Rosemount Reference Manual: Rosemount 8800D Series Vortex Flow Meter with Modbus Manuals & Guides

Reference Manual

00809-0400-4004, Rev AB

October 2021

Rosemount™ 8800D Series Vortex Flow Meter

with Modbus Protocol

2

Reference Manual Contents

00809-0400-4004 October 2021

Contents

Rosemount™ 8800D Vortex Flowmeter................................................................................. 0

Chapter 1 Safety messages.........................................................................................................7

Chapter 2 Introduction.............................................................................................................. 9

2.1 Overview..................................................................................................................................... 9

Chapter 3 Pre-installation........................................................................................................ 11

3.1 Planning.................................................................................................................................... 11

3.2 Commissioning..........................................................................................................................15

Chapter 4 Basic installation...................................................................................................... 17

4.1 Handling....................................................................................................................................17

4.2 Flow direction............................................................................................................................17

4.3 Gaskets......................................................................................................................................17

4.4 Insulation...................................................................................................................................18

4.5 Flanged-style flow meter mounting...........................................................................................18

4.6 Wafer-style flow meter alignment and mounting...................................................................... 20

4.7 Cable glands.............................................................................................................................. 22

4.8 Flow meter grounding............................................................................................................... 22

4.9 Grounding the transmitter case.................................................................................................23

4.10 Conduit installation................................................................................................................. 24

4.11 Wiring......................................................................................................................................24

4.12 Remote installation................................................................................................................. 25

4.13 Quad transmitter numbering and orientation..........................................................................30

Chapter 5 Basic configuration.................................................................................................. 33

5.1 About basic configuration..........................................................................................................33

5.2 Connect configuration tool ....................................................................................................... 33

5.3 Process variables........................................................................................................................34

5.4 Process configuration................................................................................................................ 36

5.5 Reference K-factor.....................................................................................................................37

5.6 Flange type................................................................................................................................38

5.7 Pipe I.D...................................................................................................................................... 38

5.8 Optimize Digital Signal Processing (DSP)................................................................................... 39

5.9 Modbus communication settings.............................................................................................. 39

Chapter 6 Advanced installation...............................................................................................43

6.1 Insert integral temperature sensor.............................................................................................43

6.2 Pulse output.............................................................................................................................. 44

6.3 Transient protection.................................................................................................................. 45

Chapter 7 Advanced configuration...........................................................................................47

Reference Manual 3

Contents Reference Manual

October 2021 00809-0400-4004

7.1 LCD display................................................................................................................................ 47

7.2 Compensated K-factor...............................................................................................................47

7.3 Meter body................................................................................................................................48

7.4 Meter factor...............................................................................................................................48

7.5 Variable mapping...................................................................................................................... 48

7.6 Pulse output.............................................................................................................................. 49

7.7 Signal processing.......................................................................................................................50

7.8 Special process variable units.....................................................................................................53

7.9 Flow totalizer.............................................................................................................................54

Chapter 8 Troubleshooting...................................................................................................... 57

8.1 Communication problem with HART-based communicator.......................................................57

8.2 Incorrect Modbus communication output................................................................................. 57

8.3 Modbus communication setting fails to apply............................................................................57

8.4 Incorrect pulse output............................................................................................................... 58

8.5 Error messages on a HART-based communicator.......................................................................58

8.6 Flow in Pipe, No Output............................................................................................................. 58

8.7 No flow, output......................................................................................................................... 59

8.8 Diagnostic messages................................................................................................................. 60

8.9 Electronics test points................................................................................................................63

Chapter 9 Maintenance............................................................................................................67

9.1 Transient protection.................................................................................................................. 67

9.2 Installing the LCD indicator........................................................................................................68

9.3 Hardware replacement.............................................................................................................. 70

9.4 Return of material......................................................................................................................84

Appendix A Product Specifications..............................................................................................87

A.1 Physical specifications............................................................................................................... 87

A.2 Performance specifications........................................................................................................91

A.3 Typical flow rates.......................................................................................................................96

A.4 HART specifications.................................................................................................................104

A.5 Modbus RS-485 specifications................................................................................................. 108

A.6 LCD indicator functional specifications.................................................................................... 108

A.7 Quality certificate details.........................................................................................................110

Appendix B Spacers.................................................................................................................. 113

Appendix C Electronics verification........................................................................................... 115

C.1 Electronics verification using flow simulation mode.................................................................115

C.2 Fixed flow rate simulation........................................................................................................116

C.3 Varying flow rate simulation....................................................................................................116

C.4 Verify electronics using an external frequency generator.........................................................116

C.5 Output variable calculations with known input frequency........................................................118

