Page 1

Quick Start Guide

00825-0100-4045, Rev AE

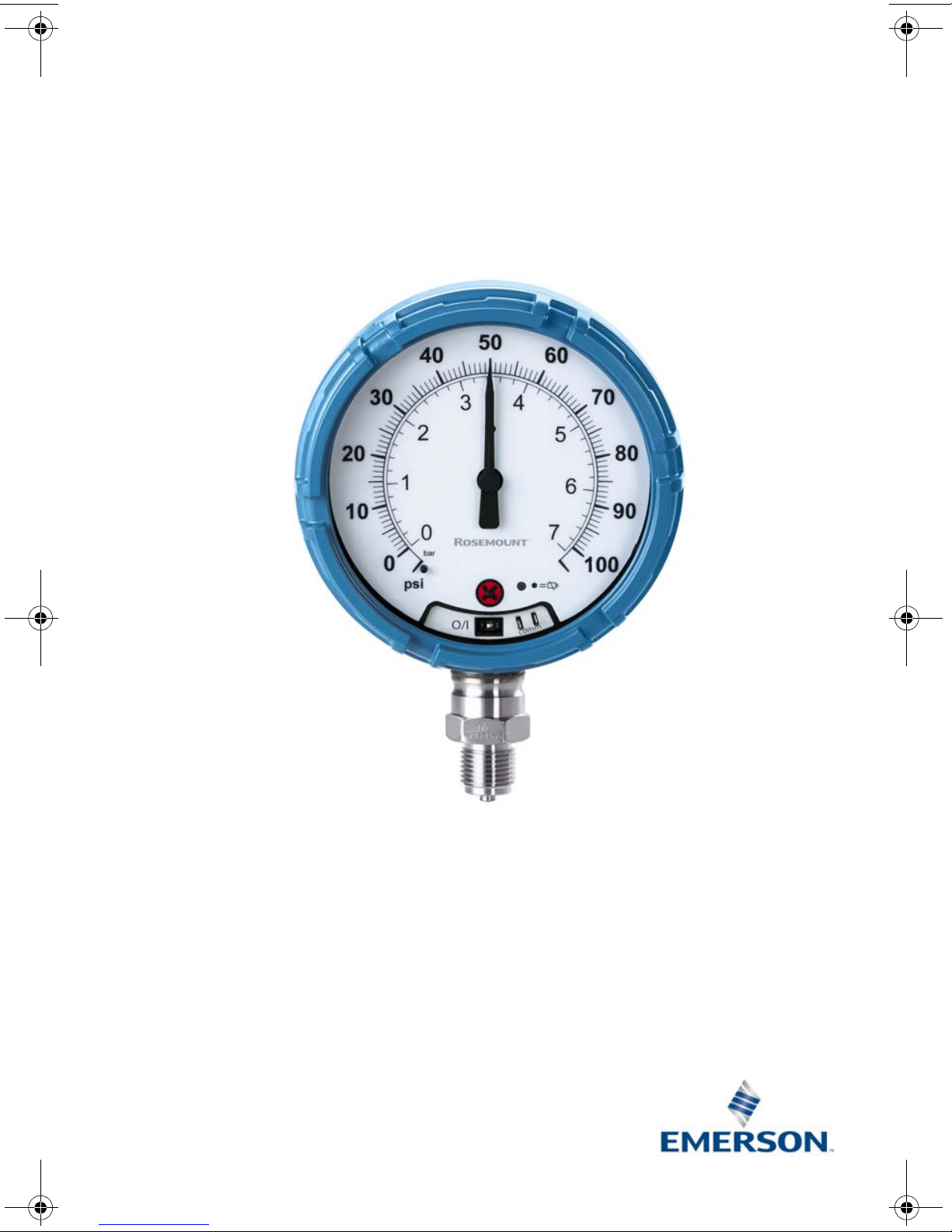

Rosemount™ Wireless Pressure Gauge

with WirelessHART® Protocol

June 2017

Page 2

Quick Start Guide

AMS

June 2017

NOTICE

This guide provides basic guidelines for Rosemount Wireless Pressure Gauges. It does not provide

instructions for configuration, diagnostics, maintenance, service, troubleshooting or intrinsically safe (I.S.)

installations. Refer to the Rosemount Wireless Pressure Gauge Reference Manual

manual and this guide are also available electronically on EmersonProcess.com\Rosemount

Shipping considerations

The unit is shipped with the battery installed.

