Quick Installation Guide

00825-0100-4003, Rev BA

February 2004

Vortex Flowmeter

Step 1: Mount the Flowmeter

Step 2: Consider Housing Rotation

Step 3: Set the Jumpers

Step 4: Connect the Wiring and Power Up

Step 5: Review Flowmeter Configuration

Product Certifications

Rosemount 8800C

Start

www.rosemount.com

¢00825-0100-4003g¤

Quick Installation Guide

Rosemount 8800C

© 2004 Rosemount Inc. All rights reserved. All marks property of owner.

Rosemount Inc.

8200 Market Boulevard

Chanhassen, MN USA

55317

T (US) (800) 999-9307

T (Intnl) (952) 906-8888

F (952) 949-7001

00825-0100-4003, Rev BA

February 2004

IMPORTANT NOTICE

This installation guide provides basic guidelines for the Rosemount® Model 8800C Vortex

Flowmeter. It does not provide instructions for detailed configuration, diagnostics,

maintenance, service, troubleshooting, Explosion-Proof, Flame-Proof, or Intrinsically

Safe (I.S.) installations. Refer to the Model 8800C reference manual (document number

00809-0100-4003) and Model 8800C Foundation fieldbus manual (document number

00809-0100-4772) for more instruction. The manuals and this QIG are also available

electronically on www.rosemount.com.

WAR N ING

Explosions could result in death or serious injury:

Installation of this transmitter in an explosive environment must be in accordance with the

appropriate local, national, and international standards, codes, and practices. Please

review the approvals section of the Model 8800C reference manual for any restrictions

associated with a safe installation.

• Before connecting a HART-based communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

• Verify the operating atmosphere of the flowmeter is consistent with the appropriate

product certifications.

In an Explosion-Proof/Flame-Proof installation, do not remove the flowmeter covers when

power is applied to the unit.

Electrical shock can result in death or serious injury

• Avoid contact with the leads and terminals. High voltage that may be present on leads

can cause electrical shock.

2

Quick Installation Guide

00825-0100-4003, Rev BA

February 2004

Rosemount 8800C

STEP 1: MOUNT THE TRANSMITTER

Design process piping so the meter body will remain full, with no entrapped air. The vortex

flowmeter can be installed in any orientation without affecting accuracy. However, the

following are guidelines for certain installations.

