Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SPS 4000

Single Probe

Autocalibration Sequencer

http://www.processanalytic.com

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures and tests its products to meet many national and

international standards. Because these instruments are sophisticated technical products, you

MUST properly install, use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions MUST be adhered to and integrated into your

safety program when installing, using, and maintaining Rosemount Analytical products. Failure to

follow the proper instructions may cause any one of the following situations to occur: Loss of life;

personal injury; property damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Rosemount Analytical repre-

sentative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and mainte-

nance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate In-

struction Manual and per applicable local and national codes. Connect all products to the

proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Rosemount. Unauthorized parts and procedures can affect the product’s performance, place the safe operation of your process at risk, and VOID YOUR WARRANTY.

Look-alike substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical shock

and personal injury.

The information contained in this document is subject to change without notice.

Emerson Process Management

Rosemount Analytical Inc.

Process Analytic Division

1201 N. Main St.

Orrville, OH 44667-0901

T (330) 682-9010

F (330) 684-4434

e-mail: gas.csc@EmersonProcess.com

http://www.processanalytic.com

HIGHLIGHTS OF CHANGES

Effective Feb., 1999 Rev. 1.0

Page Summary

Page 1-1 Added note concerning the Oxymitter 5000.

Page 1-2 Added the Oxymitter 5000 to the product matrix in Table 1-1. Removed

the disposable gas bottles and flow regulators from the product matrix

in Table 1-1 and created Table 1-2 to distinguish these components as

separate order items because the calibration gas bottles cannot be

shipped via airfreight.

Page 7-1 Added Table 7-2 to list the calibration gas bottles and flow regulators

as replacement parts.

Effective April, 2001 Rev. 1.1

Page Summary

Page 7-1 Table 7-1; changed part number of solenoid, items 24 and 30.

SPS 4000

PREFACE........................................................................................................................ P-1

Definitions ........................................................................................................................P-1

Safety Instructions .......................................................................................................... P-2

1-0 DESCRIPTION AND SPECIFICATIONS........................................................................ 1-1

1-1 Component Checklist ..................................................................................................... 1-1

1-2 Overview.......................................................................................................................... 1-1

1-3 Specifications................................................................................................................... 1-4

1-4 Physical Description ....................................................................................................... 1-5

1-5 Theory of Operation....................................................................................................... 1-6

2-0 INSTALLATION .............................................................................................................. 2-1

2-1 Overview.......................................................................................................................... 2-1

2-2 Mechanical Installation ................................................................................................... 2-1

2-3 Gas Connections ............................................................................................................ 2-1

2-4 Electrical Connections .................................................................................................... 2-3

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

TABLE OF CONTENTS

3-0 OPERATION ...................................................................................................................3-1

3-1 Overview.......................................................................................................................... 3-1

3-2 Calibration Requirements ............................................................................................... 3-1

3-3 Calibration Gas Flow Setup .......................................................................................... 3-2

3-4 Automatic Calibration ..................................................................................................... 3-2

3-5 Semi-Automatic Calibration ............................................................................................ 3-2

4-0 MAINTENANCE AND SERVICE .................................................................................. 4-1

4-1 Overview.......................................................................................................................... 4-1

4-2 Fuse Replacement ......................................................................................................... 4-1

4-3 Board Replacement ........................................................................................................ 4-1

4-4 Solenoid Replacement ................................................................................................... 4-3

4-5 Pressure Switch Replacement ...................................................................................... 4-5

4-6 Check Valve Replacement ............................................................................................ 4-6

4-7 Pressure Regulator (Optional) Maintenance ................................................................ 4-6

4-8 Flowmeter Adjustments .................................................................................................. 4-6

4-9 Flowmeter Replacement................................................................................................. 4-6

5-0 TROUBLESHOOTING .................................................................................................... 5-1

5-1 Overview.......................................................................................................................... 5-1

5-2 SPS 4000 Troubleshooting............................................................................................ 5-1

6-0 RETURN OF MATERIAL .............................................................................................. 6-1

7-0 REPLACEMENT PARTS ............................................................................................... 7-1

8-0 INDEX.............................................................................................................................. 8-1

Rosemount Analytical Inc. A Division of Emerson Process Management i

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

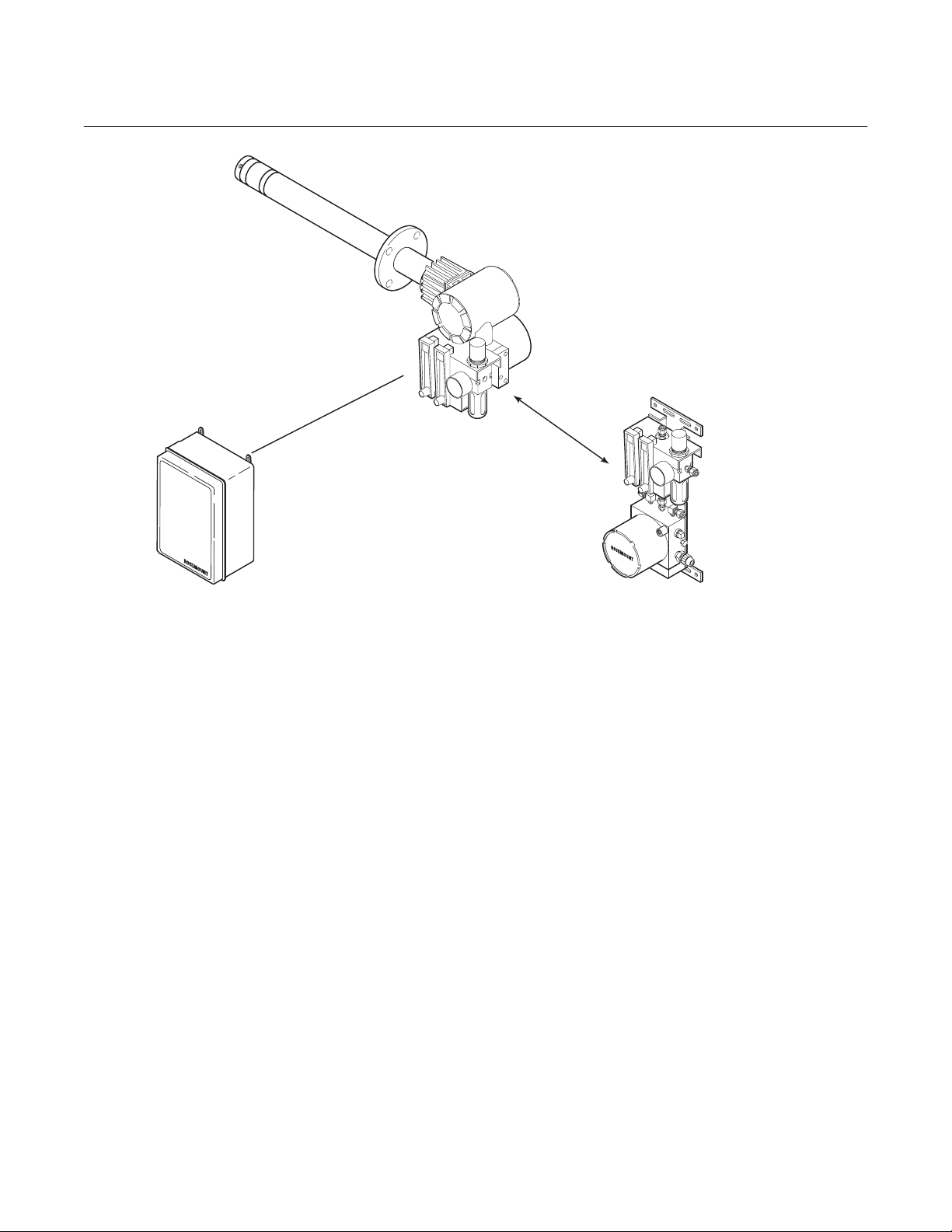

Figure 1-1. Typical SPS 4000 Package ................................................................................... 1-1

