Quick Start Guide

00825-0100-4811, Rev JF

Rosemount™ 3300 Level Transmitter

Guided Wave Radar

April 2022

Quick Start Guide April 2022

Contents

About this guide...........................................................................................................................3

Mount the transmitter head/probe.............................................................................................. 7

Set jumpers and switches........................................................................................................... 17

Connect wiring and power up.....................................................................................................19

Configure................................................................................................................................... 25

Environmental conditions.......................................................................................................... 31

Product certifications................................................................................................................. 32

2 Rosemount 3300 Level Transmitter

April 2022 Quick Start Guide

1 About this guide

This start guide provides basic guidelines for the Rosemount 3300 Level

Transmitter. Refer to Rosemount 3300 Level Transmitter Reference Manual

for more instructions. The manual and this Quick Start Guide (QSG) are also

available electronically on Emerson.com/Rosemount.

WARNING

Failure to follow safe installation and servicing guidelines could result in

death or serious injury.

• Ensure only qualified personnel perform installation or service.

• Use the equipment only as specified in this Quick Start Guide and the

Reference Manual. Failure to do so may impair the protection provided

by the equipment.

• Do not perform any service other than those contained in this manual

unless you are qualified.

• Flamepath joints are not for repair. Contact the manufacturer.

Explosions could result in death or serious injury.

• Verify that the operating environment of the transmitter is consistent

with the appropriate hazardous locations specifications. See Product

certifications in this Quick Start Guide.

• In an explosion-proof/flameproof installation, do not remove the

transmitter covers when power is applied to the unit.

• Before connecting a handheld communicator in an explosive

atmosphere, ensure the instruments are installed in accordance with

intrinsically safe or non-incendive field wiring practices.

• To avoid process leaks, only use the O-ring designed to seal with the

corresponding flange adapter.

Electrical shock could cause death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be

present on leads can cause electrical shock.

• Ensure the mains power to the transmitter is off and the lines to any

other external power source are disconnected or not powered while

wiring the transmitter.

Temperature restrictions apply for Explosion-proof versions. For limits, see

certificate-specific information in the Product certifications chapter in this

document.

Quick Start Guide 3

Quick Start Guide April 2022

WARNING

The electronics enclosures are category 2G or 2D equipment. The probes

not covered with plastic and not made of titanium, are category 1G or 1D.

The plastic covered probes or probes made of titanium, are only category 1G

equipment.

Probes with non-conducting surfaces and light metals:

• Probes covered with plastic and/or with plastic discs may generate an

ignition- capable level of electrostatic charge under certain extreme

conditions. Therefore, when the probe is used in a potentially explosive

atmosphere, appropriate measures must be taken to prevent

electrostatic discharge. These probes are not allowed in dust classified

areas.

The following probes do not contain plastic or PTFE material, and are

allowed to be placed in a Dust classified area:

Table 1-1: Probes Containing no Plastic or PTFE Material

Code Material of construction: Process connection/Probe

1 316L SST (EN 1.4404)

2 Alloy C-276 (UNS N10276) plate design if flanged version

3 Alloy 400 (UNS N04400) plate design if flanged version

5 Titanium Gr-1 and Gr-2

9 Duplex 2205 (EN 1.4462/UNS S31803) (plate design if flanged

L Alloy 625 (UNS N06625)

M Alloy 400 (UNS N04400)

H Alloy C-276 (UNS N10276)

D Duplex 2205 (EN 1.4462/UNS S31803)

version)

The Material of Construction Code can be found in the ninth character

position of the transmitter model code (for example

330xxxxx1xxxxxxxx).

4 Rosemount 3300 Level Transmitter

Category 2D

Category 1D

Applicable marking:

Probes according to Table 1-1

Ex tb [ia Da] IIIC T85 °C…T450 °C Db

II 1/2 D Ex ia IIIC T20085 °C…T200450 °C Da /

Category 2G

Category 1G

All probes possible

II 1/2 G Ex ia IIC T6…T1 Ga /

Ex db [ia Ga] IIC T6…T1 Gb

Applicable marking:

Category 2D

Category 2D

Probes according to Table 1-1

Applicable marking:

II 2 D Ex tb IIIC T85 °C…T135 °C Db

April 2022 Quick Start Guide

• Probes and flanges containing >7.5 percent magnesium or zirconium are

not allowed in explosive dust atmosphere. Contact your Emerson sales

representative for more information.

Probes and flanges containing light metals:

• When used in category 1/2G installations, probes and flanges containing

titanium or zirconium must be mounted in such a way that sparks from

impact or friction between these parts and steel cannot occur.