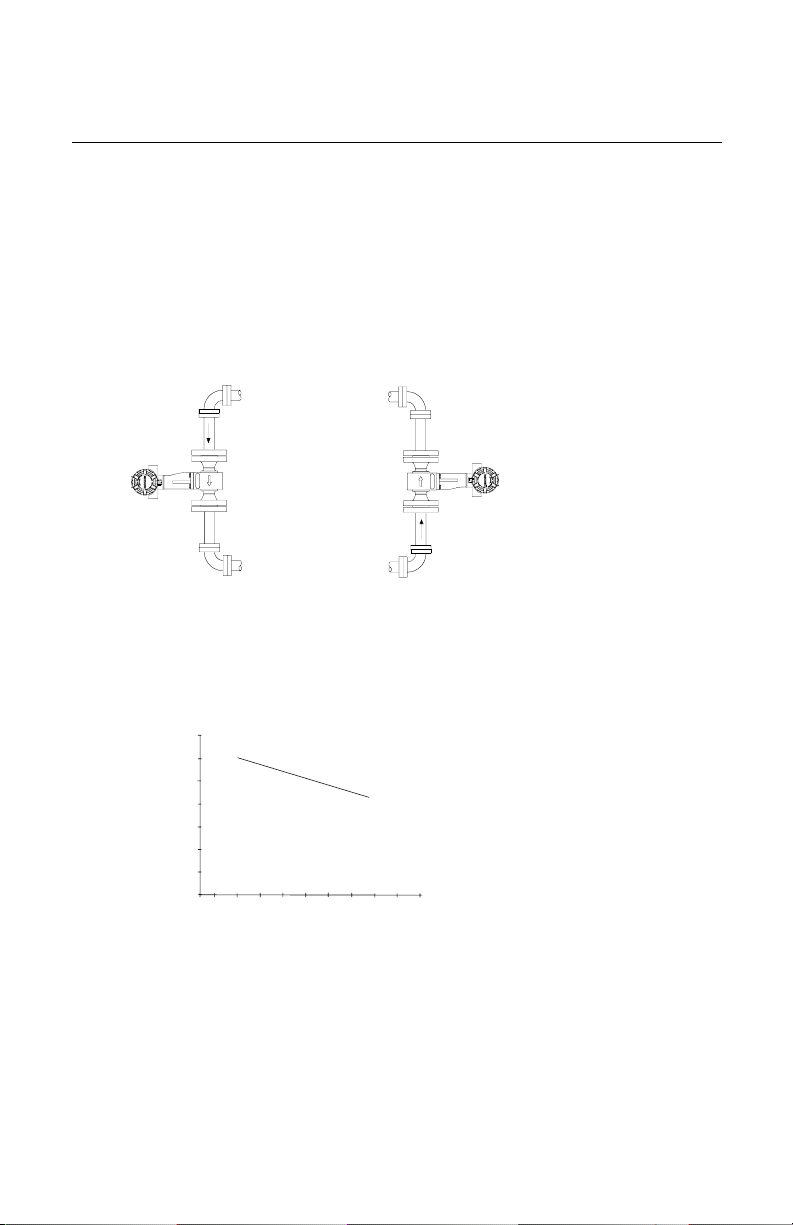

Vertical Mounting

If the vortex flowmeter will be installed in a vertical orientation:

• Install upward or downward flow for gas or steam.

• Install upward flow for liquids.

Figure 1. Vertical Installation

Gas Flow

High Temperature Mounting

The maximum temperature for integral electronics is dependent on the ambient temperature

where the flowmeter is installed. The electronics must not exceed 185°F (85°C).

Figure 2 shows combinations of ambient and process temperatures needed to maintain a

housing temperature of less than 185°F (85°C).

Figure 2. Model 8800C Ambient/Process Temperature Limits

200 (93)

180 (82)

160 (71)

140 (60)

120 (49)

100 (38)

80 (27)

60 (16)

Ambient Temperature °F (°C)

0

185°F Housing

Temperature

Limit

Liquid or Gas

Flow

8800/8800B15B.eps

200 (93)

100 (38)

Meter and pipe insulated with 3 inches of ceramic fiber insulation.

Horizontal Pipe and Vertical meter position.

400 (204)

300 (149)

Process Temperature °F (°C)

600 (316)

500 (260)

700 (371)

800 (427)

900 (482)

1000 (538)

8800_26aa.eps

3

Quick Installation Guide

d

00825-0100-4003, Rev BA

Rosemount 8800C

The following orientations are recommended for applications with high process

temperatures.

• Install with meter body beside or below process pipe.

• Insulation around pipe may be necessary to maintain ambient temperature below 185°F

(85°C).

NOTE

Insulate pipe and meter body only. Do not insulate support tube bracket so heat can be

dissipated.

