Page 1

00809-0100-4045, Rev AC

Rosemount™ Wireless Pressure Gauge

with WirelessHART® Protocol

Reference Manual

September 2019

Page 2

2

Page 3

Reference Manual Contents

00809-0100-4045 September 2019

Contents

Chapter 1 Rosemount Wireless Pressure Gauge............................................................................. 5

Chapter 2 Introduction.................................................................................................................. 7

2.1 Using this manual.............................................................................................................................7

2.2 Models covered................................................................................................................................ 7

2.3 Product recycling/disposal................................................................................................................7

Chapter 3 Hardware installation.................................................................................................... 9

3.1 Overview.......................................................................................................................................... 9

3.2 Safety messages...............................................................................................................................9

3.3 Considerations................................................................................................................................. 9

3.4 Installation procedure.................................................................................................................... 11

3.5 Impulse piping considerations........................................................................................................14

3.6 Process connection........................................................................................................................ 15

3.7 Rosemount manifolds.................................................................................................................... 16

Chapter 4 Configuration...............................................................................................................21

4.1 Overview........................................................................................................................................ 21

4.2 Safety messages.............................................................................................................................21

4.3 System readiness............................................................................................................................22

4.4 Configuration basics.......................................................................................................................22

4.5 Basic gauge setup...........................................................................................................................23

4.6 Configuration verification...............................................................................................................24

4.7 Advanced device parameter setup..................................................................................................26

4.8 Notifications and service................................................................................................................ 27

4.9 Advanced configuration................................................................................................................. 28

Chapter 5 Operation and maintenance.........................................................................................33

5.1 Overview........................................................................................................................................ 33

5.2 Safety messages.............................................................................................................................33

5.3 Pressure signal trimming................................................................................................................ 33

5.4 Replacing the battery..................................................................................................................... 38

5.5 Local device status and notifications...............................................................................................38

Chapter 6 Troubleshooting.......................................................................................................... 41

6.1 Service support...............................................................................................................................41

6.2 Local troubleshooting.....................................................................................................................41

6.3 Remote troubleshooting................................................................................................................ 42

Chapter 7 Reference data............................................................................................................. 45

7.1 Product certificatons...................................................................................................................... 45

7.2 Ordering information, specifications, and dimensional drawings....................................................45

Emerson.com/Rosemount iii

Page 4

Contents Reference Manual

September 2019 00809-0100-4045

Appendix Appendix A Field Communicator Menu Trees................................................................47

A.1 Overview........................................................................................................................................47

Appendix Appendix B Network Design Best Practices...................................................................51

B.1 Overview........................................................................................................................................ 51

B.2 Effective range............................................................................................................................... 51

Appendix Appendix C Device Variable Index................................................................................ 53

C.1 Overview........................................................................................................................................53

C.2 Messages and descriptions.............................................................................................................53

iv Emerson.com/Rosemount

Page 5

Reference Manual Rosemount Wireless Pressure Gauge

00809-0100-4045 September 2019

1 Rosemount Wireless Pressure Gauge

NOTICE

The products described in this document are NOT designed for nuclear-qualified

applications. Using non-nuclear qualified products in applications that require nuclearqualified hardware or products may cause inaccurate readings.

For information on Emerson Automation Solutions nuclear-qualified products, contact

your local Rosemount Sales Representative.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions: This device may not cause harmful interference. This device must accept any

interference received, including interference that may cause undesired operation.

Changes or modification not expressly approved by Rosemount Inc. could void the user’s

authority to operate the equipment.

Using the Rosemount Wireless Pressure Gauge in a manner other than what is specified by

the manufacturer may impair the protection provided by the equipment.

This device must be installed to ensure a minimum antenna separation distance of 20 cm

(8 in.) from all persons.

Shipping considerations

The device is shipped with the battery installed.Each device contains one “D” size primary

lithium-thionyl chloride battery. Primary lithium batteries are regulated in transportation

by the U.S. Department of Transportation, and are also covered by IATA (International Air

Transport Association), ICAO (International Civil Aviation Organization), and ARD

(European Ground Transportation of Dangerous Goods). It is the responsibility of the

shipper to ensure compliance with these or any other local requirements. Consult current

regulations and requirements before shipping.

WARNING

Explosions could result in death or serious injury.

Installation of device in an explosive environment must be in accordance with appropriate

local, national, and international standards, codes, and practices.

Ensure device is installed in accordance with intrinsically safe or non-incendive field

practices.

Before connecting a communicator in an explosive atmosphere, make sure the

instruments in the segment are installed in accordance with intrinsically safe or nonincendive field wiring practices.

Verify the operating atmosphere of the transmitter is consistent with the appropriate

hazardous locations certifications.

Emerson.com/Rosemount 5

Page 6

Rosemount Wireless Pressure Gauge Reference Manual

September 2019 00809-0100-4045

WARNING

Electrical shock could cause death or serious injury.

Care must be taken during transportation of power module to prevent electrostatic

charge build-up.

Device must be installed to ensure a minimum antenna separation distance of 8 in. (20

cm) from all persons.

Process leaks could result in death or serious injury.

Handle the device carefully.

Failure to follow these installation guidelines could result in death or serious injury.

Make sure only qualified personnel perform installation or service.

Apply wrench only to the flats, not on housing.

The battery is not replaceable in a hazardous location.

CAUTION

Keep the vent path free of any obstruction, including but not limited to paint, dust, and

lubrication by mounting the device so the process can drain away.

Interfering or blocking the atmospheric reference port will cause the device to output

erroneous pressure values.

Absolute pressure devices are calibrated at the factory. Trimming adjusts the position of

the factory characterization curve. It is possible to degrade performance of the device if

any trim is done improperly or with inaccurate equipment.

Individuals who handle products exposed to a hazardous substance can avoid injury if they

are informed of and understand the hazard. The product being returned will require a copy

of the required Safety Data Sheet (SDS) for each substance must be included with the

returned goods.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or unintentional and

needs to be protected against.

Physical security is an important part of any security program and fundamental to

protecting your system. Restrict physical access by unauthorized personnel to protect end

users’ assets. This is true for all systems used within the facility.

6 Emerson.com/Rosemount

Page 7

Reference Manual Introduction

00809-0100-4045 September 2019

2 Introduction

2.1 Using this manual

The sections in this manual provide information on installing, operating, and maintaining

the Rosemount™ Wireless Pressure Gauge with WirelessHART® protocol. The sections are

organized as follows:

Hardware installation contains mechanical and electrical installation instructions and

considerations.

Configuration provides instruction on commissioning and operating the gauge.

Information on software functions, configuration parameters, and online variables are also

included.

Operation and maintenance contains operation and maintenance techniques.

Troubleshooting provides troubleshooting techniques for the most common operating

problems.

Reference data supplies reference and specification data, as well as ordering information.

Field Communicator menu trees provides full menu trees and abbreviated fast key

sequences for commissioning tasks.

Network design best practices provides information on how to optimize network reliability

and performance.

Device variable index outlines the most important alerts in the HART command 48

additional status field for Rosemount Wireless Pressure Gauge.

2.2 Models covered

This manual covers the Rosemount Wireless Pressure Gauge.

Measures gage/absolute/compound/vacuum pressure up to 10,000 psi (689.5 bar).

2.3 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of

in accordance with local and national legislation or regulations.

Emerson.com/Rosemount 7

Page 8

Introduction Reference Manual

September 2019 00809-0100-4045

8 Emerson.com/Rosemount

Page 9

Reference Manual Hardware installation

00809-0100-4045 September 2019

3 Hardware installation

3.1 Overview

The information in this section covers installation considerations. A Quick Start Guide is

shipped with every device to describe basic installation and startup procedures.

Dimensional drawings for the Rosemount™ Smart Pressure Gauge can be found in the

Product Data Sheet.

3.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the

safety of the personnel performing the operation. Information that raises potential safety

issues is indicated with a warning symbol ( ). Refer to the following safety messages

before performing an operation preceded by this symbol.

WARNING

Explosions could result in death or serious injury.

Installation of device in an explosive environment must be in accordance with appropriate

local, national, and international standards, codes, and practices.

Ensure device is installed in accordance with intrinsically safe or non-incendive field

practices.

Electrical shock could cause death or serious injury.

Care must be taken during transportation of device to prevent electrostatic charge buildup.

Process leaks could result in death or serious injury.

Handle the device carefully.

Failure to follow safe installation guidelines could result in death or serious injury.

Only qualified personnel should install the equipment.

3.3 Considerations

3.3.1 Pre-installation

Optional: power/device check

The device is designed to be installation-ready. To check device battery prior to

installation, perform the following:

Emerson.com/Rosemount 9

Page 10

1 2 3

64 5

8 709

A

B

C

Hardware installation Reference Manual

September 2019 00809-0100-4045

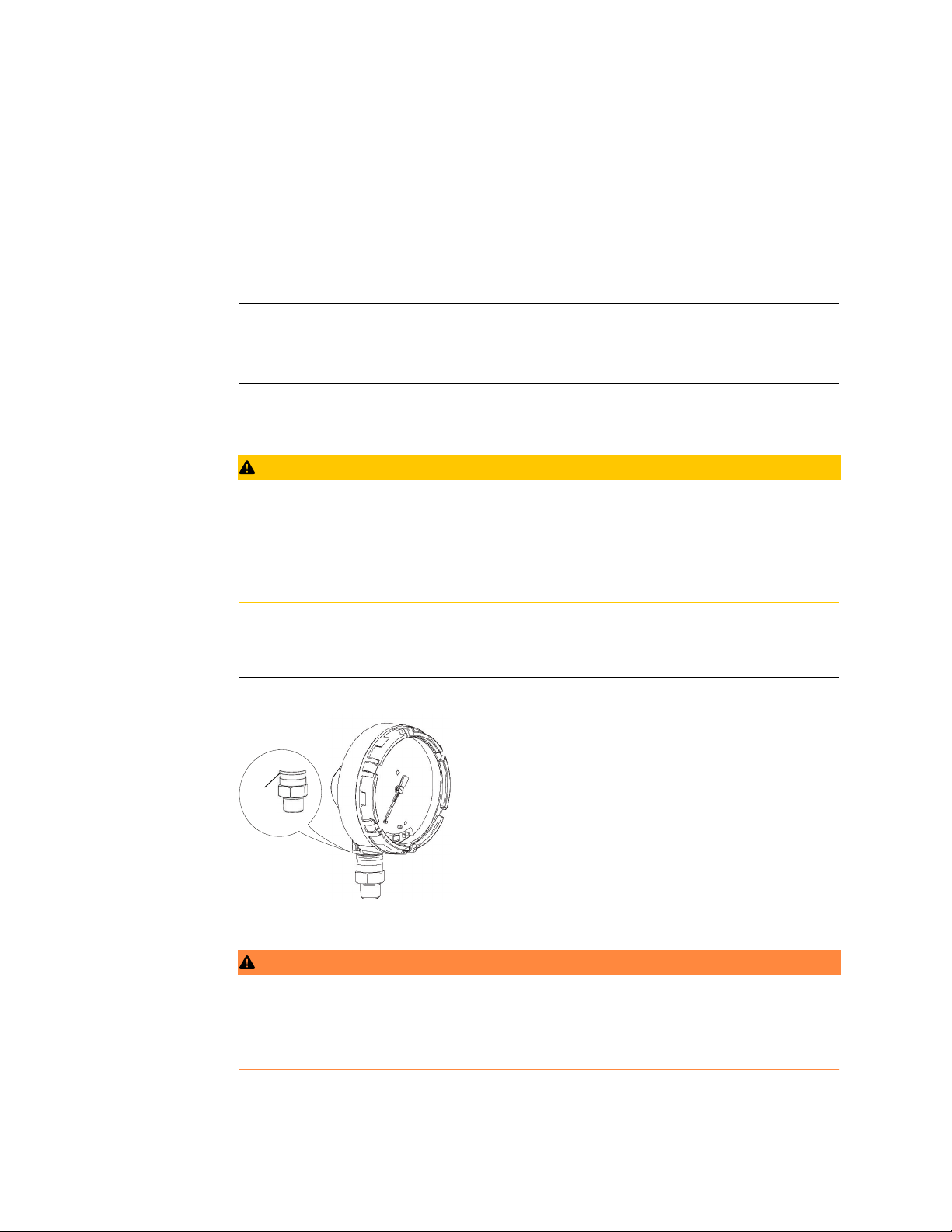

Procedure

1. Perform Turn on device.

2. Slide the ON/OFF switch to the OFF position until ready for use.

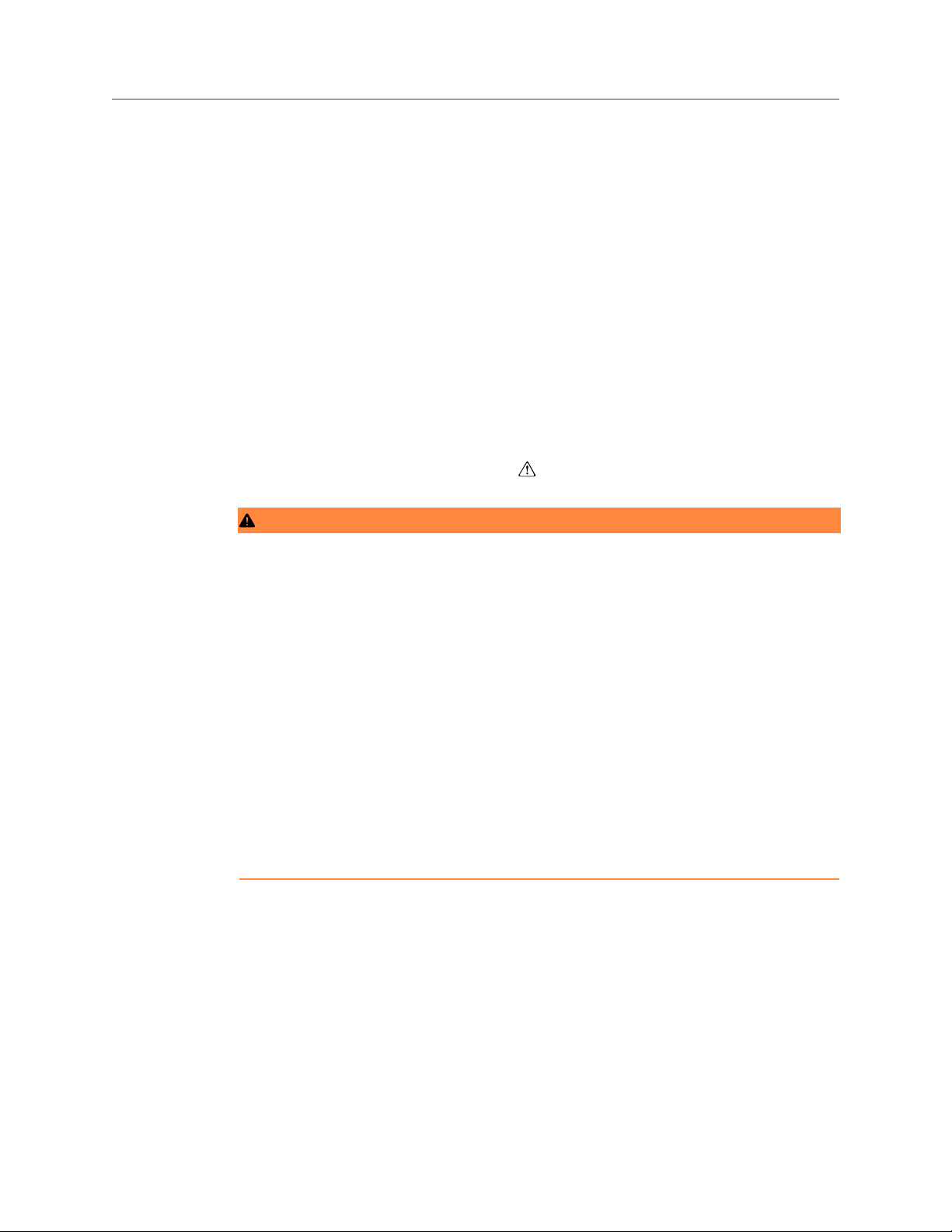

Field Communicator connections

The device needs to be turned on in order for the Field Communicator to interface with

the Rosemount Wireless Pressure Gauge. The Field Communicator connection is located

to the right of the ON/OFF switch. To communicate with the device, connect the Field

Communicator to connections labeled “COMM”. Field communication with this device

requires a HART-based tool using the correct Rosemount Smart Pressure Gauge device

driver (DD). Refer to Figure 3-1 for instructions on connecting the Field Communicator to

the device.

Figure 3-1: Connect to Device

A

B

C

Field Communicator

HART modem

AMS Device Manager

3.3.2 Installation

Measurement performance depends upon proper installation of the device and impulse

piping. Mount the device close to the process and use minimal piping to achieve best

performance. Also, consider the need for easy access, personnel safety, and a suitable

device environment. Install the device to minimize vibration, shock, and temperature

fluctuation.

10 Emerson.com/Rosemount

Page 11

Reference Manual Hardware installation

00809-0100-4045 September 2019

3.3.3 Mechanical

Location

When choosing an installation location and position, take into account the direction of the

device for future access to the COMM connections and readability of the analog display.

Electronics cover

The electronics cover is tightened so that polymer contacts polymer. When removing the

electronics cover, ensure that there is no damage done to the O-ring. If damaged, replace

before reattaching cover, ensuring polymer contacts polymer (i.e. no O-ring visible).

3.3.4 Electrical

Battery

The Rosemount Smart Pressure Gauge is self-powered. The battery contains

approximately five grams of lithium. Under normal conditions, the battery materials are

self-contained and are not reactive as the battery is maintained inside the enclosure of the

device. Care should be taken to prevent thermal, electrical, or mechanical damage.

Contacts should be protected to prevent premature discharge.

Use caution when handling the battery, it may be damaged if dropped.

The battery should be stored in a clean, dry area. For maximum battery life, storage

temperature should not exceed 86 °F (30 °C).

3.3.5

Environmental

Verify the operating atmosphere of the device is consistent with the appropriate

hazardous locations certifications.

Temperature effects

The device will operate within specifications for ambient temperatures as outlined in the

specifications section of the Product Data Sheet. Heat from the process is transferred to

the device housing. If the process temperature is high, the ambient temperature will need

to be lower to account for heat transferred to the device housing. See Temperature limits

for process temperature derating.

3.4 Installation procedure

Figure 3-2: Installation Flowchart

Emerson.com/Rosemount 11

Page 12

OR

Hardware installation Reference Manual

September 2019 00809-0100-4045

3.4.1 Seal and protect threads

3.4.2 Mount device

Note

Use wrench on flats, not on housing.