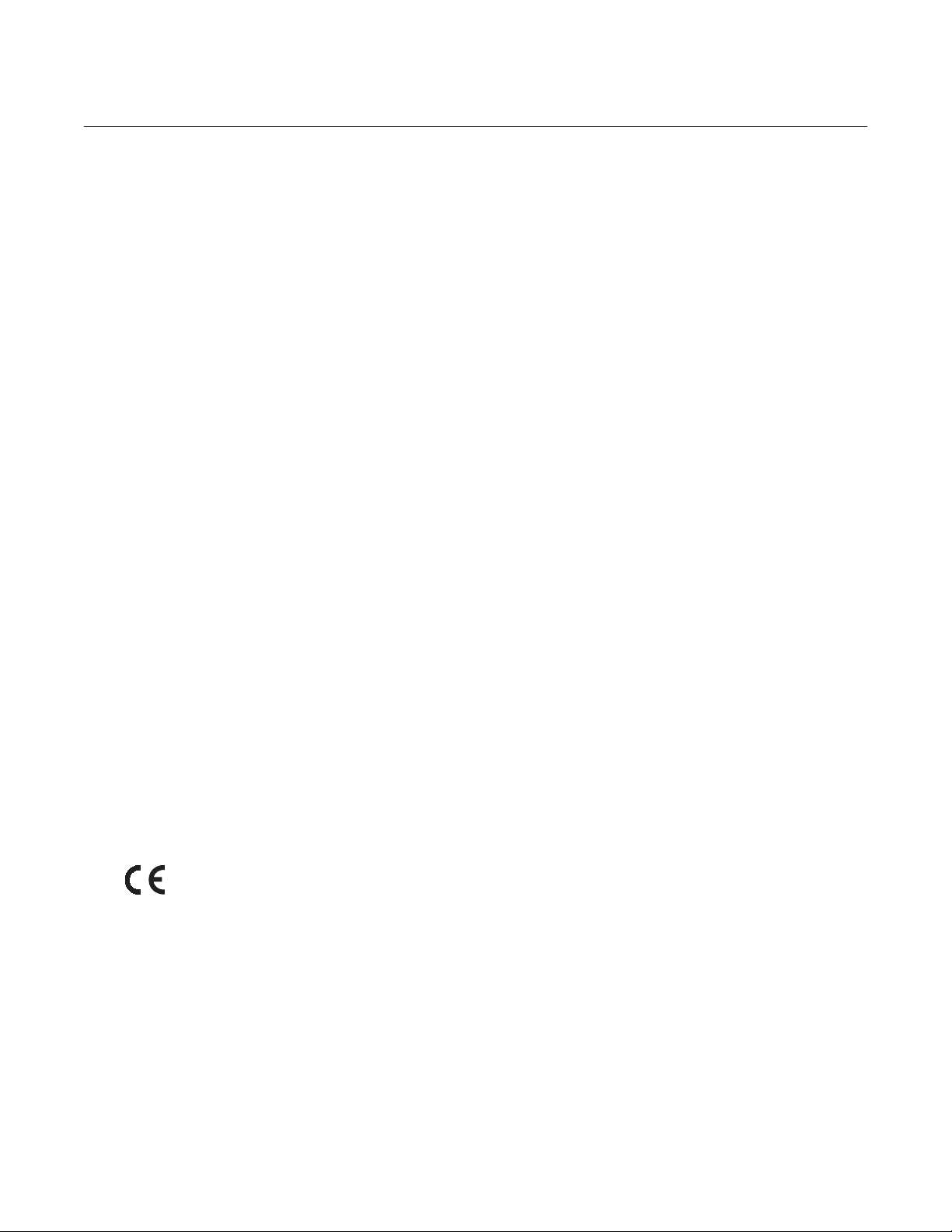

Figure 1-2. Autocalibration System Installation Options .......................................................... 1-3

Figure 1-3. SPS 4000 Components ......................................................................................... 1-5

Figure 1-4. SPS 4000 Calibration Setup .................................................................................. 1-7

Figure 2-1. Installation.............................................................................................................. 2-2

Figure 2-2. Electrical Connections ........................................................................................... 2-4

Figure 4-1. SPS 4000, Exploded View ..................................................................................... 4-2

Figure 4-2. Board Connections ................................................................................................ 4-4

Figure 5-1. SPS 4000 Troubleshooting Flowchart (Sheet 1 of 2) ............................................ 5-3

Table 1-1. Product Matrix........................................................................................................ 1-2

Table 1-2. Calibration Components ........................................................................................ 1-2

Table 5-1. SPS 4000 Fault Finding ......................................................................................... 5-2

Table 7-1. SPS 4000 Replacement Parts ............................................................................... 7-1

Table 7-2. Calibration Replacement Parts .............................................................................. 7-1

SPS 4000

LIST OF ILLUSTRATIONS

LIST OF TABLES

ii Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

The purpose of this manual is to provide information concerning the components, functions, installation and maintenance of the SPS 4000 Single Probe Autocalibration

Sequencer.

Some sections may describe equipment not used in your configuration. The user should

become thoroughly familiar with the operation of this module before operating it. Read

this instruction manual completely.

The following definitions apply to WARNINGS, CAUTIONS, and NOTES found throughout this

publication.

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

PREFACE

DEFINITIONS

Highlights an operation or maintenance

procedure, practice, condition, statement, etc. If not strictly observed, could

result in injury, death, or long-term

health hazards of personnel.

Highlights an essential operating procedure,

condition, or statement.

: EARTH (GROUND) TERMINAL

: PROTECTIVE CONDUCTOR TERMINAL

: RISK OF ELECTRICAL SHOCK

: WARNING: REFER TO INSTRUCTION BULLETIN

NOTE TO USERS

Highlights an operation or maintenance

procedure, practice, condition, statement, etc. If not strictly observed, could

result in damage to or destruction of

equipment, or loss of effectiveness.

NOTE

The number in the lower right corner of each illustration in this publication is a manual illustration number. It is not a part number, and is not related to the illustration in any technical

manner.

Rosemount Analytical Inc. A Division of Emerson Process Management P-1

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

FOR THE WIRING AND INSTALLATION

The following safety instructions apply specifically to all EU member states. They should

be strictly adhered to in order to assure compliance with the Low Voltage Directive. NonEU states should also comply with the following unless superseded by local or National

Standards.

1. Adequate earth connections should be made to all earthing points, internal and external,

where provided.

2. After installation or troubleshooting, all safety covers and safety grounds must be replaced.

The integrity of all earth terminals must be maintained at all times.

3. Mains supply cords should comply with the requirements of IEC227 or IEC245.

SPS 4000

IMPORTANT

SAFETY INSTRUCTIONS

OF THIS APPARATUS

4. All wiring shall be suitable for use in an ambient temperature of greater than 75°C.

5. All cable glands used should be of such internal dimensions as to provide adequate cable

anchorage.

6. To ensure safe operation of this equipment, connection to the mains supply should only be

made through a circuit breaker which will disconnect all circuits carrying conductors during a

fault situation. The circuit breaker may also include a mechanically operated isolating switch.

If not, then another means of disconnecting the equipment from the supply must be provided

and clearly marked as such. Circuit breakers or switches must comply with a recognized

standard such as IEC947. All wiring must conform with any local standards.

7. Where equipment or covers are marked with the symbol to the right, hazard-

ous voltages are likely to be present beneath. These covers should only be

removed when power is removed from the equipment — and then only by

trained service personnel.

8. Where equipment or covers are marked with the symbol to the right, there is a

danger from hot surfaces beneath. These covers should only be removed by

trained service personnel when power is removed from the equipment. Certain surfaces may remain hot to the touch.

9. Where equipment or covers are marked with the symbol to the right, refer to

the Operator Manual for instructions.

10. All graphical symbols used in this product are from one or more of the follow-

ing standards: EN61010-1, IEC417, and ISO3864.

P-2 Rosemount Analytical Inc. A Division of Emerson Process Management

Instruction Manual

1

IB-106-340AC Rev. 1.1

SPS 4000

SECTION 1

DESCRIPTION AND SPECIFICATIONS

NOTE

The SPS 4000 Single Probe Autocalibration Sequencer operates exactly the same with either

the Oxymitter 4000 Oxygen Transmitter or the Oxymitter 5000 Oxygen Transmitter with

OUNDATION

F

instruction bulletin also include the Oxymitter 5000. When referred to an instruction bulletin

for more information, reference IB-106-340 for the Oxymitter 4000 and IB-106-340-FB for the

Oxymitter 5000.

fieldbus Communications. Any references to the Oxymitter 4000 throughout this

April 2001

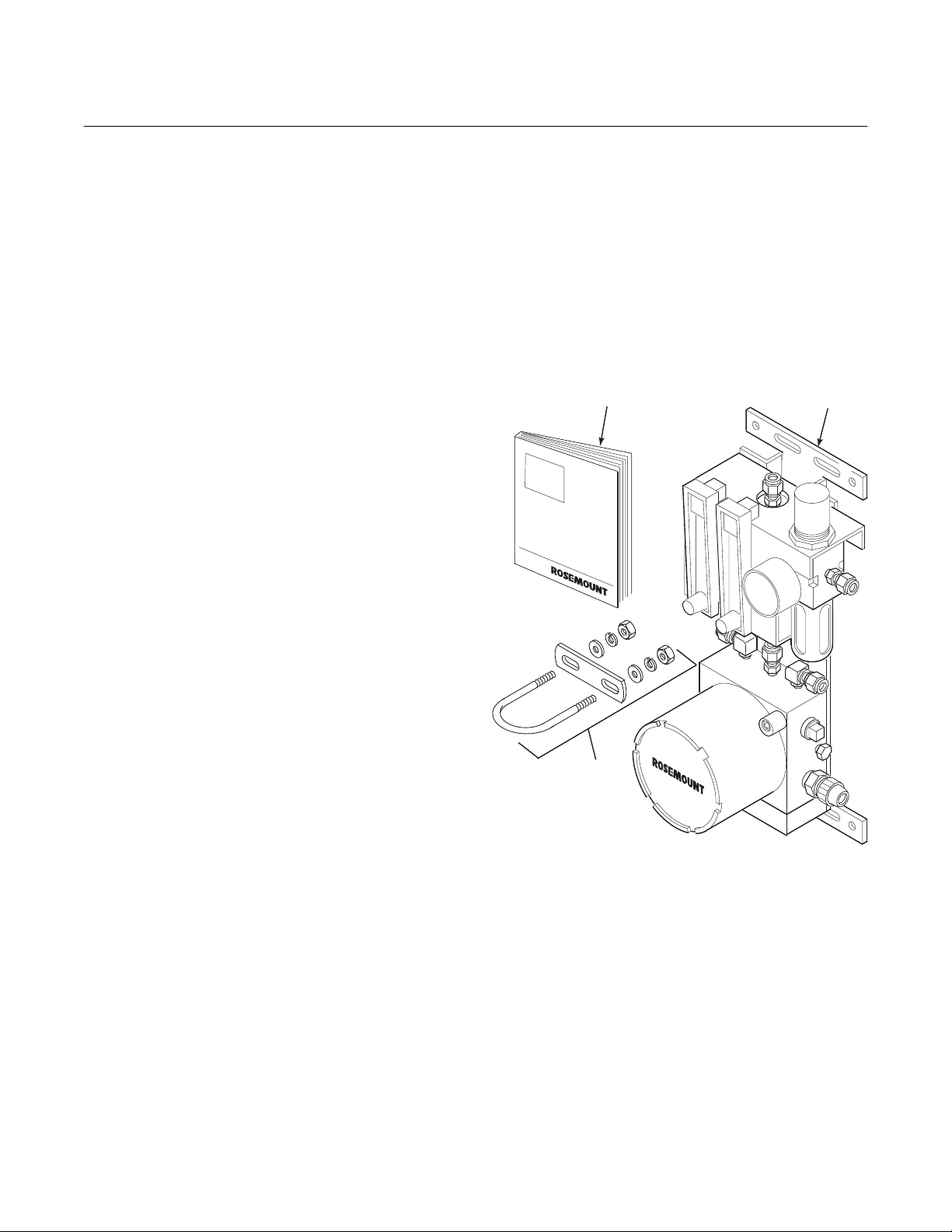

1-1 COMPONENT CHECKLIST

A typical SPS 4000 Single Probe Autocalibration Sequencer should contain the items shown

in Figure 1-1. Record the part number, serial

number, and order number for the SPS 4000 on

the first page of this manual.