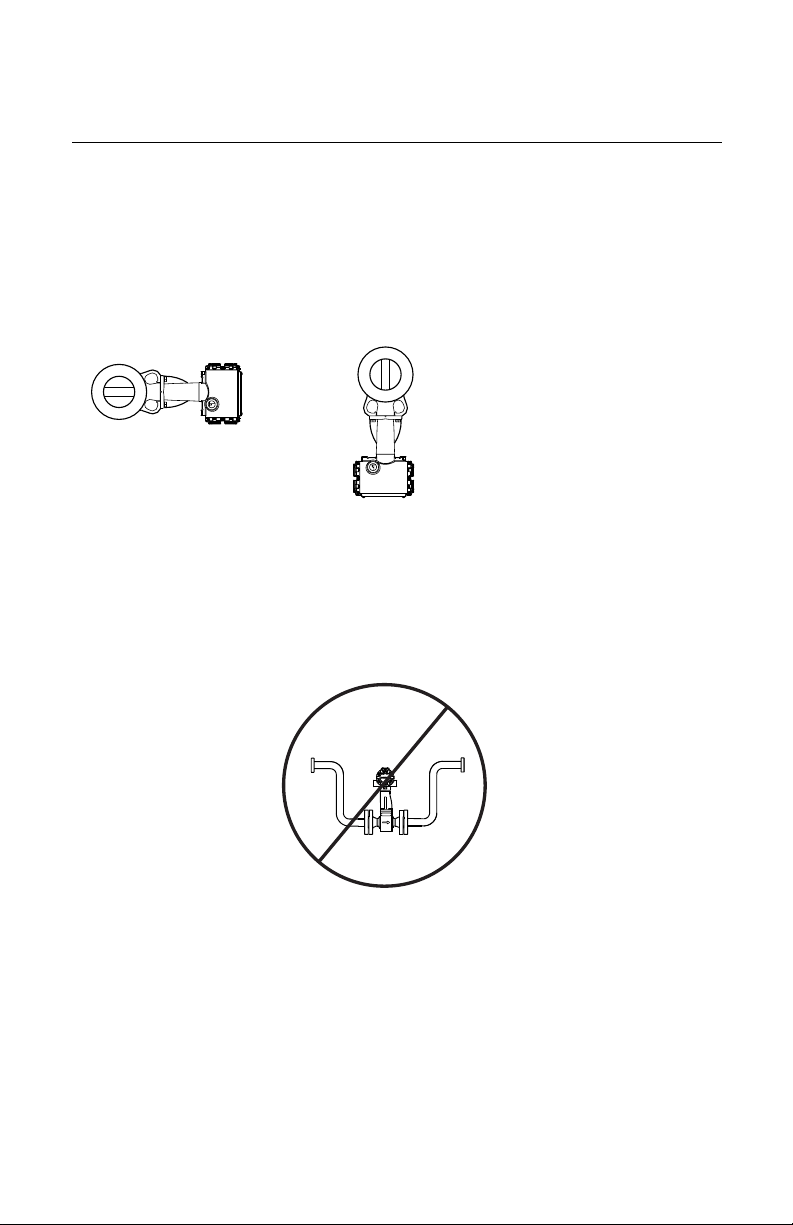

Figure 3. High Temperature Installation

The meter body installe

with the electronics

The meter body installed

with the electronics to

the side of the pipe

For steam and fluids with small solids content, it is recommended to have the flowmeter

installed with the electronics to the side of the pipe. This will minimize potential

measurement errors by allowing the condensate or solids to flow under the shedder bar

without interrupting the vortex shedding.

below the pipe

February 2004

Steam Installations

Avoid installation shown Figure 4. Such conditions may cause a water-hammer condition at

startup due to trapped condensation.

Figure 4. Improper Installation

8800g15c

Upstream/Downstream Requirements

The Model 8800C Flowmeter may be installed with a minimum of ten straight pipe diameters

(D) upstream and five straight pipe diameters (D) downstream by following the K-factor

corrections as described in the Model 8800C Installation Effects Technical Data Sheet

(00816-0100-3250). No K-factor correction is required if 35 straight pipe diameters upstream

(35D) and 10 straight pipe diameters downstream (10D) are available.

When using pressure and temperature transmitters in conjunction with the Model 8800C for

compensated mass flows install the transmitters downstream of the Model 8800C flowmeter

as shown in Figure 5.