C.6 Unit conversion table...............................................................................................................119

4 Rosemount™ 8800D Series Vortex Flow Meter with Modbus Protocol

Reference Manual Contents

00809-0400-4004 October 2021

C.7 Example calculations............................................................................................................... 119

Appendix D Modbus details.......................................................................................................125

D.1 Byte transmission order...........................................................................................................125

D.2 Input registers (Modbus function code 4)................................................................................125

D.3 Holding registers (Modbus function code 3)............................................................................128

Reference Manual 5

Contents Reference Manual

October 2021 00809-0400-4004

6 Rosemount™ 8800D Series Vortex Flow Meter with Modbus Protocol

Reference Manual Safety messages

00809-0400-4004 October 2021

1 Safety messages

WARNING

Explosion hazards. Failure to follow these instructions could cause an explosion,

resulting in death or serious injury.

• Verify the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

• Installation of this transmitter in an explosive environment must be in accordance

with the appropriate local, national, and international standards, codes, and

practices. Review the approvals documents for any restrictions associated with a safe

installation.

• Do not remove transmitter covers or thermocouple (if equipped) in explosive

atmospheres when the circuit is live. Both transmitter covers must be fully engaged

to meet explosion-proof requirements.

• Before connecting a hand-held communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

WARNING

Electrical shock hazard. Failure to follow this instruction could result in death or serious

injury. Avoid contact with the leads and terminals. High voltage that may be present on

leads can cause electrical shock.

WARNING

General hazard. Failure to follow these instructions could result in death or serious

injury.

• This product is intended to be used as a flowmeter for liquid, gas, or steam

applications. Do not use for any other purpose.

• Make sure only qualified personnel perform the installation.

Reference Manual 7

Safety messages Reference Manual

October 2021 00809-0400-4004

8 Rosemount™ 8800D Series Vortex Flow Meter with Modbus Protocol

Reference Manual Introduction

00809-0400-4004 October 2021

2 Introduction

2.1 Overview

System description

The Vortex Flow Meter consists of a meter body and transmitter, and measures volumetric

flow rate by detecting the vortices created by a fluid passing by the shedder bar.

The meter body is installed in-line with process piping. A sensor is located at the end of the

shedder bar which creates a sine wave signal due to the passing vortices. The transmitter

measures the frequency of the sine wave and converts it into a flow rate.

Safety messages

Procedures and instructions in this manual may require special precautions to ensure the

safety of the personnel performing the operations. Refer to the safety messages listed at

the beginning of this document, before performing any operations.

Chapters

Section Who uses Description

Pre-installation Planners and

installers

Basic installation Planners and

installers

Basic

configuration

Advanced

installation

Advanced

configuration

Operation Operations

Troubleshooting Installers and

Maintenance Operations

Operations

technicians

Installers Installation procedures required after initial setup for

Operations

technicians

technicians

operations

technicians

technicians

Reference information to help you verify compatibility

between the meter and its application and installation

location

Mechanical and electrical installation instructions typically

required as initial setup in all applications

Configuration parameters typically required as initial setup

in all applications

some applications

Configuration procedures required after initial setup for

some applications

Information on advanced configuration parameters and

functions that can aid in maintaining the flow meter

Troubleshooting techniques, diagnostic information, and

transmitter verification procedures

Information on maintaining the flow meter

Appendixes

Appendixes include supplementary information that may be useful in some situations.

Reference Manual 9

Introduction Reference Manual

October 2021 00809-0400-4004

10 Rosemount™ 8800D Series Vortex Flow Meter with Modbus Protocol

Reference Manual Pre-installation

00809-0400-4004 October 2021

3 Pre-installation

3.1 Planning

3.1.1 Sizing

To determine the correct meter size for optimal flow meter performance:

• Determine the limits of measuring flow.

• Determine the process conditions so that they are within the stated requirements for

Reynolds number and velocity.

Sizing calculations are required to select the proper flow meter size. These calculations

provide pressure loss, accuracy, and minimum and maximum flow rate data to guide in

proper selection. Vortex sizing software can be found using the Selection and Sizing tool.

The Selection and Sizing tool can be accessed online or downloaded for offline use using

this link: www.Emerson.com/FlowSizing.

3.1.2

3.1.3

Wetted material selection

Ensure that the process fluid is compatible with the meter body wetted materials when

specifying the Rosemount 8800D. Corrosion will shorten the life of the meter body.

Consult recognized sources of corrosion data or contact technical support for more

information.

Note

If Positive Material Identification (PMI) is required, perform test on a machined surface.

Orientation

The best orientation for the meter depends on the process fluid, environmental factors,

and any other nearby equipment.

