Rosemount World Class 3000 O2 Analyzer CENELEC with IFT 3000 Intelligent Field Transmitter-Rev 4.1 Manuals & Guides

Page 1

WORLD CLASS 3000 OXYGEN

ANALYZER (CENELEC) WITH

IFT 3000 INTELLIGENT FIELD

TRANSMITTER (CENELEC)

Instruction Bulletin IB-106-300NFX Rev. 4.1

World Class 3000 Probe

Part No. _______________

Serial No. _______________

Order No. _______________

IFT 3000

Part No. _______________

Serial No. _______________

Order No. _______________

NOTICE: The equipment described in this

Instruction Bulletin is manufactured by:

Rosemount Ireland

151 Shannon Industrial Estate

Co. Clare

Ireland

HPS 3000

Part No. _______________

Serial No. _______________

Order No. _______________

MPS 3000

Part No. _______________

Serial No. _______________

Order No. _______________

Page 2

lNTRoDUCT’oN: THIS SAFRY DATA SHEm APPLIES TO INTELEGENT FIELD TRANSMllTER

(Im3000), NPE No. 11105691. THE APPARATUS IS CERTIFIED EExd IIB T6.:

ISSeP CERTIFICATE No.

THIS APPARATUS HAS BEEN DESIGNED AND MANUFACTURED TO OPERATE

SAFELY IN CERTAIN NPES OF POTENTIALLY EXPLOSIVE ATMOSPHERES. IT 1s ESSENTIAL

THAT THE EQUIPMENT IS NOT TAMPERED WITH OR DAMAGED IN ANY WAY WHICH

MIGHT LEAD TO A REDUCTION IN IT’S ABILITY TO OPERATE SAFELY IN SUCH POTENTIALLY

EXPLOSIVE ATMOSPHERES. FOR YOUR OWN SAFETY AND THE SAFETY OF OTHERS

PLEASE BRING ANY DAMAGE TO THE ATTENTION OF THE RESPONSIBLE AUTHORITY.

THIS APPARATUS HAS BEEN DESIGNED AND MANUFACmRED IN ACCORDANCE

WITH EUROPEAN STANDARDS EN50014 8c EN50018. INSTALLATION MAINTENANCE

AND REPAIR MUST BE IN ACCORDANCE. WITH THE OFFICAL “C@ES OF

PRACTICE ON THE INSTAIATION AND MAINTAINANCE OF ELEC@ICAL APPARATUS

IN POTENTIALLY EXPLOSIVE ATMOSPHERES” FOR THE COUl@Y OF INSTALLATION

(EXAMPLE: 8~5345 IN GREAT BRITAIN). ONLY APPROPR~ATLY TRAINED PERSONNEL

ARE AUTHORISED TO PERFORM ANY W0RK ON THIS EQUIPMENT. SUCH PERSONNEL IN

ADDITION TO OPERATING TO THE ABOVE MENTlONED SAFETY STANDARDS, SHOULD TAKE

NOTE OF THE FOLLOWING SAFETY ISSUES.

(1, FLAMEPROOF APPARATUS OR NON FLAMEPROOF APPARATUS.

THE ROSEMOUNT ENCODE SHEETS (PRODUCT ORDERING MATRIX) ALLOWS A CUSTOMER

TO ORDER EITHER THE HAZARDOUS AREA (FLAMEPROOF) VERSION OF THE IFT3000

OR THE NON HAZARDOUS AREA VERSION. THE HAZARDOUS AREA VERSION HAS THE

SYMBOL “EExd” ON THE APPARATUS hIAMEPLATE. THE NON HAZARDOUS AREA VERSION

DOES NOT. ENSURE THAT IF YOU HAVE RECEIVED THE NON HAZARDOUS AREA VERSION

THAT YOU DO NOT INSTALL IT IN APOTENTIALLY EXPLOSIVE ENVIRONMENT.

(2) POWER DOWN PROCEDURE:

ISOLATION OF ELECTRICAL SUPPLY: THIS PIECE OF APPARATUS IS NOT ITSELF FIT-I-ED

WITH A MEANS OF ELECTRICAL ISOLATION. CONSULT YOUR LOCAL CODES OF PRACTICE

ON THE INSTALLATION AND MAlNTAlNAhlCE OF ELECTRICAL APPARATUS IN POTENTIALLY

EXPLOSIVE ATMOSPHRES (835345 IN IBRITAIN) FOR INSTRUCTION ON THE ISOLATION OF

ELECTRICAL SUPPLY TO THE APPARATUS. FURTHER MORE THERE MUST BE “EFFECTIVE

MEASURES TO PREVENT THE RESTORATION OF SUPPLY TO THE APPARATUS WHILE THE

RISK OF EXPOSING UNPROTECTED LIVE CONDUCTORS TO AN EXPLOSIVE ATMOSPHERE

CONTlNUES”:BS5345 PAPT 1 1989 SECTION 18.

RESTORATION OF SUPPLY FOR-EL-ICAL TESTlNG: “WHERE, FOR PURPOSES OF

ELECTRICAL TESTING, IT IS ESSENTIAL ‘TO RESTORE THE SUPPLY BEFORE THE APPARATUS

IS RE-ASSEMBLED. THEN THIS WORK SHOULD BE UNDER A CONTROLLED PROCEDURE

AND THE SPECIFIC. LOCATION ASSESSED TO ENSURE THAT POTENTIALLY FLAMMABLE

GAS OR VAPOUR IS ABSENT”:BS5345 PART 1 1989 SECTION 23.

REMOVAL OF JUNCTION BOX COVER: DO NOT OPEN THE APPARATUS COVER

WHILE THE APPARTUS IS ENERGISED. WAIT 10 MINUTES AFIER DEENERGISING BEFORE

OPENING THE APPARATUS.

(3) _\dllBu\IG OF THE APPARATUS; EACH APPARATUS MUST BE WIRED AS DETAILED IN

THE APPLICABLE INSTRUCTION BULLfllN (USER MANUAL).

(4) lNsm”cnoN BULLETINS (“sER:.MAN”AL). THE APPLICABLE INSTRUCTION BULLETIN IS:

IB-106-300NFX: USED WITH IFr3000 ELECTRONICS.

THIS INSTRUCTION BULLETIN CONTAIN ESSENTIAL INFORMATION 8c MUST BE USED

WHEN WORKING ON THE APPARATUS.

(5) CABLE GLANDS:

BAS No. EX 85B1258”) OR AN EQUIVALENT MUST BE USED. THIS GLAND IS A

BARRIER (STOPPER) GLAND. A FEATURE OF THIS GLAND IS THAT A COMPOUND

FILLED PACKING MATERIAL (PUllY), FORMS A BARRIER BETWEEN THE INDIVIDUAL

INSULATED CONDUCTORS OF THE CABLE. THIS BARRIER ACTS TO PREVENT ENTRY

INTO THE CABLE OF THE PRODUCTS OF AN EXPLOSION WITHIN THE ENCLOSURE.

THIS GLAND IS CERTIFIED Exd IIC.

HAWKE CABLE GLAND, wpE icG653 (BASEEFA cERnFlcATE :

Page 3

~~ow67 .

13/12/93 1

DEDQ5937

7-4-94 2

(6) EXlSTlNG WESTlNGHOUSE/ROSEMOUNT SUPPLIED CABLE:

ON EARLIER INSTALLATIONS WESTINGHOUSE/ROSEMOUNT SUPPLIED A CABLE

BEIWEEN THE DIGITAL ELECTRONICS AND PROBE (MODEL 218).

THE GLANDS ON THIS CABLE - ALTHOUGH HAWKE GLANDS CERTIFIED Exd IIC

WERE NOT OF THE HAWKE BARRIE:R (STOPPER) GLAND, MPE 1cG653 VARIETY.

THESE GLANDS MUST NOT BE USED. ROSEMOUNT CAN SUPPLY A BARRIER GLAND

KIT TO REPLACE SUCH GLANDS. THE KIT (PART No. lUO3066GO7), COMPRISES

OF TWO BARRIER GLANDS COMPLETE WITH PUl-fY, CRIMPS AND AN INSTRUCTION

SHEET. PLEASE NOTE THAT YOU SHOULD USE ONLY PUTIY WHICH IS PLASTIC

& CAPABLE OF BEING MIXED. YOU SHOULD NOT USE CRYSTALISED OR HARD

PUI-I-Y.

(7) CABLE ANCHORAGE

’

THIS APPARATUS DOES NOT INCLUDE ANY SPEClflC MtiNS FOR CABLE ANCHORAGE.

THE CABLE GLANDS CHOSEN FOT THE MAINS, PROBE, AND SIGNAL CABLES MUST

BE OF AMPE WHICH SUPPLY CABLE ANCHORAGE. THE BARRIER (STOPPER) GLAND

SUPPLIED BY ROSEMOUNT ASi.PART OF THE PROBE CABLE ASSEMBLY, WILL GIVE

SUCH CABLE ANCHORAGE.

(8) UNUSED CABLE ENTRY PORTS:

ALL CABLE ENTRY PORTS WHICH ARE UNUSED

ARE TO BE CLOSED OFF WITH THREADED PLUGS CERTlflED Exd IIC. THERE SHOULD

BE A MINIMUM OF 5 THREADS ENGAGED AND THE THREADS SEALED WITH

THREADLOCK (LOCKTlTE 271 OR IIQUILAVENT).

(9) NAMEPLATE (LABEL):

ENSURE THAT NAMEPLATE IS AT ALL TIMES VISIBLE.

AT INSTALLATION. ALLOWANCE MUST BE MADE FOR THIS.

(10) EARTHING OF THE APPARATUS:

THE APPARATUS HAS BEEN FITTED WITH BOTH

EXTERNAL AND INTERNAL EARTHING POINTS. ADEQUATE EARTH

CONNECTIONS

SHOULD BE MADE TO BOTH THESE POINTS.

(11) SHEET METALWORK PANELS.

THIS APPARATUS CONTAINS A NUMBER OF SHEET METALWORK PANELS FOR MOUNTING

THE PRINTER CIRCUIT BOARDS. BECAUSE THESE PANELS ARE IN CLOSE PROXIMIlY

TO THE WALLS OF THE FLAMEPROOF ENCLOSURE, IT WAS NECESSARY TO

PERFORATE THEM WITH HOLES h;ND SLOTS. THESE HOLES AND SLOTS PREVENT

PRESSURE PILING BETWEEN THE PANELS AND THE WALLS & LID OF THE

ENCLOSURE. DO NOT DO ANYTHING WHICH MIGHT OBSCURE THESE SLOTS & HOLES.

(12) LlFl-lNG AND CARRYING.

THE In3000 IS A HEAVY PIECE OF APPARATUS. LIFTING AND CARRYING PROCEDURES

SHOULD TAKE ACCOUNT OF THIS WEIGHT.

(13) CONNECTION TO HART OPTION.

HART IS A COMMUNICATIONS PROTOCOL WHICH ALLOWS REMOTE COMMUNICATION

WITH THE lFr3000 VIA THE 4-20mA OUTPUT. BECAUSE, ON THE IFT3000, THE

HART OPTION IS NOT PROTECTED BY ENERGY LIMITING BARRIERS. IT MUST NOT

BE INTERFACED FROM WITHIN THE HAZARDOUS AREA. THE 4-20mA CABLES SHOULD

BE ROUTED OUTSIDE THE HAZARDOUS AREA, AND THE CONNECTION MADE OUT

THERE. NOTE THIS IS THE CASE EVEN WHEN USING THE INTRINSICALLY SAFE

VERSION OF THE THE HANDHELD COMMUNICATOR. THE LIMITATION (ie, NO ENERGY

LIMITING BARRIER) LIES IN THE IFT3000 NOT IN THE HANDHELD UNIT.

Page 4

JD) 05554

17-2-9,’ 1

10005856 _

13/12/93 2

moo5933

7-4-94 3

%$Z

G

%o

z?”

+zP

05

3 z.z

0

-IF>

z&q

-OS;

gw

F’O

+rn

-l=z

0ll-i

rncr

Z-‘E

00

q$$

“Om

;axrz

zzz

og

b-’

zo ELECTRICAL SUPPLY TO THE APPARATUS. FURTHER MORE THERE MUST BE “EFFECTlVE

uz

‘NTRoDUCTIoN: THIS SAFRY DATA SHEET APPUES TO BOTH, HEATER POWER SUPPLY

3000 (HPS3000), lYPE No. 1 U05667 AND TO DlGlTAi ELECTRONICS, TYPE No. lUO3083.

THESE APPARATUS ARE CERTlflED EExd IIC T6.

ISSeP CERTIFICATE No. 92C.103.1037. AND INIEX CERTlFlCAiE No. 87.103.578.

