Rosemount Quick Start Guide: Rosemount 485 Annubar® Flanged Flo-Tap Assembly Manuals & Guides

Quick Start Guide

00825-0400-4809, Rev FB

Rosemount™ 485 Annubar™ Flanged

Flo-Tap Assembly

June 2016

Quick Start Guide

June 2016

NOTICE

This guide provides basic guidelines for Rosemount 485 Annubar. It does not provide instructions for

configuration, diagnostics, maintenance, service, troubleshooting, Explosion-proof, Flameproof, or

Intrinsically Safe (I.S.) installations. Refer to the Rosemount 485 Annubar Reference Manual

instruction. This manual is also available electronically on Emerso nProcess.com/Rosemount

If the Rosemount Annubar was ordered assembled to a Rosemount Pressure Transmitter, see the following

Quick Start Guides for information on configuration and hazardous locations certifications:

Rosemount 3051S Series Pressure Transmitter and Rosemount 3051SF Series Flowmeter Quick Start

Guide.

Rosemount 3051S MultiVariable Transmitter and Rosemount 3051SF Series Flowmeter MultiVariable

Tra ns mi tte r Quick Start Guide

Rosemount 3051 Pressure Transmitter and Rosemount 3051CF Series Flowmeter Transmitter Quick

Start Guide.

Rosemount 2051 Pressure Transmitter and Rosemount 2051CF Series Flowmeter Transmitter Quick

Start Guide.

Process leaks may cause harm or result in death. To avoid process leaks, only use gaskets designed to seal

with the corresponding flange and O-rings to seal process connections. Flowing medium may cause the

Rosemount 485 Annubar Assembly to become hot and could result in burns.

.

for more

.