Also, use the product matrix in Table 1-1 to

compare your order number against your unit.

The first part of the matrix defines the model.

The last part defines the various options and

features of the sequencer. Ensure the features

and options specified by your order number are

on or included with the unit.

1-2 OVERVIEW

The SPS 4000 provides the capability of performing automatic, timed or on demand, calibrations of a single Oxymitter 4000 without sending

a technician to the probe site.

The SPS 4000 can be mounted either directly to

an In situ Oxymitter 4000 or at a remote location

if space is limited. See Figure 1-2. However, this

instruction bulletin only covers remote mounted

sequencers. For information regarding integrally

mounted sequencers, refer to the Oxymitter

4000 Oxygen Transmitter Instruction Bulletin.

For information on equipping your existing

Oxymitter 4000 with an integrally mounted SPS

4000, contact Rosemount.

1

3

1. Instruction Bulletin

2. SPS 4000 (shown with optional reference air components)

3. Optional Mounting Hardware (for pipe mounting)

Figure 1-1. Typical SPS 4000 Package

2

26010001

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-1

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

Table 1-1. Product Matrix

SPS 4000 B Autocalibration System for Oxymitter 4000 or Oxymitter 5000. Mounted separate from the probe.

SPS 4000 Autocalibration System - Instruction Bulletin

Code Oxygen Analyzer System

20 Used with Oxymitter 4000 or Oxymitter 5000 system (remote mounted only)

SPS 4000

Code Reference Air

1 No reference air required

2 Reference air provided

Code Fittings and Tubing

1 Brass Fittings, Teflon Tubing

2 Stainless Steel Fittings and Tubing

Code Electrical Classification

10 NEMA 4X

20 Hazardous Area Classifications - Cenelec EExd IIB + H2

30 Hazardous Area Classifications (Class I, Div. I, Group B,C,D) - PENDING

SPS 4000 B 20 1 1 10 Example

Notes:

(1)

Reference air is recommended with 9 ft (2.74 m) and 12 ft (3.66 m) long probes. Reference air is also recommended when ambient air may

not contain the normal 20.95% O

unit nearby with leaks.

2)

Customer to pipe from remote SPS 4000 to probe.

3)

Hazardous area classifications require stainless steel fittings and tubing.

, such as when the probe is mounted into a positive pressure duct with leaks or where there is a process

2

(1)

(2)

(3)

(3)

Table 1-2. Calibration Components

Part Number Description

1A99119G01 Two disposable calibration gas bottles—0.4% and 8%

O

, balance nitrogen—550 liters each, includes bottle

2

rack*

1A99119G02 Two flow regulators for calibration gas bottles

*Calibration gas bottles cannot be shipped via airfreight.

When the bottles are used with “CALIBRATION RECOMMENDED” features,

the bottles should provide 2 to 3 years of calibrations in normal service.

1-2 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

1

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

OXYMITTER 4000

INTEGRAL OR

REMOTE

INTEGRALLY

MOUNTED SPS 4000

SINGLE PROBE

AUTOCALIBRATION

SEQUENCER

(1 PROBE)

REFER TO IB-106-340

INTELLIGENT MULTIPROBE

IMPS 4000

TEST GAS SEQUENCER

FOR USE WITH OXYMITTER 4000

(1 TO 4 PROBES)

Figure 1-2. Autocalibration System Installation Options

In addition to the SPS 4000, multiprobe sequencers are also available as shown in Figure

1-2. Rosemount has offered multiprobe autocalibration sequencer systems for many years.

These autocalibration systems are most cost

REMOTE MOUNTED SPS 4000

SINGLE PROBE

AUTOCALIBRATION SEQUENCER

FOR USE WITH OXYMITTER 4000

(EXPLO VERSIONS MUST BE REMOTE MOUNTED)

(1 PROBE)

26010003

effective for boilers and other combustion processes that utilize many probes. Users with only

one probe per combustion process can now

take advantage of Rosemount’s autocalibration

capability by utilizing the SPS 4000.

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-3

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

1-3 SPECIFICATIONS

Mounting ............................................................. Integral to Oxymitter 4000

Remote from Oxymitter 4000

Materials of Construction

Manifold/electronics enclosure ................. Aluminum

Mounting brackets .................................... 316 stainless steel (SS)

Pneumatic fittings ..................................... 1/8 in. brass NPT (SS optional)

Pneumatic tubing ...................................... 1/4 in. Teflon (SS optional)

Assembly hardware .................................. Galvanized and stainless steel

Humidity range .................................................... 100% relative humidity

Ambient temperature range ................................ -40° to 149°F (-40° to 65°C)

Electrical classification ........................................ NEMA 4X (IP56)

Explosion-proof option (both pending) ................ CENELEC EExd IIB + H2

(Class 1, Div. 1, Group B, C, D)

SPS 4000

Electrical feedthroughs........................................ 1/2 in. NPT

Input power.......................................................... 90 to 250VAC, 50/60Hz

Power consumption............................................. 5VA maximum

External electrical noise ...................................... EN 50 082-2, includes 4KV electrostatic discharge

Handshake signal to/from

Oxymitter 4000 (self-powered) ................. 5V (5mA maximum)

Cal initiate contact input from control room......... 5 to 30VDC, Form A (SPST)

(one “In-Cal”, one “Cal Failed”)

Cabling distance between SPS 4000 and

Oxymitter 4000 ......................................... Maximum 1000 ft (303 m)

Piping distance between SPS 4000 and

Oxymitter 4000 ......................................... Maximum 300 ft (91 m)

Approximate shipping weight .............................. 10 lbs (4.5 kg)

Fisher-Rosemount has satisfied all obligations coming from the European legislation to harmonize

the product requirements in Europe.

1-4 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

1

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

1-4 PHYSICAL DESCRIPTION

The main components of the SPS 4000 are described in the following paragraphs and illustrated in Figure 1-3.

a. Manifold

The manifold provides a mounting platform

for the circuit board(s) and terminations and

contains the electrical feedthroughs. Also,

calibration gases are piped into and sequenced through solenoids mounted on the

manifold.

b. Calibration Gas Solenoids

The calibration gas solenoids sequence the

calibration gases. One solenoid controls

calibration gas 1 (high calibration gas), and

the other controls calibration gas 2 (low

calibration gas). The solenoids activate and

deactivate to allow the calibration gases to

flow between the sequencer and Oxymitter

4000.

c. Pressure Switch

The pressure switch detects if the pressure

of a calibration gas is low, which can be

caused by an empty gas bottle, a disconnected gas line, etc. Calibration is prohibited when calibration gas pressure is low.

d. Power Supply Board

This board converts the incoming line voltage from AC to DC for use by the solenoids,

terminations, and the programmable logic

device. The power supply board also has a

5 A, 250 V, slow blow fuse.

REFERENCE AIR

PRESSURE REGULATOR

(OPTIONAL)

NOTE:

CALIBRATION GAS

FLOWMETER

MANIFOLD COVER IS

REMOVED TO SHOW

INTERNAL COMPONENTS.

ALSO, BOARD COMPONENTS

ARE NOT SHOWN FOR CLARITY.

PRESSURE

SWITCH

CALIBRATION GAS 1

(HIGH CAL GAS)

SOLENOID

INTERFACE

BOARD

Figure 1-3. SPS 4000 Components

REFERENCE AIR

FLOWMETER

(OPTIONAL)

MANIFOLD

CALIBRATION GAS 2

(LOW CAL GAS)

SOLENOID

POWER

SUPPLY BOARD

TERMINAL COVER

26010002

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-5

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SPS 4000

e. Interface Board

The interface board contains a programmable logic device (PLD) that has the electronics to energize and deenergize the

solenoids based on a signal from the Oxymitter 4000.

f. Calibration Gas Flowmeter

The calibration gas flowmeter indicates the

flow rate of calibration gas flowing to the

Oxymitter 4000.

g. Reference Air Flowmeter (Optional)

The reference air flowmeter indicates the

amount of reference air continuously flowing

to the Oxymitter 4000.

h. Pressure Regulator (Optional)

The pressure regulator ensures the instrument air (reference air) flowing to the Oxymitter 4000 is at a constant pressure [20 psi

(138 kPa)]. The regulator also has a filter to

remove particulates in the reference air and

a drain valve to bleed the moisture that collects in the filter bowl.

i. Terminal Strip

The terminal strip housed within the terminal cover provides convenient access for all

signal and power user connections.

describe how an Oxymitter 4000 is autocalibrated when used with the SPS 4000.

a. In addition to the calibration methods avail-

able via the Oxymitter 4000 keypad, HART

communicator, AMS software, or a remote

contact, the SPS 4000 works in conjunction

with the Oxymitter 4000’s CAL RECOMMENDED feature to perform an autocalibration. This feature automatically per-forms an

impedance check every hour on the Oxymitter 4000. If a calibration is recommended

and its contact output signal is set for

“handshaking” with the sequencer, the

Oxymitter 4000 sends a signal to the sequencer. The sequencer automatically performs a calibration upon receiving the

signal.