THESE APPARATUS HAVE BEEN DESIGNED AND MANUFACTURED TO OPERATE

SAFELY IN CERTAIN MPES OF POTENTIALLY EXPLOSNE ATMOSPHERES. IT 1s ESSENTIAL

THAT THE EQUIPMENT IS NOT TAMPERED WlTH OR DAMAGED IN ANY WAY WHICH

MIGHT LEAD TO A REDUCTION IN IT’S ABILiilY TO OPERATE SAFELY IN SUCH POTENT’IALLY

EXPLOSIVE ATMOSPHERES. FOR YOUR OWN SAFElY AND THE SAFEIY OF OTHERS

PLEASE BRING ANY DAMAGE TO THE ATTENTION OF THE RESPONSIBLE AUTHORITY.

THESE APPARATUS HAVE BEEN DESIGNED AND MANUFACTURED IN ACCORDANCE

WITH EUROPEAN STANDARDS EN50014 h EN50018. INSTALlATlON MAlNTENANcE

AND REPAIR MUST BE IN ACCORDANCE WITH THE 0mcAL “CODES OF

PRACTlCE ON THE INSTAlATlON AND MAINTAINANCE OF ELECTRICAL APPARATUS

IN POTENTIALLY EXPLOSIVE ATMOSPHERES” FOR THE COUNTRY OF INSTALlATlON

(EXAMPLE: BS5345 IN GREAT BRITAIN). ONLY APPROPRIATLY TRAlNED PERSONNEL

ARE AUTHORISED TO PERFORM ANY WORK ON THIS EQUIPMENT. SUCH PERSONNEL IN

ADDllIoN To 0PERATlNG To THE ABOVE MENTlONED SAFETY STANDARDS, SHOULD TAKE

NOTE OF THE FOLLOWING SAFEIY ISSUES.

(1, FLAMEPROOF APPARATUS OR NON FLAMEPROOF APPARATUS,

THE ROSEMOUNT ENCODE SHEETS (PRODUCT ORDERING MATRIX) ALLOWS A CUSTOMER

TO ORDER EITHER THE HAZARDOUS AREA ((FLAMEPROOF) VERSION OF THE APPARATUS

OR THE NON HAZARDOUS AREA VERSION. ‘THE HAZARDOUS AREA VERSION HAS THE

SYMBOL “EExd” ON THE APPARATUS NAMEPLATE. THE NON HAZARDOUS AREA VERSION

DOES NOT. ENSURE THAT IF YOU HAVE RE:CEIVED THE NON HAZARDOUS AREA VERSION

THAT YOU DO NOT INSTALL lT IN APOTENTIIALLY EXPLOSIVE ENVIRONMENT.

12) POWER DOWN PROCEDURE:

ISOLATION OF ELECTRICAL SUPPLY: THIS PIECE OF APPARATUS IS NOT ITSELF FlTTED

WITH A MEANS OF ELECTRICAL ISOLATION. CONSULT YOUR LOCAL CODES OF PRACTICE

ON THE INSTALLATION AND MAINTAINANCE OF ELECTRICAL APPARATUS IN POTENTlALLY

EXPLOSIVE ATMOSPHRES (855345 IN BRlTAIN) FOR INSTRUCTlON ON THE ISOLATlON OF

MEASURES TO PREVENT THE RESTORATION OF SUPPLY TO THE APPARATUS WHILE THE

RISK OF EXPOSING UNPROTECTED UVE CONDUCTORS TO AN EXPLOSlVE ATMOSPHERE

CONTlNUES”:BS5345 PAPT 1 1989 SECTION 18.

RESTORATlON OF SUPPLY FOR ELECTRICAL TESTING: “WHERE, FOR PURPOSES OF

- ELECTRICAL TESTING, lT IS ESSENTIAL TO RESTORE THE SUPPLY BEFORE THE APPARATUS

IS RE-ASSEMBLED, THEN THIS WORK SHOIJLD BE UNDER A CONTROLLED PROCEDURE

AND THE SPEClflC LOCATlON ASSESSED To ENSURE THAT POTENTlALLY FIAMMABLE

GAS OR VAPOUR IS ABSENT-:BS5345 PART 1 1989 SECTlON 23.

REMOVAL OF JUNCTlON BOX COVER: DO NOT REMOVE THE JUNCTlON BOX COVER

WHILE THE APPARTUS IS ENERGISED. WAlT 10 MINUTES AFlER DEENERGISING BEFORE

OPENING THE APPARATUS.

(3) UNG OF THF APPA- EACH APPARATUS MUST BE WIRED As DETAILED IN

THE APPLICABLE INSTRUCTION BULLETlN (USER MANUAL).

(4) lNST’R”cn0N B”LLmNs (USER MAN”Aa THE APPUCABLE INSTRUCTION BULLETINS ARE:

18-l 06-300NEX” EXCHANGE PROBF CONFlGURATlON & “FULLY CENELEC” CONFIGURATION.

IB-106-300NFX: USED WITH IFr3000 ELECTRONICS.

IB-106-300NCX: USED WITH CRE3000 ELECTRONICS.

THESE INSTRUCTlON BULLEI-INS CONTAIN ESSENTIAL INFORMATlON & MUST BE USED

E

d

WHEN WORKING ON THE APPARATUS.

(5) CABLE GLANDS: HAWKE CABLE GLAND. NPE lCG653 (BASEEFA CERTlflCATE :

BAS No. EX 85B1258”) OR AN EQUlVALENT MUST BE USED. THIS GLAND IS A

BARRIER (STOPPER) GLAND. A FEATURE OF THIS GLAND is THAT A COMPOUND

FlLLED PACKING MATERIAL (PlJlTf), FORMS A BARRIER BEIWEEN THE INDMDUAL

INSULATED CONDUCTORS OF THE CABLE. THIS BARRIER ACTS TO PREVENT ENTRY

INTO THE CABLE OF THE PRODUCTS OF AN EXPLOSION WlTHIN THE ENCLOSURE.

THIS GLAND IS CERTIFIED Exd IIC.

Page 5

(6) EXlSTlNG WESTlNGHOUSE,‘ROSEMOUNT SUPPLIED .CABLEz

ON EARUER INSTALLATIONS WESTlNGHOUSE/ROSEMOUNT SUPPUED A CABLE

mwEEN THE DIGITAL ELECTRONICS AND PROBE (MODEL 218).

THE GLANDS ON THIS CABLE - ALTHOUGH HAWKE GLANDS CERTIFIED Exd IIC

WERE No-r 0F THE HAWKE BARRIER (STOPPER) GIAND. WE lcG653 VARIEM.

THESE GLANDS MUST NOT BE USED. ROSEMOUNT CAN SUPPL’f A BARRIER GLAND

KTT TO REPLACE SUCH GLANDS. ME KTT (PART NO. iu03066~07). COMPRISES

OF TWO BARRIER GLANDS COMPLaE WITH PUTTY, CRIMPS AND AN IN!ZiTRUCTION

SHEET. PLEASE NOTE THAT YOU SHOULD USE ONLY PUTTY WHICH IS PLASTIC

& CAPABLE OF BEING MIXED. YOU SHOULD NOT USE CRYSTALISED OR HARD

PUl-lY.

(7) CABLE ANC ORAGF,

NElTHER THE H;S3000 NOR THE DlGlTAL ELECTRONICS INCLUDE ANY

SPECIFIC MEANS FOR CABLE ANCHORAGE. THE CABLE GLANDS CHOSEN FOR

THE MAINS, PROBE, AND SIGNAL CABLES MUST BE OF A TYPE WHICH

SUPPLY CABLE ANCHORAGE. THE BARRIER (STOPPER) GLAND SUPPLIED By

ROSEMOUNT As PART OF THE PROBE CABLE ASSEMBLY. WILL GIVE SUCH

CABLE ANCHORAGE.

(8) UNUSED CABLE ENTRY PORTS:

ALL CABLE ENTRY PORTS WHICH ARE UNUSED

ARE TO BE CLOSED OFF WlTH THREADED PLUGS CERTlFlED Exd IIC. THERE SHOULD

BE A MINIMUM OF 5 THREADS ENGAGED AND THE THREADS SEALED WlTH

THREADLOCK (LOCKTITE 271 OR EQ’UILAVENT),

(9) NAMEPLATE (LABEL):

ENSURE THAT NAMEPLATE IS AT ALL TlMES VISIBLE.

AT INSTALLATION, ALLOWANCE MUST BE MADE FOR THIS.

(10) EARTHING OF THE APPARATUS:

THE APPARATUS HAS BEEN FlTTED WlTH BOTH

EXTERNAL AND INTERNAL EARTHING POINTS. ADEQUATE EARTH

CONNECTIONS

SHOULD BE MADE TO BOTH THESE POINTS.

