Rosemount Reference Manual: Rosemount 3051 Pressure Transmitter with Foundation(TM) Fieldbus Protocol Manuals & Guides

Reference Manual

00809-0100-4774, Rev DB

Rosemount™ 3051 Pressure Transmitter

with FOUNDATION™ Fieldbus Protocol

July 2020

Safety messages

NOTICE

Read this manual before working with the product. For personal and system safety and for optimum product performance, ensure

you thoroughly understand the contents before installing, using, or maintaining this product.

For technical assistance, contacts are listed below:

Customer Central (Technical support, quoting, and order-related questions.)

• United States: 1-800-999-9307 (7:00 am to 7:00 pm Central Time)

• Asia Pacific: 65 777 8211

• Europe/Middle East/Africa: 49 (8153) 9390

North American Response Center (Equipment service needs.): 1-800-654-7768 (24 hours - includes Canada)

Outside of these areas, contact your local Emerson representative.

WARNING

Explosions

Explosions could result in death or serious injury.

In an explosion-proof/flameproof installation, do not remove the transmitter covers when power is applied to the unit.

Installation of device in an explosive environment must be in accordance with appropriate local, national, and international

standards, codes, and practices. Review the Product Certifications section of the Rosemount 3051 Product Data Sheet for any

restrictions associated with a safe installation.

Before connecting a handheld communicator in an explosive atmosphere, ensure the instruments are installed in accordance

with intrinsically safe or non-incendive field wiring practices.

Process leaks

Process leaks may cause harm or result in death.

Install and tighten process connectors before applying pressure.

Do not attempt to loosen or remove flange bolts while the transmitter is in service.

Electrical shock

Electrical shock can result in death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads can cause electrical shock.

Replacement equipment

Replacement equipment or spare parts not approved by Emerson for use as spare parts could reduce the pressure retaining

capabilities of the transmitter and may render the instrument dangerous.

Use only bolts supplied or sold by Emerson as spare parts.

Improper assembly

Improper assembly of manifolds to traditional flange can damage sensor module.

For safe assembly of manifold to traditional flange, bolts must break back plane of flange web (i.e., bolt hole) but must not

contact sensor module housing.

Severe changes in the electrical loop may inhibit HART Communication or the ability to reach alarm values. Therefore,

Rosemount absolutely cannot warrant or guarantee that the correct Failure alarm level (High or Low) can be read by the host

system at the time of annunciation.

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of end users’ equipment. This could

be intentional or unintentional and needs to be protected against.

Physical security is an important part of any security program and fundamental to protecting your system. Restrict physical access

by unauthorized personnel to protect end users’ assets. This is true for all systems used within the facility.

2

CAUTION

Nuclear applications

The products described in this document are not designed for nuclear-qualified applications. Using non-nuclear qualified products

in applications that require nuclear-qualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson Sales Representative.

3

4

Reference Manual Contents

00809-0100-4774 July 2020

Contents

Chapter 1 Introduction.............................................................................................................. 7

1.1 Using this manual........................................................................................................................ 7

1.2 Models covered........................................................................................................................... 7

1.3 Host files......................................................................................................................................8

1.4 Product recycling/disposal...........................................................................................................8

Chapter 2 Configuration............................................................................................................ 9

2.1 Overview..................................................................................................................................... 9

2.2 Safety messages.......................................................................................................................... 9

2.3 Device capabilities..................................................................................................................... 21

2.4 Node address.............................................................................................................................22

2.5 General block information......................................................................................................... 22

2.6 Resource block.......................................................................................................................... 26

2.7 Basic device setup......................................................................................................................33

2.8 Analog input (AI) function block................................................................................................ 39

2.9 Advanced device setup.............................................................................................................. 44

Chapter 3 Hardware installation.............................................................................................. 57

3.1 Overview................................................................................................................................... 57

3.2 Safety messages........................................................................................................................ 57

3.3 Installation considerations.........................................................................................................58

3.4 Tagging..................................................................................................................................... 59

3.5 Installation procedures.............................................................................................................. 60

3.6 Rosemount 305, 306, and 304 manifolds.................................................................................. 71

Chapter 4 Electrical installation................................................................................................83

4.1 Overview................................................................................................................................... 83

4.2 Safety messages........................................................................................................................ 83

4.3 LCD display................................................................................................................................ 84

4.4 Configuring transmitter security and simulation........................................................................84

4.5 Electrical considerations............................................................................................................ 86

4.6 Wiring........................................................................................................................................87

Chapter 5 Operation and maintenance.....................................................................................93

5.1 Overview................................................................................................................................... 93

5.2 Safety messages........................................................................................................................ 93

5.3 Calibration overview..................................................................................................................94

5.4 Trim the pressure signal.............................................................................................................97

5.5 Status...................................................................................................................................... 100

5.6 Master reset method............................................................................................................... 100

Reference Manual 5

Contents Reference Manual

July 2020 00809-0100-4774

5.7 Simulation............................................................................................................................... 101

Chapter 6 Troubleshooting.................................................................................................... 103

6.1 Overview................................................................................................................................. 103

6.2 Safety messages...................................................................................................................... 103

6.3 Disassembly procedures.......................................................................................................... 104

6.4 Reassemble............................................................................................................................. 106

6.5 Troubleshooting guides...........................................................................................................109

6.6 Troubleshooting and diagnostic messages.............................................................................. 111

6.7 Analog input (AI) function block.............................................................................................. 115

6.8 Service support........................................................................................................................116

Chapter 7 Advanced pressure diagnostics.............................................................................. 119

7.1 Overview................................................................................................................................. 119

7.2 Process Intelligence................................................................................................................. 119

7.3 PIL diagnostics.........................................................................................................................120

7.4 Process Intelligence technology...............................................................................................120

7.5 SPM configuration and operation.............................................................................................124

7.6 Plugged impulse line detection using SPM...............................................................................130

Appendix A Reference data....................................................................................................... 137

A.1 Ordering information, specifications, and drawings.................................................................137

A.2 Product certifications.............................................................................................................. 137

Appendix B Field Communicator............................................................................................... 139

B.1 Field Communicator menu trees..............................................................................................139

B.2 Field Communicator Fast Keys................................................................................................. 144

6 Rosemount 3051

Reference Manual Introduction

00809-0100-4774 July 2020

1 Introduction

1.1 Using this manual

The sections in this manual provide information on configuring, installing, operating and

maintaining, and troubleshooting Rosemount 3051 Pressure Transmitters specifically for

FOUNDATION™ Fieldbus protocol.

Configuration provides instruction on commissioning and operating the transmitters. It

also includes information on software functions, configuration parameters, and online

variables.

Hardware installation contains mechanical installation instructions.

Electrical installation contains electrical installation instructions.

Operation and maintenance provides detailed information on calibrating the transmitter.

Troubleshooting provides troubleshooting techniques for the most common operating

problems.

Reference data provides information on how to access specifications, ordering

information,and dimensional drawings.

Field Communicator menu trees and fast keys provides full menu trees and abbreviated

Fast Key sequences for commissioning tasks.

1.2 Models covered

The following Rosemount 3051 Transmitters are covered by this manual:

• Rosemount 3051C Coplanar™ Pressure Transmitter

— Measures differential and gage pressure up to 2000 psi (137.9 bar).

— Measures absolute pressure up to 4000 psia (275.8 bar).

• Rosemount 3051T In-Line Pressure Transmitter

— Measures gage/absolute pressure up to 10000 psi (689.5 bar).

• Rosemount 3051L Liquid Level Transmitter

— Measures level and specific gravity up to 300 psi (20.7 bar).

• Rosemount 3051CF Series Flowmeter

— Measures flow in line sizes from ½-in. (15 mm) to 96-in. (2400 mm).

Note

For transmitter with 4-20 mA HART® Revision 5 and 7 Selectable Protocol, see Rosemount

3051 Reference Manual.

For transmitter with PROFIBUS® PA, see Rosemount 3051 Reference Manual.

Reference Manual 7

Introduction Reference Manual

July 2020 00809-0100-4774

1.3 Host files

Before configuring the device, ensure the host has the appropriate Device Description

(DD) or Device Type Manager (DTM™) file revision for this device. The device descriptor

can be found on Fieldbus.org. The DTM can be found at Emerson.com. The current release

of the Rosemount 3051 with Foundation Fieldbus protocol is device revision 8. This

manual is for revision 8.

1.4 Product recycling/disposal

Consider recycling equipment. Dispose of packaging in accordance with local and national

legislations/regulations.

