gas 2. Enter the percent O2 used for the high O2 test gas.

3.5 Autocalibration setup

If autocalibration is desired, the Xi must be used with either an SPS 4001B or IMPS 4000.

The Xi must be properly configured before autocalibration can take place. Refer to the

applicable SPS 4001B or IMPS 4000 instruction manual for details on performing

autocalibration. Refer to Chapter 4 for details on manual calibration procedures.

3.6

An Xi is shipped from the factory without autocalibration configured. This same process

must be performed any time a replacement I/O board is installed.

Optional advanced features inside the Xi

Advanced features available inside the Xi are typically ordered as part of the initial

package. However, these advanced features are also available for field retrofit.

An Xi is shipped from the factory with the optional enhanced software features enabled

based on the configuration.

WARNING!

The I/O board is shipped from the factory without any of the enhanced software features

activated. These features must be activated once the new board has been installed and before

the remote interface is put into service.

WARNING!

If the existing I/O board has been operated with the stoichiometric enhanced software feature,

this feature must be activated in the new board before the remote interface is put back into

service. Failure to do so will cause a false analog output signal to the DCS.

Reference Manual 23

Configure

NOTICE

For enhanced software feature option upgrades or to enable the feature to duplicate the

existing configuration, contact Emerson at 1-800-433-6076. Reference the following:

• 6A00269G01: Enhanced software option upgrade, stoichiometric function

• 6A00269G02: Enhanced software option upgrade, programmable reference function

• 6A00269G03: Enhanced software option upgrade, 800 °C process function

3.6.1 Extended process temperature range to 1472 °F (800 °C)

The Oxygen Analyzer employs a heater and thermacouple to maintain a temperature

setpoint at 1357 °F (736 °C). Temperature control is maintained within ±1 °C to process

temperatures of about 1300 °F (705 °C). This is satisfactory for most applications, but

excursions to higher temperatures can occur in some processes. In these instances, the

heater is turned off and the process temperature is used to heat the sensing cell.

The oxygen reading is adjusted immediately to compensate for the varying process

temperatures. Cell life will be reduced by continuous operation at temperatures above

1300 °F (705 °C). If process temperatures are expected to be continuously above 1300 °F

(705 °C), Emerson recommends the use of an optional bypass or probe mounting jacket

accessory. The extended temperature range feature is selected in the Xi product matrix,

but may not be purchased as a field retrofit.

3.6.2

3.6.3

Stoichiometer

Process upsets can sometimes cause a combustion process to go into sub-stoichiometric

or reducing conditions. The oxygen readings from one or more probes may decline all the

way to zero. The stoichiometer cell will measure the amount of oxygen deficiency during

these reducing conditions. The trends in your DCS can be set up for a lower range limit of

-1 or -2% oxygen to depict the level of oxygen deficiency.

You can see if your control recovery actions are having the desired effect. These types of

events do not occur frequently, but knowing the parameters of the situation prevents

over-correcting while coming out of the reducing condition. The stoichiometer feature

requires purchasing the acid resistant stoichiometer cell and the stoichiometer feature

inside the Xi.

NOTICE

Make sure the DCS is configured for the same range as the Xi. For instance: -1% O2 to 10% O2.

Programmable reference

The zirconium oxide sensing technology has historically measured process oxygen by

using ambient or instrument air as a reference (20.95% oxygen). The sensor develops most

of its signal at the low oxygen levels typically found in combustion flue gases (2 to 4%

oxygen) and is most accurate at these levels. When measuring near 20.95% O2, the sensor

develops only a few millivolts of signal, and accuracy degrades.

24 Xi

Configure

The programmable reference feature permits you to use a bottled reference gas of low

oxygen value (0.4% oxygen recommended). When measuring at or near 21% oxygen, a

strong negative oxygen signal results with much improved accuracy. A bottle of reference

gas typically lasts about a month at the low flows required. Typical applications would be:

• Flue gas recirculation - controlling the mixing of flue gases into the burner windbox

ahead of the burner to reduce NOx emissions.

• Moisture monitoring - measuring the amount of moisture coming off of industrial

dryers by noting that the dilution effect water vapor has on the normal 20.95%

ambient drying air (non-combusion drying processes only).

