Page 1

Quick Start Guide

00825-0100-3008, Rev AB

Rosemount™ RBI pH/ORP Sensors

September 2020

Page 2

Quick Start Guide September 2020

Safety information

WARNING

Hot surface

Before removing the sensor, be absolutely certain that the process pressure is reduced to 0 psig and

the process temperature is lowered to a safe level.

WARNING

Corrosive substance

The solution used during calibration is an acid.

Handle with care.

Follow the directions of the acid manufacturer.

Wear proper protective equipment.

Do not let the solution come in contact with skin or clothing.

If contact with skin is made, immediately rinse with clean water.

CAUTION

Application compatiblity

The wetted sensor materials may not be compatible with process composition and operating

conditions.

Application compatibility is entirely the operator's responsibility.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of end

users’ equipment. This could be intentional or unintentional and needs to be protected against.

Physical security is an important part of any security program and fundamental to protecting your

system. Restrict physical access by unauthorized personnel to protect end users’ assets. This is true for

all systems used within the facility.

Contents

Overview......................................................................................................................................3

Installation................................................................................................................................... 5

Startup.......................................................................................................................................22

Accessories................................................................................................................................ 23

2 Emerson.com/Rosemount

Page 3

September 2020 Quick Start Guide

1 Overview

1.1 Unpack and inspect

Procedure

1. Inspect the shipping container. If it is damaged, contact the shipper

immediately for instructions.

2. If there is no apparent damage, unpack the container. Be sure all

items shown on the packing list are present. If items are missing,

notify Emerson immediately.

1.2 Specifications

Rosemount RBI pH/ORP Sensor Specifications

Measurement range

Wetted materials

Maximum

temperature

Maximum pressure

Maximum insertion

pressure (option 547)

Maximum retraction

pressure (option 547)

Process connection

pH: 0 to 14

ORP: -1500 to +1500 mV

Kynar®, titanium (retractable 547 only), porous

PTFE, wood, glass, and choice of EPDM, Viton®,

or Kalrez

248 °F (120 °C) at 40 psig (276 kPa [abs])

150 psig (1,035 kPa [abs]) at 158 °F (70 °C)

65 psig (448 kPa [abs] at 158 °F (70 °C)

40 psig (276 kPa [abs]) at 248 °F (120 °C)

Body type 546: Forward and rear facing ¾-in.

MNPT

Body type 547: None, requires user-supplied 1in. MNPT process fitting or ball valve set.

1.3 Storage and maintenance

Sensors require little care or maintenance. Simple guidelines follow:

During storage, keep sensors near room temperature and capped on the

measuring end. These caps supplied from the factory are filled with a weak

pH 7 buffer in order to keep the sensor wet. Check sensors in storage semiannually to assure that the cap retains moisture; if the pH 7 buffer

evaporates, replace it with ordinary tap water.

®

Quick Start Guide 3

Page 4

Quick Start Guide September 2020

Cleaning the pH sensor is easy. The reference usually does not require

maintenance. If a coating forms over the exposed portion of the reference,

scrape it off with a small penknife. Take care not to break the glass when

scraping the reference.

Glass pH electrodes can be cleaned in a number of ways. To remove scaling,

oils, and other stubborn coatings, soak the electrode in a five to ten percent

HCl solution for a few minutes and then rinse it under tap water. Very heavy

coatings may require more than one soaking. To clean minor coatings,

direct a stream of tap water directly onto the glass. With new sensors, wipe

the glass with a clean, soft cloth. Take care with this approach as the glass

may break when mishandled.

Oils or greases that can accumulate on the glass bulb may not be visible to

the eye. To remove these, stir the sensor in a solvent such as isopropyl

alcohol. Heavy build-up may require a number of alcohol cycles followed by

wiping with a soft cloth. You may also use a dish soap.

Run sensor cables through the conduit or protect them from the

environment; they are not weather-proof. Do not allow cables and

connectors to become wet, lay on the ground or across equipment, etc. Do

not abrade, pinch, twist, or sharply bend cables.

4 Emerson.com/Rosemount

Page 5

September 2020 Quick Start Guide

2 Installation

2.1 RBI 546 Installation

Figure 2-1: In-Line Submersion Option 546 with Integral Cable

Connection

A. Measuring electrode: choice of ruggedized hemi glass, ruggedized flat

glass, or flat platinum ORP (non-glass)

Reference junction: PTFE junction flat and flash or PTFE junction with

notched glass protection

B. L - insertion depth (see Table 2-1)

C. Kynar® body

D. ¾-in. MNPT

E. ⅞-in. wrench flats

Table 2-1: Insertion Depth

Option L

05 0.5-in. (12.7 mm)

10 1.0-in. (25.4 mm)

15 1.5-in. (38 mm)

Quick Start Guide 5

Page 6

Quick Start Guide September 2020

Figure 2-2: In-Line Submersion Option 546 with Variopol Cable

Connection

A. Insertion depth (see Table 2-2)

B. ⅞-in. flats

C. 8-in. cable

D. VP8 male connector

E. ¼-in. cable

F. ¾-in. MNPT thread

Table 2-2: Insertion Depth

Option L

05 0.5-in. (12.7 mm)

10 1.0-in. (25.4 mm)

15 1.5-in. (38 mm)

Procedure

1. For integral cable sensors, reference Figure 2-1-dimension B to select

appropriate mounting nozzle or pipe tee dimensions to achieve

desired insertion depth.

