Rosemount Process Radar in Refining Applications-Best Practices for Installation and Commissioning Manuals & Guides

Reference Manual

00809-0200-4530, Rev AB

September 2009

Rosemount Process Radar in Refining Applications

Best Practices for Installation and Commissioning

www.rosemount.com

Reference Manual

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

Rosemount Process Radar in Refining Applications

Best Practices for Installation and Commissioning

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware

or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Rosemount

Sales Representative.

This product is designed to meet FCC and R&TTE requirements for a non-intentional

radiator. It does not require any licensing whatsoever and has no tank restrictions

associated with telecommunications issues.

This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired

operation.

Cover Photo: Cover.tif

www.rosemount.com

Reference Manual

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

Table of Contents

SECTION 1

Introduction

SECTION 2

Installation

Considerations

SECTION 3

Refining Applications

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installation Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Chambers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Transmitter Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Flushing Connections and Vents . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Chamber Fabrication and Probe Selection. . . . . . . . . . . . . . . . . . 2-5

Existing Chambers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Setting Range Values - Three Options. . . . . . . . . . . . . . . . . . . . . 2-8

Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Recommended Mounting Position . . . . . . . . . . . . . . . . . . . . . . . 2-12

Nozzle Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Process Isolation for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Probe and Antenna Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Refining Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Chambers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

High temperature at low to moderate pressure -

Level Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

High Temperature and High Pressure -

Level Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

High Temperature and High Pressure -

Level and Interface Measurement . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Standard Temperature and Standard Pressure -

Level Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Standard Temperature and Standard Pressure -

Interface Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Desalters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Liquefied Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

www.rosemount.com

Rosemount Radar Level Transmitters

Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Ammonia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Solids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Storage Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Tanks with agitators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Compressor tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Tanks with very rapid level changes. . . . . . . . . . . . . . . . . . . . . . 3-13

Applications to limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Reference Manual

00809-0200-4530, Rev AB

September 2009

SECTION 4

Commissioning

SECTION 5

Measurement Validation

at Operating Conditions

SECTION 6

Troubleshooting

Procedures

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Trim Near Zone (5300 Series only) . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Store Backup and Verification Files . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

On the Bench Test (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Measurement Validation at Operating Conditions . . . . . . . . . . . . . . . . 5-2

Step 1: Verify the Correctness of Level Reading . . . . . . . . . . . . . . . 5-2

Step 2: Analog Output Signal Validation . . . . . . . . . . . . . . . . . . . . . 5-3

Step 3: Echo-Curve Verification at Operating Conditions . . . . . . . . 5-4

Step 4: Transmitter Diagnostics Review . . . . . . . . . . . . . . . . . . . . . 5-4

Step 5: Monitor Level while Emptying . . . . . . . . . . . . . . . . . . . . . . . 5-5

Step 6: Echo-Curve Verification with Empty Tank . . . . . . . . . . . . . . 5-6

Step 7: Monitor Level while Filling . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Echo Curve Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Echo Curve Constituents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

5300 Threshold Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

5400/5600 Threshold Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Common Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Sources of Measurement Error . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Installation and Location Errors . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Geometries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Analog Output Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Incorrect Dielectric Constant of the Upper Product . . . . . . . . . . 6-13

Submerged Probes with Air gap. . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Incorrect Vapor Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Reconciling Radar with other Level Measurements . . . . . . . . . . 6-15

APPENDIX 7

Checklists

TOC-2

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Commissioning Procedure Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Measurement Validation at Operating Conditions

Procedure Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Reference Manual

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

Section 1 Introduction

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

INTRODUCTION This document describes some of the best practices learned during the

installation of thousands of Rosemount process radar level transmitters in

refining applications. However, it is not a complete set of instructions; for more

detailed information refer to the respective product manual:

• Rosemount 5300 Series Reference Manual (Document No.

00809-0100-4530)

• Rosemount 5400 Series Reference Manual (Document No.

00809-0100-4026)

• Rosemount 5600 Series Reference Manual (Document No.

00809-0100-4024), and

• Rosemount 9901 Reference Manual (Document No.

00809-0100-4601).

Local restrictions, regulations, or best practices may also apply and should be

taken into consideration.

This best practices guide focuses on continuous level and interface

measurement applications used in refinery chambers. It also, where

appropriate, covers best practices for measurements in tanks and pipes.

www.rosemount.com

Rosemount Radar Level Transmitters

Reference Manual

00809-0200-4530, Rev AB

September 2009

1-2

Reference Manual

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

Section 2 Installation Considerations

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Chambers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-10

Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-12

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Explosions could result in death or serious injury.

Verify that the operating environment of the gauge is consistent with the appropriate

hazardous locations certifications.

Before connecting a HART

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Do not remove the gauge cover in explosive atmospheres when the circuit is alive.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury.

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

High voltage that may be present on leads could cause electrical shock.

Avoid contact with leads and terminals.

Make sure the main power to the transmitter is off and the lines to any other external

power source are disconnected or not powered while wiring the gauge.

Probes covered with plastic and/or with plastic discs may generate an ignition-capable

level of electrostatic charge under certain extreme conditions. Therefore, when the

probe is used in a potentially explosive atmosphere, appropriate measures must be

taken to prevent electrostatic discharge.

®

-based communicator in an explosive atmosphere, make

www.rosemount.com

Reference Manual

Error

Error

Error

Error

Effective

measuring

range

00809-0200-4530, Rev AB

Rosemount Radar Level Transmitters

September 2009

INTRODUCTION In addition to selecting the appropriate radar level transmitter, mechanical

installation is one of the most critical steps of the commissioning procedure.

When done correctly, the subsequent transmitter configuration will be

considerably simplified.

Because of the wide usage and application in the refining industry, this

section provides a framework for chamber installations. The basics of pipe

and tank installation are also covered.

INSTALLATION CONSIDERATIONS

Chambers

Figure 2-1. Effective measuring

range and possible error

sources

Chambers - also known as bridles, side-pipes, bypass-pipes, and cages - are

typically used because:

• External mounting with valves allows for servicing of the level device,

even in pressurized tanks that are in continuous operation for many

years

• They allow for radar measurement in tanks or regions with

side-connections only, such as towers

• They provide a calmer surface in case of turbulence, boiling, or other

conditions that upset the product

However, chambers also have some disadvantages:

• Inlet pipes may clog and generate a discrepancy between the level

inside the chamber and the actual level in the tank

• The effective measuring range is limited to the region between the

upper and lower inlet pipes

2-2

Reference Manual

Level

Interface

Level

00809-0200-4530, Rev AB

September 2009

Figure 2-2. The Rosemount

5300 Series is an ideal choice

for continuous measurement of

level or interface in most

chamber applications

Rosemount Radar Level Transmitters

Generally, Guided Wave Radar (GWR) is favored in these applications since

non-contacting radar may be disturbed by the inlet-pipes. The Rosemount

5300 Series can be used in chambers to measure either level or interface

level.

Table 2-1. Measured variable

options

Transmitter Selection

The Rosemount 5300 Series can measure the level of oil, the interface of oil

and water, or other liquids with significant dielectric differences and a clear

interface between the two products.

For application guidelines, refer to ”Refining Applications” on page 3-2 or to

the Rosemount 5300 Series PDS (Document No. 00813-0100-4530).

There are two different transmitter versions, Rosemount 5301 and

Rosemount 5302. The required measurement variable will determine which

transmitter should be used:

Level only

Interface Level with

fully submerged

probe

Interface Level

Use the Rosemount 5301 (or alternatively Rosemount 5302 configured

for level only measurement)

The Rosemount 5301 can be used in this case. If there is an air gap, it

will generate an offset in the interface level measurement according to:

Interface Level offset = Air gap distance X ( 1 -

For example, an air gap of 4 in. (100 mm) with oil as upper product

(dc=2) generates a 1 in. (29 mm) positive interface level offset. In case

the air gap is constant, the interface level output can be compensated

by reducing the reference height with this offset.

In case there is an air-gap or the air gap is changing, the Rosemount

5302 should be used.

dielectric constant of upper product

1

)

2-3

Rosemount Radar Level Transmitters

Rosemount 5301

Level only

Rosemount 5301

Interface only with

fully submerged

probe (no air gap

thanks to venting)

Rosemount 5302

Interface (with or

without air gap)

Air gap

Flushing ring

Figure 2-3. Rosemount 5300

Series for Level and Interface

Measurement

Reference Manual

00809-0200-4530, Rev AB

September 2009

Figure 2-4. Rosemount 5300

Series transmitter with a flushing

ring

Flushing Connections and Vents

These options are recommended to remove the air-gap in interface

applications with fully submerged probes (5301):

• A separate flushing ring may be inserted between the 5300 flange and

cages that use ANSI or DIN flanges

2-4

• Proprietary flanges are available with an integrated vent option that are

used with 1½ in. (37.5 mm) NPT threaded probes

Reference Manual

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

For further details and ordering information, see the Rosemount 5300 PDS

(Document No. 00813-0100-4530).

Venting may be needed to manipulate the level in the cage to verify the output

of the 5300, or to drain the cage. If this is the only purpose, a standard integral

cage vent is suitable, refer to the 9901 PDS (Document No.

00813-0100-4601).

Chamber Fabrication and Probe Selection

Dimensioning the chamber correctly and selecting the appropriate probe is

key to success in these applications. Either follow the recommendations

below and have the chamber manufactured accordingly, or purchase the

Rosemount 5300 Series transmitter bundled with the Rosemount 9901

chamber where Emerson has already incorporated these best practices.

The recommended chamber diameter is 3 in. (75 mm) or 4 in. (100 mm).

Chambers with a diameter less than 3 in. (75 mm) may cause problems with

build-up and it may also be difficult to center the probe. Chambers larger than

6 in. (150 mm) can be used, but provide no advantages for the radar

measurement.

With the Rosemount 5300 Series it is recommended that single probes in 3 in.

(75 mm) and 4 in. (100 mm) cages be used. Other probe types are more

susceptible to build-up and should not be used in this application.

(1)

The probe must not touch the chamber wall and should extend the full height

of the chamber, but does not need to touch the bottom of the chamber. Probe

type selection depends on the probe length:

Probe length is less than 3 ft (1 m): Use Single Rigid Probe and no

centering disk is needed.

(2)

Probe length is between 3 ft (1 m) and 10 ft (3 m): Use either Rigid Single

or Flexible Single Probe with the weight and centering disk. Rigid Single is

easier to clean and has smaller transition zones, while the Flexible Single

requires less head-space during installation and is less likely to be damaged.