Vertical installation

Vertical, upward, installation allows upward process liquid flow and is generally preferred.

Upward flow ensures that the meter body always remains full and that any solids in the

fluid are evenly distributed.

The meter can be mounted in the vertical down position when measuring gas or steam

flows. This type of application is strongly discouraged for liquid flows, although it can be

done with proper piping design.

Reference Manual 11

Pre-installation Reference Manual

October 2021 00809-0400-4004

Figure 3-1: Vertical installation

A B

A. Liquid or gas flow

B. Gas flow

Note

To ensure the meter body remains full, avoid downward vertical liquid flows where back

pressure is inadequate.

Horizontal installation

For horizontal installation, the preferred orientation is to have the electronics installed to

the side of the pipe. In liquid applications, this helps prevent any entrained air or solids

from striking the shedder bar and disrupting the shedding frequency. In gas or steam

applications, this helps prevent any entrained liquid (such as condensate) or solids from

striking the shedder bar and disrupting the shedding frequency.

Figure 3-2: Horizontal installation

B

A

A. Preferred installation—meter body installed with electronics to side of pipe

B. Acceptable installation—meter body installed with electronics above pipe

High-temperature installations

The maximum process temperature for integral electronics is dependent on the ambient

temperature where the meter is installed. The electronics must not exceed 185 °F (85 °C).

Figure 3-3 shows combinations of ambient and process temperatures needed to maintain

a housing temperature of less than 185 °F (85 °C).

12 Rosemount™ 8800D Series Vortex Flow Meter with Modbus Protocol

Reference Manual Pre-installation

00809-0400-4004 October 2021

Figure 3-3: Ambient/Process temperature limits

200 (93)

180(82)

160 (71)

600 (316)

700 (371)

C

800 (427)

900 (482)

1000 (538)

A

140 (60)

120 (49)

100 (38)

80 (27)

60 (16)

0

100 (38)

200 (93)

300 (149)

400 (204)

500 (260)

B

A. Ambient temperature °F (°C)

B. Process temperature °F (°C)

C. 185 °F (85 °C) Housing temperature limit.

Note

The indicated limits are for horizontal pipe and vertical meter position, with meter and

pipe insulated with 3 in. (77 mm) of ceramic fiber insulation.

Install the meter body so the electronics are positioned to the side of the pipe or below the

pipe as shown in Figure 3-4. Insulation may also be required around the pipe to maintain

an electronics temperature below 185 °F (85 °C). See Figure 4-2 for special insulation

considerations.

Figure 3-4: Examples of high-temperature installations

B

A

A. Preferred installation—The meter body installed with the electronics to the side of the

pipe.

B. Acceptable installation—The meter body installed with the electronics below the pipe.

3.1.4

Location

Hazardous area

The transmitter has an explosion-proof housing and circuitry suitable for intrinsically safe

and non-incendive operation. Individual transmitters are clearly marked with a tag

Reference Manual 13

Pre-installation Reference Manual

October 2021 00809-0400-4004

indicating the certifications they carry. For hazardous location installation, including

Explosion-proof, Flameproof,or Intrinsic Safety (I.S.), please consult the Emerson 8800

Approval Document 00825-VA00-0001.

Environmental considerations

Avoid excessive heat and vibration to ensure maximum flow meter life. Typical problem

areas include high-vibration lines with integrally mounted electronics, warm-climate

installations in direct sunlight, and outdoor installations in cold climates.

Although the signal conditioning functions reduce susceptibility to extraneous noise,

some environments are more suitable than others. Avoid placing the flow meter or its

wiring close to devices that produce high intensity electromagnetic and electrostatic

fields. Such devices include electric welding equipment, large electric motors and

transformers, and communication transmitters.

Upstream and downstream piping

The meter may be installed with a minimum of ten diameters (D) of straight pipe length

upstream and five diameters (D) of straight pipe length downstream.

To achieve reference accuracy, straight pipe lengths of 35D upstream and 5D downstream

are required. The value of the K-factor may shift up to 0.5% when the upstream straight

pipe length is between 10D and 35D. For optional K-factor corrections, see Rosemount

™

8800 Vortex Installation Effects Technical Data Sheet.

Steam piping

For steam applications, avoid installations such as the one shown in the following figure.

Such installations may cause a water-hammer condition at start-up due to trapped

condensation. The high force from the water hammer can stress the sensing mechanism

and cause permanent damage to the sensor.