Thus, no human interface is required for the

automatic calibration to take place.

b. When a calibration is required, the Oxymit-

ter 4000 sends a signal to the programmable logic device (PLD) on the interface

board of the sequencer. The PLD energizes

the calibration gas 1 (high O2) solenoid.

Calibration gas 1 then flows through the sequencer to the Oxymitter 4000. The Oxymitter 4000 measures the oxygen content of

calibration gas 1 and sends a signal to the

sequencer indicating that it received the

gas. When the sequencer receives the signal, the PLD deenergizes the calibration

gas 1 solenoid.

1-5 THEORY OF OPERATION

The Oxymitter 4000 is one of the few instruments found in industry that permit the permanent piping of a calibration standard into the

probe. Most instruments measuring pressure,

flow, or temperature require that a calibration

standard be brought to the instrument or that

the instrument be taken to the calibration source

in the instrument shop.

The permanent calibration gas connections allow for auto-calibrations to occur without operator intervention. The following paragraphs

1-6 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

c. Next, the PLD energizes the calibration gas

2 (low O2) solenoid, and calibration gas 2

then flows through the sequencer to the

Oxymitter 4000. The Oxymitter 4000 measures the oxygen content of calibration gas 2

and sends a signal to the sequencer indicating that it received the gas. After measuring the two calibration gases, the

Oxymitter 4000 automatically makes an internal calibration adjustment and sends the

signal to the sequencer. When the sequencer receives the signal, the PLD

deenergizes the calibration gas 2 solenoid.

SPS 4000

1

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

OXYMITTER 4000

LOGIC I/O

CALIBRATION GAS

CHECK VALVE

(SEE NOTE 1)

SPS 4000

OXYMITTER 4000 (BOTTOM VIEW)

CALIBRATION

GAS FITTING

REFERENCE AIR

(SEE NOTE 2)

INSTRUMENT

AIR IN

(SEE NOTE 2)

NOTE 1.

CALIBRATION

GAS 1

(HIGH O )

A CHECK VALVE IS REQUIRED AT THE

OXYMITTER 4000 (BETWEEN THE CALIBRATION GAS FITTING AND THE GAS LINE)

TO PREVENT THE MIGRATION OF PROCESS

GASES DOWN THE CALIBRATION GAS LINE.

CLEAN, DRY INSTRUMENT AIR IS

2.

RECOMMENDED FOR REFERENCE AIR.

NO REFERENCE AIR IS REQUIRED IF

AMBIENT AIR CONDITIONS CONTAIN

20.95% OXYGEN.

2

CALIBRATION

GAS 2

(LOW O )

2

26010004

Figure 1-4. SPS 4000 Calibration Setup

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-7

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SPS 4000

1-8 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

2

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SECTION 2

INSTALLATION

2-1 OVERVIEW

This section describes the installation of the

SPS 4000.

Before starting to install this equipment, read the “Safety Instructions for

the Wiring and Installation of this Apparatus” at the front of this Instruction

Bulletin. Failure to follow the safety

instructions could result in injury or

death.

Install all protective equipment covers

and safety ground leads after installation. Failure to install covers and

ground leads could result in serious

injury or death.

2-2 MECHANICAL INSTALLATION

a. Reference Air (Figure 2-1)

1. For units with the optional reference air

components, connect the instrument

air supply to the IN port of the pressure

regulator.

2. The pressure regulator is factory set at

20 psi (138 kPa). If necessary, readjust

by turning the knob on the top of the

regulator until the desired pressure is

obtained.

3. Next, connect the reference air from

the upper 1/4 in. tube fitting on the reference air flowmeter to the REF GAS

port on the Oxymitter 4000.

b. Calibration Gas (Figure 2-1)

1. Connect O2 calibration gas 1 (high

calibration gas) to the HIGH CAL GAS

IN 1/4 in. tube fitting on the top of the

manifold. Ensure the calibration gas

pressure is set at 20 psi (138 kPa).

The outline drawing in Figure 2-1 shows

mounting centers and clearances of the SPS

4000. The unit is designed to mount on a wall,

bulkhead, or pipe. Ensure the unit is installed

according to the following specifications.

a. Install the unit no further than 300 ft (91 m)

from the Oxymitter 4000 and no further than

1000 ft (303 m) from the electronics package or any customer-supplied remote input

or relay output connections in the control

room.

b. Locate the unit where the ambient tem-

perature is between -40° and 149°F (-40°

and 65°C).

2-3 GAS CONNECTIONS

Use the following procedure to connect the calibration gases and reference air.

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-1

Instrument air is not recommended for

the high calibration gas. Do not use

100% nitrogen as a low gas (zero gas).

It is suggested that the low (zero) gas

be between 0.4% and 2.0% O2. Do not

use gases with hydrocarbon concentrations of more than 40 parts per million. Failure to use proper gases will

result in erroneous readings.

2. Connect O2 calibration gas 2 (low calibration gas) to the LOW CAL GAS IN

1/4 in. tube fitting on the top of the

manifold. Ensure the calibration gas

pressure is set at 20 psi (138 kPa).

3. Connect the calibration gas from the

upper 1/4 in. tube fitting on the calibration gas flowmeter to the check valve

connected to the CAL GAS port on the

Oxymitter 4000.

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

1/4 IN. TUBE FITTING

FOR HIGH CALIBRATION

0.94 (23.88) 0.94 (23.88)

1/4 IN. TUBE FITTING FOR

LOW CALIBRATION GAS IN

GAS IN

1/4 IN. TUBE TO CALIBRATION

GAS FLOWMETER

SPS 4000

CALIBRATION GAS FLOWMETER

(CALIBRATION GAS OUT

TO OXYMITTER 4000)

1/2 IN. NPT CONDUIT PORTS

(SEE NOTE 2)

2.00

(50.80)

13.50

(342.90)

4.25

(107.95)

9.00 (228.60)

NOMINAL

14.81

(376.17)

NOMINAL

REFERENCE AIR

FLOWMETER (OPTIONAL)

(REFERENCE AIR OUT

TO OXYMITTER 4000)

1/2 IN. NPT

CONDUIT PORT

(SEE NOTE 2)

2.00 (50.80)

NOMINAL

CLEARANCE

TO REMOVE

COVER

NOTES: 1.

DIMENSIONS ARE IN INCHES WITH

MILLIMETERS IN PARENTHESES.

2.

THREE 1/2 IN. NPT PORTS ARE PROVIDED

FOR LOGIC I/O AND SIGNAL CONNECTIONS.

THE CABLE ROUTING WILL BE DETERMINED

BY THE CUSTOMER.

1/4 IN. TUBE FITTING

FOR INSTRUMENT

AIR IN (OPTIONAL)

1/2 IN. CONDUIT

FITTING FOR LINE

VOLTAGE

6.12 (155.45)

NOMINAL

26010006

Figure 2-1. Installation

2-2 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

2

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

2-4 ELECTRICAL CONNECTIONS

All wiring must conform to local and national

codes. Use the following procedure to connect

an SPS 4000 to an Oxymitter 4000.

Disconnect and lock out power before

connecting the unit to the power

supply.

NOTE

Ensure the Oxymitter 4000 is set up to

handshake with the sequencer by configuring the logic I/O to mode 8. Refer

to the Oxymitter 4000 Oxygen Transmitter Instruction Bulletin for more information.

a. Remove screws (20, Figure 4-1) securing

terminal cover (19) and remove the cover.

b. Route the line voltage leads into the mani-

fold through the lower 1/2 in. conduit fitting

on the right side of the manifold (Figure 2-1)

and out through the bottom of the manifold.

Connect the incoming 90 to 250 VAC, 50/60

Hz line voltage leads to the terminal strip as

indicated in Figure 2-2.

c. Route the handshake logic I/O wires

through one of the 1/2 in. NPT conduit ports

on the manifold (Figure 2-1) and out

through the bottom of the manifold. Connect

the 5V (5 mA maximum) logic I/O leads

from the Oxymitter 4000 to the terminal strip

as indicated in Figure 2-2.

d. To set up the SPS 4000 to initiate a calibra-

tion from a remote location, route the 5 VDC

calibration initiate contact input through one

of the 1/2 in. NPT conduit ports on the

manifold (Figure 2-1) and out through the

bottom of the manifold. Connect the input

leads to the terminal strip as shown in

Figure 2-2.

e. Relay output connections are available on

the unit to signal when the Oxymitter 4000

is in calibration or when calibration failed.

Relay outputs can be connected to either

indicator lights or a computer interface. The

relay contacts are capable of handling a 5

to 30 VDC maximum power source. The

cabling requirement is 1000 ft (303 m)

maximum. Route the relay output wires

through one of the 1/2 in. NPT conduit ports

on the manifold (Figure 2-1) and out

through the bottom of the manifold. Connect

the relay output wires to the terminal strip

as shown in Figure 2-2.

f. Once all connections are made, install ter-

minal cover (19, Figure 4-1) and secure with

screws (20).