Contents

Location and orientation . . . . . . . . . . . . . . . . . 4

Weld mounting hardware . . . . . . . . . . . . . . . .8

Install isolation valve . . . . . . . . . . . . . . . . . . . . .9

Mount drilling machine and drill hole . . . . .10

Remove drilling machine . . . . . . . . . . . . . . . .10

2

Mount the Rosemount Annubar Assembly . . . .11

Insert the Rosemount Annubar Sensor . . . . . . . 12

Mount the Transmitter . . . . . . . . . . . . . . . . . . . . . 13

Retracting the Rosemount Annubar Assembly 17

Product certifications . . . . . . . . . . . . . . . . . . . . . 18

June 2016

Quick Start Guide

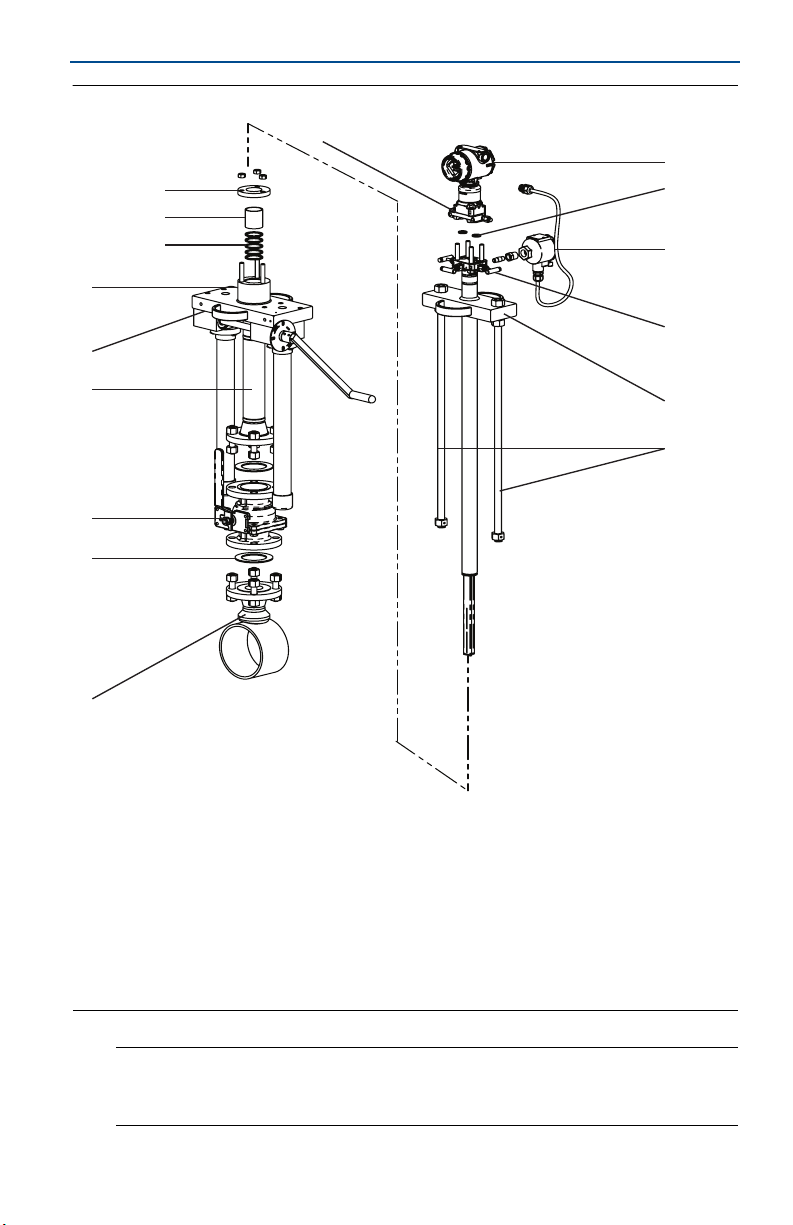

Figure 1. Rosemount 485 Annubar Flanged Flo-Tap Assembly Exploded View

P

A

O

B

N

M

C

L

D

K

J

I

H

G

A. Transmitter

B. 2⫻ O-rings J. Cage nipple

C. Temperature sensor connection housing K. Support plate

D. Direct mount transmitter connection with valves L. Packing gland

E. Head plate M. Packing

F. Drive rods N. Follower

G. Mounting flange assembly O. Compression plate

H. Gasket P. Coplanar flange with drain vents

I. Isolation valve

E

F

Note

Use an appropriate pipe sealing compound rated for the service temperature on all

threaded connections.

3

Quick Start Guide

1.0 Location and orientation

Correct orientation and straight run requirements must be met for accurate and

repeatable flow measurements. Refer to Table 1for minimum pipe diameter

distances from upstream disturbances.

Table 1. Straight Run Requirements

In plane____________Out of plane Upstream pipe diameters

June 2016

Without

straightening

vanes

In

Out of

plane

plane

A

8

1

N/A10N/A

11

2

N/A16N/A

23

3

With straightening

vanes

A’ C C’ B

A

N/A8N/A4N/A

N/A8N/A4N/A

N/A8N/A4N/A

Downstream

pipe diameters

4

4

4

4

4

4

4

N/A28N/A

12

4

N/A12N/A

N/A8N/A4N/A

4

4

4

4

4

4

June 2016

Quick Start Guide

18

5

N/A18N/A

30

6

N/A30N/A

N/A8N/A4N/A

4

N/A8N/A4N/A

4

Note

Consult the factory for instructions regarding use in square or rectangular

ducts.

“In plane A” means the bar is in the same plane as the elbow. “Out of plane A”

means the bar is perpendicular to the plane of the elbow.

If proper lengths of straight run are not available, position the mounting such

that 80% of the run is upstream and 20% is downstream.

Use straightening vanes to reduce the required straight run length.

Row 6 in Ta bl e 1 applies to gate, globe, plug, and other throttling valves that

are partially opened, as well as control valves.