Probe length is more than 10 ft (3 m): Use Flexible Single Probe with weight

and centering disk.

(1) The single probe creates a virtual coaxial probe with the chamber as the outer tube. The

extra gain provided by the twin and coaxial probes is not necessary; the electronics in the

5300 Series is very sensitive and is not a limiting factor.

(2) The transition zones, and the height of the weight, limit the usage of single flexible probes

shorter than 3 ft (1 m).

2-5

Rosemount Radar Level Transmitters

Make sure that the probe

does not come into

contact with the chamber

wall, e.g. by using a

centering disk.

A clearance

distance of 1 in.

(25 mm) between

the probe end and

the cage bottom is

recommended.

Upper Reference Point

Upper Transition Zone

Maximum

Measuring Range

Lower Transition Zone

Lower Reference Point

Figure 2-5. Improper and proper

probe positions

To avoid bending the probe (rigid probes), or twisting and coming into contact

with the chamber wall (flexible probes), a small clearance distance between

centering disk and chamber bottom is recommended. The clearance distance

of 1 in. (25 mm) is selected with a dome shaped chamber bottom in mind,

which may prevent the centering disk from reaching the bottom.

Reference Manual

00809-0200-4530, Rev AB

September 2009

Figure 2-6. Transition Zones and

Measuring Range

The location of the side-pipes and the effective measurement range is

determined by the mating tank connections. There are no diameter

requirements for the side-pipes, but build-up and clogging should be taken

into consideration. Ensure that the inlet pipes do not protrude into the

chamber because they may interfere with the radar measurement. Always

use the same material of construction for the chamber and the tank or

mechanical tensions can arise in the side-connections.

2-6

Reference Manual

A > Upper transition zone

B = Effectice Measuring

Range, determined by

mating tank connections

C > Lower transition

zone including weight

height (for flex probes)

and clearance distance

Single Rigid

Probe/chamber

diameter must

be 3 in. or 4 in.

(7.5 cm or 10 cm)

Use centering

disks for probes

> 3 ft (1 m)

Single Flex

for chambers

>= 3 ft (1 m)

Probe/chamber

diameter must

be 3 in. or 4 in.

(7.5 cm or 10 cm)

Always use a

centering disk

00809-0200-4530, Rev AB

September 2009

Table 2-2. Transition zones for

Rosemount 5300 Series

Rosemount Radar Level Transmitters

Rigid Single

Dielectric

Constant

(2)

Upper

Transition

Zone

(3)

Lower

Transition

Zone

(1) Rigid Single Lead probe without SST centering disk or with PTFE centering disk.

(2) The distance from the upper reference point where measurements have reduced accuracy, see

picture above.

(3) The distance from the lower reference point where measurements have reduced accuracy, see

picture above.

(4) Note that the weight length adds to non-measurable area and is not included in the diagram. See

section Dimensional Drawings in the 5300 Product Data Sheet (Document No. 00813-0100-4530).

(5) The measuring range for the PTFE covered Flexible Single Lead probe includes the weight when

measuring on a high dielectric media.

80 (water) 4.3 in. (11 cm) 4.3 in. (11 cm) 4.3 in. (11 cm)

2 (oil) 6.3 in. (16 cm) 6.3 in. (16 cm) 7.1 in. (18 cm)

80 (water) 2 in. (5 cm) 2 in. (5 cm) 0 in.

2 (oil) 2.8 in.

Rigid Single

(1)

Lead

(5)

(7 cm) 8 in. (20 cm) 2 in.

Transition zones, located at the very top and bottom of the probes, are

regions where measurement performance is reduced. Different factors affect

the size of the transition zones - probe type, centering disk or no centering

disk, and the material and media measured. See Table 2-2. The weight on the

flexible probes reduces the measurement range. Therefore, it is

recommended to dimension the cage (A, C) so it does not interfere with the

effective measurement range (B). The transition zones also limit the minimum

probe length.

Lead, with

metallic

centering disk

Flexible Single Lead

(4)(5)

(4)

(0 cm

(5 cm

(4)(5)

(4)

)

)

Figure 2-7. Measuring zones in

chambers

2-7

Rosemount Radar Level Transmitters

Probe length

23 in. (584 mm)

Displacer length

14 in. (356 mm)

LRV 0 in. (0 mm)

URV 14 in. (356 mm)

Tank Height

(Reference Gauge Height)

19 in. (483 mm)

An example using the guidelines for fabrication of cages

(see Table 2-2 on page 2-7 for transition zones)

Assuming level measurement of oil (worst-case); A > 6.3 in. (16 cm) and C >

9.8 in. (25 cm) for rigid single probe with a metallic centering disk, and A > 7.1

in. (18 cm) and C > 9.4 in. (24 cm) for single flexible with a standard weight.

There is a 2 in. (5 cm) clearance between the cage bottom and the end of the

probe included in the C- dimensions.

Existing Chambers

Retrofitting of existing chambers is very common, especially when replacing

old mechanical devices such as displacers. For further information, refer to

the Technical Note "Replacing Displacers with Guided Wave Radar"

(Document No. 00840-2200-4811).

Setting Range Values - Three Options

Chambers are mounted onto the tank to correspond with the desired

measurement and area of control. This is often a small portion of the overall

height.

Reference Manual

00809-0200-4530, Rev AB

September 2009

Figure 2-8. Setting range values,

Option 1 - Setting LRV to 0 in.

(0 mm) at the lower tap

For displacers, the output span corresponds to the displacer length, with

lower (LRV) and upper range values (URV) representing the bottom and top

of the displacer. In side-to-side chambers, this corresponds to

center-of-the-pipe connections to the vessel.

Option 1 - Setting LRV to 0 in. (0 mm) at the Lower Tap

The Tank Height should be set to the distance to the zero level point. In this

example, it is the lower side-pipe, located 19 in. (483 mm) below the

reference point. Output range values will equal the pipe connection heights

relative to the zero level point. LRV should be set at 0 in. (0 mm), the URV

should be set at 14 in. (356 mm), and the probe should be set to the correct

probe length.

2-8

Reference Manual

Displacer length

14 in. (356 mm)

Probe length

23 in. (584 mm)

URV 18 in.

(457 mm)

LRV 4 in.

(102 mm)

Tank Height

Reference Gauge Height)

23 in. (584 mm)

LRV 112 in. (2.8 m)

Gauge height

(Same as tank

height)

150 in. (3.75 m)

Tank bottom reference point

Displacer length

32 in. (0.8 m)

URV 144 in. (3.6 m)

00809-0200-4530, Rev AB

September 2009

Figure 2-9. Setting range values,

Option 2 - Matching displacer

output

Rosemount Radar Level Transmitters

Option 2 - Matching Displacer Output

The tank height (reference gauge height) and the probe length should be set

to the same value. The LRV is the distance from the bottom of the probe to

the lower tap. The URV is the LRV plus the distance to the upper tap. In this

example, Tank Height (Reference Gauge Height) equals the probe length of

23 in. (584 mm), the LRV is 4 in. (102 mm), and the URV is 18 in. (457 mm).

Figure 2-10. Setting range

values, Option 3 - Actual tank

level

Option 3 - Matching Actual Tank Level

For the level measurement to correspond to the actual level, the correct

gauge height needs to be entered. The LRV is the distance from the bottom of

the tank, or the common reference line, to the lower tank connection tap. For

the URV, add the tank connection distance, and the actual probe length needs

to be entered.

2-9

Rosemount Radar Level Transmitters

Example: Replacing a 32 in. (813 mm) displacer with a 41 in. (1041 mm)

probe. The gauge height is the distance from the top flange to the tank bottom

reference point. The probe length will be the actual probe length. The LRV

setting will be the height of the lower tank connection relative to the tank

bottom.

Insulation

The chamber should always be insulated in hot application to prevent

personal injuries and reduce the amount of energy needed for heating. It is

often an advantage, and sometimes even required, for the radar

measurement:

• In hot applications, insulation will reduce the amount of condensation,

since it prevents the upper part of the chamber from becoming a cold

spot

• Insulation prevents the product from solidifying inside the chamber, and

clogging the inlet-pipes

Figure 2-11. Always use

insulation in hot applications

Reference Manual

00809-0200-4530, Rev AB

September 2009

Pipes Stilling wells or pipes are used in many applications and many different types

of tanks and vessels. The reasons for having the pipes differ, but are typically

beneficial from an application standpoint, since pipes will offer a calmer,

cleaner surface and eliminate issues with disturbing obstacles.

Both Guided Wave and non-contacting Radar perform well in pipes:

• Use the 5300 Series in shorter pipes (less than 10 ft [3 m]) or if

interface measurement is required

• Use the 5400 Series in longer pipes (over 10 ft [3 m]) or if there is a risk

for build-up on a GWR probe

• The 5300 Series cannot be isolated; use the Rosemount 5402 with a

full-port ball valve for applications that cannot be taken out of operation

for service

2-10

Reference Manual

Rosemount

5400 Series

Rosemount

5300 Series

Max. 0.2 in.

(5 mm)

(N)

00809-0200-4530, Rev AB

September 2009

Figure 2-12. Pipes in a tank

Rosemount Radar Level Transmitters

Figure 2-13. 5400 in pipes and

slot size

With the 5400 Series, ensure that the cone antenna or process seal antenna

is used in the pipes, and that the size of the holes or slots is limited in size.

See Figure 2-14 on page 2-12. Holes should be drilled on one side of the

pipe. The gap between the cone-antenna and the pipe should not be larger

than 2 in. (5 mm). If needed, buy an oversized cone and cut on site. With

non-contacting radar in pipe installations with low dielectric fluids, install a

deflection plate with an approximate angle of 45° at the bottom of the pipe.

Failure to follow these requirements may affect the reliability of the level

measurement.

2-11

Rosemount Radar Level Transmitters

Min. 6 in. (150 mm)

Max. Ø: D/10. (e.g. 4" pipe

should have max 0.4" holes)

Figure 2-14. Rosemount 5400

Series recommended hole sizes

for pipe installations

For the 5300 Series the installation considerations are virtually identical with

chambers, as covered in the previous section of this document.

Reference Manual

00809-0200-4530, Rev AB

September 2009

For more details, refer to the Technical Note "Guidelines for Choosing and

Installing Radar in Stilling Wells and bypass pipes" (Document No.

00840-0200-4024).

Tanks Recommended Mounting Position

When finding an appropriate mounting position for the transmitter, the

conditions of the tank must be carefully considered.