• Enriched oxygen concentration - pure oxygen is sometimes mixed in with the

combustion air to increase heat at the flame. This is used in steel and other metals

reduction processes and in some catalyst regenerators.

Reference Manual 25

Configure

26 Xi

4 Startup and operation

4.1 Overview

Interface to the Xi for setup, calibration, and diagnostics can be via a 375/475 Field

Communicator or Asset Management System.

Setup, calibration, and diagnostic operations differ depending on the selected interface for

communications with the transmitter.

4.2 Startup

The O2 probe takes approximately 45 minutes to warm up to the 736 °C (1357 °F) heater

setpoint. The 4-20 mA signal remains at a default value of 3.5 mA through this warmup

period. Once warm, the O2 reads oxygen, and the 4-20 mA signal's reading is based on the

default range of 0-10% O2.

Startup and operation

NOTICE

The Xi offers optional advanced features, such as elevated process temperature capability to

1472 °F (800 °C), autocalibration via an SPS solenoid vox, a stoichiometer feature for indicating

the level of oxygen defiency in reducing conditions, and programmable reference to enhance

accuracy at near ambient levels of O2.

Reference Manual 27

Startup and operation

Xi display (typical)Figure 4-1:

4.2.1 Operation via Xi

The following procedures describe operations using the Xi to set up and calibrate the

system. Additional operating instructions are included in the SPS 4001B or IMPS 4000

instruction manual, if applicable to your system.

4.2.2

4.2.3

Error conditions

If there is an error condition at startup, an alarm message is displayed. Refer to Chapter 5 to

determine the cause of the error. Clear the error and cycle power. The %O2 and

temperature display should return without the alarm message.

Xi Controls

The Xi can be used to change the software and alarm settings, to adjust the high and low

gas settings, and to initiate the calibration sequence. Refer to the following control

descriptions. Use the control keys on the front panel of the Xi (Figure 4-1) to navigate and

edit the Xi menu (Figure 4-2).

• MENU toggles between three main menu options: System, Probe1, and Probe2 (if

available). The top level of the selected main menu is displayed.

• DIAG toggles between the Alarms list of the three main menus. All faults and

warnings related to the selected main menu device are displayed.

• ENTER saves newly entered data and returns you to the previous menu level.

28 Xi

Startup and operation

• EXIT returns you to the previous menu level without saving newly entered data.

When navigating the menu tree, pressing EXIT returns you to the main menu.

• Up/Down keys scroll up and down through menu items. During data entry, the Up/

Down keys increment and decrement the data values.

• Left arrow key returns you to the previous menu level. During data entry, the Left

arrow key moves the cursor one digit to the left.

• Right arrow key advances you to the next menu level and, when a menu item is

highlighted, selects the item from a list of menu options. During data entry, the

Right arrow key moves the cursor one digit to the right.

Reference Manual 29

Startup and operation

Xi menuFigure 4-2:

30 Xi

Startup and operation

Reference Manual 31

Startup and operation

4.2.4 Password protection

Beginning with Xi system software version 1.05 or higher, the main display and diagnostic

screens of the Xi can be viewed at any time, but further access and unauthorized

configuration changes can be prevented by enabling a password protection feature.

However, the Xi is shipped with password protection disabled.

Password protection can be enabled by selecting System Main Menu > Configure > LCD >

Enable Password (see Figure 4-2).

32 Xi

The factory default upon enabling the password protection is ROSE, but the password can

consist of any 4 alpha/numeric characters.

If you forget the password, call Rosemount technical support at 800-433-6076 to gain

access to a master password.

A Lock icon is displayed at the top right corner of the main display when password

protection is in effect.

The password protection relocks itself after a certain number of seconds with no button

pushes (defined as revert time in the same LCD setup menu). You can also force the front

panel to be locked by selecting System Main Menu > Log Off. The Log Off selection

performs on function if the password feature is disabled.

The Xi has a Reset function that reestablishes all factory default conditions, including the

password protection feature, i.e., the password protection falls back to a disabled

condition after a reset.

4.3 System parameter descriptions

Startup and operation

Among the parameters available through the Xi and 375/475 Field Communicator menus

are a number of system parameters. The system parameters define variables that configure

the Xi in the transmitter system. System parameters are described in the following table.