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-3

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SPS 4000

5V(5mA

MAXIMUM)

LOGIC I/O

5 VDC (SELF-POWERED)

TO REMOTE CONTACT

INPUT CONNECTION

CAL INITIATE CAL FAIL

NOT USED

WHITE

NOT USED

BLACK

HANDSHAKE

CONNECTION

TO

OXYMITTER

4000

YELLOW

BROWN

5-30VDCTO

RELAY OUTPUT

CONNECTIONS

RED

BLUE

IN CAL

++++

ORANGE

GREEN

LINE IN

GROUND

NEUTRAL

----

90 - 250 VAC,

50/60 HZ LINE

VOLTAGE

INPUT

FACTORY WIRING TO INTERFACE BOARD

Figure 2-2. Electrical Connections

FACTORY WIRING TO

POWER SUPPLY BOARD

26010007

2-4 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

3

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SECTION 3

OPERATION

3-1 OVERVIEW

This section specifies the requirements to set up

an Oxymitter 4000 calibration and how to verify

the calibration gas flow setup. It also explains

the differences between automatic and semiautomatic calibrations and how to initiate them.

3-2 CALIBRATION REQUIREMENTS

a. Two tanks of precision calibration gas mix-

tures are required. Recommended calibration gases are nominally 0.4% and 8.0%

oxygen in nitrogen.

Do not use 100% nitrogen as a low gas

(zero gas). It is suggested that gas for

the low (zero) be between 0.4% and

2.0% O2. Do not use gases with hydrocarbon concentrations of more

than 40 parts per million. Failure to

use proper gases will result in erroneous readings.

12054 S.W. Doty Avenue

Chicago, Illinois 60628

312/568-8840

603 Bergen Street

Harrison, New Jersey 07029

201/485-1995

255 Brimley Road

Scarborough, Ontario, Canada

416/266-3161

SCOTT ENVIRONMENTAL

TECHNOLOGY, INC.

SCOTT SPECIALTY GASES

2600 Cajon Blvd.

San Bernardino, California 92411

714/887-2571

TWX: 910-390-1159

1290 Combermere Street

Troy, Michigan 48084

314/589-2950

In addition to the optional disposable gas

bottles available from Rosemount, two additional sources of calibrated gas mixtures

are:

LIQUID CARBONIC GAS CORP.

SPECIALTY GAS LABORATORIES

700 South Alameda Street

Los Angeles, California 90058

213/585-2154

767 Industrial Road

San Carlos, California 94070

415/592-7303

9950 Chemical Road

Pasadena, Texas 77507

713/474-4141

Rosemount Analytical Inc. A Division of Emerson Process Management Operation 3-1

Route 611

Plumsteadville, Pennsylvania 18949

215/766-8861

TWX: 510-665-9344

2616 South Loop West

Suite 100

Houston, Texas 77054

713/669-0469

b. A check valve is required at the Oxymitter

4000 (between the calibration fitting and the

gas line) to prevent the migration of process

gases down the calibration gas line.

A typical calibration setup for the Oxymitter

4000 is shown in Figure 1-4.

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SPS 4000

3-3 CALIBRATION GAS FLOW SETUP

After installing the SPS 4000 as described in

Section 2, calibrate the Oxymitter 4000 to verify

SPS 4000 operation and the communication link

between the sequencer and Oxymitter 4000.

a. Verify that both calibration gases are con-

nected to the SPS 4000. Also verify that the

pressure regulators on both calibration gas

bottles are set to 20 psig (138 kPa gage).

b. Initiate a semi-automatic calibration using

one of the methods specified in paragraph

3-5.

NOTE

Only set the calibration gas flowmeter

upon initial installation and after

changing the diffusion element in the

Oxymitter 4000. Refer to the flowmeter

adjustments in Section 4 for more information.

c. As the Oxymitter 4000 and SPS 4000 apply

the first calibration gas, set the calibration

gas flowmeter to 5 scfh. During the application of the second calibration gas, verify that

the flowmeter reads 5 scfh. If not, adjust the

pressure regulator on the second calibration

gas bottle so the 5 scfh flow is provided.

3-4 AUTOMATIC CALIBRATION

AMS. Refer to the logic I/O information in

the HART/AMS section of the Oxymitter

4000 Oxygen Transmitter Instruction Bulletin for more information.

b. Timed Interval

An automatic calibration can also be programmed to occur at a specific time interval,

in hours, using the HART communicator or

AMS software. Refer to the HART/AMS

section of the Oxymitter 4000 Oxygen

Transmitter Instruction Bulletin for this

procedure.

3-5 SEMI-AUTOMATIC CALIBRATION

Semi-automatic calibrations are operator initiated and can be performed using the Oxymitter

4000 keypad, HART handheld communicator/

AMS software, or a remote contact. In addition,

the calibration gases must be permanently

piped to the Oxymitter 4000.

a. Oxymitter 4000 Keypad

A semi-automatic calibration can be initiated

by pressing the CAL button on the Oxymitter 4000 keypad. For more information, refer to the Oxymitter 4000 Oxygen

Transmitter Instruction Bulletin.

b. HART Handheld Communicator/AMS

Software

Automatic calibrations require no operator action and can be performed through the Oxymitter 4000 CAL RECOMMENDED feature or

through scheduled time intervals that can be

programmed through the HART/AMS for the

Oxymitter 4000. In addition, the calibration

gases must be permanently piped to the Oxymitter 4000.

a. CAL RECOMMENDED

If the Oxymitter 4000 is configured for

handshake mode with the SPS 4000, the

Oxymitter 4000 can initiate a calibration by

sending a signal to the sequencer when the

CAL RECOMMENDED LED activates. To

enable handshake mode, the Oxymitter

4000 logic I/O must be set for mode 8.

Handshake mode is configured at the factory or can be accessed through HART/

3-2 Operation Rosemount Analytical Inc. A Division of Emerson Process Management

A semi-automatic calibration can be initiated

by connecting the HART handheld communicator, or AMS software, to the Oxymitter

4000 4-20 mA signal line and using the

HART communicator keypad or computer

keyboard to access the applicable calibration menu. Refer to the Oxymitter 4000

Oxygen Transmitter Instruction Bulletin or

the available HART documentation for more

information.

c. Remote Contact

A semi-automatic calibration can be initiated

using a remote contact such as a customer’s control system. The remote contact

processes the calibration command on a

PC and sends the signal to the Oxymitter

4000. For more information on remote-site

calibrations, refer to the documentation for

the system in use.

SPS 4000

4

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SECTION 4

MAINTENANCE AND SERVICE

4-1 OVERVIEW

This section describes service and routine

maintenance of the SPS 4000. Replacement

parts referenced are available from Rosemount.

Refer to Section VI for part numbers and ordering information.

Install all protective equipment covers

and safety ground leads after equipment repair or service. Failure to install covers and ground leads could

result in serious injury or death.

4-2 FUSE REPLACEMENT

The SPS 4000 has a fuse on the power supply

board. Refer to Table 7-1 for replacement fuse

specifications. Perform the following procedure

to check or replace the fuse.

Disconnect and lock out power before

working on any electrical components.

4-3 BOARD REPLACEMENT

Perform the following procedure to replace

power supply board (23, Figure 4-1) or interface

board (31).

Disconnect and lock out power before

working on any electrical components.

a. Turn off power to the system.

b. Remove screw (22) securing manifold cover

lock (21) and remove the lock.

c. Remove manifold cover (28).

d. Remove two screws (32) attaching spacers

(35) to manifold (38).

e. Being careful not to disconnect the board

wiring, carefully lift power supply board (23)

and interface board (31) from manifold (38)

and set aside. Do not lose o-rings (36) from

the bottom of spacers (35).

f. For the board to be replaced, tag all leads

to simplify installation.

a. Turn off power to the system.

b. Remove screw (22, Figure 4-1) securing

manifold cover lock (21) and remove the

lock.

c. Remove manifold cover (28).

d. Remove fuseholder (26) by pushing in the

top and turning 1/4 turn counterclockwise.

Remove fuse (25).

e. After checking or replacing fuse (25), install

fuseholder (26) by pushing in the top and

turning 1/4 turn clockwise.

f. Install manifold cover (28) and secure with

manifold cover lock (21) and screw (22).

Rosemount Analytical Inc. A Division of Emerson Process Management Maintenance and Service 4-1

g. If replacing the power supply board, refer to

Figure 4-2. Remove the line voltage input

leads from connector J7. Also, unplug calibration gas 1 solenoid leads from connector

J5, calibration gas 2 solenoid leads from

connector J4, and pressure switch leads

from connector J2.

h. If replacing the interface board, refer to

Figure 4-2. Remove the CAL INITIATE

leads from connector J3, CAL FAIL and IN

CAL leads from connector J4, and logic I/O

handshake connection from connector J5.

i. Remove stop nuts (33, Figure 4-1), washers

(34), and screws (37) securing power supply board (23) and interface board (31) to

spacers (35).

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SPS 4000

46

47

45

48

49

50

43

44

42

51

41

40

52

39

12

10

38

3

1

5

4

2

6

8

9

10

7

28

29

30

33

32

31

34

26

27

25

35

36

37

12

11

21

22

23

24

NOTE: A STANDARD SPS 4000 IS EQUIPPED WITH TEFLON

20

TUBING AND BRASS FITTINGS. OPTIONAL STAINLESS

STEEL TUBING AND FITTINGS ARE ALSO AVAILABLE.

REFER TO SECTION VI FOR ORDERING INFORMATION.