Mounting orientation

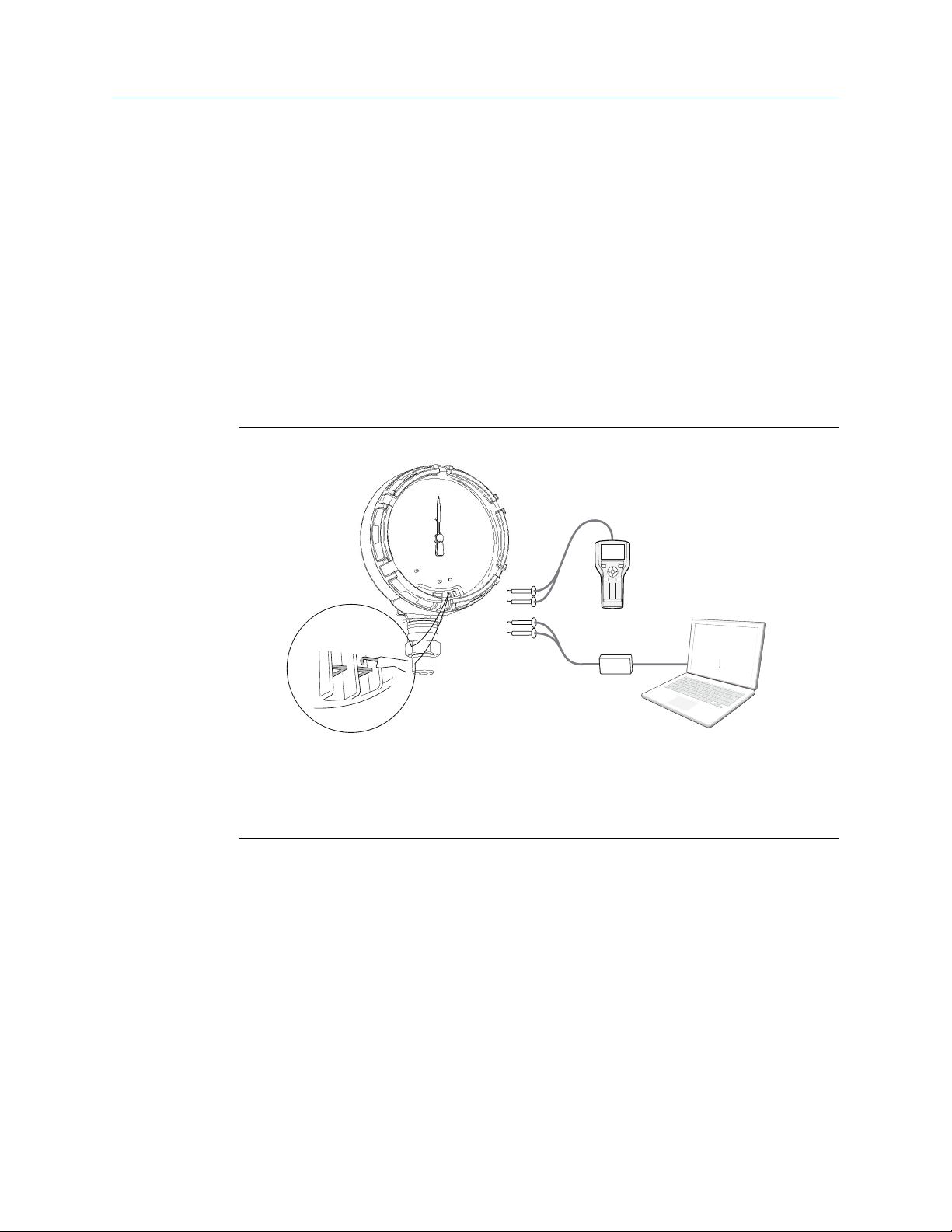

The low side pressure port (atmospheric reference) on the pressure gauge is located in the

neck of the device behind the housing. The vent path is between the housing and sensor.

See Figure 3-3.

CAUTION

Keep the vent path free of any obstruction, including but not limited to paint, dust, and

lubrication by mounting the device so the process can drain away.

12 Emerson.com/Rosemount

Page 13

A

Reference Manual Hardware installation

00809-0100-4045 September 2019

Figure 3-3: Low Side Pressure Port

A

Low side pressure port (atmospheric reference)

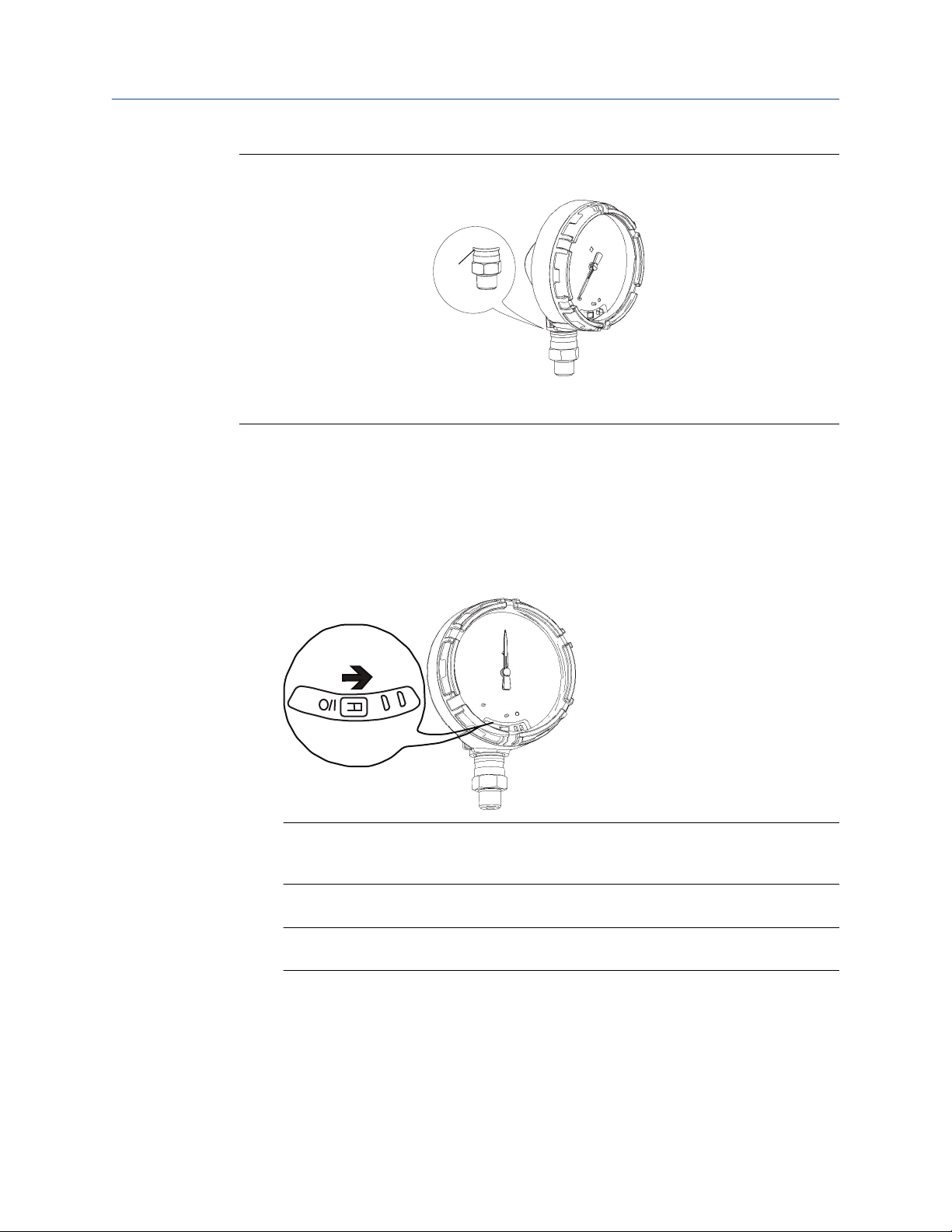

3.4.3 Turn on device

Check to ensure the device and battery are working properly.

Procedure

1. Twist the cover counterclockwise to remove it.

2. Slide the OFF/ON switch to the ON position to initiate the power sequence.

Note

During the power sequence, the dial tests full range of motion and LED flashes

amber.

3. Once the power sequence ends, verify the LED flashes green.

Note

The LED may display several colors; see Table 5-2 for device statuses.

Emerson.com/Rosemount 13

Page 14

Hardware installation Reference Manual

September 2019 00809-0100-4045

3.5 Impulse piping considerations

3.5.1 Best practices

The piping between the process and the device must accurately transfer the pressure to

obtain accurate measurements. There are five possible sources of error: leaks, friction loss

(particularly if purging is used), trapped gas in a liquid line, liquid in a gas line, and density

variations between the legs.

The best location for the device in relation to the process pipe depends on the process

itself. Use the following guidelines to determine device location and placement of impulse

piping:

• Keep impulse piping as short as possible.

• For liquid service, slope the impulse piping at least 1in. per ft. (8 cm per m) upward

from the device toward the process connection.

• For gas service, slope the impulse piping at least 1in. per ft. (8 cm per m) downward

from the device toward the process connection.

3.5.2

• Avoid high points in liquid lines and low points in gas lines.

• Make sure both impulse legs are the same temperature.

• Use impulse piping large enough to avoid friction effects and blockage.

• Vent all gas from liquid piping legs.

• When using a sealing fluid, fill both piping legs to the same level.

• When purging, make the purge connection close to the process taps and purge

through equal lengths of the same size pipe. Avoid purging through the device.

• Keep corrosive or hot (above 250 °F [121 °C]) process material out of direct contact

with the sensor module and flanges.

• Prevent sediment deposits in the impulse piping.

• Keep the liquid head balanced on both legs of the impulse piping.

• Avoid conditions that might allow process fluid to freeze within the process flange.

Mounting requirements

Liquid flow measurement

• Place taps to the side of the line to prevent sediment deposits on the process isolators.

• Mount the device beside or below the taps so gases vent into the process line.

• Mount drain/vent valve upward to allow gases to vent.

Gas flow measurement

• Place taps in the top or side of the line.

• Mount the device beside or above the taps so to drain liquid into the process line.

14 Emerson.com/Rosemount

Page 15

A

Reference Manual Hardware installation

00809-0100-4045 September 2019

Steam flow measurement

• Place taps to the side of the line.

• Mount the device below the taps to ensure that impulse piping will remain filled with

condensate.

• Fill impulse lines with water to prevent steam from contacting the device directly and

to ensure accurate measurement start-up.

Note

For steam or other elevated temperature services, it is important that temperatures do

not exceed 250 °F (121 °C) for devices with silicone fill. For vacuum service, these

temperature limits are reduced to 220 °F (104 °C) for silicone fill.

3.6 Process connection

CAUTION

Interfering or blocking the atmospheric reference port will cause the device to output

erroneous pressure values.

Keep the vent path free of any obstruction, including but not limited to paint, dust, and

lubrication by mounting the device so the process can drain away.

The low side pressure port (atmospheric reference) on the pressure gauge is located in the

neck of the device behind the housing. The vent path is between the housing and sensor.

(See Figure 3-3).

Figure 3-4: Low Side Pressure Port

A low side pressure port (atmospheric reference).

WARNING

Do not apply torque directly to the sensor module. Rotation between the sensor module

and the process connection can damage the electronics. To avoid damage, apply torque

only to the hex-shaped process connection.

