Rosemount Reference Manual: Rosemount 3051 Pressure Transmitter with HART(R) Protocol Manuals & Guides

Reference Manual

00809-0100-4007, Rev BC

Rosemount™ 3051 Pressure Transmitter

with 4-20 mA HART® Revision 5 and 7 Selectable Protocol

July 2020

Safety messages

NOTICE

Read this manual before working with the product. For personal and system safety and for optimum product performance, ensure

you thoroughly understand the contents before installing, using, or maintaining this product.

For technical assistance, contacts are listed below:

Customer Central (Technical support, quoting, and order-related questions.)

• United States: 1-800-999-9307 (7:00 am to 7:00 pm Central Time)

• Asia Pacific: 65 777 8211

• Europe/Middle East/Africa: 49 (8153) 9390

North American Response Center (Equipment service needs.): 1-800-654-7768 (24 hours - includes Canada)

Outside of these areas, contact your local Emerson representative.

WARNING

Explosions

Explosions could result in death or serious injury.

In an explosion-proof/flameproof installation, do not remove the transmitter covers when power is applied to the unit.

Installation of device in an explosive environment must be in accordance with appropriate local, national, and international

standards, codes, and practices. Review the Product Certifications section of the Rosemount 3051 Product Data Sheet for any

restrictions associated with a safe installation.

Before connecting a handheld communicator in an explosive atmosphere, ensure the instruments are installed in accordance

with intrinsically safe or non-incendive field wiring practices.

Process leaks

Process leaks may cause harm or result in death.

Install and tighten process connectors before applying pressure.

Do not attempt to loosen or remove flange bolts while the transmitter is in service.

Electrical shock

Electrical shock can result in death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads can cause electrical shock.

Replacement equipment

Replacement equipment or spare parts not approved by Emerson for use as spare parts could reduce the pressure retaining

capabilities of the transmitter and may render the instrument dangerous.

Use only bolts supplied or sold by Emerson as spare parts.

Improper assembly

Improper assembly of manifolds to traditional flange can damage sensor module.

For safe assembly of manifold to traditional flange, bolts must break back plane of flange web (i.e., bolt hole) but must not

contact sensor module housing.

Severe changes in the electrical loop may inhibit HART Communication or the ability to reach alarm values. Therefore,

Rosemount absolutely cannot warrant or guarantee that the correct Failure alarm level (High or Low) can be read by the host

system at the time of annunciation.

2

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of end users’ equipment. This could

be intentional or unintentional and needs to be protected against.

Physical security is an important part of any security program and fundamental to protecting your system. Restrict physical access

by unauthorized personnel to protect end users’ assets. This is true for all systems used within the facility.

CAUTION

Nuclear applications

The products described in this document are not designed for nuclear-qualified applications. Using non-nuclear qualified products

in applications that require nuclear-qualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson Sales Representative.

3

4

Reference Manual Contents

00809-0100-4007 July 2020

Contents

Chapter 1 Introduction.............................................................................................................. 7

1.1 Using this manual........................................................................................................................ 7

1.2 Models covered........................................................................................................................... 7

1.3 Product recycling/disposal...........................................................................................................8

Chapter 2 Configuration............................................................................................................ 9

2.1 Overview..................................................................................................................................... 9

2.2 Safety messages.......................................................................................................................... 9

2.3 System readiness.......................................................................................................................10

2.4 Configuration basics.................................................................................................................. 11

2.5 Setting the loop to manual........................................................................................................ 14

2.6 Verify configuration...................................................................................................................15

2.7 Basic setup of the transmitter.................................................................................................... 16

2.8 Configuring the LCD display.......................................................................................................23

2.9 Detailed transmitter setup.........................................................................................................24

2.10 Configuring transmitter diagnostics........................................................................................ 31

2.11 Performing transmitter tests................................................................................................... 35

2.12 Configuring burst mode...........................................................................................................37

2.13 Establishing multidrop communication................................................................................... 39

Chapter 3 Hardware installation.............................................................................................. 43

3.1 Overview................................................................................................................................... 43

3.2 Safety messages........................................................................................................................ 43

3.3 Considerations...........................................................................................................................44

3.4 Installation procedures.............................................................................................................. 46

Chapter 4 Electrical installation................................................................................................67

4.1 Overview................................................................................................................................... 67

4.2 Safety messages........................................................................................................................ 67

4.3 LCD display................................................................................................................................ 68

4.4 Configuring transmitter security................................................................................................69

4.5 Set transmitter alarm.................................................................................................................72

4.6 Electrical considerations............................................................................................................ 73

Chapter 5 Operation and maintenance.....................................................................................81

5.1 Overview................................................................................................................................... 81

5.2 Safety messages........................................................................................................................ 81

5.3 Recommended calibration tasks................................................................................................82

5.4 Calibration overview..................................................................................................................83

5.5 Trim the pressure signal.............................................................................................................87

Reference Manual 5

Contents Reference Manual

July 2020 00809-0100-4007

5.6 Trim the analog output..............................................................................................................89

5.7 Switching HART® revision.......................................................................................................... 94

Chapter 6 Troubleshooting...................................................................................................... 97

6.1 Overview................................................................................................................................... 97

6.2 Safety messages........................................................................................................................ 97

6.3 Troubleshooting for 4-20 mA output......................................................................................... 98

6.4 Diagnostic messages................................................................................................................. 99

6.5 Disassembly procedures.......................................................................................................... 107

6.6 Reassemble............................................................................................................................. 109

6.7 Service support........................................................................................................................112

Chapter 7 Safety Instrumented Systems (SIS) requirements................................................... 113

7.1 Identify Rosemount 3051 safety certification...........................................................................113

7.2 Installation in SIS applications..................................................................................................113