Separation element (EPL Ga/Gb, Da/Db):

• The materials of the separation element are > 3 mm stainless steel and a

22 mm bushing filled with 2-part epoxy. The epoxy has a continuous

operating temperature of -55 °C ≤ COT ≤ 130 °C. Under normal operation

Quick Start Guide 5

Quick Start Guide April 2022

the separation element is not pressurized or in contact with the process

media.

WARNING

Any substitution of non-authorized parts or repair, other than exchanging

the complete transmitter head or probe assembly, may jeopardize safety

and is prohibited.

• Unauthorized changes to the product are strictly prohibited as they may

unintentionally and unpredictably alter performance and jeopardize

safety. Unauthorized changes that interfere with the integrity of the

welds or flanges, such as making additional perforations, compromise

product integrity and safety. Equipment ratings and certifications are no

longer valid on any products that have been damaged or modified

without the prior written permission of Emerson. Any continued use of

product that has been damaged or modified without the written

authorization is at the customer’s sole risk and expense.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

6 Rosemount 3300 Level Transmitter

$

April 2022 Quick Start Guide

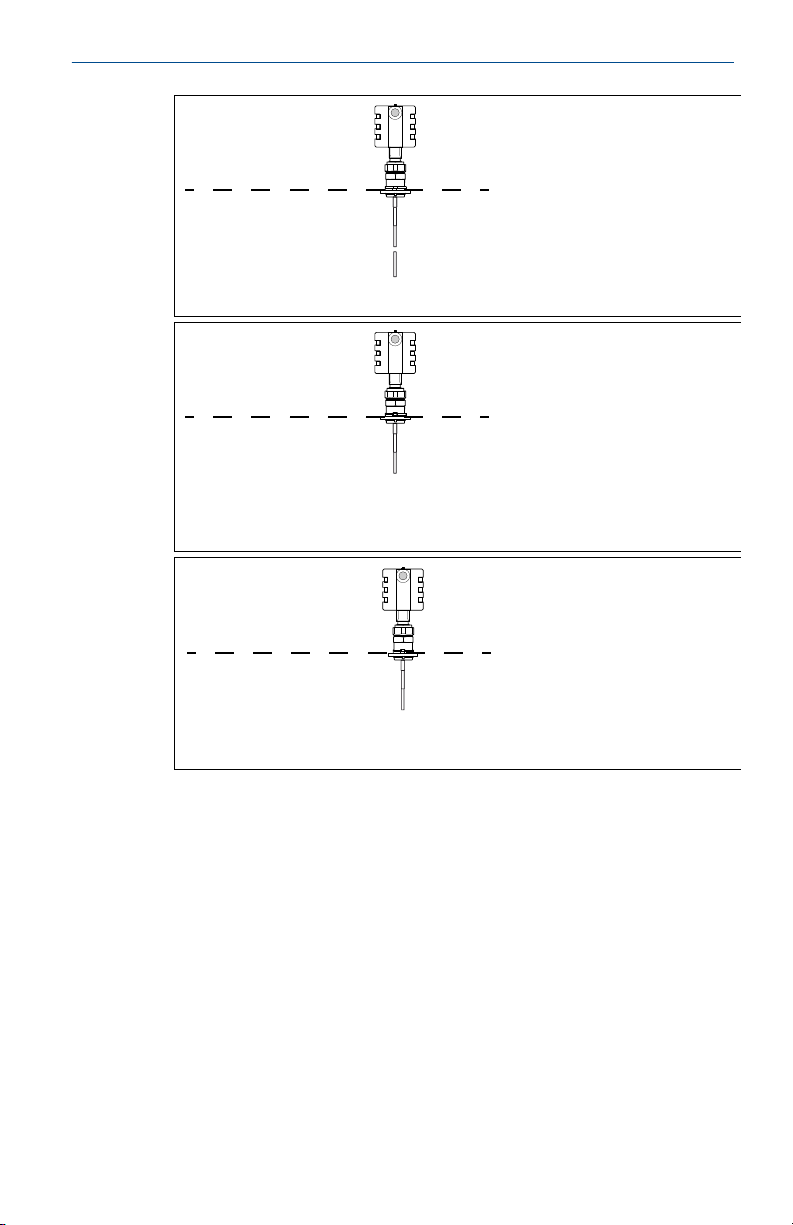

2 Mount the transmitter head/probe

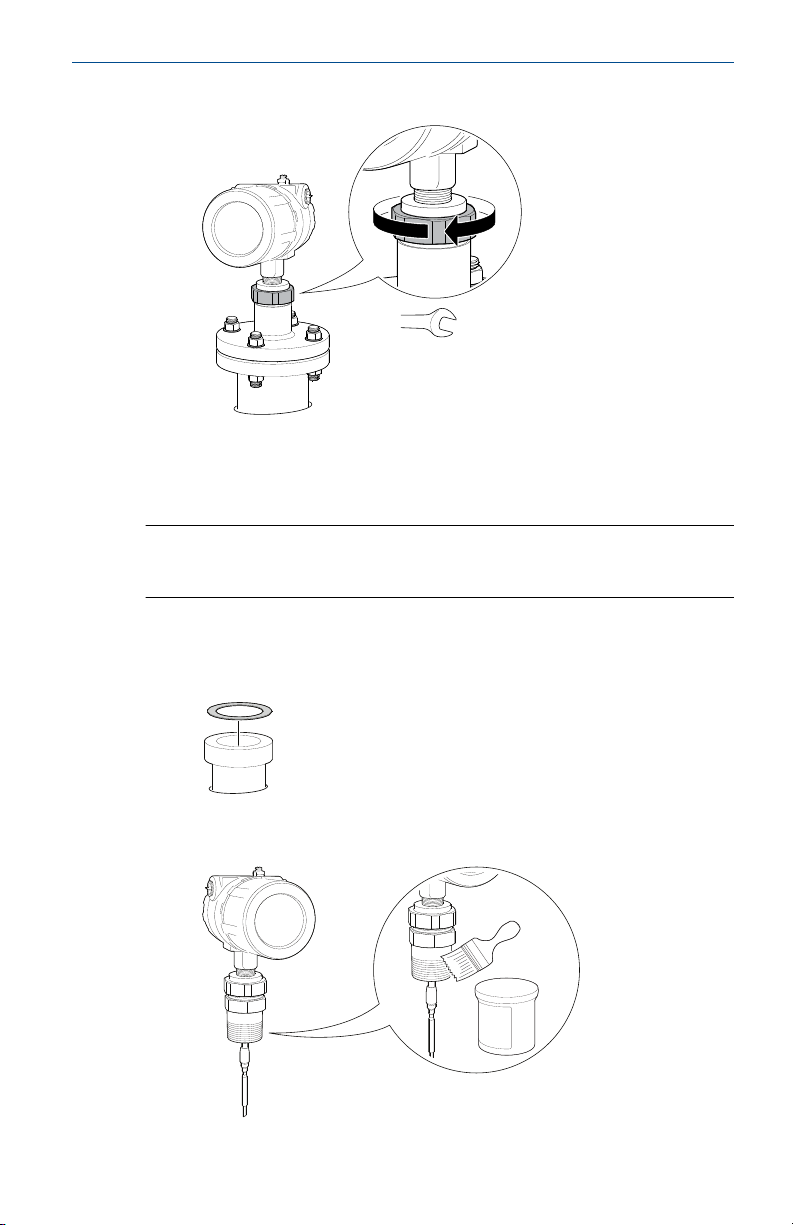

2.1 Tank connection with flange

Prerequisites

Note

PTFE covered probes must be handled carefully to prevent damage to the

coating.