8 Rosemount 3051

Reference Manual Configuration

00809-0100-4774 July 2020

2 Configuration

2.1 Overview

This section contains information on commissioning and tasks that should be performed

on the bench prior to installation, as well as tasks performed after installation.

2.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the

safety of the personnel performing the operations.

WARNING

Explosions

Explosions could result in death or serious injury.

Before connecting a handheld communicator in an explosive atmosphere, ensure that

the instruments in the loop are installed in accordance with intrinsically safe or nonincendive field wiring practices.

In an explosion-proof/flameproof installation, do not remove the transmitter covers

when power is applied to the unit.

Process leaks

Install and tighten process connectors before applying pressure.

Electrical shock

Avoid contact with the leads and terminals. High voltage that may be present on leads

can cause electrical shock.

Static electricity

Observe safe handling precautions for static-sensitive components.

Conduit/cable entries

Unless marked, the conduit/cable entries in the transmitter housing use a ½–14 NPT

thread form. Entries marked “M20” are M20 × 1.5 thread form. On devices with multiple

conduit entries, all entries will have the same thread form. Only use plugs, adapters,

glands, or conduit with a compatible thread form when closing these entries.

When installing in a hazardous location, use only appropriately listed or Ex certified plugs,

glands, or adapters in cable/conduit entries.

Reference Manual 9

Configuration Reference Manual

July 2020 00809-0100-4774

WARNING

Replacement parts

Replacement equipment or spare parts not approved by Emerson for use as spare parts

could reduce the pressure retaining capabilities of the transmitter and may render the

instrument dangerous.

Use only bolts supplied or sold by Emerson as spare parts.

Improper assembly

Improper assembly of manifolds to traditional flange can damage sensor module.

For safe assembly of manifold to traditional flange, bolts must break back plane of

flange web (i.e., bolt hole) but must not contact sensor module housing.

Severe changes in the electrical loop may inhibit HART® communication or the ability

to reach alarm values. Therefore, Rosemount cannot absolutely warrant or guarantee

that the correct Failure alarm level (High or Low) can be read by the host system at the

time of annunciation.

2.2.1

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or unintentional and

needs to be protected against.

Physical security is an important part of any security program and fundamental to

protecting your system. Restrict physical access by unauthorized personnel to protect end

users’ assets. This is true for all systems used within the facility.

Device Description (DD) and Device Type Manager (DTM™) based interfaces

The Rosemount 3051Pressure Transmitter Rev 8 has both DD based and DTM based user

interfaces available. All device configuration and maintenance tasks can be performed

using either technology.

The DD capabilities supported will vary based on host supplier and host revision. Check

with your host supplier to determine and obtain the appropriate DD for your situation. The

type of DD your host supports may influence navigation between different functions, and

the exact steps used to perform different tasks. The device menu tree has multiple ways to

navigate between and perform tasks. Not all ways will be usable on all hosts, but at least

one way will be usable on every host.