7.3 Configuring in SIS applications.................................................................................................114

7.4 SIS operation and maintenance............................................................................................... 115

7.5 Inspection................................................................................................................................117

Appendix A Reference data....................................................................................................... 119

A.1 Ordering information, specifications, and drawings.................................................................119

A.2 Product certifications.............................................................................................................. 119

Appendix B Field Communicator menu trees and fast keys........................................................ 121

B.1 Field Communicator menu trees..............................................................................................121

B.2 Field Communicator Fast Keys................................................................................................. 125

Appendix C Local Operator Interface (LOI)................................................................................ 127

C.1 LOI menu tree..........................................................................................................................127

C.2 LOI menu tree - extended menu.............................................................................................. 128

C.3 Enter numbers in the LOI......................................................................................................... 129

C.4 Enter text in the LOI................................................................................................................. 130

6 Rosemount 3051

Reference Manual

00809-0100-4007 July 2020

Introduction

1 Introduction

1.1 Using this manual

The sections in this manual provide information on installing, operating, and maintaining

the Rosemount 3051 Pressure Transmitter. The sections are organized as follows:

Configuration provides instruction on commissioning and operating the transmitters. It

also includes information on software functions, configuration parameters, and online

variables.

Hardware installation contains mechanical installation instructions and field upgrade

options.

Electrical installation contains electrical installation instructions and field upgrade options.

Operation and maintenance provides detailed information on calibrating and changing

HART revisions.

Troubleshooting provides troubleshooting techniques for the most common operating

problems.

Safety Instrumented Systems (SIS) requirements provides identification, installation,

configuration, operation and maintenance, and inspection information for Safety

Instrumented Systems.

Reference data provides information on how to access specifications, ordering

information,and dimensional drawings.

Field Communicator menu trees and fast keys provides full menu trees and abbreviated

Fast Key sequences for commissioning tasks.

Local Operator Interface (LOI) provides detailed LOI menu trees.

1.2 Models covered

The following Rosemount 3051 Transmitters are covered by this manual:

• Rosemount 3051C Coplanar™ Pressure Transmitter

— Measures differential and gage pressure up to 2000 psi (137.9 bar).

— Measures absolute pressure up to 4000 psia (275.8 bar).

• Rosemount 3051T In-Line Pressure Transmitter

— Measures absolute pressure up to 20000 psi (1378.95 bar).

• Rosemount 3051L Liquid Level Transmitter

— Measures level and specific gravity up to 300 psi (20.7 bar).

• Rosemount 3051CF Series Flowmeter

— Measures flow in line sizes from ½-in. (15 mm) to 96-in. (2400 mm).

Note

For transmitter with FOUNDATION Fieldbus, see Rosemount 3051 Reference Manual.

Reference Manual 7

Introduction Reference Manual

July 2020 00809-0100-4007

For transmitter with PROFIBUS® PA, see Rosemount 3051 Reference Manual.

1.3 Product recycling/disposal

Consider recycling equipment. Dispose of packaging in accordance with local and national

legislations/regulations.

8 Rosemount 3051

Reference Manual Configuration

00809-0100-4007 July 2020

2 Configuration

2.1 Overview

This section contains information on commissioning and tasks that should be performed

on the bench prior to installation, as well as tasks performed after installation as described

in Configuring transmitter diagnostics.

This section also provides instructions on configuring with Field Communicator, AMS

Device Manager, and Local Operator Interface (LOI). For convenience, Field Communicator

Fast Key sequences are labeled Fast Keys, and abbreviated LOI menus are provided for each

function below.

Full Field Communicator menu trees and Fast Key sequences are available in Field

Communicator menu trees and fast keys. LOI menu trees are available in Local Operator

Interface (LOI).

2.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the

safety of the personnel performing the operations.

WARNING

Explosions

Explosions could result in death or serious injury.

Before connecting a handheld communicator in an explosive atmosphere, ensure that

the instruments in the loop are installed in accordance with intrinsically safe or nonincendive field wiring practices.

In an explosion-proof/flameproof installation, do not remove the transmitter covers

when power is applied to the unit.

Process leaks

Process leaks may cause harm or result in death.

Install and tighten process connectors before applying pressure.

Electrical shock

Electrical shock can result in death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads

can cause electrical shock.

Static electricity

Observe safe handling precautions for static-sensitive components.

Reference Manual 9

Configuration Reference Manual

July 2020 00809-0100-4007

WARNING

Conduit/cable entries

Unless marked, the conduit/cable entries in the transmitter housing use a ½–14 NPT

thread form. Entries marked “M20” are M20 × 1.5 thread form. On devices with multiple

conduit entries, all entries will have the same thread form. Only use plugs, adapters,

glands, or conduit with a compatible thread form when closing these entries.

When installing in a hazardous location, use only appropriately listed or Ex certified plugs,

glands, or adapters in cable/conduit entries.

Replacement parts

Replacement equipment or spare parts not approved by Emerson for use as spare parts

could reduce the pressure retaining capabilities of the transmitter and may render the

instrument dangerous.

Use only bolts supplied or sold by Emerson as spare parts.

Improper assembly

Improper assembly of manifolds to traditional flange can damage sensor module.

For safe assembly of manifold to traditional flange, bolts must break back plane of

flange web (i.e., bolt hole) but must not contact sensor module housing.

Severe changes in the electrical loop may inhibit HART® communication or the ability

to reach alarm values. Therefore, Rosemount cannot absolutely warrant or guarantee

that the correct Failure alarm level (High or Low) can be read by the host system at the

time of annunciation.

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or unintentional and

needs to be protected against.

Physical security is an important part of any security program and fundamental to

protecting your system. Restrict physical access by unauthorized personnel to protect end

users’ assets. This is true for all systems used within the facility.