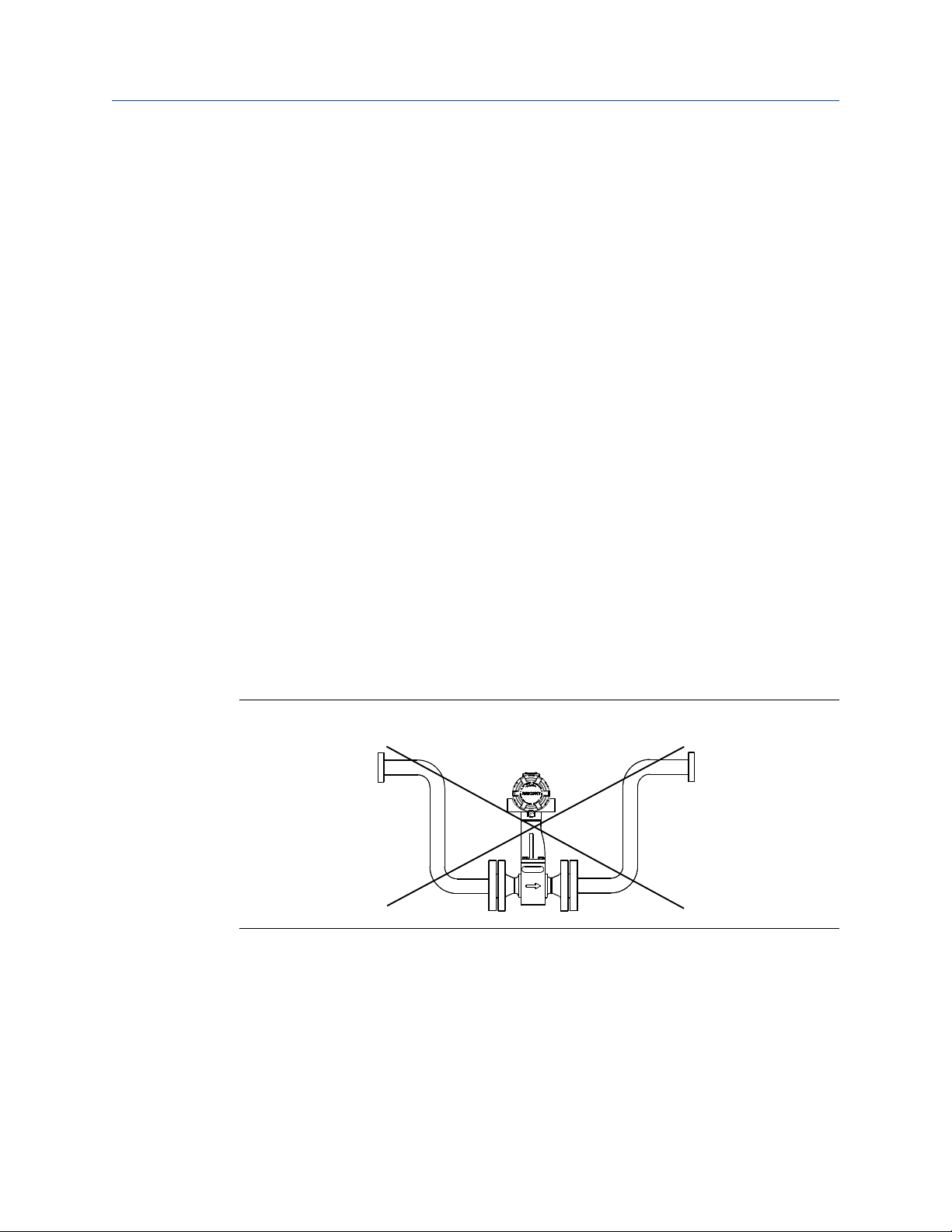

Figure 3-5: Wrong steam pipe installation

Pressure and temperature transmitter location

When using pressure and temperature transmitters in conjunction with the vortex flow

meter for compensated mass flows, install the transmitter(s) downstream of the vortex

flow meter.

14 Rosemount™ 8800D Series Vortex Flow Meter with Modbus Protocol

Reference Manual Pre-installation

00809-0400-4004 October 2021

Figure 3-6: Pressure and temperature transmitter location

C

A

B

D

A. Pressure transmitter

B. Four straight pipe diameters downstream

C. Temperature transmitter

D. Six straight pipe diameters downstream

3.1.5

Power supply

The transmitter requires 10 to 30 VDC. The maximum power consumption is 0.4 W.

3.2 Commissioning

For proper configuration and operation, commission the meter before putting it into

operation. Bench commissioning also enables you to check hardware settings, test the

flowmeter electronics, verify flowmeter configuration data, and check output variables.

Any problems can be corrected—or configuration settings changed—before going out into

the installation environment. To commission on the bench, connect a configuration

device to the signal loop in accordance the device instructions.