Each device contains one “D” size primary lithium-thionyl chloride battery. Primary lithium batteries are

regulated in transportation by the U.S. Department of Transportation, and are also covered by IATA

(International Air Transport Association), ICAO (International Civil Aviation Organization), and ARD (European

Ground Transportation of Dangerous Goods). It is the responsibility of the shipper to ensure compliance with

these or any other local requirements. Consult current regulations and requirements before shipping.

Explosions could result in death or serious injury.

Installation of device in an explosive environment must be in accordance with appropriate local, national

and international standards, codes, and practices.

Ensure device is installed in accordance with intrinsically safe or non-incendive field practices.

Electrical shock can result in death or serious injury.

Care must be taken during transportation of device to prevent electrostatic charge build-up.

Device must be installed to ensure a minimum antenna separation distance of 8 in. (20 cm) from all

persons.

for more instruction. The

.

Process leaks could result in death or serious injury.

Handle the transmitter carefully.

Failure to follow safe installation guidelines could result in death or serious injury.

Only qualified personnel should install the equipment.

Required equipment

Anti-seize paste or PTFE tape

(for NPT threaded connection)

Standard tools, e.g. screwdriver,

wrench, pliers

AMS Wireless Configurator version

12.0 or later, or Field Communicator

Contents

What’s in the box . . . . . . . . . . . . . . . . . . . . . . . . . 3

Optional: power/device check . . . . . . . . . . . . . . 3

Seal and protect threads . . . . . . . . . . . . . . . . . . 4

Mount device . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Turn on device . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2

Connect to device . . . . . . . . . . . . . . . . . . . . . . . . 5

Eliminate mounting effects . . . . . . . . . . . . . . . . 6

Activate wireless . . . . . . . . . . . . . . . . . . . . . . . . . 6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 7