2.3 System readiness

• If using HART®-based control or asset management systems, confirm the HART

capability of such systems prior to commissioning and installation. Not all systems can

communicate with HART Revision 7 devices.

• For instructions on how to change the HART revision of your transmitter, see Switching

HART® revision.

2.3.1

10 Rosemount 3051

Confirm correct device driver

• Verify the latest Device Driver (DD/DTM™) is loaded on your systems to ensure proper

communications.

Reference Manual Configuration

00809-0100-4007 July 2020

• Download the latest DD at Emerson.com or FieldCommGroup.org

• In the Browse by Member dropdown menu, select Rosemount business unit of

Emerson.

• Select desired product.

• Use the device revision numbers to find the correct Device Driver.

Table 2-1: Rosemount 3051 Device Revisions and Files

Release

date

April 2012 1.0xx 1.0xx 01 7 10 00809-0100

January

1998

(1) NAMUR Revision is located on the hardware tag of the device. Differences in level 3 changes, signfied above by xx,

represent minor product changes as defined per NE53. Compatibility and functionality are preserved, and you can use

the product interchangeably.

(2) You can read the HART software revision with a HART capable configuration tool. Value shown is minimum revision

that could correspond to NAMUR Revisions.

(3) Device Driver file names use Device and DD Revision, e.g., 10_01. HART Protocol is designed to enable legacy device

driver revisions to continue to communicate with new HART devices. To access new functionality, you must download

the new Device Driver. Emerson recommends downloading new Device Driver files to ensure full functionality.

(4) HART Revision 5 and 7 selectable, power diagnostics, safety certified, LOI, process alerts, scaled variable, configurable

alarms, expanded engineering units.

Device identification Device driver

identification

NAMUR

software

revision

N/A N/A 178 5 3 00809-0100

(1)

HART

hardware

revision

(1)

HART

software

revision

HART

universal

(2)

revision

5 9

Device

revision

(3)

Review

instructions

Manual

document

number

-4007

-4001

Review

functionality

Change

description

(4)

N/A

2.4 Configuration basics

CAUTION

Transmitter hardware adjustments

Set all transmitter hardware adjustments during commissioning to avoid exposing the

transmitter electronics to the plant environment after installation.

You can configure the transmitter either before or after installation. To ensure all

transmitter components are in working order prior to installation, configure the

transmitter on the bench using a Field Communicator, AMS Device Manager, or LOI. Verify

the Security switch is set in the Unlock position in order to proceed with configuration.

See Figure 4-2 for switch location.

2.4.1

Reference Manual 11

Configuring on the bench

To configure on the bench, you need a power supply and a Field Communicator, AMS

Device Manager, or LOI (option M4). Wire equipment as shown in Figure 2-1 below. To

ensure successful HART® Communication, verify the resistance between the transmitter

A.

B.

Configuration Reference Manual

July 2020 00809-0100-4007

and the power supply is at least 250 Ω. See Power supply for a 4-20 mA HART for more

details. Connect the Field Communicator to the terminals labeled COMM on the terminal

block.

Figure 2-1: Wiring the Transmitter

A. Vdc supply

B. RL ≥ 250 (necessary for HART Communication only)

2.4.2

Configuration tools

Configure with a Field Communicator

There are two interfaces available with the Field Communicator: Traditional and

Dashboard. All steps using a Field Communicator are described using Dashboard

interfaces.

Figure 2-2 shows the Device Dashboard interface. As stated in System readiness, it is

critical that the latest DD's are loaded into the Field Communicator. Visit Emerson.com or

FieldCommGroup.org to download latest DD library.

Field Communicator menu trees and Fast Keys are available in Field Communicator menu

trees and fast keys.

12 Rosemount 3051

SAVE

1. Overview

2. Configure

3. Service Tools

3051 FT 45B

Online

Reference Manual Configuration

00809-0100-4007 July 2020

Figure 2-2: Device Dashboard

Configure with AMS Device Manager

Full configuration capability with AMS Device Manager requires loading the most current

Device Descriptor (DD) for this device.

Download the latest DD at Emerson.com or FieldCommGroup.org.

Note

This manual describes all AMS Device Manager steps using version 11.5.

Configure with the LOI

To order the Rosemount 3051 Transmitter with the LOI, select option code M4 when

ordering.

To activate the LOI, push either configuration button. Configuration buttons are located

on the LCD display (must remove housing cover to access) or underneath the top tag of

the transmitter. See Table 2-2 for configuration button functionality and Figure 2-3 for

configuration button location. When using the LOI for configuration, several features

require multiple screens for a successful configuration. Data entered is saved on a screenby-screen basis; the LOI indicates this by flashing SAVED on the LCD display each time.

LOI menu trees are available in Local Operator Interface (LOI).