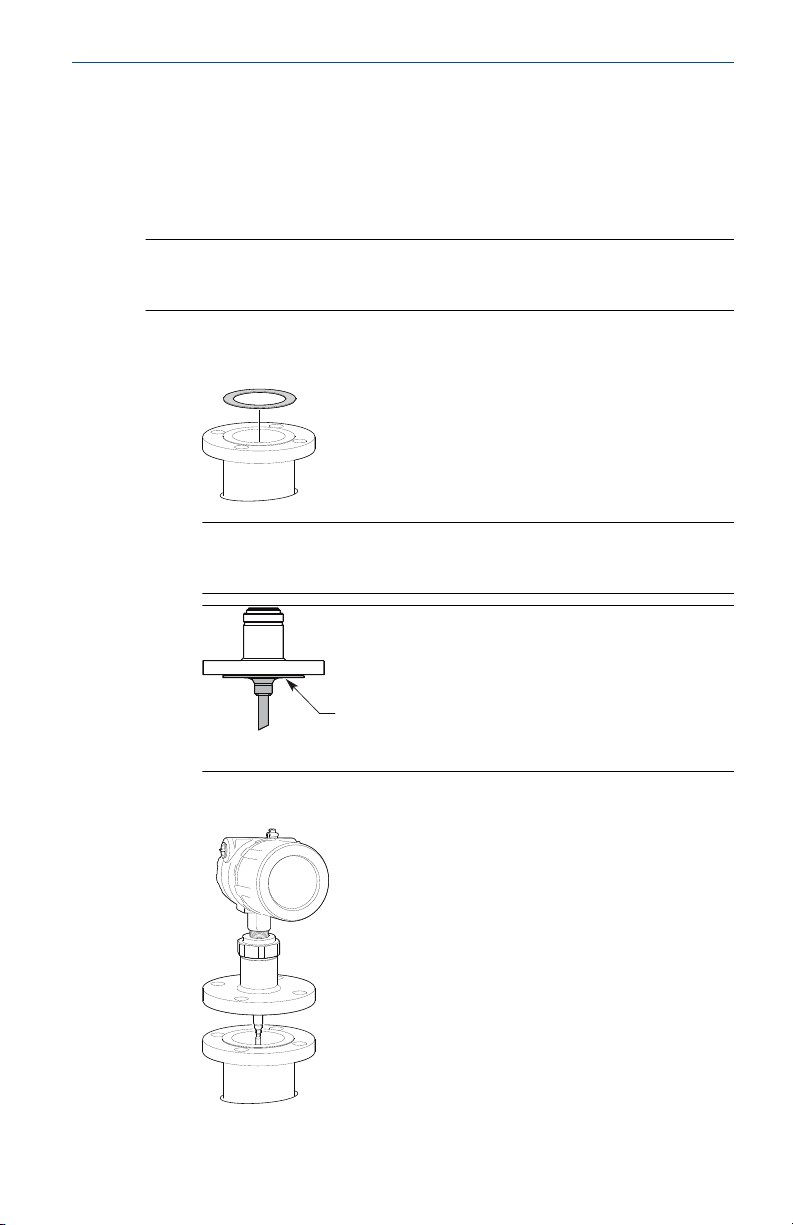

Procedure

1. Place a suitable gasket on top of the tank flange.

Note

Gasket should not be used for PTFE covered probe with protective

plate.

A. PTFE covered probe with protective plate

2. Lower the transmitter and probe with flange into the tank.

Quick Start Guide 7

60 mm

Quick Start Guide April 2022

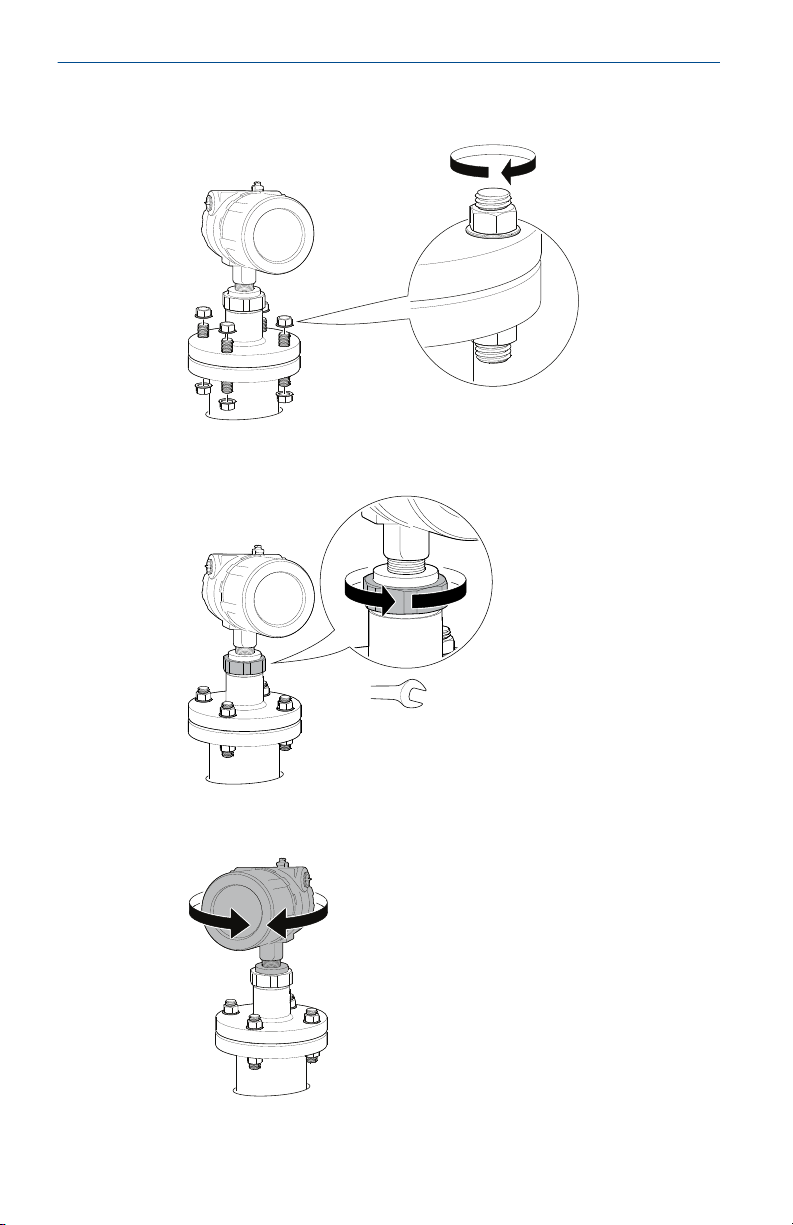

3. Tighten bolts and nuts with sufficient torque for the flange and

gasket choice.

