Safety Manual

308020EN, Edition 1

June 2007

Rosemount TankRadar Rex

Safety Manual For Use In Safety Instrumented Systems

www.rosemount-tg.com

Safety Manual

308020EN, Edition 1

June 2007

Rosemount TankRadar Rex

Safety Manual

Rosemount TankRadar Rex

First edition

www.rosemount-tg.com

Copyright

© June 2007

Rosemount Tank Radar AB

Rosemount TankRadar Rex

Copyright © June 2007

Rosemount Tank Radar AB

Spare Parts

Any substitution of non-recognized spare parts may jeopardize

safety. Repair, e.g. substitution of components etc, may also

jeopardize safety and is under no circumstances allowed.

Rosemount Tank Radar AB will not take any responsibility for

faults, accidents, etc caused by non-recognized spare parts or

any repair which is not made by Rosemount Tank Radar AB.

Safety Manual

308020EN, Edition 1

June 2007

WARNING

Do not open the Integrated Junction Box JBi

when the circuit is alive.

www.rosemount-tg.com

Safety Manual

308020EN, Edition 1

June 2007

Rosemount TankRadar Rex

Contents

Content s

1. SCOPE AND PURPOSE OF THE SAFETY MANUAL . . . . . . . . . . 1

2. R

3. S

EFERENCE DOCUMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

COPE OF THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.1 PURPOSE OF THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.2 ASSUMPTIONS AND RESTRICTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.3 FUNCTIONAL SPECIFICATION OF THE SAFETY FUNCTIONS . . . . . . . 3

3.4 PARAMETERS RELATED TO SAFETY FUNCTIONS . . . . . . . . . . . . . . . . 7

3.5 HARDWARE AND SOFTWARE CONFIGURATION . . . . . . . . . . . . . . . . . 12

4. INSTALLATION AND CONFIGURATION. . . . . . . . . . . . . . . . . . 13

4.1 CONFIGURATION WITH ONE RELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 CONFIGURATION WHEN USING TWO RELAYS IN SERIES . . . . . . . . . 17

4.3 VERIFICATION OF THE SAFETY FUNCTION . . . . . . . . . . . . . . . . . . . . . 20

4.4 WRITE PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5. PROOF TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1 TRIGGERING THE RELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 HAND DIPPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3 VERIFICATION OF THE RELAY FUNCTION . . . . . . . . . . . . . . . . . . . . . . 23

5.4 REPAIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6. TERMS AND DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Appendix FMEDA and Proven-in-use Assessment . . . . . . .27

i

Rosemount TankRadar Rex

Contents

Safety Manual

308020EN, Edition 1

June 2007

ii

Safety Manual

308020EN, Edition 1

June 2007

Rosemount TankRadar Rex

Chapter 1 Scope and Purpose of the

Safety Manual

1. Scope and Purpose of the Safety Manual

The purpose of the safety manual is to document all the

information, relating to TankRadar Rex 3900 Series, which is

required to enable the integration of TankRadar Rex into a safetyrelated system, in compliance with the requirements of IEC

61508.

1

Rosemount TankRadar Rex

Chapter 2 Reference Documents

2. Reference Documents

• IEC 61508

• IEC 61511

• Rosemount TankRadar Rex Installation Manual,

Ref. no. 308014EN

• Rosemount TankRadar Rex Service Manual,

Ref. no. 308012EN

• Rosemount TankRadar Rex Special Safety Instruction,

Ref. no. 308016E

• TankMaster WinSetup User’s Guide, Ref. no. 303027EN

• Rosemount TankRadar REX Technical Description,

Ref. no. 703010EN.

Safety Manual

308020EN, Edition 1

June 2007

2

Safety Manual

308020EN, Edition 1

June 2007

3. Scope of the Product

3.1 Purpose of the Product

The Rosemount TankRadar Rex 3900 Series is designed for high

performance level gauging in various types of storage tanks.

Temperature sensors, remote display unit, water level sensors,

pressure sensors, and other devices can be connected. Two

relays are available for alarm indication and overfill and dry run

protection.