Page 6

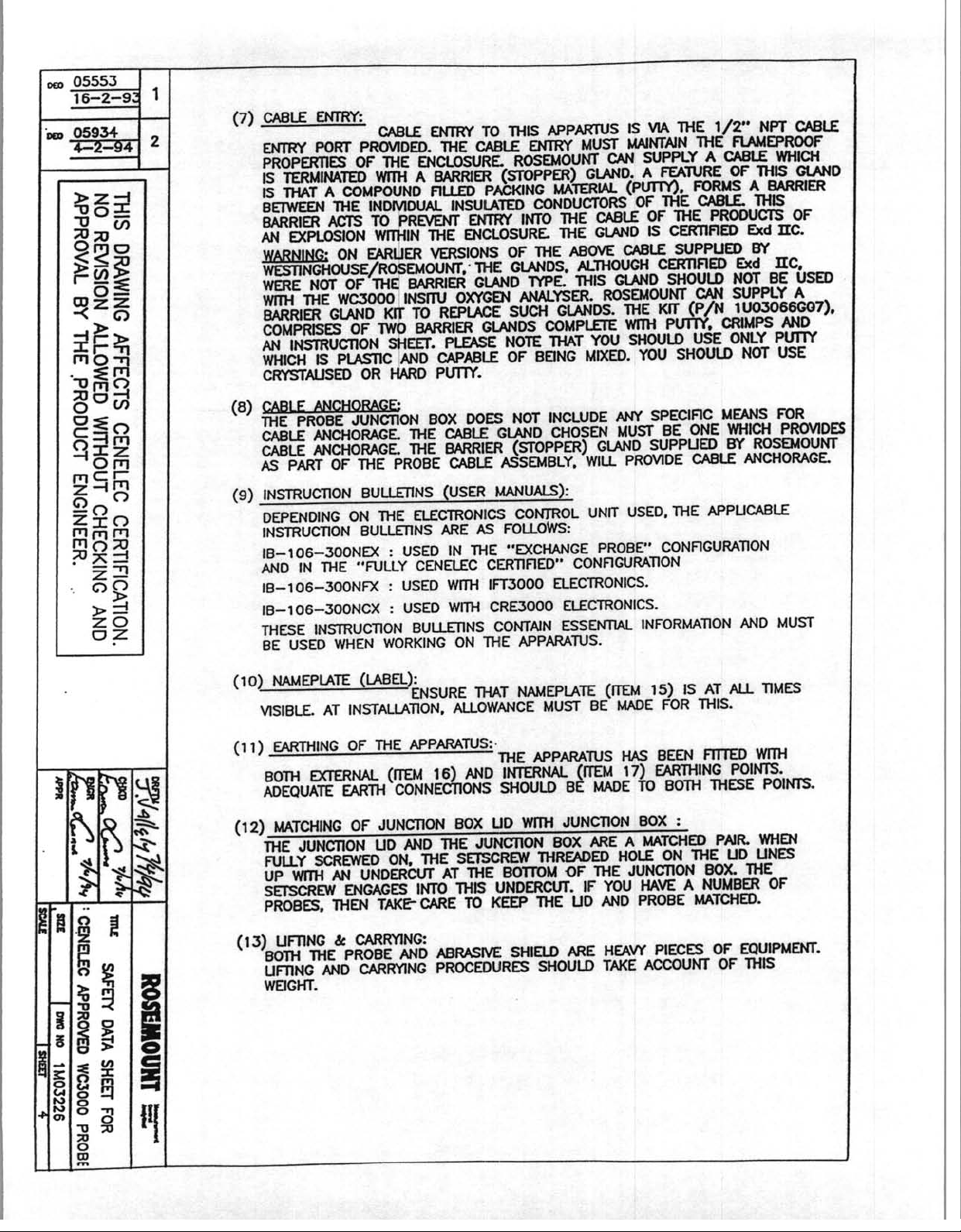

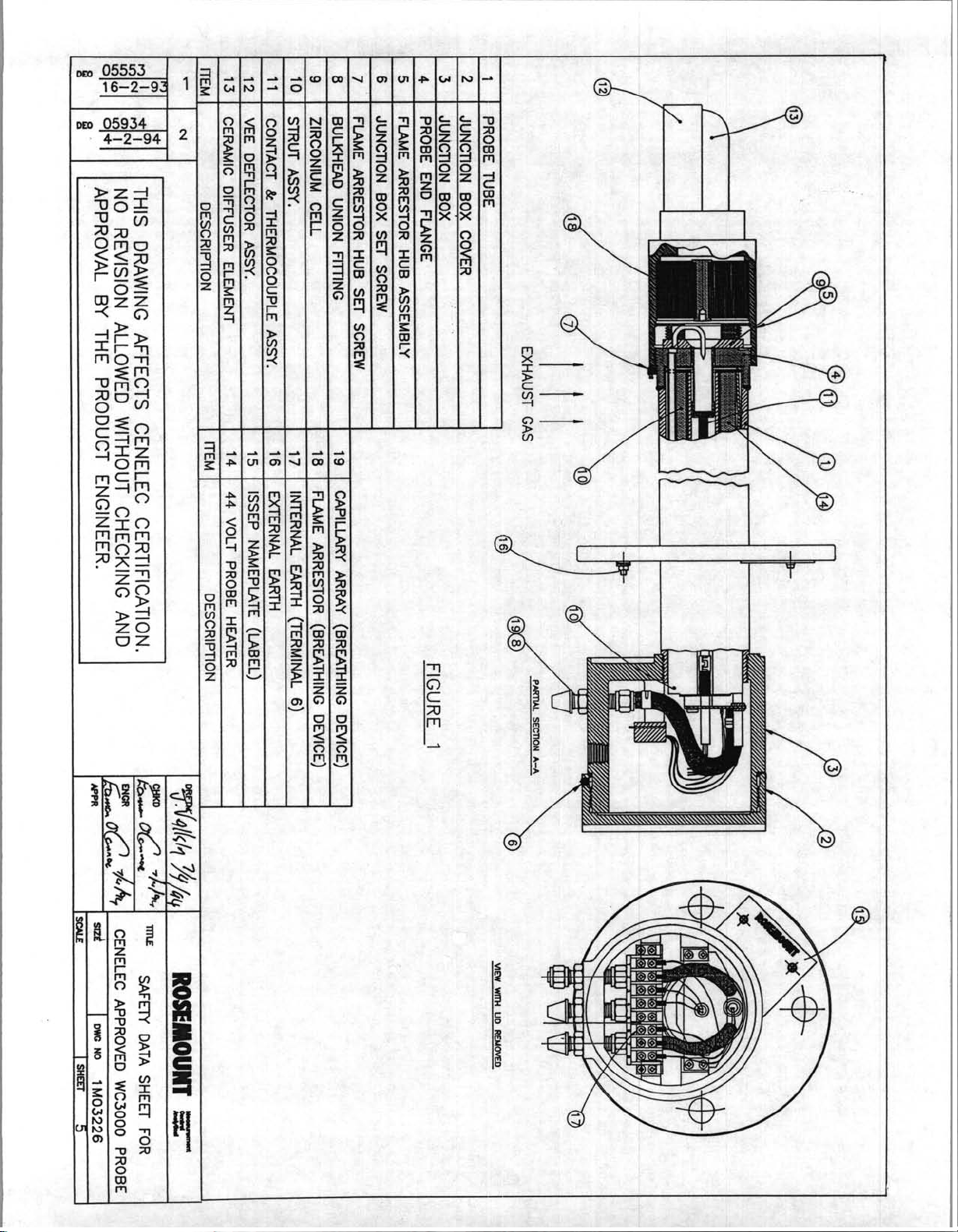

lNTRoD”C~oN: THIS SAFEIY DATA SHEET APPUES TO WC3000 lNSlTU OXYGEN ANALYSER

(pROBE),MPE No. lUO5680. THIS OXYGEN ANALYSER IS CERTlFlED EExd IIB 370 (Tl) :

ISSeP CERTlFlCATE No. 93C.103.1067.

THIS PIECE OF EQUIPMENT HAS BEEN DESIGNED AND MANUFACTURED TO OPERATE

SAFELY IN CERTAlN TYPES OF POTENTlALLY EXPLOSlVE ATMOSPHERES. lT Is ESSENTIAL

THAT THE EQUIPMENT IS NOT TAMPERED WITH OR DAMAGED IN ANY WAY WHICH

MIGHT LEAD TO A REDUCTlON IN lT’S ABIUTY TO OPERATE SAFELY IN SUCH POTENTlALLY

EXPLOSlVE ATMOSPHERES. FOR YOUR OWN SAFEIY AND THE = OF OTHERS

PLEASE BRING ANY DAMAGE TO THE AlTENTlON OF THE RESPONSIBLE AUMORllY.

THIS PIECE OF EQUIPMENT HAS BEEN DESIGNED AND MANUFACTURED IN

ACCORDANCE WITH EUROPEAN STANDARDS EN50014 & EN5001 8. INSTALlAnON

MAINTENANCE AND REPAIR MUST BE IN ACCORDANCE WITH THE OFFlCAL “CODES

OF PRACTICE ON THE INSTAlATlON AND MAINTAINANCE OF ELECTRICAL APPARATUS

IN POTENTlALLY EXPLOSlVE ATMOSPHERES” FOR THE COUNljiY OF INSTALlATlON

(EXAMPLE: BS5345 IN GREAT BRlTAlN). ONLY APPROPRIATLY TRAINED PERSONNEL

ARE AUTHORISED TO PERFORM ANY ‘WORK ON THIS EQUIPMENT. SUCH PERSONNEL IN

ADDlTlON TO OPERATlNG TO THE ABOVE MENllONED SAFETY STANDARDS, SHOULD TAKE

NOTE OF THE FOLLOWING SAFElY ISSUES.

NOTE: THROUGHOUT THIS DATA SHEEl., CONTlNUOUS REFERENCE WILL BE MADE TO

FlGURE 1.

11) POWER DOWN PROCEDURE:

ISOlATlON OF ELECTRICAL SUPPLY: THIS PIECE OF APPARATUS IS NOT lTSELF m

WlTH A MEANS OF ELECTRICAL ISOLP,nON. CONSULT YOUR LOCAL CODES OF PRACTlCE

ON THE INSTALLATION AND MAINTAINANCE OF ELECTRICAL APPARATUS IN POTENTIALLY

EXPLOSIVE ATMOSPHRES (BS5345 IN BRlTAIN) FOR INSTRUCTlON ON THE ISOlATlON OF

ELECTRICAL SUPPLY TO THE APPARATUS. FURTHER MORE THERE MUST BE “EFFECTIVE

MEASURES TO PREVENT THE RESTORATlON OF SUPPLY TO THE APPARATUS WHILE THE

RISK OF EXPOSING UNPROTECTED LIVE CONDUCTORS TO AN EXPLOSIVE ATMOSPHERE

CONTlNUES”:BS5345 PAPT 1 1989 S;ECTlON 18.

RESTORATlON OF SUPPLY FOR ELECTRICAL TESTING: “WHERE, FOR PURPOSES OF

ELECTRICAL TESTING. lT IS ESSENTIAL TO RESTORE THE SUPPLY BEFORE THE APPARATUS

IS RE-ASSEMBLED, MEN THIS WORK SHOULD BE UNDER A CONTROLLED PROCEDURE

AND .THE SPECIRC LOCATlON ASSESSED TO ENSURE THAT POTENTlALLY FLAMMABLE

GAS OR VAPOUR IS ABSENT”:BS5345 PART 1 1989 SECTlON 23.

REMOVAL OF JUNCTlON BOX COVER: DO NOT REMOVE THE JUNCTlON BOX COVER

(lTEM 2) WHILE THE APPARATUS IS ENERGISED. DO NOT REMOVE THE JUNCTlON BOX

COVER WHEN A POTENTIALLY EXPLOSIVE ATMOSPHERE IS PRESENT. REMEMBER (ALTHOUGH

THE UNlT HAS BEEN POWERED DOWN AND THE PROBE HEATER HAS BEEN ALLOWED TO

COOL DOWN), THE TEMPERATURE ON THE INTERIOR OF THE PROBE TUBE (lTEM 1) WIU Bf

SlMllAR TO THE TEMPERATURE OF THE EXHAUST GAS. IF THERE IS A POTENTIALLY

EXPLOSIVE ATMOSPHERE IN THE REGION OF THE JUNCTlON BOX (lTEM 3). THIS GAS WlLL,

ON THE REMOVAL OF THE JUNCTlON BOX COVER BE EXPOSED TO THE HOT SURFACE OF

THE TUBE INTERIOR (lTEM 1).

(2) THREADED JOINTS:

JUNCTlON BOX LID (lTEM 2) IS A THREADED JOINT. SO ALSO IS THE JOINT BElWEEN

THE PROBE END RANGE (lTEM 4) AND THE FLAME ARRESTOR HUB (lTEM 5). BOTH

THESE JOINTS ARE SECURED By SET SCREWS (ITEMS 6 & 7). BEFORE REMOVlNG

THE JUNCTlON BOX COVER (lTEM 2) OR THE RAME ARRESTOR HUB (lTEM 5). FULLY

REMOVE THE SET-SCREWS (ITEMS 6 h 7) FROM THEIR TAPPED HOLES. FAlLURE TO

DO THIS COULD RESULT IN DAMAGE TO. THE THREADS OF THE JUNCTION BOX (EM 3)

AND THE PROBE END FlANGE (lTEM 4) BY THE SET-SCREWS BEING DRAWN OVER

THE THREADS. REMEMBER WHEN REFlTllNG THE JUNCTION BOX LID AND THE FlAME

ARRESTOR HUB TO LOCK IN PLACE WITH THE SETSCREWS.

THE MATERIAL OF THE JUNCTlON BOX AND THE JUNCTION BOX UD IS ALUMINIUM

ALLOY. SPECIAL CARE SHOULD BE TAKEN TO AVOID DAMAGE TO THE THREADS.

NOTE THAT ROSEMOUNT SUPPLY ALLEN KEYS FOR REMOVAL & REPLACEMENT OF THE

SETSCREWS.

THE JOINT BEIWEEN THE JUNCTlON BOX @EM 3) AND THE

Page 7

m 05934

4-2-94 2

=A

(3) CORROSION AND ABRASION:

0 PROBE TUBE (ITEM 1): TO PROVlDE RESISTANCE AGAlNST THE EFFECTS OF CORROSIOI

AND ABRASION JHE PROBE TUBE HAS BEEN MANUFACTURED FROM 4.75mm WALL,

316 SERIES STAINLESS STEEt FOR THE MAIORllY OF APPUCATlONS THE RESISTANCE

AFFORDED BY THIS PROBE TUBE AGAINST CORROSION AND ABRASION IS MORE

THAN ADEQUATE. FOR APPLlCAllONS IN WHilCH THE EFFECTS OF CORROSION OR

ABRASION ARE SIGNIRCANT, ROSEMOUM’ CAN SUPPLY AN ABRASlVE SHIELD.

0 FIAME ARRESTOR HUB (ITEM 5): THE FLAME ARRESTOR HUB HAS BEEN

MANUFACTURED FROM 316 SERIES STAINLESS STEEL. AT TrS THINNEST SECllON

(BETWEEN ME O/D OF THE HUB AND THE MAXIMUM MAJOR DIAMETER OF THE

M70 X 2 X 6H THREAD: SEE FIGURE 2). THE MINIMUM MATERlAL THICKNESS IS

2.75mm. FOR THE MAJORlIY OF APPLlCATlONS THE PROTECTlON AFFORDED BY

THIS ARRANGEMENT AGAlNST THE EFFECTS OF CORROSION AND ABRASION IS

MORE THAN ADEQUATE. FOR APPUCATlONS IN WHICH THE EFFECTS OF CORROSION

OR ABRASION ARE SIGNIFICANT. ROSEMOUNT CAN SUPPLY AN ABRASIVE SHIELD.

Page 8

(4) BREATHING DMCES:

HAS BEEN ~rrr~~ wmi A CAPILLARY ARRAY, (BREATHING DEVICE): SEE RGURE 3.

WHEN FlTllNG TUBING, (0.25 INCH O/D), TO THE REFERENCE AIR AND CALlBRATlON

GAS PORTS, TAKE CARE NOT TO DAMAGE THE BREATHING DEVICES. THE VENT PORT

SHOULD BE LEFT CLEAR OF OBSTRUCTIONS.