4

4

4

4

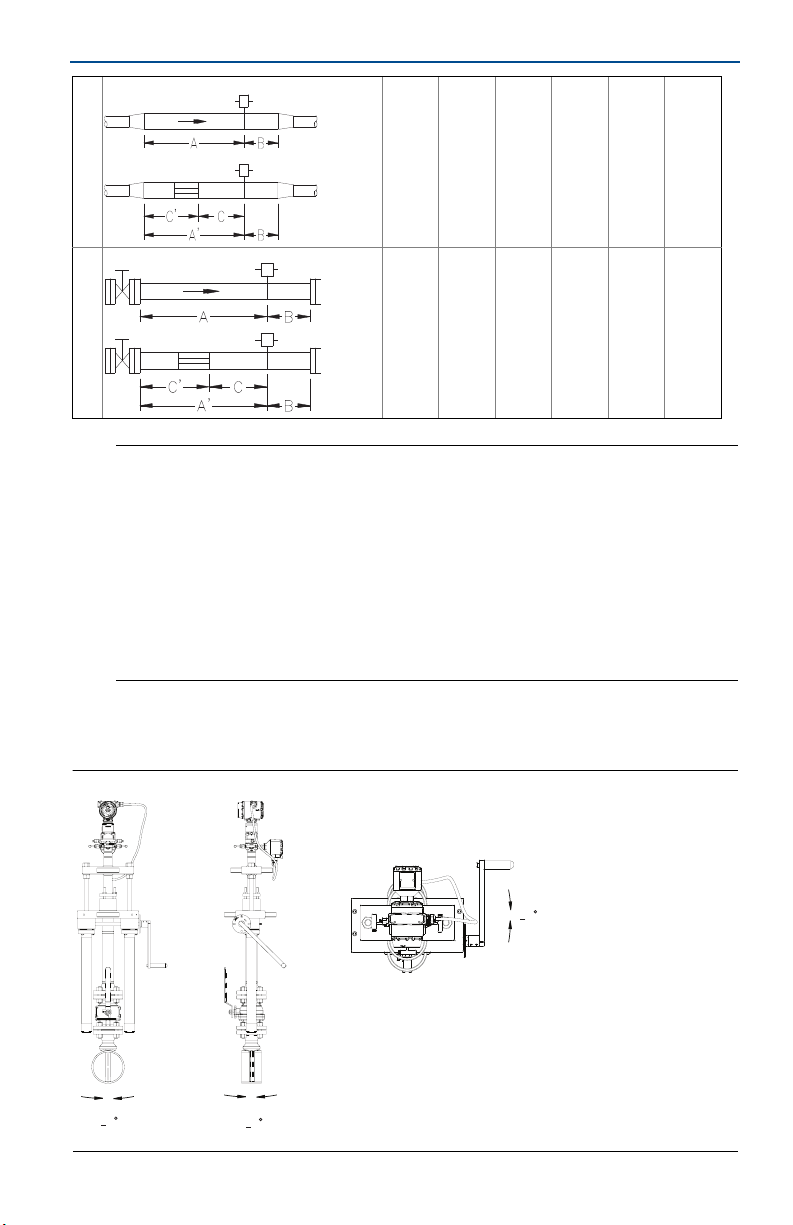

1.1 Misalignment

Rosemount 485 Annubar installation allows for a maximum misalignment of 3°.

Figure 2. Misalignment

+

3

+

3

+

3

5

Quick Start Guide

Recommended zone

30

1.2 Horizontal orientation

For proper venting and draining, the sensor should be located in the upper half of

the pipe for air and gas applications. For liquid and steam applications, the sensor

should be located in the bottom half of the pipe. The maximum temperature for a

direct mounted transmitter is 500 °F (260 °C). See “Install isolation valve” on

page 9 for remote mounted transmitter recommendations.