14

15

16

17

18

19

12

13

26010009

Figure 4-1. SPS 4000, Exploded View

4-2 Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

4

1. Reference Air Pressure

Regulator (Optional)

2. Straight Fitting

3. Mounting Bracket

4. Flat Washer

5. Lockwasher

6. Hex Nut

7. Screw

8. Tube

9. Straight Fitting

10. Elbow Fitting

11. Hex Head Plug

12. Square Head Plug

13. Conduit Fitting

14. Ground Nut

15. Terminal Base

16. Terminal Strip

17. Screw

LEGEND FOR FIGURE 4-1

18. Terminal Cover Gasket

19. Terminal Cover

20. Screw

21. Manifold Cover Lock

22. Screw

23. Power Supply Board

24. Calibration Gas 2 Solenoid

25. Fuse

26. Fuseholder

27. Pressure Switch

28. Manifold Cover

29. O-Ring

30. Calibration Gas 1 Solenoid

31. Interface Board

32. Screw

33. Stop Nut

34. Washer

35. Spacer

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

36. O-Ring

37. Screw

38. Manifold

39. Elbow Fitting (Optional)

40. Tubing (Optional)

41. Elbow Fitting (Optional)

42. Screw

43. Elbow Street Fitting (Optional)

44. Elbow Fitting

45. Reference Air Flowmeter

(Optional)

46. Calibration Gas Flowmeter

47. Elbow Fitting

48. Elbow Street Fitting (Optional)

49. Straight Fitting (Optional)

50. Flowmeter Bracket

51. Bracket

52. Screw

j. Carefully separate boards (23 and 31).

k. Connect replacement board to board (23 or

31).

l. Install screws (37), washers (34), and stop

nuts (33) to secure interface board (31) and

power supply board (23) to spacers (35).

m. Install all applicable leads in the appropriate

locations on the power supply board or interface board as shown in Figure 4-2.

n. Install power supply board (23, Figure 4-1)

and interface board (31) into manifold (38).

Align spacers (35) with the mounting holes

on the manifold and secure with screws

(32). Ensure o-rings (36) are installed between the spacers and the manifold

surface.

o. Install manifold cover (28) and secure with

manifold cover lock (21) and screw (22).

4-4 SOLENOID REPLACEMENT

Use this procedure to replace either calibration

gas 1 (high calibration gas) solenoid (30, Figure

4-1) or calibration gas 2 (low calibration gas)

solenoid (24).

Disconnect and lock out power before

working on any electrical components.

a. Turn off power to the system.

b. Shut off the calibration gases at the

cylinders.

c. Remove screw (22) securing manifold cover

lock (21) and remove the lock.

d. Remove manifold cover (28).

e. Remove two screws (32) attaching spacers

(35) to manifold (38).

Rosemount Analytical Inc. A Division of Emerson Process Management Maintenance and Service 4-3

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

TO PRESSURE

SWITCH

LINE IN

LINE

VOLTAGE

INPUT

NEUTRAL

GROUND

SPS 4000

POWER SUPPLY BOARD

TO CALIBRATION

GAS 1 SOLENOID

TO CALIBRATION

GAS 2 SOLENOID

GROUND

VAC INPUT TO OXYMITTER 4000

L1

N

INTERFACE BOARD

BLACK

WHITE

RED

BLUE

ORANGE

GREEN

YELLOWYELLOW

BROWN

+

CAL INITIATE

-

+

CAL FAIL

-

+

IN CAL

-

LOGIC I/O

+

HANDSHAKE TO

-

OXYMITTER 4000

REMOTE

CONTACT INPUT

STATUS

INDICATOR

OUTPUT

26010012

Figure 4-2. Board Connections

4-4 Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

4

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

f. Being careful not to disconnect the board

wiring, carefully lift the board and spacer

assembly from manifold (38) and set aside.

Do not lose o-rings (36) from the bottom of

spacers (35).

g. Tag and unplug solenoid (30 or 24) leads

from power supply board (23). Refer to

Figure 4-2. Calibration gas 1 solenoid wires

connect to connector J5, and calibration gas

2 solenoid wires connect to connector J4.

h. Remove the top nut of solenoid (30 or 24)

securing the coil assembly and washer to

the base. Remove the coil assembly, including the leads, and washer. Place a

13/16 in. deep socket over the solenoid

base and remove.

When installing a solenoid, do not

overtighten. Damage to the solenoid

may occur.

4-5 PRESSURE SWITCH REPLACEMENT

Use the following procedure to replace pressure

switch (27, Figure 4-1).

a. Turn off power to the system.

b. Shut off the calibration gases at the

cylinders.

c. Remove screw (22) securing manifold cover

lock (21) and remove the lock.

d. Remove manifold cover (28).

e. Remove two screws (32) attaching spacers

(35) to manifold (38).

f. Being careful not to disconnect the board

wiring, carefully lift the board and spacer

assembly from manifold (38) and set aside.

Do not lose o-rings (36) from the bottom of

spacers (35).

g. Tag and remove the leads from pressure

switch (27).

i. Install the new solenoid base. Be careful not

to overtighten. Install the new washer and

coil assembly and secure with the top nut.

Connect the leads to the proper connector

on power supply board (23). Refer to Figure

4-2 if necessary.

j. Carefully install the board and spacer as-

sembly into manifold (38, Figure 4-1) by

aligning spacers (35) with the mounting

holes on the manifold and securing with

screws (32). Ensure o-rings (36) are installed between the spacers and the manifold surface.

k. Install manifold cover (28), and secure with

manifold cover lock (21) and screw (22).

l. Turn on the calibration gases at the

cylinders.

h. Place a 1-1/16 in. 6-point socket over pres-

sure switch (27) and remove.

When installing the pressure switch,

do not overtighten. Damage to the solenoid may occur.

i. Install new pressure switch (27). Be careful

not to overtighten. Connect the leads to the

proper terminals on the pressure switch.

j. Carefully install the board and spacer as-

sembly into manifold (38, Figure 4-1) by

aligning spacers (35) with the mounting

holes on the manifold and securing with

screws (32). Ensure o-rings (36) are installed between the spacers and the manifold surface.

Rosemount Analytical Inc. A Division of Emerson Process Management Maintenance and Service 4-5

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SPS 4000

k. Install manifold cover (28), and secure with

manifold cover lock (21) and screw (22).

l. Turn on the calibration gases at the

cylinders.

4-6 CHECK VALVE REPLACEMENT

The check valve may stick or become plugged

over time. Replace when necessary. If condensation deposits are noted upon removal, consider insulating the check valve.

4-7 PRESSURE REGULATOR (OPTIONAL)

MAINTENANCE

a. Pressure Adjustments

Reference air pressure regulator (1, Figure

4-1) is factory set to 20 psi (138 kPa). Adjust using the knob on top of the pressure

regulator if necessary.

In applications with a heavy dust loading,

the O

probe diffusion element may become

2

plugged over time, causing a slower speed

of response. The best way to detect a

plugged diffusion element is to note the time

it takes the Oxymitter 4000 to return to the

normal process reading after the last calibration gas is removed and the calibration

gas line is blocked off. A plugged element

also can be indicated by a slightly lower

reading on the flowmeter.

Change the diffusion element when the

calibration gas flowmeter reads slightly

lower during calibration or when the response time to the process flue gases becomes very slow. Each time the diffusion

element is changed, reset the calibration

gas flowmeter to 5 scfh and calibrate the

Oxymitter 4000. For more information on

changing the diffusion element, refer to the

instruction bulletin for the Oxymitter 4000 in

use.

b. Reference Air Flowmeter (Optional)

Do not use fingers to release valve

stem. The valve may release air at high

pressures and cause injury.

b. Condensation Drain

To drain excess moisture from the filter bowl

of reference air pressure regulator (1), use

a screwdriver or comparable tool to periodically release the valve stem on the bottom

of the pressure regulator.

4-8 FLOWMETER ADJUSTMENTS

a. Calibration Gas Flowmeter

Calibration gas flowmeter (46, Figure 4-1)

regulates the calibration gas flow and must

be set to 5 scfh. However, only adjust the

flowmeter to 5 scfh after placing a new diffusion element on the end of the Oxymitter

4000. Adjusting the flowmeter at any other

time can pressurize the cell and bias the

calibration.

Reference air flowmeter (45) regulates the

reference air and must be set to 2 scfh.

Adjust the flow with the knob on the bottom

of the reference air flowmeter when

necessary.

4-9 FLOWMETER REPLACEMENT

Use this procedure to replace either reference

air flowmeter (45, Figure 4-1) or calibration gas

flowmeter (46).

a. Turn off power to the system.

b. Shut off the calibration gases at the

cylinders.

c. Loosen, but do not remove, four screws

(42) securing flowmeter bracket (50) to

mounting bracket (3).

d. Flex the bottom of flowmeter bracket (50)

downward and away to disengage and remove the flowmeter bracket from mounting

bracket (3).

4-6 Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

4

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

e. For reference air flowmeter (45), remove

pressure regulator (1) by disconnecting

tubing (40) from elbow fitting (39). Also, disconnect the tubing between the Oxymitter

4000 and sequencer from straight

fitting (49).

For calibration gas flowmeter (46), disconnect the tubing between the Oxymitter 4000

and the sequencer at elbow fitting (47).

Also, disconnect tube (8) from elbow

fitting (44).

f. Remove screws (52) and bracket (51) se-

curing flowmeter (45 or 46) to flowmeter

bracket (50).

g. Remove flowmeter (45 or 46), with installed

fittings, from flowmeter bracket (50).

h. For reference air flowmeter (45), remove el-

bow street fittings (43 and 48). It is not necessary to remove fittings (39 and 49) from

the street fittings.

For calibration gas flowmeter (46), remove

elbow fittings (44 and 47).

i. Apply pipe thread sealant to the threads of

top fitting (48 or 47) and bottom fitting (43 or

44) and install fittings into new flowmeter

(45 or 46).

j. Position flowmeter (45 or 46) into flowmeter

bracket (50) and secure with bracket (51)

and screw (52).

k. For reference air flowmeter (45), connect

tubing (40) to elbow fitting (39) and install

pressure regulator (1). Also, connect the

tubing between the Oxymitter 4000 and sequencer to straight fitting (49).