EACH OF THE THREE BULKHEAD UNION FlTilNGS (ITEM 8)

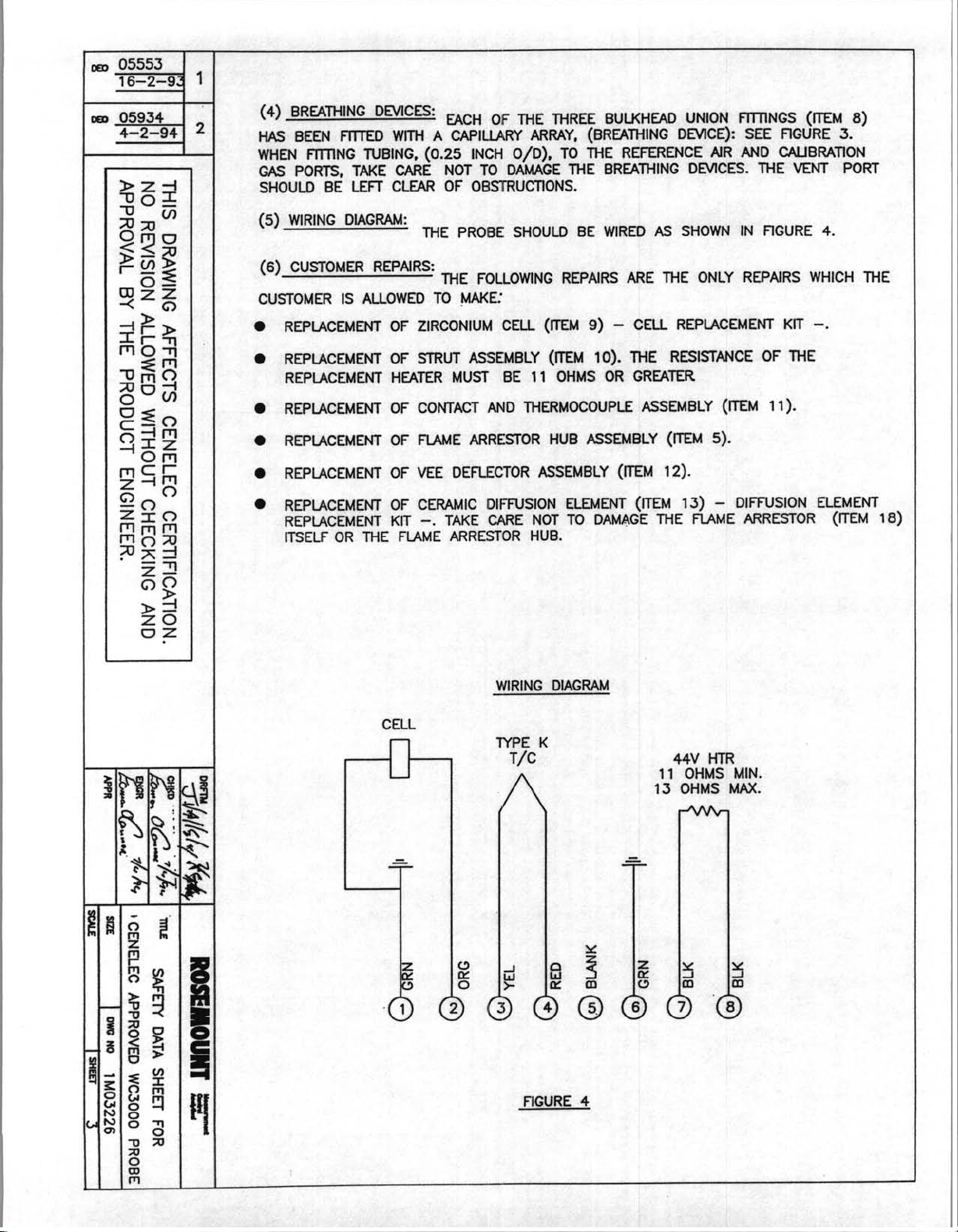

(5) WlRlNG DIAGRAM:

(6) CUSTOMER REPAIRS:

CUSTOMER IS ALLOWED TO _&&IKE:

0 REPLACEMENT OF ZIRCONIUM CELL (ITEM 9) - CELL REPIACEMENT KlT -.

0 REPLACEMENT OF STRUT ASSEMBLY @EM 10). THE RESISTANCE OF THE

REPLACEMENT HEATER MUST BE 11 OHMS OR GREATER

0 REPLACEMENT OF CONTACT AND THERMOCOUPLE ASSEMBLY (lTEM 11).

0 REPLACEMENT OF FlAME ARRESTOR HUB ASSEMBLY (lTEM 5).

0 REPLACEMENT OF VEE DEFLECTOR ASSEMBLY @EM 12).

. REPLACEMENT OF CERAMIC DIFFUSION ELEMENT (lTEM 13) - DIFFUSION ELEMENT

REPLACEMENT KIT -.

ITSELF OR THE FLAME ARRESTOR HUB.

THE PROBE SHOULD BE WlRED As SHOWN IN flGURE 4.

THE FOLLOWlNG REPAIRS ARE THE ONLY REPAIRS WHICH THE

TAKE CARE NOT TO DAMAGE THE FLAME ARRESTOR (lTEM

18)

CELL

J’lRING DIAGRAM

IYPE K

T/c

Y

3

m

5

0

FIGURE 4

44v HTR

11 OHMS MIN.

13 OHMS MAX.

Page 9

(7)

CABLE

ENTRY PORT PROVlD!

PROPERTlES OF ‘_. __ __

IS TERMINATE0 WlTH A

ISS$MF’PUND

BARRIER ACTS TO PRI

AN EXPLOSION WllHlN

WARNING; ON EARUER VERSIONS OF THE ABOVE CABLE SUPPLIED BY

WESTlNGH0USE/R0SEM0UNT;‘E: GLANDS. ALTHOUGH CERTlflED Exd EC,

WERE NOT OF THE BARRIER GLAND -lYPE. THIS GIAND SHOULD NOT BE USED

WITH THE WC3000 INSlTU OXYGEN ANALYSER. ROSEMOUNT CAN SUPPLY A

BARRIER GLAND KCf TO REPLACE: SUCH GLANDS. THE KFT (P/N lUO3066GG7).

COMPRISES OF TWO BARRIER GLANDS COMPLEIE WITH Pm, CRIMPS AND

AN IN!5TRUCTlON SHEET. PLE4SE NOTE THAT YOU SHOULD USE ONLY PUTlY

WHICH IS PLAsnC AND CAPABLE OF BUNG MIXED. YOU SHOULD NOT USE

CRYSTALlSED OR HARD PUITY.

ENTRYZ

CABLE ENTRY TO MIS APPARTUS IS VIA THE l/2’* NPT CABLE

.__3.J. ME CABLE ENTRY MUST M

THE ENCLOSlIRE.

1 RLLED PACKING MATEI

DMDUAL INSUIAED CONDUCTORS‘

?/ENT ENTRY INTO THE CABLf

THE plCtOSURE. THE GIANC

ROSEMOUNT CAN Sup

(STOPPER) GLAND. A

RW, (PUllY), FORMS A BARRIER

.._----..--

wmu~ THE RAMEPRooF

‘PLY A CABLE WHICH

FEATURE OF THlS GlAND

OF THE CABLE. THIS

: OF THE PRODUCTS OF

1 IS CERTlflEO Exd IIC.

-, -

(6)

THE PROBE JUNAON BOX DOES NOT INCLUDE ANY SPECIRC MEANS FOR

CABLE ANCHORAGE. THE CABLE GLAND CHOSEN MUST BE ONE WHICH PROVIDE!

CABLE ANCHORAGE. THE BARRIER (STOPPER) GLAND SUPPUED BY ROSEMOUM

AS PART OF THE PROBE CABLE ASSEMBLY, WILL PROVIDE CABLE ANCHORAGE.

(9) i~mwcznoN BUUNS (USER MANUALS):

DEPENDING ON THE ELECTRONICS CONTROL UNlT USED, THE APPUCABLE

INSTRUCTION BULLEllNS ARE AS FOLLOM:

IB-106-300NM :

AND IN THE “FULLY CENELEC CERTIFIED” CONFIGURATION

18-l 06-300NFX

IB-106-300NCX :

THESE INSTRUCTlON BUUETlNS CONTAlN ESSENTIAL INFORMATION AND MUST

BE USED WHEN WORKING ON MIE APPARATUS.

(10) NAMEPLATE (LABEL):

VISIBLE. AT INSTALIATION, ALLOWANCE MUST BE MADE FOR THIS.

(11) EARTHING OF THE APPARATUS:.

BOTH f!XTERNAL (tTEM 16) AND INTERNAL (lTEM 17) EAR-IHING POINFS.

ADEQUATE EARTH CONNECTIONS SHOULD BE MADE TO BOTH THESE POINTS.

2)

0

THE JUNCTION UD AND THE JUNCllON BOX ARE A MATCHED PAlR WHEN

FULLY SCREWED ON, THE SRSCREW THREADED HOLE ON THE UD UNES

UP Wrm AN UNDERCUT AT THE BOlTOM OF THE JUNCTlON BOX. ME

SEISCREW ENGAGES INTO THIS IJNDERCtTT. IF YOU HAVE A NUMBER OF

PROBES, THEN TAKE-CARE TO KEEP THE UD AND PROBE MATCHED.

ANCHQRAGF,

USED IN THE ‘*EXCHANGE PROBE” CONFlGURATlON

: USED WITH IFT3000 ELECTRONICS.

USED WITH CRE3000 ELECTRONICS.

ENSURE THAT NAMEPLATE (lTEM 15) IS AT ALL TlMES

THE APPARATUS HAS BEEN FilTED WKH

MATCHING OF JUNaON BOX UD WlTH JUNCTlON BOX :

(13) LlmNG & CARRYING:

BOTH THE PROBE AND ABRASIVE SHIM ARE HEAVY PIECES OF EpuIPMENT.

LlFllNG AND CARRYlNG PROCEDURES SHOULD TAKE ACCOUNT OF THIS

WEIGHT.

Page 10

DE0 05934

4-2-94

2

Page 11

~““““““““““‘““““‘“‘“‘--“---------------””””””~”““““““““““”””””””““““““““““““““““““““““““““”””””,

t

t I

I

Page 12

HIGHLIGHTS OF CHANGES

Effective June, 1997 Rev. 4

PAGE SUMMARY

-- General. Added snubber version of probe to manual. Text and art changed as necessary to reflect new

style of probe.

Effective February, 1998 Rev. 4.1

PAGE SUMMARY

2-2 Figure 2-1. Change calibration gas tube dimensions.

3-10 Add note on test gas flowmeter.

IB-106-300NFX

Page 13

ROSEMOUNT WARRANTY

Rosemount warrants that the equipment manufactured and sold by it will, upon shipment, be free of defects

in workmanship or material. Should any failure to conform to this warranty become apparent during a period of

one year after the date of shipment, Rosemount shall, upon prompt written notic e from the purchaser, correct such

nonconformity by repair or replacement, F.O.B. factory of the defective part or parts. Corr ection in the manner

provided above shall constitute a fulfillment of all liabilities of Rosemount with respect to the quality of the

equipment.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER

WARRANTIES OF QUALITY WHETHER WRITTEN, ORAL, OR IMPLIED (INCLUDING ANY

WARRANTY OF MERCHANTABILITY OF FITNESS FOR PURPOSE).

The remedy(ies) provided above shall be purchaser's sole remedy(ies) for any failure of Rosemount to comply

with the warranty provisions, whether claims by the purchaser are based in contract or in tort (including

negligence).

Rosemount does not warrant e quipment against normal deterioration due to environment. Factors such as

corrosive gases and solid particulates can be detrimental and can create the need for repair or replacement as part

of normal wear and tear during the warranty period.

Equipment supplied by Rosemount Ana ly tical Inc., but not manufactured by it, w ill be subject to the same

warranty as is extended to Rosemount by the original manufacturer.

At the time of installation, it is important that the required services are supplied to the system and that the

electronic controller is set up at least to the point where it is controlling the sensor heater. This will ens ur e th at

should there be a delay between installation and full commissioning, the senso r being supplied with ac power and

reference air will not be subjected to component deterioration.

IB-106-300NFX

i

Page 14

PURPOSE

The purpose of this manual is to provide a comprehensive understanding of the CENELEC Approved

World Class 3000 Oxygen Analyzer components, functions, installation, and maintenance.

This manual is desi gned to provide information about the CENELEC Approved World Class 3000 Oxygen

Analyzer. We recommend that you thoroughly familiarize yourself with the Overview and Installation sections

before installing your emissions monitor.

The overview presents the basic principles of the CENELEC oxygen analyzer al ong with its performance

charac teristics and components. The remaining sections contain detailed procedures and information necessary

to install and service the CENELEC approved oxygen analyzer.

Before contacting Rosem ount concerning any questions, first consult this manual. It describes most

situations encountered in your equipment's operation and details necessary action.

DEFINITIONS

The following definitions apply to WARNINGS, CAUTIONS, and NOTES found throughout this

publication.

Highlights an operation or maintenance

procedure, practice, condition,

statement, etc., that if not strictly

observed, could result in injury, death,

or long-term health hazards of

personnel.