2.2.2

10 Rosemount 3051

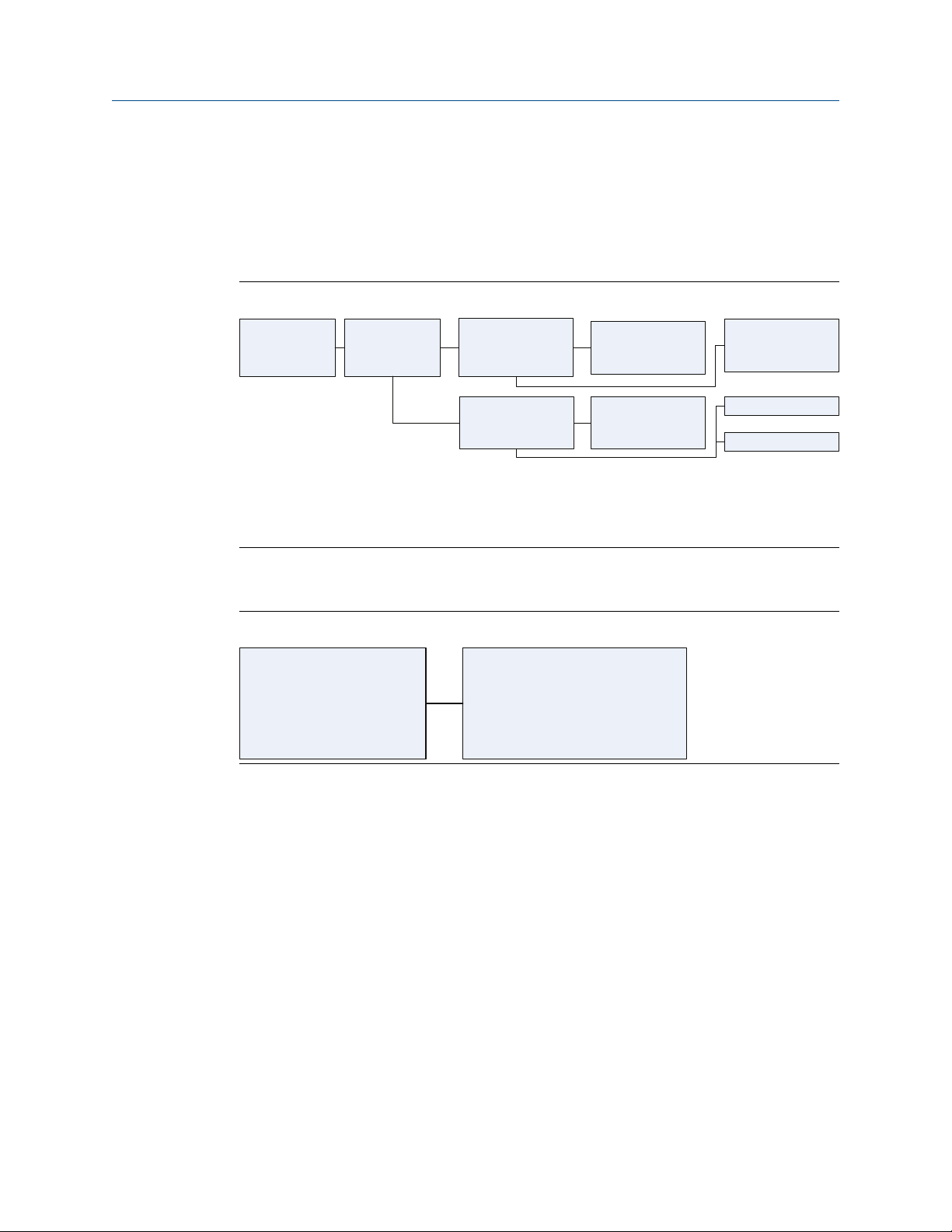

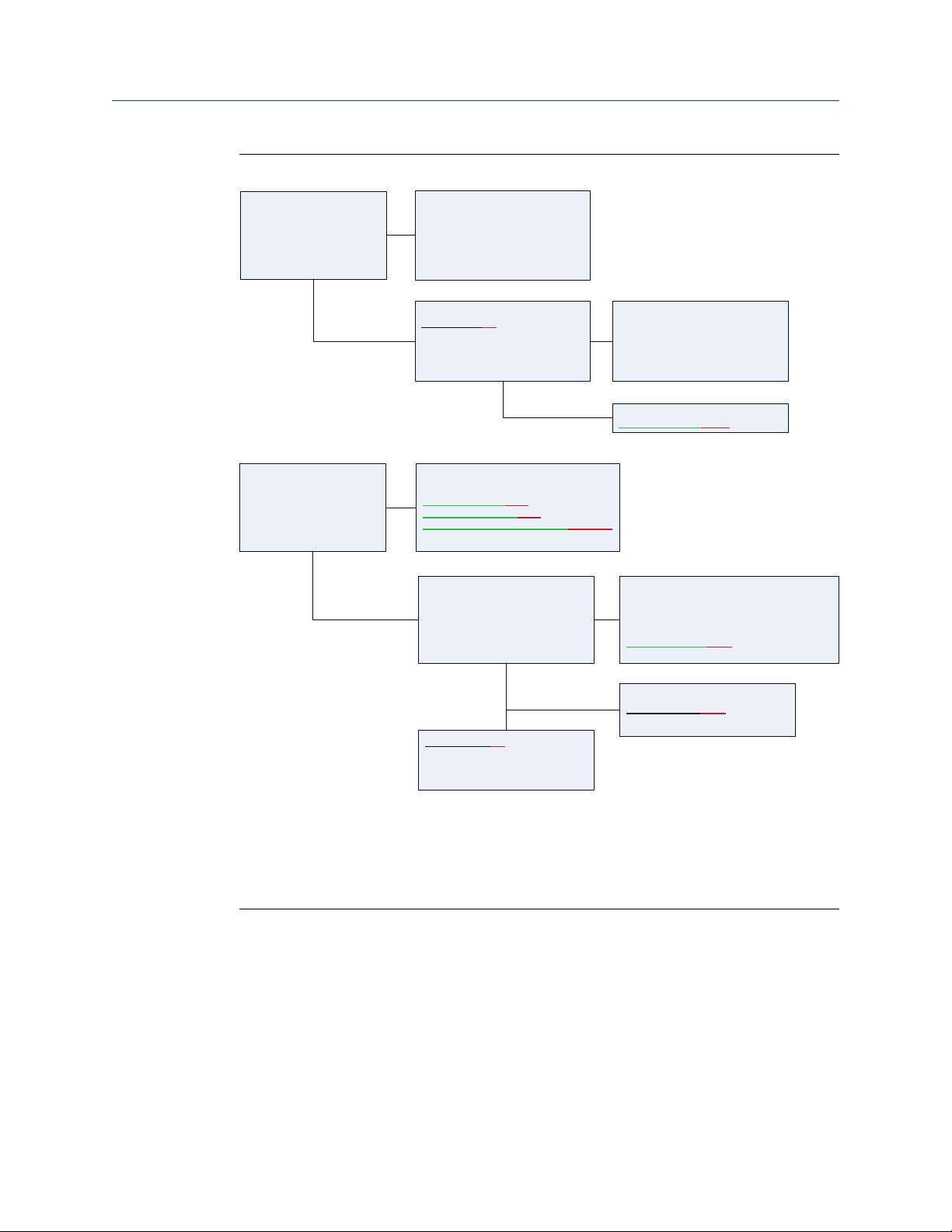

Device menu tree

Device information and device tasks are organized in a menu tree structure. The complete

menu tree is shown in Figure 2-9. A partial menu tree covering the most common device

tasks is shown in Figure 2-10.

Reference Manual Configuration

00809-0100-4774 July 2020

2.2.3 Basic organization

Device information and tasks are organized into three different menu tree branches. They

are Overview, Configure, and Service Tools. Information and tasks may be resident in more

than a single branch of the menu tree.

The device menu tree is the landing screen for the Handheld user interface. The device

menu tree is also permanently displayed on PC-based user interfaces. On PC-based user

interfaces, you can expand or collapse the menu tree as needed to facilitate navigation.

The same device menu tree applies for both handheld and PC-based user interfaces. On

the handheld, each menu tree entry has a dedicated screen (see Figure 2-3). On PC-based

user interfaces, several menu tree entries may be displayed on a single screen with each

menu tree entry used as the heading for a section of that screen (see Figure 2-2). The net

result is that you can use the menu tree to navigate all DD’s and DTM’s; however, you may

need to perform actions on one screen or several screens to perform the same task.

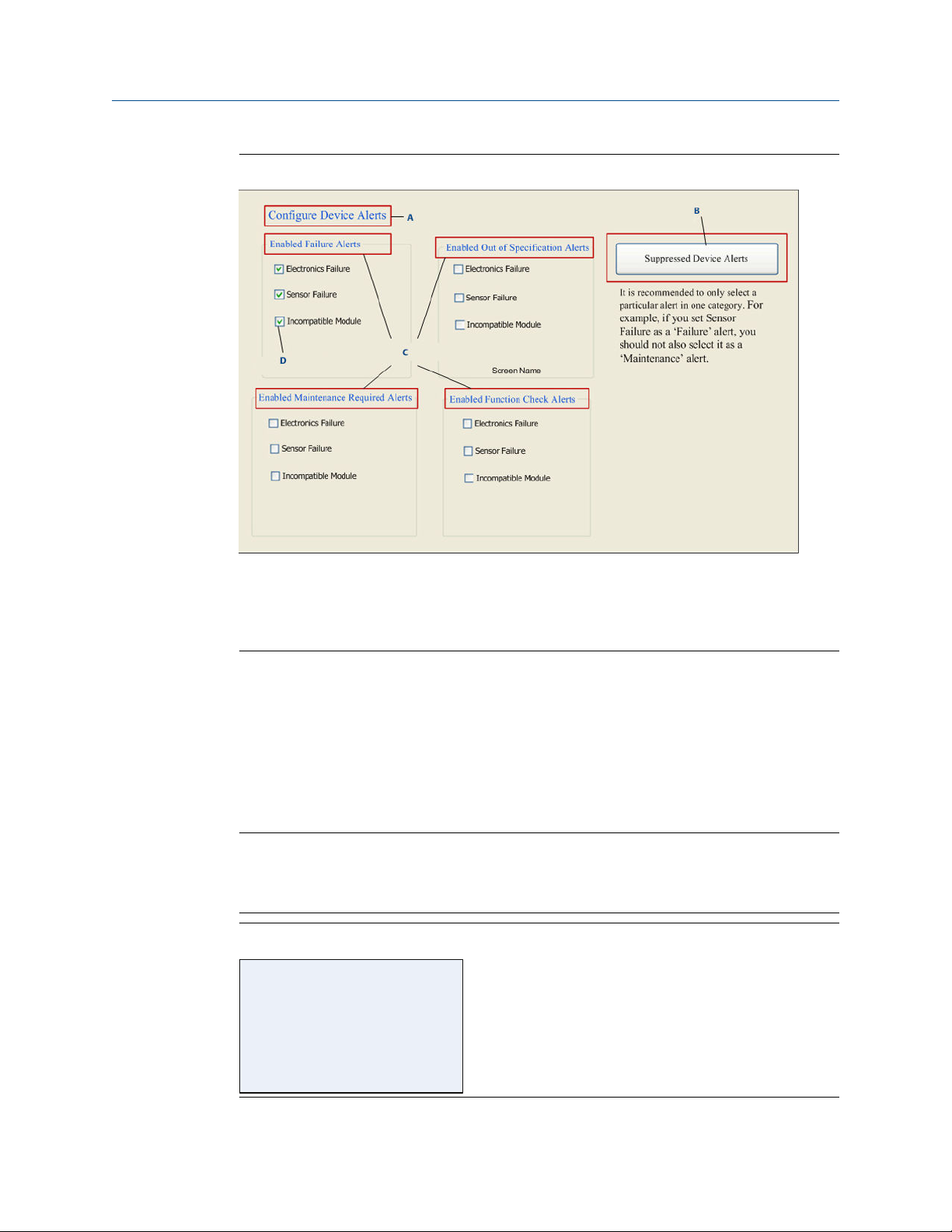

Figure 2-1: Configure Device Alerts-Multiple Screens

On devices with smaller screens the information and parameters necessary to complete a

task may be divided into several screens. In this figure, each category of alert to be

configured has a dedicated screen shown. There are four total screens used for alert

configuration.

Reference Manual 11

2YHUYLHZ

&RQILJXUH

6HUYLFH7RROV

Configuration Reference Manual

July 2020 00809-0100-4774

Figure 2-2: Configure Device Alerts-Single Screen

2.2.4

A. Screen name

B. Configure Suppressed Alerts button

C. Status signal categories

D. Alert check boxes

On this PC-based configuration screen, alert configuration for all four alert categories is

performed on a single screen.

Home screen

The Home screen provides access to the three main branches of the menu tree. These

branches are Overview, Configure, and Service Tools. From this screen, select any of the

three main branches to access detailed device functionality.

Note

Some tasks can be performed from multiple locations on the menu tree. This is done to

allow you to perform related tasks with a minimum of screen changes and keystrokes. The

organization of the device menu tree is further described below.

