Quick Installation Guide

Step 1: Mount the Transmitter

Step 2: Consider Housing Rotation

Step 3: Connect the Wiring and Power Up

Step 4: Configure the Transmitter

Step 5: Calibrate the Transmitter

Product Certifications

Start

End

Product Discontinued

00825-0100-4360, Rev BA

July 2009

Rosemount 1151

Rosemount 1151 Analog Pressure Transmitter

www.rosemount.com

¢00825-0100-4360N¤

Quick Installation Guide

IMPORTANT NOTICE

WARNING

00825-0100-4360, Rev BA

Rosemount 1151

© 2009 Rosemount Inc. All rights reserved. All marks property of owner. Rosemount and the Rosemount logotype are

registered trademarks of Rosemount Inc.

Emerson Process Management

Rosemount Division

8200 Market Boulevard

Chanhassen, MN USA 55317

T (US) (800) 999-9307

T (Intnl) (952) 906-8888

F (952) 949-7001

Emerson Process Management Asia

Pacific Private Limited

1 Pandan Crescent

Singapore 128461

T (65) 6777 8211

F (65) 6777 0947/65 6777 0743

This installation guide provides basic guidelines for Rosemount 1151 transmitters. It does

not provide instructions for configuration, diagnostics, maintenance, service,

troubleshooting, Explosion-Proof, Flame-Proof, or intrinsically safe (I.S.) installations.

Refer to the Rosemount 1151 reference manual (document number 00809-0100-4360)

for more instruction. This manual is also available electronically on

www.emersonprocess.com/rosemount.

Emerson Process Management GmbH & Co.

OHG

Argelsrieder Feld 3

82234 Wessling

Germany

T 49 (8153) 9390

F49 (8153) 939172

Beijing Rosemount Far East

Instrument Co., Limited

No. 6 North Street,

Hepingli, Dong Cheng District

Beijing 100013, China

T (86) (10) 6428 2233

F (86) (10) 6422 8586

July 2009

Explosions could result in death or serious injury:

Installation of this transmitter in an explosive environment must be in accordance with the

appropriate local, national, and international standards, codes, and practices. Please

review the approvals section of the 1151 reference manual for any restrictions associated

with a safe installation.

• In an Explosion-Proof/Flame-Proof installation, do not remove the transmitter covers

when power is applied to the unit.

Process leaks may cause harm or result in death.

• To avoid process leaks, only use the o-ring designed to seal with the corresponding

flange adapter.

Electrical shock can result in death or serious injury.

• Avoid contact with the leads and the terminals. High voltage that may be present on

leads can cause electrical shock.