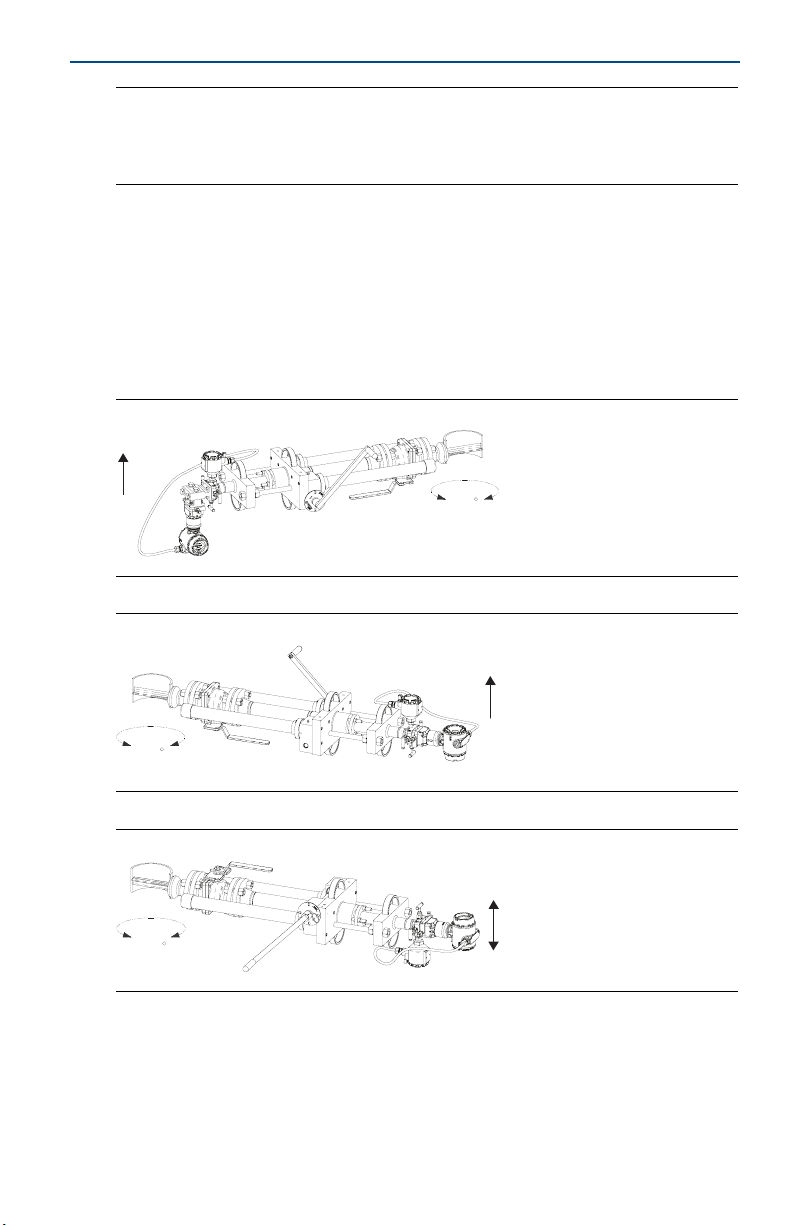

Figure 3. Gas

Recommended zone

30

s

June 2016

Figure 4. Liquid and Steam

Note

For steam applications with DP readings between 0.75 and 2 inH2O in horizontal pipes, it is

recommended to install the primary element/flowmeter mounting above the pipe.

6

June 2016

360

Flow

360

Flow

Quick Start Guide

Note

Due to the weight of the Flo-Tap mounting hardware, external support may be needed for

vertical orientation applications and horizontal orientation applications that are installed

outside of the recommended zones.