For calibration gas flowmeter (46), connect

tube (8) to elbow fitting (44) and connect the

gas tubing between the Oxymitter 4000 and

sequencer to elbow fitting (47).

l. Slide the top slots of flowmeter bracket (50)

onto screws (42). Flex the bottom of the

bracket downward and toward mounting

bracket (3) to engage the bottom bracket

slots and screws. Tighten screws.

m. Turn on the calibration gases at the

cylinders.

Rosemount Analytical Inc. A Division of Emerson Process Management Maintenance and Service 4-7

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SPS 4000

4-8 Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

5

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SECTION 5

TROUBLESHOOTING

5-1 OVERVIEW

This section describes the SPS 4000 troubleshooting procedures. Additional troubleshooting

information can be found in the Oxymitter 4000

Oxygen Transmitter Instruction Bulletin.

Install all protective equipment covers

and safety ground leads after troubleshooting. Failure to replace covers

and ground leads could result in serious injury or death.

5-2 SPS 4000 TROUBLESHOOTING

Use the CAL FAIL and IN CAL relay outputs to

identify possible SPS faults.

a. If a calibration was not successfully com-

pleted, the SPS 4000 sends a CAL FAIL

contact indication to the control room. To

determine if the SPS 4000 caused the failed

calibration, go to the Oxymitter 4000 site to

view the keypad. Or, access the HART/AMS

menus. For more information on HART/

AMS, refer to the HART/AMS section in the

Oxymitter 4000 Oxygen Transmitter Instruction Bulletin.

1. If no alarms are indicated on the keypad or in the HART/AMS STATUS submenu, the calibration did not fail because of an Oxymitter 4000 fault.

Therefore, a calibration gas flow problem occurred. Refer to Table 5-1 or

Figure 5-1 to troubleshoot the SPS

4000.

2. If the LAST CAL FAILED alarm is indicated on the keypad or in the HART/

AMS STATUS sub-menu, the failure is

due to either a bad Oxymitter 4000 cell

or a calibration gas flow problem.

(a) Verify your calibration setup per

paragraph 2-3 in Section 2, INSTAL-LATION; Section 3, OPERATION; and paragraph 4-8 in

Section 4, MAINTENANCE AND

SERVICE.

(b) Perform another calibration and

monitor the process. If the calibration fails before both calibration

gases finish sequencing, a gas

flow problem exists. Refer to Table

5-1 or Figure 5-1 to troubleshoot

the SPS 4000.

If the calibration setup is correct

and the Oxymitter 4000 indicates

an invalid slope fault (fault 12) before the gases are purged and a

last calibration failed fault (fault 14)

after the gases are purged, replace

the Oxymitter 4000 cell per the

Oxymitter 4000 Oxygen Transmitter Instruction Bulletin.

b. If a semi-automatic or manual calibration is

being performed but no 5 - 30 VDC relay

output contact (IN CAL or CAL FAIL) is being received by the control room, the interface board relays are malfunctioning.

Replace the interface board per paragraph

4-3 in Section 4, MAINTENANCE AND

SERVICE.

NOTE

If the unit is performing frequent autocalibrations, investigate at the Oxymitter 4000 site or using HART/AMS. This

condition may indicate an aging cell in

the Oxymitter 4000.

Rosemount Analytical Inc. A Division of Emerson Process Management Troubleshooting 5-1

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

Table 5-1. SPS 4000 Fault Finding

Symptom Check Fault Remedy

SPS 4000

No calibration gas

flow

Wiring Improper wire connections,

loose connections, or damaged wiring

Logic I/O Oxymitter 4000 logic I/O not

set for calibration handshaking with SPS 4000

Calibration gas lines between cylinders and manifold

Calibration gas flowmeter

knob

Calibration gas line between

manifold and calibration gas

flowmeter

Fuse on power supply board Blown fuse Replace fuse per paragraph

Interface board option Interface board not sending

Check valve Clogged check valve Replace check valve per

Clogged calibration gas line Replace clogged calibration

Flowmeter knob not turned

counterclockwise to allow

flow

Clogged calibration gas line Replace clogged calibration

signals

Properly connect wiring or

secure loose wiring connections; replace damaged wiring if necessary.

Set logic I/O to mode 8 via

HART/AMS.

gas line.

Turn calibration gas flowmeter knob counterclockwise to allow calibration

gas to flow.

gas line.

4-2.

Replace interface board per

paragraph 4-3.

paragraph 4-6.

Calibration gas line between

calibration gas flowmeter and

check valve

Calibration gas flowmeter Clogged flowmeter Replace flowmeter per para-

Power supply output Power supply failure Replace power supply board

Solenoid Solenoid failure Replace solenoid per para-

Pressure switch Pressure switch failure Replace pressure switch per

Clogged calibration gas line Replace calibration gas line.

graph 4-9.

per paragraph 4-3.

graph 4-4.

paragraph 4-5.

5-2 Troubleshooting Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

5

SYMPTOM — NO CALIBRATION GAS FLOW

CHECK ALL WIRING BETWEEN

OXYMITTER 4000 AND SPS 4000.

IS

WIRING

PROPERLY

CONNECTED

AND

SECURE?

YES

CHECK LOGIC I/O SETTING VIA

HART/AMS.

PROPERLY CONNECT WIRING OR

NO

SECURE LOOSE WIRING CONNECTIONS; REPLACE DAMAGED

WIRING.

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

IS

LOGIC I/O

SET FOR

MODE 8?

YES

DISCONNECT CAL GAS INPUT

LINES AT MANIFOLD.

IS THERE

FLOW?

YES

ENSURE CAL GAS FLOWMETER

KNOB IS TURNED COUNTERCLOCKWISE TO ALLOW FLOW.

DOES

CAL GAS

FLOWMETER

REGISTER

FLOW?

YES

CHECK FUSE F1 ON POWER

SUPPLY BOARD.

NO

NO

NO

SET LOGIC I/O TO MODE 8 VIA

HART/AMS.

REPLACED CLOGGED CAL GAS

LINE BETWEEN CAL GAS

CYLINDER AND MANIFOLD.

REPLACED CLOGGED CAL GAS

LINE BETWEEN MANIFOLD AND

CAL GAS FLOWMETER.

F1

J2

J5

J4

J3

LO GAS

HI GAS

NO GAS

CAL RET

IS

FUSE

BLOWN?

NO

CONTINUED

ON SHEET

2OF2

YES

REPLACE FUSE PER

PARAGRAPH 4-2.

POWER SUPPLY BOARD

35970001

Figure 5-1. SPS 4000 Troubleshooting Flowchart (Sheet 1 of 2)

Rosemount Analytical Inc. A Division of Emerson Process Management Troubleshooting 5-3

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SYMPTOM — NO CALIBRATION GAS FLOW (CONTINUED)

SPS 4000

CONTINUED

FROM SHEET

1OF2

PLACE JUMPER BETWEEN CAL

RET TERMINAL AND EITHER HI

GAS OR LO GAS TERMINAL OF J3.

SEE NOTE 1.

IS THERE

FLOW?

NO

USE METER (SEE NOTE 2)

TO CHECK FOR SHORT

BETWEEN CAL RET AND NO GAS

TERMINALS OF J3.

IS THERE

A SHORT?

NO

DISCONNECT SOLENOID FROM

POWER SUPPLY BOARD AND USE

METER TO MEASURE ACROSS

TWO OUTER PINS OF BOARD

CONNECTOR. SEE NOTE 4.

CHECK BOTH SOLENOIDS.

IS THERE

+30VDC?

YES

DISCONNECT CAL GAS LINE

AT MANIFOLD OUTPUT PORT.

YES

YES

NO

INTERFACE BOARD IS

NOT SENDING SIGNAL.

REPLACE INTERFACE

BOARD PER PARAGRAPH

4-3.

DISCONNECT CAL GAS

LINE AT CHECK VALVE.

REPLACE POWER

SUPPLY BOARD PER

PARAGRAPH 4-3.

NOTE 1:

NOTE 2:

NOTE 3:

NOTE 4:

DISCONNECT CAL GAS LINE

AT TOP FITTING OF CAL GAS

FLOWMETER.

REPLACE FAULTY CAL GAS

FLOWMETER PER PARAGRAPH

4-9.

SECURELY TIGHTEN ALL J3 SCREW TERMINALS ON

POWER SUPPLY BOARD TO MAKE CONNECTIONS.

USE A SIMPSON MODEL 260 OR EQUIVALENT

MULTIMETER.

IF REPLACING THE CHECK VALVE DOES NOT

CORRECT THE PROBLEM, A CLOG COULD EXIST IN

THE RED SILICON GAS TUBE WITHIN THE PROBE.

IF CHECKING CAL GAS 1 SOLENOID CONNECTOR J5,

ENSURE CAL RET TERMINAL IS JUMPERED TO HI GAS

TERMINAL OF J3. IF CHECKING CAL GAS 2 SOLENOID

CONNECTOR J4, ENSURE CAL RET TERMINAL IS

JUMPERED TO LO GAS TERMINAL OF J3.

IS THERE

FLOW?

NO

IS THERE

FLOW?

NO

YES

YES

REPLACE CHECK VALVE

PER PARAGRAPH 4-6.

SEE NOTE 3.

REPLACE CLOGGED

CAL GAS LINE BETWEEN

CAL GAS FLOWMETER

AND CHECK VALVE.

NO

IS THERE

FLOW?

YES

REPLACE PRESSURE SWITCH

PER PARAGRAPH 4-5.

REPLACE SOLENOID

PER PARAGRAPH 4-4.

35970002

Figure 5-1. SPS 4000 Troubleshooting Flowchart (Sheet 2 of 2)

5-4 Troubleshooting Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

6

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SECTION 6

RETURN OF MATERIAL

6-1 If factory repair of defective equipment is re-

quired, proceed as follows:

a. Secure a return authorization from a Rose-

mount Analytical Sales Office or Representative before returning the equipment.

