Rosemount Quick Start Guide: Rosemount™ 3051S MultiVariable™ Transmitter and 3051SF Series MultiVariable™ Flowmeter with FOUNDATION™ Fieldbus Protocol Manuals & Guides

Quick Start Guide

00825-0100-4853, Rev AG

October 2021

Rosemount™ 3051S MultiVariable

™

Transmitter and 3051SF Series Flow

Meter

with FOUNDATION™ Fieldbus Protocol

Quick Start Guide October 2021

Safety messages

NOTICE

This guide provides basic guidelines for Rosemount™ 3051S MultiVariable™ (3051SMV) FOUNDATION

Fieldbus Transmitters. It does not provide instructions for diagnostics, maintenance, service, or

troubleshooting. Refer to the Rosemount 3051SMV FOUNDATION Fieldbus Reference Manual for more

instruction.This document is also available electronically on Emerson.com/Rosemount.

™

WARNING

Explosions could result in death or serious injury.

Installation of device in an explosive environment must be in accordance with appropriate local,

national, and international standards, codes, and practices.

Review Rosemount 3051SMV FOUNDATION Fieldbus Reference Manual for any restrictions associated

with a safe installation.

• Before connecting a handheld communicator in an explosive atmosphere, ensure that the

instruments in the loop are installed in accordance with intrinsically safe or non-incendive field

wiring practices.

• In an explosion-proof/flameproof installation, do not remove the transmitter covers when power

is applied to the unit.

Process leaks could result in death or serious injury.

• Install and tighten process connectors before applying pressure.

Electrical shock could cause death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be present on leads can cause

electrical shock.

Conduit/cable entries

• Unless marked, the conduit/cable entries in the housing use a ½–14 NPT thread form. Entries

marked “M20” are M20 × 1.5 thread form. On devices with multiple conduit entries, all entries will

have the same thread form. Only use plugs, adapters, glands, or conduit with a compatible thread

form when closing these entries.

• When installing in a hazardous location, use only appropriately listed or Ex certified plugs, glands,

or adapters in cable/conduit entries.

Contents

Mount the transmitter..................................................................................................................5

Tagging......................................................................................................................................11

Consider housing rotation..........................................................................................................12

Set the switches......................................................................................................................... 14

Wiring, grounding, and power....................................................................................................16

System readiness....................................................................................................................... 21

Zero trim the transmitter........................................................................................................... 22

2 Rosemount 3051SMV

October 2021 Quick Start Guide

Product certifications................................................................................................................. 23

Quick Start Guide 3

Quick Start Guide October 2021

4 Rosemount 3051SMV

A

A

October 2021 Quick Start Guide

1 Mount the transmitter

1.1 Liquid flow applications

Procedure

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Mount the transmitter so that the drain/vent valves are oriented

upward.

A. Direction of flow

1.2 Gas flow applications

Procedure

1. Place taps in the top or side of the line.

2. Mount beside or above the taps.

A. Direction of flow

Quick Start Guide 5

A

Quick Start Guide October 2021

1.3 Steam flow applications

Procedure

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Fill impulse lines with water.

A. Direction of flow

1.4 Mounting brackets

Figure 1-1: Mounting Bracket – Coplanar Flange

Panel mount

6 Rosemount 3051SMV

Pipe mount

October 2021 Quick Start Guide

Figure 1-2: Mounting Brackets – Traditional Flange

Panel mount Pipe mount

Figure 1-3: Mounting Brackets – In-line

Panel mount Pipe mount

1.5 Bolting considerations

If the transmitter installation requires assembly of a process flange,

manifold, or flange adapters, follow these assembly guidelines to ensure a

tight seal for optimal performance characteristics of the transmitter. Only

use bolts supplied with the transmitter or sold by Emerson as spare parts.

Figure 1-4 illustrates common transmitter assemblies with the bolt length

required for proper transmitter assembly.

Quick Start Guide 7

A

4 × 1.75-in.

(44 mm)

D

4 × 1.75-in.

(44 mm)

4 × 2.25-in.

(57 mm)

C

4 × 1.75-in.

(44 mm)

4

× 1.50-in.

(38 mm)

B

4 × 2.88-in.

(73 mm)

Quick Start Guide October 2021

Figure 1-4: Common Transmitter Assemblies

A. Transmitter with coplanar flange

B. Transmitter with coplanar flange and optional flange adapters

C. Transmitter with traditional flange and optional flange adapters

D. Transmitter with coplanar flange and optional Rosemount Conventional

Manifold and flange adapters

Note

For all other manifolds, contact Customer Central technical support.