Product Certifications . . . . . . . . . . . . . . . . . . . . . 8

Page 3

June 2017

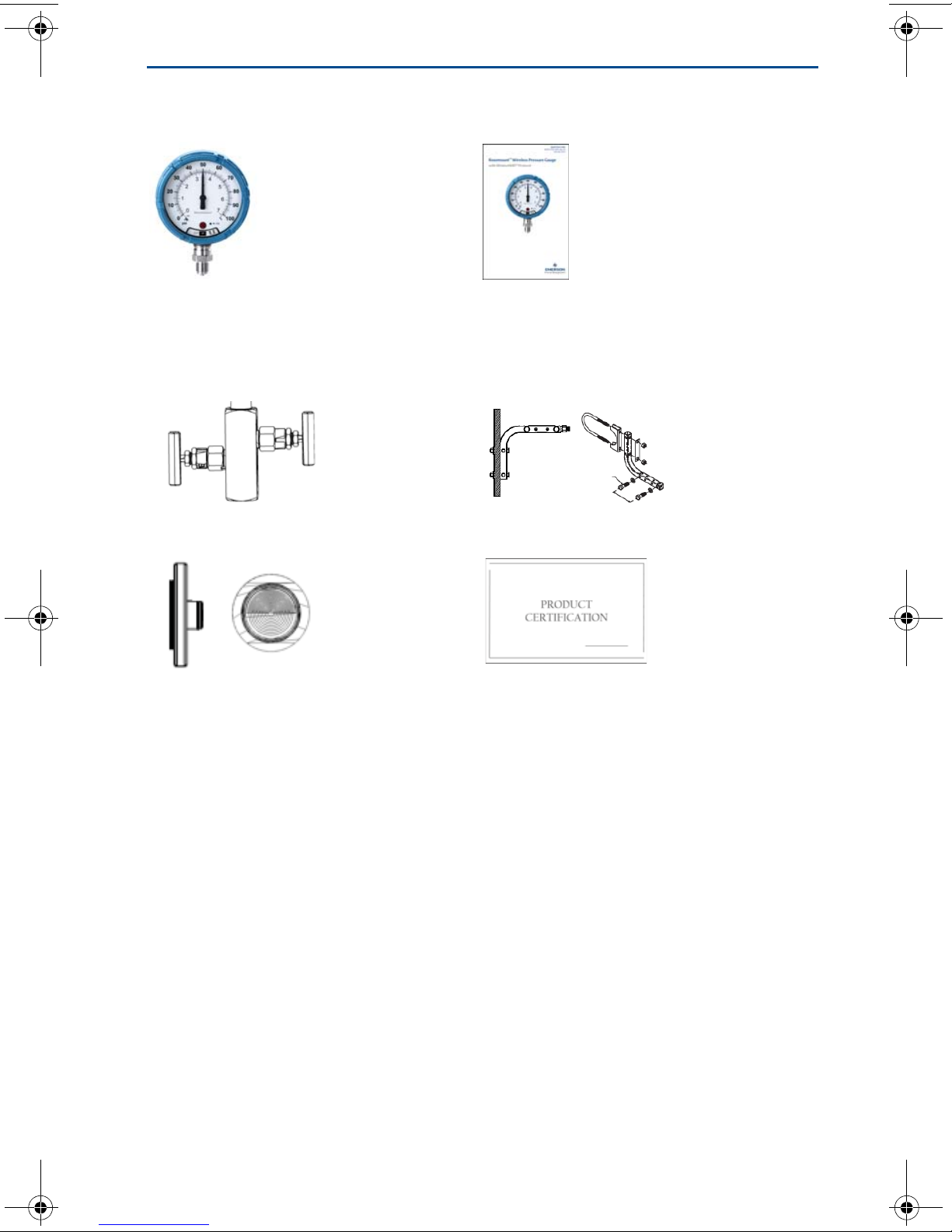

What’s in the box

Wireless Pressure Gauge Quick Start Guide

The following options are also available and will ship with the Rosemount

Wireless Pressure Gauge if ordered.

Quick Start Guide

Rosemount 306 Integral Manifold (Model Code S5) B4 Bracket (Model Code B4)

Rosemount 1199 Seal (Model Code S1) Product Certification (Model Codes below)

Q4: Calibration Cert

QG: Calibration Cert and GOST Verification Cert

QP: Calibration Cert and Tamper Evident Seal

Q8: Material Traceability cert per EN 102043.1

Q15: Cert of Compliance to NACE MR0175/ISO 15156

for wetted materials

Q25: Cert of Compliance to NACE MR00103 for wetted

materials

Optional: power/device check

The device is designed to be installation-ready. To check device battery prior to

installation, perform the following:

1. Perform “Turn on device” on page 5.

2. Slide the ON/OFF switch to the OFF position until ready for use.

3

Page 4

Quick Start Guide

OR

A

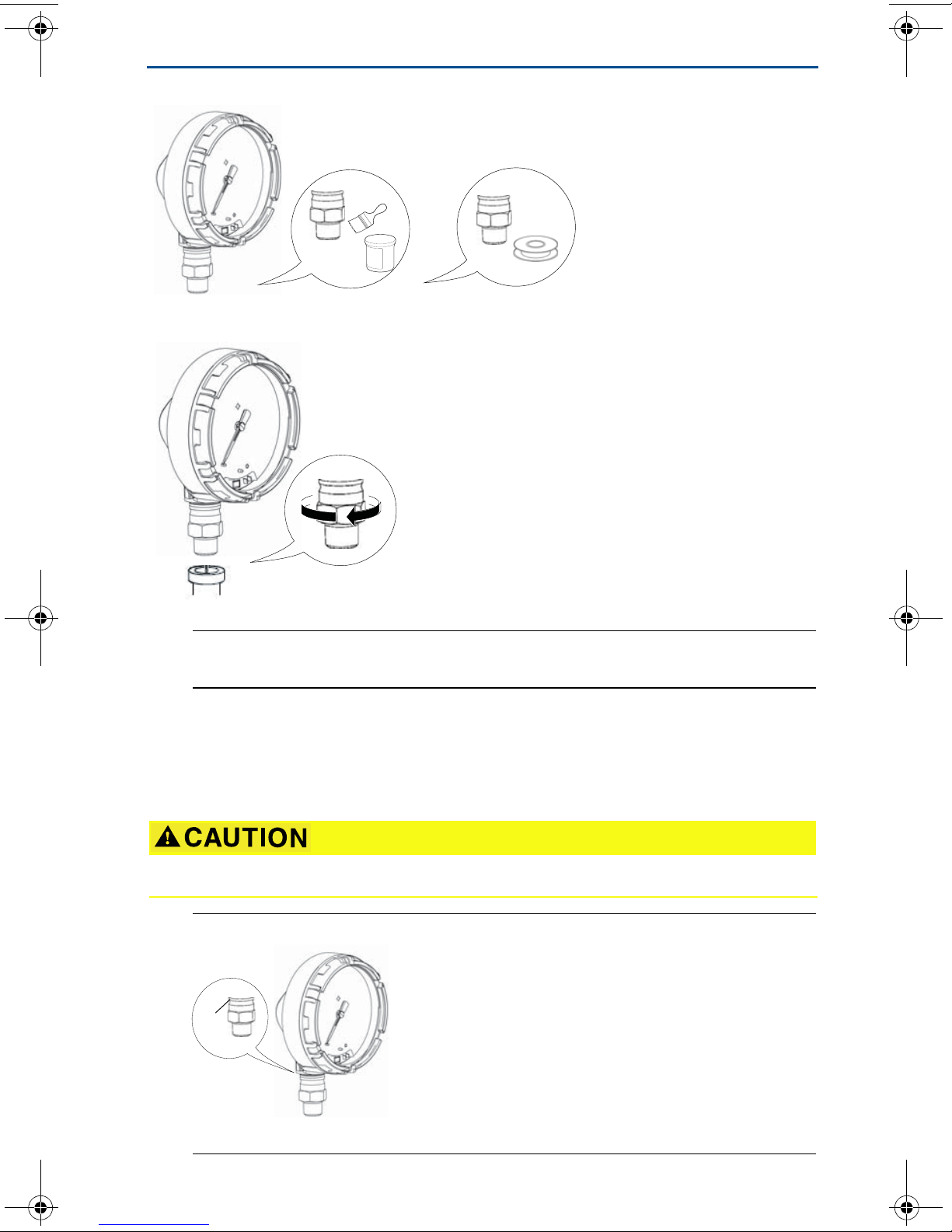

1.0 Seal and protect threads

2.0 Mount device

June 2017

Note

Use wrench on flats, not on housing.

2.1 Mounting orientation

The low side pressure port (atmospheric reference) on the process pressure

gauge is located in the neck of the device behind the housing. The vent path is

between the housing and sensor (see Figure 1).

Keep the vent path free of any obstruction, including but not limited to paint, dust, and lubrication by

mounting the device so the process can drain away.