For the Rosemount 5300 Series:

• Do not mount close to inlet pipes and ensure that the probe does not

come in contact with the nozzle (X)

• If there is a chance that the probe may come in contact with the tank

wall, nozzle or other tank obstructions, the coaxial probe is the only

recommended choice. Minimum clearance is given in Table 2-3 on

page 2-13

• Generally, the Rosemount 5400 Series is recommended in tanks with

agitators. If the probe sways due to turbulent conditions, the probe

should be anchored to the tank bottom (Y). Refer to the 5300 Series

Reference Manual (00809-0100-4530) for anchoring options. Also note

that violent fluid movements that cause high sideway forces may break

rigid probes

2-12

Reference Manual

XY

00809-0200-4530, Rev AB

September 2009

Figure 2-15. Tank with agitator

Rosemount Radar Level Transmitters

Table 2-3. Minimal clearances

of probes

Min.

clearance to

tank wall or

obstruction

Coaxial

0 in. (0 cm)

Rigid Twin

Lead

4 in. (10 cm) 4 in. (10 cm)

Flexible Twin

Lead

Rigid Single

Lead

4 in. (10 cm) in

the case of

smooth metallic

wall.

20 in. (50 cm) in

the case of

disturbing

objects, rugged

metallic or

concrete/plastic

wall.

Flexible Single

Lead

4 in. (10 cm) in

the case of

smooth metallic

wall.

20 in. (50 cm) in

the case of

disturbing

objects, rugged

metallic or

concrete/plastic

wall.

The Rosemount 5400 Series should be installed in locations with a clear and

unobstructed view of the level surface (A) for optimum performance:

• Filling inlets creating turbulence (B), and stationary metallic objects with

horizontal surfaces (C) should be kept at a distance, outside the signal

beam. See the 5400 PDS for more information (Document No.

00813-0100-4026)

• Agitators with large horizontal blades may reduce the performance of

the transmitter, so install the transmitter in a location where this effect is

minimized. Vertical or slanted blades are often invisible to radar, but

create turbulence (D)

• Do not install the transmitter in the center of the tank (E)

• Because of circular polarization, there is no clearance distance

requirement from the tank wall if it is flat and free from obstructions,

such as heating coils and ladders (F). Usually, the optimal location is

1/3 of the radius from the tank wall

2-13

Rosemount Radar Level Transmitters

DAEBFC

Figure 2-16. Proper and

improper locations for the

Rosemount 5400 Series

transmitter

Nozzle Considerations

Reference Manual

00809-0200-4530, Rev AB

September 2009

Depending on the selection of transmitter model and probe/antenna, special

considerations may have to be taken because of the nozzle.

Rosemount 5300 Series

The coaxial probe signal is unaffected by the nozzle.

The single and twin probes have some nozzle restrictions, e.g. avoid using

nozzles with reducers, and nozzles that are too tall or too narrow.

2-14

Reference Manual

Avoid nozzles with reducer

(unless using Coaxial probe)

H

D

UNZ

00809-0200-4530, Rev AB

September 2009

Figure 2-17. Mounting in nozzles

Rosemount Radar Level Transmitters

Table 2-4. Nozzle

considerations

Recommended

Nozzle Diameter (D)

Minimum Nozzle

Diameter (D)

Maximum Nozzle

Height (H)

(1) An Upper Null Zone setup may be required to mask the nozzle, which may reduce the measuring

(2) When using single flexible probes in tall nozzles, it is recommended to use the Long Stud (LS).

(1)

range.

Rosemount 5400 Series

5402 with Cone Antenna

The antenna can be used in nozzles equal to or larger than 2 in. (50 mm). It

can be recessed in smooth nozzles up to 6 ft (2 m). If the inside of the nozzle

contains disturbing objects, use the extended cone (l).

Single (Rigid/Flexible) Coaxial Twin (Rigid/Flexible)

4-6 in. (100-150 mm)

2 in. (50 mm)

4 in. + Nozzle Diameter

> Probe Diameter

> Probe Diameter 2 in. (50 mm)

N/A

4-6 in. (100-150 mm)

4 in. + Nozzle

Diameter

(2)

2-15

Rosemount Radar Level Transmitters

(I)

Smooth nozzle

Bad weldings

Spray nozzle

(J)

(K) Bad welding

(L) 0.4 in. (10 mm) or more

Figure 2-18. Rosemount 5402

with Cone Antenna

5402 with Process Seal Antenna

The antenna can be used in 2, 3, and 4 in. (50, 75, and 100 mm) nozzles up

to 6 ft (2 m) tall (J), but disturbing objects inside the nozzle (K) may impact the

measurement, and should be avoided. The flange on the tank should have a

flat or raised face, but other tank flanges may be possible. Consult your local

Emerson Process Management representative for assistance.

Reference Manual

00809-0200-4530, Rev AB

September 2009

Figure 2-19. Rosemount 5402

with Process Seal Antenna

Figure 2-20. Rosemount 5401

with Cone Antenna

5401 with Cone Antenna

This antenna can be used in tanks with nozzles equal to or larger than 4 in.

(100 mm) and can extend 0.4 in. (10 mm) or more below the nozzle (L). If

required, use the extended cone solution.

2-16

Reference Manual

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

Process Isolation for Service

It is recommended that the Rosemount 5400 Series use a full-port ball valve

in applications that cannot be taken out of operation for service.

The 5402 is required, and the preferred choice is the Process Seal Antenna,

since it does not require a spool piece. The cone antenna can also be used,

but a spool piece will be needed.

Ensure there is no edge between the ball valve and the nozzle/pipe. The

inside should be smooth.

The 5300 Series cannot be used with valves because of the protrusion of the

probe into the tank. If process isolation is needed with the 5300 Series, a

chamber is recommended.

Probe and Antenna Selection

Besides mounting position, nozzle considerations, and process isolation,

there are other factors that need to be taken into consideration when selecting

the probe or antenna:

• Single probes and cone-antennas are recommended in most

applications. Always use the largest possible antenna

• In case of turbulent surface conditions or foam, consider using the

coaxial probe with GWR. When using non-contacting radar, consider

using a stilling well

• The coaxial and twin lead probes have longer measuring ranges than

the single probes, but are more sensitive to build-up and coating

Table 2-5. Factors of probe

selection

Coaxial Twin Lead Single Lead

Maximum Viscosity

(1)

500 cP

Coating/Build-up

Coating not recommended Thin coating allowed, but no bridging Coating allowed

(1) About the same viscosity as motor oil SAE30 at room temperature.

(2) About the same viscosity as motor oil SAE70 at room temperature.

(3) About the same viscosity as molasses at room temperature.

1500 cP

(2)

8000 cP

(3)

Always ensure that the wetted materials are compatible with the process and

that the probe/antenna will withstand the application's temperature and

pressure range.

For more information, refer to the Level Selection Guide (Document No.

00803-0100-6112).

2-17

Rosemount Radar Level Transmitters

Reference Manual

00809-0200-4530, Rev AB

September 2009

2-18

Reference Manual

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

Section 3 Refining Applications

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Refining Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2

Chambers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2

Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-9

Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-10

Applications to limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-14

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Explosions could result in death or serious injury.

Verify that the operating environment of the gauge is consistent with the appropriate

hazardous locations certifications.

Before connecting a HART

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Do not remove the gauge cover in explosive atmospheres when the circuit is alive.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury.

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

High voltage that may be present on leads could cause electrical shock.

Avoid contact with leads and terminals.

Make sure the main power to the transmitter is off and the lines to any other external

power source are disconnected or not powered while wiring the gauge.

Probes covered with plastic and/or with plastic discs may generate an ignition-capable

level of electrostatic charge under certain extreme conditions. Therefore, when the

probe is used in a potentially explosive atmosphere, appropriate measures must be

taken to prevent electrostatic discharge.

®

-based communicator in an explosive atmosphere, make

www.rosemount.com

Reference Manual

Level

Rosemount 5301

Rosemount 5301

00809-0200-4530, Rev AB

Rosemount Radar Level Transmitters

September 2009

INTRODUCTION This section covers refining applications in chambers, pipes, and tanks

regarding pressure, temperature and measurement.

Besides the list of typical applications, application characteristics, and best

practices suggested here, there is also a description on the applications to

avoid at the end of the section.

REFINING APPLICATIONS

Chambers

Figure 3-1. Tower bridles and

reboiler application with

Rosemount 5301 transmitters

High temperature at low to moderate pressure Level Measurement

Typical Applications

• Distillation Towers (Lower Portions)

• Reflux/Reboilers

• Accumulator

3-2

Reference Manual

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

Application characteristics

• Boiling fluid results in a low signal return for the radar, especially

hydrocarbon products, e.g. Oils and Diesel in crude oil distillation

towers

• The product may be very viscous and cause heavy build-up in the

chamber

• Heavy vapors may result in build-up on the probe

Best Practices

• A Rosemount 5301 with a single lead probe, option code "4A" or "5A" is

recommended. A centering disk should be included, if needed

• Temperature considerations:

- The high-temperature high-pressure (HTHP) tank seal, option code

'H' should be used. It has a maximum temperature of 750 °F (400 °C)

- Use metallic centering disks, option code 'Sx'

• In applications with very low signal strength, it is recommended to

activate the transmitter firmware function Probe End Projection (PEP).

For more information, refer to Rosemount 5300 Series Reference

Manual (Document No. 00809-0100-4530)

• Insulate the chamber to reduce the amount of condensation

NOTE

In some processes, e.g. vacuum residue towers, the fluid may be too viscous

for practical use in a chamber. For these cases, a DP with flushing

connections is recommended.

If the temperature is lower than 300 °F (150 °C), the standard tank seal may

be used instead of the HTHP option. For example, this may apply to the upper

portion of a distillation tower. See Section 4 "Commissioning" on page 4-2.

3-3

Rosemount Radar Level Transmitters

Rosemount 5301

High Temperature and High Pressure Level Measurement

Typical Applications

• Boiler feedwater systems

Figure 3-2. Boiler feedwater

system

Reference Manual

00809-0200-4530, Rev AB

September 2009

Table 3-1. Properties of water

and saturated steam

Application characteristics

• Boiling water with saturated steam vapors

• Heavy water condensation

• Water and saturated steam have certain properties, see Table 3-1

- The returned signal from the surface becomes weaker as water

temperature increases.

- If not taken into account, the saturated steam alters the propagation

velocity of the radar signal and generates an error in the level reading

proportional to the measured distance. Increased pressure and

temperature will affect the error in measured distance.