3.2.1

Alarm and security jumper configuration

Two jumpers on the transmitter specify the alarm and security modes. Set these jumpers

during the commissioning stage to avoid exposing the electronics to the plant

environment. The two jumpers can be found on the electronics board stack or on the LCD

display.

Alarm

Security

The jumper setting for Alarm has no effect when the HART address is set to 1,

which is the required setting for the transmitter when configured for use on a

Modbus network.

You can protect the configuration data with the security lockout jumper. With

the security lockout jumper ON, any configuration changes attempted on the

electronics are disallowed. You can still access and review any of the operating

parameters and scroll through the available parameters, but no changes can

be made. The factory sets the jumper according to the Configuration Data

Sheet, if applicable, or OFF by default.

Reference Manual 15

Pre-installation Reference Manual

October 2021 00809-0400-4004

Note

If you will be changing configuration variables frequently, it may be useful to

leave the security lockout jumper in the OFF position to avoid exposing the

flow meter electronics to the plant environment.

To access the jumpers, remove the transmitter electronics housing or the LCD cover (if

equipped) opposite of the terminal block, See Figure 3-7 and Figure 3-8.

Figure 3-7: Alarm and security jumpers (no LCD option)

VORTEX

4-20mA

HART

TEST FREQ

IN

3.2.2

TP1

Figure 3-8: Alarm and security jumpers (with LCD option)

HI LO

HI LO

ALARM

ALARM

FLOW

SECURITY

SECURITY

ON OFF

ON OFF

Calibration

The flow meter is wet-calibrated at the factory and needs no further calibration during

installation. The calibration factor (K-factor) is indicated on each meter body and is

entered into the electronics. Verification can be accomplished with a configuration device.

16 Rosemount™ 8800D Series Vortex Flow Meter with Modbus Protocol

Reference Manual Basic installation

00809-0400-4004 October 2021

4 Basic installation

4.1 Handling

Handle all parts carefully to prevent damage. Whenever possible, transport the system to

the installation site in the original shipping containers. Keep the shipping plugs in the

conduit connections until you are ready to connect and seal them.

NOTICE

To avoid damage to the meter, do not lift the flow meter by the transmitter. Lift the meter

by the meter body. Lifting supports can be tied around the meter body as shown.

Figure 4-1: Lifting supports

4.2 Flow direction

The meter can only measure flow in the direction indicated on the meter body. Be sure to

mount the meter body so the FORWARD end of the flow arrow points in the direction of

the flow in the pipe.

4.3 Gaskets

The flow meter requires gaskets supplied by the user. Be sure to select gasket material

that is compatible with the process fluid and pressure ratings of the specific installation.

Note

Ensure the inside diameter of the gasket is larger than the inside diameter of the flow

meter and adjacent piping. If gasket material extends into the flow stream, it will disturb

the flow and cause inaccurate measurements.

Reference Manual 17

Basic installation Reference Manual

October 2021 00809-0400-4004

4.4 Insulation

Insulation should extend to the end of the bolt on the bottom of the meter body and

should leave at least 1-in. (25 mm) of clearance around the electronics bracket. The

electronics bracket and electronics housing should not be insulated. See Figure 4-2.

Figure 4-2: Insulation best practice to prevent electronics overheating

A. Support tube

CAUTION

In high temperature installations, to avoid damage to the electronics on integral units or

to the remote cable on remote units, only insulate the meter body as shown. Do not

insulate the support tube. See also Orientation.

4.5 Flanged-style flow meter mounting

Most vortex flow meters use a flanged-style process connection. Physical mounting of a

flanged-style flow meter is similar to installing a typical section of pipe. Conventional

tools, equipment, and accessories (such as bolts and gaskets) are required. Tighten the

nuts following the sequence shown in Figure 4-4.

Note

The required bolt load for sealing the gasket joint is affected by several factors, including

operating pressure and gasket material, width, and condition. A number of factors also

affect the actual bolt load resulting from a measured torque, including condition of bolt

threads, friction between the nut head and the flange, and parallelism of the flanges. Due

to these application-dependent factors, the required torque for each application may be

different. Follow the guidelines outlined in ASME PCC-1 for proper bolt tightening. Make

sure the flow meter is centered between flanges of the same nominal size and rating as

the flow meter.