Figure 2-3: Home Screen

12 Rosemount 3051

2YHUYLHZ

&RQILJXUH

6HUYLFH7RROV

2YHUYLHZ

3UHVVXUH

&DOLEUDWLRQ

'HYLFH,QIRUPDWLRQ

/RFDWH'HYLFH

6FDOH*DXJHV

&DOLEUDWLRQ

3ULPDU\9DOXH

6HQVRU7ULP

6HQVRU/LPLWV

5HVWRUH)DFWRU\&DOLEUDWLRQ

/DVW&DOLEUDWLRQ3RLQWV

&DOLEUDWLRQ'HWDLOV

'HYLFH,QIRUPDWLRQ

,GHQWLILFDWLRQ

5HYLVLRQV

0DWHULDOVRI&RQVWUXFWLRQ

6HFXULW\6LPXODWLRQ

0DWHULDOVRI&RQVWUXFWLRQ

6HQVRU

6HQVRU5DQJH

)ODQJH

5HPRWH6HDO

6HFXULW\6LPXODWLRQ

:ULWH/RFN6HWXS

3ULPDU\9DOXH

&KDQJH'DPSLQJ

6HQVRU7ULP

8SSHU

/RZHU

=HUR

5HVWRUH

5HYLVLRQV

'HYLFH'ULYHU

( )

( )

&RQILJXUH

*XLGHG6HWXS

0DQXDO6HWXS

$OHUW6HWXS

*XLGHG6HWXS

=HUR7ULP

&KDQJH'DPSLQJ

/RFDO'LVSOD\6HWXS

&RQILJXUH$QDORJ,QSXW%ORFNV

%DVLF6306HWXS

Reference Manual Configuration

00809-0100-4774 July 2020

2.2.5 Overview

The Overview branch of the menu tree provides device information and single keystroke

shortcuts to view variables and device status, access device diagnostics, and perform basic

calibration functions. The Overview screen is the landing screen for PC-based user

interfaces.

Figure 2-4: Overview

Black text - Navigation selections available

(Text) - Name of selection used on parent menu screen to access this screen

2.2.6

Green text - Automated methods

Configure

Figure 2-5: Guided Setup

The Configure branch of the menu tree provides both guided setup and manual setup.

Guided setup provides automated step by step methods for performing device

configuration. Manual setup provides user editable screens where you can perform a

configuration task by selecting or entering the necessary parameters without step by step

guidance.

Reference Manual 13

0DQXDO6HWXS

3URFHVV9DULDEOH

0DWHULDOVRI&RQVWUXFWLRQ

'LVSOD\

%DVLF630

&ODVVLF9LHZ

'LVSOD\

'LVSOD\2SWLRQV

$GYDQFHG&RQILJXUDWLRQ

$GYDQFHG&RQILJXUDWLRQ

'LVSOD\3DUDPHWHU

'LVSOD\3DUDPHWHU

'LVSOD\3DUDPHWHU

'LVSOD\3DUDPHWHU

%DVLF630

&RQILJXUDWLRQ

0DWHULDOVRI&RQVWUXFWLRQ

6HQVRU

6HQVRU5DQJH

)ODQJH

5HPRWH6HDO

3URFHVV9DULDEOH

3UHVVXUH

3UHVVXUH'DPSLQJ

6HQVRU7HPSHUDWXUH

&KDQJH'DPSLQJ

&ODVVLF9LHZ

9LHZ$OO3DUDPHWHUV

0RGH6XPPDU\

0DVWHU5HVHW

9LHZ$OO3DUDPHWHUV

5HVRXUFH%ORFN

6HQVRU7UDQVGXFHU%ORFN

/&'%ORFN

630%ORFN

0RGH6XPPDU\

5HWXUQ$OOWR6HUYLFH

3XW$OO2XWRI6HUYLFH

5HVRXUFH%ORFNದ0RGH&KDQJH

6HQVRU7UDQVGXFHU%ORFNದ0RGH&KDQJH

/&'%ORFN0RGH&KDQJH

630%ORFNದ0RGH&KDQJH

Configuration Reference Manual

July 2020 00809-0100-4774

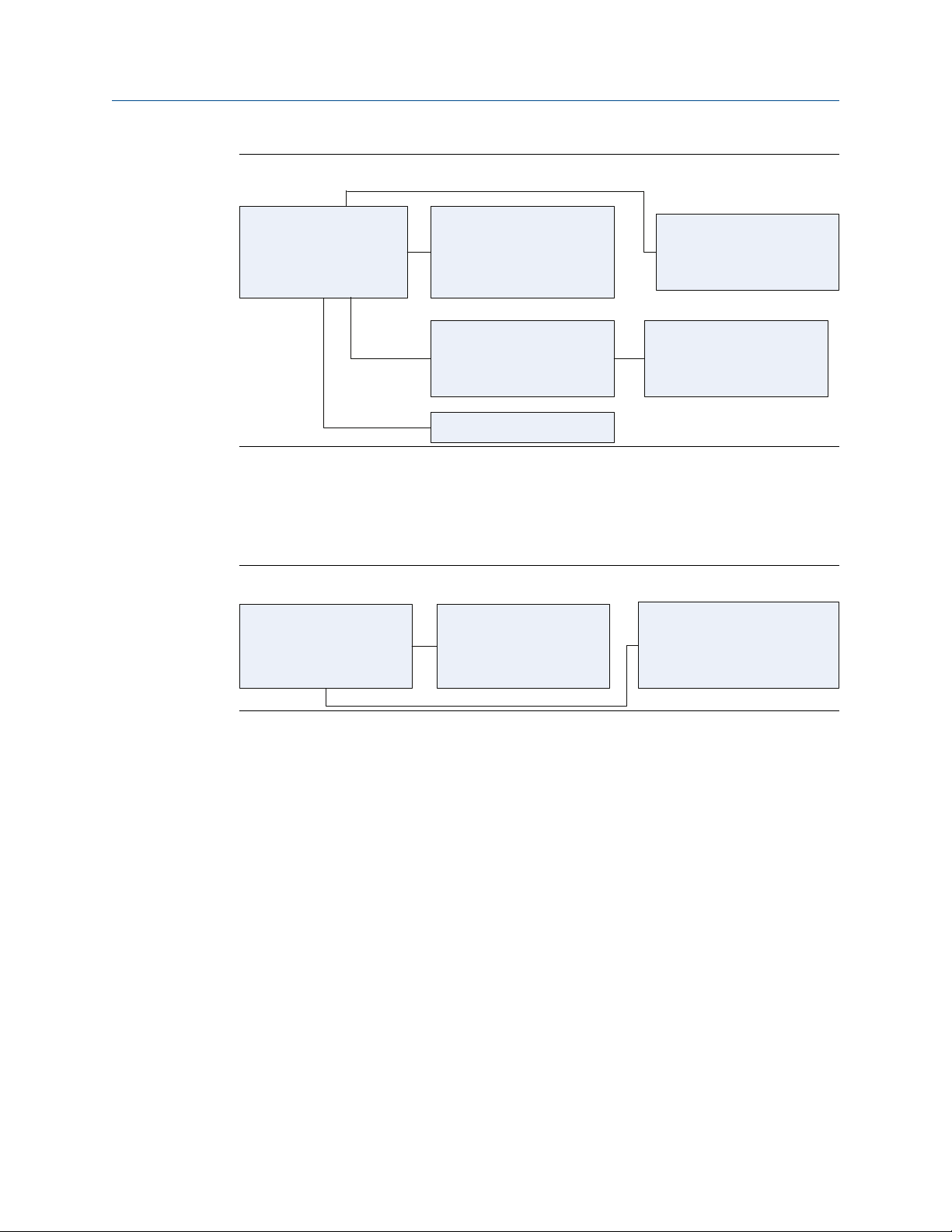

Figure 2-6: Manual Setup

Manual setup can take less time than guided setup if you are familiar with the task to be

performed. Manual setup also allows you to edit specific parameters without needing to

step through all the setup steps. If you are not familiar with a specific task, Emerson

™

recommends guided setup so task steps are done in the correct order and all needed steps

are performed.

Figure 2-7: Classic View

The Manual Setup branch also provides a view called classic view which lists block

parameters in a single scroll-down menu. Expert users may prefer this view for

configuration, as you can do multiple configuration tasks without leaving the single menu

screen.