4. Loosen the nut that connects the transmitter head to the probe

slightly.

5. Rotate the transmitter housing so the cable entries/display face the

desired direction.

8 Rosemount 3300 Level Transmitter

60 mm

Torque 30 ft-lb (40 Nm)

April 2022 Quick Start Guide

6. Tighten the nut.

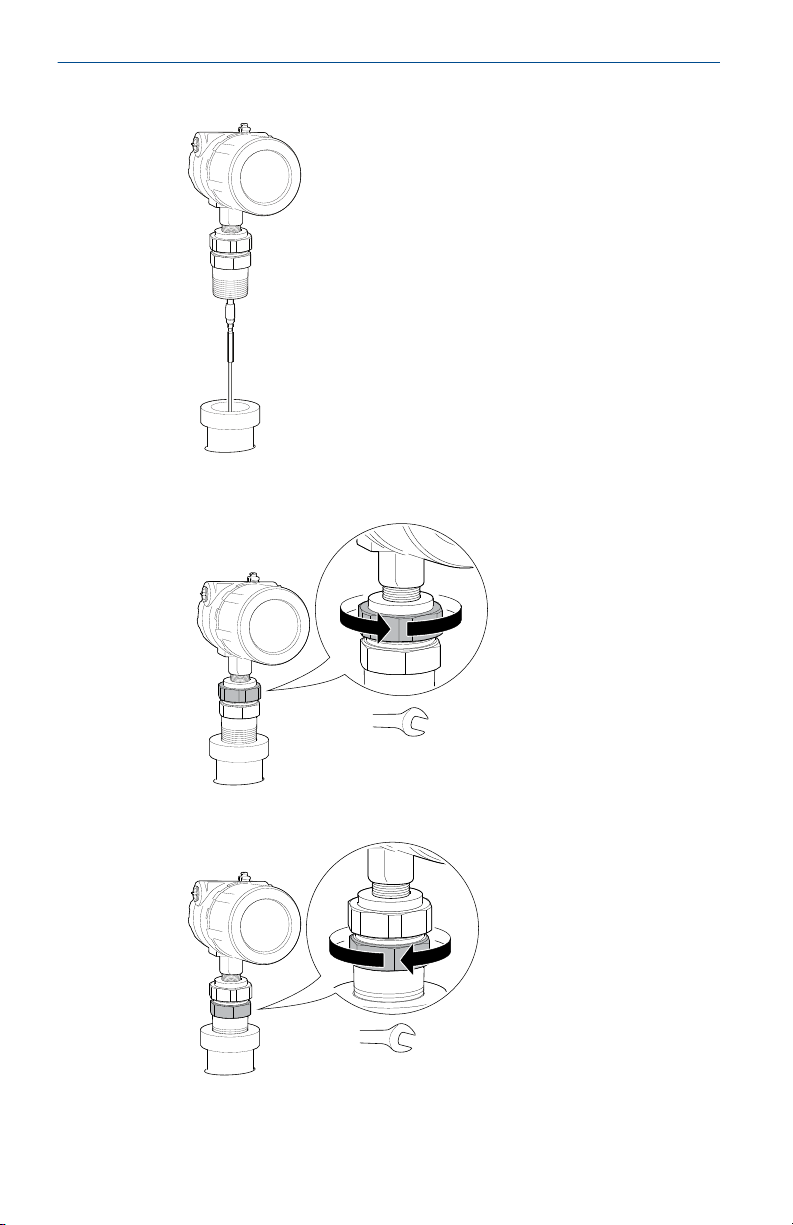

2.2 Threaded tank connection

Prerequisites

Note

PTFE covered probes must be handled carefully to prevent damage to the

coating.

Procedure

1. For adapters with BSPP (G) threads, place a suitable gasket on top of

the tank flange.

2. For adapters with NPT threads, use anti-seize paste or PTFE tape

according to your site procedures.

Quick Start Guide 9

60 mm

52 mm / 60 mm

Quick Start Guide April 2022

3. Lower the transmitter and probe into the tank.

4. Loosen the nut that connects the transmitter head to the probe

slightly.

5. Screw the adapter into the process connection.

10 Rosemount 3300 Level Transmitter

60 mm

Torque 30 ft-lb (40 Nm)

April 2022 Quick Start Guide

6. Rotate the transmitter housing so the cable entries/display face the

desired direction.