2

Quick Installation Guide

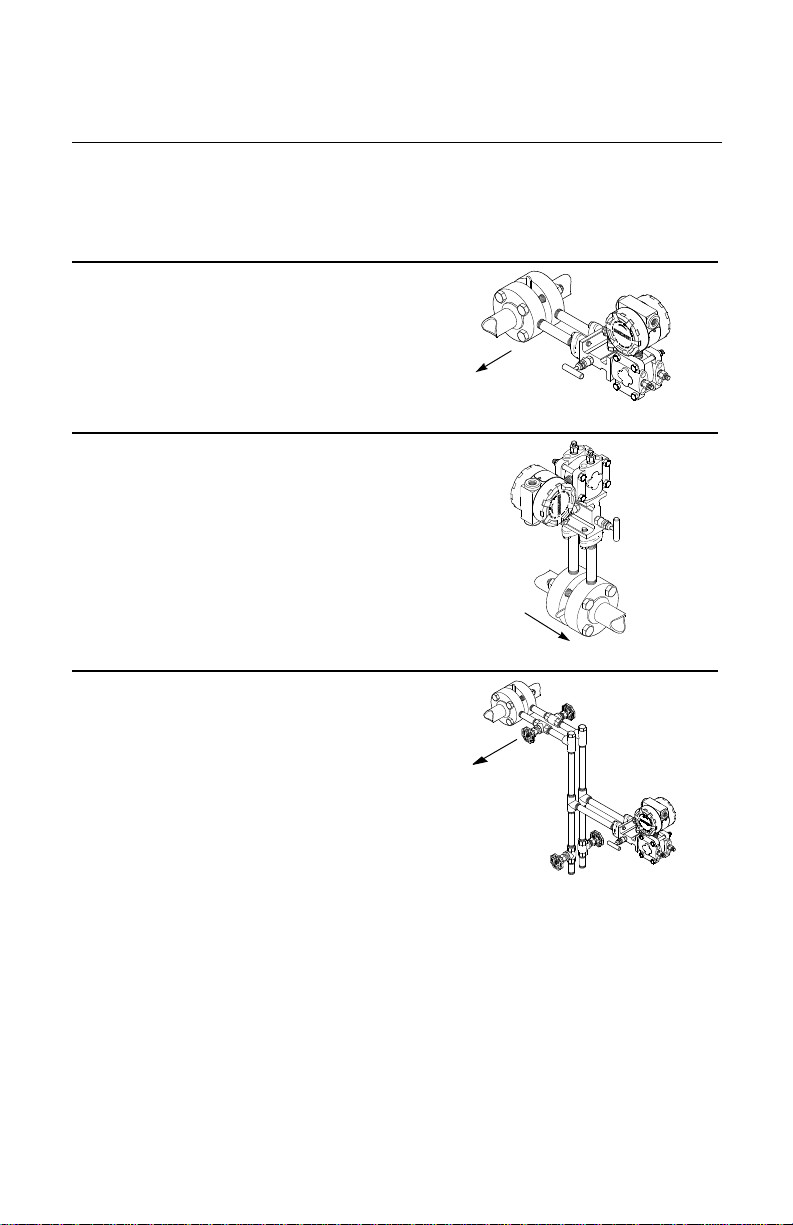

STEP 1: MOUNT THE TRANSMITTER

Flow

Flow

Flow

00825-0100-4360, Rev BA

July 2009

A. Applications

Liquid Flow Applications

1. Place taps to the side of the line.

2. Mount beside or below the taps.

Gas Flow Applications

1. Place taps in the top or side of the line.

2. Mount beside or above the taps.

Steam Flow Applications

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Fill impulse lines with water.

Rosemount 1151

3

Quick Installation Guide

STEP 1 CONTINUED...

00825-0100-4360, Rev BA

Rosemount 1151

July 2009

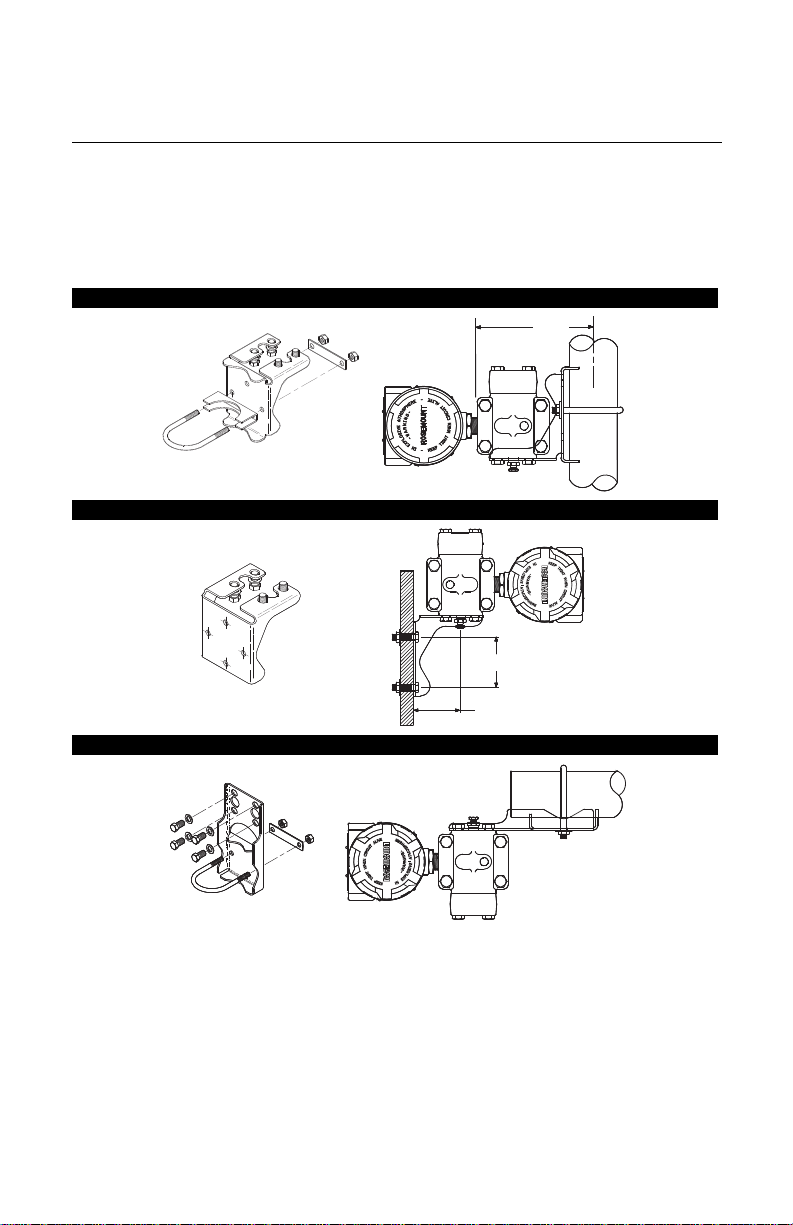

B. Optional Mounting Brackets

When installing the transmitter to one of the optional mounting brackets, torque the bracket

bolts to 125 in.-lbs. (0,9 N-m).

Pipe Mount

(1) Panel bolts are customer supplied.

Panel Mount

Flat Mount

(1)

4

Quick Installation Guide

STEP 1 CONTINUED...

WARNING

Rosemount 3051S / 3051 / 2051 / 3001 / 3095

Rosemount 1151

Flange Adapter

O-ring

Flange Adapter

O-ring

PTFE Based

Elastomer

PTFE

Elastomer

00825-0100-4360, Rev BA

July 2009

Rosemount 1151

C. O-rings with Flange Adapters

Failure to install proper flange adapter O-rings may cause process leaks, which can result in death or

serious injury. The two flange adapters are distinguished by unique O-ring grooves. Only use the O-ring

that is designed for its specific flange adapter, as shown below.

Whenever the flanges or adapters are removed, visually inspect the o-rings. Replace them if

there are any signs of damage, such as nicks or cuts. If you replace the o-rings, re-torque

the flange bolts and alignment screws after installation to compensate for seating of the

PTFE o-ring.

5

Loading...

Loading...