Emerson.com/Rosemount 15

Page 16

Hardware installation Reference Manual

September 2019 00809-0100-4045

3.7 Rosemount manifolds

The Rosemount 306 Integral Manifold mounts directly to the device. The manifold is used

with this device to provide block-and-bleed valve capabilities of up to 10,000 psi (689.5

bar).

3.7.1 Installation procedure

The Rosemount 306 Integral Manifold is for use only with a Rosemount Wireless Pressure

Gauge.

Assemble the Rosemount 306 Manifold to the device with a thread sealant.

Procedure

1. Place device into holding fixture.

2. Apply appropriate thread paste or tape to threaded instrument end of the manifold.

3. Count total threads on the manifold before starting assembly.

4. Start turning the manifold by hand into the process connection on the device.

3.7.2

Note

If using thread tape, be sure the thread tape does not strip when the manifold

assembly is started.

5. Wrench tighten manifold into process connection (minimum torque value is 425 in-

lbs).

6. Count how many threads are still showing (minimum engagement is three

revolutions).

7. Subtract the number of threads showing (after tightening) from the total threads to

calculate the revolutions engaged. Further tighten until a minimum of three

rotations is achieved.

8. For block and bleed manifold, verify the bleed screw is installed and tightened. For

2-valve manifold, verify the vent plug is installed and tightened.

9. Leak-check assembly to maximum pressure range of device.

Manifold operation

2-valve and block and bleed style manifolds

Isolating the device

In normal operation the Isolate (block) valve between the process port and device will be

open and the Test/Vent valve will be closed. On a block and bleed style manifold, a single

block valve provides device isolation and a bleed screw provides drain/vent capabilities.

16 Emerson.com/Rosemount

Page 17

Device

Test/vent

(closed)

Isolate

Process

(open)

Device

Test/vent

(closed)

Isolate

Process

(closed)

Reference Manual Hardware installation

00809-0100-4045 September 2019

Procedure

1. To isolate the device, close the isolate valve.

2. To bring the device to atmospheric pressure, open the vent valve or bleed screw.

Note

A ¼-in. male NPT pipe plug may be installed in the test/vent port and will need to be

removed with a wrench in order to vent the manifold properly.

Emerson.com/Rosemount 17

Page 18

Device

Test/vent

(open)

Isolate

Process

(closed)

Device

Test/vent

(closed)

Isolate

Process

(closed)

Device

Test/vent

(closed)

Isolate

Process

(open)

Hardware installation Reference Manual

September 2019 00809-0100-4045

3. After venting to atmosphere, perform any required calibration and then close the

test/vent valve or replace the bleed screw.

4. Open the Isolate (block) valve to return the device to service.

18 Emerson.com/Rosemount

Page 19

Reference Manual Hardware installation

00809-0100-4045 September 2019

Adjusting valve packing

This is a 20-50-word description of the value to the user in this task. REQUIRED.

Over time, the packing material inside a Rosemount manifold may require adjustment in

order to continue to provide proper pressure retention. Not all Rosemount manifolds have

this adjustment capability. The Rosemount manifold model number will indicate what

type of stem seal or packing material has been used.

The following steps are provided as a procedure to adjust valve packing.

Procedure

1. Remove all pressure from device.

2. Loosen manifold valve jam nut.

3. Tighten manifold valve packing adjuster nut ¼ turn.

4. Tighten manifold valve jam nut.

5. Re-apply pressure and check for leaks.

6. Above steps can be repeated, if necessary.

If the above procedure does not result in proper pressure retention, the complete

manifold should be replaced.

Emerson.com/Rosemount 19

Page 20

Hardware installation Reference Manual

September 2019 00809-0100-4045

A Bonnet

B Stem

C Packing

D Ball seat

E Packing adjuster

F Jam nut

G Packing follower

20 Emerson.com/Rosemount

Page 21

Reference Manual Configuration

00809-0100-4045 September 2019

4 Configuration

4.1 Overview

This section contains information on commissioning and tasks.

Field Communicator and AMS Device Manager Instructions are given to perform

configuration functions.

Full Field Communicator menu trees are available in Field Communicator menu trees.

4.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the

safety of the personnel performing the operation. Information that raises potential safety

issues is indicated with a warning symbol ( ). Refer to the following safety messages

before performing an operation preceded by this symbol.

WARNING

Explosions could result in death or serious injury.

Installation of this device in an explosive environment must be in accordance with the

appropriate local, national, and international standards, codes, and practices. Review the

approvals section of the Rosemount™ Smart Pressure Gauge Reference Manual for any

restrictions associated with a safe installation.

Before connecting a Field Communicator in an explosive atmosphere, make sure the

instruments are installed in accordance with intrinsically safe or non-incendive field wiring

practices.

Verify that the operating environment of the device is consistent with the appropriate

hazardous locations certifications.

NOTICE

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions: This device may not cause harmful interference. This device must accept any

interference received, including interference that may cause undesired operation.

This device must be installed to ensure a minimum antenna separation distance of 20 cm

(8 in.) from all persons.

Emerson.com/Rosemount 21

Page 22

Measured

process

input

P A/D

Micro Local Display output

Configuration Reference Manual

September 2019 00809-0100-4045

4.3 System readiness

4.3.1 Confirm correct device driver

Verify the latest Device Description (DD/DTM™) is loaded on your systems to ensure

proper communications.

Procedure

1. Visit the Emerson Device Install Kits Library or Fieldcommgroup.org.

2. Select desired product.

a) Within Table 4-1, use the HART Universal Revision and Device Revision

numbers to find the correct Device Description.

Table 4-1: Rosemount Smart Pressure Gauge Device Revisions and Files

Software

release

date

October

2017

(1) NAMUR Software Revision is located on the hardware tag of the device.

(2) HART Software Revision can be read using a HART capable configuration tool.

(3) Device Driver file names use Device and DD Revision (e.g. 10_01). HART Protocol is

designed to enable legacy device driver revisions to continue to communicate with new

HART devices. To access new functionality, the new Device Driver must be downloaded.

It is recommended to download new Device Driver files to ensure full functionality.

Identify device Find device driver Review

NAMUR

software

revision

1.0.0 1.0.0 2 7 1 00809-0100-4145Initial release

(1)

NAMUR

software

revision

Figure 4-1: Data Flow

4.4 Configuration basics

HART

software

revision

(2)

HART

universal

revision

Device

revision

instructions

Manual

(3)

document

number

Review

functionality

Changes to

software

4.4.1 Configuration tools

Configuration requires a Field Communicator or AMS Device Manager. Connect the Field

Communicator leads to the terminals labeled “COMM” on the front of the device (see

Figure 3-1).

When using a Field Communicator, any configuration changes made must be sent to the

device by using the Send key (F2). AMS Device Manager configuration changes are

implemented when the Apply button is selected.

22 Emerson.com/Rosemount

Page 23

Reference Manual Configuration

00809-0100-4045 September 2019

4.4.2 Connection diagrams

Figure 3-1 illustrates the wiring for a field hook-up with a Field Communicator or AMS

Device Manager. The Field Communicator or AMS Device Manager may be connected at

“COMM” on the device.

4.5 Basic gauge setup

4.5.1 Eliminate mounting effects

Devices are factory-calibrated. Once installed, it is recommended to perform this step to

eliminate potential error caused by mounting position or static pressure. Instructions for

using a Field Communicator are listed below:

Procedure

1. Vent the device.

2. Connect the Field Communicator.

3. From the HOME screen, enter the HART Fast Key sequence.

4.5.2

Fast Keys

4. Follow the commands to perform the procedure.

2, 1, 1

Activate wireless

Do not activate wireless until Emerson Wireless Gateway is installed and functioning

properly; toggling off and on reduces battery life.

Join device to network.

1. Obtain Network ID and Join Key for the wireless network (available in wireless

gateway).

2. From the HOME screen, enter the HART Fast Key sequence.

Fast Keys

3. Follow the commands to perform the procedure.

4. Select Overview > Status.

5. Verify communication status displays Connected.

Note

Joining the device to the network could take several minutes.

2, 1, 2

Emerson.com/Rosemount 23

Page 24

Configuration Reference Manual

September 2019 00809-0100-4045

4.5.3 Considerations for devices with percent of range engineering unit

Set range points

The range values command sets the lower and upper range values used for the percent of

range engineering unit.

Note

Devices are shipped from Emerson fully calibrated to the factory default of full scale (scale

range = upper range limit).

From the HOME screen, enter the Fast Key sequence.

Fast Keys

Procedure

1. Select lower or upper range value as applicable.

2. Follow the commands to perform the procedure.

2, 2, 1, 2

4.6 Configuration verification

The following is a list of factory default configurations that can be viewed by using the

Field Communicator or AMS Device Manager. Follow the steps below to review the gauge

configuration information.

Note

Information and procedures in this section that make use of Field Communicator Fast Key

sequences and AMS Device Manager assume the gauge and communication equipment

are connected, powered, and operating correctly.

4.6.1

Review pressure information

From the HOME screen, enter the Fast Key sequence.

Fast Keys

1, 2

Procedure

1. From the Home screen, select 1: Overview.

2. Select 2: Pressure.

4.6.2

24 Emerson.com/Rosemount

Review device information

From the HOME screen, enter the Fast Key sequence.

Fast Keys

1, 9

Page 25

Reference Manual Configuration

00809-0100-4045 September 2019

Procedure

1. From the Home screen, select 1: Overview.

2. Select 9: Device Information.

3. Select from the corresponding number to view each field:

• 1 Identification

• 2 Revisions

• 3 Materials of Construction

• 4 Security

• 5 Dial Faceplate

• 6 Capabilities

4.6.3

4.6.4

Review radio information

From the HOME screen, enter the Fast Key sequence.