Figure 1. Low Side Pressure Port

A. Low side pressure port (atmospheric reference)

4

Page 5

June 2017

123

645

8709

A

B

C

Quick Start Guide

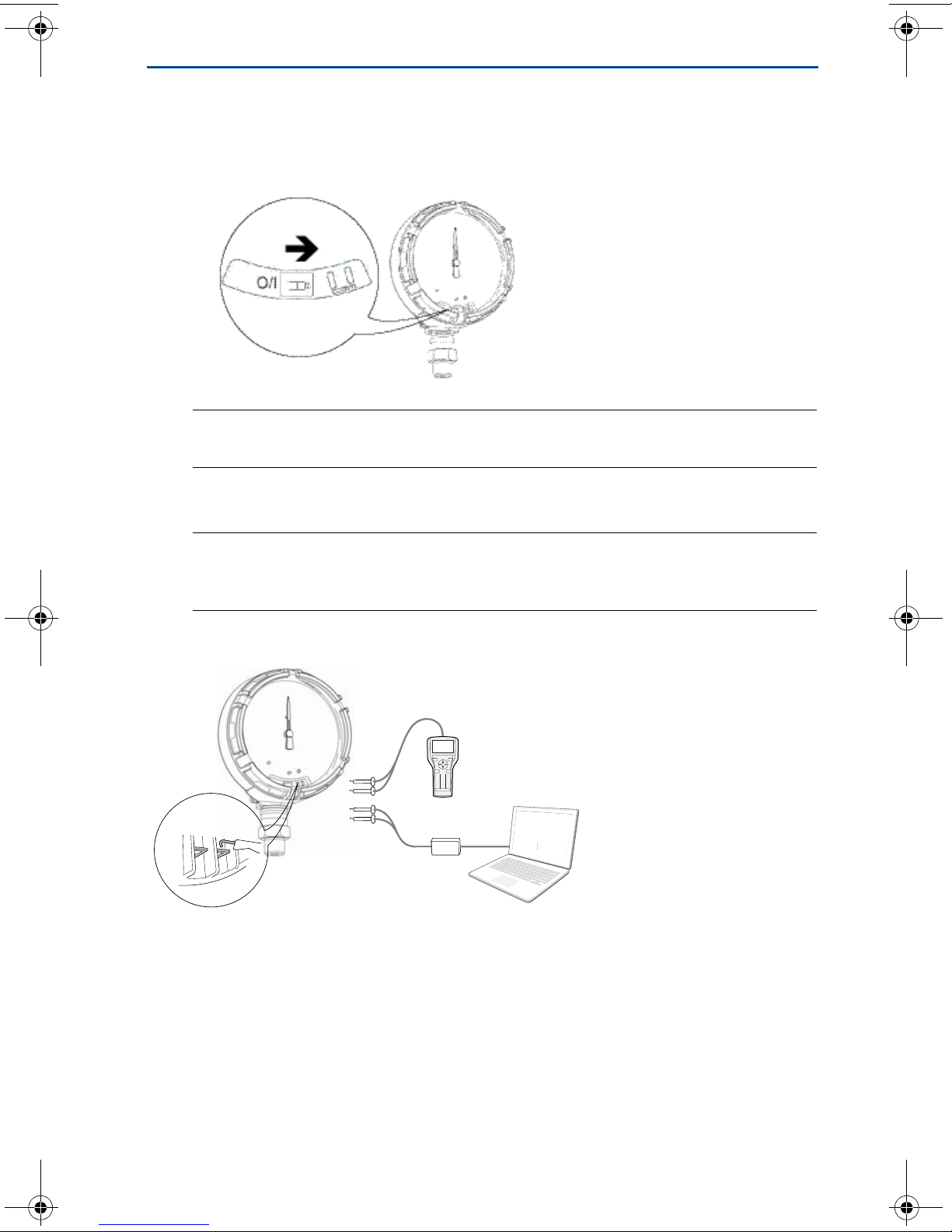

3.0 Turn on device

Check to ensure the device and battery are working properly.

1. Twist the cover counterclockwise to remove it.

2. Slide the OFF/ON switch to the ON position to initiate the power sequence.

Note

During the power sequence, the dial tests full range of motion and LED flashes amber.

3. Once the power sequence ends, verify the LED flashes green.

Note

The LED may display several colors; see Figure 1 in “Troubleshooting” on page 7 for device

statuses.

4.0 Connect to device

A. Field Communicator B. HART® Modem C. AMS Wireless Configurator

4.1 Field Communicator

1. Turn on the Field Communicator.

2. From the Main menu, select the HART symbol.

4.2 AMS Wireless Configurator

1. Start AMS Wireless Configurator.

2. From the View menu, select Device Connection View.

3. Double click the device under the HART modem.

5

Page 6

Quick Start Guide

5.0 Eliminate mounting effects

Devices are factory-calibrated. Once installed, it is recommended to perform this

step to eliminate potential error caused by mounting position or static pressure.

Instructions for using a Field Communicator are listed below.

Note

See the Rosemount Wireless Pressure Gauge Reference Manual for the following:

Using AMS Wireless Configurator

Sensor trim function on absolute gauge

1. Vent the device.

2. Connect the Field Communicator.

3. From the HOME screen, enter the HART Fast Key sequence.

June 2017

Device dashboard Fast Keys

2, 1, 1

4. Follow the commands to perform the procedure.

6.0 Activate wireless

Do not activate wireless until Smart Wireless Gateway is installed and functioning

properly; toggling off and on reduces battery life.

Note

If Network ID and Join Key is specified at order entry, then the device will automatically

search and connect to the wireless network when powered on.

6.1 Join device to network

1. Obtain Network ID and Join Key for the wireless network (available in wireless

gateway).

2. From the HOME screen, enter the HART Fast Key sequence.

Device dashboard Fast Keys

3. Follow the commands to perform the procedure.

2, 1, 2

4. Select Overview>Status.

5. Verify the communication status displays Connected.

Note

Joining the device to the network could take several minutes.

6

Page 7

June 2017

Quick Start Guide

7.0 Troubleshooting

This section provides information for basic troubleshooting. See the reference

manual (document number 00809-0100-4045) for advanced troubleshooting .