Reference Manual 13

Configuration Reference Manual

July 2020 00809-0100-4007

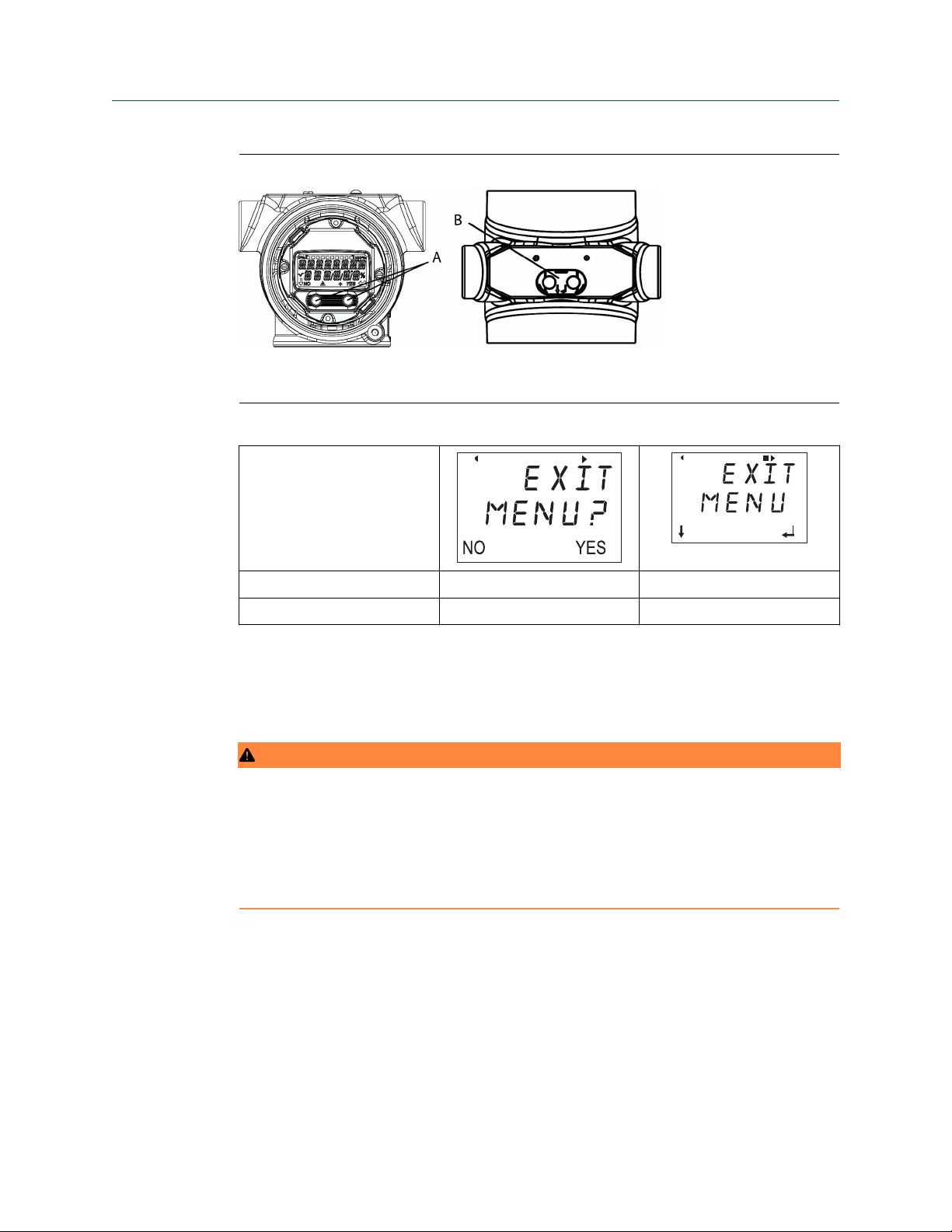

Figure 2-3: LOI Configuration Buttons

A. Internal configuration buttons

B. External configuration buttons

Table 2-2: LOI Button Operation

Button

Left No Scroll

Right Yes Enter

2.5 Setting the loop to manual

Whenever sending or requesting data that would disrupt the loop or change the output of

the transmitter, set the process application loop to manual control.

WARNING

Explosions

Explosions could result in death or serious injury.

Before connecting a handheld communicator in an explosive atmosphere, ensure the

instruments are installed in accordance with intrinsically safe or non-incendive field wiring

practices.

The Field Communicator, AMS Device Manager, or LOI will prompt you to set the loop to

manual when necessary. The prompt is only a reminder; acknowledging this prompt does

not set the loop to manual. You must set the loop to manual control as a separate

operation.

14 Rosemount 3051

Reference Manual Configuration

00809-0100-4007 July 2020

2.6 Verify configuration

Emerson recommends that you verify various configuration parameters prior to

installation into the process.

The following sections detail the various parameters for each configuration tool.

Depending on what configuration tool(s) are available, follow the steps listed relevant to

each tool.

2.6.1 Verify configuration with Field Communicator

Review configuration parameters listed in Table 2-3 prior to transmitter installation. Field

Communicator menu trees and fast keys provides a full list of configuration parameters

that can be reviewed or configured using a Field Communicator.

Table 2-3 shows Fast Key sequences for the latest DD. For Fast Key sequences for legacy

DDs, contact your local Emerson representative.

From the HOME screen, enter the Fast Key sequences listed.

Table 2-3: Device Dashboard Fast Key Sequence

Function Fast Key sequence

HART® 7 HART 5

Alarm and saturation levels 2, 2, 2, 5 2, 2, 2, 5

Damping 2, 2, 1, 1, 5 2, 2, 1, 1, 5

Primary variable 2, 1, 1, 4, 1 2, 1, 1, 4, 1

Range values 2, 1, 1, 4 2, 1, 1, 4

Tag 2, 2, 7, 1, 1 2, 2, 7, 1, 1

Transfer function 2, 2, 1, 1, 6 2, 2, 1, 1, 6

Units 2, 2, 1, 1, 4 2, 2, 1, 1, 4

2.6.2 Verify configuration with AMS Device Manager

Complete the following steps to verify the configuration parameters with the AMS Device

Manager.

Procedure

1. Right-click the device and select Configuration Properties from the menu.

2. Navigate the tabs to review the transmitter configuration data.

2.6.3

Reference Manual 15

Verify configuration with LOI

Complete the following steps to verify configuration parameters with the LOI.

Procedure

1. Press any configuration button to activate the LOI.

Configuration Reference Manual

July 2020 00809-0100-4007

2. Select VIEW CONFIG to review the below parameters.

3. Use the configuration buttons to navigate through the menu.

The parameters you need to review prior to installation include:

• Tag

• Units

• Transfer Function

• Alarm and Saturation Levels

• Primary Variable

• Range Values

• Damping

2.6.4

Verifying process variables configuration

This section describes how to verify that you selected the correct process variables.