Table 4-2:

Fast Keys 1, 9, 3

1. From the Home screen, select 1: Overview.

2. Select 9: Device Information.

3. Select 3: Radio.

4. Select from the corresponding number to view each field:

1 MAC address

2 Manufacturer

3 Device type

4 Devision revision

5 Software revisions

6 Hardware revision

7 Xmit power level

8 Min brdcst rate

Review operating parameters

The pressure output value in both engineering units and percent of range will reflect it

even when it is outside of the configured range as long as it is between the upper and

lower range limit of the device. For example, if a scale range 0 - 150 psi (LRL = 0 psi, URL =

150 psi) is ranged from 0 to 100 psi, an applied pressure of 150 psi will return a percent of

range output of 150 percent.

From the HOME screen, enter the Fast Key sequence.

Fast Keys

Emerson.com/Rosemount 25

3, 2, 1

Page 26

Configuration Reference Manual

September 2019 00809-0100-4045

Procedure

1. From the Home screen, select 3: Service Tools.

2. Select 2: Variables.

3. Select 1: All Variables.

The Operating Parameters menu displays the following information pertaining to

the device:

All variables:

• Pressure

• Pressure Quality

• Custom Scale

• Cust Scale Quality

• Percent of Range

• Percent of Rng Quality

• Sensor Temp

• Sensor Temp Quality

• Sensor Temp Unit

• Supply Voltage

• Supply Voltage Quality

4.7 Advanced device parameter setup

4.7.1 Write protect

The device has a software write protect security feature.

From the HOME screen, enter the Fast Key sequence.

Table 4-3:

Fast Keys 2, 2, 4, 1

1. Select Write Protect to enable.

2. Right click on device and select 2: Configure.

3. Select 2: Advanced Setup.

4. Select the tab labeled 4: Security.

5. Select Write Protect to enable this feature.

26 Emerson.com/Rosemount

Page 27

Reference Manual Configuration

00809-0100-4045 September 2019

4.7.2 Wireless update rate

From the HOME screen, enter the Fast Key sequence.

Fast Keys 2, 2, 3, 2

1. From the Home screen, select 2: Configure.

2. Select 2: Advanced Setup.

3. Select 3: Wireless.

4. Select 2: Update Rate.

5. Follow the commands to perform the procedure.

4.7.3

Dial update rate

From the HOME screen, enter the Fast Key sequence.

Fast Keys

Procedure

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 1: Measurements.

4. Select 1: Dial/Pressure.

5. Select 2: Dial Update Rate.

6. Follow the commands to perform the procedure.

2, 2, 1, 1, 2

4.8 Notifications and service

Notifications and service functions listed below are primarily for the user after field

installation. The device simulation feature is designed to verify proper operating

functionality, and can be performed either on the bench or in the field.

4.8.1

Simulating device variables

From the HOME screen, enter the Fast Key sequence.

Fast Keys

Procedure

1. From the Home screen, select 3: Service Tools.

2. Select 4: Simulate.

Emerson.com/Rosemount 27

3, 4

Page 28

Configuration Reference Manual

September 2019 00809-0100-4045

Note

The following parameters pertaining to the device can be simulated: Pressure,

sensor temperature, and supply voltage

4.8.2 Device reset

The master reset function will reset the device electronics. To perform a device reset:

From the HOME screen, enter the Fast Key sequence.

Fast Keys 3, 3, 1

Procedure

1. From the Home screen, select 3: Service Tools.

2. Select 3: Maintenance

3. Select 1: Device Reset

4.8.3

Join status

From the HOME screen, enter the Fast Key sequence.

Table 4-4:

Fast Keys 3, 3, 1

1. From the Home screen, select 3: Service Tools.

2. Select 3: Communications.

3. Select 1: Join Status.

Wireless devices join the secure network through a four-step process:

• Step 1. Network Found

• Step 2. Network Security Clearance Granted

• Step 3. Network Bandwidth Allocated

• Step 4. Network Join Complete

4.9 Advanced configuration

4.9.1 Overpressure notification

This notification can be used to know if a process pressure higher than 105 percentage of

the devices maximum working pressure (MWP) has been measured. The overpressure

notification must be configured to latched mode to activate the notification. If this event

occurs when the device is configured to latch, the dial will be driven to the Red X and the

LED will blink red. Additionally, it is required to acknowledge and reset the overpressure

28 Emerson.com/Rosemount

Page 29

Reference Manual Configuration

00809-0100-4045 September 2019

notification after an overpressure event before the dial can move back to an on-scale

position.

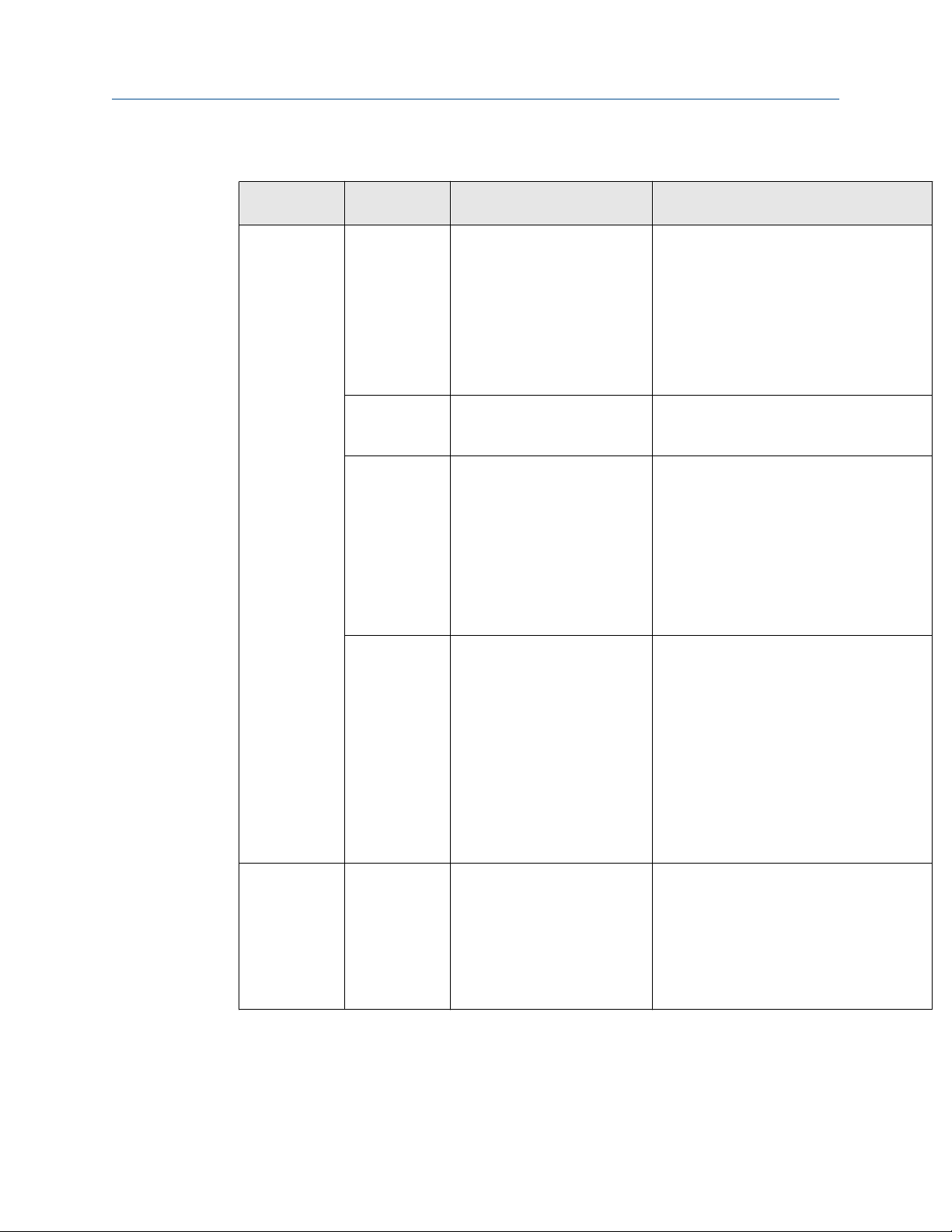

Table 4-5 contains further information on device specific MWP as it correlates to the

device specific scale range.

Table 4-5: Maximum Working Pressure

Scale range Maximum working

pressure (MWP)

Vacuum to 30 psi 30 psi 31.5 psi 750 psi

31–150 psi 150 psi 157.5 psi 1,500 psi

151–800 psi 800 psi 840 psi 1,600 psi

801–4,000 psi 4,000 psi 4,200 psi 6,000 psi

4,001-10,000 psi 10,000 psi 10,500 psi 15,000 psi

105% of MWP Maximum overpressure

limit

Table 4-6 demonstrates the different dial locations based on configuration of the

overpressure notification (Unlatched vs Latched).

Table 4-6: Dial Locations

Measured process

pressure

Within scale range

Parameter configuration

Unlatched (factory default) Latched

LED color: Green

Dial location: On-scale

Emerson.com/Rosemount 29

LED color: Green

Dial location: On-scale

Page 30

Configuration Reference Manual

September 2019 00809-0100-4045

Table 4-6: Dial Locations (continued)

Measured process

pressure

Beyond scale range

and <105% of MWP

>105% MWP

Parameter configuration

Unlatched (factory default) Latched

LED color: Green

Dial location: Off-scale

LED color: Green

Dial location: Off-scale

LED color: Green

Dial location: Off-scale

See Local device status and notifications for more information.

From the HOME screen, enter the Fast Key sequence

Fast Keys

2, 2, 1, 1, 3

Procedure

1. From the Home screen, select 2: Configure

2. Select 2: Manual Setup

3. Select 1: Measurements

4. Select 1: Dial/Pressure

5. Select 3: Over-Press Ind

6. Follow the commands to perform the procedure.

LED color: Red

Dial location: Red X

30 Emerson.com/Rosemount

Page 31

Reference Manual Configuration

00809-0100-4045 September 2019

Note

When the parameter has been set to activate, the notification must be

acknowledged and cleared for the device to return to normal operation.