2. For VP sensors, reference Figure 2-2-dimension B to select

appropriate mounting nozzle or pipe tee dimensions to achieve

desired insertion depth.

3. Wrap the sensor threads (D) with PTFE tape to prevent leakage.

a) Use front facing threads for insertion installations in a pipe

tee/process nozzle.

b) Use rear facing threads for submersion installations threaded

into conduit.

4. Do not overtighten sensor into its receptacle.

5. Hand tighten the sensor, then tighten one or two turns with a

wrench to secure in place.

6 Emerson.com/Rosemount

Page 7

September 2020 Quick Start Guide

2.2 RBI 547 installation

Figure 2-3: Titanium Sheath Dimensions (for 547 Option)

A. A length (see Table 2-3)

B. B length (see Table 2-3)

C. O-rings (see Table 2-3)

D. O-ring material I.D. (V = Viton®, E = EPDM, K = Kalrez®)

E. ¾-in. MNPT

F. Sheath material I.D. (T = titanium, H = Hastelloy C)

G. Extension Kynar

H. Swage

I. Titanium sheath

Table 2-3: Titanium Sheath Dimensions (for 547 Option)

Part number Sheath

materials

RB5104-0058E T E 7-in. (177.8 mm) 1.9-in. (48.3 mm)

RB5104-0078E H E

RB5104-0120E T E 19-in. (482.6 mm) 13.9-in. (353.1

RB5104-0120V T V

RB5104-0320E H E

RB5104-0320K H K

RB5104-0136E T E 35-in. (889 mm) 29.9-in. (759.5

RB5104-0336E H E

Quick Start Guide 7

O-ring

materials

A length B length

mm)

mm)

Page 8

Quick Start Guide September 2020

Figure 2-4: Retractable Body Type Sensor (547) with Integral Cable

Connection and Sheath

Shown with 20-in. (508 mm) sheath (RB5104-0120E/RB5104-0120V/

RB5104-0320E)

A. Blowout safety stop

B. Fitting sold separately

C. 1.00-in. (25.4 mm) diameter

D. ¾-in NPT thread

E. Kynar® extension

F. O-rings

G. Sensor sheath

H. Sensor cartridge

8 Emerson.com/Rosemount

Page 9

September 2020 Quick Start Guide

Figure 2-5: Retractable Option 547 with Variopol Cable Connection

A. O-rings

B. VP8 connector option (24 in. [609.6 mm] cable length)

C. VP8 connector cable (part #24281-XX)

D. Available options include: hemi or flat glass electrodes, notched or flush

tip configurations

E. 15/16-in. wrench flats

Quick Start Guide 9

Page 10

Quick Start Guide September 2020

Figure 2-6: RBI Retractable Body Type Sensor (547) with 1½-in. Ball

Valve Assembly (PN 23240-00)

When inch and metric dimensions are given, millimeters are over inches.

A. Length (see Table 2-4)

B. Length (see Table 2-4)

C. Cable bushing polypropylene

D. 1-in. x 1-in. Swage fitting kit (PN 23166-00 or 23166-01) required to

connect sensor directly to ball valve

E. See warning below

F. 1½-in. x 1-in. FPT reducing coupling

G. 1½-in. MPT close nipple

H. 1½-in. FPT ball valve PN 9340065

I. Ball valve kit (PN 23240-00) optional

WARNING

High pressure

10 Emerson.com/Rosemount

Page 11

September 2020 Quick Start Guide

WARNING

Residual pressure and process may remain trapped between ball valve and

male connector.

Maximum pressure at retraction: 65 psig (option 546), 40 psig (option 547)

Note

Unless otherwise specified

Table 2-4: Length

A B

11.4-in./290 mm 20.5-in./521 mm

The 1¼-in. ball valve kit assembly (PN 23765-00) is not shown above, but is

also compatible with Rosemount RBI Retractable Body Type Sensor (547).

Note

Add five inches to length of sensor if mounting a sensor-head junction box

onto the sensor.

Quick Start Guide 11

Page 12

Quick Start Guide September 2020

Figure 2-7: Typical Mounting Details for the Retractable Body Type

Sensor (547)

Note

Sensor must be mounted at an angle between 10 degrees and 90 degrees

above the horizontal. Pipe tees and weldalets are customer supplied. Figure

above shown with sensor head junction box PN 23709-00 (sold separately).

A. Butt weld branch connection (1½-in. FPT)

B. Electrode housing tip

C. Electrode

D. Flow

E. Pipe Y

F. Pipe tee

G. Flow

For dimensional information on assembled retraction sheath, refer to Figure

2-3.

All RBI 547 Assemblies consist of the pieces shown in Figure 2-4.

12 Emerson.com/Rosemount

Page 13

September 2020 Quick Start Guide

Procedure

1. Remove extension piece (G) from sensor sheath (J)

2. Loosen compression fitting (B) several turns and gently push onto

the sheath (L) with threads facing the blowout safety stop (A)

3. Lubricate O-rings on sensor cartridge (L) and Kynar extension (G) if

needed.