7.1 Device status

The flashing LED indicates device status using the colors descibed in Table 1.

Table 1. Status Descriptions

LED color Device status

Green Functioning properly

Amber Battery is low, battery replacement recommended

Red

No

color

Battery replacement required

Device is malfunctioning

No power, verify ON/OFF switch is in “on” position

OR

7.2 Pressure measurement

If the mounting effects have not been eliminated after completing Step 5.0,

perform this alternative procedure for verifying the pressure value.

1. From the HOME screen, eter the HART Fast Key sequence.

Device dashboard Fast Keys

2, 2, 1, 1, 1

2. Follow the commands to perform the procedure.

7.3 Wireless connectivity

If the device has not joined to the network after power up, verify the following:

Active Advertising has been enabled on the Smart Wireless Gateway

Network ID and Join Key in the device match the Network ID and Join Key of

the Gateway

The Network ID and Join Key may be obtained from the Smart Wireless Gateway

on the Setup > Network > Settings page on the web interface .

7

Page 8

Quick Start Guide

8.0 Product Certifications

Rev: 1.0

8.1 European Directive Information

A copy of the EC Declaration of Conformity can be found at the end of the Quick

Start Guide. The most recent revision of the EC Declaration of Conformity can be

found at EmersonProcess.com\Rosemount

8.2 Telecommunication compliance

All wireless devices require certification to ensure that they adhere to regulations

regarding the use of the RF spectrum. Nearly every country requires this type of

™

product certification. Emerson

governmental agencies around the world to supply fully compliant products and

remove the risk of violating country directives or laws governing wireless device

usage.

Process Management is working with

8.3 FCC and IC

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following conditions: This devices may not cause harmful interference, this

devices must accept any interference received, including interference that may

cause undesired operation. This device must be installed to ensure a minimum

antenna separation distance of 20 cm from all persons.

.

June 2017

This device complies with Industry Canada license-exempt RSS-247. Operation is

subject to the following two conditions: (1) this device may not cause

interference, and (2) this device must accept any interference, including

interference that may cause undesired operation of the device.

Changes or modification to the equipment not expressly approved by Emerson

Process Management could void the user's authority to operate the equipment.

Cet appareil est conforme à la Partie 15 de la réglementation FCC. Son

fonctionnement est soumis aux conditions suivantes: Cet appareil ne doit pas

causer d'interférences nuisibles. Cet appareil doit accepter toute interférence

reçue, incluant toute interférence pouvant causer un fonctionnement

indésirable. Cet appareil doit être installé pour assurer une distance minimum de

l'antenne de séparation de 20 cm de toute personne.

Cet appareil est conforme à la norme RSS-247 Industrie Canada exempt de

licence. Son fonctionnement est soumis aux deux conditions suivantes: (1) cet

appareil ne doit pas provoquer d'interférences et (2) cet appareil doit accepter

toute interférence, y compris les interférences pouvant causer un mauvais

fonctionnement du dispositif.

Les changements ou les modifications apportés à l'équipement qui n'est pas

expressément approuvé par Emerson Process Management pourraient annuler

l'autorité de l'utilisateur à utiliser cet équipement.

8

Page 9

June 2017

Ω

Ω

Quick Start Guide

8.4 Ordinary Location Certification from CSA

The product has been examined and tested to determine that the design meets

the basic electrical, mechanical, and fire protection requirements by CSA, a

nationally recognized test laboratory (NRTL) as accredited by the Federal

Occupational Safety and Health Administration (OSHA).

8.5 Installing in North America

The US National Electrical Code (NEC) and the Canadian Electrical Code (CEC)

permit the use of Division marked equipment in Zones and Zone marked

equipment in Divisions. The markings must be suitable for the area classification,

gas, and temperature class. This information is clearly defined in the respective

codes.