Verify process variables with a Field Communicator

From the HOME screen, enter the Fast Key sequence:

Device Dashboard Fast Keys

3, 2, 1

Verify process variables with AMS Device Manager

Complete the following steps to verify process variables with AMS Device Manager.

Procedure

1. Right-click the device and select Overview from the menu.

2. Select the All Variables button to display the primary, secondary, tertiary, and

quaternary variables.

2.7 Basic setup of the transmitter

This section goes through the necessary steps for basic setup of a pressure transmitter.

When installing in DP level or DP flow applications, refer to Configuring scaled variable for

setup instructions.

16 Rosemount 3051

Reference Manual Configuration

00809-0100-4007 July 2020

2.7.1 Setting pressure units

WARNING

Spare parts

Replacement equipment or spare parts not approved by Emerson for use as spare parts

could reduce the pressure retaining capabilities of the transmitter and may render the

instrument dangerous.

Use only bolts supplied or sold by Emerson as spare parts.

The pressure unit command sets the unit of measure for the reported pressure.

Set pressure units with a Field Communicator

From the HOME screen, enter the Fast Key sequence.

Device Dashboard Fast Keys

2, 2, 1, 1, 4

Set pressure units with AMS Device Manager

Complete the following steps to set pressure units with AMS Device Manager.

Procedure

1. Right-click the device and select Configure.

2. Select Manual Setup and select desired units from the Pressure Units dropdown

menu.

3. Select Send when complete.

Set pressure units with the LOI

Complete the following steps to select pressure units with the LOI.

Procedure

1. Follow Figure 2-4 to select desired pressure and temperature units. Go to UNITS →

PRESS UNITS.

Reference Manual 17

UNITS

PRESS UNITS

TEMP UNITS

BACK TO MENU

EXIT MENU

PRESS UNITS

INH2O

MMHG

CMHG0C

MHG0C

PSI

PSF

ATM

TORR

PA

KPA

...

VIEW CONFIG

ZERO TRIM

UNITS

RERANGE

LOOP TEST

DISPLAY

EXTENDED MENU

EXIT MENU

Configuration Reference Manual

July 2020 00809-0100-4007

Figure 2-4: Selecting Pressure Units with LOI

2. Use the SCROLL and ENTER buttons to select desired unit.

3. Save by selecting SAVE as indicated on the LCD display screen.

2.7.2

Setting transmitter output (transfer function)

The transmitter has two output settings: Linear and Square root.

As shown in Figure 2-6, activating the square root options makes analog output

proportional to flow and includes a fixed Low Flow Cutoff at five percent.

However, Emerson recommends using scaled variable for Differential Pressure (DP) Flow

and DP Level applications. Refer to Configuring scaled variable for setup instructions.

Set transmitter output with a Field Communicator

From the HOME screen, enter the Fast Key sequence.

Device Dashboard Fast Keys

Set transmitter output with AMS Device Manager

Complete the following steps to set transmitter output with AMS Device Manager.

Procedure

1. Right-click the device and select Configure.

2. Select Manual Setup, select output type from Analog Output Transfer Function,

and click Send.

3. Carefully read the warning and select Yes if it is safe to apply the changes.

2, 2, 1, 1, 6

18 Rosemount 3051

Set transmitter output with the LOI

Reference Figure 2-5 to select either linear or square root transfer function using the LOI.

Go to EXTENDED MENU → TRANSFER FUNCT.

EXTENDED MENU

CALIBRAT

DAMPING

TRANSFER FUNCT

SCALED VARIAB

ASSIGN PV

TAG

ALARM SAT

VALUES

PASSWORD

SIMLATE

HART REV

BACK TO MENU

EXIT MENU

TRANSFER FUNCT

LINEAR TRANSFER

FUNCTION

SQR ROOT TRANSFER

FUNCTION

BACK TO MENU

EXIT MENU

VIEW CONFIG

ZERO TRIM

UNITS

RERANGE

LOOP TEST

DISPLAY

EXTENDED MENU

EXIT MENU

A

B

C

0.5 1

% Pressure Input

0

0 10 20 30 40 50 60 70 80 90 100

4 mA

20mA

% Pressure Input

B

A

4 mA

Reference Manual Configuration

00809-0100-4007 July 2020

Figure 2-5: Set Transmitter Output with LOI

Figure 2-6: 4-20 mA HART® Square Root Output Transition Point

2.7.3

Reference Manual 19

A. Square root curve

B. 5% transition point

C. 4% transition point

Rerange the transmitter

The range values command sets each of the lower and upper range analog values (4 and

20 mA points) to a pressure. The lower range represents zero percent of range, and the

upper range point represents 100 percent of range.

In practice, you can change the transmitter range values as often as necessary to reflect

changing process requirements. For a complete listing of range and sensor limits, refer to

the Specifications section of the Rosemount 3051 Product Data Sheet.

Select from one of the methods below to rerange the transmitter. Each method is unique;

examine all options closely before deciding which method works best for your process.

RERANGE

ENTER VALUES

APPLY VALUES

BACK TO MENU

EXIT MENU

ENTER VALUES

LRV

URV

BACK TO MENU

EXIT MENU

VIEW CONFIG

ZERO TRIM

UNITS

RERANGE

LOOP TEST

DISPLAY

EXTENDED MENU

EXIT MENU

Configuration Reference Manual

July 2020 00809-0100-4007

• Rerange by manually setting range points with a Field Communicator, AMS Device

Manager, or LOI.

• Rerange with a pressure input source and a Field Communicator, AMS Device Manager,

LOI, or local Zero and Span buttons.