4. Slide sensor into sheath until the tip bottoms out. Cable should be

routed through the sheath a. For VP sensors (Figure 2-5), male VP

plug (B) must be fully routed through the kynar extension

5. Hand tighten extension piece clockwise, so the threads engage those

on the rear of the sensor.

6. If sensor cap is still in place, remove, and install sensor into process.

7. Reference Figure 2-6 for dimensional information on completed

assembly to assist in setting the correct depth for the sensor into

process

2.3 Wire sensor to transmitter

Procedure

1. Remove the protective covering on the white (reference) wire.

2. Wire the correct sensor leads to the main board using the lead

locations marked directly on the board.

See the diagrams below. You may use either integral cables or

Variopol cables.

NOTICE

Keep sensor and output signal wiring separate from loop power

wiring. Do not run sensor and power wiring in the same conduit or

close together in a cable tray.

NOTICE

Do not overtighten submersible sensors during installation.

Quick Start Guide 13

Page 14

Quick Start Guide September 2020

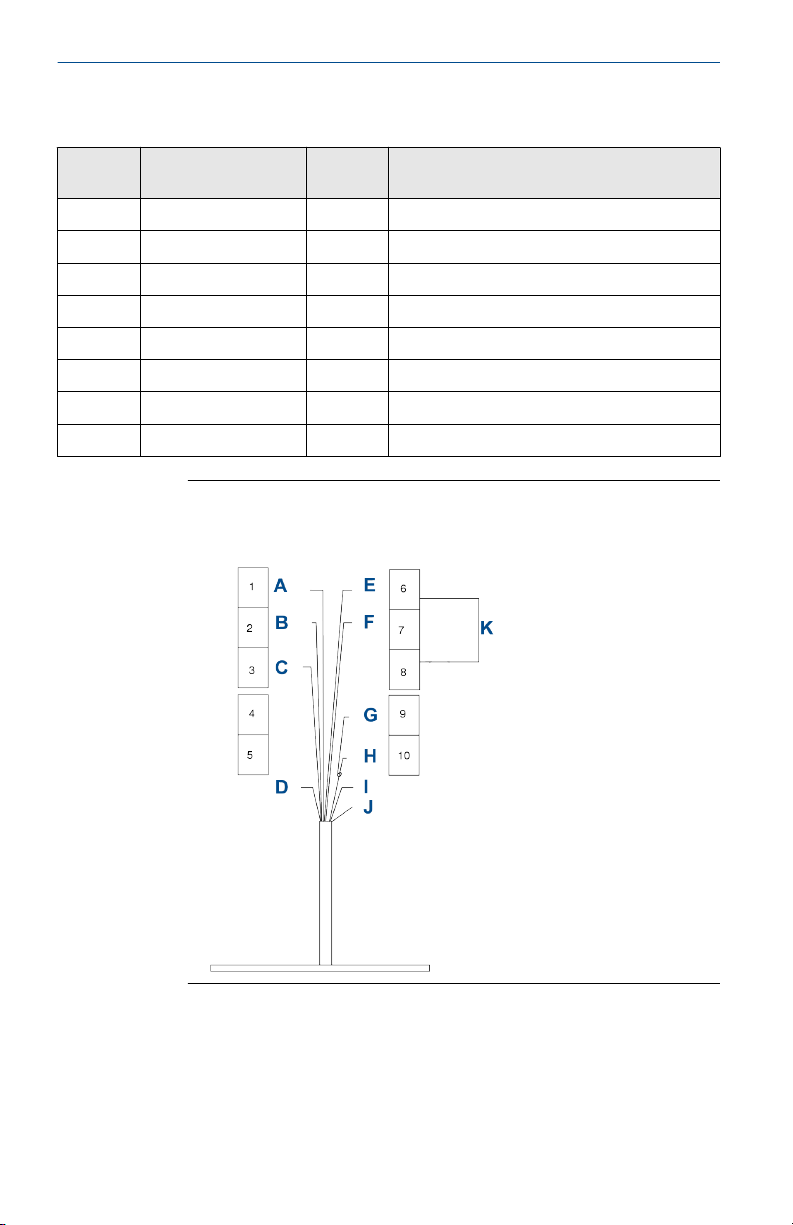

Figure 2-8: Integral Cable Wiring

A. 22 AWG leads

B. Red (resistance temperature device in)

C. Black (resistance temperature device sense)

D. Green (resistance temperature device return)

E. White (reference)

F. Remove protective insulation before wiring

G. Gray (pH shield)

H. Coaxial center (pH in)

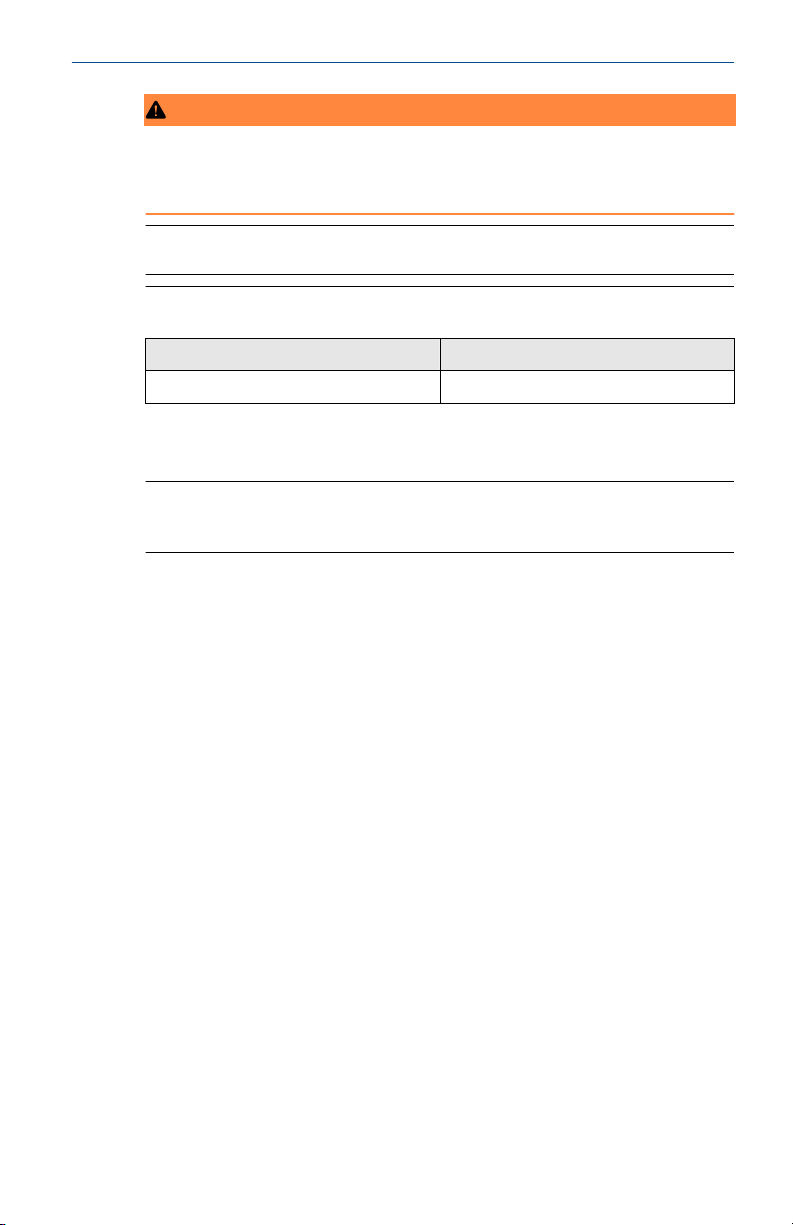

Figure 2-9: Rosemount RBI with Integral Cable Connection

Wiring Diagram for Rosemount 56, 1056, 1057, and 1066