8.6 USA

I5 U.S.A. Intrinsically Safe (IS)

Certificate: [CSA] 70047656

Standards: FM 3600 – 2011, FM 3610 – 2010, UL Standard 50 – Eleventh Edition,

UL 61010-1 – 3rd Edition, ANSI/ISA-60079-0 (12.00.01) – 2013,

ANSI/ISA-60079-11 (12.02.01) – 2013, ANSI/IEC 60529 – 2004

Markings: IS CL I, DIV 1, GP A, B, C, D T4;

Class 1, Zone 0, AEx ia IIC T4 Ga;

T4 (-40 °C ≤ Ta ≤ +70 °C)

when installed per Rosemount drawing 00G45-1020;

Type 4X; IP66/67;

Special Conditions for Safe Use (X):

1. Do not replace battery when explosive atmosphere is present.

2. Use only 00G45-9000-0001 batteries.

3. The surface resistivity of the housing is greater than 1G . To avoid electrostatic charge

build-up, it must not be rubbed or cleaned with solvents or a dry cloth.

4. Substitution of components may impair intrinsic safety.

8.7 Canada

I6 Canada Intrinsically Safe (IS)

Certificate: [CSA] 70047656

Standards: CAN/CSA C22.2 No. 0-10, CAN/CSA C22.2 No. 94-M1991 (R2011),

CAN/CSA-60079-0-11, CAN/CSA-60079-11-14, CSA Std C22.2 No.

60529-05, CAN/CSA-C22.2 No. 61010-1-12

Markings: Intrinsically Safe for Class I, Division 1, Groups A, B, C, D T4;

Ex ia IIC T4 Ga

T4 (-50 °C ≤ Ta ≤ +70 °C)

when installed per Rosemount drawing 00G45-1020;

Type 4X; IP66/67;

Special Conditions for Safe Use (X):

1. Do not replace battery when explosive atmosphere is present.

Ne pas remplacer les accumulateurs si une atmosphère explosive peut être présente.

2. Use only 00G45-9000-0001 batteries.

Utiliser uniquement des accumulateurs 00G45-9000-0001.

3. The surface resistivity of the housing is greater than 1G . To avoid electrostatic charge

build-up, it must not be rubbed or cleaned with solvents or a dry cloth.

La résistivité de surface du boÎtier est supérieure à un gigaohm. Pour éviter

9

Page 10

Quick Start Guide

l’accumulation de charge électrostatique, ne pas frotter ou nettoyer avec des produits

solvants ou un chiffon sec.

4. Substitution of components may impair intrinsic safety.

La substitution de composants peut compromettre la sécurité intrinsèque.

8.8 Europe

I1 ATEX Intrinsic Safety

Certificate: Baseefa16ATEX0005X

Standards: EN 60079-0: 2012 + A11: 2013, EN 60079-11: 2012

Markings: II 1 G Ex ia IIC T4 Ga, T4 (-40 °C ≤ Ta ≤ +70 °C)

IP66/67;

Special Conditions for Safe Use (X):

1. The plastic enclosure may constitute a potential electrostatic ignition risk and must not

be rubbed or cleaned with a dry cloth.

2. The measured capacitance between the equipment enclosure and metallic inline sensor

module is 4.7pF. This must be considered only when the WPG is integrated into a

system where the process connection is not grounded.

3. Do not change the battery when an explosive atmosphere is present.

4. Only replace battery with Rosemount Part No. 00G45-9000-0001.

June 2017

8.9 International

I7 IECEx Intrinsic Safety

Certificate: IECEx BAS 16.0012X

Standards: IEC 60079-0: 2011, IEC 60079-11: 2011

Markings: Ex ia IIC T4 Ga, T4 (-40 °C ≤ Ta ≤ +70 °C)

IP66/67;

Special Conditions for Safe Use (X):

1. The plastic enclosure may constitute a potential electrostatic ignition risk and must not

be rubbed or cleaned with a dry cloth.

2. The measured capacitance between the equipment enclosure and metallic inline sensor

module is 4.7pF. This must be considered only when the WPG is integrated into a

system where the process connection is not grounded.

3. Do not change the battery when an explosive atmosphere is present.

4. Only replace battery with Rosemount Part No. 00G45-9000-0001.

10

Page 11

June 2017

EU Declaration of Conformity

No: RMD 1108 Rev. C

Page 1 of 3

We,

Rosemount, Inc.

8200 Market Boulevard

Chanhassen, MN 55317-9685

USA

declare under our sole responsibility that the product,

Model WPG: Wireless Pressure Gauge

manufactured by,

Rosemount, Inc.