Manually rerange the transmitter by entering range points

Enter range points with a Field Communicator

From the HOME screen, enter the Fast Key sequence.

Device Dashboard Fast Keys 2, 2, 2, 1

Enter range points with AMS Device Manager

Complete the following steps to manually enter range points with AMS Device Manager.

Procedure

1. Right-click the device and select Configure.

2. Select Manual Setup and select Analog Output.

3. Enter upper and lower range values in the Range Limits box and select Send.

4. Carefully read the warning and select Yes if it is safe to apply the changes.

Enter range points with LOI

Reference Figure 2-7 to rerange the transmitter using the LOI. Go to RERANGE → ENTER

VALUES. Enter values using the SCROLL and ENTER buttons.

Figure 2-7: Rerange with LOI

Rerange the transmitter with applied pressure source

Reranging using an applied pressure source is a way of reranging the transmitter without

entering specific 4 and 20 mA points.

Rerange with an applied pressure source using a Field Communicator

From the HOME screen, enter the Fast Key sequence.

Device Dashboard Fast Keys

2, 2, 2, 2

20 Rosemount 3051

RERANGE

ENTER VALUES

APPLY VALUES

BACK TO MENU

EXIT MENU

APPLY VALUES

LRV

URV

BACK TO MENU

EXIT MENU

VIEW CONFIG

ZERO TRIM

UNITS

RERANGE

LOOP TEST

DISPLAY

EXTENDED MENU

EXIT MENU

A

Reference Manual Configuration

00809-0100-4007 July 2020

Rerange with an applied pressure source using AMS Device Manager

Complete the following steps to use an applied pressure source to rerange the transmitter

with AMS Device Manager.

Procedure

1. Right-click the device; select Configure.

2. Select the Analog Output tab.

3. Select Range by Applying Pressure button and follow the screen prompts to range

the transmitter.

Rerange with an applied pressure source using the LOI

Use Figure 2-8 to manually rerange the device using an applied pressure source with the

LOI. Go to RERANGE → APPLY VALUES.

Figure 2-8: Rerange with Applied Pressure Using LOI

Reference Manual 21

Rerange with an applied pressure source using local Zero and Span buttons

If you order them to, you can use local Zero and Span buttons (option code D4) to rerange

the transmitter with applied pressure.

Refer to Figure 2-9 for analog Zero and Span button location.

Figure 2-9: Analog Zero and Span Buttons

A. Zero and Span buttons

Configuration Reference Manual

July 2020 00809-0100-4007

To rerange the transmitter using the Zero and Span buttons:

Procedure

1. Loosen the screw holding the top tag of the transmitter housing. Rotate the label to

expose the Zero and Span buttons.

2. Confirm device has local Zero and Span buttons by verifying blue retainer under the

tag.

3. Apply transmitter pressure.

4. Rerange the transmitter.

a) To change the zero (4 mA point) while maintaining the span, press and hold

the Zero button for at least two seconds; then release.

b) To change the span (20 mA) point while maintaining the zero point, press

and hold the Span button for at least two seconds and then release.

Note

4 and 20 mA points must maintain the minimum span defined in the Specifications

section of the Rosemount 3051 Product Data Sheet.

2.7.4

• If the transmitter security is on, you cannot adjust the zero and span. Refer to

Configuring transmitter security for security information.

• The span is maintained when you set the 4 mA point. The span changes when

you set the 20 mA point. If you set the lower range point to a value that causes

the upper range point to exceed the sensor limit, the transmitter automatically

sets the upper range point to the sensor limit and adjusts the span accordingly.

• Regardless of the range points, the Rosemount 3051 measures and reports all

readings within the digital limits of the sensor. For example, if you set the 4 and

20 mA points to 0 and 10 inH2O, and the transmitter detects a pressure of 25

inH2O, it digitally outputs the 25 inH2O reading and a 250 percent of range

reading.

Damping

The damping command changes the response time of the transmitter; higher values can

smooth variations in output readings caused by rapid input changes.

CAUTION

Improper assembly

Improper assembly of manifolds to traditional flange can damage sensor module.

For safe assembly of manifold to traditional flange, bolts must break back plane of

flange web (i.e., bolt hole) but must not contact sensor module housing.

Severe changes in the electrical loop may inhibit HART® communication or the ability

to reach alarm values. Therefore, Rosemount cannot absolutely warrant or guarantee

that the correct Failure alarm level (High or Low) can be read by the host system at the

time of annunciation.

22 Rosemount 3051

EXTENDED MENU

CALIBRAT

DAMPING

TRANSFER FUNCT

SCALED VARIAB

ASSIGN PV

TAG

ALARM SAT VALUES

PASSWORD

SIMLATE

HART REV

BACK TO MENU

EXIT MENU

VIEW CONFIG

ZERO TRIM

UNITS

RERANGE

LOOP TEST

DISPLAY

EXTENDED MENU

EXIT MENU

Reference Manual Configuration

00809-0100-4007 July 2020

Determine the appropriate damping setting based on the necessary response time, signal

stability, and other requirements of the loop dynamics within your system. The damping

command uses floating point configuration, allowing you to input any damping value

within 0 - 60 seconds.

Damping with a Field Communicator

1. From the HOME screen, enter the Fast Key sequence.

Device Dashboard Fast Keys 2, 2, 1, 1, 5

2. Enter desired damping value and select APPLY.

Damping with AMS Device Manager

Complete the following steps to set the damping value with AMS Device Manager.

Procedure

1. Right-click the device, and select Configure.

2. Select Manual Setup.

3. Within the Pressure Setup box, enter desired damping value and click Send.

4. Carefully click the warning and click Yes if it is safe to apply the changes.

2.8 Configuring the LCD display

Reference Manual 23

Damping with the LOI

Reference Figure 2-10 to enter damping values using the LOI. Go to EXTENDED MENU →

DAMPING.