18 Rosemount™ 8800D Series Vortex Flow Meter with Modbus Protocol

Reference Manual Basic installation

00809-0400-4004 October 2021

Figure 4-3: Flanged-style flow meter installation

A. Installation studs and nuts (supplied by customer)

B. Gaskets (supplied by customer)

C. Flow

Figure 4-4: Flange bolt torquing sequence

Reference Manual 19

Basic installation Reference Manual

October 2021 00809-0400-4004

4.6 Wafer-style flow meter alignment and mounting

Center the wafer-style meter body inside diameter with respect to the inside diameter of

the adjoining upstream and downstream piping. This will ensure the flow meter achieves

its specified accuracy. Alignment rings are provided with each wafer-style meter body for

centering purposes. Follow these steps to align the meter body for installation. Refer to

Figure 4-5.

1. Place the alignment rings over each end of the meter body.

2. Insert the studs for the bottom side of the meter body between the pipe flanges.

3. Place the meter body (with alignment rings) between the flanges.

• Make sure the alignment rings are properly placed onto the studs.

• Align the studs with the markings on the ring that correspond to the flange you

are using.

Note

Be sure to align the flow meter so the electronics are accessible, the conduits drain,

and the flow meter is not subject to direct heat.

4. Place the remaining studs between the pipe flanges.

5. Tighten the nuts in the sequence shown in Figure 4-4.

6. Check for leaks at the flanges after tightening the flange bolts.

Note

The required bolt load for sealing the gasket joint is affected by several factors,

including operating pressure and gasket material, width, and condition. A number

of factors also affect the actual bolt load resulting from a measured torque,

including condition of bolt threads, friction between the nut head and the flange,

and parallelism of the flanges. Due to these application-dependent factors, the

required torque for each application may be different. Follow the guidelines

outlined in ASME PCC-1 for proper bolt tightening. Make sure the flow meter is

centered between flanges of the same nominal size and rating as the flow meter.

20 Rosemount™ 8800D Series Vortex Flow Meter with Modbus Protocol

Reference Manual Basic installation

00809-0400-4004 October 2021

Figure 4-5: Wafer-style flow meter installation with alignment rings

B

B

A

4.6.1

C

D

A. Installation studs and nuts (supplied by customer)

B. Alignment rings

C. Spacer (for Rosemount 8800D to maintain Rosemount 8800A dimensions)

D. Flow

Note

See for instructions on retrofitting 8800D to 8800A installations.

Stud bolts for wafer-style flow meters

The following tables list the recommended minimum stud bolt lengths for wafer-style

meter body size and different flange ratings.

Table 4-1: Stud bolt length for wafer-style flow meters with ASME B16.5 flanges

Line size Minimum recommended stud bolt lengths (in inches) for each flange

rating

Class 150 Class 300 Class 600

½-inch 6.00 6.25 6.25

1-inch 6.25 7.00 7.50

1½-inch 7.25 8.50 9.00

2-inch 8.50 8.75 9.50

3-inch 9.00 10.00 10.50

4-inch 9.50 10.75 12.25

6-inch 10.75 11.50 14.00

8-inch 12.75 14.50 16.75

Reference Manual 21

Basic installation Reference Manual

October 2021 00809-0400-4004

Table 4-2: Stud bolt length for wafer-style flow meters with EN 1092 flanges

Line size Minimum recommended stud bolt lengths (in mm) for each flange rating

PN 16 PN 40 PN 63 PN 100

DN 15 160 160 170 170

DN 25 160 160 200 200

DN 40 200 200 230 230

DN 50 220 220 250 270

DN 80 230 230 260 280

DN 100 240 260 290 310

DN 150 270 300 330 350

DN 200 320 360 400 420

Line size Minimum recommended stud bolt lengths (in mm) for each flange

rating

JIS 10k JIS 16k and 20k JIS 40k

15mm 150 155 185

25mm 175 175 190

40mm 195 195 225

50mm 210 215 230

80mm 220 245 265

100mm 235 260 295

150mm 270 290 355

200mm 310 335 410

4.7 Cable glands

If you are using cable glands instead of conduit, follow the cable gland manufacturer’s

instructions for preparation and make the connections in a conventional manner in

accordance with local or plant electrical codes. Be sure to properly seal unused ports to

prevent moisture or other contamination from entering the terminal block compartment

of the electronics housing.

4.8 Flow meter grounding

Grounding is not required in typical vortex applications; however, a proper ground will

eliminate possible noise pickup by the electronics. Grounding straps may be used to

ensure that the meter is grounded to the process piping. If you are using the transient

protection option (T1), grounding straps are required to provide a proper low impedance

ground.

22 Rosemount™ 8800D Series Vortex Flow Meter with Modbus Protocol

Reference Manual Basic installation

00809-0400-4004 October 2021

Note

Properly ground flow meter body and transmitter per the local code.

To use grounding straps, secure one end of the grounding strap to the bolt extending from

the side of the meter body and attach the other end of each grounding strap to a suitable

ground. See Figure 4-6.

