Rosemount Quick Start Guide: 6888A with Integral Autocalibration | Rosemount Manuals & Guides

Quick Start Guide

Rosemount

TM

6888 Analyzer

Overview

The 6888 is a combustion analyzer which measures the oxygen remaining in ue gases from any

combustion process (boiler, furnace, etc.) by controlling the air to fuel ratios, the optimum

ue gas O2 variations in air density, or fuel BTU that are compensated. Other benets are reaching

maximum efciency with the lowest NOx and minimum CO2 emissions.

This latest version of the 6888 has an optional online Calibration Recommended diagnostic to

indicate when the analyzer needs to be calibrated.

Also, internal gas-switching solenoids direct calibration gases to the sensing cell, which provides

on-line calibration, all while the boiler or furnace is in operation.

Calibrations can also be initiated based on time since last calibration or manually.

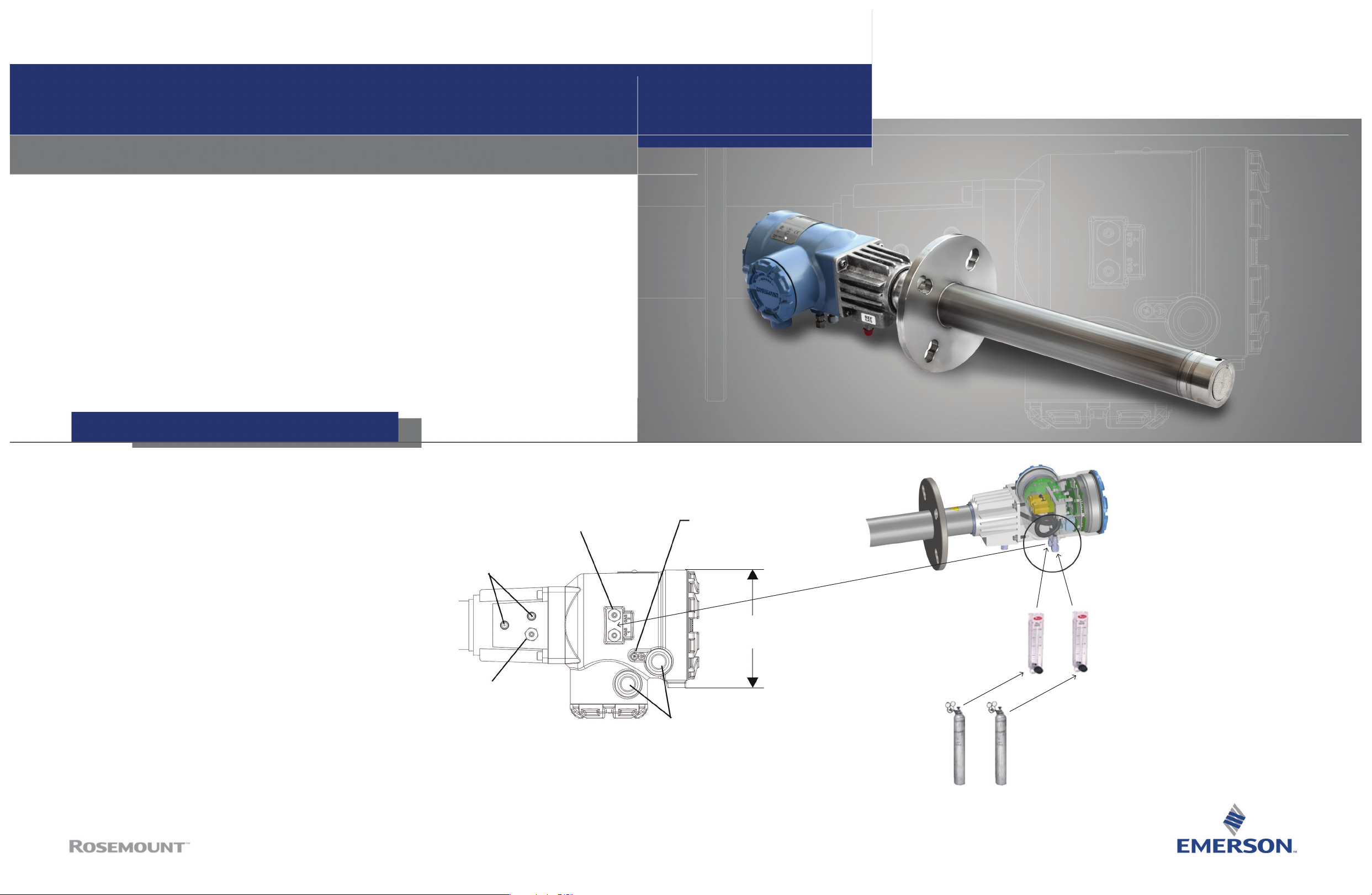

Pneumatic Installation

Manual bottle-switching is not possible with this

system, so do a good job on the installation. Do a leak

check on all the ttings to prevent bleeding of the cal gas

bottles over time.