System parametersTable 4-1:

CPU Parameter name Units Parameter description

Y Version --- Software version number for the CPU

board

Y Build Num --- Software build number for the CPU

board

Y Comm Status --- Communication status between the

CPU and I/O boards

Y Restart Cntr --- Software restarts counter for the CPU

board

N Pol Addr --- Polling address - address used to identi-

fy a field device; changeable by user

N Serial Number --- I/O board serial number

N Features --- Available advanced software features

for the I/O board.

ON: feature supported.

OFF: feature not supported.

N EE Erase Count --- This is for nonvolatile memory diagnos-

tic only.

Reference Manual 33

Startup and operation

System parameters (continued)Table 4-1:

CPU Parameter name Units Parameter description

Y Num Probe --- Number of probes configuration:

If set to 1, use One Probe configuration

for the main display.

If set to 2, use Two Probes configuration

for the main display.

Y Probe Sel --- This parameter is applicable only if the

Num Probe configuration is set to 2. It defines which probe is to be displayed.

Y Probe 1 Enable --- Probe 1 state. If enabled, the probe

menu will be displayed; otherwise it will

not be displayed. (No, Yes)

Y Probe 2 Enable --- Probe 2 state. If enabled, the probe

menu will be displayed; otherwise it will

not be displayed (No,Yes)

Y LineX Probe --- Probe number for line x. (1, 2)

Y Line 1 Data --- Main display, line 1 data; 0 displays PV

(O2), 1 displays SV (O2 temp)

Y Line 2 Data --- Main display, line 1 data; 0 displays PV

(O2), 1 displays SV (O2 temp)

Y Line 3 DataL --- Main display, line 3 left hand side data:

0 displays PV (O2)

1 displays SV (O2 temp)

2 displays TV (cell imp)

3 displays 4 V (cell mV)

4 displays CJC temp

5 displays AO

6 displays OP mode

7 displays Tag

Y Line 3 DataR --- Main display, line 3 right hand side data

0 displays PV (O2)

1 displays SV (O2 temp)

2 displays TV (cell imp)

3 displays 4 V (cell mV)

4 displays CJC temp

5 displays AO

6 displays OP mode

7 displays Tag

34 Xi

Startup and operation

System parameters (continued)Table 4-1:

CPU Parameter name Units Parameter description

Y Line 4 DataL --- Main display, line 4 left hand side data

0 displays PV (O2)

1 displays SV (O2 temp)

2 displays TV (cell imp)

3 displays 4 V (cell mV)

4 displays CJC temp

5 displays AO

6 displays OP mode

7 displays Tag

Y Line 4 DataR --- Main display, line 4 right hand side data

0 displays PV (O2)

1 displays SV (O2 temp)

2 displays TV (cell imp)

3 displays 4 V (cell mV)

4 displays CJC temp

5 displays AO

6 displays OP mode

7 displays Tag

Y Revert time min Xi display reverts to main display time.

Also locks screen if password protection

is enabled.

Y Language --- 0 displays English

1 displays Spanish

2 displays German

Y Contrast --- Display contrast (120 to 200)

Y Alarms --- See Chapter 5

Y Password --- Security password

Y Enable password --- Enables/disables security password pro-

tection

Reference Manual 35

Startup and operation

4.4 Probe parameter descriptions

Among the parameters available through the Xi and 375/475 Field Communicator menus

are a number of Probe Parameters. The probe parameters define variables that configure a

specific probe in the transmitter system. Probe parameters are described in the following

table:

Probe parametersTable 4-2:

TX I/O Parameter name Units Parameter description

Y Y O2 % Current oxygen concentra-

tion value (O2%). The value

should reflect the last good

O2 value if it is in the Lock

state during calibration.

Y Y O2 Temp ° C Current O2 sensor tempera-

ture.

Y Y CJC Temp ° C Current cold junction tem-

perature.

N Y Elec Temp ° C Current electronic tempera-

ture measured at the I/O

board.

Y Y O2 Cell mV Raw mV value for ZrO2 sen-

sor.

N Y TC Volt mV O2 T/C voltage.

Y Y Cell Imp Ohm Cell impedance/sensor re-

sistance measured.

Y Y Htr Volt Volt Heater voltage

Y Y CPU Volt Volt Transmitter CPU voltage.

Y Y O2 AO mA Analog output value repre-

sents the O2 concentration

measurement.