7. Tighten the nut.

Quick Start Guide 11

Quick Start Guide April 2022

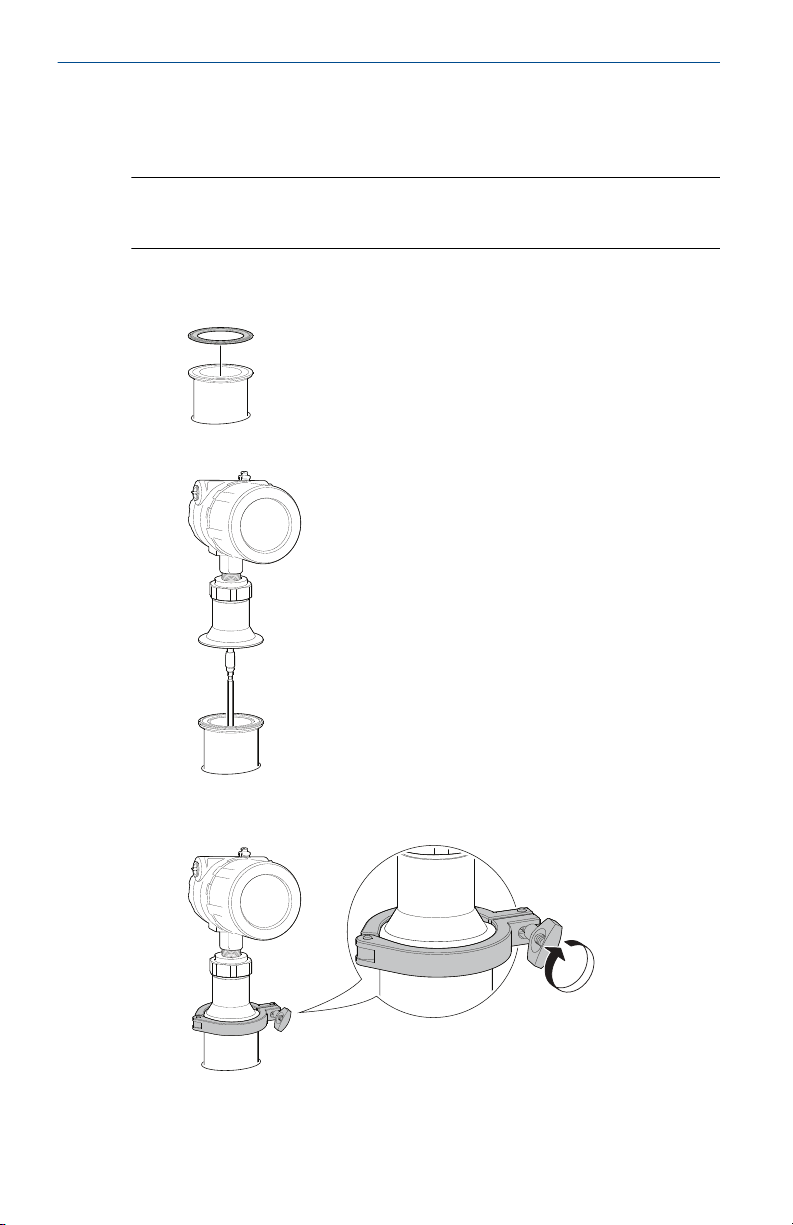

2.3 Tank connection with Tri-Clamp

Prerequisites

Note

PTFE covered probes must be handled carefully to prevent damage to the

coating.

Procedure

1. Place a suitable gasket on top of the tank flange.

2. Lower the transmitter and probe into the tank.

®

3. Tighten the clamp to the recommended torque (see the

manufacturer’s instruction manual).

12 Rosemount 3300 Level Transmitter

60 mm

60 mm

Torque 30 ft-lb (40 Nm)

April 2022 Quick Start Guide

4. Loosen the nut that connects the transmitter head to the probe

slightly.

5. Rotate the transmitter housing so the cable entries/display face the

desired direction.