Highlights an operation or maintenance

procedure, practice, condition,

statement, etc., that if not strictly

observed, could result in damage to or

destruction of equipment, or loss of

effectiveness.

NOTE

Highlights an essential oper ating pr oce dure ,

condition, or statement.

: EARTH (GROUND) TERMINAL

: PROTECTIVE CONDUCTOR TERMINAL

: RISK OF ELECTRICAL SHOCK

: WARNING: REFER TO INSTRUCTION BULLETIN

NOTE TO USERS

The number in the lower right corner of each illustration in this publication is a manual

illustration number. It is not a part number and is not related to the illustration in any

technical manner.

IB-106-300NFX

IB-106-300NFX

ii

ii

Page 15

IMPORTANT

SAFETY INSTRUCTIONS FOR THE WIRING AND

INSTALLATION OF THIS APPARATUS

The following safety instructions apply specifically to all EU member

states. They should be strictly adhered to in order to assure

compliance with the Low Voltage Directive. Non-EU states should

also comply with the following unless superseded by local or National

Standards.

1. Adequate earth connections s h ou ld be made to all earthing points, intern al an d ex tern al, where provided.

2. After installation or troubleshooting, all safety covers and safety grounds must be replaced. The integrity

of all earth terminals must be maintained at all tim es.

3. Mains supply cords should comply with the requirements of IEC227 or IEC245.

4. All wiring sh all be s u itable f or us e in an ambient temperature of greater than 75°C .

5. All cable glands used sh ou ld be of such internal dime n sion s as to prov ide adequ ate cable an ch orag e.

6. To ensure safe operation o f this equip ment, connection to the mains supply should only be made thro ugh

a circuit breaker which will disconnect all circuits carrying conductors during a fault situation. The circuit

breaker may also include a mechanically operated isolating switch. If not, then another means of

disconnecting the equipment from the supply must be provided and clearly marked as such. Circuit

breakers or switches must comply with a recognized standard such as IEC947. All wiring must conform

with any local s tan dards.

7. Where equipment or covers are marked with the symbol to the right, hazardous

voltages are likely to be present beneath. These covers should only be removed

when power is removed from the equipment — and then only by trained service

personnel.

8. Where equipment or covers are marked with the symbol to the right, there is a

danger from hot surfaces beneath. These covers should only be removed by

trained service personnel when power is removed from the equipment. Certain

surfaces may remain hot to the touch.

9. Where equipment or covers are marked with the symbol to the right, refer to the

Operator Manual for instructions.

10. All graphical symbols used in this product are from one or more of the following standards: EN61010-1,

IEC417, and ISO3864.

IB-106-300NFX

iii

Page 16

BELANGRIJK

Veiligheidsvoorschriften voor de aansluiting en installatie van dit toestel.

De hierna volgende veiligheidsvoorschriften zijn vooral bedoeld voor de EU lidstaten. Hier moet aan

gehouden worden om de onderworpenheid aan de Laag Spannings Richtlijn (Low Voltage Directive) te

verzekeren. Niet EU staten zouden deze richtlijnen moeten volgen tenzij zij reeds achterhaald zouden zijn

door plaatselijke of nationale voorschriften.

1. Degelijke aardingsaansluitingen moeten gemaakt worden naar alle voorziene aardpunten, intern en extern.

2. Na installatie of controle moeten alle veiligheidsdeksels en -aardingen terug geplaatst worden. Ten alle tijde

moet de betrouwbaarheid van de aarding behouden blijven.

3. Voedingskabels moeten onderworpen zijn aan de IEC227 of de IEC245 voorschriften.

4. Alle bekabeling moet geschikt zijn voor het gebruik in omgevingstemperaturen, hoger dan 75°C.

5. Alle wartels moeten zo gedimensioneerd zijn dat een degelijke kabel bevestiging verzekerd is.

6. Om de veilige werking van dit toestel te verzekeren, moet de voeding door een stroomonderbreker gevoerd

worden (min 10A) welke alle draden van de voeding moet onderbreken. De stroomonderbreker mag een

mechanische schakelaar bevatten. Zoniet moet een andere mogelijkheid bestaan om de voedingsspanning

van het toestel te halen en ook duidelijk zo zijn aangegeven. Stroomonderbrekers of schakelaars moeten

onderworpen zijn aan een erkende standaard zoals IEC947.

7. Waar toestellen of deksels aangegeven staan met het symbool is er meestal

hoogspanning aanwezig. Deze deksels mogen enkel verwijderd worden nadat de

voedingsspanning werd afgelegd en enkel door getraind onderhoudspersoneel.

8. Waar toestellen of deksels aangegeven staan met het symbool is er gevaar

voor hete oppervlakken. Deze deksels mogen enkel verwijderd worden door

getraind onderhoudspersoneel nadat de voedingsspanning verwijderd werd.

Sommige oppper-vlakken kunnen 45 minuten later nog steeds heet aanvoelen.

9. Waar toestellen of deksels aangegeven staan met het symbool gelieve het handboek

te raadplegen.

10. Alle grafische symbolen gebruikt in dit produkt, zijn afkomstig uit een of meer van devolgende standaards;

EN61010-1, IEC417 en ISO3864.

IB-106-300NFX

iv

Page 17

VIGTIGT

Sikkerhedsinstruktion for tilslutning og installering af dette udstyr.

Følgende sikkerhedsinstruktioner gælder specifikt i alle EU-medlemslande. Instruktionerne skal nøje

følges for overholdelse af Lavsspændingsdirektivet og bør også følges i ikke EU-lande medmindre andet er

specificeret af lokale eller nationale standarder.

1. Passende jordforbindelser skal tilsluttes alle jordklemmer, interne og eksterne, hvor disse forefindes.

2. Efter installation eller fejlfinding skal alle sikkerhedsdæksler og jordforbindelser reetableres.

3. Forsyningskabler skal opfylde krav specificeret i IEC227 eller IEC245.

4. Alle ledningstilslutninger skal være konstrueret til omgivelsestemperatur højere end 75° C.

5. Alle benyttede kabelforskruninger skal have en intern dimension, så passende kabelaflastning kan etableres.

6. For opnåelse af sikker drift og betjening skal der skabes beskyttelse mod indirekte berøring gennem afbryder

(min. 10A), som vil afbryde alle kredsløb med elektriske ledere i fejlsitua-tion. Afbryderen skal indholde en

mekanisk betjent kontakt. Hvis ikke skal anden form for afbryder mellem forsyning og udstyr benyttes og

mærkes som sådan. Afbrydere eller kontakter skal overholde en kendt standard som IEC947.

7. Hvor udstyr eller dæksler er mærket med dette symbol, er farlige

spændinger normalt forekom-mende bagved. Disse dæksler bør kun

afmonteres, når forsyningsspændingen er frakoblet - og da kun af

instrueret servicepersonale.

8. Hvor udstyr eller dæksler er mærket med dette symbol, forefindes

meget varme overflader bagved. Disse dæksler bør kun afmonteres af

instrueret servicepersonale, når forsyningsspænding er frakoblet. Visse

overflader vil stadig være for varme at berøre i op til 45 minutter efter

frakobling.

9. Hvor udstyr eller dæksler er mærket med dette symbol, se da i

betjeningsmanual for instruktion.

10. Alle benyttede grafiske symboler i dette udstyr findes i én eller flere af følgende standarder:- EN61010-1,

IEC417 & ISO3864.

IB-106-300NFX

v

Page 18

BELANGRIJK

Veiligheidsinstructies voor de bedrading en installatie van dit apparaat.

Voor alle EU lidstaten zijn de volgende veiligheidsinstructies van toepassing. Om aan de geldende

richtlijnen voor laagspanning te voldoen dient men zich hieraan strikt te houden. Ook niet EU lidstaten

dienen zich aan het volgende te houden, tenzij de lokale wetgeving anders voorschrijft.

1. Alle voorziene interne- en externe aardaansluitingen dienen op adequate wijze aangesloten te worden.

2. Na installatie,onderhouds- of reparatie werkzaamheden dienen alle beschermdeksels /kappen en aardingen

om reden van veiligheid weer aangebracht te worden.

3. Voedingskabels dienen te voldoen aan de vereisten van de normen IEC 227 of IEC 245.

4. Alle bedrading dient geschikt te zijn voor gebruik bij een omgevings temperatuur boven 75°C.

5. Alle gebruikte kabelwartels dienen dusdanige inwendige afmetingen te hebben dat een adequate verankering

van de kabel wordt verkregen.

6. Om een veilige werking van de apparatuur te waarborgen dient de voeding uitsluitend plaats te vinden via

een meerpolige automatische zekering (min.10A) die

foutconditie optreedt. Deze automatische zekering mag ook voorzien zijn van een mechanisch bediende

schakelaar. Bij het ontbreken van deze voorziening dient een andere als zodanig duidelijk aangegeven

mogelijkheid aanwezig te zijn om de spanning van de apparatuur af te schakelen. Zekeringen en schakelaars

dienen te voldoen aan een erkende standaard zoals IEC 947.

alle

spanningvoerende geleiders verbreekt indien een

7. Waar de apparatuur of de beschermdeksels/kappen gemarkeerd zijn met het

volgende symbool, kunnen zich hieronder spanning voerende delen bevinden die

gevaar op kunnen leveren. Deze beschermdeksels/kappen mogen uitsluitend

verwijderd worden door getraind personeel als de spanning is afgeschakeld.

8. Waar de apparatuur of de beschermdeksels/kappen gemarkeerd zijn met het

volgende symbool, kunnen zich hieronder hete oppervlakken of onderdelen

bevinden. Bepaalde delen kunnen mogelijk na 45 min. nog te heet zijn om aan te

raken.

9. Waar de apparatuur of de beschermdeksels/kappen gemarkeerd zijn met het

volgende symbool, dient men de bedieningshandleiding te raadplegen.

10. Alle grafische symbolen gebruikt bij dit produkt zijn volgens een of meer van de volgende standaarden:

EN 61010-1, IEC 417 & ISO 3864.

IB-106-300NFX

vi

Page 19

TÄRKEÄÄ

Turvallisuusohje, jota on noudatettava tämän laitteen asentamisessa ja kaapeloinnissa.

Seuraavat ohjeet pätevät erityisesti EU:n jäsenvaltioissa. Niitä täytyy ehdottomasti noudattaa jotta

täytettäisiin EU:n matalajännitedirektiivin (Low Voltage Directive) yhteensopivuus. Myös EU:hun

kuulumattomien valtioiden tulee nou-dattaa tätä ohjetta, elleivät kansalliset standardit estä sitä.

1. Riittävät maadoituskytkennät on tehtävä kaikkiin maadoituspisteisiin, sisäisiin ja ulkoisiin.

2. Asennuksen ja vianetsinnän jälkeen on kaikki suojat ja suojamaat asennettava takaisin pai-koilleen.

Maadoitusliittimen kunnollinen toiminta täytyy aina ylläpitää.

3. Jännitesyöttöjohtimien täytyy täyttää IEC227 ja IEC245 vaatimukset.

4. Kaikkien johdotuksien tulee toimia >75°C lämpötiloissa.

5. Kaikkien läpivientiholkkien sisähalkaisijan täytyy olla sellainen että kaapeli lukkiutuu kun-nolla kiinni.

6. Turvallisen toiminnan varmistamiseksi täytyy jännitesyöttö varustaa turvakytkimellä (min 10A), joka kytkee

irti kaikki jännitesyöttöjohtimet vikatilanteessa. Suojaan täytyy myös sisältyä mekaaninen erotuskytkin. Jos

ei, niin jännitesyöttö on pystyttävä katkaisemaan muilla keinoilla ja merkittävä siten että se tunnistetaan

sellaiseksi. Turvakytkimien tai kat-kaisimien täytyy täyttää IEC947 standardin vaatimukset näkyvyydestä.

7. Mikäli laite tai kosketussuoja on merkitty tällä merkillä on merkinnän takana tai alla

hengenvaarallisen suuruinen jännite. Suojaa ei saa poistaa jänniteen ollessa kytkettynä

laitteeseen ja poistamisen saa suorittaa vain alan asian-tuntija.

8. Mikäli laite tai kosketussuoja on merkitty tällä merkillä on merkinnän takana tai alla

kuuma pinta. Suojan saa poistaa vain alan asiantuntija kun jännite-syöttö on katkaistu.

Tällainen pinta voi säilyä kosketuskuumana jopa 45 mi-nuuttia.

9. Mikäli laite tai kosketussuoja on merkitty tällä merkillä katso lisäohjeita käyttöohjekirjasta

10. Kaikki tässä tuotteessa käytetyt graafiset symbolit ovat yhdestä tai useammasta seuraavis-ta standardeista:

EN61010-1, IEC417 & ISO3864.

IB-106-300NFX

vii

Page 20

IMPORTANT

Consignes de sécurité concernant le raccordement et l’installation de cet appareil.