N Y O2 AO% % O2 analog output percent-

age for O2 AO

Y Y O2 Temp Max ° C This is the highest O2 sensor

temperature reached since

last reset.

Y Y CJC Temp Max ° C This is the highest tempera-

ture reached at the cold

junction since last reset.

N Y Elec Temp Max ° C This is the highest tempera-

ture reached at the I/O board

since last reset.

Y Y Htr Volt Max ° C This is the highest heater

voltage reached since last reset.

36 Xi

Startup and operation

Probe parameters (continued)Table 4-2:

TX I/O Parameter name Units Parameter description

Y Y Htr Duty Cycle --- O2 heater duty cycle. Value

between 0 and 1.

Y Y PID SP ° C PID temperature set point.

Y Y Htr Ramp Rate ° C/s Heater ramp rate calculated

in degree C per second.

N Y Flame Stat In --- Flame input state. (OFF/ON)

N Y SPS/IMPS In --- SPS/IMPS input state. (OFF/

ON)

N Y SPS/IMPS out --- SPS/IMPS output state. (OFF/

ON)

N Y Alm Relay 1 Out --- Alarm Relay 1 output state.

N Y Alarm Relay 2 Out --- Alarm Relay 2 output state.

(OFF/ON)

Y Y OP Mode --- Device operating mode: PO

= Power up; WU = Warm up

(analog output is railed); NM

= Normal operation; CA =

Calibrating (analog output

can be tracking or locked at

last good value based on AO

Tracks configuration; AL =

Alarm detected (recoverable); SF=Alarm detected

(non-recoverable)

Y Y Tag --- Device tag

Y Y Device ID --- Unique device ID number

(HART)

Y Y PV is --- Primary variable assignment

(HART)

Y Y SY is --- Secondary variable assign-

ment (HART)

Y Y TY is --- Third variable assignment

(HART)

Y Y QV is --- Fourth variable assignment

(HART)

Y Y Cal Slope mV/Dec Current calibration slope.

This is the slope value that

was calculated as a result of

the last successful calibration.

Reference Manual 37

Startup and operation

Probe parameters (continued)Table 4-2:

TX I/O Parameter name Units Parameter description

Y Y Cal Const mV Current calibration constant.

This is the constant value

that was calculated as a result of the last successful calibration.

Y Y Cal Imp Ohm Cell impedance. This is the

sensor resistance that was

calculated as a result of the

last successful calibration.

N Y Prev Slope mv/Dec Previous calibration slope.

There are ten calibration results. 1 is the most recent,

and 10 is the least recent calibration slope.

N Y Prev Const mV Previous calibration con-

stant. There are ten calibration results. 1 is the most recent, and 10 is the least recent calibration constant.

N Y Prev Cal Imp Ohm Previous cell impedance.

This is the sensor resistance

that was calculated as a result of the previous successful calibration. There are ten

calibration results. Index 1 is

the most recent, and Index

10 is the least recent sensor

resistance measured.

N Y Failed Slope mV/Dec Failed calibration slope.

N Y Failed Const mV Failed calibration constant.

Y Y Cal Result mV Calibration result.

N Y Delta Imp --- Delta impedance since last

calibration.

N Y Cal Step --- This represents the step the

calibration cycle is in.

N Y Time remain sec Time remaining in the

present calibration cycle

state.

Y Y O2 slope mV/Dec O2 slope. This is the slope

value that will be used to calculate O2.

Y Y O2 Const mV O2 constant. This is the con-

stant value that will be used

to calculate O2.

38 Xi

Startup and operation

Probe parameters (continued)Table 4-2:

TX I/O Parameter name Units Parameter description

N Y T90 filter sec Analog output T90 time. It

represents the time to take a

step change in oxygen to

reach 90% of the final value

at the filter output.

N Y O2 Cell Ref % O2 sensor reference gas per-

centage. It allows a sensor

reference gas other than air.