6. Tighten the nut.

Quick Start Guide 13

4X

A

B

4X

Quick Start Guide April 2022

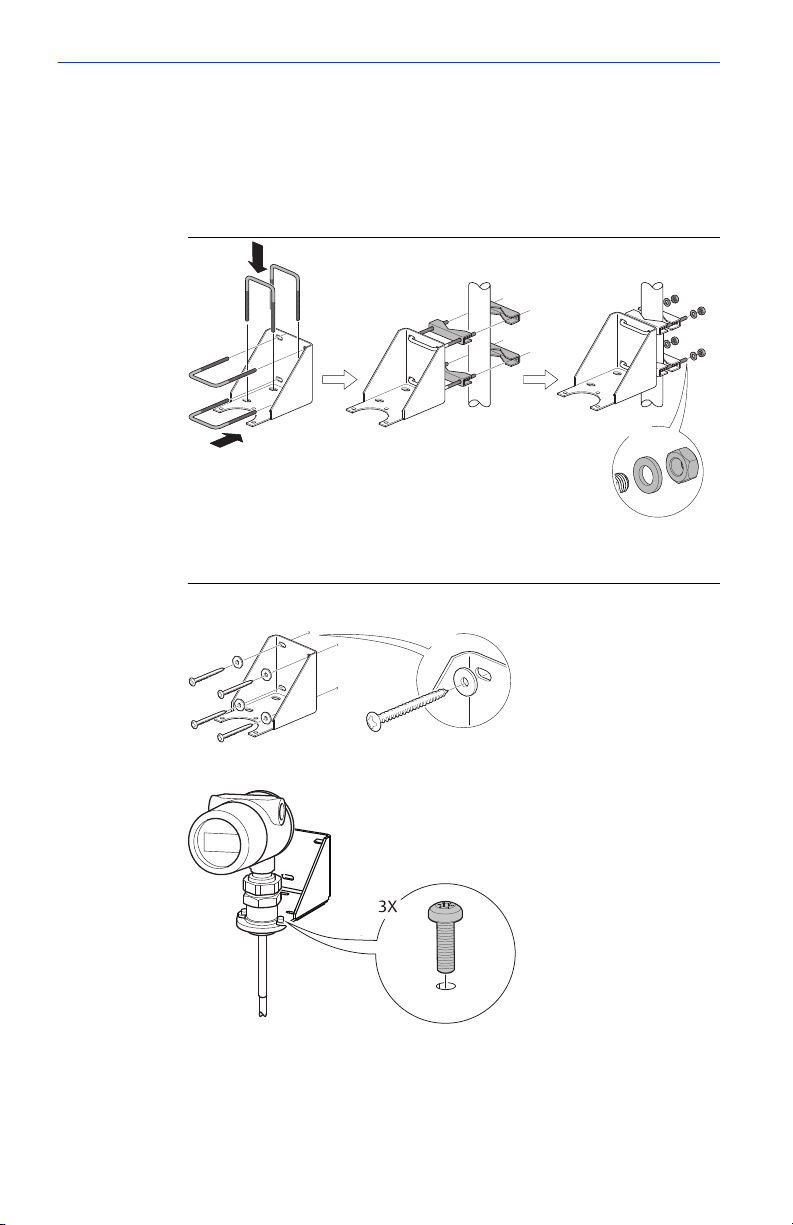

2.4 Bracket mounting

Procedure

1. Mount the bracket to the pipe/wall.

On pipe:

A. Horizontal pipe

B. Vertical pipe

On wall:

2. Mount the transmitter with probe to the bracket.

14 Rosemount 3300 Level Transmitter

$

Torque 30 ft-lb (40 Nm)