Les consignes de sécurité ci-dessous s’adressent particulièrement à tous les états membres de la

communauté européenne. Elles doivent être strictement appliquées afin de satisfaire aux directives

concernant la basse tension. Les états non membres de la communauté européenne doivent également

appliquer ces consignes sauf si elles sont en contradiction avec les standards locaux ou nationaux.

1. Un raccordement adéquate à la terre doit être effectuée à chaque borne de mise à la terre, interne et externe.

2. Après installation ou dépannage, tous les capots de protection et toutes les prises de terre doivent être remis

en place, toutes les prises de terre doivent être respectées en permanence.

3. Les câbles d’alimentation électrique doivent être conformes aux normes IEC227 ou IEC245

4. Tous les raccordements doivent pouvoir supporter une température ambiante supérieure à 75°C.

5. Tous les presse-étoupes utilisés doivent avoir un diamètre interne en rapport avec les câbles afin d’assurer

un serrage correct sur ces derniers.

6. Afin de garantir la sécurité du fonctionnement de cet appareil, le raccordement à l’alimentation électrique

doit être réalisé exclusivement au travers d’un disjoncteur (minimum 10A.) isolant tous les conducteurs en

cas d’anomalie. Ce disjoncteur doit également pouvoir être actionné manuellement, de façon mécanique.

Dans le cas contraire, un autre système doit être mis en place afin de pouvoir isoler l’appareil et doit être

signalisé comme tel. Disjoncteurs et interrupteurs doivent être conformes à une norme reconnue telle

IEC947.

7. Lorsque les équipements ou les capots affichent le symbole suivant, cela signifie que des tensions

dangereuses sont présentes. Ces capots ne doivent être démontés que lorsque l’alimentation est

coupée, et uniquement par un personnel compétent.

8. Lorsque les équipements ou les capots affichent le symbole suivant, cela signifie que des surfaces

dangereusement chaudes sont présentes. Ces capots ne doivent être démontés que lorsque

l’alimentation est coupée, et uniquement par un personnel compétent. Certaines surfaces peuvent

rester chaudes jusqu’à 45 mn.

9. Lorsque les équipements ou les capots affichent le symbole suivant, se reporter au manuel

d’instructions.

10. Tous les symboles graphiques utilisés dans ce produit sont conformes à un ou plusieurs des standards

suivants: EN61010-1, IEC417 & ISO3864.

IB-106-300NFX

viii

Page 21

Wichtig

Sicherheitshinweise für den Anschluß und die Installation dieser Geräte.

Die folgenden Sicherheitshinweise sind in allen Mitgliederstaaten der europäischen Gemeinschaft gültig.

Sie müssen strickt eingehalten werden, um der Niederspannungsrichtlinie zu genügen.

Nichtmitgliedsstaaten der europäischen Gemeinschaft sollten die national gültigen Normen und

Richtlinien einhalten.

1. Alle intern und extern vorgesehenen Erdungen der Geräte müssen ausgeführt werden.

2. Nach Installation, Reparatur oder sonstigen Eingriffen in das Gerät müssen alle Sicherheitsabdeckungen und

Erdungen wieder installiert werden. Die Funktion aller Erdverbindungen darf zu keinem Zeitpunkt gestört

sein.

3. Die Netzspannungsversorgung muß den Anforderungen der IEC227 oder IEC245 genügen.

4. Alle Verdrahtungen sollten mindestens bis 75 °C ihre Funktion dauerhaft erfüllen.

5. Alle Kabeldurchführungen und Kabelverschraubungen sollten in Ihrer Dimensionierung so gewählt werden,

daß diese eine sichere Verkabelung des Gerätes ermöglichen.

6. Um eine sichere Funktion des Gerätes zu gewährleisten, muß die Spannungsversorgung über mindestens 10

A abgesichert sein. Im Fehlerfall muß dadurch gewährleistet sein, daß die Spannungsversorgung zum Gerät

bzw. zu den Geräten unterbrochen wird. Ein mechanischer Schutzschalter kann in dieses System integriert

werden. Falls eine derartige Vorrichtung nicht vorhanden ist, muß eine andere Möglichkeit zur

Unterbrechung der Spannungszufuhr gewährleistet werden mit Hinweisen deutlich gekennzeichnet werden.

Ein solcher Mechanismus zur Spannungsunterbrechung muß mit den Normen und Richtlinien für die

allgemeine Installation von Elektrogeräten, wie zum Beispiel der IEC947, übereinstimmen.

7. Mit dem Symbol sind Geräte oder Abdeckungen gekennzeichnet, die eine gefährliche

(Netzspannung) Spannung führen. Die Abdeckungen dürfen nur entfernt werden,

wenn die Versorgungsspannung unterbrochen wurde. Nur geschultes Personal darf an

diesen Geräten Arbeiten ausführen.

8. Mit dem Symbol sind Geräte oder Abdeckungen gekennzeichnet, in bzw. unter denen

heiße Teile vorhanden sind. Die Abdeckungen dürfen nur entfernt werden, wenn die

Versorgungsspannung unterbrochen wurde. Nur geschultes Personal darf an diesen

Geräten Arbeiten ausführen. Bis 45 Minuten nach dem Unterbrechen der Netzzufuhr

können derartig Teile noch über eine erhöhte Temperatur verfügen.

9. Mit dem Symbol sind Geräte oder Abdeckungen gekennzeichnet, bei denen vor dem

Eingriff die entsprechenden Kapitel im Handbuch sorgfältig durchgelesen werden

müssen.

10. Alle in diesem Gerät verwendeten graphischen Symbole entspringen einem oder mehreren der nachfolgend

aufgeführten Standards: EN61010-1, IEC417 & ISO3864.

IB-106-300NFX

ix

Page 22

IMPORTANTE

Norme di sicurezza per il cablaggio e l’installazione dello strumento.

Le seguenti norme di sicurezza si applicano specificatamente agli stati membri dell’Unione Europea, la cui

stretta osservanza è richiesta per garantire conformità alla Direttiva del Basso Voltaggio. Esse si applicano

anche agli stati non appartenenti all’Unione Europea, salvo quant o disposto dalle vigenti normative locali

o nazionali

1. Collegamenti di terra idonei devono essere eseguiti per tutti i punti di messa a terra interni ed esterni, dove

2. Dopo l’installazione o la localizzazione dei guasti, assicurarsi che tutti i coperchi di protezione siano stati

3. I cavi di alimentazione della rete devono essere secondo disposizioni IEC227 o IEC245.

4. L’intero impianto elettrico deve essere adatto per uso in ambiente con temperature superiore a 75°C.

5. Le dimensioni di tutti i connettori dei cavi utilizzati devono essere tali da consentire un adeguato ancoraggio

.

previsti.

collocati e le messa a terra siano collegate. L’integrità di ciscun morsetto di terra deve essere costantemente

garantita.

al cavo.

6. Per garantire un sicuro funzionamento dello strumento il collegamento alla rete di alimentazione principale

dovrà essere eseguita tramite interruttore automatico (min.10A), in grado di disattivare tutti i conduttori di

circuito in caso di guasto. Tale interruttore dovrà inoltre prevedere un sezionatore manuale o altro

dispositivo di interruzione dell’alimentazione, chiaramente identificabile. Gli interruttori dovranno essere

conformi agli standard riconosciuti, quali IEC947.

7. Il simbolo riportato sullo strumento o sui coperchi di protezione indica probabile presenza di

elevati voltaggi. Tali coperchi di protezione devono essere rimossi esclusivamente da personale

qualificato, dopo aver tolto alimentazione allo strumento.

8. Il simbolo riportato sullo strumento o sui coperchi di protezione indica rischio di contatto con

superfici ad alta temperatura. Tali coperchi di protezione devono essere rimossi esclusivamente da

personale qualificato, dopo aver tolto alimentazione allo strumento. Alcune superfici possono

mantenere temperature elevate per oltre 45 minuti.

9. Se lo strumento o il coperchio di protezione riportano il simbolo, fare

riferimento alle istruzioni del manuale Operatore.

10. Tutti i simboli grafici utilizzati in questo prodotto sono previsti da uno o più dei seguenti standard:

EN61010-1, IEC417 e ISO3864.

IB-106-300NFX

x

Page 23

VIKTIG

Sikkerhetsinstruks for tilkobling og installasjon av dette utstyret.

Følgende sikkerhetsinstruksjoner gjelder spesifikt alle EU medlemsland og land med i EØS-avtalen.

Instruksjonene skal følges nøye slik at installasjonen blir i henhold til lavspenningsdirektivet. Den bør

også følges i andre land, med mindre annet er spesifisert av lokale- eller nasjonale standarder.

1. Passende jordforbindelser må tilkobles alle jordingspunkter, interne og eksterne hvor disse forefinnes.

2. Etter installasjon eller feilsøking skal alle sikkerhetsdeksler og jordforbindelser reetableres.

Jordingsforbindelsene må alltid holdes i god stand.

3. Kabler fra spenningsforsyning skal oppfylle kravene spesifisert i IEC227 eller IEC245.

4. Alle ledningsforbindelser skal være konstruert for en omgivelsestemperatur høyere en 750C.

5. Alle kabelforskruvninger som benyttes skal ha en indre dimensjon slik at tilstrekkelig avlastning oppnåes.

6. For å oppnå sikker drift og betjening skal forbindelsen til spenningsforsyningen bare skje gjennom en

strømbryter (minimum 10A) som vil bryte spenningsforsyningen til alle elektriske kretser ved en

feilsituasjon. Strømbryteren kan også inneholde en mekanisk operert bryter for å isolere instrumentet fra

spenningsforsyningen. Dersom det ikke er en mekanisk operert bryter installert, må det være en annen måte

å isolere utstyret fra spenningsforsyningen, og denne måten må være tydelig merket. Kretsbrytere eller

kontakter skal oppfylle kravene i en annerkjent standard av typen IEC947 eller tilsvarende.

7. Der hvor utstyr eller deksler er merket med symbol for farlig spenning, er det

sannsynlig at disse er tilstede bak dekslet. Disse dekslene må bare fjærnes når

spenningsforsyning er frakoblet utstyret, og da bare av trenet servicepersonell.

8. Der hvor utstyr eller deksler er merket med symbol for meget varm overflate, er det

sannsynlig at disse er tilstede bak dekslet. Disse dekslene må bare fjærnes når

spenningsforsyning er frakoblet utstyret, og da bare av trenet servicepersonell. Noen

overflater kan være for varme til å berøres i opp til 45 minutter etter

spenningsforsyning frakoblet.

9. Der hvor utstyret eller deksler er merket med symbol, vennligst referer til

instruksjonsmanualen for instrukser.

10. Alle grafiske symboler brukt i dette produktet er fra en eller flere av følgende standarder: EN61010-1,

IEC417 & ISO3864.

IB-106-300NFX

xi

Page 24

IMPORTANTE

Instruções de segurança para ligação e instalação deste aparelho.

As seguintes instruções de segurança aplicam-se especificamente a todos os estados membros da UE.

Devem ser observadas rigidamente por forma a garantir o cumprimento da Directiva sobre Baixa Tensão.

Relativamente aos estados que não pertençam à UE, deverão cumprir igualmente a referida directiva,

exceptuando os casos em que a legislação local a tiver substituído.

1. Devem ser feitas ligações de terra apropriadas a todos os pontos de terra, internos ou externos.

2. Após a instalação ou eventual reparação, devem ser recolocadas todas as tampas de segurança e terras de

protecção. Deve manter-se sempre a integridade de todos os terminais de terra.

3. Os cabos de alimentação eléctrica devem obedecer às exigências das normas IEC227 ou IEC245.

4. Os cabos e fios utilizados nas ligações eléctricas devem ser adequados para utilização a uma temperatura

ambiente até 75º C.

5. As dimensões internas dos bucins dos cabos devem ser adequadas a uma boa fixação dos cabos.

6. Para assegurar um funcionamento seguro deste equipamento, a ligação ao cabo de alimentação eléctrica

deve ser feita através de um disjuntor (min. 10A) que desligará todos os condutores de circuitos durante uma

avaria. O disjuntor poderá também conter um interruptor de isolamento accionado manualmente. Caso

contrário, deverá ser instalado qualquer outro meio para desligar o equipamento da energia eléctrica,

devendo ser assinalado convenientemente. Os disjuntores ou interruptores devem obedecer a uma norma

reconhecida, tipo IEC947.

7. Sempre que o equipamento ou as tampas contiverem o símbolo, é provável a existência de tensões

perigosas. Estas tampas só devem ser retiradas quando a energia eléctrica tiver sido desligada e

por Pessoal da Assistência devidamente treinado.