N Y O2 Temp SP deg C O2 sensor set point. It allows

measurement of oxygen

with an elevated sensor temperature. (0 =736 deg C set

point; 1 = 834 deg C set

point)

N Y Features --- Advanced software features

(0=Stoichiometer; 1=Programmable Reference;

2=Elevated Temperature)

Y Y O2 URV % Primary variable (O2%) upper

range value

Y Y O2 LRV % Primary variable (O2% lower

range value)

N Y O2 AO Range --- Analog output polarity. (0 =

4-20 mA; 1 = 20-4 mA)

Y Y O2 Alarm Level --- O2 alarm level. (0 = 3.5 mA; 1

= 21.1 mA)

N Y Alarm Relay 1 --- Alarm Relay 1 mode. (no

alarm; unit alarm; low O

alarm; low O2/unit alarm; Cal

recommended; Cal recommended/unit alarm; low O2/

Cal recommended, low O2/

unit alarm/Cal recommended.)

N Y Alarm Relay 2 --- Alarm Relay 2 mode. (no

alarm; unit alarm; low O

alarm; low O2/unit alarm; Cal

recommended; Cal recommended/unit alarm; low O2/

Cal recommended, low O2/

unit alarm/Cal recommended; Heater relay)

N Y Low O2 Alm % Low O2 alarm threshold.

2

2

Reference Manual 39

Startup and operation

Probe parameters (continued)Table 4-2:

TX I/O Parameter name Units Parameter description

N Y Hi Temp Alm % High temperature alarm

threshold.

N Y AO Tracks --- Analog output track O2 sen-

sor measurement during a

calibration. (No, Yes)

N Y Auto Cal --- Enable/disable automatic

calibration.

No = Set to manual calibration mode.

Yes = Set to automatic calibration mode.

N Y Start On CalRec --- Start automatic calibration

on Cal Recommended state.

(No, Yes)

Y Y Cal Gas 1 % Test Gas 1 value. This is the

actual value of the gas being

applied during the Test Gas 1

phase of a calibration.

Y Y Cal gas 2 % Test Gas 2 value. This is the

actual value of the gas being

applied during the Test Gas 2

phase of a calibration.

Y Y Gas Time sec Test Gas application time.

This is the length of time test

gases are applied to the O

probe during low or high

Test Gas phase of a calibration.

Y Y Purge Time sec Test Gas purge time. This is

the length of time before the

output will be returned to

the process reading after a

calculation.

N Y Cal Interval hr Automatic calibration inter-

val. The number 9999 disables the automatic timed

calibration.

N Y Next Cal Time hr Automatic calibration inter-

val. The number 9999 disables the automatic timed

calibration.

Y Y T EE Val --- Transmitter board nonvola-

tile memory diagnostic

2

40 Xi

Startup and operation

Probe parameters (continued)Table 4-2:

TX I/O Parameter name Units Parameter description

N Y IO EE Val --- I/O board nonvolatile memo-

ry diagnostic

Y Y Version --- Software version number for

the transmitter.

N Y Version --- Software version number for

the I/O board.

Y Y T Restart Cntr --- Software restarts count for

the transmitter.

N Y IO Restart Cntr --- Software restarts count for

the I/O board.

Y Y Alarms --- Current alarms (see

Chapter 5).

4.5 Operation via HART/AMS

The 375/475 Field Communicator is a handheld communications interface device. It

provides a common communications link to all microprocessor-based instruments that are

HART compatible. The handheld communicator contains a liquid crystal display (LCD) and

21 keys. A pocket-sized manual, included with the 375/475 Field Communicator, details

the specific functions of all the keys.

The 375/475 Field Communicator accomplishes its task using a frequency shift keying

(FSK) technique. With the use of FSK, high-frequency digital communications signals are

superimposed on the Xi's 4-20 mA current loop. The 375/475 Field Communicator does

not disturb the 4-20 mA signal, as no net energy is added to the loop.

NOTICE

The 375 Field Communicator must be upgraded to System Software 2.0 with Graphic License

for operation with the Xi. The AMS software must be upgraded to AMS 8.0 or above for

operation with the Xi.

Contact Emerson's Global Service Center (GSC) at 1-800-833-8314 to upgrade the 375 Field

Communicator software to System Software 2.0 with Graphic License.

4.5.1

Field communicator signal line connections

When working at the Xi, the 375/475 Field Communicator can be connected directly to

test points TP21 and TP22 on the Xi I/O board as shown in Figure 4-3. The AM+ and AMtest points are provided to monitor the 4-20 mA signal without breaking into the loop.