Figure 2-10: Damping with LOI

Use the LCD display configuration command to customize of the LCD display to suit

application requirements. The LCD display will alternate between the selected items.

• Pressure units

DISPLAY

PRESS (on/off)

SCALED (on/off)

TEMP (on/off)

%RANGE (on/off)

ANALOG (on/off)

STRTUP (on/off)

BACK TO MENU

EXIT MENU

VIEW CONFIG

ZERO TRIM

UNITS

RERANGE

LOOP TEST

DISPLAY

EXTENDED MENU

EXIT MENU

Configuration Reference Manual

July 2020 00809-0100-4007

• % of range

• Scaled variable

• Sensor temperature

• mA output

Using the following instructions, you can configure the LCD display to display

configuration information during the device setup. Select Review Parameters at Startup to

enable or disable this functionality.

2.8.1 Configure LCD display with a Field Communicator

From the HOME screen, enter the Fast Key sequence.

Device Dashboard Fast Keys

2, 2, 4

2.8.2 Configure LCD display with AMS Device Manager

Complete the following steps to configure the LCD display with AMS Device Manager.

Procedure

1. Right-click the device and select Configure.

2. Click Manual Setup and select the Display tab.

3. Select desired display options and select Send.

2.8.3

Configure LCD display with the LOI

Refer to Figure 2-11 for LCD display configuration using the LOI. Go to DISPLAY.

Figure 2-11: Display with LOI

2.9 Detailed transmitter setup

2.9.1 Configuring alarm and saturation levels

24 Rosemount 3051

In normal operation, the transmitter drives the output in response to pressure from the

lower and upper saturation points. If the pressure goes outside of the sensor limits, or if

Reference Manual Configuration

00809-0100-4007 July 2020

the output would be beyond the saturation points, the output will be limited to the

associated saturation point.

The Rosemount 3051 Transmitter automatically and continuously performs selfdiagnostic routines. If the self-diagnostic routines detect a failure, the transmitter drives

the output to configured alarm and value based on the position of the alarm switch. See

Set transmitter alarm.

Table 2-4: Rosemount Alarm and Saturation Values

Level 4-20 mA saturation 4-20 mA alarm

Low 3.9 mA ≤ 3.75 mA

High 20.8 mA ≥ 21.75 mA

Table 2-5: NAMUR-Compliant Alarm and Saturation Values

Level 4-20 mA saturation 4-20 mA alarm

Low 3.8 mA ≤ 3.6 mA

High 20.5 mA ≥ 22.5 mA

Table 2-6: Custom Alarm and Saturation Values

Level 4-20 mA saturation 4-20 mA alarm

Low 3.7 - 3.9 mA 3.6 - 3.8 mA

High 20.1 - 22.9 mA 20.2 - 23.0 mA

You can configure failure mode alarm and saturation levels using a Field Communicator,

AMS Device Manager, or the LOI. The following limitations exist for custom levels:

• Low alarm level must be less than the low saturation level.

• High alarm level must be higher than the high saturation level.

• Alarm and saturation levels must be separated by at least 0.1 mA.

The configuration tool provides an error message if the configuration rule is violated.

Note

Transmitters set to HART® multidrop mode send all saturation and alarm information

digitally; saturation and alarm conditions will not affect the analog output. See also

Establishing multidrop communication.

Configure alarm and saturation levels using a Field Communicator

From the HOME screen, enter the Fast Key sequence.

Device Dashboard Fast Keys

Reference Manual 25

2, 2, 2, 5, 6

EXTENDED MENU

CALIBRAT

DAMPING

TRANSFER FUNCT

SCALED VARIAB

ASSIGN PV

TAG

ALARM SAT VALUES

PASSWORD

SIMULATE

HART REV

BACK TO MENU

EXIT MENU

ALARM SAT VALUES

ROSEMOUNT VALUES

NAMUR VALUES

OTHER VALUES

BACK TO MENU

EXIT MENU

VIEW CONFIG

ZERO TRIM

UNITS

RERANGE

LOOP TEST

DISPLAY

EXTENDED MENU

EXIT MENU

Configuration Reference Manual

July 2020 00809-0100-4007

Configure alarm and saturation levels with AMS Device Manager

Complete the following steps to configure alarm and saturation levels with AMS Device

Manager.

Procedure

1. Right-click the device and select Configure.

2. Select the Configure Alarm and Saturation Levels button.

3. Follow screen prompts to configure alarm and saturation levels.

Configure alarm and saturation levels using the LOI

Refer to Figure 2-12 for instructions to configure alarm and saturation levels. Go to

EXTENDED MENU → ALARM SAT VALUES.

Figure 2-12: Configuring Alarm and Saturation with LOI

2.9.2

26 Rosemount 3051

Configuring process alerts

The transmitter uses process alerts to indicate when it exceeds the configured data point.

You can set process alerts for pressure, temperature, or both. An alert is displayed on a

Field Communicator or AMS Device Manager status screen or in the error section of the

LOI/LCD display. The alert will reset once the value returns within range.

Note

HI alert value must be higher than LO alert value. Both alert values must be within the

pressure or temperature sensor limits.

Configure process alerts using a Field Communicator

Complete the following steps to configure process alerts with a Field Communicator.

Procedure

1. From the HOME screen, enter the Fast Key sequence.

Reference Manual Configuration

00809-0100-4007 July 2020

Device Dashboard Fast Keys 2, 3

2. Select either Pressure Alert or Temperature Alert and press ENTER.

3. Select Configure Alert.

4. Follow screen prompts to configure process alerts.

Configure process alarts using AMS Device Manager

Complete the following steps to configure process alerts with AMS Device Manager.