8. Sempre que o equipamento ou as tampas contiverem o símbolo, há perigo de existência de

superfícies quentes. Estas tampas só devem ser retiradas por Pessoal da Assistência devidamente

treinado e depois de a energia eléctrica ter sido desligada. Algumas superfícies permanecem

quentes até 45 minutos depois.

9. Sempre que o equipamento ou as tampas contiverem o símbolo, o Manual de Funcionamento deve

ser consultado para obtenção das necessárias instruções.

10. Todos os símbolos gráficos utilizados neste produto baseiam-se em uma ou mais das seguintes normas:

EN61010-1, IEC417 e ISO3864.

IB-106-300NFX

xii

Page 25

IMPORTANTE

Instrucciones de seguridad para el montaje y cableado de este aparato.

Las siguientes instrucciones de seguridad , son de aplicacion especifica a todos los miembros de la UE y se

adjuntaran para cumplir la normativa europea de baja tension.

1. Se deben preveer conexiones a tierra del equipo, tanto externa como internamente, en aquellos terminales

previstos al efecto.

2. Una vez finalizada las operaciones de mantenimiento del equipo, se deben volver a colocar las cubiertas de

seguridad aasi como los terminales de tierra. Se debe comprobar la integridad de cada terminal.

3. Los cables de alimentacion electrica cumpliran con las normas IEC 227 o IEC 245.

4. Todo el cableado sera adecuado para una temperatura ambiental de 75ºC.

5. Todos los prensaestopas seran adecuados para una fijacion adecuada de los cables.

6. Para un manejo seguro del equipo, la alimentacion electrica se realizara a traves de un interruptor

magnetotermico ( min 10 A ), el cual desconectara la alimentacion electrica al equipo en todas sus fases

durante un fallo. Los interruptores estaran de acuerdo a la norma IEC 947 u otra de reconocido prestigio.

7. Cuando las tapas o el equipo lleve impreso el simbolo de tension electrica peligrosa,

dicho alojamiento solamente se abrira una vez que se haya interrumpido la

alimentacion electrica al equipo asimismo la intervencion sera llevada a cabo por

personal entrenado para estas labores.

8. Cuando las tapas o el equipo lleve impreso el simbolo, hay superficies con alta

temperatura, por tanto se abrira una vez que se haya interrumpido la alimentacion

electrica al equipo por personal entrenado para estas labores, y al menos se esperara

unos 45 minutos para enfriar las superficies calientes.

9. Cuando el equipo o la tapa lleve impreso el simbolo, se consultara el manual de

instrucciones.

10. Todos los simbolos graficos usados en esta hoja, estan de acuerdo a las siguientes normas EN61010-1,

IEC417 & ISO 3864.

IB-106-300NFX

xiii

Page 26

VIKTIGT

Säkerhetsföreskrifter för kablage och installation av denna apparat.

Följande säkerhetsföreskrifter är tillämpliga för samtliga EU-medlemsländer. De skall följas i varje

avseende för att överensstämma med Lågspännings direktivet. Icke EU medlemsländer skall också följa

nedanstående punkter, såvida de inte övergrips av lokala eller nationella föreskrifter.

1. Tillämplig jordkontakt skall utföras till alla jordade punkter, såväl internt som externt där så erfordras.

2. Efter installation eller felsökning skall samtliga säkerhetshöljen och säkerhetsjord återplaceras. Samtliga

jordterminaler måste hållas obrutna hela tiden.

3. Matningsspänningens kabel måste överensstämma med föreskrifterna i IEC227 eller IEC245.

4. Allt kablage skall vara lämpligt för användning i en omgivningstemperatur högre än 75ºC.

5. Alla kabelförskruvningar som används skall ha inre dimensioner som motsvarar adekvat kabelförankring.

6. För att säkerställa säker drift av denna utrustning skall anslutning till huvudströmmen endast göras genom

en säkring (min 10A) som skall frånkoppla alla strömförande kretsar när något fel uppstår. Säkringen kan

även ha en mekanisk frånskiljare. Om så inte är fallet, måste ett annat förfarande för att frånskilja

utrustningen från strömförsörjning tillhandahållas och klart framgå genom markering. Säkring eller

omkopplare måste överensstämma med en gällande standard såsom t ex IEC947.

7. Där utrustning eller hölje är markerad med vidstående symbol föreliggerisk för

livsfarlig spänning i närheten. Dessa höljen får endast avlägsnas när strömmen ej är

ansluten till utrustningen - och då endast av utbildad servicepersonal.

8. När utrustning eller hölje är markerad med vidstående symbol föreligger risk för

brännskada vid kontakt med uppvärmd yta. Dessa höljen får endast avlägsnas av

utbildad servicepersonal, när strömmen kopplats från utrustningen. Vissa ytor kan

vara mycket varma att vidröra även upp till 45 minuter efter avstängning av

strömmen.

9. När utrustning eller hölje markerats med vidstående symbol bör

instruktionsmanualen studeras för information.

10.

Samtliga grafiska symboler som förekommer i denna produkt finns angivna i en eller flera av följande

föreskrifter:- EN61010-1, IEC417 & ISO3864.

IB-106-300NFX

xiv

Page 27

IB-106-300NFX

xv/xvi

Page 28

TABLE OF CONTENTS

Section Page

Probe Safety Data Sheet (1M03226)

HPS 3000 Safety Data Sheet (1M03243)

IFT 3000 Safety Data Sheet (1M03296)

Rosemount Warranty ......................................................................... i

Purpose .......................................................................... ii

I. DESCRIPTION

1-1Component Checklist of Typical System (Package Contents) ............................... 1-1

1-2System Overview ................................................................. 1-1

II. INSTALLATION

2-1Oxygen Analyzer (Probe) Installation ............................................... 2-1

2-2Intelligent Field Transmitter (IFT) Installation ......................................... 2-8

2-3Heater Power Supply Installation ................................................... 2-16

2-4Multiprobe Test Gas Sequencer Installation ............................................ 2-20

III. GUI OPERATION

3-1Overview ....................................................................... 3-1

3-2IFT with GUI and LDP Front Panel Controls and Indicators ............................... 3-1

3-3HELP Key ...................................................................... 3-2

3-4Status Line ...................................................................... 3-2

3-5Quick Reference Chart............................................................. 3-2

3-6MAIN Menu ..................................................................... 3-3

3-7PROBE DATA Sub-Menu .......................................................... 3-3

3-8CALIBRATE O

3-9SETUP Sub-Menu ................................................................ 3-3

3-10System Calibration ................................................................ 3-8

Sub-Menu ......................................................... 3-3

2

IV. LDP OPERATION

4-1Overview ....................................................................... 4-1

4-2IFT with LDP Front Panel Controls and Indicators ....................................... 4-1

4-3LDP Displays .................................................................... 4-1

4-4LDP Defaults .................................................................... 4-2

4-5Calibration ...................................................................... 4-2

V. SYSTEM TROUBLESHOOTING

5-1Overview ....................................................................... 5-1

5-2Special Troubleshooting Notes ...................................................... 5-1

5-3System Troubleshooting ............................................................ 5-2

VI. RETURNING EQUIPMENT TO THE FACTORY

INDEX

.......................................................................... I-1

IB-106-300NFX

IB-106-300NFX

xvii

xvii

...................................... 6-1

Page 29

TABLE OF CONTENTS (Continued)

Section Page

APPENDIX AX. WORLD CLASS 3000 OXYGEN ANALYZER (PROBE)

(CENELEC APPROVED VERSION)

APPENDIX BX. HPS 3000 HEATER POWER SUPPLY FIELD MODULE

(CENELEC APPROVED VERSION)

APPENDIX DX. MPS 3000 MULTI PROBE TEST GAS SEQUENCER

APPENDIX EX. IFT 3000 INTELLIGENT FIELD TRANSMITTER

APPENDIX JX. HART COMMUNICATOR MODEL 275D9E IFT 3000 APPLICATIONS

LIST OF ILLUSTRATIONS

Figure Page

1-1 Typical System Package ................................................................ 1-1

1-2 Typical System Installation ............................................................. 1-5

1-3 World Class 3000 Typical Application with Intelligent Field Transmitters - CENELEC Approved ..... 1-6

2-1 Probe Installation ..................................................................... 2-2

2-2 Orienting the Vee Deflector ............................................................. 2-7

2-3 Air Set, Plant Air Connection ............................................................ 2-8

2-4 Outline of Intelligent Field Transmitter .................................................... 2-9

2-5 Power Supply Board Jumper Configuration ................................................. 2-10

2-6 IFT Power Supply Board Jumpers ........................................................ 2-11

2-7 Wiring Layout for IFT 3000 System without HPS ............................................ 2-12

2-8 IFT Microprocessor Board Jumper Configuration ............................................ 2-13

2-9 IFT Microprocessor Board Jumpers ....................................................... 2-14

2-10 Interconnect Board Jumper Configuration .................................................. 2-14

2-11 IFT Interconnect Board Output Connections ................................................ 2-15

2-12 Outline of CENELEC Approved Heater Power Supply ........................................ 2-16

2-13 Wiring Layout for IFT 3000 (CENELEC approved) with HPS .................................. 2-17

2-14 CENELEC Approved Heater Power Supply Wiring Connections ................................ 2-19

2-15 Jumper Selection Label ................................................................. 2-19

2-16 Jumpers on HPS Motherboard ........................................................... 2-20

2-17 MPS Module ......................................................................... 2-21

2-18 MPS Gas Connections ................................................................. 2-21

2-19 MPS Electrical Connections ............................................................. 2-23

3-1 IFT with GUI and LDP Front Panel ....................................................... 3-1

3-2 Typical Calibration Setup ............................................................... 3-10

3-3 Portable Rosemount Oxygen Test Gas Kit .................................................. 3-11

3-4 Typical Portable Test Calibration Setup .................................................... 3-12

3-5 Typical Automatic Calibration System ..................................................... 3-13

4-1 IFT with LDP Front Panel .............................................................. 4-1

IB-106-300NFX

IB-106-300NFX

xviii

xviii

Page 30

SECTION I. DESCRIPTION

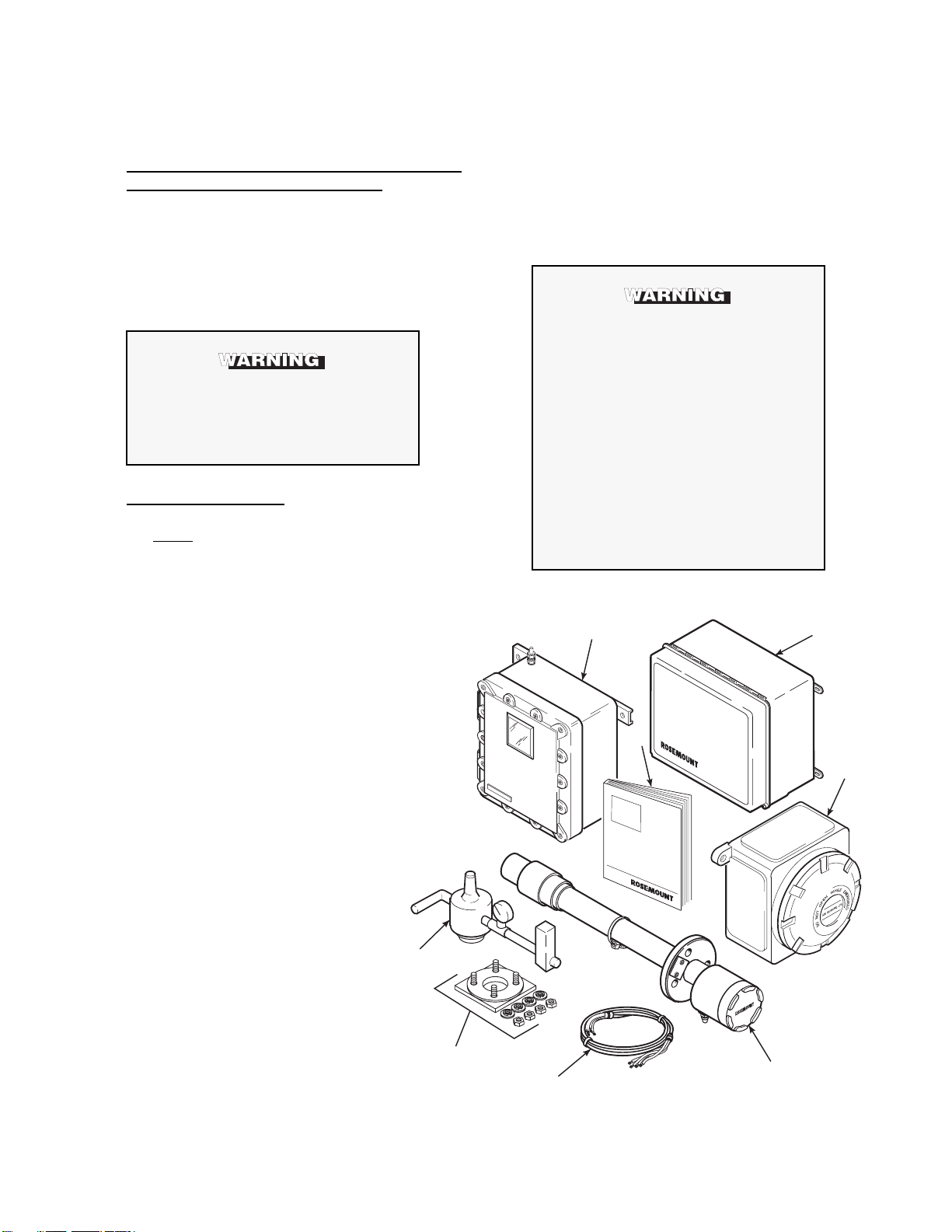

1-1. COMPONENT CHECKLIST OF TYPICAL

SYSTEM (PACKAGE CONTENTS).