14 Rosemount 3051

$OHUW6HWXS

'HYLFH$OHUWV

3URFHVV$OHUWV

'LDJQRVWLF$OHUWV

'HYLFH$OHUWV

(QDEOH)DLOXUH$OHUWV

(QDEOH2XWRI6SHFLILFDWLRQ$OHUWV

(QDEOH0DLQWHQDQFH5HTXLUHG$OHUWV

(QDEOH)XQFWLRQ&KHFN$OHUWV

6XSSUHVVHG'HYLFH$OHUWV

6XSSUHVVHG'HYLFH$OHUWV

)DLOXUH$OHUWV

2XWRI6SHFLILFDWLRQ$OHUWV

0DLQWHQDQFH5HTXLUHG$OHUWV

)XQFWLRQ&KHFN$OHUWV

3URFHVV$OHUWV

(QDEOH)DLOXUH$OHUWV

(QDEOH2XWRI6SHFLILFDWLRQ$OHUWV

(QDEOH0DLQWHQDQFH5HTXLUHG$OHUWV

(QDEOH)XQFWLRQ&KHFN$OHUWV

6XSSUHVVHG3URFHVV$OHUWV

'LDJQRVWLF$OHUWV

(QDEOH)DLOXUH$OHUWV

(QDEOH2XWRI6SHFLILFDWLRQ$OHUWV

(QDEOH0DLQWHQDQFH5HTXLUHG$OHUWV

(QDEOH)XQFWLRQ&KHFN$OHUWV

6XSSUHVVHG'HYLFH$OHUWV

6XSSUHVVHG3URFHVV$OHUWV

)DLOXUH$OHUWV

2XWRI6SHFLILFDWLRQ$OHUWV

0DLQWHQDQFH5HTXLUHG$OHUWV

)XQFWLRQ&KHFN$OHUWV

6XSSUHVVHG'LDJQRVWLF$OHUWV

)DLOXUH$OHUWV

2XWRI6SHFLILFDWLRQ$OHUWV

0DLQWHQDQFH5HTXLUHG$OHUWV

)XQFWLRQ&KHFN$OHUWV

Reference Manual Configuration

00809-0100-4774 July 2020

Figure 2-8: Alert Setup

Black text - Navigation selections available

(Text) Name of selection used on parent menu screen to access this screen

Green text - Automated methods

The final Configure branch supports alert setup. The same configuration process supports

both NE107 alerts (the factory default Device alerts), and PlantWeb® alerts. Note the

diagnostics performed and the recommended actions for NE107 alerts and Plantweb

alerts are identical. The only difference is that NE107 alerts and Plantweb alerts annunciate

the alerts using different categories.

NE107 requires device manufacturers to provide a way for you to enable, suppress, and recategorize alerts. NE107 alerts can be defined as any of four categories. They are Failure

Alerts, Out of Specification Alerts, Maintenance Required Alerts, and Function Check Alerts. To

minimize configuration tasks and time, the Rosemount 3051 ships from the factory with

alerts enabled and pre-categorized. Emerson recommends using factory default

categories if the defaults meet plant standards and there is no identified benefit to

changing categories.

Note

The NE107 specification allows a single alert to be included in multiple categories. As a

general practice, Emerson does not recommend this as alarm management can become

needlessly complex.

You can suppress NE107 alerts. If you configure an alert to reside in multiple categories,

you can suppress it in some categories, but not others. To completely suppress an alert,

you must suppress it in every category where it is configured.

Reference Manual 15

6HUYLFH7RROV

$OHUWV

9DULDEOHV

7UHQGV

%DVLF630

0DLQWHQDQFH

6LPXODWH

9DULDEOHV

3UHVVXUH

6HQVRU7HPSHUDWXUH

7UHQGV

3UHVVXUH

6HQVRU7HPSHUDWXUH

%DVLF630

0HDQ

6WDQGDUG'HYLDWLRQ

/DVW6WDWXV8SGDWH

6LPXODWH

6LPXODWH$OHUWV

(QDEOH'LVDEOH$OHUW6LPXODWLRQV

0DLQWHQDQFH

&DOLEUDWH

5HVHW5HVWRUH

&DOLEUDWH

3ULPDU\9DOXH

&KDQJH'DPSLQJ

6HQVRU7ULP

8SSHU/RZHU=HUR

5HVWRUH

6HQVRU/LPLWV

/DVW&DOLEUDWLRQ3RLQW

&DOLEUDWLRQ'HWDLOV

5HVHW5HVWRUH

0DVWHU5HVHW

5HVWRUH)DFWRU\&DO

Configuration Reference Manual

July 2020 00809-0100-4774

2.2.7 Service tools

Black text - Navigation selection available

(Text) - Name of selection used on parent menu screen to access this screen

Green text - Automated methods

The Service Tools branch of the menu tree allows you to perform typical device

maintenance tasks, simulate alerts and parameters, and perform some configuration

resets to return devices to as-manufactured settings.