Transmitters

14 Emerson.com/Rosemount

Page 15

September 2020 Quick Start Guide

Table 2-5: Rosemount RBI with Integral Cable Connection Wiring Diagram for

Rosemount 56, 1056, 1057, and 1066 Transmitters

Letter Wire color Terminal

number

A Green 1 Resistance temperature device (RTD) return

B Black 2 Resistance temperature device (RTD) sense

C Red 3 Resistance temperature device (RTD) in

D N/A 4 Ground

N/A N/A 5 +5 Vdc

N/A N/A 6 -5 Vdc

E Gray 7 pH shield

F Coaxial 8 pH in

G None 9 Reference shield

H White 10 Reference

I N/A 4 to 10 Jumper

Description

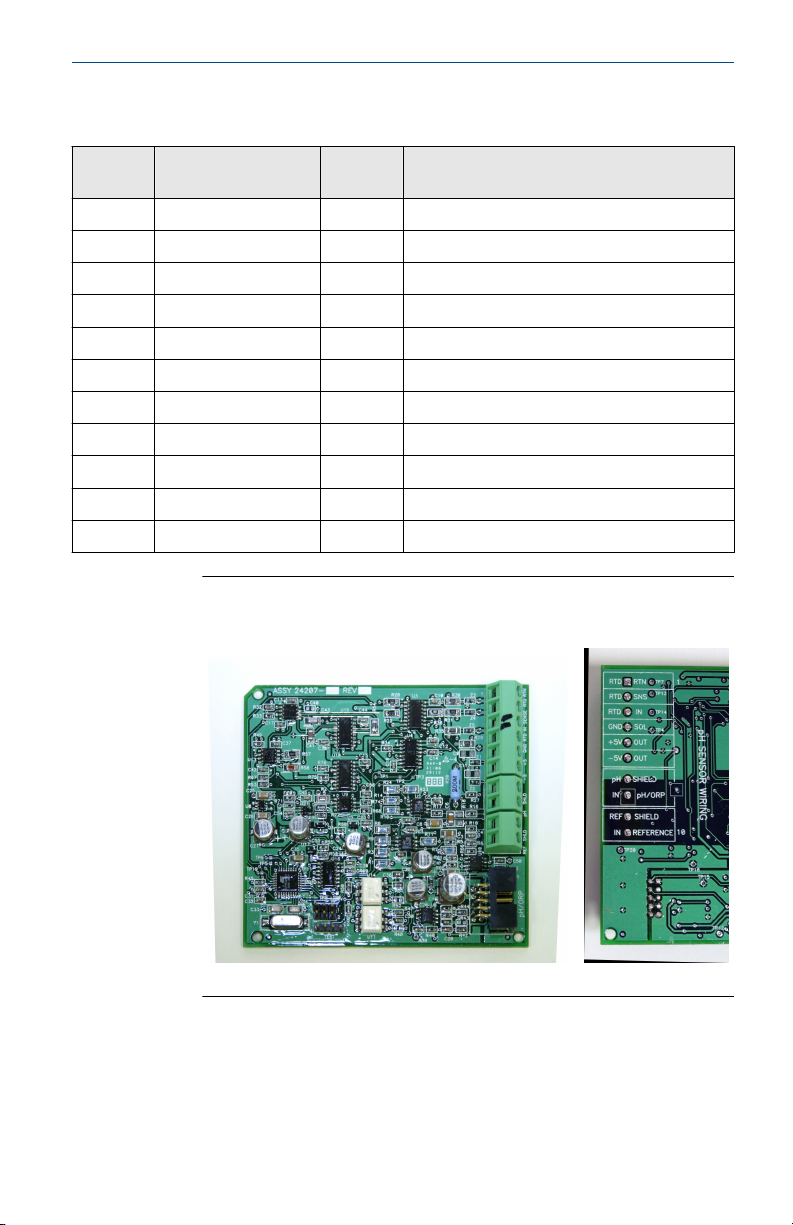

Figure 2-10: Example of Printed Circuit Board of the pH Card for

Rosemount 1056, 56, and 1057 Transmitters

Quick Start Guide 15

Page 16

Quick Start Guide September 2020