Reference air is optional. (You can just leave this port

open to atmosphere.)

If used, make sure that the instrument air is clean and

dry, and mount the reference air owmeter similarly to

the cal gas owmeters.

CMB_QS_6888AutoCal

July 2017

Reference Air Vents

Reference Gas

1/4 Tube Fitting

2.0 SCFH (1.0 L/min)

20 PSI (138k Pa)

Calibration Gas

1/4 Tube Fittings

5.0 SCFH (2.4 L/min)

20 PSI (138 kPa)

#10 Soc Hd Cap Scr

(EXTERNAL GROUND)

[138.4]

1/2 NPT

Conduit Connection

(POWER, SIGNAL)

5.45

Pipe cal gases into bottom,

and out the top

Use dual-stage

pressure regulators

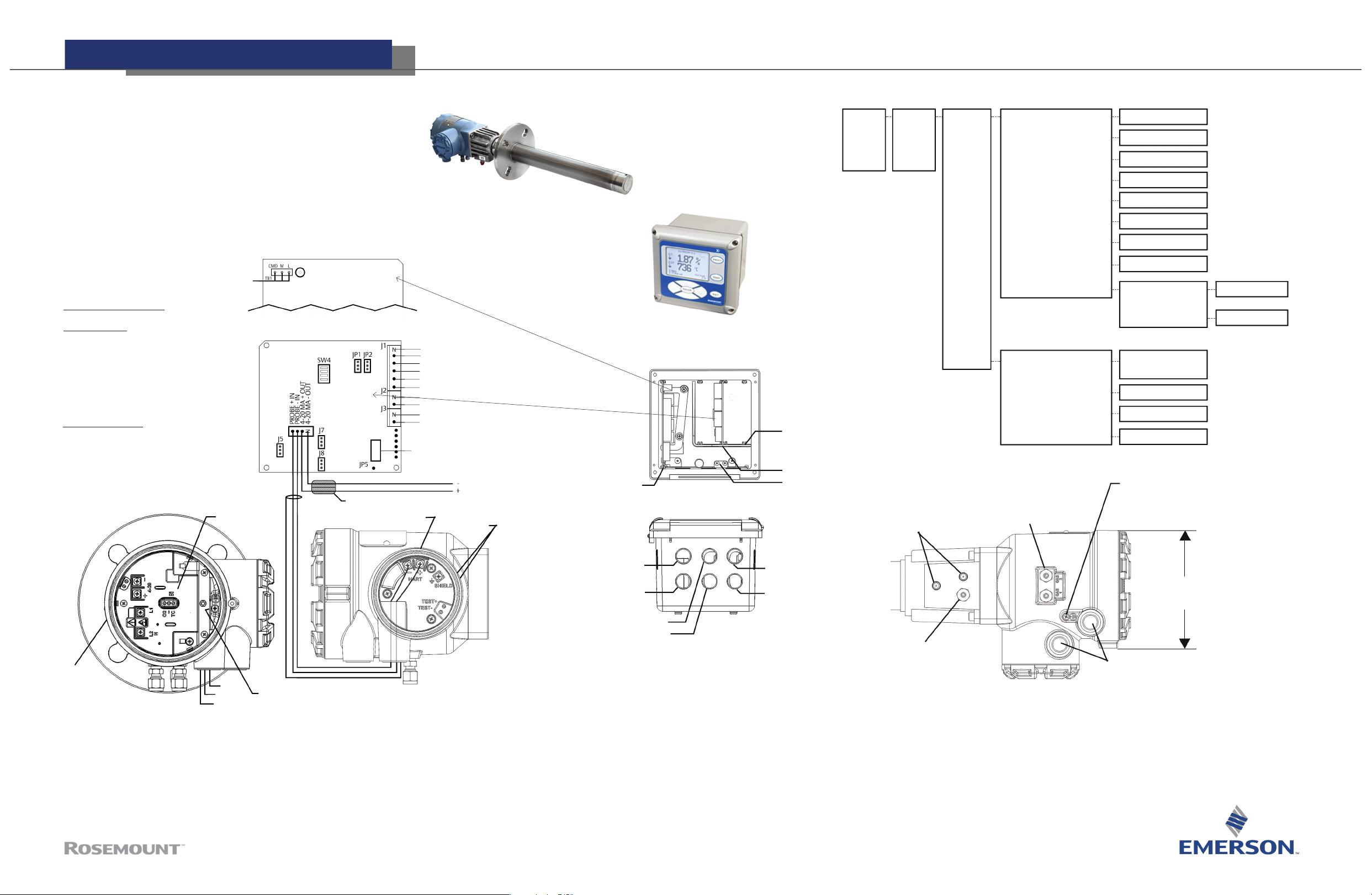

HART Electrical Installation

Notes:

Except for JP5, JP7, and JP8 on the IO Board, jumper and switch setting

are factory set and are shown for reference only.

IO Board 4–20 mA/HART loop power settings

JP5: Pins 1–2 Internal power 6888Xi to 6888 Transmitter

Pins 2–4 External power 6888Xi to 6888 Transmitter

(Requires 250 Resistor across J4, PR+ to PR-)

JP7/JP8: Pins 1–2 Internal power 6888Xi to DCS

Pins 2–4 External power 6888Xi to DCS

Power Supply Board

AC Input

IO Board Switch / Jumpers

Jumper Settings

JP1: Pins 2–3

JP2: Pins 2–3

JP5: Pins 1–2 Int power

Pins 2–3 Ext power

JP7: Pins 1–2 Int power

Pins 2–3 Ext power

JP8: Pins 1–2 Int power

Pins 2–3 Ext power

SW4 Switch Settings

Pos 1 - Off

Pos 2 - Off

Pos 3 - Off

Pos 4 - Off

Test Point Group

IO Board - Channel 1

PR+

PR-

Ferrite Clamp

Power Supply Card

Alarm 1 NO

Alarm 1 COM

Alarm 1 NO

Alarm 2 NO

Alarm 2 COM

Alarm 2 NO

FS

}

Optional

FS

CAL INIT

INPUT