16 Rosemount 3051

2YHUYLHZ

&RQILJXUH

6HUYLFH7RROV

2YHUYLHZ

3UHVVXUH

&DOLEUDWLRQ

'HYLFH,QIRUPDWLRQ

/RFDWH'HYLFH

6FDOH*DXJHV

&DOLEUDWLRQ

3ULPDU\9DOXH

6HQVRU7ULP

6HQVRU/LPLWV

5HVWRUH)DFWRU\&DOLEUDWLRQ

/DVW&DOLEUDWLRQ3RLQWV

&DOLEUDWLRQ'HWDLOV

'HYLFH,QIRUPDWLRQ

,GHQWLILFDWLRQ

5HYLVLRQV

0DWHULDOVRI&RQVWUXFWLRQ

6HFXULW\6LPXODWLRQ

0DWHULDOVRI&RQVWUXFWLRQ

6HQVRU

6HQVRU5DQJH

)ODQJH

5HPRWH6HDO

&RQILJXUH

*XLGHG6HWXS

0DQXDO6HWXS

$OHUW6HWXS

0DQXDO6HWXS

3URFHVV9DULDEOH

0DWHULDOVRI&RQVWUXFWLRQ

'LVSOD\

%DVLF630

&ODVVLF9LHZ

0DWHULDOVRI&RQVWUXFWLRQ

6HQVRU

6HQVRU5DQJH

)ODQJH

5HPRWH6HDO

'LVSOD\

'LVSOD\2SWLRQV

$GYDQFHG&RQILJXUDWLRQ

$GYDQFHG&RQILJXUDWLRQ

'LVSOD\3DUDPHWHU

'LVSOD\3DUDPHWHU

'LVSOD\3DUDPHWHU

'LVSOD\3DUDPHWHU

%DVLF630

&RQILJXUDWLRQ

&ODVVLF9LHZ

9LHZ$OO3DUDPHWHUV

0RGH6XPPDU\

0DVWHU5HVHW

9LHZ$OO3DUDPHWHUV

5HVRXUFH%ORFN

6HQVRU7UDQVGXFHU%ORFN

/&'%ORFN

630%ORFN

$OHUW6HWXS

'HYLFH$OHUWV

3URFHVV$OHUWV

'LDJQRVWLF$OHUWV

'HYLFH$OHUWV

(QDEOH)DLOXUH$OHUWV

(QDEOH2XWRI6SHFLILFDWLRQ$OHUWV

(QDEOH0DLQWHQDQFH5HTXLUHG$OHUWV

(QDEOH)XQFWLRQ&KHFN$OHUWV

6XSSUHVVHG'HYLFH$OHUWV

6XSSUHVVHG'HYLFH$OHUWV

)DLOXUH$OHUWV

2XWRI6SHFLILFDWLRQ$OHUWV

0DLQWHQDQFH5HTXLUHG$OHUWV

)XQFWLRQ&KHFN$OHUWV

3URFHVV$OHUWV

(QDEOH)DLOXUH$OHUWV

(QDEOH2XWRI6SHFLILFDWLRQ$OHUWV

(QDEOH0DLQWHQDQFH5HTXLUHG$OHUWV

(QDEOH)XQFWLRQ&KHFN$OHUWV

6XSSUHVVHG3URFHVV$OHUWV

'LDJQRVWLF$OHUWV

(QDEOH)DLOXUH$OHUWV

(QDEOH2XWRI6SHFLILFDWLRQ$OHUWV

(QDEOH0DLQWHQDQFH5HTXLUHG$OHUWV

(QDEOH)XQFWLRQ&KHFN$OHUWV

6XSSUHVVHG'HYLFH$OHUWV

6XSSUHVVHG3URFHVV$OHUWV

)DLOXUH$OHUWV

2XWRI6SHFLILFDWLRQ$OHUWV

0DLQWHQDQFH5HTXLUHG$OHUWV

)XQFWLRQ&KHFN$OHUWV

6XSSUHVVHG'LDJQRVWLF$OHUWV

)DLOXUH$OHUWV

2XWRI6SHFLILFDWLRQ$OHUWV

0DLQWHQDQFH5HTXLUHG$OHUWV

)XQFWLRQ&KHFN$OHUWV

6HUYLFH7RROV

$OHUWV

9DULDEOHV

7UHQGV

%DVLF630

0DLQWHQDQFH

6LPXODWH

9DULDEOHV

3UHVVXUH

6HQVRU7HPSHUDWXUH

7UHQGV

3UHVVXUH

6HQVRU7HPSHUDWXUH

%DVLF630

0HDQ

6WDQGDUG'HYLDWLRQ

/DVW6WDWXV8SGDWH

6LPXODWH

6LPXODWH$OHUWV

(QDEOH'LVDEOH$OHUW6LPXODWLRQV

0DLQWHQDQFH

&DOLEUDWH

5HVHW5HVWRUH

3URFHVV9DULDEOH

3UHVVXUH

3UHVVXUH'DPSLQJ

6HQVRU7HPSHUDWXUH

&KDQJH'DPSLQJ

6HFXULW\6LPXODWLRQ

:ULWH/RFN6HWXS

*XLGHG6HWXS

=HUR7ULP

&KDQJH'DPSLQJ

/RFDO'LVSOD\6HWXS

&RQILJXUH$QDORJ,QSXW%ORFNV

%DVLF6306HWXS

3ULPDU\9DOXH

&KDQJH'DPSLQJ

6HQVRU7ULP

8SSHU

/RZHU

=HUR

5HVWRUH

5HYLVLRQV

'HYLFH'ULYHU

0RGH6XPPDU\

5HWXUQ$OOWR6HUYLFH

3XW$OO2XWRI6HUYLFH

5HVRXUFH%ORFNದ0RGH&KDQJH

6HQVRU7UDQVGXFHU%ORFNದ0RGH&KDQJH

/&'%ORFN0RGH&KDQJH

630%ORFNದ0RGH&KDQJH

&DOLEUDWH

3ULPDU\9DOXH

&KDQJH'DPSLQJ

6HQVRU7ULP

8SSHU/RZHU=HUR

5HVWRUH

6HQVRU/LPLWV

/DVW&DOLEUDWLRQ3RLQW

&DOLEUDWLRQ'HWDLOV

5HVHW5HVWRUH

0DVWHU5HVHW

5HVWRUH)DFWRU\&DO

Reference Manual Configuration

00809-0100-4774 July 2020

Figure 2-9: Complete Menu Tree

Black text - Navigation selection available

(Text) - Name of selection used on parent menu screen to access this screen

Green text - Automated methods

Reference Manual 17

2YHUYLHZ

3UHVVXUH

&DOLEUDWLRQ

'HYLFH,QIRUPDWLRQ

/RFDWH'HYLFH

6FDOH*DXJHV

&DOLEUDWLRQ

3ULPDU\9DOXH

6HQVRU7ULP

6HQVRU/LPLWV

5HVWRUH)DFWRU\&DOLEUDWLRQ

/DVW&DOLEUDWLRQ3RLQWV

&DOLEUDWLRQ'HWDLOV

'HYLFH,QIRUPDWLRQ

,GHQWLILFDWLRQ

5HYLVLRQV

0DWHULDOVRI&RQVWUXFWLRQ

/LFHQVH

6HFXULW\6LPXODWLRQ

0DWHULDOVRI&RQVWUXFWLRQ

6HQVRU

6HQVRU5DQJH

)ODQJH

5HPRWH6HDO

&RQILJXUH

*XLGHG6HWXS

0DQXDO6HWXS

$OHUW6HWXS

0DQXDO6HWXS

3URFHVV9DULDEOH

0DWHULDOVRI&RQVWUXFWLRQ

'LVSOD\

%DVLF630

&ODVVLF9LHZ

'LVSOD\

'LVSOD\2SWLRQV

$GYDQFHG&RQILJXUDWLRQ

&ODVVLF9LHZ

9LHZ$OO3DUDPHWHUV

0RGH6XPPDU\

0DVWHU5HVHW

3URFHVV9DULDEOH

3UHVVXUH

3UHVVXUH'DPSLQJ

6HQVRU7HPSHUDWXUH

&KDQJH'DPSLQJ

6HFXULW\6LPXODWLRQ

:ULWH/RFN6HWXS

*XLGHG6HWXS

=HUR7ULP

&KDQJH'DPSLQJ

/RFDO'LVSOD\6HWXS

&RQILJXUH$QDORJ,QSXW%ORFNV

%DVLF6306HWXS

Configuration Reference Manual

July 2020 00809-0100-4774

Figure 2-10: Partial Menu Tree

2.2.8

Black text - Navigation selection available

(Text) - Name of selection used on parent menu screen to access this screen

Green text - Automated methods

Red text - Configuration task numbers from configuration flow chart

Navigation

To navigate, click the navigation button labeled with the task you wish to perform. This

takes you to the next navigation screen or the screen where the you can perform the

desired function or launches a guided configuration automated procedure.

Note that you can perform some tasks from several different locations in the menu tree.

This allows you to perform multiple tasks while minimizing the total navigation required to

access and use the desired functions.

18 Rosemount 3051

Reference Manual Configuration

00809-0100-4774 July 2020

Guided setup with automated task procedures (methods)

Guided setup provides automated task procedures for tasks which require multiple steps

to perform. Guided setup also provides notification of recommended actions, such as

suggesting the device user contact control room personnel to have the process loop

placed in manual mode prior to configuration.

Guided setup generally proceeds in three stages. The first is preparation. In this stage, the

device gives user notifications and and performs steps neede3d to prepare the device for

task setup. The second is task execution where the task is performed in a series of steps.

Sometimes the number and sequence of steps is changed based on the values or

parameters selected. This eliminates your need to understand and track how each

configuration choice may influence what can be done in succeeding steps. The third task is

post-setup processing. In this step, the device returns to operation or gracefully cancels a

task.

Guided setup handles mode management as part of preparation and post processing. This

means blocks that must be placed in manual or out of service mode for configuration will

be placed in those modes and upon completion of the configuration task, will return those

blocks to the normal operating mode.

Guided setup helps you complete tasks with the highest probability of success and

gracefully terminate partially completed tasks by returning device parameters to the

values that existed before the terminated task was started. If you are not very familiar with

a device, consider using guided configuration.

2.2.9

Manual setup with manual and automated task procedures

If you are familiar with the mode changes and configuration steps needed to complete a

task and properly return the device to service, you can use manual setup. You can also use

manual setup used when you need to change a single parameter and don't want to

execute the full sequence of steps that are part of guided configuration.

You can sometimes complete manual setup in less time than guided setup; however,

manual setup doesn’t provide the comprehensive guidance or graceful task termination of

guided setup. If you are very familiar with tasks and wish to perform them in the least

time, consider using manual setup.

Classic view

Classic view provides an alternate way to view parameters and perform manual setup. In

the classic view, the individual screens used for manual setup are replaced by a single

scrollable list of parameters. The classic view reduces screen to screen navigation to a

minimum, but requires that you know all the parameters which need to be used and the

order of those parameters to perform each task. You also need to know how to manage

modes, both to perform tasks and to return devices to operation.

Expert users will use classic view to review all block parameters, and to perform some

configuration or service tasks. Emerson does not recommend classic view to anyone who

is not a device and FOUNDATION™ Fieldbus expert.

Reference Manual 19

Configuration Reference Manual

July 2020 00809-0100-4774

Control function block configuration

The Rosemount 3051 uses standard control function blocks.

You can configure these function blocks and link them into control strategies on the

control host using the configuration screens and tools specific to that control host. To

configure control function blocks and use those in control strategies, consult your control

host user documentation.

The device configuration tools support configuration of analog input blocks as needed to

select the channel and perform signal conditioning and scaling. The transmitter ships from

the factory with Analog Input Block 1 linked to the primary variable of the transducer block

and scheduled to run. This is necessary to configure signal conditioning and scaling.

Emerson encourages you to use Analog Input Block 1 for the primary variable when

configuring control strategies.

2.2.10

Confirm correct device driver

• Verify the latest Device Driver (DD/DTM™) is loaded on your systems to ensure proper

communications.

• Download the latest DD at Emerson.com or Fieldbus.org.

• In the Browse by Member dropdown menu, select Rosemount business unit of

Emerson.

• Select desired product.

• Use the device revision numbers to find the correct Device Driver.

Table 2-1: F

Device revision

8 All DD4: DD Rev 1 Fieldbus.org Emerson.com

7 All DD4: DD Rev 3 Fieldbus.org Emerson.com

OUNDATION Fieldbus Device Revisions and Files

(1)

Host Device driver (DD)

All DD5: DD Rev 1 Fieldbus.org

Emerson AMS V 10.5 or higher: DD

Rev 2

Emerson AMS V 8 to 10.5: DD Rev 1 Emerson.com

Emerson 375/475: DD Rev 2 Easy upgrade utility

(2)

DD download web

address

Emerson.com

Device driver (DTM)

All DD5: NA N/A

Emerson Emerson.com

Emerson 375/475: DD Rev 6 Easy upgrade utility

(1) FOUNDATION Fieldbus device revision can be read using a FOUNDATION Fieldbus capable configuration tool.