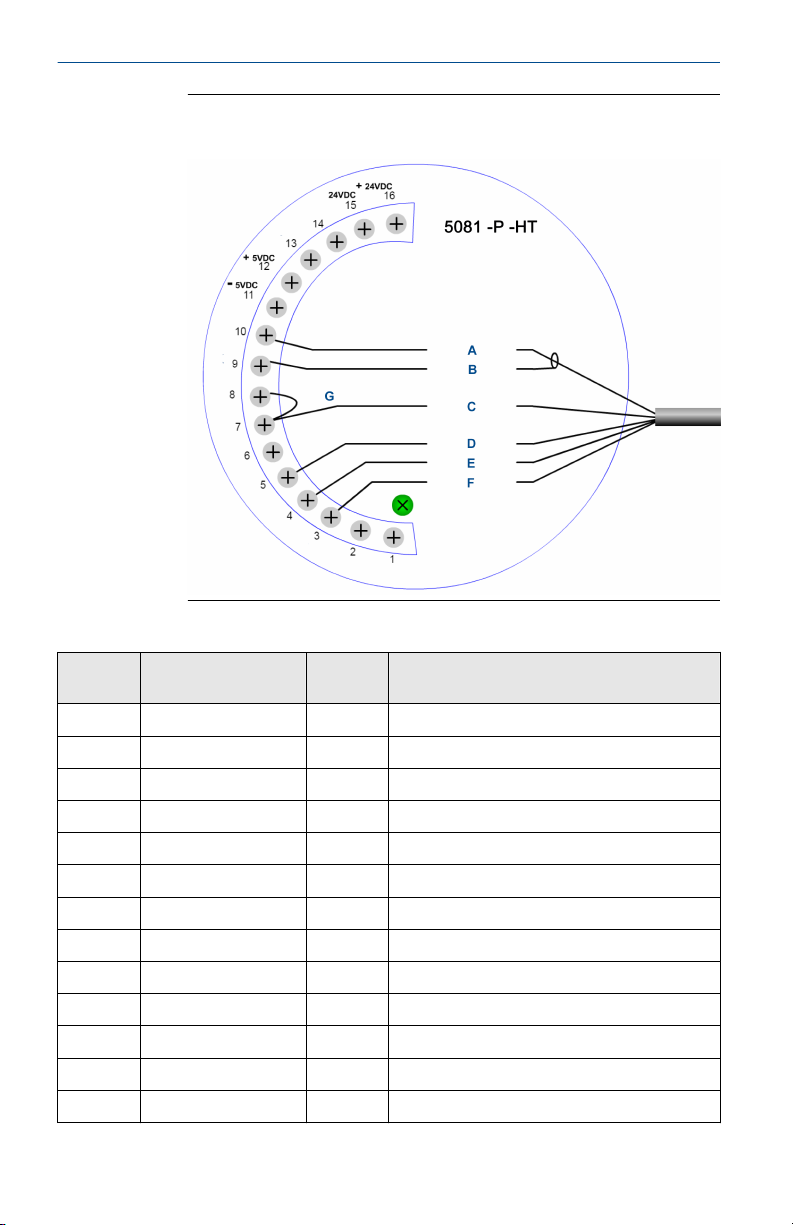

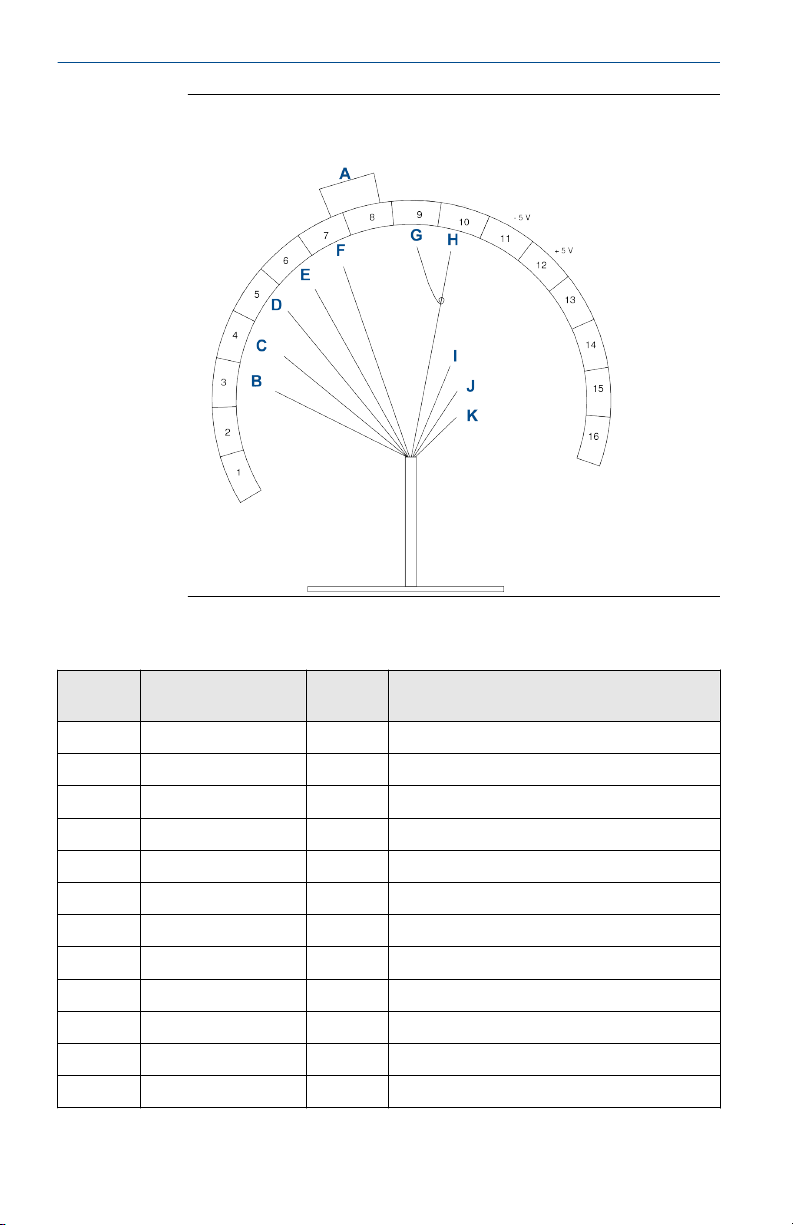

Figure 2-11: Rosemount RBI with Integral Cable Connection

Wiring Diagram for Rosemount 5081 Transmitters

Table 2-6: Rosemount RBI with Integral Cable Wiring to Rosemount 5081

Letter Wire color Terminal

number

N/A NA 1 N/A

N/A N/A 2 N/A

F Green 3 Resistance temperature device (RTD) return

E Black 4 Resistance temperature device (RTD) sense

D Red 5 Resistance temperature device (RTD) in

N/A N/A 6 Drain

C White 7 Reference

G Jumper 8 Solution ground

B Gray 9 Drain

A Coaxial 10 mV in

N/A N/A 11 -5 Vdc

N/A N/A 12 +5 Vdc

N/A N/A 13 Anode

16 Emerson.com/Rosemount

Description

Page 17

September 2020 Quick Start Guide

Table 2-6: Rosemount RBI with Integral Cable Wiring to Rosemount 5081

(continued)