8200 Market Boulevard

Chanhassen, MN 55317-9685

USA

to which this declaration relates, is in conformity with the provisions of the European Union

Directives, including the latest amendments, as shown in the attached schedule.

Assumption of conformity is based on the application of the harmonized standards and, when

applicable or required, a European Union notified body certification, as shown in the attached

schedule.

Vice President of Global Quality

Chris LaPoint

6-June-2017

Quick Start Guide

Figure 2. Rosemount Wireless Pressure Gauge Declaration of Conformity

(signature)

(name)

(function)

(date of issue)

11

Page 12

Quick Start Guide

EU Declaration of Conformity

No: RMD 1108 Rev. C

Page 2 of 3

EMC Directive (2014/30/EU)

Model WPG Wireless Pressure Gauge

Harmonized Standards:

EN 61326-1: 2013

Radio Equipment Directive (RED) (2014/53/EU)

Model WPG Wireless Pressure Gauge

Harmonized Standards:

EN 300 328 V2.1.1

EN 301 489-1 V2.2.0

EN 301 489-17: V3.2.0

EN 61010-1: 2010

EN 62479: 2010

ATEX Directive (2014/34/EU)

Model WPG Wireless Pressure Gauge

Baseefa16ATEX0005X - Intrinsic Safety Certificate

Equipment Group II Category 1 G

Ex ia IIC T4 Ga, T4(-&7D&

Harmonized Standards:

EN 60079-0: 2012 + A11: 2013

EN 60079-11: 2012

June 2017

12

Page 13

June 2017

EU Declaration of Conformity

No: RMD 1108 Rev. C

Page 3 of 3

ATEX Notified Bodies

Baseefa [Notified Body Number: 1180]

Rockhead Business Park

Staden Lane

Buxton, Derbyshire

SK17 9RZ United Kingdom

ATEX Notified Body for Quality Assurance

Baseefa [Notified Body Number: 1180]

Rockhead Business Park

Staden Lane

Buxton, Derbyshire

SK17 9RZ United Kingdom

Quick Start Guide

13

Page 14

Quick Start Guide

ᴹ

China RoHS

㇑㇑᧗⢙䍘䎵䗷ᴰབྷ⎃ᓖ䲀٬Ⲵ䜘Ԧරࡇ㺘

Rosemount WPG

List of Rosemount WPG Parts with China RoHS Concentration above MCVs

䜘Ԧ〠

Part Name

ᴹᇣ⢙䍘䍘

/ Hazardous Substances

Lead

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Hexavalent

Chromium

(Cr +6)

Polybrominated

biphenyls

(PBB)

㚄㤟䟊

Polybrominated

diphenyl ethers

(PBDE)

⭥ᆀ㓴Ԧ

Electronics

Assembly

XO O O O O

༣փ㓴Ԧ

Housing

Assembly

OO O O O O

Րᝏಘ㓴Ԧ

Sensor

Assembly

XO O O O O

⭥⊐㓴Ԧ

Battery

Assembly

XO O O O O

ᵜ㺘Ṭ㌫ᦞ

SJ/T11364

Ⲵ㿴ᇊ㘼ࡦ

This table is proposed in accordance with the provision of SJ/T11364.

O:

Ѫ䈕䜘ԦⲴᡰᴹ൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿൷վҾ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

X:

Ѫ൘䈕䜘Ԧᡰ֯⭘Ⲵᡰᴹ൷䍘ᶀᯉ䟼ˈ㠣ቁᴹа㊫൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿儈Ҿ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

June 2017

䜘

䫵䫵

⊎⊎

ᴹ

䭹䭹

ޝޝԧ䬜䬜

ཊཊⓤ㚄㚄㤟

ཊཊⓤ㚄

14

Page 15

June 2017

Quick Start Guide

15

Page 16

*00825-0100-4045*

Quick Start Guide

00825-0100-4045, Rev AE

June 2017

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com Linkedin.com/company/Emerson-Process-Management

Europe Regional Office

Emerson Automation Solutions

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/ user/RosemountMeasurement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found at

www.Emerson.com/en-us/pages/Terms-of-Use.aspx

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

Rosemount and Rosemount logotype are trademarks of Emerson.

HART and WirelessHART are registered trademarks of the

FieldComm Group.

All other marks are the property of their respective owners.

© 2017 Emerson Process Management. All rights reserved.

Loading...

Loading...