Figure 4-6: Grounding connections

A. Internal ground connection

B. External ground assembly

4.9 Grounding the transmitter case

The transmitter case should always be grounded in accordance with national and local

electrical codes. The most effective transmitter case grounding method is direct

connection to earth ground with minimal impedance. Methods for grounding the

transmitter case include:

Internal

Ground

Connection

External

Ground

Assembly

Note

Grounding the transmitter case using the threaded conduit connection may not provide a

sufficient ground. The transient protection terminal block (Option Code T1) does not

provide transient protection unless the transmitter case is properly grounded. For

transient terminal block grounding, see Transient protection. Use the above guidelines to

The Internal Ground Connection screw is inside the FIELD TERMINALS

side of the electronics housing. This screw is identified by a ground

symbol ( ), and is standard on all Rosemount 8800D transmitters.

This assembly is located on the outside of the electronics housing and

is included with the optional transient protection terminal block

(Option Code T1). The External Ground Assembly can also be ordered

with the transmitter (Option Code V5) and is automatically included

with certain hazardous area approvals. See Figure 4-6 for the location

of the external ground assembly.

Reference Manual 23

Basic installation Reference Manual

October 2021 00809-0400-4004

ground the transmitter case. Do not run the transient protection ground wire with signal

wiring as the ground wire may carry excessive electric current if a lightning strike occurs.

4.10 Conduit installation

Prevent condensation in any conduit from flowing into the housing by mounting the

flowmeter at a high point in the conduit run. If the flowmeter is mounted at a low point in

the conduit run, the terminal compartment could fill with fluid.

If the conduit originates above the flowmeter, route conduit below the flowmeter to form

a drip loop before entry. In some cases a drain seal may need to be installed.

Figure 4-7: Proper conduit installation

A A

A. Conduit line

4.11 Wiring

1. Supply 10–30 VDC to the positive (+) and negative (–) terminals. The power

terminals are polarity insensitive: the polarity of the DC power leads does not

matter when connecting to the power terminals.

24 Rosemount™ 8800D Series Vortex Flow Meter with Modbus Protocol

Reference Manual Basic installation

00809-0400-4004 October 2021

Figure 4-8: Modbus and power supply wiring

C

A. RS-485 (A)

B. RS-485 (B)

C. 10–30 VDC power supply

2. Connect Modbus RTU communication wires to the Modbus A and B terminals.

Note

Twisted pair wiring is required for RS-485 bus wiring. Wiring runs under 1000 ft

(305 m) should be AWG 22 or larger. Wiring runs from 1000 to 4000 ft. (305 to

1219 m) should be AWG 20 or larger. Wiring should not exceed AWG 16.

4.12 Remote installation

If a remote electronics option (Rxx or Axx) was ordered, the flow meter assembly will be

shipped in two parts:

• The meter body with an adapter installed in the support tube and an interconnecting

coaxial cable attached to it.

B

A

• The electronics housing installed on a mounting bracket.

If an armored remote electronics option (Axx) was ordered, follow the same instructions as

for the standard remote cable connection with the exception that the cable may not need

to be run through conduit. Both standard and armored cable include cable glands.

Information on remote installation can be found in Cable connections.

4.12.1

Reference Manual 25

Mounting

Mount the meter body in the process flow line as described earlier in this section. Mount

the bracket and electronics housing in the desired location. The housing can be

repositioned on the bracket to facilitate field wiring and conduit routing.

Basic installation Reference Manual

October 2021 00809-0400-4004

4.12.2 Cable connections

Complete these steps for connecting the loose end of the coaxial cable to the electronics

housing. If connecting/disconnecting the meter adapter to the meter body,.

Figure 4-9: Remote installation

A

B

C

D

E

F

G

H

P

O

N

J

K

I

M

L

A. ½ NPT conduit adapter or cable gland (supplied by customer for Rxx options)

B. Coaxial cable

C. Meter adapter

D. Union

E. Washer

F. Nut

G. Sensor cable nut

H. Support tube

I. Meter body

J. Electronics housing

K. Coaxial cable SMA nut

L. ½ NPT conduit adapter or cable gland (supplied by customer for Rxx options)

M. Housing adapter screws

N. Housing adapter

O. Housing base screw (one of four)

P. Ground connection

26 Rosemount™ 8800D Series Vortex Flow Meter with Modbus Protocol

Reference Manual Basic installation

00809-0400-4004 October 2021

CAUTION

To prevent moisture from entering the coaxial cable connections, install the

interconnecting coaxial cable in a single dedicated conduit run or use sealed cable

glands at both ends of the cable.