Temperature

°F (°C)

100 (38) 0.95 74 1.001 0.0

200 (93) 11.5 57 1.005 0.2

300 (149) 67 44 1.022 1.1

400 (204) 247 34 1.069 3.4

500 (260) 680 25 1.180 8.6

600 (315) 1543 18 1.461 20.9

Pressure

psia

DC of liquid

DC of saturated

steam

Error in distance

(%) if uncorrected

3-4

Reference Manual

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

Best Practices

• It is recommended that the Rosemount 5301 use a single lead probe,

option-code "4A" or "5A", and a centering disk if needed

Temperature considerations:

- Use the high-temperature high-pressure (HTHP) tank seal, option

code 'H', with maximum P/T 2940 psig at 752 °F (203 bar at 400 °C)

- Use metallic centering disks, option-code 'Sx'

• Insulate the chamber to reduce condensation

• When commissioning the transmitter, the specific properties of water

and saturated steam must be taken into account:

Configure the transmitter when the tank is in operation, otherwise the

signal returned from the surface will be too high and the transmitter will

not be configured correctly.

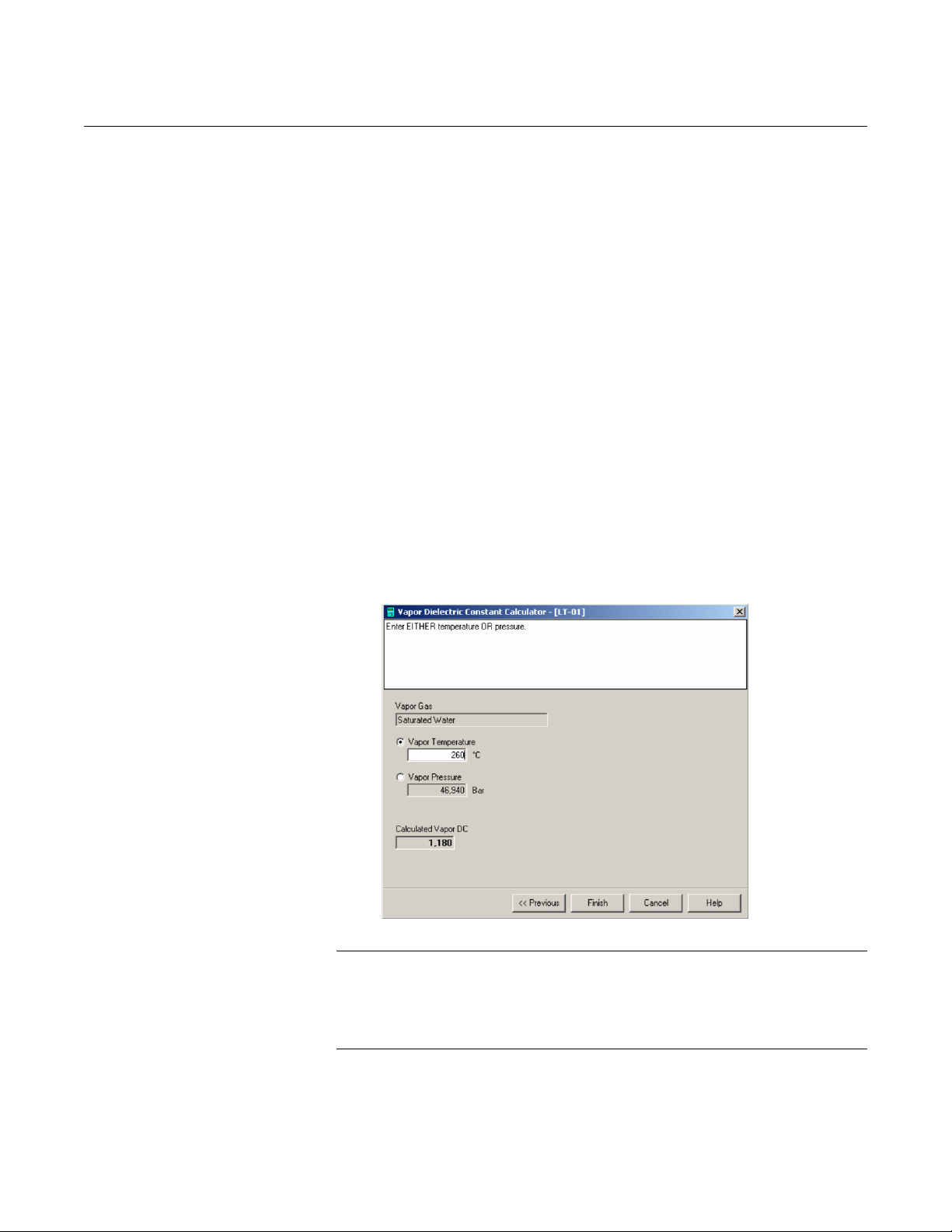

Rosemount Radar Master (RRM) can be used to compensate for the

error induced by the saturated steam:

Figure 3-3. Vapor Dielectric

Constant Calculator (LT-01)

Setup > Tank > Environment > Activate Advanced Mode > Vapor

Dielectric Constant Calculator

NOTE

The saturated steam compensation is fixed and will only adjust the level

reading at specified conditions. This means that the transmitter shows a

correct level reading during operation, but not during startup and shutdown

when these conditions are not fulfilled. See Table 3-2 on page 3-6.

3-5

Rosemount Radar Level Transmitters

5301

5302

5302

5301

Table 3-2. Level Reading Errors

during shutdown, with fixed

saturated water steam

correction activated

Entered Vapor

DC

1.001 0 in. (0 mm) 0 in. (0 mm) 0 in. (0 mm)

1.022 0.2 in. (4 mm) 0.3 in. (8 mm) 0 in. (0 mm)

1.180 1.3 in. (33 mm) 2.6 in. (65 mm) 0 in. (0 mm)

Error in reading, when actual Vapor DC is 1

(corresponding to water at room temperature)

Surface at 15 in (380 mm)

from flange

High Temperature and High Pressure Level and Interface Measurement

Typical Applications

• Separators, such as cold HP, hot LP in the hydrotreater

• Coalescers

Reference Manual

00809-0200-4530, Rev AB

September 2009

Offset in reading,

if Vapor DC is

configured

correctly

Surface at 30 in. (760

mm) from flange

Figure 3-4. Separators with

Rosemount 5300 Series

transmitters

Application characteristics

• There may be a fairly large emulsion between the products, which may

make the interface indistinct

• Vapors may generate build-up

3-6

Reference Manual

Level

Rosemount 5301

5301

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

Best Practices

• Use the Rosemount 5301 with a separate flushing ring or flange and

the integrated venting option. Alternatively, if there is an air gap, use

the 5302

• Refer to the 5300 Product Data Sheet (Document No.

00813-0100-4530) to ensure that the conditions for interface

measurement are fulfilled, especially with respect to the emulsion layer

• For chambers, it is recommended that the single lead probe,

option-code "4A" or "5A" is used along with a centering disk, if needed

• Temperature and pressure considerations:

- Use the high-temperature high-pressure (HTHP) tank seal, option

code 'H', maximum P/T 2940 psig at 752 °F (203 bar at 400 °C).

- Use metallic centering disks, option-code 'Sx'

• Because of the emulsion layer, Interface Threshold may need manual

adjustment

Standard Temperature and Standard Pressure Level Measurement

Figure 3-5. Distillation tower and

separator with Rosemount 5300

Series transmitter

Typical Applications

• Distillation Towers (Upper portions)

• Separators

• Knock-out drums

• Accumulators/Feed tanks

3-7

Rosemount Radar Level Transmitters

5302

Best Practices

• It is recommended that the Rosemount 5301 with a single lead probe,

option-code "4A" or "5A" is used along with a centering disk, if needed

• Use the standard tank seal, option code 'S', with pressure and

temperature range 15 psig (-1bar) to 580 psig (40 bar) @ 302 °F (150

°C)

• Besides the metallic centering disk, PTFE may also be used, option

code 'Px'

Standard Temperature and Standard Pressure Interface Measurement

Typical Applications

• Accumulators

• Settling Tanks

• Skimmers

• Separators

Best Practices

• Use the Rosemount 5301 with a separate flushing ring or flange and

integrated venting option. Alternatively, if there is an air gap, use the

5302

• For chambers, it is recommended that the single lead probe, option

code "4A" or "5A" is used along with a centering disk, if needed

• Use the standard tank seal, option code 'S', with pressure and

temperature range 15 psig (-1bar) to 580 psig (40 bar) @ 302 °F (150

°C)

• Besides the metallic centering disk, PTFE may also be used, option

code 'Px'