Bolts are typically carbon steel or stainless steel. Confirm the material by

viewing the markings on the head of the bolt and referencing Table 1-1 . If

bolt material is not shown in Table 1-1, contact the local Emerson

representative for more information.

Use the following bolt installation procedure:

Procedure

1. Carbon steel bolts do not require lubrication and the stainless steel

bolts are coated with a lubricant to ease installation. However, no

additional lubricant should be applied when installing either type of

bolt.

2. Finger-tighten the bolts.

3. Torque the bolts to the initial torque value using a crossing pattern.

See Table 1-1 for initial torque value.

4. Torque the bolts to the final torque value using the same crossing

pattern. See Table 1-1 for final torque value.

8 Rosemount 3051SMV

B7M

316

316

316

SW

316

STM

316

R

B8M

A

B

October 2021 Quick Start Guide

5. Verify the flange bolts are protruding through the sensor module

before applying pressure (see Figure 1-5).

Example

Table 1-1: Torque Values for the Flange and Flange Adapter Bolts

Bolt material Head markings Initial torque Final torque

Carbon Steel

300 in-lb 650 in-lb

(CS)

Stainless Steel

150 in-lb 300 in-lb

(SST)

Figure 1-5: Proper Bolt Installation

A. Bolt

B. Sensor module

Quick Start Guide 9

A

B

C

D

Quick Start Guide October 2021

1.6 O-rings with flange adapters

WARNING

Failure to install proper flange adapter O-rings may cause process leaks,

which can result in death or serious injury. Only use the O-ring that is

designed for its specific flange adapter.

A. Flange adapter

B. O-ring

C. PTFE-based profile (square)

D. Elastomer profile (round)

Whenever the flange or adapters are removed, visually inspect the O-rings.

Replace them if there are any signs of damage, such as nicks or cuts. If the Orings are replaced, re-torque the flange bolts and alignment screws after

installation to compensate for seating of the O-rings.

10 Rosemount 3051SMV

Commissioning Tag

DEVICE ID:

0011513051010001440-12169809172 5

DEVICE REVISION: 7.2

PHYSICAL DEVICE TAG

DEVICE ID:

0011513051010001440-12169809172 5

DEVICE REVISION: 7.2

S / N :

PHYSICAL DEVICE TAG

Device Barcode

A

Commissioning Tag

DEVICE ID:

001151AC00010001440-1216980917 25

DEVICE REVISION: 8.1

PHYSICAL DEVICE TAG

DEVICE ID:

001151AC00010001440-121698091725

DEVICE REVISION: 8.1

S / N :

PHYSICAL DEVICE TAG

Device Barcode

October 2021 Quick Start Guide

2 Tagging

2.1 Commissioning tag

The transmitter is supplied with a removable commissioning tag that

contains both the Device ID (the unique code that identifies a particular

device in the absence of a device tag) and a space to record the device tag

(PD_TAG) (the operational identification for the device as defined by the

Piping and Instrumentation Diagram [P&ID]).

When commissioning more than one device on a Fieldbus segment, it can be

difficult to identify which device is at a particular location. The removable

tag, provided with the transmitter, can aid in this process by linking the

Device ID to its physical location. The installer should note the physical

location of the transmitter on both the upper and lower location of the

commissioning tag. Tear off the bottom portion for each device on the

segment and use it for commissioning the segment in the control system.

Figure 2-1: Commissioning Tag

Quick Start Guide 11

A. Device revision

Quick Start Guide October 2021

3 Consider housing rotation

To improve field access to wiring or to better view the optional LCD display:

Procedure

1. Loosen the housing rotation set screw.

2. Turn the housing up to 180° left or right of its original (as shipped)

position.

3. Re-tighten the housing rotation set screw.

Figure 3-1: Transmitter Housing Set Screw

A. LCD display

B. Housing rotation set screw (3/32-in.)

CAUTION

Do not rotate the housing more than 180° without first performing a

disassembly procedure. Over-rotation may sever the electrical

connection between the sensor module and the electronics.

3.1

12 Rosemount 3051SMV

Rotate the LCD display

Transmitters ordered with the LCD display will be shipped with the display

installed.

In addition to housing rotation, the optional LCD display can be rotated in

90° increments by squeezing the two tabs, pulling out, rotating and

snapping back into place.

If LCD display pins are inadvertently removed from the electronics board,

carefully re-insert the pins before snapping the LCD display back into place.

Use the following procedure and Figure 3-2 to install the LCD display:

Procedure

1. If the transmitter is installed in a loop, then secure the loop and

disconnect power.

B

C

A

October 2021 Quick Start Guide

2. Required: Remove the transmitter cover on the electronics board

side (opposite the field terminals side). Do not remove instrument

covers in explosive environments when circuit is live.