(2) Device driver file names use device and DD revision. To access functionality, the correct device driver must be installed

on your control and asset management hosts and on your configuration tools.

20 Rosemount 3051

Reference Manual Configuration

00809-0100-4774 July 2020

2.3 Device capabilities

2.3.1 Link active scheduler (LAS)

The transmitter can be designated to act as the backup LAS in the event that the LAS is

disconnected from the segment. As the backup LAS, the Rosemount 3051 will take over

the management of communications until the host is restored.

The host system may provide a configuration tool specifically designed to designate a

particular device as a backup LAS.

2.3.2 Capabilities

Virtual Communication Relationship (VCRs)

There are a total of 20 VCRs. Two are permanent, and 18 are fully configurable by the host

system. 25 link objects are available.

Network parameter Value

Slot time 6

Maximum response delay 4

Maximum inactivity to claim LAS delay 47

Minimum inter DLPDU delay 7

Time sync class 4 (1 ms)

Maximum scheduling overhead 21

Per CLPDU PhL overhead 4

Maximum inter-channel signal skew 0

Required number of post-transmission-gab-ext units 0

Required number of preamble-extension units 1

Host timer recommendations

T1 = 96000

T2 = 9600000

T3 = 480000

Table 2-2:

Block Time (in ms)

Analog input 20

PID 25

Arithmetic 20

Input selection 20

Signal characterizer 20

Reference Manual 21

Configuration Reference Manual

July 2020 00809-0100-4774

Table 2-2: (continued)

Block Time (in ms)

Integrator 20

Output splitter 20

Control selector 20

2.4 Node address

The transmitter is shipped at a temporary (248) address. This enables FOUNDATION

Fieldbus host systems to automatically recognize the device and move it to a permanent

address.

™

2.5 General block information

2.5.1 FOUNDATION™ Fieldbus function blocks

Reference information on the process control function blocks can be found in the Function

Block Reference Manual.

Resource block

The resource block contains diagnostic, hardware, and electronics information. There are

no linkable inputs or outputs to the resource block.

Sensor transducer block

The sensor transducer block contains sensor information including the sensor diagnostics

and the ability to trim the pressure sensor or recall factory calibration.

LCD display transducer block

The LCD display transducer block is used to configure the LCD display meter.

Statistical process monitoring (SPM) block

The SPM block is available on a new transmitter if the D01 option is ordered.

With this block, you can view, configure, and monitor the statistical process monitoring

diagnostics used for process monitoring and plugged impulse line detection.

Analog input block

The analog input (AI) function block processes the measurements from the sensor and

makes them available to other function blocks. The output value from the AI block is in

engineering units and contains a status indicating the quality of the measurement. The AI

block is widely used for scaling functionality.

22 Rosemount 3051

Reference Manual Configuration

00809-0100-4774 July 2020

Note

Typically, instrument personnel configure the channel, Set XD_Scale, Set L_Type, and

sometimes Set Out_Scale. The control systems configuration engineer configures other AI

block parameters, block links, and schedule.

Input selector block

You can use the input selector (ISEL) function block to select the first good, Hot Backup™,

maximum, minimum, or average of as many as eight input values and place it at the

output. The block supports signal status propagation.

Integrator block

The integrator (INT) function block integrates one or two variables over time. The block

compares the integrated or accumulated value to pre-trip and trip limits and generates

discrete output signals when the limits are reached.

The INT block is used as a totalizer. This block will accept up to two inputs and has six

options to totalize the inputs and two trip outputs.

Arithmetic block

The arithmetic (ARTH) function block provides the ability to configure a range extension

function for a primary input. You can also use it to compute nine different arithmetic

functions, including flow with partial density compensation, electronic remote seals,

hydrostatic tank gauging, ratio control, and others.

Signal characterizer block

The signal characterizer (SGCR) function block characterizes or approximates any function

that defines an input/output relationship. The function is defined by configuring as many

as 20 X,Y coordinates. The block interpolates an output value for a given input value using

the curve defined by the configured coordinates. You can process two separate analog

input signals simultaneously to give two corresponding separate output values using the

same defined curve.

PID block

The PID function block combines all of the necessary logic to perform proportional/

integral/derivative (PID) control. The block supports mode control, signal scaling and

limiting, feed forward control, override tracking, alarm limit detection, and signal status

propagation.

The block supports two forms of the PID equation: standard and series. You can select the

appropriate equation using the MATHFORM parameter. The standard ISA PID equation is

the default selection.

Control selector block

The control selector (CSEL) function block selects one of two or three inputs to be the

output. The inputs are normally connected to the outputs of PID or other function blocks.

One of the inputs would be considered normal and the other two overrides.

Reference Manual 23

Configuration Reference Manual

July 2020 00809-0100-4774

Output splitter block

The output splitter (OSPL) function block provides the capability to drive two control

outputs from a single input. It takes the output of one PID or other control block to control

two valves or other actuators.

Index numbers

Table 2-3: Block Index Numbers

Block name Revision 7 Revision 8

Resource block 1000 1000

Sensor transducer block 1100 1100

Display transducer block 1200 1200

Analog input block 1400, 1500 1400, 1500, 2300, 2400

PID block 1600 1600

Input selector block 1700 1700

2.5.2

Signal characterizer block 1800 1800

Arithmetic block 1900 1900

Integrator block 2000 2000

Control selector block N/A 2100

Output splitter block N/A 2200

Function blocks with default block indexes up to 1500 are permanent. Function blocks

with default block addresses 1600 and higher are instantiated and can be deleted.

Modes

The resource, transducer, and all function blocks in the device have modes of operation.

These modes govern the operation of the block. Every block supports both automatic

(AUTO) and out of service (OOS) modes. The blocks may also support other modes.

Changing modes

To change the operating mode, set the MODE_BLK.TARGET to the desired mode. After a

short delay, the parameter MODE_BLK.ACTUAL should reflect the mode change if the

block is operating properly. The automated procedures (methods) make appropriate

resource, transducer, and analog input block mode changes for most configuration tasks.

Permitted modes

You can prevent unauthorized changes to the operating mode of a block. To do this,

configure MODE_BLK.PERMITTED to allow only the desired operating modes. Emerson

recommends always selecting OOS as one of the permitted modes.

24 Rosemount 3051

Reference Manual Configuration

00809-0100-4774 July 2020

Types of modes

For procedures described in this manual, it is helpful to understand the following modes.

AUTO

The functions performed by the block will execute. If the block has any outputs, these will

continue to update. This is typically the normal operating mode.

Out of Service (OOS)

The functions performed by the block will not execute. If the block has any outputs, these

will typically not update and the status of any values passed to downstream blocks will be

BAD. To make some changes to the configuration of the block, change the mode of the

block to OOS. When the changes are complete, change the mode back to AUTO.

MAN

In this mode, you can manually set variables that are passed out of the block for testing or

override purposes.

Other types of modes

2.5.3

Other types of modes are Cas, RCas, ROut, IMan, and LO. For more information, see the

Function Block Reference Manual.

Mode propagation

Note

When an upstream block is set to OOS, this will impact the output status of all

downstream blocks. The figure below depicts the hierarchy of blocks:

Block instantiation

When a device supports block instantiation, you can define the number of blocks and

block types to match specific application needs. The number of blocks that can be

instantiated is only limited by the amount of memory within the device and the block

types that are supported by the device. Instantiation does not apply to standard device

blocks like the resource, sensor transducer, LCD display transducer, and SPM blocks.

Block instantiation is done by the host control system or configuration tool, but not all

hosts are required to implement this functionality. Refer to your specific host or

configuration tool manual for more information.

Reference Manual 25

Configuration Reference Manual

July 2020 00809-0100-4774

2.5.4 Simulation

Simulation is the functionality of the AI block. There are two ways to simulate values as

follows:

Procedure

1. Change the mode of the block to Manual and adjust the output value.

2. Enable simulation through the configuration tool and manually enter a value for the

measurement value and its status (this single value will apply to all outputs).

In both cases, first set the ENABLE switch on the field device.

With simulation enabled, the actual measurement value has no impact on the OUT

value or the status. The OUT values will all have the same value as determined by the

simulate value.