A typical

Rosemount World Class 3000 Oxygen Analyzer

(CENELEC approved) with IFT 3000 Intel ligent Field

Transmitter (CENELEC approved) should contain the

items shown in Figure 1-1. Record the Part Number,

Serial Number, and Order Number for each com ponent

of your system in the table located on the c over of this

manual.

The IFT 3000, Oxygen Analyzer (Probe),

and probe abrasive shield are heavy.

Lifting and carrying procedures should

take account of this weight.

1-2. SYSTEM OVERVIEW

a. Scope

This Instruction Bulletin has been designed

.

.

to supply details needed to install, start up,

operate, and maintain the Rosemount World

Class 3000 Oxygen Analyzer (CENELEC

approved) with IFT 3000 Intelligent Field

Transmitter (CENELEC approved). The Intelligent

Field Transmitter (IFT) can be interfaced with one

World Class 3000 probe. The IFT provides all

necessary intelligence for controlling the probe and

optional MPS 3000 Multiprobe Gas Sequencer.

The Rosemount encode sheets (Product

Ordering Matrix) allow a customer to

order either the hazardous area version

of the IFT 3000 or the non-hazardous

area version. The hazardous area version

has the symbol "EExd" on the apparatus

nameplate. The non-hazardous area

version does not. Ensure that i f you have

received the non-hazardous version that

you do not install it in a potentially

explosive atmosphere. This also appl ies to

the hazardous/non-hazardous ver sions of

the HPS 3000.

1

3

ITEM DESCRIPTION

1 Intelligent Field

Transmitter (CENELEC approved)

2 Instruction Bulletin

3 Multiprobe Test Gas Sequencer

(Optional)

4 Heater Power Supply (CENELEC

approved)(Optional)

5 Oxygen Analyzer (Probe)

(CENELEC approved)

6 System Cable

7 Mounting Plate with Mounting

Hardware and Gasket

8 Reference AIR set (optional)

ROSEMOUNT

8

7

6

Figure 1-1. Typical System Package

IB-106-300NFX

1-1

2

4

E

N

E

E

L

I

R

H

G

I

W

S

E

N

D

E

P

O

T

G

O

N

N

I

N

O

E

D

P

O

S

E

E

R

E

O

L

F

A

E

B

B

E

L

5

23800016

Page 31

b. System Description.

The Rosemount Oxygen

Analyzer (Probe) is designed to measure the net

concentration of oxygen in an industrial process;

i.e., the oxygen remaining after all fuels have

been oxidized. The probe is permanently

positioned within an exhaust duct or stack and

performs its task without the use of a sampling

system.

The equipment measures oxygen percentage by

reading the voltage developed across a heated

electrochemical cell, which consists of a small

Yttria-stabilized, Zirconia disc. Both sides of the

disc are coated with porous metal electrodes.

When operated at the proper temperature, the

millivolt output voltage of the cell is given by the

following Nernst equation:

EMF = KT log

10(P1/P2

) + C

Where:

1. P

is the partial pressure of the oxygen in the

2

measured gas on one side of the cell,

is the partial pressure of the oxygen in the

2. P

1

reference gas on the other side,

3. T is the absolute temperature,

4. C is the cell constant,

5. K is an arithmetic constant.

NOTE

For best results, use clean, dry , instrume nt

air (20.95% oxygen) as a reference gas.

When the cell is at operating temperature, and

there are unequal oxygen concentrations across the

cell, oxygen ions will travel from the high partial

pressure of oxygen side to the low part ial pressure

side of the cell. The resulting logarithmic output

voltage is approximately 50 mV per decade.

Because the magnitude of the output is

proportional to the logarithm of the inverse of the

sample of the oxygen partial pressure, the output

signal increases as the oxygen concentration of the

sample gas decreases. This characteristic enables

the oxygen analyzer to provide exceptional

sensitivity at low oxygen concentrations.

Oxygen analyzer equipment measures net oxygen

concentration in the presence of all the products of

combustion, including water vapor. Therefore, it

may be c onsidered an analysis on a "wet"

basis. In comparison with older methods, such as

the Orsat apparatus, which provides an analysis on

a "dry" gas basis, the "wet" analysis will, in

general, indicate a lower percentage of oxygen.

The differ ence will be proportional to the water

content of the sampled gas stream.

The equipment discussed

c. System Configuration

.

in this manual consists of three m ajor components :

the oxygen analyzer (CENELEC approved)

(probe), the intelligent field transmitter

(CENELEC approved) (IFT), and an optional

heater power supply (CENEL EC approved) (HPS).

The HPS is required when the cable run between

the electronics and the probe exceeds 45 m (150

ft). There is also an optional multiprobe test gas

sequencer (MPS), which can be used to facilitate

the automatic calibration of a multiple probe

configuration.

CENELEC approved probes are available in three

length options, giving the u ser the flexibility to use

an in situ penetration appropriate to the size of the

stack or duct. The options on length are 457 mm

(18 in.), 0.91 m (3 ft), and 1.83 m (6 ft). The probe

is certified EExd IIB T1 [370(C (698(F)] to

CENELEC standards EN50014 and EN50018.

The IFT contains electronics that control probe

temperature (in conjunction with the optional

HPS) and supply power, and provide isolated

outputs that are proportional to the measured

oxygen concentration. The oxygen sensing cell is

maintained at a constant temperature by

modulating the duty c yc le of the probe heater. The

IFT accepts millivolt signals generated by the

sensing cell and produces outputs to be used by

remotely connected devices. The IFT output is

isolated and selectable to provide linearized

voltage or current.

The heater power supply CENELEC approved

(HPS) can provide an interface between the IFT

and the probe. The HPS contains a transformer for

supplying proper voltage to the probe heater. The

unit is certified EExd IIC T6 to CENELEC

standards EN50014 and EN50018.

Systems with multiprobe and multiple IFT

applications may employ an optional MPS 3000

Multiprobe Test Gas Sequencer. The MPS 3000

provides automatic test gas sequencing for up to

four probes and IFTs to accommodate automatic

calibration. The M PS 3000 must be installed in a

non-hazardous, explosive-free environment.

IB-106-300NFX

1-2

Page 32

d. System Features.

1. Unique a nd patented electronic cell protection

action that automatically protects sensor cell

when the analyzer detects reducing

atmospheres.

2. Output voltage and sensitivity increase as the

oxygen concentration decreases.

3. User friendly, menu driv en operator interface

with context-sensitive on-line help.

4. Field replaceable cell.

5. Analyzer constructed of rugged 316 LSS for

all wetted parts.

6. The intelligent field transmitter (IFT) can be

located up to 45 m (150 ft) from the probe

when used without optional heater power

supply (HPS). When the system includes the

optional H PS, the HPS can be located up to

45 m (150 ft) from the probe and the IFT may

be located up to 364 m (1200 ft) from the

HPS.

7. All electronic modules are adaptable to 120,

220, and 240 line voltages.

e. Handling the Oxygen Analyzer

.

It is important that printed circuit

boards and integrated circuits are

handled only when adequate antistatic

precautions have been taken to prevent

possible equipment damage.

The oxygen analyzer is designed for

industrial application. Treat each

component of the system with care to

avoid physical damage. The probe

contains components made from

ceramics, which are susceptible to shock

when mishandled. See Safety Data Sheets

1M03243, 1M03226, and 1M03296 for

safety related information.

NOTE

Retain packaging in which the oxygen

analyzer arrived from the factory in case any

components are to be shipped to another site.

This packaging has been designed to pr otect

the product.

8. Five languages may be selected for use with

the IFT. These are:

English

French

German

Italian

Spanish

9. An operator can set up, calibrate, or

troubleshoot the IFT in one of two ways:

(a) Optional General User Interface (GUI).

The GUI is housed within the IFT

electronics enclosure and makes use of

an LCD display and keypad.

(b) Optional LED Display Panel (LDP).

The LED display and a limited function

keypad permit calibration only.

Prior to installation of

f. System Considerations

.

your Rosemount CENELEC approved World

Class 3000 Oxygen Analyzer with Intelligent Field

Transmitter make sure that you have all of the

components necessary to make the system

installation. Ensure that all the components are

properly integrated to mak e the system functional.

Once you have verified that you have all the

components, select mounting locations and

determine how each component will be placed in

terms of available power supply, ambient

temperatures, environmental considerations,

convenience, and serviceability. A typical system

installation is illustrated in Figure 1-2. Figure 1-3

shows a typical system wiring. For details on

installing the individual components of the system ,

refer to Section II, Installation.

IB-106-300NFX

1-3

Page 33

After selecting the probe mounting location,

provision should be made for a platform where the

probe can be easily serviced. The intelligent field

transmitter (IFT) can be located up to 45 m (150

ft) cabling distance from the probe when used

without optional heater power supply (HPS).

When the system includes the optional HPS, the

HPS can be located up to 45 m (150 ft) cabling

distance from the probe and the IFT may be

located up to 364 m (1200 ft) cabling distance

from the HPS.

A source of instrument air is required at the probe

for reference gas use. Since the probe is

equipped with an in-place calibration feature,

provision should be made for connecting test gas

tanks to the oxygen analyzer when the probe is to

be calibrated.

If the test gas bottles will be permanently hooked

up, a check valve must be connected to the

calibration gas fitting on the probe junction box.

This is to prevent breathing of calibr ation g as line

and subsequent gas condensation and corrosion.

The check valve is in addition to the stop valve in

the test gas kit or the solenoid valve in the

multiprobe test gas sequencer units.

IB-106-300NFX

1-4

Page 34

GASES

STACK

STANDARD

DUCT

CALIBRATION

INSTRUMENT

AIR SUPPLY

(REF. GAS)

FIELD TRANSMITTER

GAS

PRESSURE

REGULATOR

FLOWMETER

INTELLIGENT

EExd IIB T6

*MULTIPROBE TEST

(NON-HAZARDOUS AREA)

GAS SEQUENCER

ADAPTER

OXYGEN

ANALYZER

EExd IIB T1

o

(370 C) (PROBE)

ADAPTER

PLATE

HEATER POWER

SUPPLY EExd IIC T6

LINE

VOLTAGE

}

PLATE

CALIBRATION

GAS

GASES

STACK

OPTIONS

DUCT

OXYGEN ANALYZER

EExd IIB T1 (370 C)

(PROBE)

o

*NOTE: THE MPS 3000 MUST BE

INSTALLED IN A NON-HAZARDOUS

EXPLOSIVE FREE ENVIRONMENT.

Figure 1-2. Typical System Installation

SUPPLY

INST. AIR

TEST GAS 1

TEST GAS 2

REFERENCE AIR

FIELD TRANSMITTER

IB-106-300NFX

1-5

INTELLIGENT

EExd IIB T6

HEATER POWER

SUPPLY EExd IIC T6

LINE

VOLTAGE

}

23800017

Page 35

Stack Thermocouple

(optional)

2-Conductor T/C

Wire [46 (150) max]

(optional)

(OPTIONAL)

Line Voltage

4 Twisted Pair Plus 2 Twisted Pair

for Options [366 (1200) max]

Line Voltage

World Class 3000

Probe

World Class 3000

Probe

7-Conductor Cable

[46 (150) max]

2-Pneumatic Lines

by Customer

[91 (300) max]

HPS 3000

HPS 3000

(OPTIONAL)

*MPS 3000

TEST GAS

SEQUENCER

Modular Design

Up to 4 Probes

[HPS not required for lengths of less than 46 (150) max]

7-Conductor Cable

[46 (150) max]

Line Voltage

Test Gas

by

Customer

IFT 3000

Intelligent Field Transmitter

Line Voltage

100 to 120 Volt

220 to 240 Volt

5 Conductor

[305 (1000) max]

Line Voltage

Stack Thermocouple

(optional)

*NOTE 1:

NOTE 2:

2-Conductor T/C

Wire [46 (150) max]

(optional)