Letter Wire color Terminal

number

N/A N/A 14 Cathode

N/A N/A 15 -24 Vdc

N/A N/A 16 +24 Vdc

Description

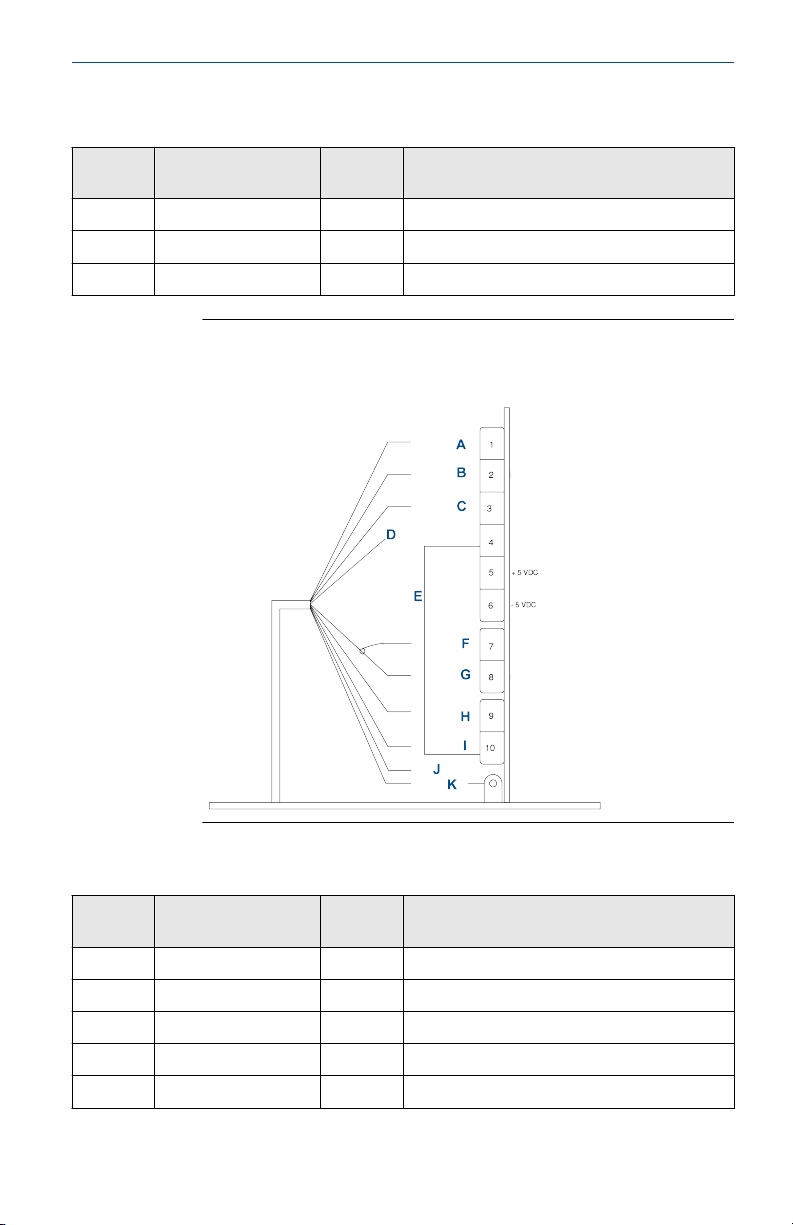

Figure 2-12: Rosemount RBI with Variopol Cable (24281-XX)

Wiring Diagram for Rosemount 56, 1056, and 1057 Transmitters

Table 2-7: Rosemount RBI with Variopol Cable (24281-xx) Wiring to Rosemount

56, 1056, and 1057 Transmitters

Letter Wire color Terminal

number

A White 1 Resistance temperature device (RTD) return

B White/red 2 Resistance temperature device (RTD) sense

C Red 3 Resistance temperature device (RTD) in

D Blue N/A No connect (cap)

E Jumper 4 to 10 Ground

Quick Start Guide 17

Description

Page 18

Quick Start Guide September 2020

Table 2-7: Rosemount RBI with Variopol Cable (24281-xx) Wiring to Rosemount

56, 1056, and 1057 Transmitters (continued)

Letter Wire color Terminal

number

N/A N/A 5 +5 Vdc

N/A N/A 6 -5 Vdc

F Clear 7 pH shield

G Orange 8 pH in

H White/gray 9 Reference shield

I Gray 10 Reference

J Clear ID N/A ID - no connect

K Green N/A N/A

Description

Figure 2-13: Rosemount RBI with Variopol Cable (24281-XX)

Wiring Diagram for Rosemount 1066 Transmitters

18 Emerson.com/Rosemount

Page 19

September 2020 Quick Start Guide

Table 2-8: Rosemount RBI with Variopol Cable (24281-xx) Wiring to Rosemount

1066 Transmitters

Letter Wire color Terminal

number

A White 1 Resistance temperature device (RTD) return

B White/red 2 Resistance temperature device (RTD) sense

C Red 3 Resistance temperature device (RTD) in

N/A N/A 4 + volts

N/A N/A 5 - volts

D Green N/A No connect (cap)

E Gray 6 Reference in

F White/gray 7 Reference shield

N/A N/A 8 Solution ground

K N/A 6 to 8 Jumper

G Clear 9 pH shield

H Clear 10 pH in

I N/A N/A No connect (cap)

J Blue N/A No connect (cap)

Description

Quick Start Guide 19

Page 20

Quick Start Guide September 2020

Figure 2-14: Rosemount RBI with Variopol Cable (24281-XX)

Wiring Diagram for Rosemount 5081 Transmitters

Table 2-9: Rosemount with Variopol Cable (24281-xx) Wiring to Rosemount 56,

1056, and 1057 Transmitters

Letter Wire color Terminal

number

N/A N/A 1 Reserved

N/A N/A 2 Reserved

B White 3 Resistance temperature device (RTD) return

C White/red 4 Resistance temperature device (RTD) sense

D Red 5 Resistance temperature device (RTD) in

E White/gray 6 Reference guard

F Gray 7 Reference in

A Jumper 8 Solution ground

G Clear 9 pH/ORP ground

H Orange 10 pH/ORP in

N/A N/A 11 -5 V

N/A N/A 12 +5 V

20 Emerson.com/Rosemount

Description

Page 21

September 2020 Quick Start Guide

Table 2-9: Rosemount with Variopol Cable (24281-xx) Wiring to Rosemount 56,

1056, and 1057 Transmitters (continued)