2.6 Resource block

2.6.1

This section contains information on the Resource Block. It includes descriptions of all

Resource Block parameters, errors, and diagnostics. It also discusses the modes, alarm

detection, status handling, and troubleshooting.

FEATURES and FEATURES_SEL

The FEATURES parameter is read only and defines which host accessible features are

supported by the transmitter. See the Specifications section of the Rosemount 3051S

Product Data Sheet for the complete list.

Use FEATURES_SEL to turn on any of the supported features that are found in the

FEATURES parameter.

UNICODE

All configurable string variables in the transmitter, except tag names, are octet strings.

You may use either ASCII or Unicode. If the configuration device is generating Unicode

octet strings, you must set the Unicode option bit.

REPORTS

The transmitter supports alert reports. You must set the Reports option bit in the features

bit string to use this feature. If it is not set, the host must poll for alerts. If this bit is set, the

transmitter will actively report alerts.

SOFT W LOCK and HARD W LOCK

Inputs to the security and write lock functions include the hardware security switch, the

hardware and software write lock bits of the FEATURE_SEL parameter, and the

WRITE_LOCK parameter.

The WRITE_LOCK parameter prevents modification of parameters within the device

except to clear the WRITE_LOCK parameter. During this time, the block will function

26 Rosemount 3051

Reference Manual Configuration

00809-0100-4774 July 2020

normally, updating inputs and outputs and executing algorithms. When the condition is

cleared, an alert is generated with a priority that corresponds to the WRITE_PRI

parameter.

The FEATURE_SEL parameter enables you to select any one of the following: a hardware

write lock, a software write lock, or no write lock capability. To enable the hardware

security function, enable the HARD W LOCK bit in the parameter. When this bit has been

enabled, the WRITE_LOCK parameter becomes read only and reflects the state of the

hardware switch. In order to enable the software write lock, place the hardware write lock

switch in the unlocked position. Then set the SOFT W LOCK bit in the FEATURE_SEL

parameter. Once this bit is set, you may set the WRITE_LOCK parameter to Locked or Not

Locked. Once you have set the WRITE_LOCK parameter to Locked with either the software

or the hardware lock, all user requested writes will be rejected.

2.6.2

2.6.3

MAX_NOTIFY

The MAX_NOTIFY parameter value of seven is the maximum number of alert reports the

resource can have sent without getting a confirmation from the host, corresponding to

the amount of buffer space available for alert messages. You can set the number lower, to

control alert flooding, by adjusting the LIM_NOTIFY parameter value. If LIM_NOTIFY is set

to zero, then no alerts are reported.

Alerts/alarms

The transmitter annunciates alerts as either Plantweb™ or NE107 Status Signals. All alerts

are configured, masked, and mapped as NE 107 Status Signals. If the control host is

DeltaV™ version 11.5 or older, alerts are automatically annunciated as PlantWeb Alerts. No

user configuration is needed for this conversion.

The alerts and recommended actions should be used in conjunction with Troubleshooting.

See Resource Block for more information on resource block parameters.

The resource block acts as a coordinator for alerts. Depending on user configuration, each

device will have either three or four alert parameters. If Plantweb alerts are annunciated,

the three alert parameters will be: FAILED_ALARM, MAINT_ALARM, and ADVISE_ALARM. If

NE107 alerts are annunciated, the four alert parameters called status signals will be:

FD_FAIL_ACTIVE, FD_OFFSPEC_ACTIVE, FD_MAINT_ACTIVE, and FD_CHECK_ACTIVE.

Note

NE107 alerts and Plantweb alerts annunciate the same diagnostics and display the same

recommended actions. The only difference in the alerts reported is the parameters or

status signals used to annunciate the alert conditions. The default factory configuration

has NE107 alerts enabled.

Alerts processing within the device

Procedure

1. Diagnostics perform comprehensive checks and update status within the device.

These status conditions allow you to troubleshoot probable causes and take

corrective actions.

Reference Manual 27

1. Detailed status includes

conditions found by all

diagnostics the device

runs.

Detailed status for

NE 107 and PlantWeb

alerts are identical.

2. Consolidated status

groups diagnostics by

probable cause and

corrective action.

Consolidated status for

NE 107 and PlantWeb

alerts are identical.

3. Mapping of conditions

defines how conditions will

be reported. NE 107

mapping can be user

modified.

4. Masking of conditions

determines which

conditions are reported to

the host and which are not

by status signal. All

status signals remain

5. Unmasked active

conditions are reported to

the host. The unmasked

or PlantWeb Alert

Sensor Status condition 1

Detailed Status

Sensor Status condition N

Electronics Status condition

1

Electronics Status condition

N

Extended Sensor Status

condition

“Sensor Failure”

Extended Electronics

Status condition

“Electronics Failure”

Additional Status

conditions

User Actionable

Consolidated Status

Mapping of Status

Conditions to Status

Signals

FD _FAIL _MAP

FD _MAINT _MAP

Additional Status

Signals Mapped

Masking of Alert Parameters

FD _MAINT _MASK

Alert Conditions reported to host

as NE 107 Status Signals or

Sensor Failure

Electronics Failure

Additional Alert Conditions

by Status Signal

within each status signal

diagnostic conditions and

visible within the device.

conditions are reported by

status signal categories

categories.

PlantWeb Alerts

Configuration Reference Manual

July 2020 00809-0100-4774

2. The status conditions are then mapped into four status signals that can be used for

annunciation on the segment to the host.

3. Before annunciation, a check is made to determine if you have masked any alert

parameters. Any masked parameters will not be annunciated to the host, but will be

visible using the device DD or DTM.

4. Unmasked alert conditions are annunciated by the appropriate status signal to the

host.

Plantweb™ Alerts and NE107 Alerts are both processed using the steps described above

and annunciate the same consolidated status parameters.

Figure 2-11: NE107 Alert Processing Diagram

28 Rosemount 3051

Reference Manual Configuration

00809-0100-4774 July 2020

Figure 2-12: NE 107 Status Signal to Plantweb Alert Mapping

The alert priority enumeration value

Alerts have priorities that determine if they occur and where and how they are

annunciated.

NE107 status signals and Plantweb™ alerts use the same priorities and annunciate the

same ways.

0

Alerts will not occur. If there is an existing alert and the priority is changed from a

number greater than zero to zero, it will clear. Active device diagnostics are still

shown within the Device Description even if the alert has been cleared.

1

The associated alert is not sent as a notification. If the priority is above 1, then the

alert must be reported.

2

Reserved for alerts that do not require the attention of a plant operator, e.g.

diagnostic and system alerts. Block alert, error alert, and update event have a fixed

priority of 2.

3-7

Increasing higher priorities - advisory alerts.

8–15

Increasing higher priority - critical alerts.

Configure Plantweb Alert priorities with DeltaV™.

Reference Manual 29

Configuration Reference Manual

July 2020 00809-0100-4774

NE107 alerts overview

NE107 alert parameters

NE107 has four alert status signals. They are in order from highest to lowest priority:

1. FD_FAIL_ACTIVE

2. FD_OFFSPEC_ACTIVE

3. FD_MAINT_ACTIVE

4. FD_CHECK_ACTIVE

You can configure any of the eight alert conditions to annunciate as any of the four status

signals. You can also map individual alert conditions into multiple status signals.

Alert parameter definitions and factory defaults

Note

All eight alert conditions are factory assigned to appropriate status signals. Change the

parameter assignment of individual alert conditions only if needed.

Devices are shipped from the factory with all applicable alerts enabled. The factory default

alert conditions reported in each status signal are:

1. FD_FAIL_ACTIVE

a. Incompatible module

b. Sensor failure

c. Electronics failure

A FD_FAIL_ACTIVE status signal indicates a failure within a device that will make the

device or some part of the device non-operational. This implies that the process

variable may no longer be available and the device is in need of immediate repair.

2. FD_OFFSPEC_ACTIVE

a. Pressure out of limits

b. Sensor temperature out of limits

A FD_OFFSPEC_ACTIVE status signal indicates that the device is experiencing

pressure or temperature conditions that are outside the device operating range.

This implies that the process variable may no longer be accurate. It also implies that

if the condition is ignored the device will eventually fail.

3. FD_MAINT_ACTIVE

a. Display update failure

b. Variation change detected

A FD_MAINT_ACTIVE status signal indicates the device is still functioning but an

abnormal process or device condition exists. The device should be checked to

determine the type of abnormal condition and recommended actions to resolve it.

4. FD_CHECK_ACTIVE

a. Function check

30 Rosemount 3051

Loading...

Loading...