In remote mount configurations when ordered with a hazardous area option code, the

remote sensor cable and the interconnecting thermocouple cable are protected by

separate intrinsic safety circuits, and must be segregated from each other, other

intrinsically safe circuits, and non-intrinsically safe circuits per local and national wiring

code.

CAUTION

The coaxial remote cable cannot be field terminated or cut to length. Coil any extra

coaxial cable with no less than a 2-in. (51 mm) radius.

1. If you plan to run the coaxial cable in conduit, carefully cut the conduit to the

desired length to provide for proper assembly at the housing. A junction box may

be placed in the conduit run to provide a space for extra coaxial cable length.

2. Slide the conduit adapter or cable gland over the loose end of the coaxial cable and

fasten it to the adapter on the meter body support tube. If coaxial remote cable

originates or any part of the cable is above the flow meter, route cable below the

flow meter to form a drip loop before the meter body support tube.

3. If using conduit, route the coaxial cable through the conduit.

4. Place a conduit adapter or cable gland over the end of the coaxial cable.

5. Remove the housing adapter from the electronics housing.

6. Slide the housing adapter over the coaxial cable.

7. Remove one of the four housing base screws.

8. Attach the coaxial cable ground wire to the housing via the housing base ground

screw.

9. Attach and hand tighten the coaxial cable SMA nut to the electronics housing to 7

in-lbs (0.8 N-m).

Reference Manual 27

Basic installation Reference Manual

October 2021 00809-0400-4004

Figure 4-10: Attaching and tightening SMA nut

A

B

A. SMA nut

B. Hand tighten

Note

Do not over-tighten the coaxial cable nut to the electronics housing.

4.12.3

10. Align the housing adapter with the housing and attach with two screws.

11. Tighten the conduit adapter or cable gland to the housing adapter.

Housing rotation

The entire electronics housing may be rotated in 90° increments for easy viewing. Use the

following steps to change the housing orientation,

1. Loosen the housing rotation set screws at the base of the electronics housing with a

5/32” hex wrench by turning the screws clockwise (inward) until they clear the

support tube.

2. Slowly pull the electronics housing out of the support tube.

CAUTION

Do not pull the housing more than 1.5 in. (40 mm) from the top of the support

tube until the sensor cable is disconnected. Damage to the sensor may occur if

this sensor cable is stressed.

3. Unscrew the sensor cable from the housing with a 5/16” open end wrench.

4. Rotate the housing to the desired orientation.

5. Hold it in this orientation while you screw the sensor cable onto the base of the

housing.

CAUTION

Do not rotate the housing while the sensor cable is attached to the base of the

housing. This will stress the cable and may damage the sensor.

6. Place the electronics housing into the top of the support tube.

28 Rosemount™ 8800D Series Vortex Flow Meter with Modbus Protocol

Reference Manual Basic installation

00809-0400-4004 October 2021

7. Use a hex wrench to turn the housing rotation screws counter-clockwise (outward)

to engage the support tube.

4.12.4 Specifications and requirements for remote sensor cable

If using a Rosemount remote sensor cable, observe these specifications and requirements.

• The remote sensor cable is a proprietary design tri-axial cable

• It is considered a low voltage signal cable

• It is rated for and/or part of intrinsically safe installations

• Non armored version is designed to be run through metal conduit

• Cable is water resistant, but not submersible. As a best practice, exposure to moisture

should be avoided if possible

• Rated operating temperature is –58°F to +392°F (–50°C to +200°C)

• Flame Resistant in accordance with IEC 60332-3

• Non-armored and armored version minimum bend diameter is 8 inches (203 mm)

• Nominal O.D. of the non-armored version is 0.160 inches (4 mm)

• Nominal O.D. of the armored version is 0.282 inches (7.1 mm)

Figure 4-11: Non-armored cable

A. Transmitter end

B. Sensor end

C. Minimum bend diameter

D. Nominal O.D.

Reference Manual 29

Basic installation Reference Manual

October 2021 00809-0400-4004

Figure 4-12: Armored cable

A. Transmitter end

B. Sensor end

C. Minimum bend diameter

4.13 Quad transmitter numbering and orientation

When quad vortex flow meters are ordered, for configuration purposes, the transmitters

are identified as Transmitter 1, Transmitter 2, Transmitter 3, and Transmitter 4. The

transmitter and meter body nameplate of a Quad Vortex flow meter can be used to

identify and verify the transmitter number. See Figure 4-13 for Quad transmitter

orientation and nameplate locations. See Figure 4-14 and 4-15 for Quad transmitter and

meter body nameplate number location.

30 Rosemount™ 8800D Series Vortex Flow Meter with Modbus Protocol

Loading...

Loading...