Ribbon Cable to display

BOARD J2 “Sensor 1”

4–20 MA/HART

Signal

Test Points

With FOUNDATION™ eldbus probes

no Xi is required to conduct AutoCal

Note: I/O Board - Channel 2 is a

duplicate of Channel 1

OUTPUT

I/O Card

Power Supply

Board

6888 XI

Front View

6888 XI

Bottom View

Xi electronics

Channel #1

IO Board

Channel #2

IO Board

Shield Ground

Recommended Menu selections

PROBE #1

Detailed

Setup

Reference Air Vents

Calibration AO TRACK

Auto

Calibration

Enable Auto Cal

Start on Cal Recommended

Cal Interval

Next Cal Time

Calibration Gas

1/4 Tube Fittings

5.0 SCFH (2.4 L/min)

20 PSI (138 kPa)

TOL CHECK

CAL Recommended

CAL Acknowledge

CAL Gas #1

CAL Gas #2

Gas Time

Purge Time

Diffuser

Yes

No

Yes

No

0.4 % O

2

8 % O

2

300 Seconds

300 Seconds

Plugged Diffuser

Auto Advance CAL

No - Std. Housing

Yes - AutoCal Housing

No

672 hours (1 month)

Variable

#10 Soc Hd Cap Scr

(EXTERNAL GROUND)

Rate

Yes

- 9999 = manual initiate

Power

GND

L2

Transmitter Probe

Field Connections

©2017 Emerson Automation Solutions. All rights reserved.

L1

#8 Pan Hd Scr

(INTERNAL GROUND)

Channel #2 Alarm Relay, SPS/IMPS

Channel #2 4–20 mA/HART output

www.Emerson.com/RosemountGasAnalysis

Rosemount

8200 Market Blvd

Chanhassen, MN 55317

Toll free: + 1 800 999 9307

F +1 952 949 7001

gas.csc@emerson.com

AC Input to P/S

Plug

Channel #1

Alarm Relay, SPS/IMPS

Channel #1

4–20 mA/HART output

Reference Gas

1/4 Tube Fitting

2.0 SCFH (1.0 L/min)

20 PSI (138k Pa)

5.45

[138.4]

1/2 NPT

Conduit Connection

(Power, Signal)

Loading...

Loading...