Procedure

1. Right-click the device and select Configure.

2. Select Guided Setup.

3. Select the Process Alerts button.

4. Follow screen prompts to configure process alerts.

2.9.3

Configuring scaled variable

With the scaled variable configuration, you can create a relationship/conversion between

the pressure units and user-defined/custom units. There are two use cases for a scaled

variable. The first is to allow custom units to be displayed on the transmitter's LOI/LCD

display. The second is to allow custom units to drive the transmitter's 4-20 mA output.

If you desire custom units to drive the 4-20 mA output, you must remap scaled variable as

the primary variable. Refer to Re-mapping device variables.

The scaled variable configuration defines the following items:

• Scaled variable units: Custom units to be displayed.

• Scaled data options: Defines the transfer function for the application.

— Linear

— Square root

• Pressure value position 1: Lower known value point with consideration of linear offset.

• Scaled variable value position 1: Custom unit equivalent to the lower known value

point.

• Pressure value position 2: Upper known value point.

• Scaled variable value position 2: Custom unit equivalent to the upper known value

point.

• Linear offset: The value required to zero out pressures effecting the desired pressure

reading.

• Low flow cutoff: Point at which output is driven to zero to prevent problems cause by

process noise. Emerson highly recommends using the low flow cut off function in order

to have a stable output and avoid problems due to process noise at a low flow or no

flow condition. Enter a low flow cutoff value that is practical for the flow element in the

application.

Reference Manual 27

EXTENDED MENU

CALIBRAT

DAMPING

TRANSFER FUNCT

SCALED VARIAB

ASSIGN PV

TAG

ALARM SAT VALUES

PASSWORD

SIMLATE

HART REV

BACK TO MENU

EXIT MENU

SCALED VARIAB

VIEW SCALED

CONFIG SCALED

BACK TO MENU

EXIT MENU

VIEW CONFIG

ZERO TRIM

UNITS

RERANGE

LOOP TEST

DISPLAY

EXTENDED MENU

EXIT MENU

Configuration Reference Manual

July 2020 00809-0100-4007

Configure scaled variable using a Field Communicator

Complete the following steps to configure a scaled variable with a Field Communicator.

Procedure

1. From the HOME screen, enter the Fast Key sequence.

Device Dashboard Fast Keys 2, 1, 5, 7

2. Follow the screen prompts to configure scaled variable.

• When configuring for level, select Linear under Select Scaled data options.

• When configuring for flow, select Square Root under Select Scaled data options.

Configure scaled variable using AMS Device Manager

Complete the following steps to configure the scaled variable with AMS Device Manager.

Procedure

1. Right-click the device and select Configure.

2. Select the Scaled Variable tab and select the Scaled Variable button.

3. Follow screen prompts to configure the scaled variable.

• When configuring for level applications, select Linear under Select Scaled data

options.

• When configuring the flow applications, select Square Root under Select Scaled

data options.

Configure scaled variable using the LOI

Refer to Figure 2-13 for instructions on configuring scaled variable using the LOI. Go to

EXTENDED MENU → SCALED VARIAB → CONFIG SCALED.

Figure 2-13: Configuring Scaled Variable Using the LOI

28 Rosemount 3051

H

L

230-in.

200-in.

12-in.

0.94 sg

Reference Manual Configuration

00809-0100-4007 July 2020

DP Level example

Figure 2-14: Example Tank

Us a differential transmitter in a level application. Once installed on an empty tank with the

taps vented, the process variable reading is -209.4 inH2O. The process variable reading is

the head pressure created by fill fluid in the capillary. Based on Table 2-7, the scaled

variable configuration would be as follows:

Table 2-7: Scaled Variable Configuration for Tank Application

Scaled variable units inch

Scaled data options linear

Pressure value position 1 0 inH2O

Scaled variable position 1 12-in.

Pressure value position 2 188 inH2O

Reference Manual 29

Configuration Reference Manual

July 2020 00809-0100-4007

Table 2-7: Scaled Variable Configuration for Tank Application (continued)

Scaled variable position 2 212-in.

Linear offset -209.4 inH2O

DP Flow example

Use a differential pressure transmitter in conjunction with an orifice plate in a flow

application where the differential pressure at full scale flow is 125 inH2O.

Emerson highly recommends using the low flow cutoff function in order to have a stable

output and avoid problems due to process noise at a low flow or no flow condition. Enter a

low flow cutoff value that is practical for the flow element in the application. In this

particular example, the low flow cutoff value is 1000 gallons of water per hour. Based on

this information, the scaled variable configuration would be as follows:

Table 2-8: Scaled Variable Configuration for Flow Application

Scaled variable units gal/h

Scaled data options square root

2.9.4

Pressure value position 2 125 inH2O

Scaled variable position 2 20,000 gal/h

Low flow cutoff 1000 gal/h

Note

Pressure value position 1 and scaled variable position 1 are always set to zero for a flow

application. You don't have to configure these values.

Re-mapping device variables

Use the re-mapping function to configure the transmitter primary, secondary, tertiary,

and quaternary variables (PV, 2V, 3V, and 4V). You can map the PV with a Field

Communicator, AMS Device Manager, or the LOI. You can only re-map variables (2V, 3V,

and 4V) via Field Communicator or AMS Device Manager.

Note

The variable assigned to the primary variable drives the 4-20 mA output. You can select

this value as Pressure or Scaled Variable. The 2, 3, and 4 variables only apply if you are

using HART® burst mode.

Re-map using a Field Communicator

From the HOME screen, enter the Fast Key sequence.

Fast Keys

30 Rosemount 3051

2, 1, 1, 3

Loading...

Loading...