55 mm

April 2022 Quick Start Guide

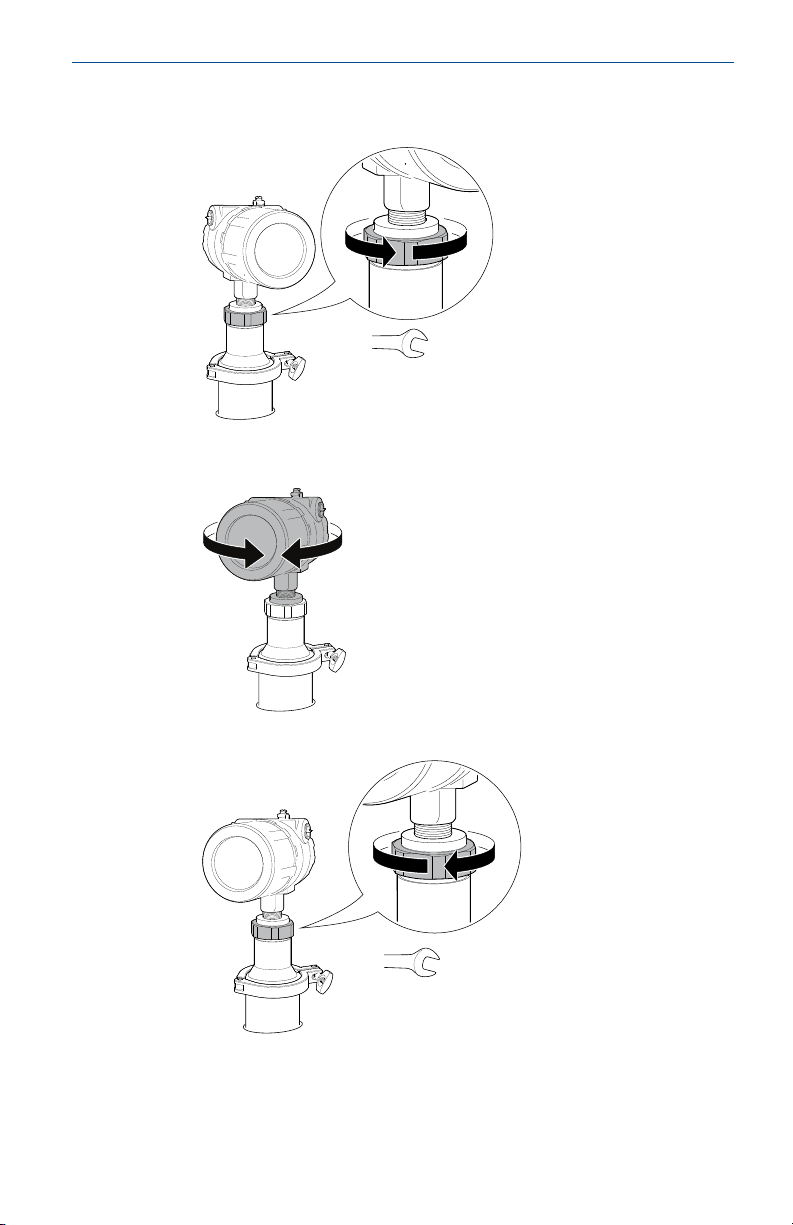

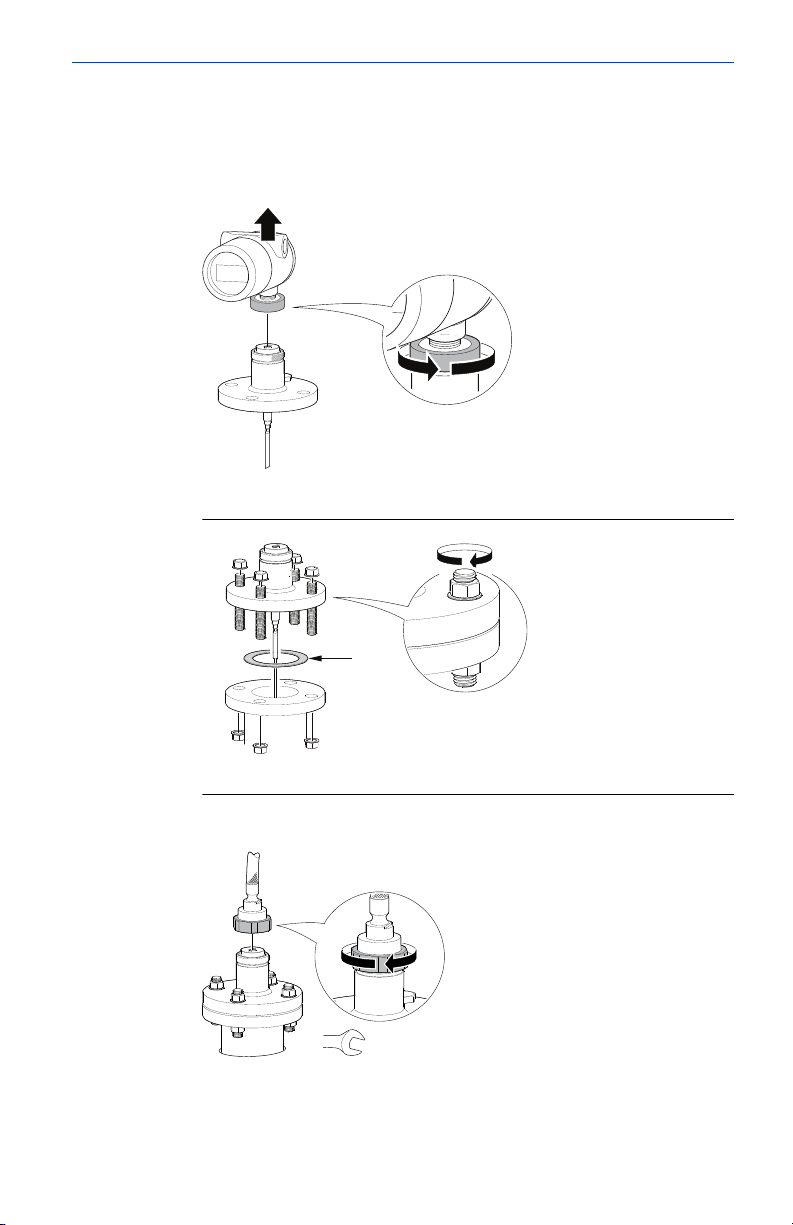

2.5 Install remote housing

Procedure

1. Carefully remove the transmitter.

2. Mount the probe on tank.

A. Gasket

3. Mount the remote connection on the probe.

Quick Start Guide 15

4X

A

B

3X

Torque 30 ft-lb (40 Nm)

Quick Start Guide April 2022

4. Mount the bracket to the pipe.

A. Horizontal pipe

B. Vertical pipe

5. Fasten the housing support.

6. Mount the transmitter head.

16 Rosemount 3300 Level Transmitter

Loading...

Loading...