4.9.2 Acknowledge and reset overpressure notification

From the HOME screen, enter the Fast Key sequence

Fast Keys 3, 4, 3

1. From the Home screen, select 3: Service Tools.

2. Select 4: Maintenance.

3. Select 3: Acknowledge Over-Pressure.

4. Follow the commands to perform the procedure.

Emerson.com/Rosemount 31

Page 32

Configuration Reference Manual

September 2019 00809-0100-4045

32 Emerson.com/Rosemount

Page 33

Reference Manual Operation and maintenance

00809-0100-4045 September 2019

5 Operation and maintenance

5.1 Overview

This section contains information on commissioning and operating Rosemount™ Wireless

Pressure Gauges.

Field Communicator and AMS Device Manager instructions are provided for convenience.

5.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the

safety of the personnel performing the operation. Information that raises potential safety

issues is indicated with a warning symbol ( ). Refer to the following safety messages

before performing an operation preceded by this symbol.

5.3 Pressure signal trimming

Calibrating a Rosemount Wireless Pressure Gauge may include the sensor trim procedure

to adjust for mounting effects.

Sensor trimming requires an accurate pressure input and adds additional compensation

that adjusts the position of the factory trim to optimize performance over a specific

pressure range.

Note

Sensor trimming adjusts the position of the factory trim. It is possible to degrade the

performance of the gauge if the trim is done improperly or with inaccurate equipment.

CAUTION

Absolute pressure devices are calibrated at the factory. Trimming adjusts the position of

the factory characterization curve. It is possible to degrade performance of the device if

any trim is done improperly or with inaccurate equipment.

Table 5-1: Recommended Calibration Tasks

Measurement type Tasks

Gage

Compound

Vacuum

1. Reconfigure parameters if necessary.

2. Zero trim the device to compensate for mounting effects or static pressure

effects.

3. Optional: Perform a sensor trim. (Accurate pressure source required.)

Emerson.com/Rosemount 33

Page 34

Operation and maintenance Reference Manual

September 2019 00809-0100-4045

Table 5-1: Recommended Calibration Tasks (continued)

Measurement type Tasks

Absolute 1. Reconfigure parameters if necessary.

2. Perform low trim value section of the sensor trim procedure to correct for

mounting position effects.

3. Optional: Perform a sensor trim if equipment available (accurate absolute

pressure source required), otherwise perform the low trim value section of

the sensor trim procedure.

Note

For devices with absolute measurement type, an accurate absolute pressure source is

required.

5.3.1

5.3.2

Determining necessary sensor trims

Bench calibrations allow for calibrating the instrument for its desired range of operation.

Straightforward connections to pressure source allow for a full calibration at the planned

operating points. Exercising the device over the desired pressure range allows for

verification of the output value. Sensor trim discusses how the trim operations change the

calibration. It is possible to degrade the performance of the device if a trim is done

improperly or with inaccurate equipment. The device can be set back to factory settings

using the Recall factory trim — sensor trim command in Manifold operation.

For devices that are field installed, the manifolds discussed in Manifold operation allow the

device to be zeroed using the zero trim function. This field calibration will eliminate any

pressure offsets caused by mounting effects (head effect of the oil fill) and static pressure

effects of the process.

Determine the necessary trims with the following steps.

Procedure

1. Apply pressure.

2. Check pressure. If the pressure does not match the applied pressure, perform a

digital zero trim. See Manifold operation.

Sensor trim overview

A sensor trim corrects the pressure offset and pressure range to match a pressure

standard. The upper sensor trim corrects the pressure range and the lower sensor trim

(zero trim) corrects the pressure offset. An accurate pressure standard is required for full

calibration. A zero trim can be performed if the process is vented.

Zero trim is a single-point offset adjustment. It is useful for compensating for mounting

position effects and is most effective when performed with the device installed in its final

mounting position. Since this correction maintains the slope of the characterization curve,

it should not be used in place of a sensor trim over the full sensor range.

34 Emerson.com/Rosemount

Page 35

Reference Manual Operation and maintenance

00809-0100-4045 September 2019

When performing a zero trim, ensure the equalizing valve is open and all wet legs are filled

to the correct levels. Line pressure should be applied to the device during a zero trim to

eliminate line pressure errors. Refer to Manifold operation.

Note

Do not perform a zero trim on the Rosemount Smart Pressure Gauge with absolute

measurement type. Zero trim uses a zero reference against ambient air pressure for gage,

vacuum, and compound pressure devices, while absolute pressure devices reference

absolute zero. To correct mounting position effects on a Smart Pressure Gauge with

absolute measurement type, perform a low trim within the sensor trim function. The low

trim function provides an offset correction similar to the zero trim function, but it does not

require zero-based input.

Sensor trim is a two-point sensor calibration where two end-point pressures are applied,

and output is linearized. Always adjust the low trim value first to establish the correct

offset. Adjustment of the high trim value provides a slope correction to the

characterization curve based on the low trim value. The trim values allow you to optimize

performance over your specified measuring range at the calibration temperature.

During a trim operation, the device is placed in high power refresh mode, which provides

frequent pressure measurement updates. This behavior allows for more accurate

calibration of the device. When the device is in high power refresh mode, the battery

power supply will be depleted more rapidly.

Figure 5-1: Sensor Trim Example

A

B

5.3.3 Sensor trim

When performing a sensor trim, both the upper and lower limits can be trimmed. If both

upper and lower trims are to be performed, the lower trim must be done before the upper

trim.

Note

Use a pressure input source at least four times more accurate than the device, and allow

the input pressure to stabilize for 60 seconds before entering any values.

Before trim

After trim

From the HOME screen, enter the Fast Key sequence

Emerson.com/Rosemount 35

Page 36

Operation and maintenance Reference Manual

September 2019 00809-0100-4045

Fast Keys 2, 2, 1, 1, 1

Procedure

1. Assemble and power the entire calibration system including the gauge, Field

Communicator or AMS Device Manager, power supply, pressure input source, and

readout device.

2. From the Home screen, select 2: Configure.

3. Select 2: Manual Setup.

4. Select 1: Measurements.

5. Select 1: Dial/Pressure.

6. Select 1: Verify/Calibrate.

Note

Select pressure points so that lower and upper values are equal to or outside the

expected process operation range.

Note

The applied pressure must be within five percent of the selected pressure points

when performing sensor trim.

5.3.4

7. Follow the on-screen instructions to complete the adjustment of the lower value.

8. Repeat the procedure for the upper value.

Performing a digital zero trim

Devices are factory-calibrated. Once installed, it is recommended to perform this step to

eliminate potential error caused by mounting position or static pressure. Instructions for

using a Field Communicator are listed below.

Fast Keys

1. Vent the device.

2. Connect the Field Communicator.

3. From the HOME screen, enter the HART Fast Key sequence.

4. Follow the commands to perform the procedure.

2, 1, 1

Dial adjustment

Dial adjustment can be used to adjust the dial above or below zero and allows for

adjustments up to 13 percent of span. Dial adjustment only impacts needle position and

does not impact sensor.

Note

Dial adjustment adjusts the position of the factory dial calibration. It is possible to degrade

the performance of the gauge if the operation is done improperly or inaccurately.

From the HOME screen, enter the Fast Key sequence

36 Emerson.com/Rosemount

Page 37

Reference Manual Operation and maintenance

00809-0100-4045 September 2019

Fast Keys 2, 2, 1, 1, 1, 1

Procedure

1. Select 2: Configure.

2. Select 2: Manual Setup.

3. Select 1: Measurements.

4. Select 1: Dial/Pressure.

5. Select 1: Verify/Calibrate.

6. Select 1: Verify/Calibrate Dial+Digital Pressure.

7. Adjust dial indicator until it points to lower endpoint.

The following adjustments are available and can be used to complete the dial

adjustment.

• Fine counterclockwise (0.1 percent of Span)

• Fine clockwise (0.1 percent of Span)

• Coarse counterclockwise (0.3 percent of Span)

5.3.5

• Coarse clockwise (0.3 percent of Span)

8. Select 5: Save Dial.

Recall factory trim — sensor trim

The recall factory trim—sensor trim command allows the restoration of the as-shipped

factory settings of the sensor trim. This command can be useful for recovering from an

inadvertent zero trim of an absolute pressure unit or inaccurate pressure source.

Fast Keys

1. From the HOME screen, enter the Fast Key sequence

2. Select 3: Service Tools.

3. Select 4: Restore to Default Settings.

4. Select 2: Restore to Default Settings.

5. Follow the screen prompts to recall sensor and dial trim.

3, 4, 2

Emerson.com/Rosemount 37

Page 38

Operation and maintenance Reference Manual

September 2019 00809-0100-4045

5.4 Replacing the battery

WARNING

The Rosemount Pressure Gauge shall be used only with the battery (00G45-9000-0001)

supplied by Rosemount. This battery has been officially tested with the device as required

by the I.S. standards during the assessment of the Rosemount Pressure Gauge.

The battery is not replaceable in a hazardous location.

Dispose of battery in accordance with local and national jurisdictions.

Procedure to replace the battery:

Procedure

1. Remove enclosure cover.

2. Switch the device “OFF”.

3. Loosen the screw holding the electronics assembly to the enclosure.

Note

Use caution as the electronics assembly is connected to the pressure sensor via a

cable. Take care not to over stretch this cable as this could damage the device.

4. Release battery connection from electronics board.

5. Loosen the two screws on the battery holder and slide the battery holder to the left.

Note

The screws holding down the electronics board do not need to be removed, just

loosened. Take care not to let the battery fall out of the enclosure.

6. Remove battery from enclosure.

7. Installation of new battery is the reverse of the removal.

5.5 Local device status and notifications

The flashing LED indicates device status using the colors described in Table 5-2. For start

up considerations, refer to Turn on device.

Table 5-2: Status Descriptions

LED color Device status

Green Functioning properly

Amber Battery is low, battery replacement recommended

38 Emerson.com/Rosemount

Page 39

Reference Manual Operation and maintenance

00809-0100-4045 September 2019

Table 5-2: Status Descriptions (continued)

LED color Device status

Red Battery replacement required OR Device is

malfunctioning

No color No power, verify ON/OFF switch is in “on” position

If the dial is pointing towards the red “X”, refer to Troubleshooting for more information.