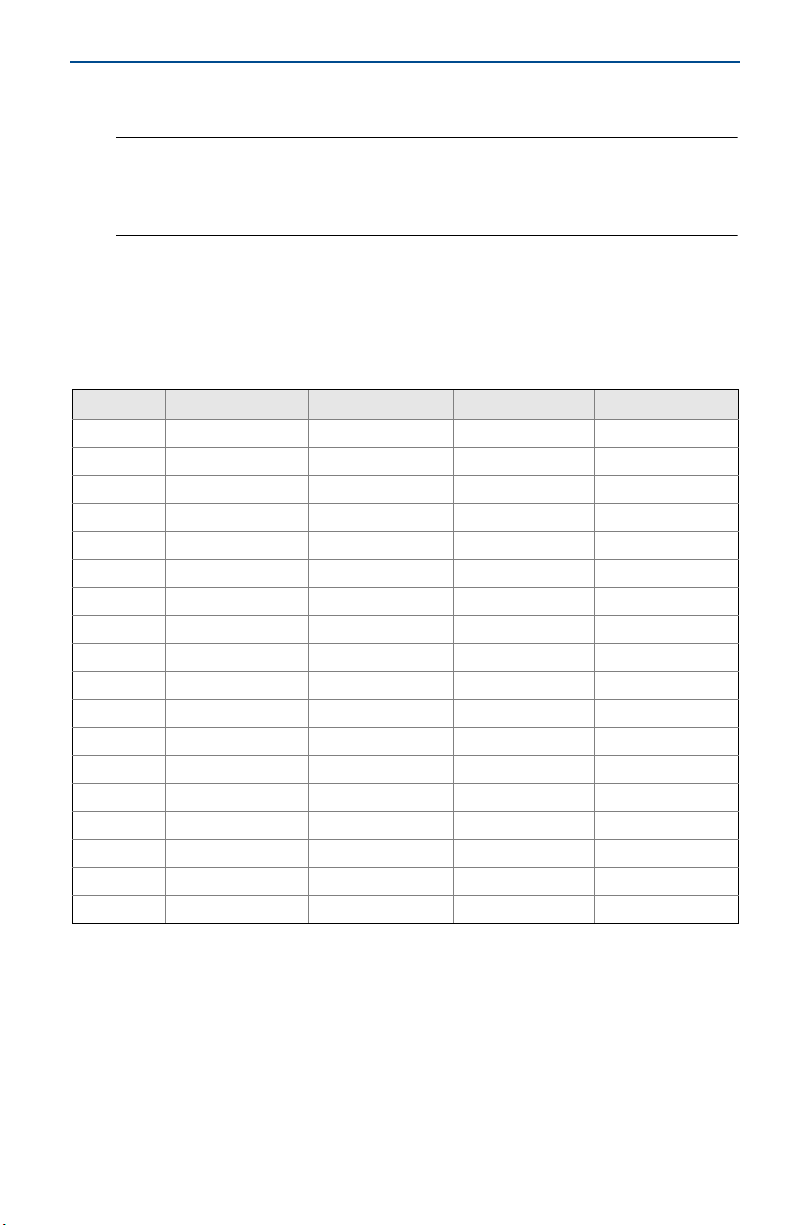

1.3 Vertical orientation

The sensor can be installed in any position around the circumference of the pipe,

provided the vents are positioned properly for bleeding or venting. Optimal

results for liquid or steam are obtained when flow is up. For steam applications, a

90° spacer will be added to provide water legs to ensure the transmitter stays

within temperature limits. The maximum temperature for a direct mounted

transmitter is 500 °F (260 °C).

Figure 5. Steam

Figure 6. Liquid

Figure 7. Gas

360

Flow

7

Quick Start Guide

June 2016

2.0 Weld mounting hardware

Note

Rosemount-supplied mounting has an integral alignment built into the mounting hardware

that assists in the correct drilling of the mounting hole. It also assists in the alignment of the

sensor to the mounting hole for insertion.

1. At the pre-determined position, place the flanged assembly on the pipe, gap

1

/16-in. (1.6 mm), and measure the distance from the outer diameter of the

pipe to the face of the flange. Compare this toTa b le 2 and adjust the gap as

necessary.

Table 2. Flange Sizes and Outer Diameter to Flange (ODF) per Sensor Size

Sensor size Flange size ODF (in. [mm]) Flange size ODF (in. [mm])

1 11/2-in. 150# 3.88 (98,5) DN40 PN16 3.09 (78,6)

1 11/2-in. 300# 4.13 (104,9) DN40 PN40 3.21 (81,6)

1 11/2-in. 600# 4.44 (112,7) DN40 PN100 3.88 (98,6)

1 11/2-in. 900# 4.94 (125,4) N/A N/A

1 11/2-in. 1500# 4.94 (125,4) N/A N/A

1 11/2-in. 2500# 6.76 (171,6) N/A N/A

2 2.0-in. 150# 4.13 (104,8) DN50 PN16 3.40 (86,3)

2 2.0-in. 300# 4.38 (111,2) DN50 PN40 3.51 (89,3)

2 2.0-in. 600# 4.76 (120,8) DN50 PN100 4.30 (109,3)

2 2.0-in. 900# 5.88 (149,2) N/A N/A

2 2.0-in. 1500# 5.88 (149,2) N/A N/A

2 3.0-in. 2500# 9.87 (250,7) N/A N/A

3 3.0-in. 150# 4.63 (117,5) DN80 PN16 3.84 (97,6)

3 3.0-in. 300# 5.00 (126,9) DN80 PN40 4.16 (105,6)

3 3.0-in. 600# 5.38 (136,6) DN80 PN100 4.95 (125,6)

3 4.0-in. 900# 8.19 (208,0) N/A N/A

3 4.0-in. 1500# 8.56 (217,5) N/A N/A

3 4.0-in. 2500# 11.19 (284,2) N/A N/A

8

Loading...

Loading...