Equipment must be returned with complete

identification in accordance with Rosemount

instructions or it will not be accepted.

In no event will Rosemount be responsible

for equipment returned without proper

authorization and identification.

b. Carefully pack the defective unit in a sturdy

box with sufficient shock absorbing material

to ensure no additional damage occurs

during shipping.

c. In a cover letter, describe completely:

1. The symptoms that determined the

equipment is faulty.

2. The environment in which the equipment was operating (housing, weather,

vibration, dust, etc.).

3. Site from where the equipment was

removed.

4. Whether warranty or nonwarranty

service is requested.

5. Complete shipping instructions for the

return of the equipment.

d. Enclose a cover letter and purchase order

and ship the defective equipment according

to instructions provided in a Rosemount

Return Authorization, prepaid, to:

Rosemount Analytical Inc.

RMR Department

1201 N. Main Street

Orrville, Ohio 44667

If warranty service is requested, the defective unit will be carefully inspected and

tested at the factory. If failure was due to

conditions listed in the standard Rosemount

warranty, the defective unit will be repaired

or replaced at Rosemount's option, and an

operating unit will be returned to the customer in accordance with shipping instructions furnished in the cover letter.

For equipment no longer under warranty,

the equipment will be repaired at the factory

and returned as directed by the purchase

order and shipping instructions.

Rosemount Analytical Inc. A Division of Emerson Process Management Return of Material 6-1

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SPS 4000

6-2 Return of Material Rosemount Analytical Inc. A Division of Emerson Process Management

Instruction Manual

7

IB-106-340AC Rev. 1.1

SPS 4000

SECTION 7

REPLACEMENT PARTS

Table 7-1. SPS 4000 Replacement Parts

Figure and Index No. Part Number Description

Figure 1-4 6292A97H03 Check Valve

Figure 4-1, 29 1A99089H01 Cover O-ring

Figure 4-1, 46 771B635H01 Flowmeter Assembly, Calibration Gas

Figure 4-1, 45 771B635H02 Flowmeter Assembly, Reference Air (Optional)

Figure 4-1, 1 1A99094H01 Reference Air Pressure Regulator (Optional)

Figure 4-1, 25 1A97913H03 Fuse, 5A, 250V, 5 20 mm, Slow Blow

Figure 4-1, 31 4850B56G01 Interface Board

Figure 4-1, 23 4850B54G01 Power Supply Board

Figure 4-1, 27 7305A67H01 Pressure Switch

Figure 4-1, 24 and 30 3D39435G01 Solenoid

Figure 4-1, 18 4850B75H01 Terminal Cover Gasket

Figure 4-1, 16 1A99147H01 Terminal Strip

April 2001

Table 7-2. Calibration Replacement Parts

Figure and Index No. Part Number Description

Figure 1-4 1A99119G01 Calibration Gas Bottles — 0.4% and 8% O2, balance nitrogen

— 550 liters each, includes bottle rack*

Figure 1-4 1A99119G02 Two flow regulators (for calibration gas bottles)

*Calibration gas bottles cannot be shipped via airfreight.

Rosemount Analytical Inc. A Division of Emerson Process Management Replacement Parts 7-1

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SPS 4000

7-2 Replacement Parts Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

I

This index is an alphabetized listing of parts, terms, and procedures having to do with the Hazardous Area Oxygen/Combustibles Transmitter. Every item listed in this index refers to a location

in the manual by one or more page numbers.

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SECTION 8

INDEX

A

Ambient Temperature Range, 1-4, 2-1

AMS, 1-6, 3-2, 5-1, 5-2, 5-3

Autocalibration, 1-1, 1-2, 1-3, 1-6

Automatic Calibration, 3-2

C

Calibration Gas, 1-5, 1-6, 2-1, 3-1, 3-2, 4-1, 4-6, 4-7,

5-2, 5-3

Calibration Gas Bottles, 1-2, 7-1

Check Valve, 2-1, 3-1, 4-6, 5-2, 5-4

Condensation Drain, 4-6

Contact Input, 1-4, 2-3

D

Drain Valve, 1-6

E

Electrical Classification, 1-2, 1-4

Electrical Connections, 2-3, 2-4

Electrical Feedthroughs, 1-4, 1-5

Electrical Noise, 1-4

Explosion-proof Rating, 1-4

F

Flow Regulators, 1-2, 7-1

Flowmeter, 1-6, 2-1, 3-2, 4-3, 4-6, 4-7, 5-2, 5-3, 5-4

Fuse, 4-1, 5-2, 5-3

G

Gas Connections, 2-1

H

Handshake Signal, 1-4, 2-3, 3-2

HART, 1-6, 3-2, 5-1, 5-2, 5-3

Humidity, 1-4

I

Input Power, 1-4

Interface Board, 1-6, 2-4, 4-1, 4-3, 4-4, 5-1, 5-2, 5-4

L

Line Voltage, 2-3

Logic I/O, 2-3, 2-4, 3-2, 5-2, 5-3

M

Manifold, 1-4, 1-5, 2-1

Mechanical Installation, 2-1

Mounting, 1-4, 2-1

Multiprobe Sequencers, 1-3

P

Piping Distance, 1-4

PLD, 1-6

Power Consumption, 1-4

Power Supply Board, 1-5, 4-1, 4-3, 4-4, 5-2, 5-3, 5-4

Pressure Regulator, 1-6, 2-1, 3-2, 4-3, 4-6, 4-7

Pressure Switch, 1-5, 4-3, 4-5, 5-2, 5-4

Product Matrix, 1-1, 1-2

R

Reference Air, 1-1, 1-2, 1-6, 2-1, 4-3, 4-6, 4-7

Relay Output, 2-1, 2-3

Remote Contact, 1-6, 3-2

Replacement Parts, 7-1

Return of Material, 6-1

S

Semi-automatic Calibration, 3-1, 3-2

Solenoid, 1-5, 1-6, 4-3, 4-5, 5-2, 5-4

Specifications, 1-4

T

Terminal Strip, 1-6

Troubleshooting, 5-1, 5-2, 5-3, 5-4

W

Weight, 1-4

Rosemount Analytical Inc. A Division of Emerson Process Management Index 8-1

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SPS 4000

8-2 Index Rosemount Analytical Inc. A Division of Emerson Process Management

WARRANTY

Goods and part(s) (excluding consumables) manufactured by Seller are warranted to be free from

defects in workmanship and material under normal use and service for a period of twelve (12)

months from the date of shipment by Seller. Consumables, glass electrodes, membranes, liquid

junctions, electrolyte, o-rings, etc., are warranted to be free from defects in workmanship and

material under normal use and service for a period of ninety (90) days from date of shipment by

Seller. Goods, part(s) and consumables proven by Seller to be defective in workmanship and/or

material shall be replaced or repaired, free of charge, F.O.B. Seller's factory provided that the

goods, part(s) or consumables are returned to Seller's designated factory, transportation charges

prepaid, within the twelve (12) month period of warranty in the case of goods and part(s), and in

the case of consumables, within the ninety (90) day period of warranty. This warranty shall be in

effect for replacement or repaired goods, part(s) and the remaining portion of the ninety (90) day

warranty in the case of consumables. A defect in goods, part(s) and consumables of the commercial unit shall not operate to condemn such commercial unit when such goods, part(s) and

consumables are capable of being renewed, repaired or replaced.

The Seller shall not be liable to the Buyer, or to any other person, for the loss or damage directly

or indirectly, arising from the use of the equipment or goods, from breach of any warranty, or from

any other cause. All other warranties, expressed or implied are hereby excluded.

IN CONSIDERATION OF THE HEREIN STATED PURCHASE PRICE OF THE GOODS,

SELLER GRANTS ONLY THE ABOVE STATED EXPRESS WARRANTY. NO OTHER WARRANTIES ARE GRANTED INCLUDING, BUT NOT LIMITED TO, EXPRESS AND IMPLIED

WARRANTIES OR MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Limitations of Remedy. SELLER SHALL NOT BE LIABLE FOR DAMAGES CAUSED BY DELAY IN PERFORMANCE. THE SOLE AND EXCLUSIVE REMEDY FOR BREACH OF WARRANTY SHALL BE LIMITED TO REPAIR OR REPLACEMENT UNDER THE STANDARD

WARRANTY CLAUSE. IN NO CASE, REGARDLESS OF THE FORM OF THE CAUSE OF ACTION, SHALL SELLER'S LIABILITY EXCEED THE PRICE TO BUYER OF THE SPECIFIC

GOODS MANUFACTURED BY SELLER GIVING RISE TO THE CAUSE OF ACTION. BUYER

AGREES THAT IN NO EVENT SHALL SELLER'S LIABILITY EXTEND TO INCLUDE INCIDENTAL OR CONSEQUENTIAL DAMAGES. CONSEQUENTIAL DAMAGES SHALL INCLUDE, BUT

ARE NOT LIMITED TO, LOSS OF ANTICIPATED PROFITS, LOSS OF USE, LOSS OF REVENUE, COST OF CAPITAL AND DAMAGE OR LOSS OF OTHER PROPERTY OR EQUIPMENT.

IN NO EVENT SHALL SELLER BE OBLIGATED TO INDEMNIFY BUYER IN ANY MANNER

NOR SHALL SELLER BE LIABLE FOR PROPERTY DAMAGE AND/OR THIRD PARTY CLAIMS

COVERED BY UMBRELLA INSURANCE AND/OR INDEMNITY COVERAGE PROVIDED TO

BUYER, ITS ASSIGNS, AND EACH SUCCESSOR INTEREST TO THE GOODS PROVIDED

HEREUNDER.

Force Majeure. Seller shall not be liable for failure to perform due to labor strikes or acts beyond

Seller's direct control.

3491

3536/4-01