Emerson.com/Rosemount 39

Page 40

Operation and maintenance Reference Manual

September 2019 00809-0100-4045

40 Emerson.com/Rosemount

Page 41

Reference Manual Troubleshooting

00809-0100-4045 September 2019

6 Troubleshooting

6.1 Service support

To expedite the return process outside of the United States, contact the nearest Emerson

representative.

Contact information for a regional Rosemount™ office is provided on the last page of this

document.

The center will ask for product model and serial numbers, and will provide a Return

Material Authorization (RMA) number. The center will also ask for the process material to

which the product was last exposed.

CAUTION

Individuals who handle products exposed to a hazardous substance can avoid injury if they

are informed of and understand the hazard. The product being returned will require a copy

of the required Safety Data Sheet (SDS) for each substance must be included with the

returned goods.

Emerson representatives will explain the additional information and procedures necessary

to return goods exposed to hazardous substances.

6.2 Local troubleshooting

Table 6-1: Interpreting Local Notifications

LED color Dial location Device status Recommended action(s)

Green

Amber

Red

Functioning properly No action required.

Battery is low Battery replacement recommended.

Battery is low, device is

malfunctioning

Battery replacement

required

OR

Device is

malfunctioning

Investigate active notification via a HART

Communicator. Replace battery if device is

determined to be functioning properly and

notifications have been verified.

Investigate active notification via a HART

Communicator. Replace battery if device is

determined to be functioning properly and

notifications have been verified.

®

Emerson.com/Rosemount 41

Page 42

Troubleshooting Reference Manual

September 2019 00809-0100-4045

Table 6-1: Interpreting Local Notifications (continued)

LED color Dial location Device status Recommended action(s)

Black, no color N/A No power Verify ON/OFF switch is in “ON” position.

6.3 Remote troubleshooting

Table 6-2: Interpreting Plantweb™ Statuses

Plantweb

status

Good None Functioning properly No action required

Advisory

Notification Description Recommended action(s)

Database

Storage Error

High Power

Active

Simulate Active The device is in simulation

Non-Critical

User Data

The device has failed to write to

the database memory at some

point in the past. Any data

written during this time nay

have been lost.

The device is operating in high

power mode. This is not

recommended for this device.

mode and may not be reporting

actual informaiton.

A user written parameter does

not match its expected value.

1. Perform a Device Reset.

2. If logging dynamic data is not needed,

this advisory alert can be safely ignored.

3. If the condition persists, replace the

device.

1. Disable high power mode.

1. Verify that simulation is no longer

required.

2. Disable simulation mode.

3. Reset the device.

1. Restart the device.

2. Reconfirm all configuration items in the

device.

3. Restore the default settings and

reconfigure device.

4. If the condition persists, replace the

device.

Sensor

Temperature

Out of Limits

Maintenance

42 Emerson.com/Rosemount

The sensor temperature has

exceeded its safe operating

range.

1. Verify process and ambient

temperature is within the device’s

operating range.

2. Remote mount the device away from

process and environmental conditions.

3. Reset the device.

4. If the condition persists, replace the

device.

Page 43

Reference Manual Troubleshooting

00809-0100-4045 September 2019

Table 6-2: Interpreting Plantweb™ Statuses (continued)

Plantweb

status

Notification Description Recommended action(s)

Pressure Out of

Limits

The pressure has exceed the

maximum measurement range.

1. Check the pressure applied to ensure it

is within the sensor limits.

2. Check the device pressure connection

to make sure it is not plugged or that

the isolating diaphragms are not

damaged.

3. If the condition persists, replace the

device.

Voltage

Conditions Out

of Range

Environmental

Conditions Out

of Range

The supply voltage is low and

may soon affect device

operation.

The device is outside its normal

environmental operating

conditions which may affect

accuracy and/or proper

operation.

1. Replace the battery.

1. Verify process and ambient

temperature is within the device’s

operating range.

2. Remote mount the device away from

process and environmental conditions.

3. Reset the device.

4. If the condition persists, replace the

device.

Failure

Capacity

Denied

Configuration

Alert

The device has failed to acquire

the wirless communication

bandwidth necessary to

support the configured update

rates.

The device has detected a

configuration error.

1. Obtaining the bandwidth may take

some time depending on the

configured update rates and other

devices in the network. Wait several

minutes to see if the error resolves

itself.

2. There may be too many devices

attached to the WirelessHART

®

network, or the updates rates may be

too fast. Try using a different network,

or slowing down the update rate on one

or more devices.

1. Click on details for more information.

2. Correct the parameter that has a

configuration error.

3. Reset the device.

4. If the condition persists, replace the

device.

Emerson.com/Rosemount 43

Page 44

Troubleshooting Reference Manual

September 2019 00809-0100-4045

Table 6-2: Interpreting Plantweb™ Statuses (continued)

Plantweb

status

Notification Description Recommended action(s)

Over-pressure

Seen

Critical Power

Failure

Electronics

Failure

Dial Failure The device is no longer able to

The pressure has gone beyond

the maximum operating limits

of the device, which may have

caused permanent damage to

the sensor.

The supply voltage is too low

for the device to update.

An electronics error that could

impact the device

measurement reading has

occurred.

validate the position of the dial.

1. Check the pressure applied to ensure it

is within the sensor limits.

2. Check the device pressure connection

to make sure it is not plugged or that

the isolating diaphragms are not

damaged.

3. Acknowledge the over pressure

condition to clear the latched

indication, and verify the integrity of

the sensor.

4. If the condition persists, replace the

device.

1. Replace the battery.

1. Restore device to default settings.

2. Perform a Device Reset.

3. If the condition persists, replace the

device.

1. Reset the device.

2. If condition persists, replace the device.

44 Emerson.com/Rosemount

Page 45

Reference Manual Reference data

00809-0100-4045 September 2019

7 Reference data

7.1 Product certificatons

To view current Rosemount™ Wireless Pressure Gauge Product Certifications, follow these

steps:

Procedure

1. Go to Emerson.com/Rosemount/Rosemount-Wireless-Pressure-Gauge.

2. Scroll as needed to the green menu bar and select Documents & Drawings.

3. Click Manuals & Guides.

4. Select the appropriate Quick Start Guide.

7.2 Ordering information, specifications, and dimensional drawings

To view current Rosemount Wireless Pressure Gauge ordering information, s, and

dimensional drawings, follow these steps:

Procedure

1. Go to Emerson.com/Rosemount/Rosemount-Wireless-Pressure-Gauge.

2. Scroll as needed to the green menu bar and click Documents & Drawings.

3. For installation drawings, select Drawings & Schematics and select the appropriate

document.

4. For ordering information, specifications, and dimensional drawings, select Data

Sheets & Bulletins.