Reference Manual

00809-0200-4530, Rev AB

September 2009

Figure 3-6. Interface

measurement in a separator

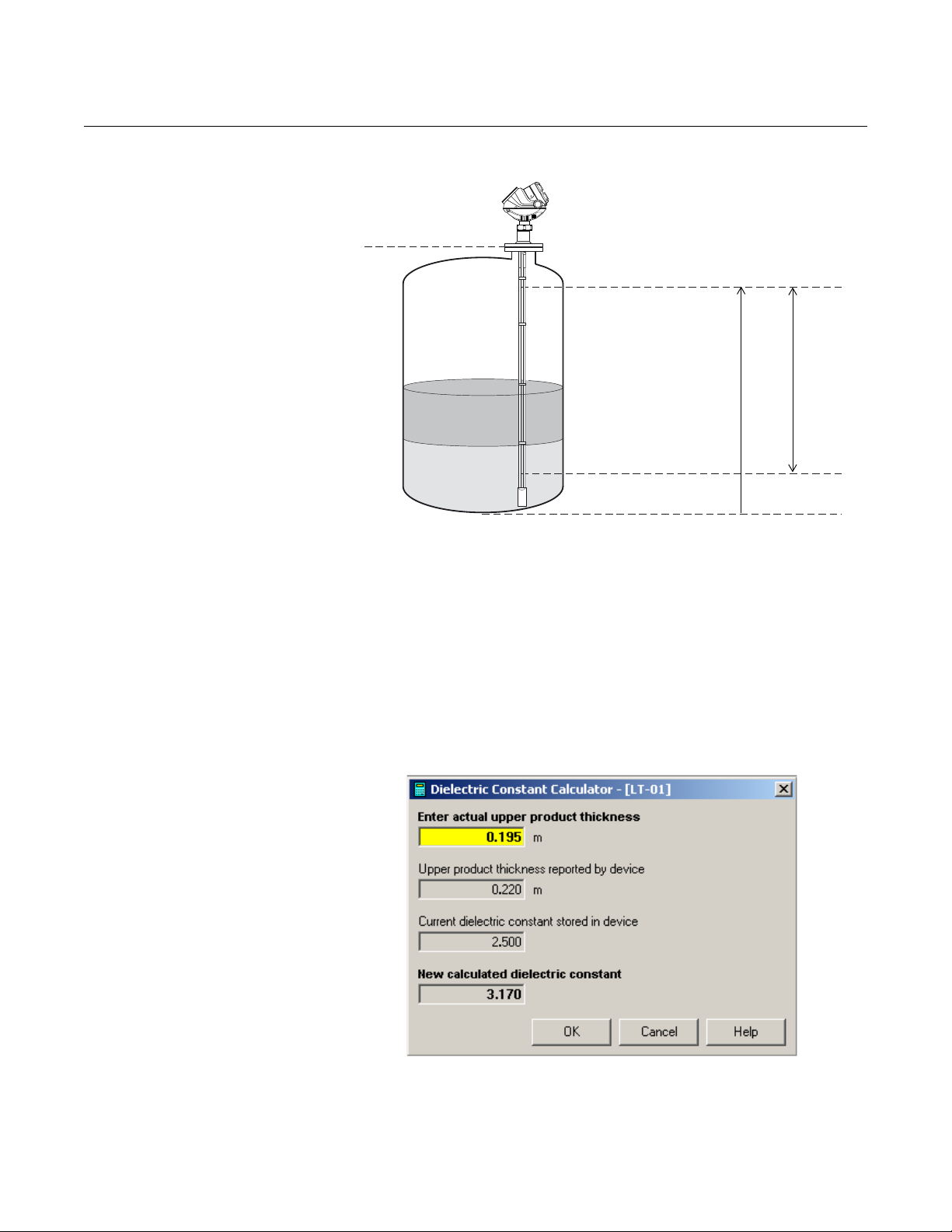

using a Rosemount 5302

transmitter

3-8

Reference Manual

Wash

Water

Wash

Water

Chemicals

Crude Oil

Oil

Rosemount 5302

00809-0200-4530, Rev AB

September 2009

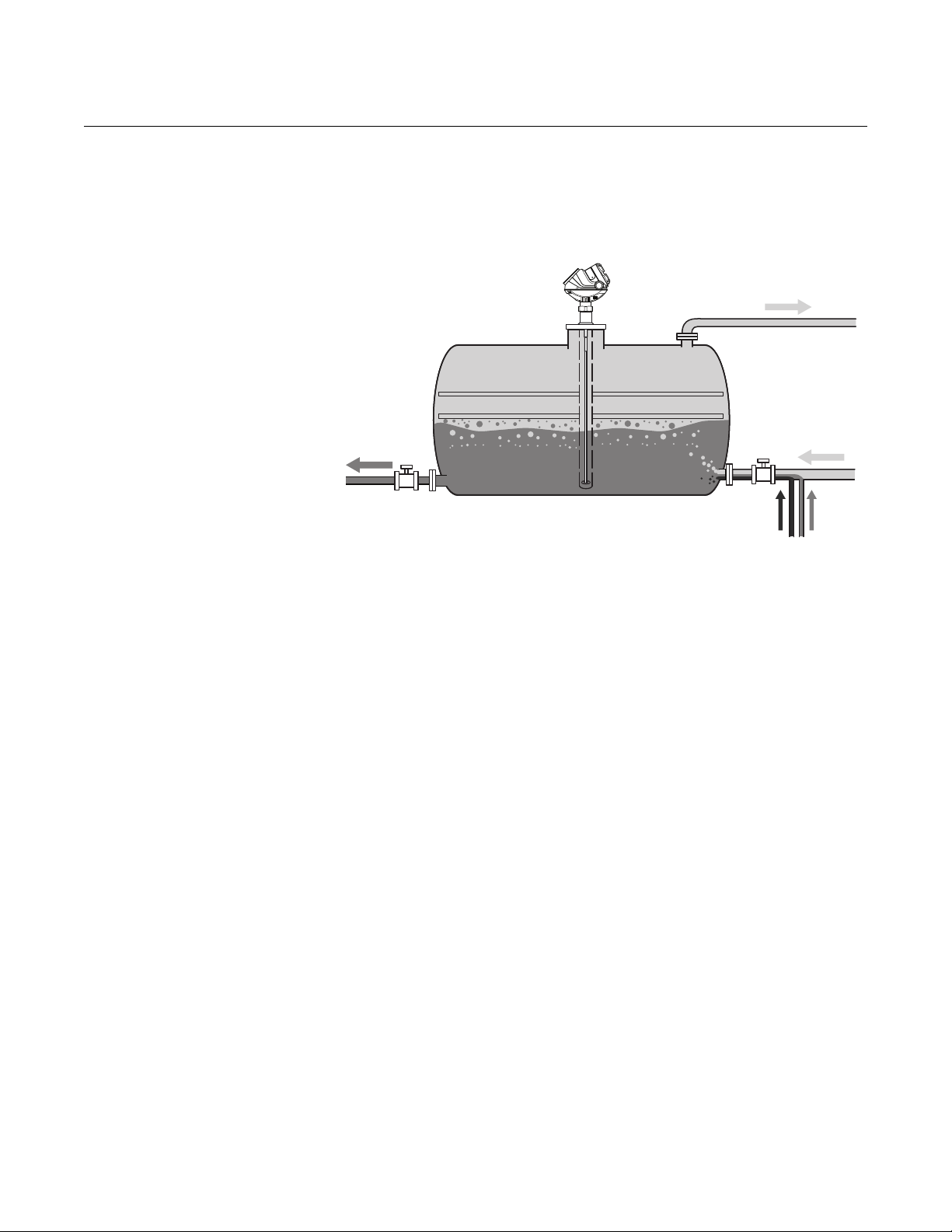

Pipes Desalters

Figure 3-7. Desalter with a

Rosemount 5302 transmitter

Rosemount Radar Level Transmitters

Application characteristics

• The crude oil is viscous and dirty with solids and water content

• The interface is indistinct, because of a large emulsion layer between

the two products

Best Practices

• Use the Rosemount 5302 with multivariable output for measurement of

both level and interface

• It is required to insert the probe in a 4 in. (100 mm) stilling-well to

reduce the emulsion layer. Drill as many holes as possible, since these

effectively set the resolution for the interface measurement

• It is recommended to use a single lead probe, option code "4A" or "5A",

with a centering disk, option-code 'Px' or 'Sx'

• Use the standard tank seal, option code 'S', with pressure and

temperature range -15 psig (-1 bar) to 580 psig (40 bar) @ 302 ºF (150

ºC)

• Ensure that the electronics housing does not get warmer than the

specified temperature limit; if needed, use the high-temperature

high-pressure (HTHP) tank seal, option code ’H’, to move the

transmitter housing further away from the process

• Besides the metallic centering disk, PTFE may also be used, option

code 'Px'

• Because of the emulsion layer, it is likely that the Interface Threshold

will need manual adjustment

Liquefied Gases

Typical Applications

• Small containers of LNG, LPG

3-9

Rosemount Radar Level Transmitters

Application Characteristics

• Liquefied gases have a very low dielectric constant and a very small

signal return

• Boiling fluid reduces the signal return additionally

Best Practices

• For non-inventory measurements, the Rosemount 5402 with cone- or

process-seal antenna can be used

• A 2-4 in. (50-100 mm) stilling well is required to calm the surface

• A full-port ball-valve should be used for process isolation

Tanks Ammonia

Application characteristics

• Anhydrous ammonia has heavy vapors that attenuate the signal

Best Practices

• Use 5301 with any of the probe-types

• Ensure the wetted materials are compatible with the process. For

example, many users consider Viton

incompatible with this process. The High Pressure tank seal, option

code 'P', can be used if a solution without O-rings is preferred.

• For further information, see Technical Note (Document No.

00840-0100-4811).

Reference Manual

00809-0200-4530, Rev AB

September 2009

®

and Buna-N® O-rings to be

Solids

Typical Applications

• Coke Bins

• Spent Catalyst Hopper

• Sulfur pits

3-10

Reference Manual

Rosemount 5402 Process Seal

with nozzle insulation

Rosemount 5600 and

5303 with dust cover

00809-0200-4530, Rev AB

September 2009

Figure 3-8. A sulfur pit with a

Rosemount 5402 transmitter

(above)

Catalyst Hopper with a

Rosemount 5600 transmitter

(below)

Rosemount Radar Level Transmitters

Application characteristics

• The surface of solid materials is rarely flat or horizontal, and the angle

of repose, or surface inclination, will change as the vessel fills and

empties

• The dielectric value of most solids is fairly low. For radar, this is a key

indicator of the amount of signal that will be reflected back to the gauge

• There is often a lot of dust during the fill cycle

• Heavier materials can create a pull force that can break cables. This

can be an issue in vessels taller than 50 ft (15 m), and should be taken

into account to guard against this

Best Practices

• Sulfur pits: use Rosemount 5402 with process-seal antenna. Purge,

insulate, heat-trace the nozzle or similar to reduce the amount of

build-up

• Spent catalyst hopper

under 60 ft (18 m): use Rosemount 5303 with long-stud and standard

6A-probe

over 60 ft (18 m): use Rosemount 5601 parabolic with dust-cover

• Coke bins: use Rosemount 5600 parabolic with dust-cover

3-11

Rosemount Radar Level Transmitters

Rosemount 5402

Rosemount 5400 Series

Storage Tanks

Typical Applications

• Chemical storage - acids, caustics, fuels, ..