3.2 Assumptions and Restrictions

Install the TankRadar Rex according to the instructions in this

document. The Rosemount TankRadar Rex Installation Manual

and the Rosemount TankRadar Rex Special Safety Instruction

provide further instructions for a safe installation.

Rosemount TankRadar Rex

Chapter 3 Scope of the Product

Note that the TankRadar Rex is not safety-rated during

maintenance work, configuration changes, or other activity that

affects the Safety Function. Alternative means should be used to

ensure process safety during such activities.

False echoes within the radar beam from flat obstructions with a

sharp edge may lead to a situation where the TankRadar Rex can

no longer be used for safety related functions with the listed failure

rates, Safe Failure Fraction and PFD

. However, reduced proof

AVG

test intervals can help to detect such unwanted causes.

Operating conditions are available in the TankRadar Rex

Technical Description, ref no. 703010EN.

3.3 Functional Specification of the Safety Functions

The Safety Function is based on the relay output (one or two

relays) used as the primary safety variable for overfill and dry run

protection. The relay function is configured to activate the alarm

mode at a preset product Level or product Ullage (Ullage is the

space between the top of the tank and the product surface).

3

Rosemount TankRadar Rex

Chapter 3 Scope of the Product

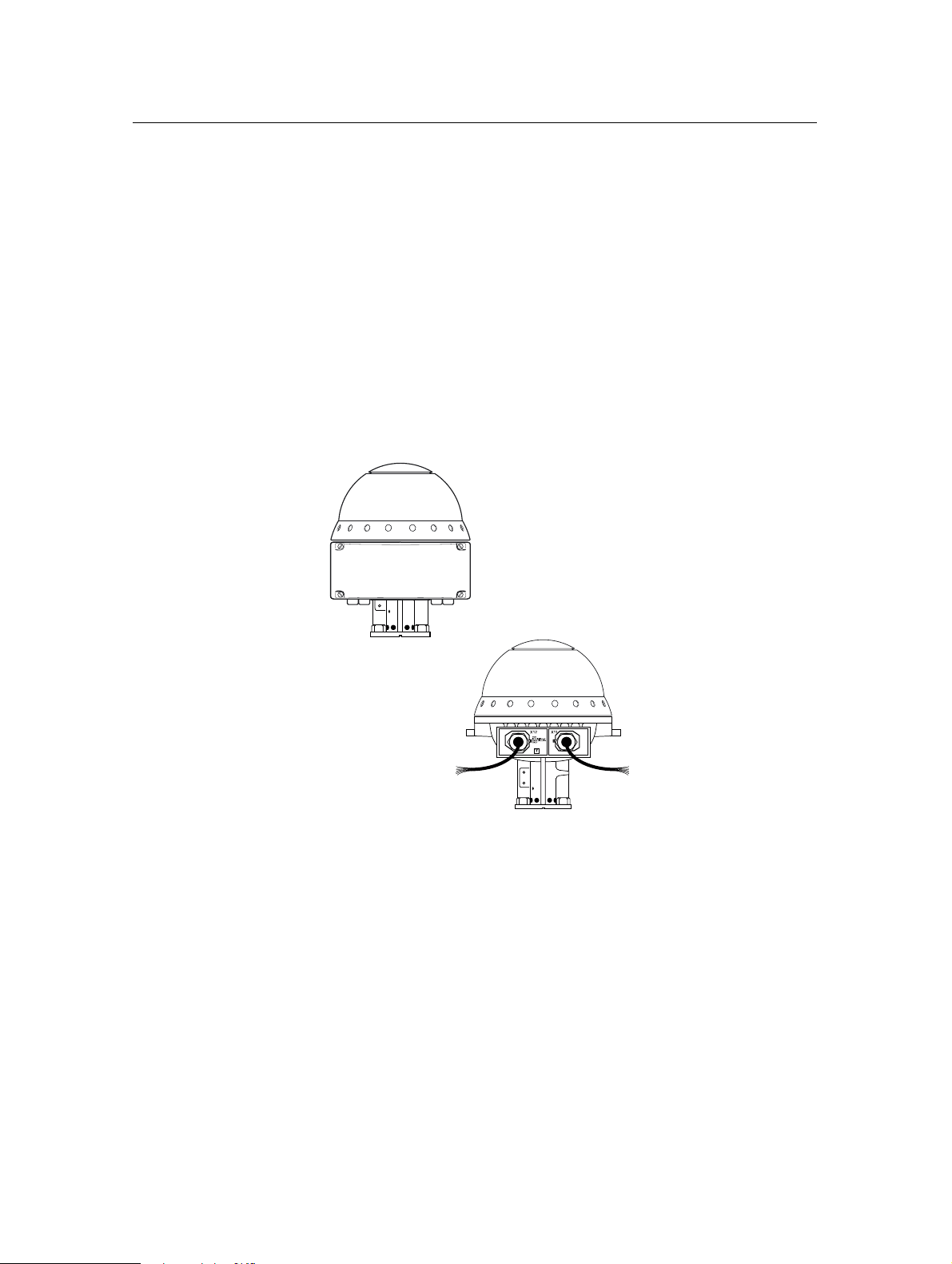

TankRadar Rex is equipped with two cable outputs for intrinsically

safe and non-intrinsically safe connections, respectively. Wires

are clearly marked with numbers and designation of wires is

shown on a printed plate at the cable outputs. The transmitter can

also be equipped with an Integrated Junction Box (JBi).

W1 1 is for the relays, the TRL/2 Bus, and the non-intrinsically safe

power supply.

W12 is for the intrinsically safe connection of Data Acquisition Unit

(DAU), Remote Display Unit RDU40, analog inputs, and

temperature sensors.

Safety Manual

308020EN, Edition 1

June 2007

Integrated Junction Box (JBi)

W12 Intrinsically

safe connections

W11 Non-Intrinsically

safe connections

Figure 1. Electrical connections on the TankRadar REX.

Connect to the relay ports on the W11 side, or to the X11 terminal

if the TankRadar REX with Integrated Junction Box JBi is used:

4

Safety Manual

308020EN, Edition 1

June 2007

Rosemount TankRadar Rex

Chapter 3 Scope of the Product

K1A