4

Quick Installation Guide

00825-0100-4003, Rev BA

February 2004

Figure 5. Upstream/Downstream Piping

4 Downstream

6 Downstream

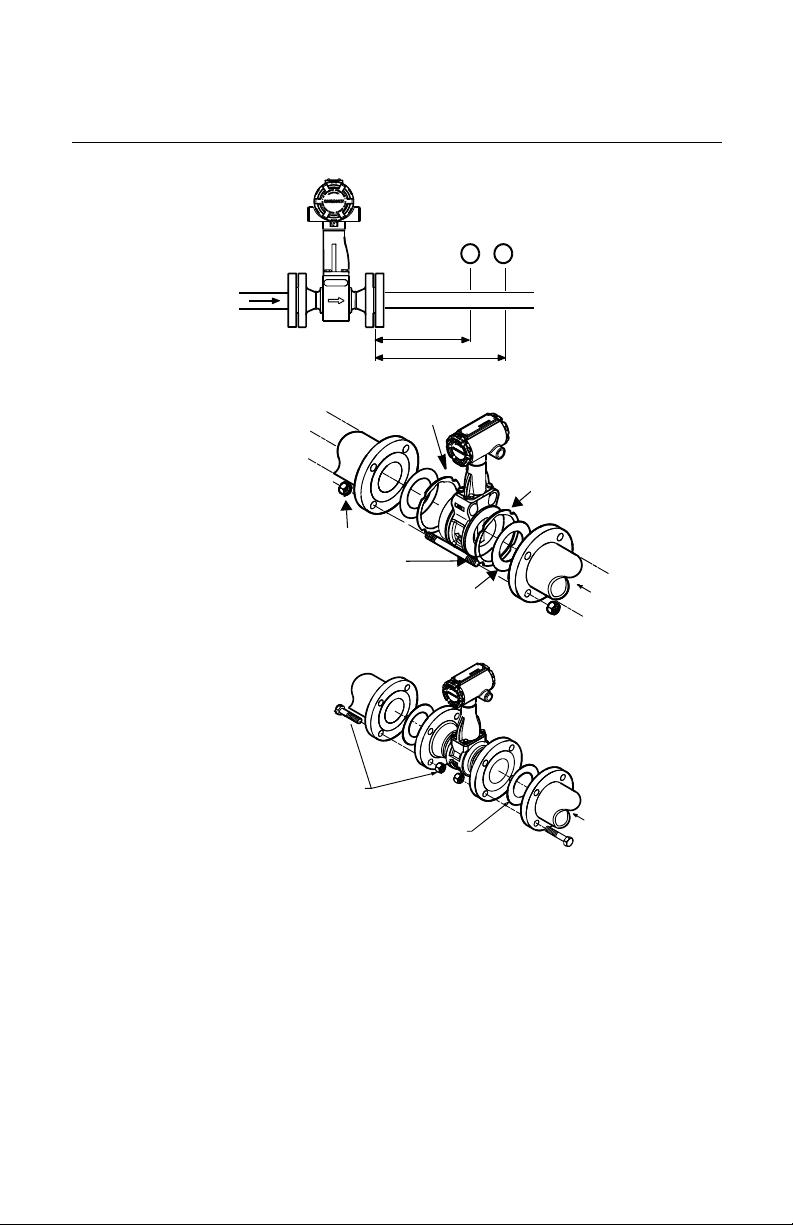

Install Wafer Style Flowmeters according to Figure 6.

Figure 6. Wafer Style Installation

Install Flanged-Style Flowmeters according to Figure 7.

Figure 7. Flanged-Style Flowmeter Installation

Alignment Ring

Installation

Studs and

Nuts (Supplied

by Customer)

Gaskets

(Supplied by

Customer)

Rosemount 8800C

P

T

8800g15a

Alignment

Ring

Flow

8800-0465A01d.eps

Installation Bolts

and Nuts (Supplied

by Customer)

(Supplied by Customer)

NOTE

Gaskets

Flow

8800-065A02B

The required bolt load for sealing the gasket joint is affected by several factors, including

operating pressure and gasket material, width, and condition. A number of factors also

affect the actual bolt load resulting from a measured torque, including condition of bolt

threads, friction between the nut head and the flange, and parallelism of the flanges. Due to

these application-dependent factors, the required torque for each application may be

different. Follow the guidelines outlined in the ASME Pressure Vessel Code (Section VIII,

Division 2) for proper bolt tightening. Make sure the flowmeter is centered between flanges

of the same nominal size as the flowmeter.