5. Select the appropriate Product Data Sheet.

Emerson.com/Rosemount 45

Page 46

Reference data Reference Manual

September 2019 00809-0100-4045

46 Emerson.com/Rosemount

Page 47

Reference Manual Field Communicator menu trees

00809-0100-4045 September 2019

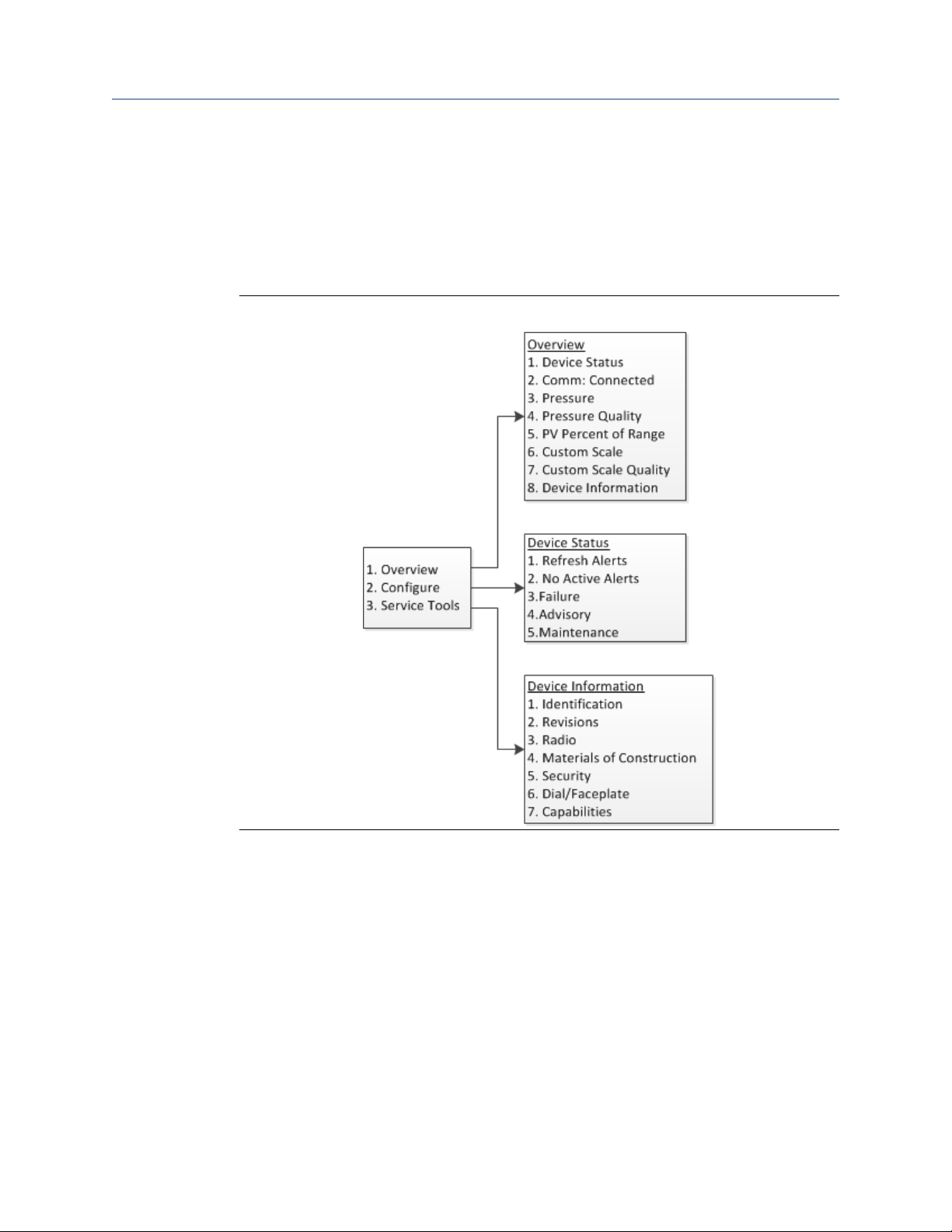

A Field Communicator menu trees

A.1 Overview

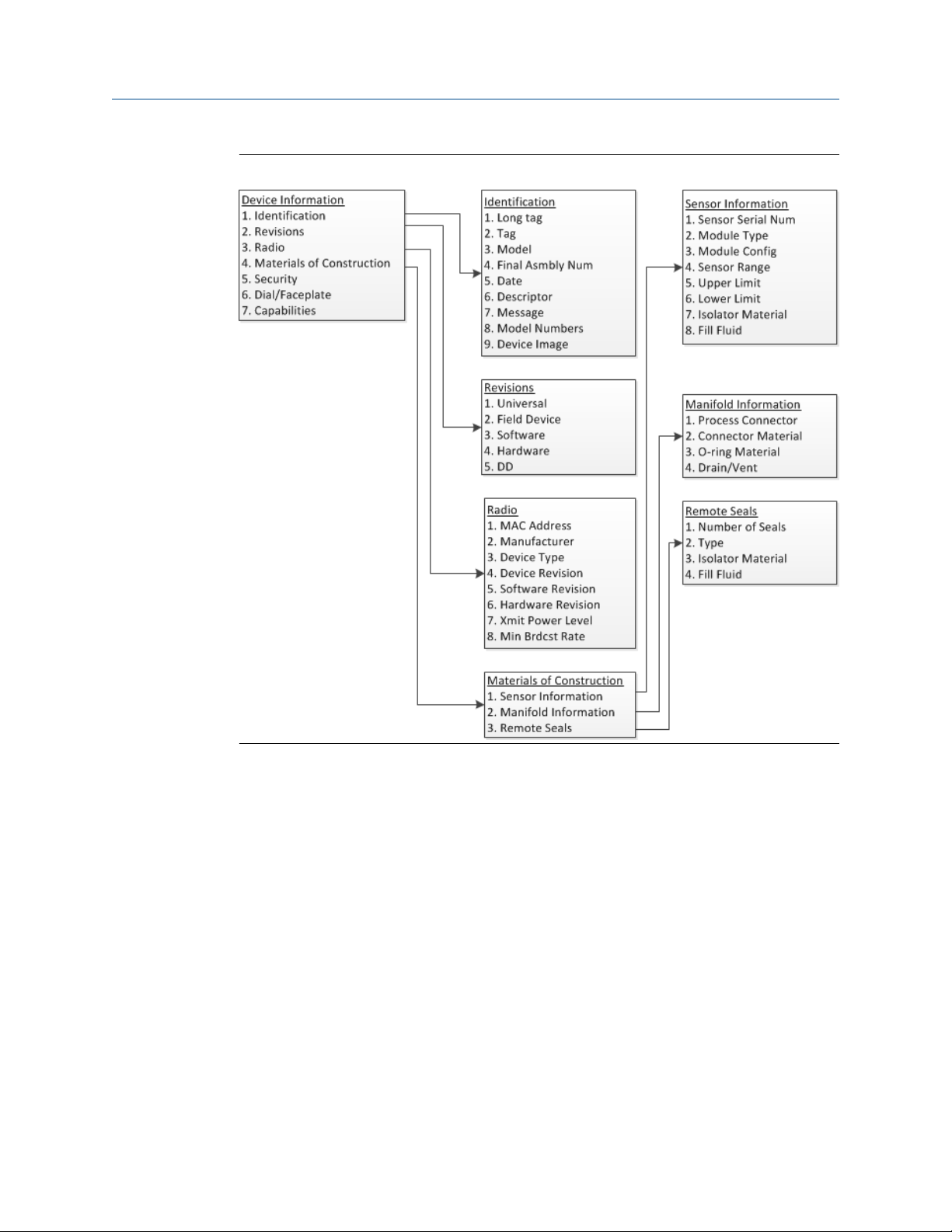

Figure A-1: Overview

Emerson.com/Rosemount 47

Page 48

Field Communicator menu trees Reference Manual

September 2019 00809-0100-4045

Figure A-2: Configure

Figure A-3: Service Tools

48 Emerson.com/Rosemount

Page 49

Reference Manual Field Communicator menu trees

00809-0100-4045 September 2019

Figure A-4: Device Information

Emerson.com/Rosemount 49

Page 50

Field Communicator menu trees Reference Manual

September 2019 00809-0100-4045

Figure A-5: Device Information (continue)

50 Emerson.com/Rosemount

Page 51

Reference Manual Network design best practices

00809-0100-4045 September 2019

B Network design best practices

B.1 Overview

All recommended practices should be followed to ensure highest data reliability. Deviation

from these best practices may require device repeaters in the network to maintain 99

percent data reliability. The following are guidelines to achieve the best possible wireless

network.

• Each wireless network field should be scoped to a single process unit.

• Minimize the number of hops to the Gateway in order to reduce latency. A minimum of

five wireless instruments should be within effective range of the Emerson Wireless

Gateway.

• Each device in the network should have at minimum three devices with potential

communication paths. A mesh network gets its reliability from multiple

communication pathways. Ensuring each device has multiple neighbors within range

will result in the most reliable network.

• Have 25 percent of wireless instruments in the network within range of Emerson

Wireless Gateway. Other enhancing modifications include creating a higher

percentage of devices within effective range of the gateway to 35 percent or more.

This clusters more devices around the gateway and ensures fewer hops and more

bandwidth available to WirelessHART® devices with fast scan rates.

• Effective range is determined by type of process unit and the density of the

infrastructure that surrounds the network.

B.2 Effective range

Heavy Obstruction: 100 ft. (30 m). Typical heavy density plant environment. Cannot drive

a truck or equipment through.

Medium Obstruction: 250 ft. (76 m). Typical light process areas, lots of space between

equipment and infrastructure.

Light Obstruction: 500 ft. (152 m). Typical of tank farms. Despite tanks being big

obstructions themselves, lots of space between and above makes for good RF

propagation.

Line of Sight: 750 ft. (230 m). No obstructions between WirelessHART® devices and devices

mounted a minimum of 6 ft. (2 m) above ground or obstructions.

For examples and complete explanations, refer to the IEC62591 WirelessHART System

Engineering Guide.

Emerson.com/Rosemount 51

Page 52

Network design best practices Reference Manual

September 2019 00809-0100-4045

52 Emerson.com/Rosemount

Page 53

Reference Manual Device variable index

00809-0100-4045 September 2019

C Device variable index

C.1 Overview

This section outlines the most important alerts in the HART® command 48 additional

status field for Rosemount™ Wireless Pressure Gauge. The information in this section can

be used by DeltaV™ for notification monitoring, and in the Emerson Wireless Gateways for

additional status mapping in Modbus®, OPC, etc.

C.2 Messages and descriptions

A complete list of additional status bits is available in the Gateway.

Table C-1: Device Variable

Device Variable Index

0 Supply voltage

1 Pressure

2 Custom

3 Sensor temperature

Table C-2: Failures

Message Additional status

Radio failure Byte 12 :: Bit 4 Wireless radio has detected a

Configuration alert Byte 2 :: Bit 6 Device has detected a

Over-pressure seen Byte 4 :: Bit 0 Pressure has gone beyond the

Critical power failure Byte 6 :: Bit 2 Supply voltage is too low for

Electronics failure Byte 8 :: Bit 6 Electronics error that could

(1)

Description

failure or stopped

communicating.

configuration error.

maximum operating limits of

the device, which may have

caused permanent damage to

the sensor.

the device to broadcast

updates.

impact the device

measurement reading has

occurred.

Dial failure Byte 4 :: Bit 4 Device has detected a failure or

unable to confirm dial location.

(1) Location of the alert in the HART command 48 Additional Status field.

Emerson.com/Rosemount 53

Page 54

Device variable index Reference Manual

September 2019 00809-0100-4045

Table C-3: Maintenance

Message Additional status

Voltage condition out of range Byte 8 :: Bit 4 Supply voltage is low and may

Pressure out of limits Byte 3 :: Bit 5 Pressure has exceeded the

Capacity denied Byte 12 :: Bit 0 Device has failed to acquire the

(1)

Description

soon affect device operation.

maximum measurement

range.

wireless communication

bandwidth necessary to

support the configured update

rates.

Sensor temperature beyond

sensor limits

Byte 3 :: Bit 1 Sensor temperature has

exceeded its safe operating

range.

Environmental conditions out

of range

Byte 8 :: Bit 5 Device is outside its normal

environmental operating

conditions which may affect

accuracy and/or proper

operation.

(1) Location of the alert in the HART command 48 Additional Status field.

Table C-4: Advisory

Message Additional status

Database storage error Byte 0 :: Bit 2 Device has failed to write to the

Simulation active Byte 8 :: Bit 0 Device is in simulation mode

High power active Byte 1 :: Bit 7 Device is operating in a high

(1)

Description

database memory at some

point in the past; any data

written during this time may

have been lost.

and is not reporting actual

information.

power mode; this is not

recommended for this device.

Non-critical user data warning Byte 2 :: Bit 1 User-written parameter does

not match its expected value.

(1) Location of the alert in the HART command 48 Additional Status field.

54 Emerson.com/Rosemount

Page 55

Reference Manual

00809-0100-4045 September 2019

Emerson.com/Rosemount 55

Page 56

00809-0100-4045

Rev. AC

2019

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RFQ.RMD-RCC@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RMT-NA.RCCRFQ@Emerson.com

Europe Regional Office

Emerson Automation Solutions Europe

GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/RosemountMeasurement

©

2019 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric Co. Rosemount is a mark of one of the

Emerson family of companies. All other marks are the property of their respective owners.

Loading...

Loading...