K1B

K2A

K2B

relay K1relay K1relay K1

relay K2

Figure 2. Connecting to the relay ports via Integrated Junction

Box (JBi).

Note! Depending on system configuration one or two relays are available.

3.3.1 Safety Function Using One Relay

The Safety Function is based on the relay output (relay K1 or relay

K2) used as the primary safety variable for overfill and dry run

protection. The Safety Function requires that the relay output is

configured as Normally Open. Normally Open refers to the

contact position when the relay is de-energized. This is also

referred to as the Alarm state. The terminology for Normally Open

can be summarized as described in Table 1 below:

Normally Open

Open Closed

De-energized Energized

Not active Active

Alarm (reset) Normal

Table 1. Relay terminology for relays configured as Normally

Open.

See the TankRadar REX Installation Manual for information on

how to configure the Relay Output Card (ROC) for operation in

Normally Open mode.

5

Rosemount TankRadar Rex

Chapter 3 Scope of the Product

3.3.2 Safety Function Using Two Relays in Series

This Safety Function is based on the two relay outputs coupled in

series used as the primary safety variable for overfill and dry run

protection. The Safety Function requires that the two relay outputs

are configured as follows: one relay Normally Open and the other

relay Normally Closed.

The default setting is Normally Open for both relays K1 and K2.

See the TankRadar REX Installation Manual for information on

how to configure the Relay Output Card (ROC) for operation in

Normally Open or Normally Closed mode.

The relays are configured in such manner that when the set point

(e.g. overfill) is reached one of the relays will "pull" while the

second relay will "release". Below the set point (normal operation)

the relays will be in the positions as shown in Figure 3:

Safety Manual

308020EN, Edition 1

June 2007

A

Relay K1

Relay K2

Figure 3. A. Relay positions under normal operation.

B. Wiring diagram for Safety Function using two relays coupled in series.

B

The system state is given by the states of the two relays according

to Table 2:

System state

Normal Energized De-energized

Alarm De-energized Energized

Relay K1

(Normally Open)

Relay K2

(Normally Closed)

Alarm Energized Energized

Alarm De-energized De-energized

Table 2. System state versus relay state with Safety Function using

two relays coupled in series.

6

Loading...

Loading...