• Waste water

• Crude oil buffer storage

Figure 3-9. Chemical storage

Reference Manual

00809-0200-4530, Rev AB

September 2009

Figure 3-10. Tank with agitator

using Rosemount 5400 Series

transmitters

Best Practices

• Use Rosemount 5402 with Cone antenna

• Consider material compatibility

Tanks with agitators

Typical Applications

• Mixing tanks - acids, catalysts

• Blending tanks

• Reactors

3-12

Reference Manual

00809-0200-4530, Rev AB

September 2009

Figure 3-11. Compressor tank

Rosemount Radar Level Transmitters

Application characteristics

• May be corrosive, vapors, turbulence, foam

Best Practices

• Typically 5400 is used

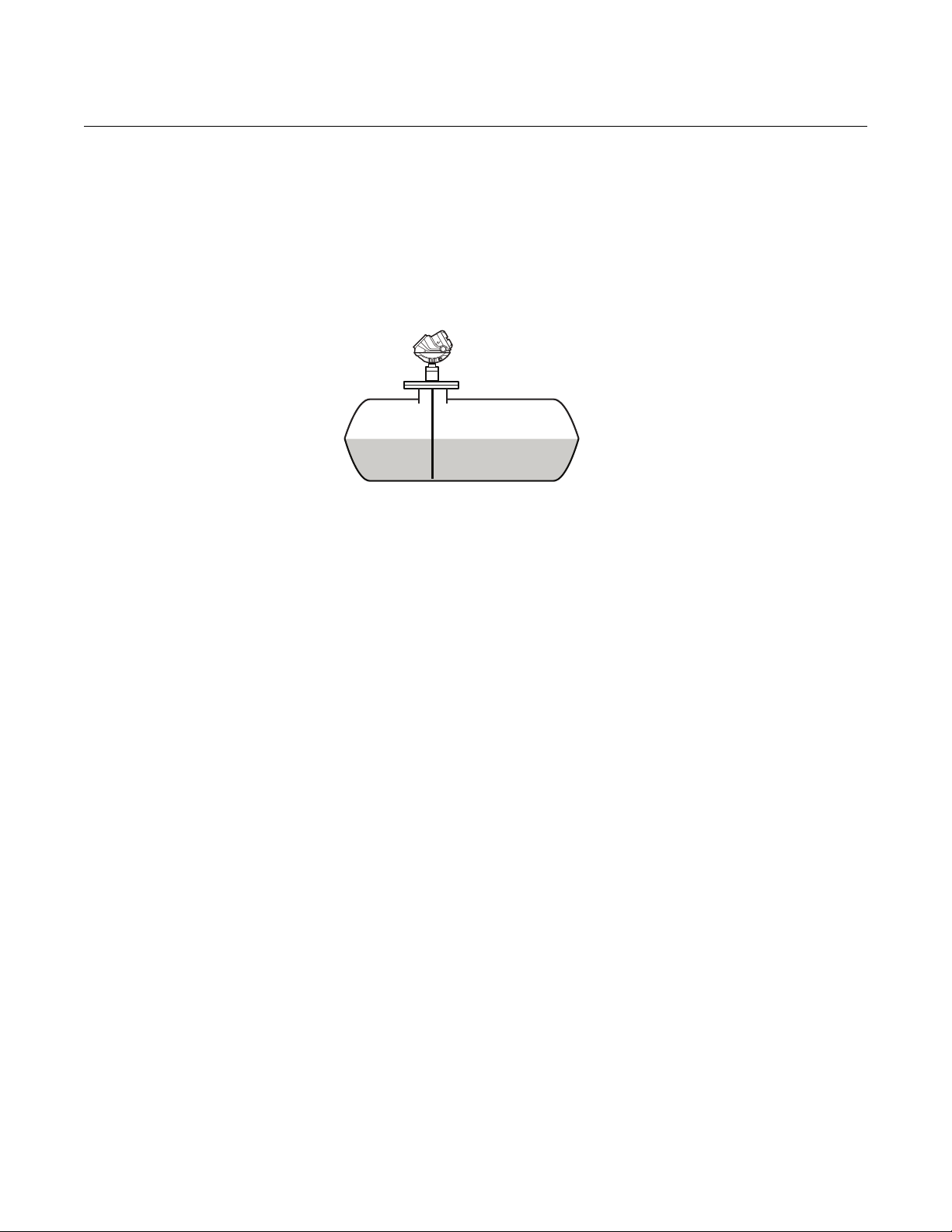

Compressor tanks

Application characteristics

• Small tank containing oil

• The tank may be too small to fit a chamber - direct connection is more

likely

Best Practices

• Rosemount 5301 standard single is recommended

Tanks with very rapid level changes

Typical Applications

• Blowdown drum

3-13

Rosemount Radar Level Transmitters

Figure 3-12. Blowdown drum

with a Rosemount 5600 Series

transmitter

Reference Manual

00809-0200-4530, Rev AB

September 2009

Application characteristics

• Tank may fill up very rapidly, for example because of upset in the

process

Best Practices

• Use Rosemount 5600

Applications to limit Generally, GWR is not suitable for extremely viscous products where fluid flow

is minimal. If GWR is used in a chamber with very viscous fluids, the chamber

should be heat traced and insulated to ensure fluidity. A vacuum residue unit

is an example of this type of application. Coke drums, where the fluid

hardens, is not a suitable application for GWR. Applications where heavy

coating is likely, such as asphalt, are more suitable for non-contacting radar.

Very small vessels (less than 18 inches [450 mm]) may cause measurements

that are more within the transition zones than the active measurement region.

In addition, if the fluid has a low dielectric constant and is hot, and/or

turbulent, then threshold settings may require more care. Contact your local

Emerson Process Management representative for assistance.

3-14

Reference Manual

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

Section 4 Commissioning

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-1

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-2

Trim Near Zone (5300 Series only) . . . . . . . . . . . . . . . . . . page 4-2

Store Backup and Verification Files . . . . . . . . . . . . . . . . . page 4-3

On the Bench Test (optional) . . . . . . . . . . . . . . . . . . . . . . . page 4-3

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Explosions could result in death or serious injury.

Verify that the operating environment of the gauge is consistent with the appropriate

hazardous locations certifications.

Before connecting a HART

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Do not remove the gauge cover in explosive atmospheres when the circuit is alive.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury.

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

High voltage that may be present on leads could cause electrical shock.

Avoid contact with leads and terminals.

Make sure the main power to the transmitter is off and the lines to any other external

power source are disconnected or not powered while wiring the gauge.

Probes covered with plastic and/or with plastic discs may generate an ignition-capable

level of electrostatic charge under certain extreme conditions. Therefore, when the

probe is used in a potentially explosive atmosphere, appropriate measures must be

taken to prevent electrostatic discharge.

®

-based communicator in an explosive atmosphere, make

www.rosemount.com

Reference Manual

00809-0200-4530, Rev AB

Rosemount Radar Level Transmitters

September 2009

INTRODUCTION This section is a brief outline of commissioning, and does not provide

comprehensive information on the whole procedure.

For the commissioning process, follow the steps of the product-related Quick

Installation Guides. For your convenience, a checklist is provided in the

Appendix of this Manual Supplement.

COMMISSIONING The transmitter installation should be carried out as described in the Quick

Installation Guide that is enclosed with every transmitter. Even though the

transmitter may be installed on the bench, it must be configured to the actual

process conditions.

For a 5300 Series transmitter, do not bend the probe during any part of the

installation. It may be necessary to shorten the probe, mount a centering disk,

or anchor the probe during the mechanical installation. For more information,

see the Reference Manual (00809-0100-4530).

Beside these required steps, the procedures below are recommended as best

practices.

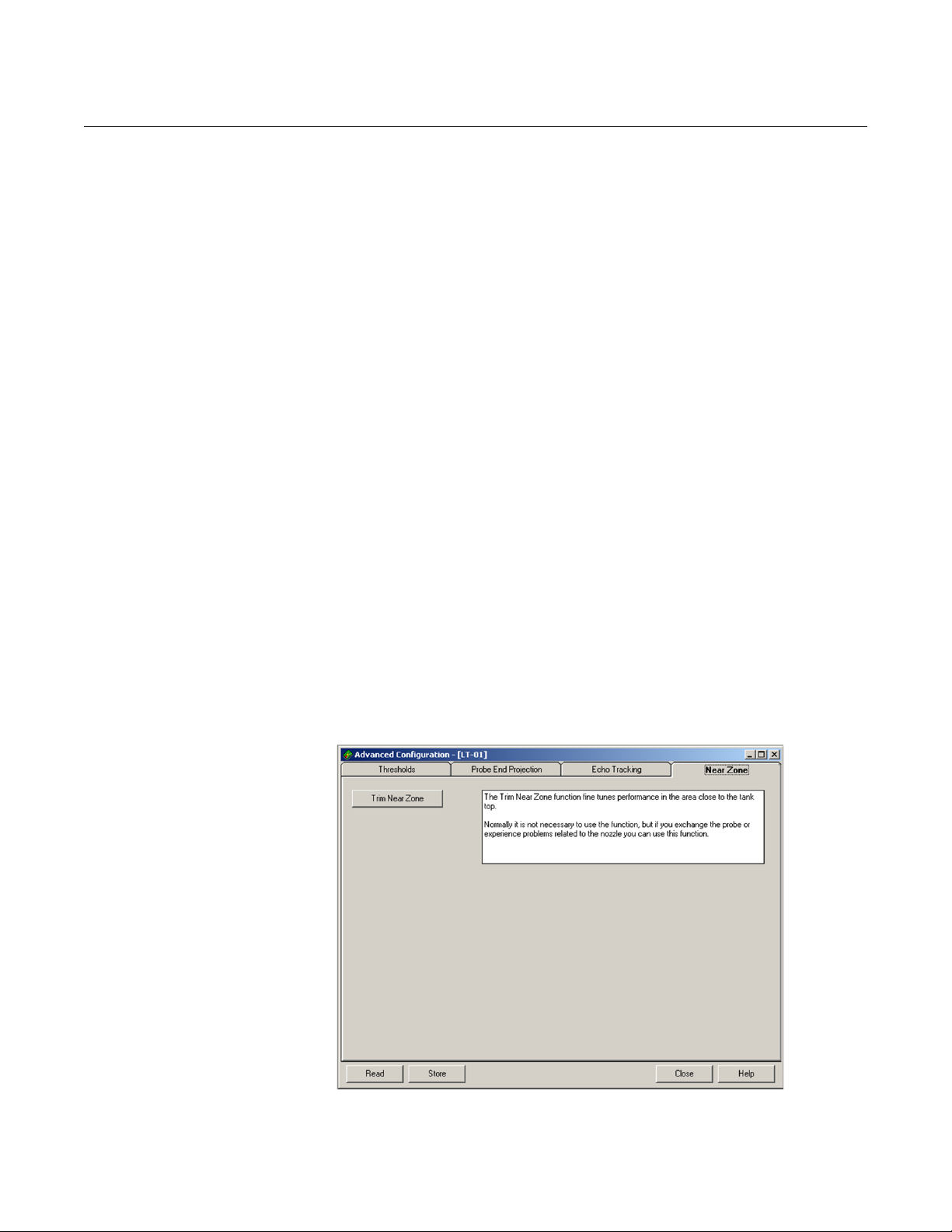

Trim Near Zone (5300 Series only)

Figure 4-1. Advanced

Configuration - [LT-01]

The Rosemount 5300 Series is equipped with a firmware functionality that

minimizes the Upper Transition Zone based on actual mounting conditions.