3. Engage the four-pin connector into the electronics board and snap

LCD display into place.

4. Required: In order to meet explosion-proof requirements, reinstall

the housing cover and tighten so the cover is fully seated with metal

to metal contact between the housing and cover. After the cover is

seated properly, replace the flathead screw located on the bottom of

the housing cover.

Figure 3-2: Optional LCD Display

A. Electronics board

B. LCD display

C. Display cover

Quick Start Guide 13

SECURITY

SIMULATE

ENABLE

DISABLE

C

D

E

F

B

A

Quick Start Guide October 2021

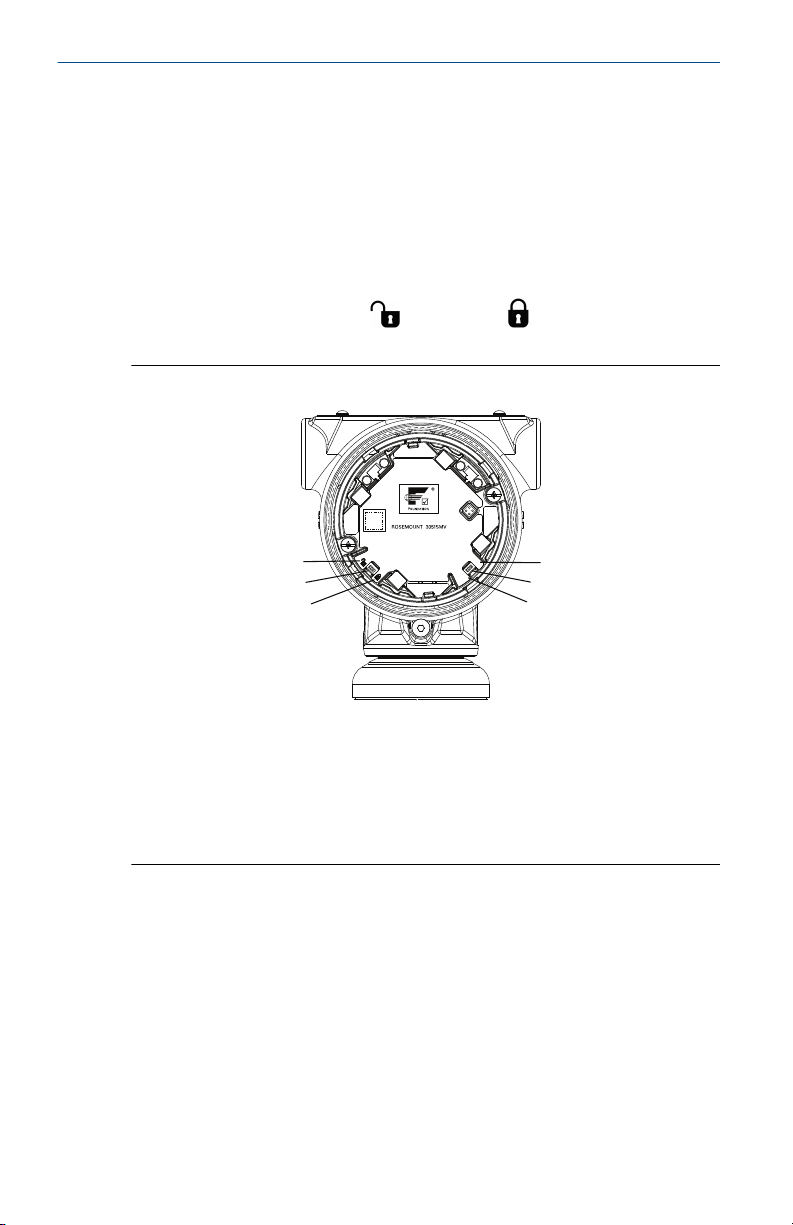

4 Set the switches

Prerequisites

Set Simulate and Security switch position before installation (location of

switches shown in Figure 4-1), as desired.

• The Simulate switch enables or disables the ability to set simulated alerts

or simulated measured value and status.

• The Security switch allows (

) or prevents ( ) any configuration of

the transmitter.

Figure 4-1: Simulate and Security Switches

A. Security unlocked position

B. Security switch

C. Security locked position

D. Simulate disabled position

E. Simulate switch

F. Simulate enabled position

Further security settings are available in the software, including settings

which use a software lock. Additionally, these settings can be used to disable

both hardware and software locks.

Use the following procedure to change the switch configuration:

Procedure

1. If the transmitter is installed, secure the segment, and remove

power.

14 Rosemount 3051SMV

Loading...

Loading...