5

Quick Installation Guide

00825-0100-4003, Rev BA

Rosemount 8800C

February 2004

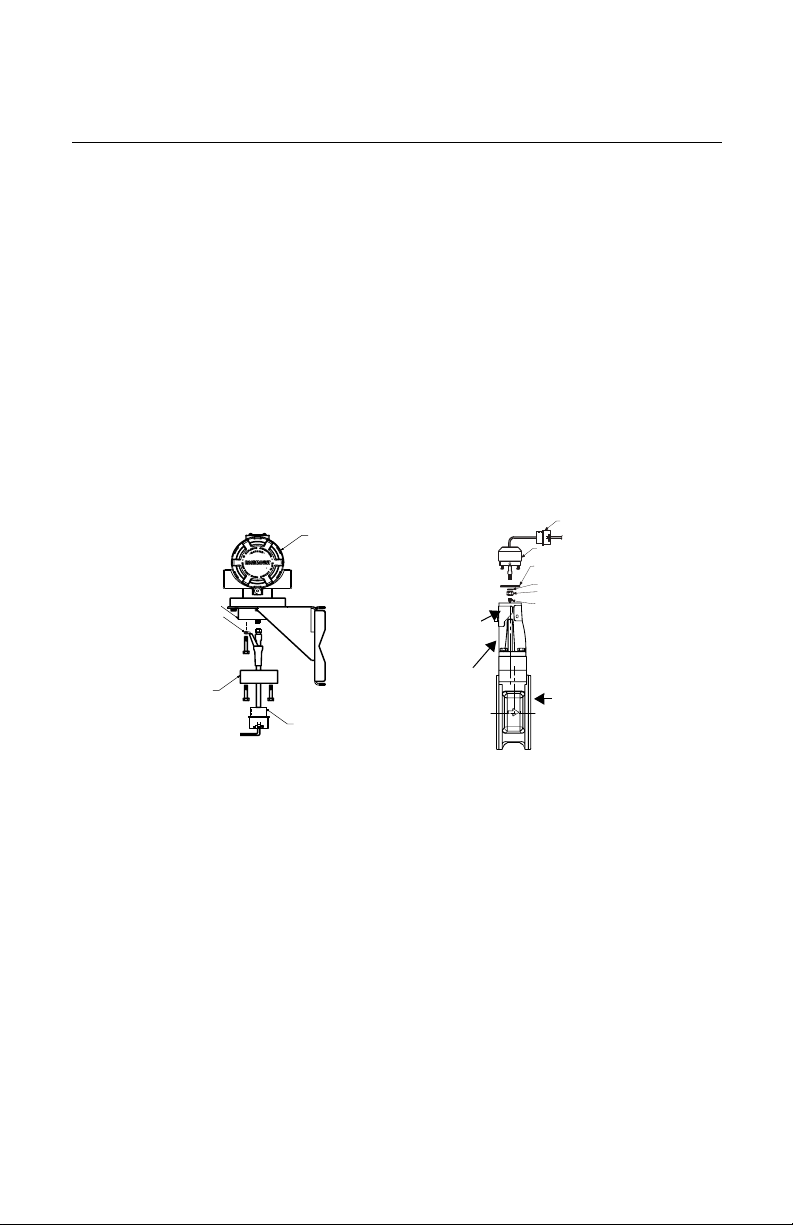

Remote Electronics

If you order one of the remote electronics options (options R10, R20, R30, or RXX), the

flowmeter assembly ships in two parts:

1. The meter body with an adapter installed in the support tube and an interconnecting

coaxial cable attached to it.

2. The electronics housing installed on a mounting bracket.

Mounting

Mount the meter body in the process flow line as described earlier in this section. Mount the

bracket and electronics housing in the desired location. The housing can be repositioned on

the bracket to facilitate field wiring and conduit routing.

Cable Connections

Refer to Figure 8 and the instructions on page 7 to connect the loose end of the coaxial

cable to the electronics housing.

Figure 8. Remote Electronics Installation

Optional ½–14

Electronics

Housing

Housing

Base

Ground

Connection

Housing

Adapter

Coaxial

Cable

* Access Cover is available only in 6 inch (DN50) and 8 inch (DN 200) wafer style flowmeters.

Mounting

Bracket for

Wall or

2-Inch Pipe

Optional ½–14 NPT

Conduit Adapter

or Cable Gland *

Access

Cover *

Support

Tube

NPT Conduit

Adapter or

Cable Gland *

Meter Adapter

Insulating Disk

Washer

Nut

Sensor

Connection

Meter

Body

6

Loading...

Loading...