Best practice in refining applications, where short chambers are often used,

this function is advised.

To activate this function, ensure that the tank or chamber is empty, and that

the (upper) product is not closer than 40 in. (1 m). Then execute the Trim

Near Zone command.

Rosemount Radar Master > Advanced > Near Zone > Trim Near Zone

4-2

For detailed information on the Trim Near Zone function, refer to 5300 Series

Reference Manual (Document No. 00809-0100-4530).

Reference Manual

Water

Distance

Amplitude

How it would look with

actual product (oil) in tank

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

Store Backup and Verification Files

On the Bench Test (optional)

As the last step of the commissioning procedure, it is recommended that both

the transmitter settings and the echo curve be stored. For example, these can

be used for subsequent transmitter verification or troubleshooting.

Rosemount Radar Master > Device > Backup Config to file

Rosemount Radar Master > Tools > Echo Curve > Record

Sometimes the actual process is not available and the transmitter is

pre-commissioned on the bench. In this case, the level is often simulated

using metal-plates, water, or other targets.

Although, these tests provide a basic verification of the transmitter, they do

not verify that the transmitter functions properly at the actual process

conditions.

Bench tests complement verification tests, but do not replace them. The

instructions in Section 5 ”Measurement Validation at Operating Conditions”

should be followed and the bench test is considered optional.

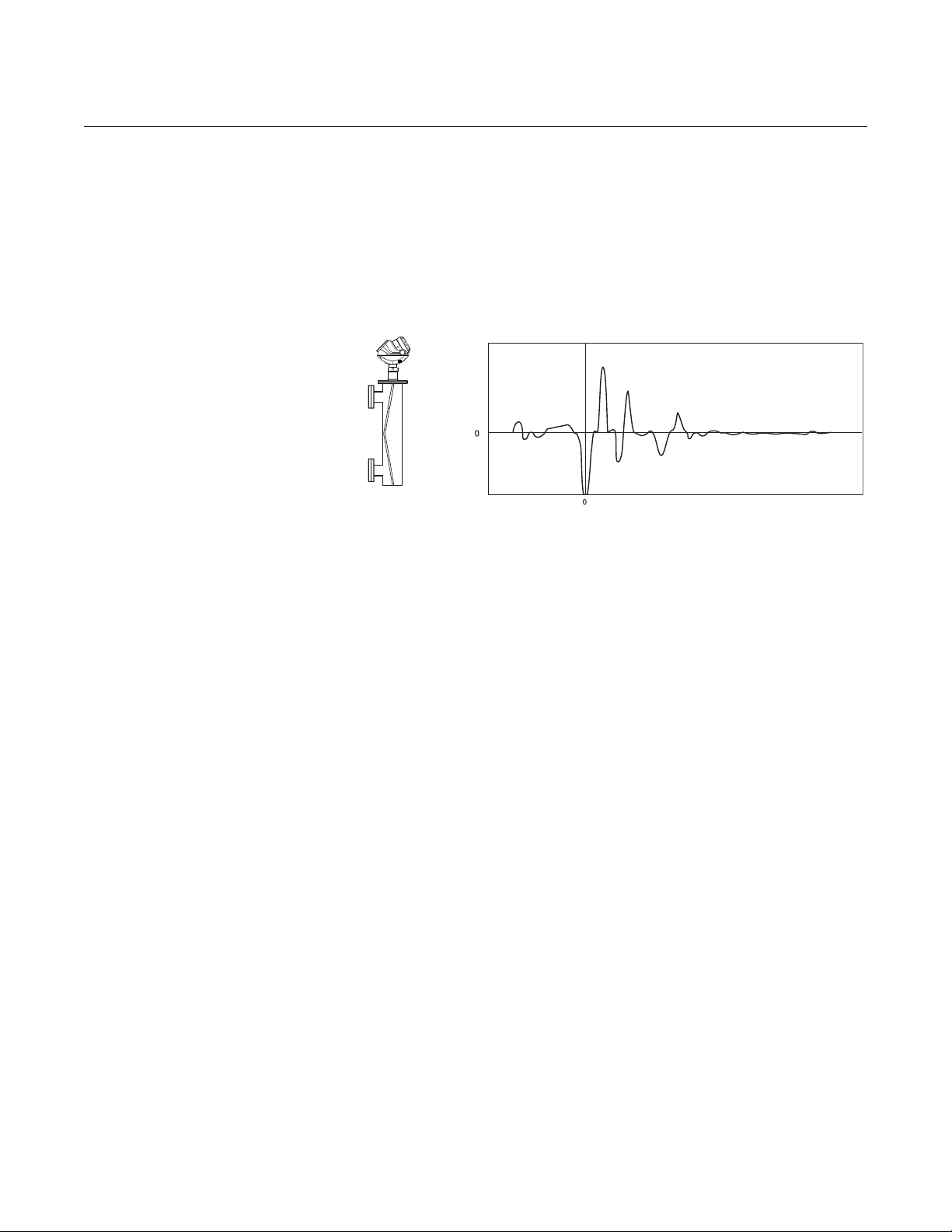

One of the largest differences between the simulated level and the actual

level during operating conditions is the amplitude of the surface peak. For

example, in a 4 in. (100 mm) chamber using the 5300 Series transmitter and a

single probe, the peak of water can be 10,000 mV, while oil would be 2,000

mV under the same conditions.

Never set the thresholds according to simulated level values since there

is a major risk that the thresholds are set too high.

Figure 4-2. The difference

between the amplitude of

surface peaks in the case of

simulated and actual liquid

levels

Generally, it is advised to accept the automatic settings. If it is necessary to

adjust the thresholds, do the adjustments the first time the process is started

at actual operating conditions.

Normally, the thresholds do not require any adjustments on the custom

settings.

4-3

Rosemount Radar Level Transmitters

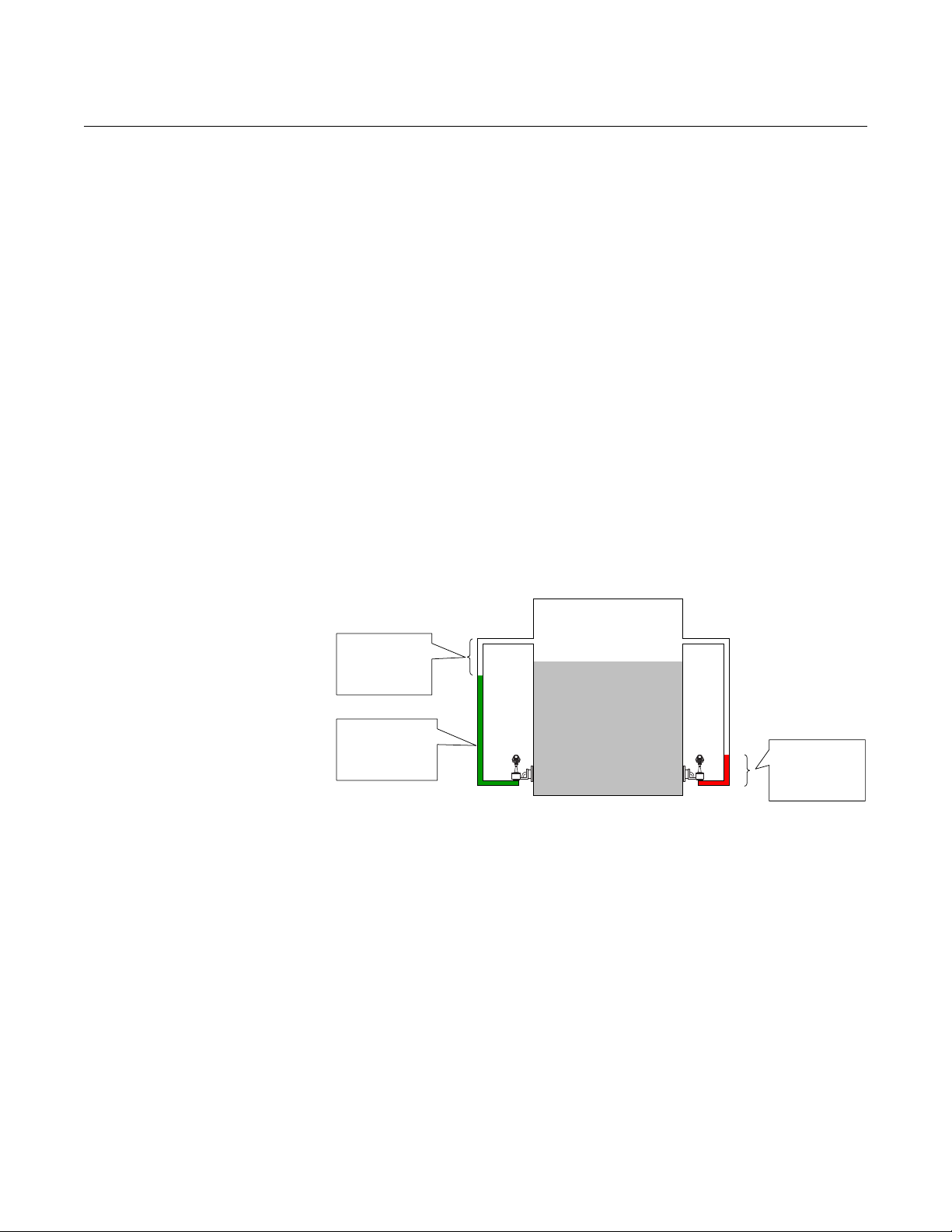

Example

A 5300 Series transmitter mounted in a chamber can be verified by

connecting flexible transparent tubing to the bottom drain, ensuring that there

are no crimps or folds in the bend to impede the flow.

The inlet-pipes are sealed by closing the valves, and filling the chamber with

water using the upper vent hole. The level is varied between the 4-20 mA

set-points to verify that the basic transmitter settings have been configured

correctly.

Once the chamber is mounted on the actual tank and the process is started, a

complete verification is carried out according to Section 5, ”Measurement

Validation at Operating Conditions”.