Reference Manual 41

Startup and operation

375/475 Field Communicator connection at the XiFigure 4-3:

4.5.2 Field Communicator menu trees

Connect the 375/475 Field Communicator in the Xi (Xi-to-DCS) 4-20 mA signal loop or to

the Xi terminals shown in Figure 4-3 and refer to Figure 4-4 for the 375/475 Field

Communicator Xi menu tree.

42 Xi

Startup and operation

375/475 Field Communicator Xi menu treeFigure 4-4:

Reference Manual 43

Startup and operation

4.6 Offline and online operations

The 375/475 Field Communicator can be operated both offline and online.

44 Xi

Offline operations are those in which the communicator is not connected to the O2 probe.

Offline operations include interfacing the 375/475 Field Communicator with a PC (refer to

applicable HART documentation regarding HART/PC applications).

In the online mode, the 375/475 Field Communicator is connected to the 4-20 mA analog

output signal line. The communicator is connected in parallel to the O2 probe or in parallel

to the 250 ohm load resistor.

4.7 Calibration - general

New O2 cells may operate for more than a year without requiring calibration, but older

cells may require recalibration every few weeks as they near the end of their life.

A CALIBRATION RECOMMENDED alarm provides notice of when a calculation is required. This

strategy ensures that the O2 reading is always accurate and eliminates many unnecessary

calibrations based on calendar days or weeks since previous calibration.

The O2 probe(s) can be calibrated manually through the handheld 375/475 Field

Communicator or the Xi. Fully automatic calibration can be performed automatically using

the Xi and the SPS 4001B Single Probe Autocalibration Sequencer or the IMPS 4000

Intelligent Multiprobe Sequencer.

Startup and operation

4.8 O2 calibration

This section covers manual calibration. For automatic calibration details, see the

Instruction Manual for the SPS 4001B Single Probe Autocalibration Sequencer or the IMPS

4000 Intelligent Multiprobe Test Gas Sequencer.

Calibration can be performed using three basic calibration methods. The methods

available to you for use depend on the configuration of your system. The sections that

follow describe how to perform a calibration for two basic system configurations shown in

Figure 4-5.

Included in the calibration procedures are instructions for setting up the calibration

parameters. Setup of the calibration parameters should be performed before the first O

calibration. Thereafter, perform calibration setup only as needed to change the calibration

parameters or to reset the parameters following the replacement of primary system

components.

Before calibrating, verify that the configuration gas parameters are correct. Refer to

Chapter 3.

2

Reference Manual 45

Startup and operation

Calibration methods, simplifiedFigure 4-5:

4.8.1 O2 calibration with Xi

For systems with configuration 1, shown in Figure 4-5, use the following procedure to

perform a calibration using the Xi. If necessary, use the Xi menu tree in Figure 4-2 for

reference.

NOTICE

To select a menu item, use the up and down arrow keys to scroll to the menu item and press

the right arrow key to select the menu item. To return to a preceding menu, press the left

arrow key.

Procedure

1. From the Main Menu, select SYSTEM to access the Xi System menu.

2. From the Xi SYSTEM menu, scroll down and select DETAILED SETUP.

3. Select menu item 4, CAL SETUP, to input the cal gas and flow times.

4. Return to the SYSTEM menu and select the last menu item, CALIBRATION, to access

the CALIBRATION menu.

5. From the O2 CALIBRATION options, select Start Cal to start the O2 calibration

procedure.

46 Xi

WARNING!

Failure to remove the Xi from automatic control loops prior to performing this

procedure may result in a dangerous operating condition.

In the first Start Cal screen, a "Loop should be removed from automatic control"

warning appears.

6. Remove the Xi from any automatic control loops to avoid a potentially dangerous

operating condition and press OK.

7. Follow the Xi display prompts to perform the O2 cal procedure.

4.8.2 O2 calibration with Xi and Field Communicator

For systems with configuration 2, shown in Figure 4-5, use the following procedure to

perform a calibration of the system using the 375/475 Field Communicator. If necessary,

use the menu tree in Figure 4-2 for reference.

NOTICE

Startup and operation

To select a menu item, use the up and down arrow keys to scroll to the menu item and press

the right arrow key to select the menu item. To return to a preceding menu, press the left

arrow key.

Procedure

1. Select DEVICE SETUP.

2. From the DEVICE SETUP screen, select menu item 4, DETAILED SETUP.

3. Select menu item 3, CAL SETUP, to input the cal gas and gas flow times.