Letter Wire color Terminal

number

N/A N/A 13 Anode/reserved

N/A N/A 14 Cathode/reserved

N/A N/A 15 HART®/FOUNDATION™ Fieldbus (-)

N/A N/A 16 HART/FOUNDATION Fieldbus (+)

I Blue N/A No connect (cap)

J Green N/A Chassis screw

K Clear N/A ID - no connect (cap)

Description

3. After wiring the sensor leads, carefully take up the excess sensor

cables through the cable gland.

Quick Start Guide 21

Page 22

Quick Start Guide September 2020

3 Startup

Refer to the manual for your transmitter (Rosemount 56, 1056, 1057, 1066,

or 5081) for directions on operating the transmitter after it has been wired

to the sensor.

Procedure

1. Wire sensor(s) to the signal boards.

See Wire sensor to transmitter for wiring diagrams.

2. Once connections are secured and verified, apply power to the

transmitter.

WARNING

Risk of electrical shock

Electrical installation must be in accordance with the National

Electrical Code (ANSI/NFPA-70) and/or any other national or local

codes.

When the transmitter is initially powered up, Quick Start screens

appear.

3. Refer to the manual for your transmitter to complete the steps in the

Quick Start process.

22 Emerson.com/Rosemount

Page 23

September 2020 Quick Start Guide

4 Accessories

Part number Description

RB5104-0058E 8-in. (203,2 mm) titanium, Kynar®, EPDM, 547 retractable

RB5104-0078E 8-in. (203,2 mm) Hastelloy-C, Kynar, EPDM, 547 retractable

RB5104-0120E 20-in. (508 mm) titanium, Kynar, EPDM, 547 retractable

RB5104-0120V 20 in.(508 mm) titanium, Kynar, Viton®, 547 retractable

RB5104-0136E 36-in. (914,4 mm) titanium, Kynar, EPDM, 547 retractable

RB5104-0320E 20-in. (508 mm) Hastelloy-C, Kynar, EPDM, 547 retractable

RB5104-0336E 36-in. (914,4 mm) Hastelloy-C, Kynar, EPDM, 547 retractable

RB5104-0320K 20-in. (508 mm) Hastelloy-C, Kynar, Kalrez®, 547 retractable

23166-00 1-in. x 1-in. process connector, 316 stainless steel

23166-01 1-in. x 1-in. process connector, titanium

23240-00 1½-in. ball valve kit assembly, 316 stainless steel (does not

23765-00 1¼-in. ball valve kit assembly, 316 stainless steel (does not

24281-00 15-ft. (4,6 m) cable with mating VP8 connector

24281-01 25-ft. (7,6 m) cable with mating VP8 connector

24281-02 2.5-ft. (0,8 m) cable with mating VP8 connector

24281-05 4-ft. (1,2 m) cable with mating VP8 connector

24281-06 10-ft. (3 m) cable with mating VP8 connector

24281-07 20-ft. (6,1 m) cable with mating VP8 connector

24281-08 30-ft. (9,1 m) cable with mating VP8 connector

insertion sheath

insertion sheath

insertion sheath

insertion sheath

insertion sheath

insertion sheath

insertion sheath

insertion sheath

include process connector)

include process connector)

Quick Start Guide 23

Page 24

*00825-0100-3008*

EMERSON AUTOMATION SOLUTIONS

6021 Innovation Blvd.

Shakopee, MN 55379

+1 866 347 3427

+1 952 949 7001

RMTNA.RCCPO@Emerson.com

00825-0100-3008, Rev. AB

Quick Start Guide

September 2020

NORTH AMERICA

Emerson Automation Solutions

8200 Market Blvd

Chanhassen, MN 55317

Toll Free +1 800 999 9307

F +1 952 949 7001

RMTNA.RCCPO@Emerson.com

MIDDLE EAST AND AFRICA

Emerson Automation Solutions

Emerson FZE

Jebel Ali Free Zone

Dubai, United Arab Emirates, P.O. Box

17033

+971 4 811 8100

+971 4 886 5465

RMTNA.RCCPO@Emerson.com

LinkedIn.com/company/Emerson-

Automation-Solutions

Twitter.com/rosemount_news

Facebook.com/Rosemount

Youtube.com/RosemountMeasurement

EUROPE

Emerson Automation Solutions

Neuhofstrasse 19a PO Box 1046

CH-6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RMTNA.RCCPO@Emerson.com

ASIA-PACIFIC

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

Republic of Singapore

+65 6 777 8211

+65 6 777 0947

RMTNA.RCCPO@Emerson.com

©

2020 Emerson. All rights reserved.

The Emerson logo is a trademark and service

mark of Emerson Electric Co. Rosemount is a

mark of one of the Emerson family of companies.

All other marks are the property of their

respective owners.

Loading...

Loading...