Figure 4-3. Verification of

transmitter measurement in

bridle application using tubing

Reference Manual

00809-0200-4530, Rev AB

September 2009

Fill water here

Measure

here

Closed

Valves

4-4

Reference Manual

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

Section 5 Measurement Validation at

Operating Conditions

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5-2

Step 1: Verify the Correctness of Level Reading . . . . . . . page 5-2

Step 2: Analog Output Signal Validation . . . . . . . . . . . . . page 5-3

Step 3: Echo-Curve Verification at Operating Conditions page 5-4

Step 4: Transmitter Diagnostics Review . . . . . . . . . . . . . page 5-4

Step 5: Monitor Level while Emptying . . . . . . . . . . . . . . . page 5-5

Step 6: Echo-Curve Verification with Empty Tank . . . . . . page 5-6

Step 7: Monitor Level while Filling . . . . . . . . . . . . . . . . . . page 5-6

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Explosions could result in death or serious injury.

Verify that the operating environment of the gauge is consistent with the appropriate

hazardous locations certifications.

Before connecting a HART

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Do not remove the gauge cover in explosive atmospheres when the circuit is alive.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury.

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

High voltage that may be present on leads could cause electrical shock.

Avoid contact with leads and terminals.

Make sure the main power to the transmitter is off and the lines to any other external

power source are disconnected or not powered while wiring

the gauge.

Probes covered with plastic and/or with plastic discs may generate an ignition-capable

level of electrostatic charge under certain extreme conditions. Therefore, when the

probe is used in a potentially explosive atmosphere, appropriate measures must be

taken to prevent electrostatic discharge.

®

-based communicator in an explosive atmosphere, make

www.rosemount.com

Reference Manual

00809-0200-4530, Rev AB

Rosemount Radar Level Transmitters

September 2009

INTRODUCTION In this section, the steps of measurement validation at operating conditions

are described.

For measurement validation, the actual liquid must be used to ensure the

accuracy of the measurement data.

MEASUREMENT VALIDATION AT OPERATING CONDITIONS

Step 1: Verify the Correctness of Level Reading

Once a Rosemount Radar transmitter has been installed and configured, it

will continuously deliver measurements with a minimum of maintenance. The

electronics are self-adjusting, so no re-calibration is needed.

This sample procedure is intended to be a part of the startup process, or as a

re-occurring functional check, to validate the integrity of the transmitter during

actual operating conditions. If the verification fails, refer to Section 6,

”Troubleshooting Procedures”.

All of the steps in this sample verification procedure are independent and

although it is not recommended, single steps may be omitted.

Before you start the verification procedure, ensure that proper actions have

been taken so as not to affect the safety or performance of the process.

A checklist is provided in the Appendix for this stage of the process for your

convenience.

At normal operating conditions, compare the transmitter level, or interface

reading, with an independent measurement. Unfortunately, it often happens

that two independent measurements will not match up perfectly, but check the

sanity and the acceptable deviation.

The independent measurement can be done using a number of different

complementary devices, ranging from sight-glasses and hand-dipping to

redundant differential-pressure and displacer.

Figure 5-1. The verification of

measurement data using a

sight-glass

5-2

Reference Manual

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

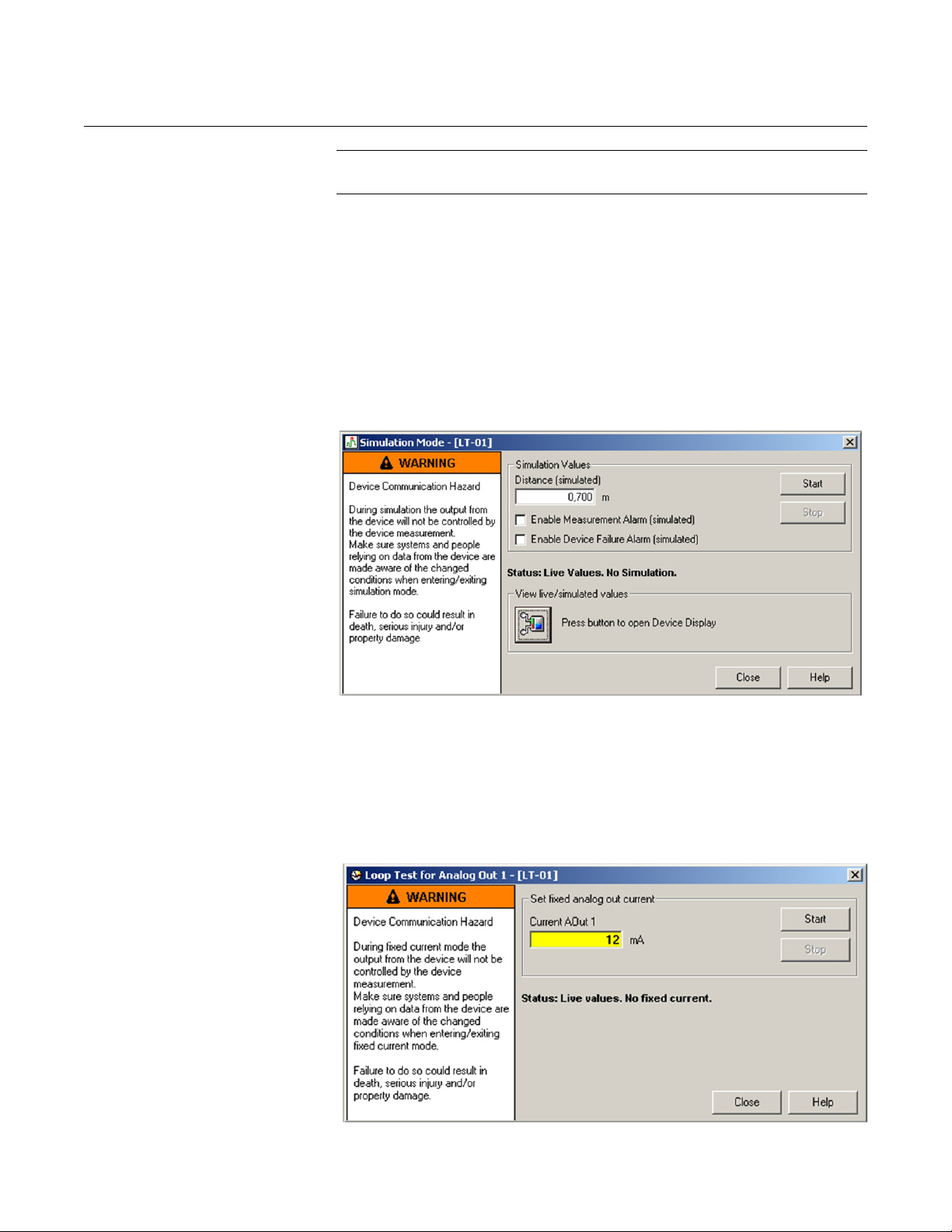

Step 2: Analog Output Signal Validation

Figure 5-2. Simulation Mode [LT-01)

NOTE

This section refers to 4-20 mA/HART units only.

Ensure that the loop has been set to manual mode in the DCS for the

applicable transmitter.

Use the transmitter’s built-in simulation mode to verify the analog output

settings. Output at least one arbitrary level or interface and verify that the

reading in the DCS match up.

Rosemount Radar Master > Tools > Simulation Mode

Figure 5-3. Loop test for Analog

Out 1 - [LT-01]

Also, or alternatively, activate the transmitter’s loop test function. Output 4, 12,

and 20 mA and verify that the reading in the DCS match up.

Rosemount Radar Master > Output > Analog Out > Loop Test

5-3

Rosemount Radar Level Transmitters

UNZ

Surface

peak

Interface

peak

Interface

threshold

Surface

threshold

Reference

peak

Distance

Amplitude

Reference Manual

00809-0200-4530, Rev AB

September 2009

Step 3: Echo-Curve Verification at Operating Conditions

Figure 5-4. Peak amplitudes and

threshold settings

At normal operating conditions, download and review the echo-curve

according to the following steps:

1. Check Reference Pulse amplitude and position

Compare the result against the previous plots, taken during

commissioning, and previous verification rounds.

2. Review peak amplitudes and threshold settings

Verify that the surface and/or interface peaks are visible and that the

thresholds have been set according to the best practices in Section 6,

”Troubleshooting Procedures”. If possible, compare the current

echo-curve with previously stored echo-curves taken during operating

conditions. There should be no major differences.

3. Store the echo-curve

Permanently store the echo-curve for future use, with re-occurring

verification procedures.

Step 4: Transmitter Diagnostics Review

Figure 5-5. Diagnostics - [LT-01]

5-4

The transmitter contains valuable diagnostics that monitor the health of the

device to make sure that it does not report any errors or warnings.

Rosemount Radar Master > Tools > Diagnostics

Reference Manual

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

Step 5: Monitor Level while Emptying

Figure 5-6. Log Registers

During Step 1, the current level/interface reading was verified correct. This

step will verify that the transmitter correctly tracks the surface during the

emptying of the tank.

Begin by activating log functionality for the transmitter level/interface output.

Either the DCS-trend or a stand-alone tool can be used:

Rosemount Radar Master > Tools > Log

Figure 5-7. Emptying a tank or

chamber

Start emptying the tank or chamber making sure not to stop until it is

completely empty. With a chamber, do not forget to close the process valves

before draining.

2: Open

vent

1: Close valves

3: Open

drain

5-5

Rosemount Radar Level Transmitters

Finally, review the level/interface trend for accuracy.

Reference Manual

00809-0200-4530, Rev AB

September 2009

Step 6: Echo-Curve Verification with Empty Tank

Step 7: Monitor Level while Filling

When the tank or chamber is empty, download and review the echo-curve

according to the following steps:

1. Compare echo-curve with previous plots

Compare the echo-curve with previous plots, taken during

commissioning. There should be no major differences. Especially make

sure to review:

• the amplitude and position of the reference pulse

• if all noise is below the threshold

• the amplitude and position of the bottom or probe-end pulse.

2. Store the echo-curve

Permanently store the echo-curve for future use, with re-occurring

verification procedures.

Repeat Step 5, but fill the tank or chamber instead of emptying it.

5-6

Reference Manual

00809-0200-4530, Rev AB

September 2009

Rosemount Radar Level Transmitters

Section 6 Troubleshooting Procedures

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6-2

Echo Curve Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6-3

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Explosions could result in death or serious injury.

Verify that the operating environment of the gauge is consistent with the appropriate

hazardous locations certifications.

Before connecting a HART-based communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Do not remove the gauge cover in explosive atmospheres when the circuit is alive.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury.

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

High voltage that may be present on leads could cause electrical shock.

Avoid contact with leads and terminals.

Make sure the main power to the transmitter is off and the lines to any other external

power source are disconnected or not powered while wiring

the gauge.

Probes covered with plastic and/or with plastic discs may generate an ignition-capable